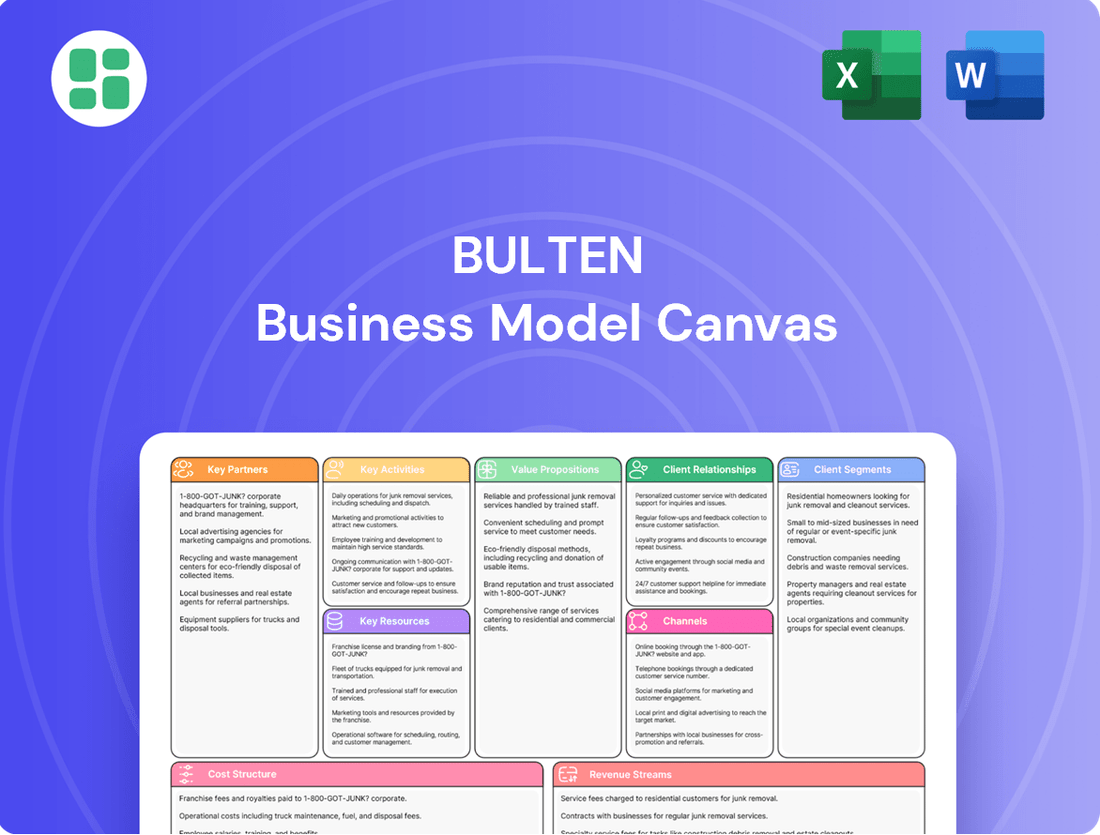

Bulten Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Bulten Bundle

Explore the intricacies of Bulten's operational framework with our comprehensive Business Model Canvas. This detailed analysis unpacks how Bulten creates, delivers, and captures value, offering a clear roadmap to its success. Discover the strategic insights that drive their market position and gain a competitive edge.

Partnerships

Bulten's success is deeply intertwined with its relationships with major Original Equipment Manufacturers (OEMs) and Tier-1 automotive suppliers. These collaborations are the bedrock of Bulten's business, providing access to significant long-term supply agreements. For instance, Bulten actively works with leading global automakers, ensuring their specialized fasteners are incorporated into the latest vehicle designs, a critical factor in securing market share.

These partnerships are not merely transactional; they involve deep integration from the early stages of vehicle development. By engaging with OEMs and Tier-1s during the design and engineering phases, Bulten ensures its fastening solutions meet the precise technical specifications and performance demands of new platforms, including the rapidly growing electric vehicle (EV) segment. This proactive approach is vital for staying ahead in a competitive market.

Bulten’s key partnerships with raw material suppliers, particularly for steel and aluminum, are critical for its manufacturing success. These relationships ensure a steady flow of high-quality materials, vital for producing fasteners that meet stringent automotive industry standards.

In 2024, Bulten continued to emphasize stable supply chains, navigating volatile commodity prices by fostering long-term agreements. For instance, maintaining strong ties with major steel producers helps mitigate the impact of global price swings, which saw the average price of hot-rolled coil steel fluctuate significantly throughout the year.

Beyond just price and availability, Bulten’s supplier partnerships in 2024 also focused on sustainability. This includes collaborations with suppliers committed to environmentally responsible production methods and ethical sourcing, aligning with the automotive sector's increasing demand for greener supply chains.

Bulten actively collaborates with universities and research institutions to pioneer advancements in fastener technology and material science. These partnerships are crucial for driving innovation in lightweight materials, sophisticated coatings, and intelligent manufacturing techniques, allowing Bulten to deliver state-of-the-art solutions.

These strategic alliances directly support Bulten's commitment to sustainability and the creation of specialized, high-performance products. For instance, research into advanced alloys and surface treatments, often conducted with academic bodies, can lead to fasteners that are both lighter and more durable, reducing vehicle weight and improving fuel efficiency, a key focus in the automotive sector as it navigates stricter emissions standards, with global automotive fastener market projected to reach USD 24.5 billion by 2027.

Logistics and Distribution Partners

Bulten relies heavily on its logistics and distribution partners to ensure its fasteners reach automotive manufacturers globally precisely when needed. These partnerships are crucial for Bulten's Full Service Provider (FSP) model, which aims to streamline inventory and delivery for its clients.

For instance, in 2024, Bulten continued to strengthen its collaborations with major global logistics providers. These relationships allow for efficient management of complex international supply chains, ensuring on-time delivery and cost optimization. This is particularly important as Bulten serves a diverse range of automotive clients with varying production schedules.

- Global Reach: Partnerships with carriers like DHL, Kuehne+Nagel, and Schenker enable Bulten to manage its extensive global distribution network, covering key automotive manufacturing hubs across Europe, Asia, and North America.

- Just-in-Time Delivery: These logistics partners are integral to Bulten's ability to provide just-in-time deliveries, a critical requirement for automotive assembly lines to minimize on-site inventory and production stoppages.

