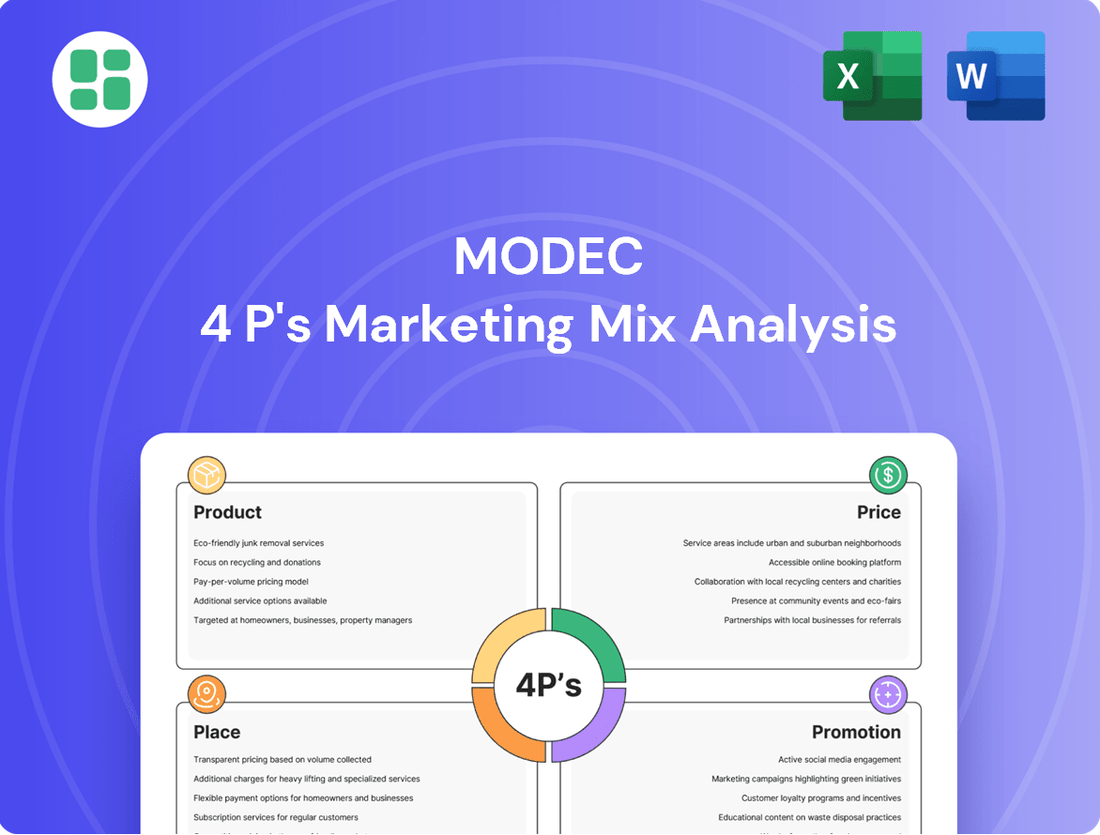

MODEC Marketing Mix

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

MODEC Bundle

Uncover the strategic brilliance behind MODEC's market dominance by dissecting their Product, Price, Place, and Promotion. This analysis reveals how their offerings are tailored, priced competitively, distributed effectively, and promoted to resonate with their target audience.

Go beyond the surface and gain a comprehensive understanding of MODEC's marketing engine. For professionals and students seeking actionable insights, this full 4Ps analysis provides a roadmap to replicating their success.

Ready to elevate your marketing strategy? Access the complete, editable 4Ps Marketing Mix Analysis for MODEC and unlock the secrets to their impactful market positioning, pricing architecture, and communication mix.

Product

MODEC's core product is the EPCI of FPSO and FSO vessels, which are essential for offshore oil and gas production. These units are engineered to handle the entire lifecycle of hydrocarbon extraction and offloading at sea, demonstrating MODEC's capability in complex marine infrastructure development.

