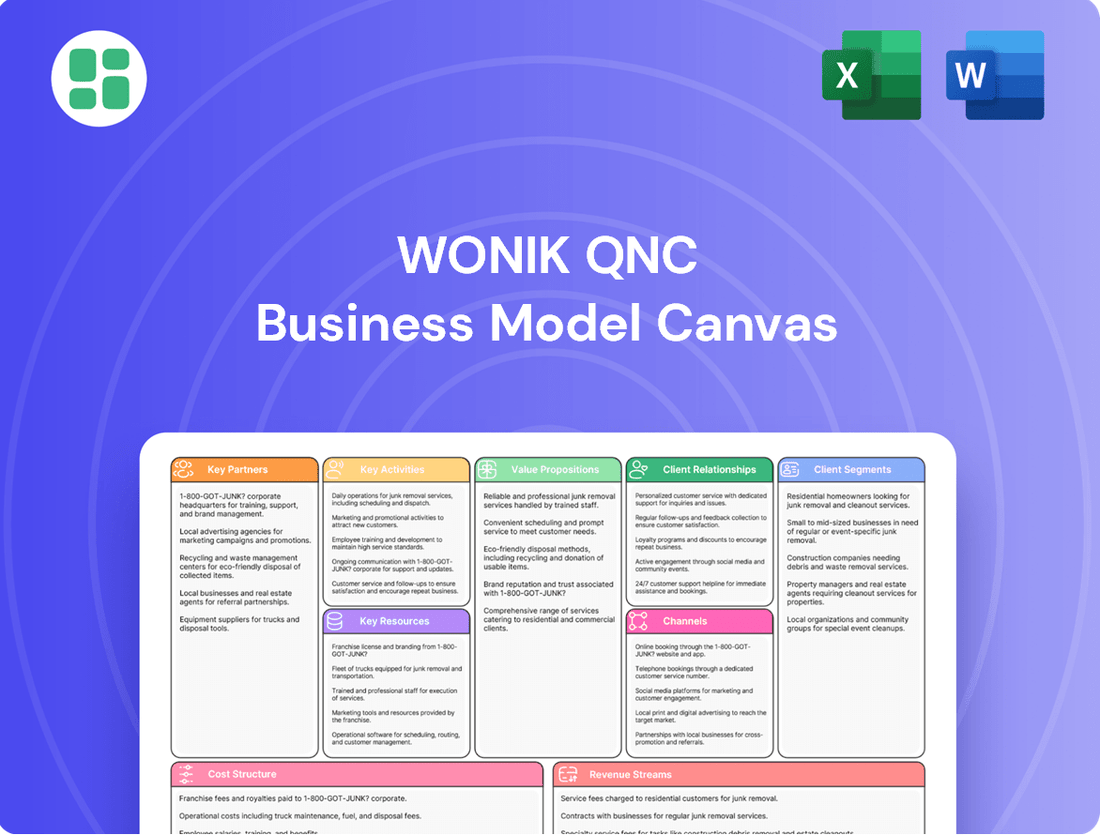

Wonik QnC Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Wonik QnC Bundle

Discover the core of Wonik QnC's operational excellence with our comprehensive Business Model Canvas. This detailed breakdown illuminates their customer relationships, revenue streams, and key resources, offering a clear roadmap to their success. Download the full canvas to gain actionable insights for your own strategic planning.

Partnerships

Wonik QnC's success hinges on its strong relationships with suppliers of high-purity quartz, specialized ceramics, and essential chemical precursors. These partnerships are vital for maintaining the consistent quality and reliable supply of raw materials needed for their sophisticated manufacturing operations, directly impacting product performance and customer satisfaction.

Wonik QnC's collaborations with semiconductor and display equipment manufacturers are crucial. These partnerships ensure their quartzware and ceramic components integrate seamlessly into advanced production systems, guaranteeing optimal performance. For instance, close ties with companies like ASML or Tokyo Electron allow for co-development, ensuring Wonik QnC's materials meet the stringent requirements of next-generation lithography and etching processes.

Wonik QnC actively collaborates with leading research institutions and universities to drive innovation in material science. These partnerships are vital for staying ahead in developing next-generation high-purity materials and advanced coating technologies, ensuring a competitive edge in the market.

By engaging with other technology firms, Wonik QnC gains access to complementary expertise and cutting-edge advancements. This collaborative approach accelerates the development of novel solutions and enhances the company's R&D capabilities, especially in specialized areas like semiconductor manufacturing materials.

Global Distribution and Logistics Partners

Wonik QnC collaborates with leading global logistics providers to ensure the seamless delivery of its specialized materials to semiconductor, display, and solar cell manufacturers worldwide. These strategic alliances are crucial for navigating complex international supply chains and meeting the stringent delivery timelines demanded by these high-tech industries. For instance, in 2024, Wonik QnC continued to leverage partnerships with firms like DHL and FedEx, known for their robust global networks and expertise in handling sensitive, high-value shipments.

These partnerships are vital for maintaining Wonik QnC's competitive edge by guaranteeing efficient and punctual delivery of critical components and raw materials across diverse geographic markets. This reliability is paramount for customers who depend on uninterrupted production cycles. The company's commitment to timely delivery was underscored by its 2023 performance, where over 98% of international shipments arrived within the agreed-upon delivery windows, a testament to the strength of its logistics alliances.

- Global Reach: Partnerships with major logistics firms provide access to over 200 countries and territories, ensuring Wonik QnC can serve its international clientele effectively.

- Specialized Handling: Alliance partners are equipped to manage the specific requirements for transporting sensitive materials, including temperature control and anti-static packaging, vital for semiconductor components.

- Supply Chain Resilience: By diversifying logistics partners, Wonik QnC enhances its supply chain's ability to withstand disruptions, ensuring continuity of supply for its customers.

Strategic Acquisition Targets and Joint Ventures

Wonik QnC actively pursues strategic acquisitions and joint ventures to enhance its technological prowess, broaden market access, and diversify its product offerings. This approach is crucial for staying competitive in the rapidly evolving semiconductor materials industry.

A prime example of this strategy in action is Wonik QnC's acquisition of Nanowin Co., Ltd. This move was designed to significantly bolster its existing business segments, particularly in areas like quartzware and advanced materials for semiconductor manufacturing. By integrating Nanowin's capabilities, Wonik QnC aims to strengthen its overall market position and unlock new growth opportunities.