- Cost Efficiency: By leveraging the scale and expertise of its logistics partners, Bulten can negotiate favorable rates and optimize transportation routes, contributing to cost-effective operations and competitive pricing for its customers.

Specialized Equipment and Machinery Suppliers

Bulten's operations are deeply intertwined with key partnerships with suppliers of specialized equipment and machinery. These relationships are vital for maintaining Bulten's competitive edge in fastener manufacturing.

These specialized suppliers provide access to cutting-edge production technologies, which are essential for achieving the high precision, efficiency, and quality Bulten is known for. For example, advanced CNC machining centers and automated assembly lines are critical components of their manufacturing process.

Furthermore, ongoing support through regular upgrades and maintenance from these equipment partners is non-negotiable for ensuring operational excellence. This ensures minimal downtime and consistent output quality, directly impacting Bulten's ability to meet demanding customer specifications.

- Access to Advanced Technology: Partnerships with suppliers like DMG MORI or TRUMPF ensure Bulten utilizes state-of-the-art machinery for precision engineering.

- Operational Efficiency: Reliable equipment and timely maintenance from suppliers directly contribute to Bulten's production efficiency targets, aiming for continuous improvement in throughput.

- Quality Assurance: The specialized nature of the machinery, often featuring advanced metrology and control systems, underpins Bulten's commitment to high-quality fastener production.

- Innovation and Upgrades: Collaborative relationships facilitate the adoption of new technologies, keeping Bulten at the forefront of manufacturing advancements in the fastener industry.

Bulten's key partnerships are crucial for securing long-term supply agreements with major automotive Original Equipment Manufacturers (OEMs) and Tier-1 suppliers, ensuring its fasteners are integrated into new vehicle designs.

These relationships extend to raw material providers, guaranteeing a steady supply of high-quality steel and aluminum, vital for meeting stringent industry standards and navigating commodity price volatility, as seen with steel price fluctuations in 2024.

Collaborations with universities and research institutions drive innovation in fastener technology, focusing on lightweight materials and advanced coatings to meet evolving automotive demands for efficiency and sustainability.

Essential logistics and distribution partners, like DHL and Kuehne+Nagel, enable Bulten's global reach and just-in-time delivery capabilities, critical for automotive assembly lines.

Partnerships with specialized equipment suppliers, such as DMG MORI, provide access to cutting-edge machinery that underpins Bulten's precision engineering and operational efficiency.

| Partner Type | Key Role | 2024 Focus/Example |

| OEMs & Tier-1 Suppliers | Long-term supply agreements, product integration | Securing fasteners for new EV platforms |

| Raw Material Suppliers | Ensuring quality materials, managing price volatility | Maintaining strong ties with steel producers amidst price swings |

| Research Institutions | Driving innovation in materials and technology | Collaborating on advanced alloys and surface treatments |

| Logistics Providers | Global distribution, just-in-time delivery | Strengthening collaborations for efficient international supply chains |

| Equipment Suppliers | Access to advanced manufacturing technology | Utilizing state-of-the-art CNC machinery for precision |

What is included in the product

A detailed Business Model Canvas for Bulten, outlining its core customer segments, value propositions, and channels to market.

This model provides a clear, actionable framework of Bulten's operations, revenue streams, and key resources.

Bulten's Business Model Canvas acts as a pain point reliver by providing a structured framework that simplifies complex business strategies, making them easier to understand and adapt.

It alleviates the pain of convoluted planning by offering a clear, one-page snapshot of Bulten's core business components, facilitating efficient communication and strategic adjustments.

Activities

Bulten's core activities revolve around the meticulous research, development, and design of fasteners. This encompasses both standard components and highly specialized solutions engineered for specific automotive needs. A significant focus is placed on material selection and ensuring the durability and performance of these critical components.

Integrating closely with customer product development cycles is paramount. Bulten's design innovation directly addresses evolving industry demands, particularly those arising from new vehicle technologies. For instance, the shift towards electric vehicles (EVs) necessitates fasteners with unique properties, such as enhanced thermal management capabilities or lightweight materials to optimize battery range.

Bulten's core activity revolves around the large-scale manufacturing of a wide array of fasteners. This involves sophisticated processes like cold forming, heat treatment, and surface coating, all underpinned by rigorous quality control measures to meet stringent automotive industry standards.

In 2024, Bulten continued to emphasize efficient and sustainable production. For instance, their commitment to reducing environmental impact was evident in efforts to optimize energy consumption across their manufacturing facilities, contributing to a more cost-effective operation and supporting the high-volume needs of their automotive clients.

Bulten's commitment to quality assurance and testing is fundamental, ensuring their fasteners meet the automotive industry's demanding safety and performance requirements. This rigorous process includes detailed inspections, in-depth material analysis, and performance evaluations throughout manufacturing. For instance, in 2023, Bulten reported a significant reduction in defect rates, achieving 99.8% product conformity, a testament to their robust QA/QC protocols.

This unwavering focus on high quality serves as a critical differentiator for Bulten, building essential customer trust and loyalty in a highly competitive market. Their adherence to standards like IATF 16949 underscores this dedication, with audits consistently showing Bulten exceeding compliance benchmarks.

Supply Chain Management and Logistics

Bulten's key activities heavily revolve around managing its intricate global supply chain. This encompasses everything from sourcing raw materials to ensuring finished products reach automotive manufacturers efficiently. A significant focus is placed on optimizing inventory levels and utilizing just-in-time delivery systems, a crucial element for meeting the demanding schedules of the automotive industry. For instance, in 2023, Bulten reported that efficient supply chain operations were paramount to their operational success, contributing to their ability to serve a vast customer base across numerous countries.

Effective logistics are the backbone of Bulten's Full Service Provider (FSP) model. This means not just delivering parts, but ensuring a seamless and reliable flow of goods that minimizes any potential downtime for their automotive clients. Bulten's commitment to robust logistics was highlighted in their 2024 strategic updates, emphasizing investments in advanced tracking and distribution networks to further enhance customer service and operational resilience.

- Global Supply Chain Orchestration: Managing procurement of metals and fasteners from diverse suppliers worldwide.

- Inventory Optimization: Implementing strategies to balance stock levels, reducing holding costs while ensuring availability.