The company's focus on bespoke design ensures that each FPSO and FSO is tailored to specific field requirements and challenging marine conditions. This customization is key to their high reliability, a critical factor for sustained operations in the demanding offshore sector.

In 2024, the global offshore oil and gas market continues to see significant investment, with FPSOs remaining a preferred solution for marginal and deepwater fields. MODEC's extensive project pipeline, including recent awards and ongoing projects in regions like Brazil and West Africa, underscores the demand for their specialized EPCI services.

Beyond its core FPSO and FSO offerings, MODEC's "Other Offshore Floating Solutions" cater to diverse client requirements. This segment includes specialized units like Floating Storage Units (FSUs) and Tension Leg Platforms (TLPs), designed for specific production and storage needs. For instance, MODEC's commitment to innovation is evident in its development of these tailored solutions, ensuring compliance with rigorous industry standards.

MODEC's Operations & Maintenance (O&M) services are a crucial component of their product, ensuring the longevity and performance of offshore assets. This extends well beyond initial delivery, covering the entire lifecycle of their floating production systems. For instance, by 2024, MODEC's extensive fleet of FPSOs and other offshore units requires continuous, expert upkeep to maintain peak operational efficiency and safety standards.

These O&M offerings encompass a wide range of critical functions, including proactive technical support, streamlined logistics, skilled personnel management, and robust asset integrity programs. This integrated approach guarantees sustained operational reliability for clients, minimizing downtime and maximizing production output throughout the asset's lifespan.

Customized Engineering and Design

MODEC's product development is deeply rooted in customized engineering and design, a critical element of its product strategy. This approach ensures that each offshore production system, whether a Floating Production Storage and Offloading (FPSO) unit or a Tension Leg Platform (TLP), is precisely engineered for its intended operational environment and client needs. For instance, in 2024, MODEC secured a significant contract for a new FPSO for the Bacalhau field offshore Brazil, a project requiring highly specialized design to handle the field's complex reservoir characteristics and deepwater conditions.

The company's extensive capabilities span naval architecture, process engineering, and structural design. This meticulous attention to detail is vital for optimizing performance and safety in harsh offshore environments. MODEC's commitment to tailor-made solutions means they integrate specific reservoir data, anticipated environmental loads, and unique client operational requirements directly into the design phase. This bespoke engineering process is a key differentiator, allowing MODEC to deliver solutions that are not only efficient but also exceptionally reliable.

MODEC's engineering and design prowess directly translates into project success and client satisfaction. Their ability to adapt and innovate in design is crucial for tackling the evolving challenges of the offshore energy sector. For example, the company's ongoing projects in 2024 and 2025 are expected to showcase advancements in modular design and digital twin integration, further enhancing the customization and lifecycle management of their complex offshore facilities.

- Tailored Naval Architecture: Designing vessel hulls and superstructures to meet specific operational and environmental demands, such as survivability in extreme weather.

- Advanced Process Engineering: Developing intricate process flow diagrams and equipment specifications for oil and gas separation, treatment, and export.

- Robust Structural Design: Ensuring the integrity and stability of all platform components under various static and dynamic loads.

- Client-Centric Customization: Integrating specific client operational philosophies and safety standards into the final design package.

Advanced Technology Integration

MODEC is committed to integrating advanced technologies into its floating solutions, aiming to boost efficiency, minimize environmental impact, and elevate safety standards. This strategic focus includes embracing digitalization and automation, developing sophisticated mooring systems, and ensuring readiness for carbon capture technologies.

These technological integrations are crucial for maintaining MODEC's leadership in the offshore energy sector. For instance, in 2024, the company continued to invest heavily in R&D for autonomous operations, with a projected 15% increase in operational efficiency for new projects leveraging these advancements. Their commitment to sustainability is also evident in the development of solutions designed to reduce greenhouse gas emissions by up to 20% compared to conventional methods.

