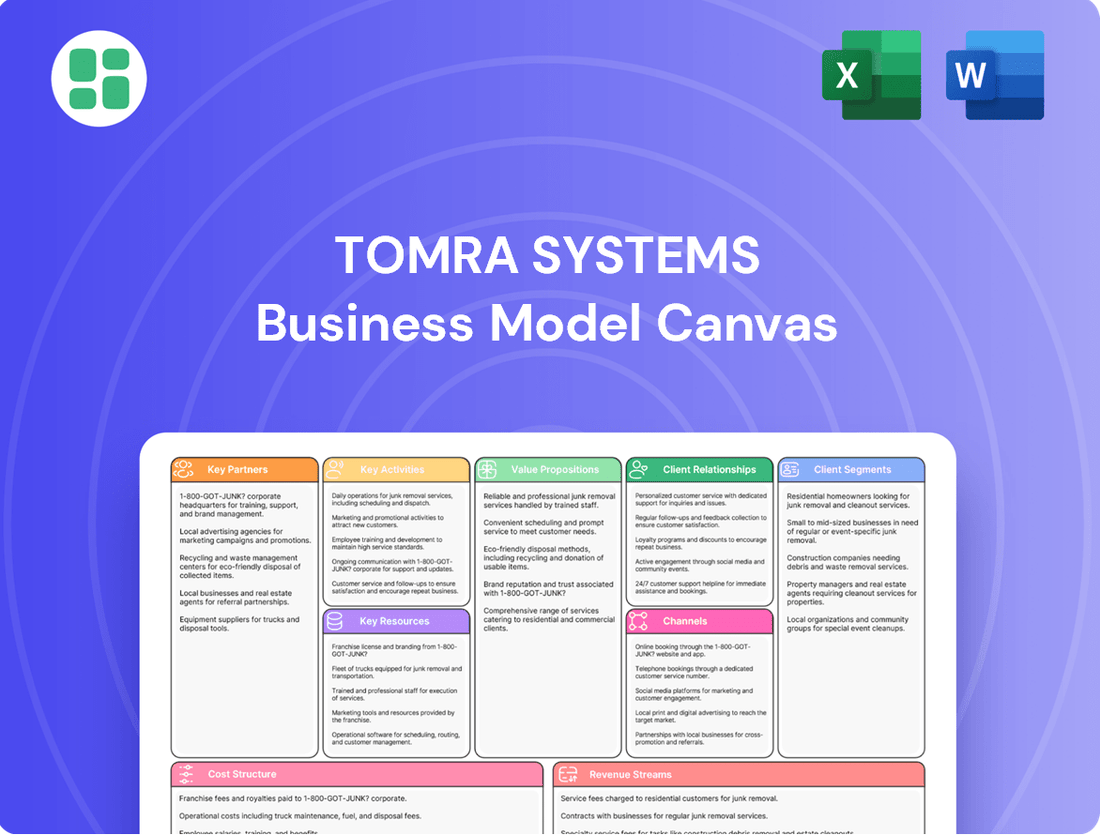

Tomra Systems Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Tomra Systems Bundle

Unlock the strategic blueprint behind Tomra Systems's innovative business model. This comprehensive Business Model Canvas reveals how they create value through advanced sorting and recycling solutions, engage key partners in the circular economy, and capture revenue streams from technology and service offerings. Discover their customer relationships and channels for reaching global markets.

Want to understand the core drivers of Tomra Systems's success? This detailed Business Model Canvas breaks down their key resources, activities, and cost structures, offering a clear view of their operational efficiency and competitive advantages. It's the perfect tool for anyone looking to replicate or adapt their winning strategies.

Dive deep into Tomra Systems's proven strategy with our complete Business Model Canvas. From their unique value propositions in sustainability to their revenue streams and cost management, this downloadable resource provides actionable insights for entrepreneurs, investors, and strategists. Get the full picture and accelerate your own business planning.

Partnerships

TOMRA's commitment to innovation is fueled by strategic technology and R&D collaborations. These partnerships, often with leading universities and specialized tech firms, focus on enhancing sensor technology, artificial intelligence, and machine learning. For instance, ongoing research aims to refine the accuracy and speed of sorting processes, directly impacting the efficiency of systems like the AUTOSORT™ PULSE.

TOMRA's key partnerships with waste management and recycling integrators are foundational to its business. These collaborations involve providing advanced sorting and collection technologies, like sensor-based sorting systems, which are critical for enhancing the efficiency of recycling processes. For instance, TOMRA's systems enable facilities to achieve higher purity rates for recycled materials, a vital factor in the circular economy.

These partnerships are not just about supplying equipment; they are about integrating TOMRA's solutions into the core operations of major waste management players worldwide. This integration allows for more effective material recovery, ultimately supporting global sustainability goals. In 2024, the demand for high-quality recycled content continues to grow, making these partnerships even more critical for achieving circularity targets.

TOMRA's Collection division thrives on strong collaborations with beverage manufacturers, bottlers, and retailers. These alliances are crucial for rolling out and managing deposit return schemes (DRS) effectively.

These partnerships are the backbone of TOMRA's reverse vending machine network, driving consumer engagement in recycling. For instance, in 2024, TOMRA's systems facilitated the collection of over 45 billion used beverage containers globally, a testament to the reach these collaborations enable.

Food Processing and Mining Industry Players

TOMRA's key partnerships within the food processing and mining industries are crucial for deploying its advanced sorting technologies. These collaborations focus on integrating TOMRA's solutions directly into customer production lines, driving significant improvements.

These partnerships are designed to optimize resource recovery, boost product quality, and enhance overall operational efficiency for clients. For instance, in the food sector, TOMRA's optical sorters help remove foreign materials and defective products, ensuring higher quality output. In mining, their sensor-based sorting technology allows for the pre-concentration of valuable minerals, reducing downstream processing costs and environmental impact.

The impact of these collaborations is substantial. For example, in 2024, TOMRA reported that its sorting solutions in the food industry helped customers reduce waste by an average of 15%, leading to significant cost savings and improved sustainability. Similarly, in the mining sector, the adoption of TOMRA's sorters has been linked to an average increase in recovery rates of up to 5% for certain minerals, directly impacting profitability.

- Food Processing: Collaborations with major food manufacturers to integrate optical sorting for quality control and waste reduction.