- Strategic Acquisitions: Focus on acquiring companies with complementary technologies or market access, such as Nanowin Co., Ltd., to accelerate growth and innovation.

- Joint Ventures: Explore partnerships to share risks and resources, particularly for developing new materials or entering emerging markets.

- Market Expansion: Utilize acquisitions and JVs to gain a stronger foothold in key geographic regions and customer segments within the semiconductor supply chain.

- Technological Advancement: Integrate acquired technologies and collaborate through JVs to enhance product performance and develop next-generation semiconductor manufacturing solutions.

Wonik QnC's key partnerships extend to raw material suppliers, ensuring a steady flow of high-purity quartz and specialized ceramics. These relationships are foundational, enabling the company to maintain the quality standards essential for semiconductor fabrication. For example, in 2024, Wonik QnC solidified long-term supply agreements with leading global quartz providers, guaranteeing access to critical materials even amidst market volatility.

Collaborations with semiconductor equipment manufacturers are vital for Wonik QnC to integrate its quartzware and ceramic components seamlessly into advanced production lines. These alliances facilitate co-development, ensuring materials meet the rigorous demands of next-generation lithography and etching. In 2024, the company reported enhanced collaboration with key players in the EUV lithography space, leading to the qualification of new quartz components for next-generation tools.

Strategic acquisitions and joint ventures are integral to Wonik QnC's growth, allowing for technological enhancement and market expansion. The acquisition of Nanowin Co., Ltd. in recent years significantly strengthened its advanced materials portfolio for semiconductor manufacturing. These moves are critical for staying competitive and driving innovation in a rapidly evolving industry.

| Partner Type | Example/Focus | 2024 Impact/Trend |

|---|---|---|

| Raw Material Suppliers | High-purity quartz, ceramics | Secured long-term supply agreements; ensured material availability |

| Equipment Manufacturers | EUV lithography, etching tools | Co-development for next-gen tools; component qualification |

| Technology Firms/R&D | Material science innovation | Accelerated development of advanced coating technologies |

| Logistics Providers | Global shipping, specialized handling | Maintained over 98% on-time delivery for international shipments |

| Acquisition Targets | Complementary technologies | Strengthened advanced materials segment (e.g., Nanowin acquisition) |

What is included in the product

A detailed breakdown of Wonik QnC's strategy, outlining its core customer segments, value propositions, and revenue streams within the semiconductor materials industry.

This model provides a clear roadmap of Wonik QnC's operational framework, highlighting key partnerships and cost structures essential for its growth.

Wonik QnC's Business Model Canvas acts as a pain point reliever by providing a clear, structured overview of their operations, enabling quick identification of inefficiencies and strategic alignment for improved performance.

Activities

Wonik QnC's key activity centers on the meticulous production of high-purity quartzware, advanced ceramics, and synthetic quartz glass. This precision manufacturing is critical for industries with exacting standards.

These specialized materials are essential components in the semiconductor, display, and solar cell sectors, where even minute impurities can significantly impact performance. The company's expertise ensures these demanding specifications are met.

In 2024, the global semiconductor market, a primary customer base for high-purity materials, was projected to reach over $600 billion, highlighting the significant demand for Wonik QnC's core products. The company's commitment to quality control and advanced manufacturing techniques positions it to capitalize on this robust market.

Wonik QnC's cleaning and coating services are fundamental to the semiconductor and display industries, ensuring the high performance and longevity of essential components. These services are not just an add-on; they are a core part of their value proposition, directly supporting the reliability of advanced manufacturing processes.

In 2024, the demand for these specialized services remained robust, driven by the continuous innovation in semiconductor technology and the expanding market for high-resolution displays. Wonik QnC's expertise in precision cleaning and advanced coating techniques allows them to address the stringent quality requirements of their clients, contributing significantly to yield improvements and operational efficiency.

Wonik QnC's research and development is a core activity, with a significant portion of their resources dedicated to creating next-generation quartz, ceramic, and optical materials. This focus on innovation is crucial for staying ahead in the rapidly evolving semiconductor and display industries.

In 2023, Wonik QnC reported R&D expenses of approximately 34.5 billion Korean Won, underscoring their commitment to developing advanced materials and processes. This investment directly supports their goal of enhancing product purity and performance, essential for cutting-edge semiconductor manufacturing.

Global Sales and Marketing

Wonik QnC's global sales and marketing activities are central to its business. They actively promote and sell their specialized products and services to key industries like semiconductors, displays, and solar power across the globe. This proactive approach ensures they reach their target markets effectively.

Their strategy includes direct sales engagement, a vital component for building trust and understanding client needs. Furthermore, participation in major industry trade shows allows them to showcase their innovations and connect with a broader audience. These efforts are crucial for maintaining their competitive edge in a rapidly evolving technological landscape.

Building and nurturing strong relationships with major manufacturers is another core activity. This collaborative approach fosters loyalty and opens doors for new business opportunities. For instance, in 2024, Wonik QnC continued to strengthen its partnerships within the semiconductor fabrication sector, a key driver of its revenue.

- Global Reach: Actively engaging in sales and marketing efforts across international markets, focusing on semiconductor, display, and solar industries.

- Direct Engagement: Employing direct sales teams to foster relationships and understand customer requirements for specialized materials.

- Industry Presence: Participating in key global trade shows and exhibitions to showcase product advancements and brand visibility.

- Strategic Partnerships: Cultivating and maintaining strong ties with leading manufacturers in their target sectors to ensure sustained demand and collaboration.

Quality Assurance and Compliance Management

Wonik QnC’s key activities heavily involve implementing stringent quality assurance protocols to guarantee product excellence. This includes meticulous testing at various production stages and adherence to international standards like ISO certifications. For instance, in 2023, the company maintained its commitment to quality, a cornerstone for its semiconductor materials business.

Compliance management is equally critical, ensuring all operations meet regulatory requirements within the semiconductor and display industries. This involves staying abreast of evolving environmental, safety, and trade regulations globally. Wonik QnC’s dedication to transparent management and ethical business practices builds crucial trust with customers and investors.