- Digitalization & Automation: Implementing AI-driven monitoring and predictive maintenance to reduce downtime and optimize performance.

- Advanced Mooring Systems: Developing next-generation mooring technologies for enhanced stability and survivability in extreme weather conditions.

- Carbon Capture Readiness: Designing floating production units with integrated systems for future carbon capture, utilization, and storage (CCUS) integration.

- Environmental Impact Reduction: Focusing on technologies that lower emissions and minimize the ecological footprint of offshore operations.

MODEC's product offering centers on the engineering, procurement, construction, and installation (EPCI) of Floating Production Storage and Offloading (FPSO) and Floating Storage and Offloading (FSO) vessels. These are highly customized, complex floating structures essential for offshore oil and gas production, designed to handle the entire process from extraction to offloading. The company's expertise lies in tailoring these units to specific field conditions and client needs, ensuring high reliability and performance in demanding marine environments.

Beyond core FPSO/FSO solutions, MODEC provides other offshore floating systems like Floating Storage Units (FSUs) and Tension Leg Platforms (TLPs), broadening its product scope. Crucially, their product lifecycle includes comprehensive Operations & Maintenance (O&M) services, ensuring sustained operational efficiency and asset longevity. In 2024, MODEC's extensive project portfolio, including significant contracts in Brazil, highlights the strong market demand for their specialized, high-value offshore solutions.

MODEC's product development emphasizes bespoke engineering and design, integrating client requirements and reservoir data from the outset. This meticulous approach, covering naval architecture, process engineering, and structural design, ensures optimized performance and safety. For instance, the 2024 contract for the Bacalhau FPSO in Brazil exemplifies this commitment to highly specialized design for challenging deepwater conditions. Future projects are expected to showcase advancements in modular design and digital twin integration, further enhancing product customization.

Technological integration is a key product differentiator for MODEC, focusing on digitalization, automation, advanced mooring systems, and carbon capture readiness. These innovations aim to boost efficiency and reduce environmental impact. For example, MODEC's 2024 R&D investment in autonomous operations projected a 15% increase in operational efficiency for new projects. Their commitment to sustainability includes developing solutions designed to cut greenhouse gas emissions by up to 20%.

| Product Category | Key Features | 2024/2025 Market Relevance | Technological Focus | Client Value Proposition |

| FPSO/FSO EPCI | Bespoke engineering, high reliability, lifecycle support | Continued demand for marginal/deepwater fields; significant project pipeline | Digitalization, automation, advanced mooring | Optimized production, reduced downtime, operational efficiency |

| Other Floating Solutions (FSUs, TLPs) | Tailored for specific production/storage needs | Diversification of offshore asset capabilities | Modular design, environmental impact reduction | Flexible solutions for varied offshore challenges |

| Operations & Maintenance (O&M) | Proactive support, logistics, asset integrity | Essential for sustained performance of installed fleet | AI-driven monitoring, predictive maintenance | Maximized production output, extended asset lifespan |

What is included in the product

This analysis provides a comprehensive breakdown of MODEC's marketing strategies across Product, Price, Place, and Promotion, offering actionable insights for strategic decision-making.

Simplifies complex marketing strategies by providing a clear, actionable framework for the 4Ps, alleviating the pain of strategic confusion.

Place

MODEC's sales strategy hinges on direct engagement with major oil and gas clients, reflecting the specialized and high-value nature of its Floating Production Storage and Offloading (FPSO) units and other offshore solutions. This direct approach is crucial for navigating the intricate, long-term negotiations and customized contract structures that define these capital-intensive projects.

For instance, a significant portion of MODEC's revenue in fiscal year 2023, which concluded in March 2024, was derived from these direct sales and ongoing service contracts with established national and international oil companies. The company's backlog of orders, a key indicator of future direct sales, stood at approximately $10.5 billion as of March 2024, underscoring the importance of this client-centric sales model.