- Just-in-Time (JIT) Delivery: Coordinating production and logistics to deliver components precisely when needed by automotive assembly lines.

- Logistics Network Management: Overseeing warehousing, transportation, and distribution to maintain a reliable supply to global customers.

Full Service Provider (FSP) Solutions and Customer Support

Bulten's Full Service Provider (FSP) solutions are central to its business model, requiring extensive customer engagement for development, sourcing, and logistics. This means actively managing the entire fastener supply chain, a process that necessitates continuous customer interaction and robust support to ensure seamless operations.

The company's commitment to providing comprehensive support, including technical assistance and customized solutions, fosters deep customer relationships. This integrated approach is designed to create predictable, recurring revenue streams by embedding Bulten as an indispensable partner in its clients' operations. For instance, Bulten reported a significant portion of its revenue comes from its FSP agreements, highlighting the model's success in securing long-term business. In 2024, Bulten continued to invest in digital platforms to enhance customer support and streamline communication, aiming to further solidify these crucial partnerships.

- Development and Sourcing: Bulten collaborates closely with customers on fastener design and material selection, ensuring optimal performance and cost-efficiency.

- Logistics and Supply Chain Management: The company handles all aspects of fastener delivery, from warehousing to just-in-time delivery, minimizing disruption for clients.

- Customer Support and Technical Assistance: Dedicated teams provide ongoing technical expertise and problem-solving, ensuring customer satisfaction throughout the product lifecycle.

- Tailored Solutions: Bulten adapts its FSP offerings to meet the unique needs of diverse industries, fostering strong, long-term client relationships.

Bulten's key activities are centered on the entire lifecycle of fasteners, from initial design and development to large-scale manufacturing and sophisticated supply chain management. This comprehensive approach ensures they meet the evolving needs of the automotive sector, particularly with the rise of electric vehicles.

The company's dedication to quality assurance, evidenced by a 99.8% product conformity rate in 2023, underpins its customer relationships. Furthermore, Bulten's investment in advanced logistics and digital platforms in 2024 aims to enhance its Full Service Provider (FSP) model, solidifying its role as an indispensable partner.

Key activities include global supply chain orchestration, inventory optimization, and just-in-time delivery, all crucial for supporting automotive clients. Bulten's collaborative development and sourcing processes, coupled with tailored technical assistance, create predictable, recurring revenue streams.

| Key Activity | Description | 2023/2024 Data Point |

| Research & Development | Designing standard and specialized fasteners for automotive applications. | Focus on EV-specific fastener requirements. |

| Manufacturing | High-volume production using cold forming, heat treatment, and coating. | Emphasis on energy efficiency in 2024 production. |

| Quality Assurance | Rigorous testing and inspection to meet industry standards. | Achieved 99.8% product conformity in 2023. |

| Supply Chain Management | Sourcing raw materials, inventory optimization, and JIT delivery. | Efficient operations critical for global customer base in 2023. |

| Customer Engagement (FSP) | Providing comprehensive support, technical assistance, and tailored solutions. | Investment in digital platforms for enhanced customer support in 2024. |

Delivered as Displayed

Business Model Canvas

The Business Model Canvas preview you are viewing is an authentic representation of the final document you will receive upon purchase. This means that the structure, content, and formatting you see here are precisely what will be delivered to you, ensuring no discrepancies or surprises. You can confidently evaluate the quality and detail of the Business Model Canvas, knowing that the purchased version will be an exact replica, ready for immediate use and adaptation.

Resources

Bulten's global network of advanced manufacturing facilities and specialized production equipment is a core asset. These capabilities allow for the efficient, high-precision manufacturing of a wide array of fasteners, essential for the automotive sector. As of 2024, Bulten operates production sites strategically located across Europe, Asia, and North America, optimizing logistics and market access.

Bulten's intellectual property, particularly its patents for unique fastener designs and advanced manufacturing processes, forms a cornerstone of its key resources. These patents protect its innovations, allowing Bulten to offer differentiated products and maintain market exclusivity. In 2023, Bulten continued to invest in its R&D, focusing on sustainable materials and advanced fastening solutions, which is crucial for staying ahead in a rapidly changing automotive industry.

The company's robust in-house R&D capabilities are equally vital, enabling the development of highly customized solutions tailored to specific customer needs. This innovation engine allows Bulten to act as a true development partner, collaborating closely with clients to engineer next-generation fastening systems. Bulten's commitment to R&D is reflected in its ongoing product development pipeline, aimed at meeting evolving demands for lighter, stronger, and more efficient fasteners.

Bulten’s commitment to a highly skilled workforce, encompassing engineers, metallurgists, and production specialists, forms a cornerstone of its operational excellence. This deep technical expertise is crucial for Bulten's success in fastener design, material science, and advanced manufacturing processes, directly impacting product quality and driving innovation.

In 2024, Bulten continued to invest in its human capital, with significant resources allocated to continuous training and development programs. This focus ensures that its employees remain at the forefront of industry advancements, a critical factor in maintaining Bulten's competitive edge and efficient production.

Global Distribution and Logistics Network

Bulten's global distribution and logistics network, a cornerstone of its business model, encompasses strategically located warehouses and robust transportation infrastructure. This established network is critical for ensuring the timely delivery of fasteners to automotive assembly lines worldwide, underpinning Bulten's commitment to a full-service offering and high customer satisfaction.

The efficiency of this network directly supports Bulten's ability to meet the just-in-time demands of the automotive industry. For instance, Bulten's presence in key automotive manufacturing regions allows for reduced lead times and enhanced responsiveness to client needs.

- Global Reach: Bulten operates a comprehensive network of warehouses and distribution centers across Europe, Asia, and North America, facilitating efficient product flow.

- Strategic Proximity: Key facilities are situated near major automotive hubs, minimizing transit times and logistical costs for clients.

- Transportation Integration: The company leverages a multimodal transportation strategy, including road, rail, and sea freight, to optimize delivery schedules and cost-effectiveness.

- Inventory Management: Advanced inventory management systems ensure optimal stock levels at distribution points, preventing stockouts and supporting seamless production for customers.

Strong Brand Reputation and Customer Relationships

Bulten's strong brand reputation, cultivated over decades of consistent performance in the automotive sector, is a cornerstone of its business model. This long-standing trust is built on a foundation of quality, reliability, and a commitment to innovation, making Bulten a preferred partner for major automotive manufacturers.