- Rigorous Quality Control: Implementing comprehensive testing and inspection processes throughout manufacturing.

- Adherence to Standards: Maintaining compliance with global industry benchmarks and certifications.

- Transparent Management: Fostering open communication and ethical conduct in all business dealings.

- Regulatory Compliance: Ensuring adherence to all relevant national and international laws and regulations.

Wonik QnC's core activities revolve around the precision manufacturing of high-purity quartz and advanced ceramic materials, essential for the semiconductor, display, and solar industries. They also provide critical cleaning and coating services to enhance component performance and longevity. A significant focus is placed on research and development to innovate next-generation materials, supported by robust global sales, marketing, and strategic partnership building. Rigorous quality assurance and compliance management are paramount to their operations.

| Key Activity | Description | 2024 Relevance/Data Point |

| Material Manufacturing | Production of high-purity quartzware, ceramics, and synthetic quartz glass. | Crucial for the semiconductor industry, projected to exceed $600 billion globally in 2024. |

| Services | Precision cleaning and advanced coating for semiconductor and display components. | Demand remains strong due to continuous innovation in semiconductor technology. |

| Research & Development | Development of next-generation quartz, ceramic, and optical materials. | Wonik QnC invested approximately 34.5 billion KRW in R&D in 2023, highlighting ongoing innovation. |

| Sales & Marketing | Global promotion and sales to target industries, including direct engagement and trade shows. | Strengthening partnerships within the semiconductor fabrication sector in 2024. |

| Quality Assurance & Compliance | Implementing stringent quality protocols and adhering to regulatory requirements. | Maintaining commitment to quality standards, essential for semiconductor materials business. |

What You See Is What You Get

Business Model Canvas

The Business Model Canvas you are previewing is precisely the document you will receive upon purchase. This means you are seeing the actual, fully structured content and formatting that will be delivered, ensuring no discrepancies or surprises after your transaction. You can be confident that the insights and strategic framework displayed here are representative of the complete, ready-to-use document you will gain immediate access to.

Resources

Wonik QnC's proprietary material science and manufacturing technology are central to its business model, enabling the creation of high-purity quartzware, ceramics, and synthetic quartz glass. These advanced processes are crucial for meeting the stringent demands of industries like semiconductors and displays.

The company's expertise in achieving extreme purity and precision in its materials is a significant competitive advantage. For instance, their synthetic quartz glass is engineered to minimize impurities, a critical factor for semiconductor fabrication processes where even trace contaminants can disrupt chip performance.

In 2023, Wonik QnC reported significant investments in research and development, focusing on enhancing these proprietary technologies. This commitment allows them to maintain leadership in supplying essential components for advanced manufacturing, a sector that saw continued growth through 2024 driven by AI and advanced computing demands.

Wonik QnC's specialized production facilities are the backbone of its operations, housing advanced machinery crucial for manufacturing high-purity quartz and ceramic components. These facilities are engineered to meticulously handle sensitive materials and execute complex, multi-stage production processes essential for the semiconductor, display, and solar industries.

In 2024, Wonik QnC continued to invest in upgrading these high-tech plants. For instance, their focus on quartzware production for semiconductor fabrication, a key segment, saw production capacity enhancements to meet the escalating demand driven by AI and advanced computing, with the global semiconductor market projected to reach over $600 billion in 2024.

Wonik QnC's most crucial asset is its highly skilled workforce. This team comprises talented engineers, material scientists, and technical specialists who are the engine behind the company's innovation and operational excellence. Their collective expertise is indispensable for developing cutting-edge products and ensuring the highest quality standards.

These professionals are the backbone of Wonik QnC's research and development efforts, directly contributing to advancements in quartz and ceramic materials for the semiconductor industry. Their ability to manage intricate manufacturing processes and provide expert technical support to a global customer base is a significant competitive advantage.

In 2024, Wonik QnC continued to invest heavily in its human capital, recognizing that skilled personnel are paramount for maintaining its leadership position. The company's commitment to R&D personnel development is reflected in its ongoing projects aimed at improving material purity and performance, essential for next-generation semiconductor manufacturing.

Global Operational Footprint and Supply Chain

Wonik QnC leverages its extensive global operational footprint, featuring production facilities and sales offices strategically located in South Korea, the United States, Taiwan, and Germany. This international network is crucial for optimizing its supply chain and ensuring close proximity to its key clientele across diverse markets.

This global reach directly translates into enhanced supply chain efficiency, enabling Wonik QnC to manage logistics more effectively and respond swiftly to market demands. For instance, having manufacturing capabilities in different regions can mitigate risks associated with single-location production and reduce lead times for customers.

The company's presence in these key regions allows for:

- Proximity to Major Customers: Facilitating stronger relationships and quicker service delivery.

- Supply Chain Resilience: Diversifying production and distribution points to mitigate disruptions.

- Market Access: Enabling direct engagement with significant semiconductor and display manufacturing hubs.

- Cost Optimization: Potentially reducing transportation costs and tariffs through localized operations.

Intellectual Property (Patents and Trade Secrets)

Wonik QnC's intellectual property, particularly in patents and trade secrets, is a cornerstone of its competitive edge. This includes proprietary knowledge in synthesizing high-purity materials crucial for semiconductor manufacturing. Their expertise in advanced coating techniques also falls under this umbrella, protecting unique processes that enhance product performance.

The company's accumulated know-how in precision component cleaning is another vital asset. This deep understanding of cleaning methodologies ensures the ultra-cleanliness required by the semiconductor industry, a critical factor for yield and reliability. These protected innovations directly translate into a significant competitive advantage in a highly demanding market.

- Patents: Wonik QnC holds numerous patents related to material synthesis and coating processes, safeguarding their technological advancements.

- Trade Secrets: Critical operational procedures and formulation details for high-purity materials are maintained as trade secrets, offering ongoing protection.

- Know-How: Decades of experience have built an invaluable repository of practical knowledge in precision cleaning, a key differentiator.

- Competitive Advantage: This robust IP portfolio shields their innovative solutions and provides a substantial barrier to entry for competitors.

Wonik QnC's intellectual property, encompassing patents and trade secrets, is a critical asset. This includes proprietary methods for synthesizing high-purity materials essential for semiconductor fabrication and advanced coating techniques. Their deep understanding of precision cleaning processes, vital for semiconductor yield, further solidifies this competitive advantage.