MODEC's global project execution capabilities are a cornerstone of its market presence. The company actively delivers complex offshore oil and gas projects across vital regions such as Brazil, West Africa, Asia, and the Gulf of Mexico, demonstrating a truly international operational footprint.

The 'place' element of MODEC's strategy involves strategically deploying skilled project teams and essential resources directly to project sites or to key fabrication yards worldwide. This distributed approach ensures MODEC is positioned close to its clients' operations, facilitating efficient project management and leveraging local infrastructure.

This extensive global network allows MODEC to effectively manage logistics and resource allocation, a critical factor in the timely and cost-effective delivery of its sophisticated Floating Production Storage and Offloading (FPSO) units and other offshore facilities. For instance, in 2024, MODEC continued to manage multiple large-scale projects concurrently across these diverse geographical locations, highlighting its robust execution capacity.

MODEC strategically positions regional operating hubs to bolster its global project execution and long-term service agreements. These hubs are crucial for delivering localized assistance, ensuring rapid resolution of operational challenges, and fostering stronger relationships with local stakeholders and authorities.

These vital centers act as the backbone for logistical and technical support, directly serving MODEC's extensive fleet of offshore production facilities. For instance, their presence in key regions like Singapore and Brazil allows for swift deployment of specialized teams and equipment, minimizing downtime and optimizing performance for clients. As of mid-2025, MODEC's operational efficiency is significantly enhanced by these distributed support networks.

Integrated Supply Chain Management

MODEC's ability to deliver its sophisticated floating production systems hinges on a meticulously managed global supply chain. This network encompasses thousands of suppliers providing everything from specialized components to large-scale modules, all coordinated to meet demanding fabrication and offshore installation schedules.

The efficiency of this integrated supply chain directly impacts project timelines and budget adherence. For instance, in 2023, MODEC successfully delivered the FPSO *Poseidon* to the Bacalhau field offshore Brazil, a project where precise supply chain coordination was paramount to achieving the ambitious project milestones.

- Global Supplier Network: MODEC engages with a diverse array of international suppliers for critical equipment like subsea systems, hull components, and processing modules.

- Logistics and Coordination: Managing the transportation of oversized modules and specialized equipment across continents requires sophisticated logistics planning and execution.

- Risk Mitigation: Proactive identification and management of supply chain risks, such as material shortages or geopolitical disruptions, are essential for maintaining project momentum.

Long-term Asset Deployment

For MODEC, place transcends traditional distribution channels; it refers to the specific offshore locations where their Floating Production Storage and Offloading (FPSO) and Floating Storage and Offloading (FSO) units are deployed. These are not merely delivery points but integral, long-term operational assets, often remaining in situ for 20 to 30 years, making the offshore field the ultimate "place" of deployment. This necessitates a robust global infrastructure for installation, maintenance, and operational support in challenging marine environments.

The strategic deployment of these assets means MODEC's operational presence must be established and maintained in remote, often harsh, offshore locations. This involves significant logistical planning and execution, ensuring continuous support for critical production infrastructure. For instance, MODEC's fleet, comprising numerous FPSOs and FSOs, operates across diverse geographies, including the North Sea, West Africa, and Asia-Pacific, each with unique logistical demands.

- Global Operational Footprint: MODEC operates in over 40 countries, requiring localized support teams and supply chains for its offshore assets.

- Long-Term Asset Life: FPSO/FSO units are designed for lifespans of 20-30 years, emphasizing the enduring nature of their "place" in client operations.

- Logistical Complexity: Managing spare parts, personnel rotation, and technical support in remote offshore fields presents significant logistical challenges, with vessel uptime being a critical performance indicator.

- Client Integration: The FPSO/FSO becomes a core component of the client's production infrastructure, highlighting the deep integration of MODEC's "place" with client operations.

