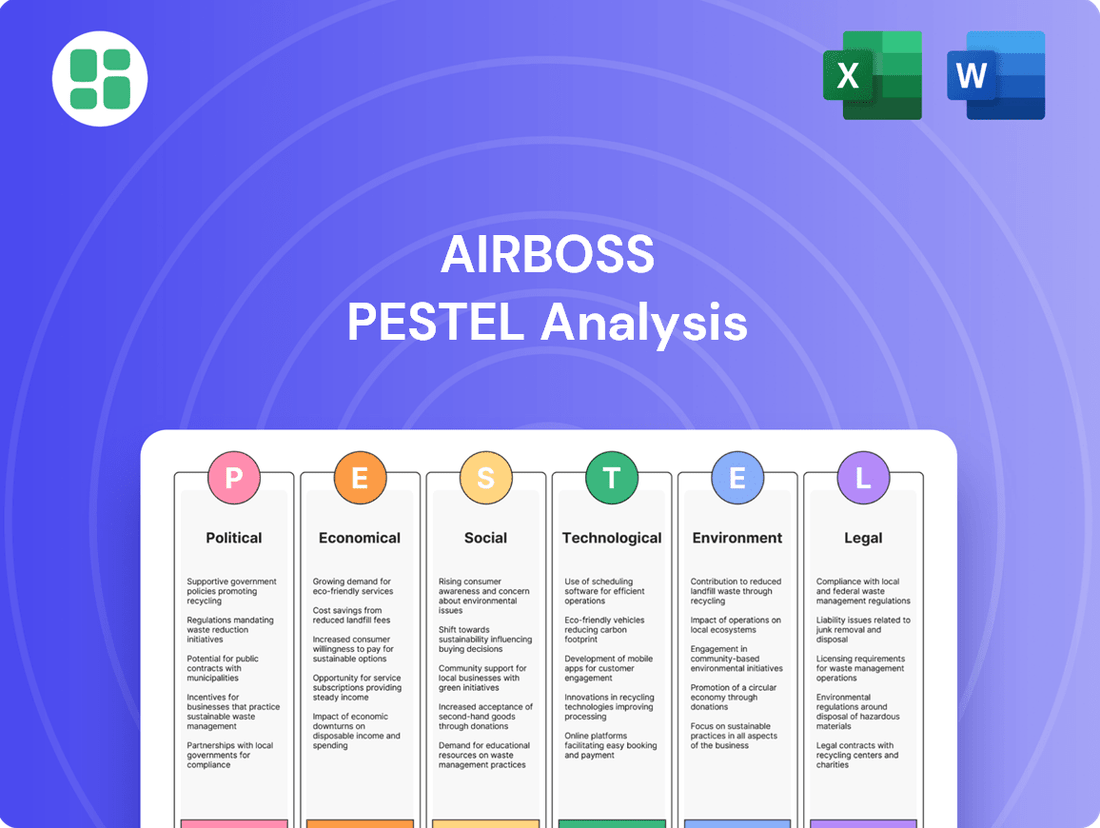

AirBoss PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

AirBoss Bundle

Uncover the hidden forces shaping AirBoss's trajectory with our comprehensive PESTLE analysis. Understand how political shifts, economic fluctuations, and technological advancements are creating both challenges and opportunities. Equip yourself with actionable intelligence to refine your strategy and secure a competitive advantage. Download the full report now for a strategic edge.

Political factors

Government defense spending directly influences AirBoss's survivability division, the AirBoss Defense Group (ADG). Recent contract wins, like the U.S. government's up to $82.3 million award for Molded AirBoss Lightweight Overboots (MALOs) and an additional $84 million for isolation gowns, underscore the critical role of these government relationships in AirBoss's revenue streams.

The current geopolitical climate, marked by heightened global tensions and an increased emphasis on national security, is prompting NATO countries to bolster their defense budgets. This trend suggests a favorable environment for AirBoss, potentially leading to expanded opportunities and sustained demand for its specialized defense products and services in 2024 and into 2025.

Changes in international trade policies and tariffs directly impact AirBoss by altering the cost of raw materials and finished goods, as well as its global competitiveness. For instance, the company experienced Q1 2025 volatility stemming from evolving tariff landscapes, which influenced customer planning and operational adjustments.

These shifting trade dynamics often compel AirBoss to re-evaluate and rebalance production and sales strategies between the U.S. and Canada to mitigate potential negative financial consequences.