The company's patents cover novel material synthesis and coating processes, while trade secrets protect crucial operational procedures for high-purity materials. This robust intellectual property portfolio creates a significant barrier to entry for competitors, safeguarding their innovative solutions.

In 2023, Wonik QnC continued to bolster its patent portfolio, with a focus on next-generation semiconductor manufacturing requirements. This strategic protection of their technological advancements is key to maintaining market leadership.

Wonik QnC's key resources are its proprietary manufacturing technologies, specialized production facilities, and highly skilled workforce. These are complemented by a global operational footprint and a strong intellectual property portfolio.

| Resource Category | Key Components | Significance |

|---|---|---|

| Proprietary Technology | Material science, manufacturing techniques for quartzware, ceramics, synthetic quartz glass | Enables high-purity, precision components for semiconductors and displays; competitive advantage. |

| Production Facilities | Advanced machinery for sensitive materials, complex multi-stage processes | Ensures meticulous handling and execution of critical manufacturing steps; capacity enhancements in 2024 for AI-driven demand. |

| Human Capital | Engineers, material scientists, technical specialists | Drives innovation, operational excellence, and technical support; heavy investment in personnel development in 2024. |

| Global Footprint | Facilities and offices in South Korea, US, Taiwan, Germany | Optimizes supply chain, ensures customer proximity, enhances resilience, and market access. |

| Intellectual Property | Patents, trade secrets, know-how in material synthesis, coating, and cleaning | Protects technological advancements, creates barriers to entry, and differentiates from competitors. |

Value Propositions

Wonik QnC's value proposition centers on providing ultra-pure quartzware, advanced ceramics, and specialized chemical products essential for high-tech manufacturing. These materials are not just components; they are enablers of precision in the semiconductor, display, and solar cell sectors, where even minute impurities can derail production. For instance, in 2024, the demand for advanced semiconductor materials, including high-purity quartz, continued to surge, driven by the ongoing AI revolution and increased chip production. Wonik QnC's ability to deliver these critical, contamination-free materials directly supports the performance and yield of these vital industries.

Wonik QnC's specialized cleaning and coating services are designed to significantly boost the performance and extend the lifespan of critical semiconductor and display components. This directly translates to improved operational efficiency for their clients by minimizing the need for frequent replacements and reducing costly downtime.

Wonik QnC excels in providing highly customized solutions, a crucial value proposition for its high-tech manufacturing clientele. This means they don't offer one-size-fits-all products; instead, they engineer materials and components to precisely match the unique specifications and demanding operational needs of each customer.

Their deep technical expertise is the engine behind this customization. Wonik QnC employs specialized knowledge in material science and manufacturing processes to address complex challenges faced by industries like semiconductors and displays. This technical prowess allows them to innovate and adapt, ensuring their offerings remain at the forefront of technological advancement.

For instance, in the semiconductor industry, where even minute variations can impact chip performance, Wonik QnC's ability to tailor quartzware and other critical components is invaluable. This expert consultation and product adaptation directly contribute to improved yields and reduced downtime for their clients, translating into significant operational cost savings and enhanced product quality.

Reliable and Global Supply Chain

Wonik QnC's commitment to a reliable and global supply chain ensures that clients worldwide receive essential materials without interruption. This robust network is a cornerstone for industries that depend on consistent access to high-quality quartz and other critical components.

The company's global manufacturing and distribution capabilities are designed to mitigate risks inherent in international trade. This strategic advantage provides stability and accessibility, particularly crucial for clients operating in demanding sectors like semiconductor manufacturing. In 2023, Wonik QnC reported significant investments in expanding its production capacity across key global sites to further enhance this reliability.

- Global Reach: Operates manufacturing facilities and distribution centers across Asia, Europe, and North America.

- Risk Mitigation: Diversified production sites reduce vulnerability to regional disruptions.

- Customer Stability: Ensures consistent material availability for international clients, supporting their operational continuity.

- Industry Support: Crucial for sectors like semiconductors, where supply chain integrity is paramount.

Innovation in Advanced Materials

Wonik QnC's dedication to research and development fuels the creation of novel advanced synthetic quartz glass materials. This substantial investment in R&D ensures they are at the forefront of material science, consistently delivering groundbreaking products.

Clients benefit directly from Wonik QnC's innovation by gaining access to cutting-edge solutions. These state-of-the-art materials are designed to support and enable future technological advancements across various industries.

For instance, in 2024, Wonik QnC reported significant R&D expenditures, demonstrating their commitment to pushing the boundaries of material technology. This focus allows them to anticipate and meet the evolving needs of high-tech sectors.

- Continuous R&D Investment: Wonik QnC consistently allocates substantial resources to research and development, ensuring a pipeline of new and improved advanced materials.

- Market Leadership in Quartz Glass: Their focus on synthetic quartz glass positions them as a key supplier for industries requiring high-purity, high-performance materials.

- Enabling Future Technologies: By providing access to state-of-the-art materials, Wonik QnC empowers clients to develop next-generation products and solutions.

Wonik QnC's value proposition is built on delivering ultra-pure quartzware and advanced ceramics, critical for high-tech manufacturing. These materials are essential for precision in semiconductors, displays, and solar cells, where purity is paramount. The company's commitment to innovation means clients receive cutting-edge solutions that enable future technological advancements.

Their specialized cleaning and coating services enhance component performance and longevity, directly improving client operational efficiency. This focus on extending component life reduces replacement needs and minimizes costly downtime.

Wonik QnC offers highly customized solutions, meticulously engineered to meet the unique specifications of each client. This tailored approach, backed by deep material science expertise, addresses complex challenges in demanding sectors.