- Mining: Partnerships with mining operations globally to implement sensor-based sorting for pre-concentration of valuable ores.

- Resource Optimization: Joint efforts to improve material recovery rates and reduce the processing of waste materials.

- Efficiency Gains: Working with industry players to streamline production lines and lower operational costs through advanced sorting.

Government Bodies and NGOs

TOMRA's engagement with government bodies and NGOs is crucial for advancing circular economy principles and influencing policy. This collaboration helps shape regulations that support sustainable resource management, such as the EU's Packaging and Packaging Waste Regulation (PPWR). For instance, in 2024, TOMRA continued its advocacy for deposit return systems as a key driver for increased collection rates and reduced waste across Europe.

These partnerships are instrumental in fostering an environment where innovative recycling technologies can thrive. By working with policymakers and environmental organizations, TOMRA can demonstrate the economic and environmental benefits of advanced sorting and collection systems. This proactive involvement ensures that future legislation is informed by practical, real-world data and technological capabilities.

Key areas of collaboration include:

- Policy Advocacy: Engaging with governmental bodies to inform and shape legislation related to waste management and the circular economy, including input on the PPWR.

- Promoting Circular Economy: Partnering with NGOs to raise public awareness and drive the adoption of circular economy practices, emphasizing the role of effective recycling.

- Data Sharing: Providing data and insights from their operations to support evidence-based policymaking and the development of effective environmental strategies.

- Standard Setting: Contributing to the development of industry standards and best practices for collection and recycling systems.

TOMRA's Key Partnerships are vital for its ecosystem, spanning technology development, waste management, and retail. These alliances ensure the effective deployment and continuous improvement of its sorting and collection solutions, driving the circular economy forward.

Collaborations with waste management and recycling integrators are crucial for implementing TOMRA's advanced sorting technologies, leading to higher purity rates for recycled materials. In 2024, these partnerships were instrumental in meeting the growing demand for high-quality recycled content, a key driver for achieving circularity targets.

The Collection division relies heavily on partnerships with beverage manufacturers, bottlers, and retailers to successfully operate deposit return schemes (DRS). These relationships underpin TOMRA's extensive reverse vending machine network, facilitating the collection of billions of used beverage containers annually, such as the over 45 billion collected globally in 2024.

TOMRA also partners with food processing and mining industries to integrate its sensor-based sorting technologies directly into client operations, optimizing resource recovery and enhancing product quality. For instance, in 2024, food industry clients saw an average waste reduction of 15% using TOMRA's sorters, while mining operations reported up to a 5% increase in recovery rates for certain minerals.

| Partner Type | Purpose | Impact/Example (2024 Data) |

|---|---|---|

| Technology & R&D Firms/Universities | Enhance sensor technology, AI, ML for sorting | Refining accuracy and speed of sorting processes (e.g., AUTOSORT™ PULSE) |

| Waste Management & Recycling Integrators | Deploy advanced sorting, improve recycling efficiency | Achieve higher purity rates for recycled materials, enabling circular economy goals |

| Beverage Manufacturers, Bottlers, Retailers | Roll out and manage Deposit Return Schemes (DRS) | Facilitated collection of over 45 billion used beverage containers globally |

| Food Processing & Mining Companies | Integrate sorting into production lines for resource optimization | Food: 15% average waste reduction; Mining: Up to 5% increased recovery rates for minerals |

| Government Bodies & NGOs | Shape policy, promote circular economy principles | Advocacy for DRS, input on regulations like EU's PPWR |

What is included in the product

A comprehensive, pre-written business model tailored to Tomra's strategy, detailing customer segments, value propositions, and revenue streams in the context of their reverse vending and sensor-based sorting solutions.

Reflects Tomra's real-world operations and plans, organized into 9 classic BMC blocks with full narrative and insights for informed decision-making.

Tomra Systems' Business Model Canvas acts as a pain point reliever by offering a clear, structured overview of their complex recycling and resource management solutions, simplifying understanding and strategic alignment for stakeholders.

Activities

TOMRA's commitment to Research and Development is central to its business model, driving innovation in sensor-based sorting and collection technologies. The company consistently invests in cutting-edge areas like Artificial Intelligence, deep learning, and Laser-Induced Breakdown Spectroscopy (LIBS) to enhance material recovery and purity.

This focus on R&D ensures TOMRA's solutions remain at the forefront of market demands, anticipating future needs in resource management and recycling. For instance, in 2023, TOMRA continued to advance its digital capabilities, integrating AI for improved object recognition and sorting accuracy, a key driver for their recycling and food segments.

Tomra Systems' core activity is the sophisticated manufacturing of sensor-based sorting and reverse vending machines. These high-precision systems are crucial for their various business segments, demanding rigorous quality control throughout the production process to meet substantial global demand.

In 2023, Tomra reported a significant increase in revenue, reaching NOK 15.1 billion, driven by strong performance across its divisions, which directly reflects the output and efficiency of its manufacturing operations.

TOMRA’s core activities revolve around the global sales, installation, and commissioning of its sophisticated sorting and collection systems. This extensive reach ensures their technology is deployed across diverse markets, from food processing to reverse vending.

Post-installation, TOMRA prioritizes robust after-sales service, maintenance, and technical support. This commitment is crucial for maintaining optimal machine performance and ensuring high levels of customer satisfaction, a key differentiator in their service-oriented business model.

In 2023, TOMRA's service segment demonstrated strong growth, contributing significantly to the company's overall revenue, highlighting the importance of these ongoing customer relationships.

Software Development and Data Analytics

Developing and integrating advanced software platforms, like TOMRA Insight and AI-driven analytics, is central to their operations. These digital tools allow for continuous monitoring and optimization of sorting processes, offering customers deep insights.

This focus on software and data analytics empowers customers to make better decisions and improve operational efficiency. For instance, TOMRA Insight provides performance data that can be used to fine-tune sorting parameters, leading to higher recovery rates and reduced waste.

- Software Development: Creating and enhancing proprietary sorting software and digital platforms.

- Data Analytics: Leveraging AI and machine learning for process optimization and customer insights.

- Platform Integration: Ensuring seamless integration of hardware and software solutions for end-to-end performance.

- Customer Support: Providing data-driven support and consulting services based on collected operational data.