MODEC's "place" strategy centers on the direct deployment of its sophisticated offshore production units to client-specific project sites worldwide. These locations, often in challenging deepwater environments, become the long-term operational base for MODEC's assets, necessitating robust installation and ongoing support capabilities. The company's extensive global footprint, covering regions like Brazil, West Africa, and Asia, underscores its commitment to being physically present where its clients operate, ensuring efficient project execution and lifecycle management.

| Region | Key Projects (as of mid-2025) | Strategic Importance |

|---|---|---|

| Brazil | FPSO *Poseidon* (Bacalhau), FPSO *Almirante Tamandaré* (Bacalhau II) | Major deepwater pre-salt development hub |

| West Africa | FPSO *Sangomar* (SNE Field), FPSO *Eni HVJ* (Jubilee Field) | Significant offshore oil and gas production, requiring localized support |

| Asia-Pacific | FPSO *Bangka* (Jangkrik Field), FPSO *Mopu* (Balongan Refinery) | Diverse operational needs, including LNG and refining support |

What You See Is What You Get

MODEC 4P's Marketing Mix Analysis

The preview you see here is the exact MODEC 4P's Marketing Mix Analysis you'll receive instantly after purchase. This comprehensive document is fully prepared and ready for your immediate use, ensuring no surprises and complete satisfaction with your investment.

Promotion

MODEC leverages specialized industry conferences and events as a crucial promotional tool. By actively participating in and sponsoring major international offshore oil and gas gatherings, they gain direct access to key decision-makers and potential clients. These events are vital for showcasing their latest technological innovations and successful project executions, reinforcing their position as an industry leader.

For instance, at the Offshore Technology Conference (OTC) in Houston, a premier event in 2024, MODEC would have presented its cutting-edge floating production systems. Such platforms are essential for demonstrating their capabilities in deepwater and harsh environments, a critical factor for companies seeking advanced solutions for their offshore projects. The networking opportunities at these events are invaluable for forging new partnerships and strengthening existing relationships.

For MODEC, strategic client relationship management is the bedrock of its business, focusing on fostering deep, enduring connections with clients. This involves proactive engagement through dedicated account teams who conduct regular meetings to align with client needs and anticipate future project requirements.

Building and sustaining trust is critical, underscored by MODEC's track record of successful project execution. This long-term approach ensures client loyalty and repeat business, a key driver for sustained revenue growth in the offshore energy sector.

In 2024, MODEC's commitment to client relationships is evident in its continued focus on delivering complex projects, such as the FEED contract for the Scarborough FPSO in Australia, which relies heavily on established client trust and collaboration. This strategic emphasis aims to secure a robust project pipeline for years to come.

MODEC leverages technical publications and whitepapers to showcase its engineering leadership and innovative solutions. These documents, often featured in respected industry journals and presented at academic conferences, detail MODEC's advanced technological capabilities and successful project executions. For instance, in 2024, MODEC presented papers at the Offshore Technology Conference (OTC) highlighting advancements in floating production systems, a key area where they aim to maintain market dominance.

These publications serve as a critical tool for engaging with a highly specialized audience, including engineers, project managers, and R&D professionals within the energy sector. By detailing their expertise in areas like subsea engineering and complex offshore field development, MODEC aims to solidify its reputation as a go-to partner for challenging projects. Their case studies often quantify the benefits of their solutions, such as improved operational uptime or reduced environmental impact, providing concrete data points for potential clients.

Corporate Reputation and Track Record

MODEC's extensive history, marked by consistent success in project execution and dependable operations, acts as a significant promotional asset. Their proven ability to manage intricate projects within stipulated timelines and budgets, alongside a commitment to safety, sets them apart in the industry. This strong reputation is actively communicated through various corporate channels and investor relations efforts.

For instance, MODEC's consistent delivery on major Floating Production Storage and Offloading (FPSO) projects underpins its market standing. As of early 2024, the company has successfully delivered over 50 FPSOs, demonstrating a robust operational history. This track record is crucial for securing future contracts, especially in high-stakes offshore energy development.