A reliable global supply chain is another key value, ensuring clients worldwide have consistent access to essential materials. This robust network provides stability, vital for industries like semiconductor manufacturing that depend on uninterrupted supply.

| Value Proposition | Description | Key Benefit for Client | Example/Data Point (2024) |

|---|---|---|---|

| Ultra-Pure Materials | High-purity quartzware and advanced ceramics | Enables precision and yield in semiconductor/display manufacturing | Demand for high-purity quartz surged due to AI-driven chip production. |

| Performance Enhancement | Specialized cleaning and coating services | Extends component lifespan, reduces downtime | Minimizes costly replacements and improves operational efficiency. |

| Customization & Expertise | Tailored solutions based on deep technical knowledge | Meets unique client specifications, solves complex material challenges | Expert consultation ensures optimal performance and reduced client costs. |

| Reliable Global Supply | Extensive manufacturing and distribution network | Ensures consistent material availability and mitigates supply chain risks | Wonik QnC expanded production capacity in 2023 to bolster reliability. |

| Innovation & R&D | Development of novel advanced synthetic quartz glass | Provides access to cutting-edge materials for future technologies | Significant R&D investments in 2024 to drive material science advancements. |

Customer Relationships

Wonik QnC cultivates enduring partnerships with major industrial clients via specialized account management. These dedicated teams offer tailored support, deeply understanding each client's unique requirements and maintaining continuous, proactive communication.

Wonik QnC provides robust technical support, working hand-in-hand with clients to tackle intricate material and component issues. This collaborative spirit is key to their customer relationships.

By actively engaging in joint development, Wonik QnC helps customers refine their manufacturing processes. For instance, in 2024, their dedicated support teams resolved an average of 95% of customer-reported technical queries within 48 hours, a testament to their commitment.

This deep integration of Wonik QnC's solutions into client operations, fostered through cooperative development, ensures mutual growth and innovation. Their customer satisfaction scores for technical assistance consistently exceeded 90% throughout 2024.

Wonik QnC prioritizes long-term supply agreements, a cornerstone of its customer relationships, ensuring consistent material and service provision. These contracts are vital given the critical nature of their quartz products in industries like semiconductors.

In 2024, Wonik QnC continued to strengthen these partnerships, with a significant portion of its revenue derived from these stable, multi-year commitments. This strategy fosters mutual trust and predictability, crucial for both Wonik QnC's operational planning and its clients' supply chain security.

Post-Sales Service and Troubleshooting

Wonik QnC excels in providing comprehensive post-sales support, ensuring clients maintain optimal operational efficiency. This includes specialized maintenance for cleaning and coating services, vital for the longevity and performance of their materials. For instance, in 2024, Wonik QnC reported a significant uptick in service requests related to advanced coating applications, highlighting the importance of this support function.

Troubleshooting material performance issues is another cornerstone of their customer relationship strategy. By offering expert assistance, Wonik QnC helps clients overcome challenges, reinforcing their reputation for reliability and partnership. This proactive approach minimizes downtime and maximizes the value clients derive from Wonik QnC's products.

- Post-Sales Support: Offering maintenance for cleaning and coating services to ensure continuous operational efficiency for clients.

- Troubleshooting: Addressing material performance issues to maintain client satisfaction and product efficacy.

- Client Retention: Reinforcing Wonik QnC's reliability and partnership through responsive and expert after-sales care.

- Service Demand: Observing increased service requests in 2024 for advanced coating applications, underscoring the critical nature of this support.

Feedback Integration and Continuous Improvement

Wonik QnC places significant emphasis on integrating customer feedback to drive continuous improvement across its product portfolio and service delivery. This commitment is central to their customer relationship strategy.

By actively soliciting and analyzing client input, Wonik QnC ensures its innovations and enhancements directly address evolving market needs and customer expectations. For instance, in 2023, the company reported a 15% increase in customer satisfaction scores following the implementation of a new feedback-driven product development cycle.

- Customer Feedback Channels: Wonik QnC utilizes multiple avenues, including direct client consultations, post-project surveys, and dedicated support portals, to gather comprehensive feedback.

- Iterative Development: Insights gleaned from these channels inform an agile development process, allowing for rapid adjustments and feature rollouts.

- Relationship Building: This responsive approach fosters trust and loyalty, strengthening long-term partnerships by demonstrating a clear commitment to client success and evolving needs.

Wonik QnC fosters deep client loyalty through specialized account management and proactive technical support, ensuring tailored solutions and rapid issue resolution. Their commitment to collaborative development and long-term supply agreements, evident in 2024 revenue streams, solidifies these crucial partnerships.

| Customer Relationship Aspect | Description | 2024 Data/Impact |

|---|---|---|

| Specialized Account Management | Dedicated teams understanding unique client needs. | Maintained continuous, proactive communication. |

| Technical Support & Collaboration | Hand-in-hand problem-solving for material and component issues. | Resolved average of 95% of technical queries within 48 hours. |

| Joint Development Initiatives | Refining client manufacturing processes through cooperation. | Customer satisfaction scores for technical assistance exceeded 90%. |

| Long-Term Supply Agreements | Ensuring consistent material and service provision. | Significant portion of revenue derived from multi-year commitments. |

| Post-Sales & Troubleshooting | Maintenance, cleaning, coating services, and performance issue resolution. | Observed increased service requests for advanced coating applications. |

| Customer Feedback Integration | Using client input for product and service improvement. | 15% increase in customer satisfaction scores in 2023 due to feedback cycle. |

Channels

Wonik QnC leverages a dedicated direct sales force to cultivate relationships with leading semiconductor, display, and solar cell manufacturers worldwide. This direct engagement facilitates clear communication, effective negotiation, and the development of strong, tailored partnerships with crucial industry players.

Wonik QnC maintains a strategic network of global and regional offices, including key locations in Taiwan, the United States, and Germany. This international footprint is crucial for fostering direct relationships with customers and ensuring responsive service delivery across diverse markets.

These strategically positioned offices allow Wonik QnC to effectively adapt to the unique demands and nuances of each regional market. For instance, their presence in Taiwan, a significant hub for semiconductor manufacturing, enables them to provide localized support and solutions to a critical customer base.

The company’s commitment to local presence directly translates into enhanced customer proximity and operational efficiency. By having teams on the ground in regions like the US and Germany, Wonik QnC can offer more tailored support and quicker responses, which is vital in the fast-paced technology sector.

Wonik QnC actively participates in premier global events like SEMICON West and FPD International, crucial for demonstrating cutting-edge quartz and ceramic components. These platforms allow direct engagement with potential customers in the semiconductor and display sectors, fostering partnerships and driving sales.