Market Development and Policy Advocacy

Tomra Systems actively shapes new markets, particularly for deposit return schemes (DRS), by engaging with governments and industry to establish and expand these systems globally. This involves demonstrating the environmental and economic benefits of DRS to encourage adoption and regulatory support. For instance, by 2024, Tomra's technology is integral to DRS in over 40 markets, processing billions of containers annually, contributing to higher recycling rates and reduced waste.

Policy advocacy is a cornerstone of Tomra's strategy, focusing on promoting circular economy principles and robust waste management regulations. They work with policymakers to develop effective legislation that incentivizes recycling and the use of recycled materials. This proactive engagement ensures that regulatory frameworks align with their business model and support a more sustainable future for resource management, influencing policy decisions that drive market growth.

- Market Shaping: Tomra's efforts in developing and expanding deposit return schemes (DRS) are critical. By 2024, their technology is deployed in over 40 markets, facilitating the collection and recycling of billions of containers annually, thereby fostering a circular economy.

- Policy Advocacy: The company actively engages with policymakers worldwide to advocate for legislation supporting the circular economy and effective waste management, including the implementation and enhancement of DRS.

- Stakeholder Engagement: Tomra collaborates with governments, industry partners, and non-governmental organizations to drive regulatory changes and promote sustainable resource management practices.

Tomra Systems' key activities are deeply rooted in the development, manufacturing, and global deployment of advanced sensor-based sorting and collection solutions. This encompasses robust R&D, focusing on AI and advanced analytics to enhance material recovery and purity, alongside the meticulous production of high-precision sorting and reverse vending machines. Furthermore, the company excels in global sales, installation, and comprehensive after-sales service, ensuring optimal performance and customer satisfaction. A crucial element also involves shaping new markets, particularly for deposit return schemes (DRS), through policy advocacy and stakeholder engagement to promote circular economy principles.

| Key Activity | Description | 2023/2024 Data/Impact |

|---|---|---|

| Research & Development | Innovation in sensor-based sorting and collection technologies, AI, deep learning, LIBS. | Continued advancement of digital capabilities and AI for improved sorting accuracy. |

| Manufacturing | Production of sophisticated sensor-based sorting and reverse vending machines. | Revenue of NOK 15.1 billion in 2023 reflects strong output and efficiency. |

| Sales, Installation & Service | Global deployment, commissioning, and ongoing technical support for systems. | Service segment showed strong growth in 2023, contributing significantly to revenue. |

| Software & Data Analytics | Development of platforms like TOMRA Insight for monitoring and optimization. | Empowering customers with data-driven insights to improve operational efficiency. |

| Market Shaping & Policy Advocacy | Expanding DRS, engaging with governments to promote circular economy. | Technology integral to DRS in over 40 markets by 2024, processing billions of containers. |

Delivered as Displayed

Business Model Canvas

The Business Model Canvas preview you are viewing is an authentic representation of the final document you will receive upon purchase. This is not a sample or mockup; it's a direct glimpse into the comprehensive analysis of Tomra Systems' business strategy. Upon completing your transaction, you will gain full access to this exact, professionally structured document, ready for your immediate use and adaptation.

Resources

TOMRA's competitive edge is deeply rooted in its proprietary sensor technologies, a key resource for its business model. These include advanced Near-Infrared (NIR), X-ray, and laser systems, which are crucial for the precise identification and separation of materials in their sorting solutions.

Furthermore, TOMRA significantly leverages its intellectual property (IP) in advanced Artificial Intelligence (AI) and deep learning algorithms. This AI integration enhances the performance and adaptability of its sorting and collection systems, allowing for increasingly sophisticated material analysis and separation capabilities.

The company's commitment to innovation in sensor technology and IP development is evident in its substantial R&D investments. For example, in 2023, TOMRA's research and development expenses amounted to NOK 1,476 million, underscoring the importance of these resources in maintaining their market leadership.

Tomra Systems relies heavily on its highly specialized workforce of R&D engineers, software developers, and technical experts. This talent pool is the engine driving innovation and ensuring Tomra maintains its technological edge in sensor-based sorting solutions. In 2023, Tomra reported significant investment in research and development, with personnel costs for R&D and engineering forming a substantial portion of their operational expenses, underscoring the critical nature of this resource.

TOMRA's extensive manufacturing facilities and robust global supply chain are the backbone of its operations, enabling the efficient production and worldwide delivery of its advanced sorting and recycling systems. This critical infrastructure supports the large-scale deployments required by its customers and ensures consistent access to essential components and materials, even amidst global supply chain fluctuations. For instance, in 2023, TOMRA continued to invest in optimizing its production capacity and logistics networks to meet growing demand for its solutions, particularly in the circular economy sector.

Global Sales and Service Network

Tomra's extensive global sales and service network is a cornerstone of its business model, ensuring direct customer engagement and localized support in over 100 markets. This widespread infrastructure is crucial for maintaining operational uptime and fostering strong customer relationships.

The company's commitment to a robust service network means that customers benefit from efficient maintenance and timely support for their installed systems, regardless of their location. This global reach is a significant competitive advantage.

- Global Reach: Operations spanning over 100 countries.

- Customer Proximity: Direct sales force and localized service teams.

- Operational Uptime: Focus on efficient maintenance and support.

- Relationship Building: Essential for long-term customer partnerships.

Brand Reputation and Market Leadership

TOMRA's brand reputation as a pioneer in sensor-based sorting and collection systems is a cornerstone of its business model. This established leadership isn't just about recognition; it translates directly into tangible benefits by drawing in a consistent stream of customers and valuable partnerships.

The company's market leadership, particularly in areas like reverse vending machines and food sorting, fosters trust and encourages repeat business. This strong market position also makes TOMRA an attractive employer, helping it secure top talent essential for innovation and sustained growth.

In 2023, TOMRA's commitment to sustainability, a key driver of its brand, was further emphasized by its role in advancing the circular economy. For instance, its collection solutions processed billions of containers, contributing to higher recycling rates globally.

- Global Leader: TOMRA is recognized worldwide for its expertise in sensor-based sorting and automated collection solutions.

- Customer Attraction: Strong brand recognition and market leadership directly attract new customers and retain existing ones.

- Talent Magnet: The company's reputation as an industry leader makes it a desirable workplace, aiding in talent acquisition.