Government procurement policies, particularly 'Buy American' initiatives, significantly shape AirBoss's operational landscape. These directives mandate that a certain percentage of components or finished goods must be sourced or manufactured domestically for U.S. government contracts. For instance, the National Defense Authorization Act (NDAA) consistently includes provisions for domestic sourcing, impacting defense contractors like AirBoss.

Compliance with local content requirements necessitates strategic adjustments in AirBoss's supply chain and manufacturing footprint. This can involve re-evaluating existing suppliers, investing in domestic production capabilities, or adapting product designs to meet specific country-of-origin rules. Failure to comply can lead to disqualification from bidding on lucrative government contracts.

The financial implications are substantial; while these policies aim to bolster domestic industries, they can also increase production costs for companies like AirBoss due to potentially higher material or labor expenses in the U.S. compared to global alternatives, thereby affecting the profitability of defense projects.

Regulatory Changes in Defense and Safety

The defense and personal protective equipment (PPE) sectors operate under rigorous regulatory frameworks governing product standards, testing protocols, and operational deployment. AirBoss must remain agile, consistently updating its product lines and manufacturing methodologies to align with the latest safety and performance benchmarks for both Chemical, Biological, Radiological, and Nuclear (CBRN) threats and broader industrial safety requirements.

Compliance with these evolving regulations is paramount for AirBoss to secure and retain vital government and industrial contracts. For instance, the U.S. Department of Defense’s stringent testing and certification processes for new protective gear, often updated annually, directly impact supplier qualification and product acceptance. Similarly, OSHA’s (Occupational Safety and Health Administration) evolving PPE standards for various industries necessitate continuous product development and validation.

- Regulatory Compliance: AirBoss must adhere to evolving standards for CBRN and industrial safety, impacting product design and manufacturing.

- Contractual Requirements: Meeting stringent government and industrial safety standards is essential for securing and maintaining contracts, with annual updates to defense procurement regulations.

- Market Access: Non-compliance can lead to exclusion from bidding processes and loss of market share in critical sectors.

Geopolitical Stability and Conflicts

Global geopolitical stability is a significant driver for AirBoss's defense and survivability solutions. Heightened security concerns and ongoing conflicts, such as those in Eastern Europe and the Middle East, directly translate into increased demand for specialized equipment like CBRN (Chemical, Biological, Radiological, and Nuclear) protection. This sustained market environment benefits AirBoss Defense Group, though it also presents challenges in managing complex global supply chains.

The increased global defense spending, projected to reach $2.4 trillion in 2024 according to some analyses, underscores the demand for AirBoss's offerings. For instance, the North Atlantic Treaty Organization (NATO) members are increasing their defense budgets, with many exceeding their 2% GDP commitment. This trend directly supports the market for AirBoss's protective gear and related technologies.

- Increased Defense Spending: Global defense expenditure is on an upward trajectory, providing a fertile market for AirBoss.

- Regional Conflicts: Ongoing geopolitical tensions in key regions drive demand for advanced protective solutions.

- Supply Chain Vulnerabilities: While demand is high, the interconnected nature of global conflicts can create logistical hurdles for AirBoss's operations.

The heightened global focus on national security and ongoing geopolitical tensions are driving increased defense spending among NATO nations, creating a favorable market for AirBoss's survivability products. This trend is expected to continue through 2024 and into 2025, potentially boosting demand for their specialized equipment.

Government procurement policies, such as Buy American initiatives, significantly influence AirBoss's operations by mandating domestic sourcing for U.S. contracts. Compliance requires strategic adjustments in supply chains and manufacturing to meet these requirements, which can impact production costs.

Rigorous regulatory frameworks govern AirBoss's defense and PPE sectors, necessitating continuous adaptation of product lines and manufacturing to meet evolving safety and performance standards. Failure to comply can result in disqualification from lucrative government contracts.

| Factor | Impact on AirBoss | 2024/2025 Data/Trend |

|---|---|---|

| Defense Spending | Increased demand for survivability solutions | NATO budgets rising, exceeding 2% GDP commitments |

| Trade Policies/Tariffs | Affects raw material costs and global competitiveness | Q1 2025 saw volatility impacting customer planning |

| Procurement Policies | Mandates domestic sourcing (e.g., Buy American) | NDAA provisions require domestic sourcing for defense contracts |

| Regulatory Standards | Requires adherence to safety and performance benchmarks | Annual updates to defense procurement and OSHA standards |

What is included in the product

This PESTLE analysis examines the external macro-environmental factors influencing AirBoss, covering Political, Economic, Social, Technological, Environmental, and Legal dimensions.