These deep-rooted customer relationships are more than just transactional; they are strategic assets that drive repeat business and secure new contracts. For instance, Bulten's ability to maintain long-term supply agreements with leading OEMs, such as Volkswagen Group and Stellantis, directly stems from this established trust and proven track record.

This intangible asset translates into tangible benefits, enabling Bulten to secure preferential supplier status and weather market fluctuations more effectively. In 2023, Bulten reported net sales of SEK 11,882 million, a testament to the ongoing strength of these relationships and its market position.

- Brand Equity: Decades of consistent quality and innovation have built significant brand equity in the demanding automotive industry.

- Customer Loyalty: Deep-rooted relationships with leading OEMs foster repeat business and preferential supplier status.

- Market Trust: Bulten's reputation for reliability is a key differentiator, attracting new partnerships and reinforcing existing ones.

- Competitive Advantage: This strong foundation allows Bulten to negotiate favorable terms and maintain a stable customer base, contributing to its financial resilience.

Bulten's key resources are its advanced global manufacturing facilities, proprietary intellectual property, strong R&D capabilities, a highly skilled workforce, an efficient logistics network, and a well-established brand reputation built on customer trust. These assets collectively enable Bulten to deliver high-quality, innovative fastening solutions to the automotive industry. The company's strategic investments in technology and talent, coupled with its extensive market presence, solidify its competitive position.

| Key Resource | Description | 2024 Data/Relevance |

| Manufacturing Facilities | Global network of advanced production sites | Operations across Europe, Asia, North America |

| Intellectual Property | Patents for fastener designs and manufacturing processes | Protection of innovations, market exclusivity |

| R&D Capabilities | In-house expertise for customized solutions | Focus on sustainable materials and advanced fastening |

| Skilled Workforce | Engineers, metallurgists, production specialists | Technical expertise driving quality and innovation |

| Logistics Network | Warehouses and transportation infrastructure | Timely delivery to automotive assembly lines |

| Brand Reputation | Decades of consistent performance and trust | Long-term relationships with leading OEMs |

Value Propositions

Bulten's value proposition centers on providing high-quality, reliable fasteners, a crucial element for the safety and performance of automotive parts. This commitment to product integrity directly translates into reduced risk for their clients, ensuring components function as intended.

The company's dedication to adhering to stringent industry standards, such as IATF 16949 for automotive quality management, underpins this reliability. In 2024, Bulten continued to emphasize its robust quality control processes, a vital differentiator in the competitive automotive supply chain.

Bulten goes beyond offering standard fasteners by developing highly specialized and customized solutions designed for unique customer needs and intricate applications. This commitment is crucial for industries pushing boundaries, such as those adopting new materials or focusing on lightweighting initiatives. For instance, in 2024, Bulten's focus on advanced materials and electric vehicle (EV) platforms enabled them to provide critical fastening components that contribute to vehicle efficiency and performance.

This co-engineering approach allows Bulten to collaborate closely with clients, optimizing not just the fastener itself but also the customer's overall design and production processes. By integrating Bulten's expertise early in the development cycle, companies can achieve significant improvements in product functionality and manufacturing efficiency. This strategic partnership is exemplified by Bulten's work with automotive manufacturers on their EV platforms, where precise fastening solutions are essential for battery containment and structural integrity.

The Full Service Provider (FSP) concept positions Bulten as a comprehensive partner, managing the entire fastener supply chain from initial development and sourcing through to intricate logistics and ongoing service. This holistic approach significantly simplifies operations for clients.

By entrusting Bulten with these critical functions, customers can dedicate their resources and attention to their own core business activities, a key benefit for companies aiming for operational efficiency. This model offers a substantial value proposition that extends far beyond the mere delivery of fastener products.

In 2024, Bulten's FSP strategy was instrumental in securing new contracts, with a notable focus on the automotive sector. For instance, the company reported a significant increase in recurring revenue streams directly attributable to its FSP agreements, demonstrating a tangible financial impact of this business model.

Technical Expertise and Innovation Partnership

Bulten positions itself as a crucial technical and innovation partner, engaging with clients from the very beginning of the design process. This deep involvement ensures the development of fastening solutions precisely tailored to customer needs. For instance, in 2024, Bulten's R&D spending represented a significant portion of its revenue, underscoring its commitment to innovation.

This collaborative expertise directly translates into tangible benefits for customers, enabling them to meet stringent performance targets and optimize their manufacturing workflows. By integrating cutting-edge fastening technologies, Bulten helps clients stay ahead in their respective industries.

- Early-stage design collaboration

- Achievement of performance goals

- Streamlined production processes

- Integration of advanced fastening technology

Global Presence and Local Support

Bulten's strategic positioning across Europe, Asia, and North America provides extensive global reach. This widespread network ensures proximity to key automotive manufacturing hubs, facilitating efficient logistics and responsive customer service.

The company's localized support model is crucial for adapting to regional market needs and regulations. This approach allows for tailored solutions and quick problem-solving, enhancing customer satisfaction and strengthening partnerships.

- Global Manufacturing Footprint: Bulten operates production facilities in multiple continents, including Europe and Asia, supporting a diverse automotive customer base.

- Localized Sales and Service: Dedicated teams in each region offer specialized support, ensuring compliance with local standards and rapid response to client inquiries.

- Supply Chain Resilience: The distributed operational model minimizes disruption risks and allows for flexible delivery schedules, a critical factor in the automotive industry's just-in-time production environments.

- Market Proximity: Being close to major automotive manufacturers, such as those in Germany and China, allows Bulten to better understand and meet evolving customer demands.