- Partnership Catalyst: Market leadership facilitates strategic alliances and collaborations that further enhance its offerings.

TOMRA's intellectual property portfolio, encompassing patents and proprietary algorithms, is a critical resource. This IP protects its advanced sensor technologies and AI capabilities, providing a significant competitive advantage in the market.

The company's substantial investment in research and development, exemplified by its NOK 1,476 million R&D expenditure in 2023, fuels the continuous innovation of these core technologies and ensures its market leadership.

TOMRA's brand reputation as a pioneer in sensor-based sorting and collection systems is a vital intangible asset. This strong market position, particularly in reverse vending and food sorting, attracts customers and facilitates strategic partnerships.

In 2023, TOMRA's collection solutions processed billions of containers, highlighting its significant contribution to the circular economy and reinforcing its brand image.

| Key Resource | Description | 2023 Relevance |

|---|---|---|

| Proprietary Sensor Technologies | Advanced NIR, X-ray, and laser systems for material identification and separation. | Core to TOMRA's sorting solutions, enabling precise material analysis. |

| Intellectual Property (AI & Algorithms) | Patents and proprietary AI/deep learning algorithms enhancing system performance. | Drives innovation and adaptability in sorting and collection systems. |

| R&D Investment | Significant financial commitment to technological advancement. | NOK 1,476 million invested in 2023, underscoring commitment to innovation. |

| Brand Reputation | Pioneering status in sensor-based sorting and collection systems. | Attracts customers, fosters partnerships, and aids talent acquisition. |

Value Propositions

TOMRA's advanced sorting technologies dramatically boost the recovery of valuable materials from waste. For instance, their sensor-based sorting systems can achieve recovery rates exceeding 90% for certain plastics, turning what was once discarded into a valuable resource.

These systems also ensure a higher purity of recovered materials. This means customers can transform waste into high-quality secondary raw materials, essential for building a robust circular economy and reducing reliance on virgin resources.

TOMRA's solutions significantly boost operational efficiency by automating complex sorting tasks, directly reducing the need for manual labor. This automation minimizes errors and material loss, which in 2024, translates to substantial cost savings for their clients in recycling, food processing, and mining sectors. For instance, their sensor-based sorting technology can achieve accuracy rates exceeding 95%, a stark improvement over manual methods.

By optimizing material flow and reducing waste, TOMRA's systems directly contribute to improved profitability for their customers. Recycling facilities, for example, can see a reduction in operational expenses by up to 20% due to less reliance on labor and reduced product giveaway. This focus on cost reduction and efficiency makes TOMRA a key partner for businesses aiming to enhance their bottom line.

TOMRA's innovative sorting and collection technologies are fundamental to building a circular economy. By enabling the efficient reuse and recycling of materials, these solutions directly combat waste, preserve precious natural resources, and significantly cut down on carbon emissions. This is crucial as global sustainability targets and increasing regulatory demands push industries towards more responsible practices.

For instance, in 2023, TOMRA's Food segment processed over 1.5 million tons of food, diverting a substantial amount from landfill and contributing to resource efficiency. Their systems are designed to recover high-quality materials, making recycling economically viable and environmentally impactful, which is a key driver for businesses aiming to meet their environmental, social, and governance (ESG) commitments.

Improved Product Quality and Safety (Food & Mining)

TOMRA's sorting systems significantly elevate product quality and safety across industries. In the food sector, their advanced optical sorters identify and remove unwanted materials like stones, plastics, and damaged produce, ensuring consumers receive safer, higher-grade food items. This technology is crucial for meeting stringent regulatory standards and consumer expectations for purity.

For the mining industry, TOMRA's solutions provide substantial value by optimizing ore sorting processes. These systems enhance mineral recovery rates and improve the purity of extracted materials, directly boosting the economic viability of mining operations. By accurately separating valuable minerals from waste rock, TOMRA's technology increases the overall value of the mined resources.

- Food Industry Impact: TOMRA's technology helps food processors achieve up to a 99% accuracy rate in removing foreign materials, reducing recalls and enhancing brand reputation.

- Mining Efficiency Gains: In mining, TOMRA's sensor-based sorting can increase head grade by 2-5% and reduce processing costs by up to 15% by pre-concentrating ore.

- Safety Assurance: By eliminating contaminants, TOMRA's systems are vital for food safety, preventing incidents that could lead to product recalls or health issues.

- Resource Optimization: In mining, the ability to sort at higher cut-off grades means more valuable ore is processed, maximizing the return on investment for extracted resources.

Compliance with Regulatory Requirements

TOMRA's advanced sorting and collection systems are instrumental in helping businesses meet stringent environmental regulations. This is particularly vital in regions implementing or expanding deposit return schemes (DRS), ensuring compliance with recycling targets and waste management laws.

For instance, in 2024, many European countries continued to strengthen their DRS frameworks, with some aiming for collection rates exceeding 90%. TOMRA's technology directly supports these goals by enabling efficient and accurate sorting of beverage containers, thereby reducing the burden of non-compliance for retailers and producers.

- Facilitates adherence to evolving environmental legislation.

- Supports achievement of high recycling rates mandated by DRS.

- Minimizes risks associated with non-compliance in regulated markets.

TOMRA's value proposition centers on transforming waste into valuable resources through advanced sorting. Their sensor-based technology achieves over 90% recovery rates for certain plastics, turning waste into high-quality secondary raw materials crucial for a circular economy.

Furthermore, TOMRA significantly enhances operational efficiency by automating sorting tasks, reducing manual labor needs and minimizing errors. This automation leads to substantial cost savings for clients in 2024, with accuracy rates exceeding 95% in their sorting systems.

The company's solutions directly boost customer profitability by optimizing material flow and reducing waste. For recycling facilities, this can mean up to a 20% reduction in operational expenses, making TOMRA a key partner for enhancing bottom lines.