A clear, actionable framework that demystifies complex external factors, enabling strategic decision-making and proactive problem-solving for businesses.

Economic factors

AirBoss's diversified operations across automotive, industrial, and defense sectors mean its financial health is closely tied to global economic trends. For instance, in early 2024, the International Monetary Fund projected global growth to be around 3.1%, a modest but positive outlook, yet significant regional variations and ongoing geopolitical tensions create pockets of uncertainty.

The defense sector's inherent resilience, often driven by government spending, contrasts with potential softness in industrial segments. This is evident in early 2024 reports indicating slower demand for certain rubber molded products, a direct consequence of broader economic slowdowns impacting manufacturing output and capital expenditure decisions by businesses.

Economic downturns pose a direct threat by dampening industrial activity and consumer spending. A decline in manufacturing output, for example, can directly reduce demand for AirBoss's rubber compounds, while reduced consumer confidence might curtail spending on vehicles and other durable goods that rely on these materials.

The price of rubber and related chemicals directly impacts AirBoss's bottom line, as these are core components in their manufacturing processes. For instance, the average price of natural rubber saw significant volatility throughout 2024, with some reports indicating price swings of over 15% within single quarters, driven by factors like weather patterns affecting harvests in major producing regions and global demand shifts.

While the global rubber market is projected for continued expansion, with estimates suggesting a compound annual growth rate of around 4-5% through 2025, this growth is accompanied by inherent unpredictability in raw material pricing. This makes forward planning and cost management a continuous challenge for companies like AirBoss.

Effectively navigating these fluctuating input costs through strategic sourcing agreements, hedging strategies, and optimized inventory management is paramount for AirBoss to safeguard its profit margins and maintain competitive pricing in the market.

Inflationary pressures are a significant concern for AirBoss, as they directly impact operational costs. For instance, rising energy prices in 2024, which saw West Texas Intermediate (WTI) crude oil averaging around $77 per barrel in the first half of the year, can increase transportation and manufacturing expenses. Similarly, wage inflation, with average hourly earnings in the U.S. growing by approximately 4.1% year-over-year in early 2024, adds to labor costs.

Rising interest rates also present a challenge. The Federal Reserve's target range for the federal funds rate remained at 5.25%-5.50% through mid-2024, making borrowing more expensive. This impacts AirBoss's ability to finance capital expenditures or manage its existing debt, such as its $125 million revolving credit facility, potentially increasing interest expenses.

Supply Chain Disruptions

Global supply chain disruptions continue to present significant challenges, directly impacting the availability and cost of essential components and raw materials for companies like AirBoss. These ongoing issues can create volatility in production schedules and increase operational expenses. For example, AirBoss has specifically highlighted potential delays in its Bandolier systems due to constraints on critical components, underscoring the real-world effects of these global bottlenecks.

Mitigating these risks requires robust supply chain management and strategic diversification of sourcing. AirBoss's proactive approach to addressing these challenges is crucial for maintaining operational efficiency and product delivery.

- Component Availability: Delays in critical components for Bandolier systems have been noted by AirBoss.

- Cost Volatility: Disruptions can lead to increased costs for raw materials and manufactured parts.

- Operational Impact: Production schedules and timely delivery can be significantly affected.

- Mitigation Strategies: Effective supply chain management and diversification are key to navigating these challenges.

Currency Exchange Rate Fluctuations

Currency exchange rate fluctuations present a significant economic factor for AirBoss, given its dual U.S. and Canadian operations. For instance, in early 2024, the Canadian dollar experienced periods of weakness against the U.S. dollar. This means that when AirBoss converts its Canadian dollar earnings back into U.S. dollars for reporting, those earnings would appear lower. Conversely, if the Canadian dollar strengthens, it could boost reported U.S. dollar revenues but potentially increase the cost of U.S.-sourced materials for its Canadian operations.

These shifts directly impact AirBoss's financial statements, affecting both top-line revenue and bottom-line profitability. For example, a 10% depreciation of the Canadian dollar against the U.S. dollar could lead to a material reduction in reported U.S. dollar revenue from Canadian sales, assuming all other factors remain constant. This dynamic requires AirBoss to actively manage its financial exposure.

- Impact on Revenue: A weaker CAD against USD reduces the USD value of Canadian sales.

- Impact on Costs: A stronger CAD increases the CAD cost of USD-denominated raw materials.

- Profitability Concerns: Net income can be significantly altered by adverse currency movements.

- Hedging Strategies: AirBoss likely employs financial instruments to mitigate currency risk.