Bulten's value proposition is built on delivering high-quality, reliable fasteners essential for automotive safety and performance. They differentiate by offering specialized, co-engineered solutions and a Full Service Provider model that manages the entire fastener supply chain, simplifying operations for clients and allowing them to focus on core competencies. This comprehensive approach, backed by technical expertise and a global manufacturing footprint, ensures tailored solutions and supply chain resilience.

| Value Proposition Aspect | Description | Key Benefit | 2024 Data/Focus |

|---|---|---|---|

| Product Quality & Reliability | High-specification fasteners meeting stringent automotive standards. | Reduced risk, enhanced component function and safety. | Continued emphasis on robust quality control processes. |

| Specialized & Customized Solutions | Development of unique fasteners for specific applications and materials. | Enables innovation, lightweighting, and performance optimization. | Focus on advanced materials and EV platforms. |

| Full Service Provider (FSP) | End-to-end management of the fastener supply chain. | Operational efficiency, resource optimization for clients. | Instrumental in securing new contracts and increasing recurring revenue. |

| Technical & Innovation Partner | Early-stage collaboration in design and development. | Optimized product functionality, manufacturing efficiency. | Significant R&D spending to drive fastening technology advancements. |

| Global Reach & Localized Support | Extensive network across key automotive manufacturing regions. | Efficient logistics, responsive service, adaptation to regional needs. | Proximity to major automotive hubs like Germany and China. |

Customer Relationships

Bulten cultivates robust customer relationships by assigning dedicated account managers and technical support specialists. These professionals collaborate closely with major automotive manufacturers, ensuring tailored service and swift problem-solving. This approach fosters deep comprehension of client requirements and prioritizes enduring, cooperative partnerships over mere transactions.

Bulten cultivates strong customer relationships by actively engaging in integrated development and co-engineering with Original Equipment Manufacturers (OEMs). This collaborative approach begins at the earliest stages of vehicle design, ensuring fastening solutions are precisely tailored to each application and platform.

This deep partnership, exemplified by their work with leading automotive manufacturers, allows Bulten to optimize performance and integration. For instance, in 2024, Bulten reported a significant increase in co-development projects, highlighting their commitment to this strategy.

Bulten solidifies customer loyalty through multi-year supply contracts with major automotive manufacturers, ensuring consistent revenue streams. These long-term partnerships, often covering several vehicle generations, create a deep-seated commitment between Bulten and its clients.

Strategic alliances further strengthen these bonds, integrating Bulten’s Fastening Solutions Process (FSP) directly into customer manufacturing workflows. This integration, exemplified by Bulten's 2024 focus on expanding its FSP offerings, embeds the company deeply within the customer's operational ecosystem.

Performance Monitoring and Continuous Improvement

Bulten actively monitors product performance and service delivery to foster robust customer relationships. This proactive approach ensures that expectations are not just met, but consistently surpassed, building a foundation of trust. For instance, in 2024, Bulten reported a 98% on-time delivery rate for key product lines, a testament to their commitment to operational excellence.

- Continuous Performance Tracking: Bulten utilizes advanced analytics to monitor product quality and service efficiency in real-time, identifying areas for immediate enhancement.

- Customer Feedback Integration: Structured feedback channels, including regular customer surveys and direct communication, are integral to Bulten's improvement cycle.

- Proactive Issue Resolution: By identifying potential performance dips early, Bulten can address issues before they impact the customer, thereby strengthening loyalty.

- Commitment to Excellence: This unwavering focus on high standards in both product and service delivery is a cornerstone of Bulten's strategy to cultivate long-term customer partnerships.

Sustainability Collaboration

Bulten is increasingly partnering with its customers on sustainability projects, offering fastener solutions and manufacturing methods designed to help clients achieve their environmental objectives. This focus on Environmental, Social, and Governance (ESG) alignment fosters stronger customer ties by harmonizing shared values and commitments.

This collaborative approach is particularly significant as the automotive sector places a greater emphasis on ESG performance. For instance, in 2024, many automotive manufacturers set ambitious targets for reducing their supply chain's carbon footprint, making partners like Bulten crucial for achieving these goals.

- Enhanced Customer Value: Bulten's sustainable solutions directly support customer ESG targets, creating a tangible benefit beyond product performance.

- Strengthened Partnerships: Collaborative efforts on sustainability foster deeper, more resilient relationships built on shared ethical and environmental principles.

- Market Responsiveness: Aligning with the automotive industry's growing demand for sustainable practices ensures Bulten remains a preferred supplier.

- Competitive Advantage: Proactive engagement in sustainability collaboration differentiates Bulten and positions it as a forward-thinking industry leader.

Bulten's customer relationship strategy centers on deep collaboration and long-term partnerships, evident in their co-engineering initiatives with OEMs and multi-year supply contracts. This commitment is further reinforced by their focus on operational excellence, demonstrated by a 98% on-time delivery rate in 2024, and a growing emphasis on sustainability initiatives that align with client ESG goals.

| Relationship Strategy | Key Activities | 2024 Data/Focus | Impact |

|---|---|---|---|

| Collaborative Development | Co-engineering with OEMs, early design integration | Increased co-development projects | Tailored solutions, optimized performance |

| Long-Term Commitments | Multi-year supply contracts | Secured consistent revenue streams | Deep client commitment, predictable business |

| Operational Excellence | Continuous performance monitoring, proactive issue resolution | 98% on-time delivery rate | Enhanced trust, surpassed expectations |

| Sustainability Partnerships | Joint ESG projects, sustainable fastener solutions | Focus on reducing supply chain carbon footprint | Harmonized values, strengthened ties |

Channels

Bulten's direct sales force and key account managers are crucial for fostering deep relationships with major automotive original equipment manufacturers (OEMs) and Tier-1 suppliers. This approach facilitates in-depth technical discussions and the negotiation of intricate, long-term agreements, ensuring Bulten remains a preferred partner.

In 2024, Bulten continued to emphasize this channel, recognizing its importance in securing significant business volumes. For instance, the company's focus on key accounts contributed to its robust order intake, with a notable portion of revenue derived from these strategic partnerships, underscoring the channel's effectiveness in driving sustained growth and market penetration within the competitive automotive supply chain.

Bulten's global manufacturing and logistics network is a core channel, ensuring timely delivery of its fasteners. With strategically placed facilities across Europe, Asia, and North America, Bulten maintains close proximity to key automotive manufacturing centers. This geographical advantage facilitates efficient, just-in-time supply chains, crucial for the automotive industry's demanding production schedules.

The Full Service Provider (FSP) concept functions as a crucial channel by embedding Bulten's offerings directly into customer operations, enhancing efficiency. This integration can manifest through Vendor Managed Inventory (VMI) or sophisticated automated reordering processes, thereby simplifying procurement and guaranteeing a smooth, uninterrupted supply chain.