TOMRA's technologies are foundational to the circular economy, enabling efficient material reuse and recycling, which in turn combats waste, conserves resources, and cuts carbon emissions. This aligns with increasing global sustainability targets and regulatory demands pushing industries towards responsible practices.

| Key Value Proposition | Description | Supporting Data/Impact |

|---|---|---|

| Resource Recovery & Transformation | Turning waste into valuable secondary raw materials. | Recovery rates exceeding 90% for certain plastics. |

| Operational Efficiency & Cost Savings | Automating sorting to reduce labor and errors. | Accuracy rates over 95%; up to 20% reduction in operational expenses for recycling facilities. |

| Enhanced Product Quality & Safety | Removing contaminants for purer materials. | Up to 99% accuracy in removing foreign materials in food processing. |

| Sustainability & Regulatory Compliance | Enabling circular economy and meeting recycling mandates. | Supports Deposit Return Schemes (DRS) with high collection rate goals. |

Customer Relationships

TOMRA fosters enduring relationships with its industrial and commercial clients, often evolving into strategic alliances. These partnerships focus on co-developing and implementing advanced sorting and recycling technologies, ensuring customers receive highly customized solutions and continuous operational support.

TOMRA's customer relationships are built on a foundation of dedicated account management and robust technical support. This ensures clients receive personalized attention and expert assistance, crucial for optimizing the performance of their advanced sorting and recycling technologies.

Customers benefit from 24/7 remote monitoring and on-site assistance, guaranteeing the seamless operation of TOMRA's complex machinery and enabling rapid issue resolution. In 2024, TOMRA reported a significant increase in customer uptime, directly attributable to the effectiveness of these support services.

Tomra's sales approach is deeply consultative, focusing on understanding each customer's unique operational challenges. This involves meticulous analysis to tailor sorting and collection solutions, ensuring optimal performance for specific needs.

For instance, in 2024, Tomra continued to emphasize this consultative process across its various segments, from food sorting to recycling technologies. Their teams work closely with clients to identify precise requirements, leading to customized system designs that maximize efficiency and yield.

Training and Knowledge Transfer

TOMRA is committed to ensuring its customers can effectively utilize their sorting and recycling technologies. They offer comprehensive training programs designed to equip customer personnel with the necessary skills for operating and maintaining TOMRA systems. This focus on knowledge transfer is crucial for maximizing equipment efficiency and extending its operational lifespan, ultimately contributing to better recycling outcomes and operational cost savings for their clients.

These training initiatives are a cornerstone of TOMRA's customer relationship strategy, fostering self-sufficiency and operational excellence among their clientele. By investing in customer education, TOMRA aims to build long-term partnerships grounded in trust and mutual success. For instance, in 2023, TOMRA continued to expand its digital learning platforms, offering a wider array of modules accessible globally, reflecting a growing emphasis on accessible and continuous learning for their diverse customer base.

- Comprehensive Training Programs: TOMRA delivers in-depth training on system operation and maintenance.

- Empowering Customers: This empowers clients to enhance equipment efficiency and longevity.

- Focus on Knowledge Transfer: A key element in building strong, long-term customer relationships.

- Digital Learning Expansion: Continued growth in digital platforms for accessible, global training.

Digital Platforms and Data-Driven Insights

TOMRA Systems cultivates strong customer relationships through its digital platforms, notably TOMRA Insight. This platform enables direct data sharing, providing customers with valuable analytics to optimize their operations. For example, in 2024, TOMRA reported a significant increase in the utilization of its digital services, with customers leveraging the data to achieve an average of 15% improvement in sorting efficiency.

This data-driven approach transforms the customer interaction into a true partnership. By offering insights into performance and resource management, TOMRA empowers clients to make more informed decisions, leading to enhanced process control and sustainability. This fosters a collaborative environment where continuous improvement is driven by shared data.

- Data Sharing and Analytics: TOMRA Insight provides customers with real-time performance data and advanced analytics.

- Informed Decision-Making: Customers use this data to identify areas for process improvement and optimize resource management.

- Data-Driven Partnership: This fosters a collaborative relationship focused on achieving tangible operational benefits and sustainability goals.

- Efficiency Gains: In 2024, users of TOMRA's digital platforms reported an average of 15% improvement in sorting efficiency.

TOMRA's customer relationships are characterized by a deep commitment to ongoing support and collaborative development. This includes providing 24/7 remote monitoring and on-site assistance, ensuring maximum uptime for their advanced sorting and recycling technologies. In 2024, TOMRA saw a notable rise in customer satisfaction directly linked to the efficacy of these support services.

TOMRA Insight, their digital platform, plays a crucial role by enabling direct data sharing and providing valuable operational analytics. In 2024, TOMRA reported that customers leveraging these digital services achieved an average of 15% improvement in sorting efficiency, highlighting a data-driven partnership approach.

| Key Relationship Element | Description | 2024 Impact/Focus |

| Technical Support | 24/7 remote monitoring and on-site assistance | Increased customer uptime, improved operational efficiency |

| Consultative Sales | Understanding unique client challenges to tailor solutions | Customized system designs maximizing efficiency and yield |

| Digital Platforms (TOMRA Insight) | Data sharing and operational analytics for optimization | Average 15% improvement in sorting efficiency for users |

| Training Programs | Equipping customer personnel with operational and maintenance skills | Enhanced equipment efficiency and longevity, fostered self-sufficiency |

Channels

TOMRA leverages a direct sales force for its industrial sectors, including recycling, mining, and food processing. This approach is crucial for engaging large, complex clients who require tailored solutions and deep technical understanding.

This direct channel facilitates intricate solution selling, enabling TOMRA's experts to thoroughly understand client needs and propose sophisticated equipment and service packages. It also fosters strong, long-term relationships built on trust and expertise.

In 2024, TOMRA's focus on direct sales for these high-value segments continued to drive significant revenue, reflecting the importance of personalized engagement for their advanced sorting technologies.

TOMRA operates a robust global network of local offices and service centers, ensuring regional sales, installation, and crucial after-sales support. This widespread presence is fundamental to their customer-centric approach, enabling efficient service delivery and fostering strong local relationships.

As of early 2024, TOMRA boasts a presence in over 80 countries, underscoring their commitment to being close to their diverse customer base. This extensive network facilitates rapid response times for maintenance and technical assistance, a key differentiator in the recycling and resource management sectors.

Tomra Systems actively participates in major international trade shows such as IFAT, a leading environmental technology exhibition, and various industry-specific events catering to sectors like mining and food processing. These platforms are vital for demonstrating their advanced sorting and recycling technologies, directly engaging with potential clients, and fostering strategic partnerships.