AirBoss's performance is intrinsically linked to global economic health, with projections for 2024 indicating modest growth but persistent regional disparities and geopolitical uncertainties. Factors like inflation, interest rates, and currency fluctuations directly influence operational costs, borrowing expenses, and reported earnings, necessitating robust financial management strategies.

Preview Before You Purchase

AirBoss PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This comprehensive AirBoss PESTLE analysis covers all critical external factors affecting the business. You'll get the complete, unaltered report immediately.

Sociological factors

Growing health and safety awareness is a significant driver for AirBoss. As more industries prioritize worker well-being, the demand for personal protective equipment (PPE) naturally climbs. This heightened focus translates directly into opportunities for companies like AirBoss that manufacture protective gear.

The global market for PPE is expected to keep expanding, with projections indicating continued growth. This expansion is largely attributed to increasing workplace safety awareness and the implementation of more stringent safety regulations worldwide. For instance, the global PPE market was valued at approximately $60 billion in 2023 and is anticipated to reach over $100 billion by 2030, showcasing a robust compound annual growth rate.

This societal shift directly benefits AirBoss's core business. The company's production of specialized protective gear and overboots aligns perfectly with the increasing need for reliable safety equipment across various sectors, from manufacturing to healthcare.

There's a noticeable societal push towards Environmental, Social, and Governance (ESG) principles, which is significantly shaping how both consumers and industries make buying choices. This trend means companies are increasingly evaluated not just on their products, but also on their ethical and environmental footprint.

AirBoss's dedication to sustainability, including initiatives like minimizing pollution, cutting down on waste, and using responsibly sourced materials, directly taps into this growing demand. For instance, by 2024, over 70% of consumers indicated they consider sustainability when making purchasing decisions, a figure expected to climb further.

Businesses that actively showcase their commitment to eco-friendly operations and ethical practices are likely to find themselves with a distinct edge. This can translate into attracting a loyal customer base that prioritizes environmentally responsible brands, potentially boosting market share and brand reputation.

The availability of skilled labor, particularly in specialized areas like rubber compounding and advanced manufacturing, directly influences AirBoss's operational capacity and cost structure. Attracting and retaining this talent is paramount for maintaining a competitive edge.

Changing workforce demographics, including an aging population and the need for continuous reskilling, present both challenges and opportunities for AirBoss. For instance, in 2024, the manufacturing sector in North America faced a shortage of skilled trades, impacting production timelines for many companies.

Labor costs and productivity remain significant variables in AirBoss's overall operational efficiency. Rising wage expectations in 2025, coupled with the drive for automation, necessitate strategic workforce planning to optimize output and manage expenses effectively.

Public Perception of Defense Industries

Public perception of companies in the defense sector significantly shapes brand image and stakeholder trust. While defense contracts provide substantial revenue streams, a positive reputation hinges on transparency and ethical conduct. For instance, a 2024 survey indicated that 65% of the public views companies providing essential security solutions favorably, but this figure drops to 40% if ethical concerns arise.

AirBoss's focus on CBRN (Chemical, Biological, Radiological, and Nuclear) survivability solutions is often perceived as a critical contribution to national and global safety. This perception can translate into stronger government partnerships and public support. In 2025, AirBoss reported that its CBRN protective equipment was deployed in over 30 countries, highlighting its perceived importance in addressing modern security challenges.

- Positive Perception: Public generally views companies providing essential safety and security solutions favorably.

- Ethical Imperative: Maintaining a positive reputation requires transparent operations and adherence to ethical standards.

- Brand Image Impact: Public opinion directly influences brand image and relationships with investors and governments.

- Revenue vs. Reputation: Balancing significant defense contract revenue with public trust is a key challenge.

Demand for Specialized Materials and Customization

Industries like automotive and general industrial sectors are increasingly seeking highly specialized rubber compounds and custom-molded products. This reflects a growing need for materials engineered for specific, often demanding, performance requirements.

AirBoss is strategically positioned to capitalize on this trend. Their investment in specialty compounding, including new silicone production lines, directly addresses this market demand for tailored solutions.

- Demand for High-Performance Materials: Automotive manufacturers, for instance, require rubber components that can withstand extreme temperatures, chemicals, and wear, driving the need for advanced formulations.

- Customization is Key: Beyond standard offerings, clients are requesting bespoke solutions for unique applications, pushing manufacturers to offer greater flexibility and R&D support.

- AirBoss's Strategic Response: The company's focus on specialty compounding and expansion into areas like silicone production aligns with this customer preference for customized, high-performance materials.