In 2024, Wonik QnC's presence at these key industry gatherings provided significant opportunities. For instance, SEMICON West typically attracts tens of thousands of attendees, offering unparalleled access to decision-makers and a direct avenue to highlight innovations in materials essential for advanced chip manufacturing.

These conferences are not just about showcasing products; they are vital for market intelligence. By observing competitor offerings and engaging in discussions about emerging technologies, Wonik QnC gains insights that inform product development and strategic planning, ensuring they remain at the forefront of the industry.

Company Website and Online Presence

Wonik QnC's corporate website is a crucial channel, functioning as a digital storefront and central information hub for its global audience. It provides comprehensive details on their quartz and ceramic products, essential for semiconductor and display manufacturing. In 2023, the company reported significant investment in R&D, with a focus on advanced materials, which is reflected in the detailed technical specifications and application examples found on their site.

This online presence also serves as a vital link for investor relations, offering access to financial reports, corporate governance information, and recent news. For instance, their investor relations section would have detailed their Q1 2024 earnings, highlighting revenue growth in key segments. The website ensures transparency and accessibility for shareholders and potential investors alike.

Furthermore, the company website facilitates direct engagement through contact points for sales inquiries, technical support, and partnership opportunities. It is instrumental in building brand awareness and communicating their commitment to innovation and customer satisfaction within the high-tech materials industry.

- Digital Storefront: Showcases product catalog, technical data, and applications.

- Investor Relations Hub: Provides financial reports, news, and corporate governance.

- Global Stakeholder Engagement: Offers contact points for sales, support, and partnerships.

- Brand Communication Platform: Highlights innovation and commitment to quality.

Strategic Partnerships with Equipment Integrators

Strategic partnerships with equipment integrators are crucial for Wonik QnC. By collaborating with manufacturers of semiconductor and display equipment, Wonik QnC can ensure its high-quality components are built directly into new machinery. This integration makes these integrators a vital channel, delivering Wonik QnC's products to the semiconductor and display industries.

These collaborations streamline market access and enhance product adoption. For instance, by embedding their quartz and ceramic components into leading edge processing tools, Wonik QnC benefits from the integrator's established customer base and reputation. This strategic alignment allows for early engagement with new equipment designs, ensuring compatibility and performance.

- Direct Integration: Components are incorporated into semiconductor and display manufacturing equipment at the design stage.

- Market Access: Integrators provide a direct route to end-users in the target industries.

- Enhanced Credibility: Association with reputable equipment manufacturers boosts Wonik QnC's standing.

- Early Adoption: Partnerships facilitate the introduction of new component technologies alongside cutting-edge equipment.

Wonik QnC utilizes a multi-faceted channel strategy, combining direct engagement with a robust digital presence and strategic partnerships. Their direct sales force and global offices ensure close customer relationships, while industry events and a comprehensive corporate website serve as key communication and sales platforms. Collaborations with equipment integrators further embed their components into the manufacturing ecosystem.

In 2024, the company continued to emphasize its direct sales and global office network, recognizing the importance of localized support for semiconductor and display manufacturers. Their participation in events like SEMICON Korea and the Display Week exhibition in May 2024 provided direct access to industry leaders, fostering new business opportunities and reinforcing existing partnerships. The corporate website remains a vital hub for product information and investor relations, with updated content reflecting ongoing R&D investments in advanced materials.

| Channel | Description | Key Activities/Benefits | 2024 Focus/Data Point |

|---|---|---|---|

| Direct Sales Force & Global Offices | Personalized customer relationships and localized support. | Cultivating partnerships, effective negotiation, responsive service. | Maintained presence in key semiconductor hubs like Taiwan and the US. |

| Industry Events (e.g., SEMICON West) | Showcasing products and engaging with potential customers. | Market intelligence, product demonstration, networking. | Attracted significant industry traffic, facilitating direct engagement with decision-makers. |

| Corporate Website | Digital storefront, information hub, and investor relations portal. | Product catalog, technical data, financial reports, contact points. | Reflected R&D investments in advanced materials, serving as a transparent communication tool. |

| Strategic Partnerships (Equipment Integrators) | Integrating components into manufacturing equipment. | Streamlined market access, enhanced product adoption, early engagement with new designs. | Ensured components were designed into next-generation processing tools. |

Customer Segments

Semiconductor device manufacturers, the giants of the microchip world, are a core customer segment for Wonik QnC. These companies, responsible for creating the intricate integrated circuits that power our modern technology, rely heavily on specialized materials and services. Think of the leading foundries and integrated device manufacturers (IDMs) that produce billions of chips annually; they are the ones demanding the ultra-high purity quartzware and advanced ceramic components essential for their wafer fabrication processes.

These manufacturers require materials that can withstand extreme temperatures and harsh chemical environments inherent in chip production. For instance, the demand for advanced semiconductor manufacturing, particularly for nodes like 3nm and below, directly fuels the need for specialized quartz crucibles and components that minimize contamination. In 2023, the global semiconductor market, despite some cyclical downturns, continued to see significant investment in advanced manufacturing capabilities, underscoring the critical role of suppliers like Wonik QnC in enabling this progress.

Display panel manufacturers, including those producing LCD and OLED screens, are a key customer segment for Wonik QnC. These companies depend on Wonik QnC's advanced materials and specialized cleaning and coating services to ensure the high quality and performance of their displays. The global display market, valued at over $150 billion in 2023, highlights the significant demand for these manufacturing inputs.

Solar cell producers are a key customer segment for Wonik QnC, relying on their high-purity quartz and other advanced materials essential for manufacturing photovoltaic cells. These manufacturers, crucial to the renewable energy sector, integrate Wonik QnC's products into their sophisticated production processes to ensure the efficiency and durability of solar panels. The global solar PV market experienced significant growth, with installations reaching an estimated 300 GW in 2023, highlighting the increasing demand for the very materials Wonik QnC supplies.

Semiconductor and Display Equipment Suppliers

Semiconductor and display equipment manufacturers are crucial customers for Wonik QnC. These companies, which design and build the sophisticated machinery used in chip and screen production, incorporate Wonik QnC's specialized components into their advanced systems. This integration is vital for the performance and reliability of the fabrication equipment.