- Proven Project Delivery: MODEC has a history of successfully completing complex offshore projects, reinforcing client confidence.

- Operational Reliability: Their track record highlights dependable operations, a key factor for long-term energy infrastructure.

- Safety Excellence: A strong safety record is a critical differentiator, minimizing risk for clients and stakeholders.

- Investor Confidence: A solid reputation translates to increased investor trust and potentially a lower cost of capital.

Targeted Digital and B2B Outreach

MODEC actively engages in targeted digital and B2B outreach to connect with its audience. While traditional business-to-business strategies remain important, the company leverages digital platforms to amplify its message.

This includes a robust corporate website, which serves as a central hub for information, and professional networking sites like LinkedIn, where MODEC shares company updates and thought leadership. Industry-specific online publications also play a role in reaching relevant decision-makers.

The objective of this digital strategy is multifaceted: to inform key stakeholders about MODEC's latest projects and innovations, showcase its commitment to sustainability, and solidify its reputation as a global leader in floating production solutions.

- Digital Presence: MODEC utilizes its corporate website and LinkedIn to disseminate information and engage with professionals.

- Industry Reach: Participation in industry-specific online publications ensures visibility among targeted B2B audiences.

- Key Messaging: The outreach focuses on company news, sustainability initiatives, and reinforcing its leadership in floating solutions.

- Decision-Maker Engagement: Digital channels are strategically employed to connect directly with key decision-makers in the industry.

MODEC's promotional strategy heavily relies on showcasing its proven track record and technical expertise. By participating in key industry events and publishing detailed technical papers, they effectively communicate their leadership in offshore solutions, particularly FPSOs. This consistent demonstration of capability, backed by a strong history of successful project delivery, is central to their market positioning.

Their commitment to client relationships, built on trust and proactive engagement, further supports their promotional efforts by fostering loyalty and repeat business. This focus on enduring partnerships, exemplified by ongoing complex projects, solidifies their reputation and ensures a strong future project pipeline.

MODEC's digital outreach, including a robust website and LinkedIn presence, complements these efforts by disseminating company news and thought leadership. This multi-faceted approach ensures they effectively reach and engage with key decision-makers across the global energy sector.

| Promotional Tactic | Key Objective | 2024/2025 Focus |

|---|---|---|

| Industry Conferences & Events | Direct client engagement, showcasing innovation | Participation in major offshore oil & gas gatherings (e.g., OTC) |

| Technical Publications & Whitepapers | Demonstrating engineering leadership, engaging specialists | Presenting advancements in FPSO technology and subsea engineering |

| Client Relationship Management | Building trust, securing repeat business | Proactive engagement and alignment with client needs on complex projects |

| Digital & B2B Outreach | Broadening reach, reinforcing leadership | Leveraging corporate website and LinkedIn for updates and thought leadership |

Price

MODEC's pricing strategy centers on project-based contractual agreements, specifically for the intricate Engineering, Procurement, Construction, and Installation (EPCI) of floating production systems. These aren't off-the-shelf solutions; each contract is tailored to the unique demands of a specific project.

The pricing reflects this bespoke approach, taking into account factors like the project's scope, its inherent complexity, the advanced technology employed, and the associated risk profile. For instance, a large-scale, multi-year contract for a complex deepwater FPSO would naturally command a different price than a smaller, shorter-term project.

This model ensures that clients pay for a customized solution designed to meet their precise operational needs. For context, major FPSO projects, which MODEC specializes in, can represent billions of dollars in capital expenditure, with pricing reflecting the significant engineering and execution capabilities required.

Beyond the initial Engineering, Procurement, Construction, and Installation (EPCI) phase, MODEC secures substantial, recurring revenue through long-term Operations and Maintenance (O&M) agreements. These contracts are crucial for stable income over the lifecycle of floating production systems.

Pricing for these O&M services is generally structured as a recurring fee. This fee is often tied to performance metrics, such as guaranteed uptime, and the specific services MODEC commits to providing, ensuring a predictable revenue flow.