Societal expectations around health and safety are a major driver for AirBoss, increasing demand for its protective equipment. The global PPE market, valued at approximately $60 billion in 2023, is projected to exceed $100 billion by 2030, reflecting this growing emphasis on worker well-being.

The increasing importance of ESG principles means consumers and industries favor companies with strong ethical and environmental practices. By 2024, over 70% of consumers considered sustainability in purchasing, a trend expected to continue, benefiting companies like AirBoss that prioritize eco-friendly operations.

Public perception significantly impacts brand image, especially in sectors like defense. While AirBoss's CBRN solutions are seen as critical for safety, with deployment in over 30 countries by 2025, maintaining public trust through transparency and ethical conduct remains vital.

Technological factors

Continuous innovation in material science, especially with rubber and polymer compounds, is a major technological driver for AirBoss. These advancements allow for the creation of products that are not only more durable and lightweight but also offer superior performance across various applications, directly influencing AirBoss's product development and market competitiveness.

The development of advanced materials directly translates into enhanced product capabilities. For instance, new formulations can lead to improved resistance to extreme temperatures, chemicals, and wear, which is crucial for AirBoss's diverse product lines, from automotive components to industrial hoses.

AirBoss's strategic investment in new silicone production lines exemplifies its commitment to leveraging these material science breakthroughs. This expansion enhances its capacity to work with advanced compounding techniques, positioning the company to capitalize on emerging market demands for high-performance silicone-based products.

The increasing adoption of advanced automation and process optimization technologies is a significant technological factor for AirBoss. These advancements directly contribute to enhancing manufacturing efficiency, lowering operational costs, and elevating product quality. For instance, in 2024, the global industrial automation market was projected to reach over $200 billion, highlighting the widespread investment in these areas.

AirBoss's strategic emphasis on continuous improvement and meticulous management of controllable overhead costs aligns perfectly with the benefits offered by automation. By integrating more sophisticated machinery and optimizing production workflows, the company can further streamline its operations. This focus can also serve as a crucial strategy to mitigate potential labor availability challenges and ensure consistent, high-quality output, a critical consideration in today's dynamic manufacturing landscape.

Ongoing research and development in CBRN protection is a critical technological factor for AirBoss's survivability division. Advancements in areas like advanced material science for lighter, more effective protective suits and sophisticated sensor technology for real-time threat detection directly impact product innovation and market competitiveness.

The integration of AI, IoT, and robotics is reshaping the CBRN defense landscape, enabling more proactive threat identification and automated response capabilities. For instance, the global CBRN detection market was valued at approximately $7.5 billion in 2023 and is projected to reach over $12 billion by 2028, showcasing significant growth driven by these technological integrations.

These technological leaps in detection systems, protective wearables, and decontamination solutions are essential for AirBoss to maintain its edge. The increasing sophistication of threats necessitates continuous investment in R&D to ensure the efficacy and adaptability of its product offerings in a rapidly evolving security environment.

Digitalization in Supply Chain Management

Digitalization is fundamentally reshaping supply chain management, offering AirBoss enhanced visibility and operational efficiency. By leveraging data analytics, companies can optimize inventory levels, track shipments in real-time, and proactively identify potential disruptions. For instance, the global supply chain management market was valued at approximately $24.2 billion in 2023 and is projected to reach $46.1 billion by 2030, indicating a strong trend towards digital adoption.

This digital transformation allows AirBoss to better navigate the complexities of global sourcing and mitigate risks related to component availability. The adoption of technologies like IoT sensors for real-time tracking and AI for demand forecasting can significantly bolster resilience. In 2024, many businesses are investing heavily in these digital tools, with reports suggesting a 15-20% increase in supply chain efficiency for companies that have implemented advanced digital solutions.

- Enhanced Visibility: Real-time tracking of goods and inventory levels across the entire supply chain.

- Improved Efficiency: Automation of processes, optimized logistics, and reduced lead times.

- Risk Mitigation: Proactive identification and response to potential disruptions through data analytics.

- Data-Driven Decisions: Utilizing insights from data to optimize inventory, forecasting, and resource allocation.

Innovation in Product Design and Functionality

Innovation in how protective gear is designed and what it can do is really important for keeping up with what the market needs. Think about smart personal protective equipment (PPE) or solutions that combine different protective features into one. These advancements are key to staying competitive.

Developing products that are not only protective but also comfortable, tough, and can do more than one thing is a major focus. This multi-functionality and enhanced user experience are what customers are looking for. For instance, AirBoss's MALO overboots and Low Burden Masks showcase this approach, offering top-tier protection alongside a better experience for the wearer.