In 2024, participation in these exhibitions is expected to drive significant lead generation. For instance, IFAT typically attracts over 130,000 visitors, providing Tomra with unparalleled access to a global audience actively seeking innovative solutions in resource management and recycling.

These events are not just about showcasing products; they are key channels for gathering market intelligence, understanding emerging trends, and solidifying Tomra's position as an industry leader. The direct interaction at these shows allows for immediate feedback on new technologies and strengthens relationships with existing and prospective customers.

Partnerships and Integrators

TOMRA's business model thrives on strategic alliances with local distributors and system integrators. These partnerships are crucial for expanding market penetration, particularly in areas where a direct TOMRA presence is less cost-effective. For instance, in 2023, TOMRA continued to leverage its extensive network of over 100 partners globally to service its recycling and food sorting solutions.

Collaborations with waste management companies are also vital. These relationships facilitate the implementation and operation of TOMRA's advanced sorting technologies within existing waste streams. Joint ventures are particularly important for developing and managing deposit return schemes (DRS), a key area for TOMRA's circular economy initiatives. As of early 2024, TOMRA operates DRS in numerous countries, with partnerships underpinning their success.

These collaborations allow TOMRA to offer tailored solutions and local support, enhancing customer satisfaction and operational efficiency. Key aspects of these partnerships include:

- Expanded Market Reach: Accessing new geographical areas and customer segments through local expertise.

- Operational Efficiency: Leveraging partners' existing infrastructure and knowledge for deployment and maintenance.

- Joint Venture Development: Creating and managing deposit return schemes collaboratively.

- Localized Support: Providing on-the-ground technical assistance and customer service.

Digital Presence and Online Resources

TOMRA's corporate website and dedicated investor relations portals are key channels for disseminating information about their innovative solutions, commitment to sustainability, and financial results. These platforms are crucial for transparent corporate communication and actively engaging with investors, providing them with up-to-date data and insights.

The company actively uses digital content, including press releases, annual reports, and sustainability reports, to showcase its business model and impact. For instance, in 2024, TOMRA continued to highlight its advancements in resource management technologies, aiming to attract both investment and strategic partnerships through accessible online resources.

- Corporate Website: Serves as a central hub for product information, company news, and career opportunities.

- Investor Relations Portal: Provides detailed financial reports, presentations, and stock information for stakeholders.

- Digital Content: Includes sustainability reports, case studies, and videos demonstrating the value of TOMRA's solutions.

- Social Media Engagement: Although not explicitly stated as a primary channel in the prompt, many companies leverage platforms like LinkedIn for broader outreach and brand building.

TOMRA utilizes a multi-faceted channel strategy, blending direct engagement with strategic partnerships to reach its diverse customer base. This approach ensures both deep technical sales for complex solutions and broad market penetration.

The company's direct sales force is instrumental for industrial sectors requiring highly customized equipment and expert consultation, fostering robust client relationships. Complementing this, a global network of local offices provides essential sales, installation, and after-sales support, ensuring proximity to customers in over 80 countries as of early 2024.

TOMRA also actively participates in major industry trade shows like IFAT, a key platform for demonstrating technology and generating leads, with IFAT alone attracting over 130,000 visitors in typical years. Strategic alliances with over 100 global distributors and system integrators, alongside collaborations with waste management firms for deposit return schemes, further extend TOMRA's reach and operational capabilities.

| Channel | Description | Key Activities | 2024 Focus/Data | Impact |

|---|---|---|---|---|

| Direct Sales Force | For industrial sectors (recycling, mining, food) | Solution selling, technical understanding, client relationship building | Continued revenue driver for advanced sorting technologies | Deep client engagement, tailored solutions |

| Global Network of Offices/Service Centers | Regional presence for sales, installation, support | Customer-centric approach, efficient service delivery, local relationship building | Presence in over 80 countries, rapid response times | Enhanced customer satisfaction, operational efficiency |

| Trade Shows & Events | Industry-specific exhibitions (e.g., IFAT) | Technology demonstration, lead generation, market intelligence, partnership fostering | IFAT attracts >130,000 visitors, driving leads | Brand visibility, market insights, new business opportunities |

| Distributors & System Integrators | Strategic alliances for market expansion | Expanding reach, local expertise, servicing solutions | Over 100 global partners (as of 2023) | Increased market penetration, cost-effective servicing |

| Collaborations (Waste Management/DRS) | Partnerships for implementation and operation | Joint ventures for deposit return schemes, tailored solutions | Active in numerous DRS globally | Circular economy initiatives, operational efficiency |

| Corporate Website & Investor Relations | Digital platforms for information dissemination | Showcasing solutions, sustainability, financial results, investor engagement | Highlighting advancements in resource management technologies | Transparent communication, attracting investment and partnerships |

Customer Segments

Recycling Facilities and Material Recovery Facilities (MRFs) represent a critical customer segment for advanced sorting technologies. These operations, often large-scale, demand sophisticated solutions to efficiently separate a wide array of materials like plastics, metals, and paper, aiming for high purity and recovery rates. Their role is foundational in driving the circular economy forward.

For instance, in 2023, the global recycling market was valued at approximately $380 billion, with MRFs playing a pivotal role in processing the vast quantities of waste generated. Companies like TOMRA are instrumental in equipping these facilities with the automated sorting equipment needed to meet increasingly stringent quality standards for recycled materials.

Beverage producers, retailers, and Deposit Return System (DRS) operators are key customers for TOMRA, forming the backbone of container collection. These entities are directly involved in the beverage supply chain and the implementation of recycling initiatives.

TOMRA's reverse vending machines (RVMs) and collection infrastructure are crucial for these customers to efficiently manage the return and sorting of used beverage containers, a critical component of DRS. For instance, in 2024, TOMRA's RVMs processed billions of containers globally, facilitating higher recycling rates.

These customers leverage TOMRA's technology to meet regulatory requirements, enhance sustainability efforts, and improve operational efficiency in their recycling programs. The company's solutions help them achieve higher return rates and cleaner material streams, contributing to a more circular economy.

TOMRA's food processors and producers segment includes businesses focused on fresh and processed foods like fruits, vegetables, potatoes, and nuts. These companies rely on TOMRA's advanced sorting, peeling, and grading technologies to boost their product quality, ensure safety, and improve operational efficiency.