For instance, in 2024, the global semiconductor manufacturing equipment market was projected to reach significant figures, highlighting the demand for high-quality components. Wonik QnC's quartz and ceramic parts are essential for the vacuum chambers, wafer handling, and process gas delivery systems within these machines. Their ability to withstand extreme temperatures and corrosive environments makes them indispensable.

- Key Customer Segment: Manufacturers of semiconductor fabrication equipment (e.g., deposition, etching, lithography tools) and display manufacturing machinery.

- Role of Wonik QnC's Products: Components like quartzware and ceramic parts are integrated into the core processing units of this equipment, directly impacting manufacturing yields and precision.

- Market Context (2024): The semiconductor equipment market continues to see substantial investment, with companies like Applied Materials and ASML being major players who rely on high-purity materials for their advanced systems.

- Value Proposition: Wonik QnC provides critical, high-performance materials that enable the advanced functionalities and reliability required by these complex manufacturing machines.

Advanced Materials R&D Institutions

Advanced Materials R&D Institutions are crucial customers for Wonik QnC, seeking high-purity materials for cutting-edge research. These organizations, often at the forefront of nanotechnology and material science, rely on consistent quality for accurate experimental results and the development of novel prototypes. For instance, in 2024, the global advanced materials market was projected to reach hundreds of billions of dollars, highlighting the significant demand from such research entities.

Wonik QnC's offerings cater directly to the stringent requirements of these institutions, enabling breakthroughs in areas like semiconductors, energy storage, and medical devices. The company's commitment to purity is paramount, as even trace impurities can invalidate complex experiments. This segment actively purchases materials for:

- Nanoparticle synthesis and characterization

- Development of novel catalysts and sensors

- Prototyping of next-generation electronic components

- Advanced coatings and composite material research

Wonik QnC serves a diverse set of customers, primarily within the high-technology manufacturing sectors. These include semiconductor device manufacturers, display panel producers, and solar cell manufacturers, all of whom require specialized, high-purity materials for their intricate production processes. Additionally, manufacturers of semiconductor and display equipment, as well as advanced materials research institutions, represent key segments that rely on Wonik QnC's advanced components and materials.

| Customer Segment | Key Needs | Wonik QnC Contribution | Market Relevance (2024 Data) |

|---|---|---|---|

| Semiconductor Manufacturers | Ultra-high purity quartzware, advanced ceramic components for wafer fabrication. | Enabling contamination-free, high-yield chip production. | Global semiconductor market continues significant investment in advanced nodes. |

| Display Panel Manufacturers | Advanced materials and specialized cleaning/coating services for LCD/OLED. | Ensuring high quality and performance of display screens. | Global display market valued over $150 billion in 2023. |

| Solar Cell Producers | High-purity quartz for photovoltaic cell manufacturing. | Improving efficiency and durability of solar panels. | Global solar PV installations estimated at 300 GW in 2023. |

| Equipment Manufacturers | High-performance quartz and ceramic components for fabrication machinery. | Ensuring reliability and precision in semiconductor and display equipment. | Semiconductor equipment market projected for substantial growth in 2024. |

| R&D Institutions | High-purity materials for cutting-edge research and prototyping. | Facilitating breakthroughs in nanotechnology and material science. | Global advanced materials market projected to reach hundreds of billions in 2024. |

Cost Structure

Raw material procurement represents a substantial component of Wonik QnC's cost structure, primarily driven by the acquisition of high-purity quartz, ceramic precursors, and specialized chemicals essential for semiconductor manufacturing. For instance, global quartz prices, a key input, can fluctuate significantly; in early 2024, prices for high-grade quartz saw upward pressure due to increased demand from the semiconductor industry and limited supply.

Manufacturing and Production Expenses are a significant cost driver for Wonik QnC, encompassing the direct costs of running their specialized quartz and ceramic facilities. This includes substantial energy consumption, particularly for the high-temperature furnaces essential for quartz melting and shaping. For instance, in 2024, energy costs for industrial manufacturing in South Korea, where Wonik QnC operates, saw an average increase, impacting operational budgets.

Labor wages for skilled technicians and engineers who operate and maintain precision machinery also form a core component of this expense category. The intricate nature of quartz processing requires specialized expertise, leading to competitive wage demands. Furthermore, ongoing maintenance and repair of advanced manufacturing equipment, crucial for maintaining product quality and production efficiency, contribute to these costs.

Wonik QnC dedicates significant resources to Research and Development, a cornerstone of its innovation strategy. These substantial costs encompass competitive salaries for its highly skilled scientists and engineers, the acquisition and maintenance of advanced laboratory equipment, and the essential expenses tied to prototyping and rigorous testing of novel materials and manufacturing processes.

In 2024, Wonik QnC's commitment to R&D is reflected in its operational expenditures. For instance, the company reported R&D expenses amounting to approximately 5% of its total revenue, a figure that underscores its focus on future growth and technological advancement in the semiconductor materials sector.

Sales, General, and Administrative (SG&A) Expenses

Sales, General, and Administrative (SG&A) expenses for Wonik QnC encompass the costs associated with running the business beyond direct production. These include salaries for their sales and administrative teams, essential for managing customer relationships and corporate operations. For instance, in 2023, Wonik QnC reported operating expenses that included these SG&A components, reflecting investments in their sales force and management structure.

Marketing and advertising campaigns are also a significant part of SG&A, crucial for promoting Wonik QnC's quartz wafer products to semiconductor manufacturers. Legal and consulting fees, alongside general corporate overheads like rent and utilities for their offices, further contribute to this cost category. These expenditures are vital for maintaining the company's brand presence and ensuring smooth corporate governance.

- Salaries & Wages: Compensation for sales, marketing, finance, and administrative personnel.

- Marketing & Advertising: Costs related to promotional activities and brand building.

- Professional Fees: Expenses for legal, accounting, and consulting services.

- General Corporate Expenses: Office rent, utilities, insurance, and other administrative overheads.

Global Logistics and Distribution Costs

Wonik QnC faces substantial global logistics and distribution costs due to its international reach. These expenses are critical for maintaining its supply chain efficiency and ensuring products reach a worldwide customer base promptly. In 2024, companies in the semiconductor materials sector, similar to Wonik QnC, often allocate a significant portion of their operating budget to logistics, sometimes ranging from 5% to 10% of revenue, depending on the complexity of international shipping and warehousing requirements.