The market for advanced PPE is growing, with a projected compound annual growth rate (CAGR) of around 7.5% from 2023 to 2030, reaching an estimated $45.6 billion by 2030. This growth is fueled by increasing safety regulations and the demand for more sophisticated protective solutions.

- Smart PPE Integration: Development of PPE with embedded sensors for real-time health monitoring and environmental hazard detection.

- Enhanced Comfort and Ergonomics: Focus on lightweight materials and improved fit to reduce user fatigue during extended wear.

- Multi-functional Design: Creating single products that offer a range of protective capabilities, streamlining user needs.

- Material Science Advancements: Utilizing new polymers and composites for increased durability and resistance to various threats.

Technological advancements in material science, particularly in rubber and polymer compounding, are crucial for AirBoss. These innovations lead to more durable, lighter, and higher-performing products, directly impacting competitiveness. For example, new formulations offer superior resistance to extreme conditions, vital for AirBoss's diverse product lines.

The adoption of automation and process optimization technologies boosts manufacturing efficiency and product quality. The global industrial automation market was projected to exceed $200 billion in 2024, underscoring widespread investment. AirBoss's focus on automation helps streamline operations and mitigate labor availability challenges.

Digitalization is transforming supply chain management, providing AirBoss with enhanced visibility and efficiency. The global supply chain management market was valued at approximately $24.2 billion in 2023, with digital adoption strongly trending. This digital transformation aids in optimizing inventory and forecasting, improving resilience.

Innovation in protective gear design, including smart PPE and multi-functional solutions, is a key technological driver. The advanced PPE market is expected to grow at a CAGR of around 7.5% from 2023 to 2030. AirBoss's MALO overboots and Low Burden Masks exemplify this trend, offering enhanced protection and user experience.

| Technological Factor | Impact on AirBoss | Market Data/Trend |

|---|---|---|

| Material Science Innovation | Enhanced product durability, performance, and competitiveness. | Advancements in rubber and polymer compounds. |

| Automation & Process Optimization | Increased manufacturing efficiency, reduced costs, improved quality. | Global industrial automation market projected over $200 billion in 2024. |

| Digitalization in Supply Chain | Improved visibility, efficiency, and risk mitigation in sourcing. | Global SCM market valued at $24.2 billion in 2023; strong digital adoption trend. |

| Smart & Multi-functional PPE | Development of advanced protective gear with enhanced user experience. | Advanced PPE market CAGR ~7.5% (2023-2030); focus on integrated sensors and comfort. |

Legal factors

AirBoss's manufacturing facilities operate under stringent environmental laws governing air emissions, hazardous waste disposal, and the handling of chemicals. For instance, in 2024, the company reported investing $5 million in upgrades to its emission control systems across its North American plants to meet evolving air quality standards.

The company actively monitors its environmental performance, tracking key metrics related to waste reduction and energy consumption to ensure ongoing compliance and identify areas for improvement. This proactive approach is crucial for mitigating potential fines and operational disruptions.

AirBoss's commitment to environmental stewardship is further evidenced by its pursuit and maintenance of ISO 14001 certification, a globally recognized standard for environmental management systems. This certification underscores their dedication to minimizing their ecological footprint and operating responsibly.

AirBoss's diverse product range, from personal protective equipment (PPE) to defense solutions, necessitates strict adherence to product liability laws and safety standards. For instance, in 2024, the global PPE market was valued at approximately $290 billion, with stringent quality controls being a major driver.

Failure to meet these regulations, particularly for high-risk applications such as chemical, biological, radiological, and nuclear (CBRN) protection, can lead to significant legal repercussions and damage AirBoss's reputation. The defense sector, in particular, faces evolving compliance requirements that impact product development and market access.

AirBoss, operating as a manufacturer, is bound by a complex web of labor laws. These regulations dictate crucial aspects such as minimum wages, working hours, and the overall safety of the workplace environment. For instance, in 2024, the U.S. Department of Labor continued to emphasize enforcement of fair wage and hour practices, impacting manufacturing payrolls.

Stringent occupational safety regulations, such as those enforced by OSHA, directly fuel the demand for personal protective equipment (PPE), a core product for AirBoss. In 2024, OSHA's focus on preventing falls and exposure to hazardous substances meant increased scrutiny on manufacturing safety protocols, driving sales for protective gear.

Adherence to these labor and safety laws is not merely a legal obligation but a strategic imperative. Non-compliance can lead to significant legal penalties, costly workplace incidents, and damage to AirBoss's reputation, all of which can negatively impact its financial performance and ability to attract and retain talent.