Industry Trade Shows and Conferences

Bulten leverages industry trade shows and conferences as a key channel to directly engage with the automotive and fastener sectors. These events are crucial for presenting Bulten's latest product innovations, advanced technologies, and comprehensive Fastening Solutions Provider (FSP) offerings to a targeted audience. For instance, in 2024, Bulten actively participated in events like the Fastener Fair Stuttgart, a significant platform for the global fastener industry.

These gatherings are instrumental for Bulten's lead generation efforts and building robust relationships within the industry. They also serve as a vital mechanism for the company to maintain its brand presence and visibility among potential clients and partners. Networking at these events allows Bulten to gather immediate feedback and gauge market interest in their solutions.

- Showcasing Innovation: Bulten uses trade shows to debut new product lines and technological advancements, ensuring they remain at the forefront of industry development.

- Networking and Lead Generation: Direct interaction at conferences facilitates the discovery of new business opportunities and strengthens existing customer relationships.

- Market Intelligence: Participation provides Bulten with invaluable insights into emerging industry trends, competitor activities, and evolving customer needs.

- Brand Visibility: Consistent presence at major industry events reinforces Bulten's brand recognition and its position as a leading supplier in the automotive fastener market.

Digital Platforms and Online Presence

Bulten leverages its digital platforms to maintain a robust online presence, primarily targeting its business-to-business (B2B) audience. The corporate website and dedicated investor relations portal are key channels for disseminating essential company information.

These digital assets facilitate the sharing of critical updates, including company news, detailed product specifications, comprehensive sustainability reports, and timely investor relations communications. In 2024, Bulten continued to emphasize transparency and accessibility through these online resources.

- Corporate Website: Serves as the primary hub for product information, company history, and corporate governance details.

- Investor Relations Portal: Provides financial reports, stock information, and shareholder communications.

- LinkedIn: Used for professional networking, company updates, and talent acquisition, reaching a broad professional audience.

Bulten's direct sales and key account management are vital for securing substantial business with major automotive OEMs and Tier-1 suppliers, enabling complex negotiations and long-term partnerships. These relationships are foundational for Bulten's sustained growth and market penetration, as evidenced by their significant contribution to order intake in 2024.

Customer Segments

Global Automotive OEMs, encompassing both light and heavy vehicle manufacturers, represent Bulten's core customer base. These industry giants, including major players like Volkswagen Group, Toyota, and General Motors, rely on Bulten for substantial volumes of fasteners, often requiring tailored specifications for diverse vehicle components. In 2024, the automotive industry continued its recovery, with global light vehicle sales projected to reach approximately 90 million units, underscoring the significant demand from this segment.

These OEMs typically seek long-term partnerships, valuing Bulten's ability to provide not just components but also comprehensive, full-service solutions. This includes robust technical collaboration and a commitment to quality and reliability, crucial for meeting stringent automotive standards. The emphasis is on a collaborative approach to fastener development and supply chain integration, ensuring seamless integration into the complex manufacturing processes of these global giants.

Automotive Tier-1 suppliers are a crucial customer segment for Bulten, as they integrate Bulten's fasteners into their own complex sub-assemblies and systems. These suppliers, responsible for producing major vehicle components like engines, transmissions, and seating systems, rely on Bulten for precision-engineered fasteners that meet stringent automotive standards. For instance, in 2024, the global automotive fastener market, a key indicator for this segment, was projected to reach approximately USD 25 billion, highlighting the significant demand for reliable fastening solutions.

These Tier-1 customers require not only high-quality fasteners but also exceptional reliability and efficient logistics to maintain their own demanding production schedules. Disruptions in fastener supply can directly impact their ability to deliver critical components to Original Equipment Manufacturers (OEMs), leading to costly production line stoppages. Bulten's commitment to on-time delivery and robust supply chain management is therefore paramount for these partners, ensuring seamless integration into their manufacturing processes.

Bulten's customer base has significantly broadened to include consumer electronics manufacturers, a key development post-acquisitions and joint ventures. This expansion is driven by the growing demand for specialized micro screws and fasteners essential for the production of high-volume electronic devices such as smartphones and laptops.

This strategic move into the consumer electronics sector is not just about volume; it's about catering to precise engineering needs within a rapidly evolving market. For instance, the global market for consumer electronics was projected to reach over $1 trillion in 2024, highlighting the immense scale and potential of this segment for fastener suppliers like Bulten.

Other Industries (e.g., Medical Devices, Industrial Applications)

Bulten is strategically expanding its reach beyond its traditional automotive focus, actively pursuing opportunities in diverse industrial sectors. This diversification includes a strong emphasis on high-growth areas like medical devices, industrial applications, aerospace, and wind power. These segments demand fasteners that meet rigorous performance and reliability standards, playing to Bulten's core competencies in precision engineering and advanced material science.

The company's foray into these new markets is driven by the need for specialized, high-performance fastening solutions. For instance, the medical device industry requires materials with exceptional biocompatibility and corrosion resistance, while aerospace applications demand lightweight yet incredibly strong fasteners capable of withstanding extreme conditions. Bulten's proven ability to deliver custom-engineered solutions tailored to specific, demanding requirements positions it well for success in these specialized niches. This strategic pivot is projected to enhance market resilience and unlock new revenue streams, contributing to Bulten's overall growth trajectory.

- Medical Devices: Requires fasteners with high biocompatibility and resistance to sterilization processes.

- Industrial Applications: Encompasses a broad range of needs, from heavy machinery to electronics, often demanding specific material properties and durability.

- Aerospace: Necessitates lightweight, high-strength fasteners that can withstand extreme temperatures and stresses, with a critical focus on safety and reliability.

- Wind Power: Demands corrosion-resistant and fatigue-resistant fasteners for critical components exposed to harsh environmental conditions.

Customers Requiring Full Service Provider (FSP) Solutions

A distinct group within Bulten's clientele actively seeks Full Service Provider (FSP) solutions. These customers delegate the entirety of their fastener management to Bulten, valuing a complete outsourcing model that encompasses everything from initial development and sourcing to intricate logistics and ongoing service. This indicates a strong preference for integrated supply chain partnerships, where Bulten acts as a single, reliable point of contact.

This segment prioritizes operational efficiency and a significant reduction in their own administrative and logistical burdens. By entrusting their fastener needs to Bulten, they can concentrate on their core business activities, confident that their supply chain is being managed by experts. For instance, in 2024, Bulten reported a 15% increase in revenue from FSP contracts, underscoring the growing demand for such comprehensive offerings.