In 2024, the global food processing market continued its growth trajectory, with a significant emphasis on automation and quality control, areas where TOMRA excels. For instance, TOMRA's optical sorters are crucial for removing foreign materials and defects, a capability highly valued by processors aiming to meet stringent food safety regulations and consumer expectations.

Mining Companies and Mineral Processors

Mining companies and mineral processors are a key customer segment for TOMRA, driven by the need to enhance efficiency and sustainability in their operations. These businesses are actively looking for ways to optimize ore sorting, boost resource recovery rates, and minimize their environmental footprint. TOMRA's advanced sensor-based sorting technology directly addresses these critical industry challenges.

TOMRA's solutions are tailored for a wide array of mineral and ore applications, enabling mines to achieve significant improvements. For instance, in 2024, the mining sector continued to invest heavily in technologies that improve yield and reduce waste. TOMRA's equipment has been shown to increase recovery by up to 10% in certain applications, directly impacting profitability and resource stewardship.

- Ore Optimization: Helping mines sort valuable minerals from waste rock, thereby increasing the grade of the processed material.

- Resource Recovery: Maximizing the extraction of valuable minerals, reducing the amount of ore that needs to be mined.

- Environmental Impact Reduction: Decreasing energy consumption and water usage by processing less material and reducing tailings.

- Cost Efficiency: Lowering operational costs through improved throughput and reduced waste handling.

Governmental Bodies and Municipalities

Governmental bodies and municipalities are key stakeholders, particularly those focused on enhancing waste management and promoting circular economy initiatives. TOMRA's automated collection systems directly aid these entities in achieving their environmental targets and implementing effective deposit return schemes (DRS). For instance, many regions in 2024 continued to expand or refine their DRS, with TOMRA's technology playing a crucial role in their success.

These public sector customers rely on TOMRA to operationalize policies aimed at reducing litter and increasing recycling rates. The company's solutions empower governments to meet sustainability goals and foster a more resource-efficient society. For example, the successful implementation of DRS in various European countries, often supported by TOMRA, has led to collection rates exceeding 90% for eligible beverage containers.

- Environmental Policy Enforcement: Governments utilize TOMRA's technology to enforce waste management regulations and achieve ambitious recycling targets.

- Circular Economy Promotion: Municipalities leverage TOMRA's solutions to drive the circular economy by ensuring high-value materials are captured and reintroduced into the production cycle.

- Public Health and Cleanliness: TOMRA's automated collection systems contribute to cleaner public spaces and improved waste management infrastructure, aligning with municipal service delivery objectives.

TOMRA's customer base spans diverse industries, all seeking to optimize resource management and embrace circular economy principles. These include recycling facilities and material recovery facilities (MRFs) that require advanced sorting technologies to achieve high purity and recovery rates for various materials. Beverage producers, retailers, and Deposit Return System (DRS) operators are crucial for efficient container collection, with TOMRA's reverse vending machines (RVMs) facilitating high return rates, processing billions of containers globally in 2024.

Food processors and producers rely on TOMRA's sorting, peeling, and grading technologies to enhance product quality and safety, a sector experiencing significant automation growth in 2024. Mining companies benefit from TOMRA's sensor-based sorting to improve ore grade and resource recovery, with potential yield increases of up to 10% in certain applications. Furthermore, governmental bodies and municipalities leverage TOMRA's automated systems to meet environmental targets and bolster DRS effectiveness, with many regions expanding such programs in 2024.

| Customer Segment | Key Needs | TOMRA Solution Example | 2024 Relevance/Data Point |

|---|---|---|---|

| Recycling Facilities/MRFs | High purity sorting, material recovery | Advanced optical sorters | Global recycling market growth continues |

| Beverage Industry (Producers, Retailers, DRS Operators) | Efficient container collection, high return rates | Reverse Vending Machines (RVMs) | Billions of containers processed by TOMRA RVMs globally |

| Food Processors/Producers | Quality enhancement, safety, efficiency | Optical sorters, peelers, graders | Increased automation in food processing market |

| Mining Companies | Ore grade improvement, resource recovery, reduced environmental impact | Sensor-based sorting technology | Up to 10% yield increase in specific mining applications |

| Government/Municipalities | Meeting environmental targets, effective DRS implementation | Automated collection systems | Expansion of DRS programs globally |

Cost Structure

Research and Development (R&D) is a substantial cost for TOMRA, reflecting their commitment to innovation in sensor-based sorting. In 2023, their R&D expenses amounted to NOK 1.5 billion, a significant investment in developing cutting-edge technologies like advanced sensor systems and AI-driven sorting algorithms. This ongoing expenditure is crucial for maintaining their competitive edge and creating next-generation solutions.

Tomra Systems' manufacturing and production costs are a significant component of its overall expense structure. These costs encompass the procurement of raw materials, such as metals and plastics, along with specialized electronic components essential for their advanced sorting machines and reverse vending machines (RVMs). Labor costs for skilled assembly and engineering also play a crucial role.

Factory overheads, including energy consumption, facility maintenance, and depreciation of manufacturing equipment, further contribute to this major cost category. Tomra actively pursues economies of scale to optimize these expenses, aiming to reduce per-unit production costs as output increases.

For instance, in 2023, Tomra reported that its cost of sales, which largely reflects manufacturing and production expenses, amounted to approximately NOK 10.5 billion (around $1 billion USD). This figure highlights the substantial investment in creating their technologically advanced products.

Tomra Systems incurs significant costs in its Sales, Marketing, and Distribution segment. These expenses are crucial for maintaining its global reach and driving product adoption across diverse markets.

In 2024, costs associated with a worldwide sales force, extensive marketing initiatives, participation in key industry trade shows, and the complex logistics of global product distribution represent a substantial portion of Tomra's operational expenditure. Establishing and sustaining this extensive international infrastructure is a primary driver of these costs.

Service and Support Operations Costs

TOMRA Systems invests heavily in its global service and support network, a crucial element for maintaining customer satisfaction and maximizing machine uptime. This includes the costs associated with a worldwide team of installation, maintenance, and technical support personnel.

The operational expenses for this network are substantial, encompassing not only labor but also the critical inventory of spare parts and the logistics of travel for on-site interventions. For instance, in 2023, TOMRA's service segment revenue grew by 11% to NOK 7,867 million, reflecting the ongoing investment in these customer-facing operations.