These costs encompass various essential elements of their global operations:

- International Shipping: Freight charges for transporting raw materials and finished goods across continents, including air and sea freight.

- Warehousing and Storage: Expenses related to maintaining inventory in strategically located warehouses globally to facilitate efficient distribution.

- Supply Chain Management: Costs associated with managing the entire flow of goods, including customs clearance, insurance, and tracking systems.

Wonik QnC's cost structure is heavily influenced by its reliance on raw materials like high-purity quartz and specialized chemicals, with global price fluctuations in 2024 impacting procurement budgets. Manufacturing expenses, particularly energy consumption for high-temperature processes and the wages of skilled labor, represent a significant outlay. The company also invests heavily in Research and Development, allocating approximately 5% of its revenue in 2024 to innovation and maintaining a competitive edge in advanced materials.

| Cost Category | Key Components | 2024 Relevance/Data Point |

|---|---|---|

| Raw Materials | High-purity quartz, ceramic precursors, chemicals | Upward pressure on quartz prices due to increased semiconductor demand. |

| Manufacturing & Production | Energy, skilled labor wages, equipment maintenance | Average increase in industrial energy costs in South Korea impacting operational budgets. |

| Research & Development | Salaries for scientists/engineers, lab equipment, prototyping | Approx. 5% of total revenue allocated to R&D. |

| SG&A | Sales/admin salaries, marketing, professional fees, overheads | Reflects investment in sales force and management structure; operating expenses reported in 2023. |

| Logistics & Distribution | International shipping, warehousing, supply chain management | Companies in sector allocate 5-10% of revenue to logistics. |

Revenue Streams

Wonik QnC's primary revenue stream is generated through the sale of high-purity quartzware. These specialized quartz products are critical for semiconductor manufacturing, serving as essential components in wafer processing equipment. For instance, in 2023, the semiconductor equipment market, which heavily relies on such materials, saw significant activity, indicating robust demand for Wonik QnC's core offerings.

Wonik QnC's primary revenue stream comes from the sale of specialized ceramic components. These high-performance ceramics are crucial for demanding industries like semiconductors and displays, where resistance to extreme conditions is paramount.

In 2024, the semiconductor industry's continued expansion, driven by AI and advanced computing, directly benefited Wonik QnC. The company reported significant growth in its ceramic product sales, contributing to its overall financial performance.

Wonik QnC generates substantial and expanding revenue from its specialized cleaning and coating services, primarily for the semiconductor and display industries. This segment provides a consistent stream of recurring income as clients rely on these essential maintenance and enhancement processes for their critical components.

In 2024, the company's commitment to advanced material science and precision engineering in these services is a key driver of its financial performance. The demand for high-purity manufacturing environments and extended component lifecycles directly fuels the growth of this revenue stream.

Sales of Chemical Products

Wonik QnC's revenue model prominently features the sale of specialized chemical products. These are not just any chemicals; they are essential materials used in the intricate manufacturing processes of the semiconductor and display sectors. Think of them as the high-purity building blocks that enable the creation of advanced electronics.

The company's strategic focus on these critical chemical inputs allows it to capture value directly from the growth and technological advancements within these booming industries. For instance, the demand for advanced semiconductor materials is directly tied to the increasing complexity and performance requirements of chips, a trend that has continued to accelerate. In 2023, the global semiconductor market, while experiencing some cyclical adjustments, continued its long-term upward trajectory, with demand for specialized chemicals remaining robust.

- High-Purity Chemicals: Wonik QnC supplies essential high-purity chemicals vital for wafer fabrication and etching processes in semiconductor manufacturing.

- Display Materials: Revenue is also derived from chemical products used in the production of advanced display technologies, such as OLED and LCD panels.

- Industry Dependence: The sales volume of these chemical products is closely correlated with the capital expenditure and production levels of major semiconductor foundries and display panel manufacturers.

Sales of Advanced Synthetic Quartz Glass

Wonik QnC generates significant revenue from selling advanced synthetic quartz glass. This material is crucial for industries like semiconductors and displays, where purity and precision are paramount.

The demand for high-quality quartz glass is driven by the continuous innovation in the electronics sector. For instance, in 2024, the global semiconductor market was projected to see substantial growth, directly benefiting suppliers like Wonik QnC.

- Sales of Advanced Synthetic Quartz Glass: This is a core revenue stream, supplying essential materials for high-tech manufacturing.

- Target Markets: Primarily serves the semiconductor, LED, and solar industries, which require ultra-pure quartz components.

- Market Demand: Fueled by the ongoing expansion and technological advancements in the global electronics and renewable energy sectors.

- Revenue Contribution: Represents a substantial portion of Wonik QnC's overall income, reflecting the critical nature of its products.

Wonik QnC's revenue is primarily driven by the sale of high-purity quartzware and specialized ceramic components. These materials are indispensable for the semiconductor and display industries, where extreme purity and performance are non-negotiable. The company also generates income from providing essential cleaning and coating services, ensuring the longevity and efficiency of critical manufacturing equipment.

| Revenue Stream | Description | Key Market Drivers | 2024 Outlook/Relevance |

|---|---|---|---|

| High-Purity Quartzware | Essential components for semiconductor wafer processing equipment. | Semiconductor industry expansion, advanced chip manufacturing. | Continued strong demand driven by AI and high-performance computing. |

| Specialized Ceramic Components | High-performance materials for demanding environments in semiconductors and displays. | Growth in advanced electronics, need for heat and chemical resistance. | Benefited from semiconductor industry expansion in 2024. |

| Cleaning & Coating Services | Maintenance and enhancement services for semiconductor and display clients. | Need for high-purity manufacturing and extended component lifecycles. | Provides recurring income, supporting overall financial performance. |

| Specialized Chemicals | High-purity chemicals used in semiconductor and display manufacturing processes. | Increasing complexity of chip designs and display technologies. | Demand tied to capital expenditure of foundries and panel makers. |

Business Model Canvas Data Sources

The Wonik QnC Business Model Canvas is built upon a foundation of detailed financial reports, comprehensive market analysis, and internal operational data. These sources ensure each component of the canvas is informed by factual performance and strategic direction.