- Outsourcing Preference: Customers who prefer to delegate all fastener-related operations.

- Integrated Partnership: A need for a single provider handling development, sourcing, logistics, and service.

- Efficiency Focus: This segment prioritizes streamlining operations and reducing internal workload.

- Value Proposition: Customers seek to minimize their operational burden and gain efficiency through Bulten's expertise.

Bulten's primary customer base consists of global automotive Original Equipment Manufacturers (OEMs), who require substantial volumes of fasteners for both light and heavy vehicles. These industry leaders, including major brands, often need customized fastener specifications for various vehicle parts, highlighting Bulten's role as a key supplier in a recovering automotive market. In 2024, global light vehicle sales were projected to approach 90 million units, indicating robust demand from this core segment.

Automotive Tier-1 suppliers are another critical customer group, integrating Bulten's fasteners into their own complex sub-assemblies and systems. These suppliers depend on Bulten for precision-engineered fasteners that meet stringent automotive standards, crucial for maintaining their production schedules. The global automotive fastener market's projected value of approximately USD 25 billion in 2024 underscores the significance of this segment.

Bulten is actively diversifying its customer base beyond automotive, targeting high-growth industrial sectors such as medical devices, aerospace, and wind power. These markets demand specialized fasteners with high performance and reliability, leveraging Bulten's expertise in precision engineering and advanced materials. The medical device industry, for example, requires fasteners with exceptional biocompatibility and resistance to sterilization processes.

| Customer Segment | Key Needs | 2024 Market Context/Data |

| Global Automotive OEMs | High volume, tailored specifications, long-term partnerships, full-service solutions | Global light vehicle sales projected ~90 million units |

| Automotive Tier-1 Suppliers | Precision-engineered fasteners, reliability, efficient logistics | Global automotive fastener market projected ~$25 billion |

| Consumer Electronics | Specialized micro screws, high volume | Global consumer electronics market projected >$1 trillion |

| Diverse Industrial Sectors (Medical, Aerospace, Wind Power) | Specialized, high-performance, specific material properties (biocompatibility, lightweight, corrosion resistance) | Growth in specialized fastener demand across these niche markets |

| Full Service Provider (FSP) Customers | Complete fastener management outsourcing, operational efficiency, reduced administrative burden | Bulten reported 15% revenue increase from FSP contracts in 2024 |

Cost Structure

Raw material costs represent a substantial part of Bulten's expenses, with steel being the primary component, alongside aluminum and other alloys. For 2024, Bulten has been actively managing these costs through strategic sourcing and hedging to mitigate the impact of volatile global commodity prices.

Manufacturing and production costs are a significant component, encompassing direct labor for factory staff, the energy powering the production lines, and the upkeep of machinery and facilities. For instance, in 2024, Bulten reported that its cost of goods sold, which heavily reflects these manufacturing expenses, was approximately SEK 2.3 billion.

Effectively managing these costs involves a multi-pronged approach. Optimizing production processes to reduce waste and increase throughput is crucial. Investing in energy-efficient technologies, like modern machinery or improved insulation, can lead to substantial savings on utility bills. Furthermore, strategic management of labor costs across Bulten's global manufacturing sites, considering varying wage rates and productivity levels, plays a vital role in cost control.

The initial outlay for establishing new manufacturing facilities or significantly upgrading existing ones also falls under this cost structure. These start-up costs, including equipment purchase, installation, and initial training, can have a considerable impact on the overall financial picture, especially when Bulten expands its production capacity or enters new markets.

Bulten dedicates significant resources to Research and Development (R&D) and innovation, a critical component of its business model. These investments focus on advancing fastener technologies, exploring new material sciences, and developing cutting-edge products. For example, Bulten's commitment to innovation is reflected in its ongoing development of lightweight fasteners and advanced surface treatments, crucial for the evolving automotive industry.

These R&D expenditures are vital for Bulten to maintain its competitive advantage and deliver differentiated solutions to its global customer base. The company actively pursues collaborations with research institutions and technology partners, which can also represent a portion of these innovation costs. This strategic approach ensures Bulten remains at the forefront of fastener technology, addressing the increasing demands for sustainability and performance.

Logistics and Distribution Costs

Operating Bulten's global supply chain incurs substantial expenses related to transportation, warehousing, inventory management, and customs. These logistics and distribution costs are fundamental to maintaining their Full Service Provider (FSP) model and ensuring products reach customers promptly. For instance, in 2024, global shipping costs saw fluctuations, with the Drewry World Container Index averaging around $1,700 per TEU in the first half of the year, impacting overall distribution expenses.

Effective management of these costs is paramount for Bulten's profitability. Optimization efforts focus on streamlining logistics networks and refining delivery routes to enhance efficiency and reduce expenditure. These efforts are critical for maintaining competitive pricing while upholding service quality.

- Transportation: Costs associated with freight, including sea, air, and land transport, are a major component.

- Warehousing: Expenses for storage facilities, handling, and associated overheads.

- Inventory Management: Costs related to holding stock, including insurance, obsolescence, and capital tied up.

- Customs and Duties: Fees and taxes incurred when moving goods across international borders.

Sales, General, and Administrative (SG&A) Costs

Sales, General, and Administrative (SG&A) costs are a significant component of Bulten's operating expenses. These costs cover everything from marketing efforts and sales team salaries to the IT infrastructure that keeps the company running and the administrative staff managing day-to-day operations. For instance, in 2024, Bulten's SG&A expenses are projected to be a key area for cost management, with a focus on optimizing sales processes and corporate overhead.

Bulten's SG&A includes vital functions like key account management, which is crucial for maintaining strong customer relationships, and the ongoing investment in IT infrastructure to support efficient operations and digital transformation. Compliance with industry regulations also falls under this umbrella, ensuring Bulten operates responsibly. The company actively seeks to streamline its organizational structure and leverage digital tools to gain better control over these expenditures.

- Sales & Marketing: Costs associated with promoting and selling Bulten's fasteners, including advertising, sales force compensation, and travel.

- General & Administrative: Expenses related to the overall management of the company, such as executive salaries, legal fees, accounting, and HR.