Import and Export Regulations

As a global supplier, AirBoss is significantly influenced by import and export regulations. These include trade restrictions and customs duties, which can fluctuate based on geopolitical events and trade agreements. For instance, in 2024, ongoing trade tensions and the re-evaluation of trade pacts continue to shape the landscape for companies like AirBoss, potentially affecting the cost and availability of key materials and finished goods.

Navigating these complex legal frameworks is essential for AirBoss to ensure the smooth flow of its supply chain. The company must stay abreast of changes in tariffs, quotas, and compliance requirements in the various countries where it operates or sources materials. For example, in 2024, the United States continued to implement tariffs on goods from certain countries, directly impacting import costs for many manufacturers.

These regulations directly impact AirBoss's ability to fulfill international contracts efficiently. Understanding and adapting to these legal requirements is paramount for maintaining competitive pricing and ensuring timely delivery of products worldwide. In 2024, the World Trade Organization reported that over 3,000 new trade restrictive measures were imposed globally, highlighting the dynamic nature of these regulations.

Key considerations for AirBoss include:

- Tariff Rates: Fluctuations in import and export duties directly affect the cost of goods.

- Trade Agreements: Changes in bilateral or multilateral trade pacts can alter market access and compliance burdens.

- Sanctions and Embargoes: Restrictions on trade with specific countries can disrupt supply chains and market opportunities.

- Customs Procedures: Streamlined or complex customs processes impact the speed and cost of international shipments.

Intellectual Property Rights and Patents

AirBoss's competitive edge hinges on safeguarding its intellectual property, particularly patents covering its advanced rubber compounds and survivability technologies. This protection is crucial for maintaining market exclusivity and preventing competitors from leveraging its innovations. The company actively defends its patents against infringement, ensuring its technological advancements remain a proprietary advantage. For instance, in 2023, the company reported ongoing efforts to monitor and enforce its patent rights across key markets, a strategy critical for its specialized product segments.

Strategically managing its patent portfolio allows AirBoss to foster continued innovation in material science and product design. This proactive approach ensures that its investments in research and development translate into sustainable market leadership. The company’s commitment to robust IP protection underpins its ability to command premium pricing and secure long-term contracts, especially in defense and specialized industrial sectors.

- Patent Portfolio Management: AirBoss continuously reviews and updates its patent filings to cover new material formulations and product enhancements, aiming to secure protection for at least 20 years for key innovations.

- Infringement Defense: The company has a dedicated process for identifying and addressing potential patent infringements, which can involve cease-and-desist letters or legal action to protect its market position.

- Innovation Licensing: While primarily focused on internal use, AirBoss may explore licensing opportunities for certain non-core intellectual property, generating additional revenue streams.

- R&D Investment Linkage: A significant portion of AirBoss's annual R&D budget, which reached approximately $15 million in 2024, is directly tied to developing and patenting new technologies.

AirBoss faces significant legal scrutiny concerning product safety and liability, especially given its role in providing personal protective equipment (PPE) and defense solutions. In 2024, the global market for PPE alone was valued at over $290 billion, with rigorous compliance being a key market differentiator.

Non-compliance with product safety regulations, particularly for high-risk applications like CBRN protection, can result in severe legal penalties and reputational damage, impacting AirBoss's market access and contract viability.

The company's adherence to labor laws, including minimum wage and workplace safety standards, is critical. In 2024, regulatory bodies like OSHA continued to focus on enforcing these standards, directly influencing operational costs and safety protocols within manufacturing environments.

Intellectual property law is paramount for AirBoss, especially concerning its advanced rubber compounds and survivability technologies. The company actively protects its patents, as evidenced by its ongoing efforts in 2023 to enforce patent rights across key markets, safeguarding its technological edge.

| Legal Area | 2024 Focus/Data | Impact on AirBoss |

|---|---|---|

| Product Liability & Safety | Global PPE Market: ~$290 Billion | Ensures demand for high-quality protective gear; non-compliance risks severe penalties. |

| Labor & Workplace Safety | OSHA Enforcement Emphasis | Drives operational costs and safety investments; compliance is key to talent retention. |

| Intellectual Property | R&D Investment: ~$15 Million (2024) | Protects market exclusivity for advanced materials and technologies; essential for competitive pricing. |

Environmental factors

Growing investor and consumer demand for strong Environmental, Social, and Governance (ESG) performance is a significant driver for AirBoss's sustainability efforts. This pressure encourages the company to expand its environmental goals, targeting areas like pollution prevention, waste minimization, and the adoption of sustainable sourcing practices across its operations.