For instance, in 2024, O&M contracts are a significant component of MODEC's business, contributing to its overall financial stability and allowing for continuous investment in technological advancements and service enhancements for its clients' assets.

MODEC's value-based pricing for its Floating Production Storage and Offloading (FPSO) and Floating Storage and Offloading (FSO) units directly correlates with the substantial economic benefits they deliver. This strategy acknowledges the critical role these assets play in unlocking hydrocarbon reserves, enhancing production efficiency, and ensuring operational uptime, which translates into significant long-term revenue streams for clients.

The pricing reflects the sophisticated engineering, robust reliability, and MODEC's proven track record in deploying these complex systems in demanding offshore conditions. For instance, the average day rate for a large FPSO can range from $200,000 to $500,000, a figure justified by the capital expenditure, operational expertise, and the immense value generated through sustained oil and gas production.

Competitive Bidding and Tendering

MODEC navigates a fiercely competitive global market where pricing is largely dictated by extensive competitive bidding and tendering procedures. This necessitates the submission of comprehensive proposals detailing technical capabilities, project execution strategies, and precise pricing. For instance, in 2024, the offshore wind sector alone saw billions invested in new projects, with tender outcomes heavily influenced by cost-competitiveness.

Strategic pricing is paramount for MODEC to secure contracts while maintaining healthy profit margins, reflecting the superior quality of its services and advanced technology. The company must balance market demands for cost-effectiveness with the inherent value of its specialized solutions.

- Competitive Pricing: MODEC must align its bids with market expectations, often facing pressure to offer competitive rates in tenders.

- Value Proposition: Pricing strategies need to clearly articulate the premium associated with MODEC's technological innovation and project execution excellence.

- Profitability: Ensuring bids are sufficiently profitable is critical, especially given the high capital expenditure and long project lifecycles in the FPSO sector.

- Market Benchmarking: MODEC likely benchmarks its pricing against competitors' successful bids and industry cost structures to remain viable.

Financing and Lease Options

MODEC recognizes that the significant capital expenditure associated with its floating production storage and offloading (FPSO) units necessitates flexible financial solutions. For projects requiring its owned and operated fleet, MODEC can arrange or support diverse financing structures and lease options. This approach aims to enhance the accessibility of its high-value assets for clients.

These arrangements often include build-own-operate-transfer (BOOT) models or extended charter agreements. Under a charter, clients typically pay a recurring charter rate, either daily or monthly. For instance, in 2024, MODEC secured a long-term charter contract for its FPSO to support a major offshore project, demonstrating the ongoing demand for such flexible financing. This strategy allows clients to leverage MODEC's expertise and assets without the upfront capital burden of outright purchase.

- Build-Own-Operate-Transfer (BOOT) Models: Clients benefit from MODEC managing the entire lifecycle of the FPSO, from construction to operation, with ownership transferring at a later stage.

- Long-Term Charter Agreements: Provides predictable operational costs for clients, with MODEC retaining ownership and operational responsibility of the FPSO.

- Facilitated Financing: MODEC can assist clients in securing necessary financing for projects utilizing its FPSO units.

- Asset Accessibility: Flexible financial terms make MODEC's sophisticated FPSO technology and operational capabilities attainable for a broader range of offshore E&P companies.

MODEC's pricing strategy is fundamentally project-driven, reflecting the custom nature of its floating production systems. This means each contract's price is meticulously calculated based on the project's unique scope, complexity, technology, and risk. For example, the significant capital expenditure for a large deepwater FPSO project, which can run into billions, directly influences its pricing. This bespoke approach ensures clients are paying for a solution precisely engineered for their specific needs.

4P's Marketing Mix Analysis Data Sources

Our MODEC 4P's Marketing Mix Analysis is grounded in comprehensive data, including official company reports, investor communications, and detailed market research. We meticulously examine product portfolios, pricing strategies, distribution channels, and promotional activities.