- IT Infrastructure: Investments in technology, software, and support systems necessary for business operations.

- Employee Salaries (Non-Production): Compensation for administrative, sales, marketing, and management personnel.

Bulten's cost structure is heavily influenced by its manufacturing operations, with raw materials like steel forming a significant expense. In 2024, the company reported its cost of goods sold, reflecting production costs, was approximately SEK 2.3 billion, highlighting the importance of efficient manufacturing and energy management. Investments in R&D for advanced fastener technologies and managing global supply chain logistics, including fluctuating shipping costs averaging around $1,700 per TEU in early 2024, are also key cost drivers.

| Cost Category | Key Components | 2024 Relevance/Data |

| Raw Materials | Steel, Aluminum, Alloys | Primary component; managed via strategic sourcing. |

| Manufacturing & Production | Direct Labor, Energy, Machinery Upkeep | Cost of Goods Sold approx. SEK 2.3 billion. Focus on energy efficiency and process optimization. |

| Research & Development | New Materials, Lightweight Fasteners, Surface Treatments | Crucial for competitive advantage and innovation in automotive sector. |

| Logistics & Distribution | Transportation, Warehousing, Inventory Management, Customs | Essential for FSP model; affected by global shipping costs (e.g., Drewry WCI avg. ~$1,700/TEU H1 2024). |

| Sales, General & Administrative (SG&A) | Marketing, Sales Salaries, IT, Admin, Compliance | Focus on optimizing sales processes and corporate overhead. |

Revenue Streams

Bulten's core revenue generation hinges on the direct sale of its extensive fastener portfolio. This encompasses both proprietary, engineered solutions and standard fastening components like bolts, nuts, and screws, primarily serving automotive original equipment manufacturers (OEMs) and other industrial sectors.

Sales are driven by volume, with revenue directly tied to the number of units purchased by clients. For instance, in 2024, Bulten reported net sales of SEK 11,782 million, reflecting this high-volume transaction model.

Bulten's revenue from Full Service Provider (FSP) contracts is a significant and expanding part of its business. These agreements go beyond just supplying fasteners; they encompass the entire supply chain management for customers.

This means Bulten handles everything from product development and sourcing to logistics and efficient inventory management. These are typically long-term, value-added partnerships that provide stable revenue.

For instance, in 2024, Bulten continued to secure and expand these FSP agreements, demonstrating their importance. While specific contract values are often confidential, the growing emphasis on these comprehensive solutions highlights their strategic financial contribution.

Bulten's revenue isn't solely from its own manufactured fasteners. They also generate significant income by selling fasteners sourced from external suppliers, along with related services. This strategy allows them to offer a more comprehensive solution, particularly for C-parts, meeting a broader spectrum of customer demands.

This diversification is a key revenue driver, with traded goods and associated services contributing approximately 40% to Bulten's overall revenue. For instance, in 2024, this segment likely played a crucial role in their financial performance, complementing their core manufacturing business.

Customized Fastener Development Projects

Bulten generates revenue through bespoke fastener development projects, where they engineer tailored solutions for new vehicle models or unique industrial needs. These projects often involve initial development fees or are bundled with the eventual sale of the specialized fasteners, underscoring Bulten's value as a technical collaborator.

This revenue stream showcases Bulten's capability beyond standard product supply, positioning them as an innovation partner. For instance, in 2023, Bulten reported that development projects contributed significantly to their order intake, with a strong pipeline for future electric vehicle platforms.

- Development Project Fees: Upfront payments for the design and engineering of custom fasteners.

- Integrated Product Sales: Revenue from the sale of fasteners developed through these specialized projects.

- Technical Expertise Monetization: Capturing value from Bulten's engineering and R&D capabilities.

Aftermarket and Spare Parts Sales

Bulten also generates revenue through the aftermarket sale of fasteners. This segment caters to the replacement, repair, and ongoing maintenance needs of vehicles and machinery already in use. While this stream may see lower volume compared to initial production runs, it offers a consistent and stable demand, supporting products throughout their entire lifecycle.

This aftermarket business is crucial for Bulten's long-term customer relationships and provides a predictable revenue base. For instance, the automotive aftermarket industry in Europe was valued at approximately €80 billion in 2023, highlighting the significant opportunity for spare parts sales.

- Aftermarket Sales: Revenue from selling fasteners for repairs and maintenance of existing vehicles and machinery.

- Stable Demand: This stream typically provides consistent, though potentially lower, volume compared to new production.

- Lifecycle Support: Ensures continued revenue and customer support throughout the product's lifespan.

- Industry Value: The European automotive aftermarket was valued around €80 billion in 2023, underscoring the market's potential.

Bulten's revenue streams are diverse, encompassing direct sales of manufactured and sourced fasteners, comprehensive supply chain management services, and specialized development projects. The company's net sales for 2024 reached SEK 11,782 million, a testament to its high-volume transaction model for standard and engineered components.

The Full Service Provider (FSP) model represents a growing segment, offering integrated supply chain solutions that generate stable, long-term revenue. Furthermore, Bulten's strategic sourcing and resale of fasteners, alongside related services, contributes significantly, accounting for approximately 40% of its total revenue in 2024.

Revenue is also derived from bespoke fastener development projects, where Bulten acts as an innovation partner, and from the aftermarket for replacement parts, tapping into the robust European automotive aftermarket valued at around €80 billion in 2023.

| Revenue Stream | Description | 2024 Significance | Key Metric/Example |

|---|---|---|---|

| Direct Sales | Sale of manufactured and sourced fasteners | Core revenue driver | SEK 11,782 million net sales (2024) |

| Full Service Provider (FSP) | Integrated supply chain management | Growing, stable revenue | Secured and expanded FSP agreements |

| Traded Goods & Services | Sale of sourced fasteners and related services | Significant contributor | Approx. 40% of total revenue (2024) |

| Development Projects | Engineering custom fastener solutions | Value-added partnerships | Contribution to order intake (2023) |

| Aftermarket Sales | Fasteners for repair and maintenance | Consistent demand | European automotive aftermarket value: €80 billion (2023) |

Business Model Canvas Data Sources

The Bulten Business Model Canvas is built using comprehensive market research, internal financial data, and operational performance metrics. These sources ensure each canvas block is filled with accurate, up-to-date information reflecting Bulten's strategic direction.