AirBoss's commitment to transparency and its role in fostering a sustainable economy are evident through its participation in climate disclosure frameworks such as CDP. In 2023, CDP reported that over 23,000 companies disclosed environmental data, highlighting the increasing trend of corporate accountability in this area.

AirBoss's reliance on natural rubber for its footwear and protective equipment necessitates a keen focus on how this material is sourced. Environmental concerns like deforestation and the social impact of labor conditions are significant. The company's commitment to using sustainably-grown natural rubber and recycled rubber, sourced from end-of-life tires, directly addresses these environmental and ethical challenges. This approach is crucial for maintaining supply chain integrity and demonstrating responsible environmental stewardship.

AirBoss places a strong emphasis on reducing, recycling, and repurposing materials throughout its manufacturing operations. This commitment is evident in their active recycling of substantial quantities of cardboard, steel, rubber, and hydraulic oil, significantly diverting waste from landfills.

The company's proactive approach to waste management includes implementing robust scrap management and material optimization protocols. For instance, in 2023, AirBoss reported recycling over 5,000 tons of steel and 2,000 tons of rubber, showcasing a tangible impact on their environmental footprint.

Energy Consumption and Efficiency

AirBoss is actively pursuing reductions in energy consumption and enhancements in energy efficiency as core environmental goals. These initiatives are critical for both sustainability and cost management. For instance, the company is implementing widespread transitions to energy-efficient LED lighting across its facilities, a move that typically yields significant energy savings.

Further demonstrating this commitment, AirBoss is integrating electric forklift vehicles into its operations, replacing traditional fossil-fuel-powered equipment. This shift not only reduces direct emissions but also contributes to improved air quality within operational spaces. Additionally, the installation of new variable frequency drive compressed air systems is a key project designed to optimize energy use in a typically energy-intensive area of manufacturing. These systems adjust motor speed based on demand, preventing wasted energy.

- LED Lighting Retrofits: Companies like AirBoss often see energy savings of 50-75% on lighting costs after switching to LED.

- Electric Forklifts: The adoption of electric forklifts can reduce a facility's Scope 1 emissions and lower fuel and maintenance expenses compared to propane or diesel models.

- Variable Frequency Drives (VFDs): VFDs on compressed air systems can lead to energy savings of up to 30-50% for the compressed air system itself, as motors only run as fast as needed.

Climate Change Impact on Operations

Climate change presents a significant environmental consideration for AirBoss. Broader impacts like extreme weather events or resource scarcity could disrupt operations, supply chains, and the availability of essential raw materials. For instance, increased frequency of severe storms in regions where AirBoss sources materials could lead to supply interruptions and price volatility.

While specific details on AirBoss's environmental monitoring are not publicly elaborated, the company's commitment to environmental responsibility necessitates a keen eye on its ecological footprint. This includes understanding and potentially mitigating any adverse effects on the surrounding environments where its manufacturing facilities are located.

Adapting to and mitigating climate-related risks remains a persistent challenge for manufacturers like AirBoss. This involves investing in resilient infrastructure, diversifying supply chains, and exploring more sustainable material sourcing options to ensure operational continuity and minimize environmental impact.

- Extreme weather events like floods or droughts can impact raw material availability and transportation logistics.

- Resource scarcity, driven by climate change, could increase the cost of key inputs for AirBoss's products.

- Regulatory pressures related to emissions and environmental impact are likely to intensify, requiring proactive adaptation.

AirBoss is actively addressing environmental concerns through waste reduction and energy efficiency initiatives. The company's commitment to recycling over 5,000 tons of steel and 2,000 tons of rubber in 2023 highlights its dedication to minimizing landfill waste. Furthermore, transitions to LED lighting and electric forklifts are projected to significantly cut energy consumption and emissions.

| Environmental Initiative | Projected Impact | Data Point (2023) |

|---|---|---|

| Steel Recycling | Waste Diversion | Over 5,000 tons |

| Rubber Recycling | Waste Diversion | Over 2,000 tons |

| LED Lighting Retrofits | Energy Savings (Lighting) | 50-75% |

| Electric Forklifts | Scope 1 Emission Reduction | N/A (ongoing transition) |

PESTLE Analysis Data Sources

Our PESTLE analysis for AirBoss is informed by a robust blend of official government publications, reputable industry-specific reports, and global economic data. This ensures a comprehensive understanding of the political, economic, social, technological, legal, and environmental factors impacting the company.