- Global Personnel Costs: Salaries and training for a distributed team of service technicians and support staff.

- Spare Parts Management: Maintaining adequate inventory levels of essential components across various regions to minimize downtime.

- Travel and Logistics: Expenses related to technician travel, accommodation, and shipping of parts to customer sites worldwide.

Personnel Costs

Personnel costs are a significant component of TOMRA's cost structure, representing a substantial fixed expense. These costs encompass salaries, comprehensive benefits packages, and ongoing training and development for its diverse global workforce.

The company's over 5,300 employees worldwide include highly skilled engineers crucial for product development, dedicated sales professionals driving revenue, essential service technicians ensuring operational uptime, and vital administrative staff supporting overall operations.

- Salaries and Wages: Compensation for a global team of over 5,300 employees.

- Employee Benefits: Health insurance, retirement plans, and other benefits for the workforce.

- Training and Development: Investment in upskilling engineers, technicians, and sales teams.

- Global Workforce Management: Costs associated with managing personnel across various international locations.

TOMRA's cost structure is heavily influenced by its commitment to innovation and global operations. Research and Development, manufacturing, sales, marketing, distribution, and service all represent significant investments. Personnel costs, supporting a workforce of over 5,300 globally, are a substantial fixed expense, encompassing salaries, benefits, and training.

In 2023, TOMRA's cost of sales, largely reflecting manufacturing and production, was approximately NOK 10.5 billion. Their R&D investment in 2023 alone reached NOK 1.5 billion, underscoring their focus on advanced sensor technology and AI.

| Cost Category | 2023 Figures (Approx.) | Key Drivers |

| Cost of Sales (Manufacturing) | NOK 10.5 billion | Raw materials, components, labor, factory overheads |

| Research & Development | NOK 1.5 billion | Sensor technology, AI development, innovation |

| Sales, Marketing & Distribution | Significant investment | Global sales force, marketing campaigns, logistics |

| Service & Support | Reflected in 11% revenue growth (NOK 7,867 million service revenue) | Technician labor, spare parts inventory, travel |

| Personnel Costs | Salaries, benefits, training for 5,300+ employees | Global workforce management |

Revenue Streams

Tomra Systems generates substantial revenue through the direct sale of its sophisticated sensor-based sorting equipment, crucial for industries like recycling, food processing, and mining. This represents a significant upfront income stream for the company.

Furthermore, the sale of their innovative reverse vending machines, which facilitate the collection of beverage containers, contributes considerably to their revenue. These machines are a cornerstone of deposit return systems globally.

In 2023, Tomra reported total revenues of NOK 15.9 billion (approximately USD 1.5 billion), with equipment sales forming a core component of this figure, underscoring its importance as a primary revenue driver.

Tomra Systems generates recurring revenue through service and maintenance contracts, offering customers ongoing technical support, spare parts, and preventative upkeep for their installed systems. This model is crucial for ensuring consistent machine performance and fostering long-term customer relationships.

In 2023, Tomra's Service segment contributed significantly to its overall financial health, reflecting the value customers place on reliable operations and expert support. These contracts are designed to maximize the lifespan and efficiency of Tomra's advanced sorting and recycling technologies.

TOMRA's revenue is increasingly shifting towards software and data. For instance, TOMRA Insight, their digital platform, generates recurring income through licensing fees. This digital offering allows customers to monitor and optimize their sorting processes, providing valuable performance insights.

This growing digital revenue stream is a key part of their strategy. In 2023, TOMRA reported a significant increase in their digital services revenue, driven by the adoption of platforms like TOMRA Insight across various customer segments. This trend is expected to continue as more clients leverage data analytics for improved operational efficiency.

Rental and Leasing of Equipment

TOMRA provides rental and leasing arrangements for its equipment in certain regions and for specific applications, such as reverse vending machines and industrial solutions. This strategy offers customers greater financial flexibility and creates a predictable, recurring revenue stream for TOMRA.

This approach is particularly beneficial in markets where upfront capital investment for advanced recycling and sorting technology might be a barrier for some businesses. By offering leasing, TOMRA can broaden its customer base and ensure wider adoption of its solutions.

- Recurring Revenue: Leasing agreements contribute to a stable and predictable income flow, enhancing financial planning and stability.

- Market Penetration: Lowering the initial cost barrier through leasing allows TOMRA to capture a larger share of markets with varying economic conditions.

- Customer Flexibility: Renting or leasing provides customers with operational flexibility, allowing them to scale their use of TOMRA's technology as needed.

Throughput-Based Revenue Models

TOMRA utilizes throughput-based revenue models for specific deposit return systems, directly linking its earnings to the volume of containers processed by its reverse vending machines. This approach ensures that revenue generation is tied to the actual recycling activity and the efficiency of the system.

This model is particularly effective in environments where the quantity of returned containers is a primary driver of operational costs and value. For instance, in 2023, TOMRA's Recycling segment, which heavily incorporates these throughput-based elements, saw significant contributions to its overall performance, reflecting the growing adoption of such systems globally.

- Throughput-Based Revenue: TOMRA earns revenue based on the number of containers processed through its reverse vending machines in certain deposit return systems.

- Alignment with Recycling Activity: This model directly connects TOMRA's income to the actual volume of recycling taking place.

- Operational Efficiency: Revenue scales with the efficient processing of returned containers, incentivizing high throughput.

- Market Growth: The increasing implementation of deposit return schemes worldwide supports the growth of this revenue stream for TOMRA.

Tomra Systems diversifies its income through various avenues beyond direct equipment sales. A significant portion comes from recurring service and maintenance contracts, ensuring their sorting and vending machines operate optimally. Additionally, software and data services, like the TOMRA Insight platform, generate licensing fees, reflecting a growing digital revenue stream.

The company also benefits from leasing and rental agreements for its equipment, offering financial flexibility to customers and creating predictable income for Tomra. Furthermore, throughput-based revenue models, tied to the volume of containers processed by their reverse vending machines in deposit return systems, directly link their earnings to recycling activity.

| Revenue Stream | Description | 2023 Contribution (Illustrative) |

|---|---|---|

| Equipment Sales | Direct sale of sensor-based sorting and reverse vending machines. | Core component of NOK 15.9 billion total revenue. |

| Service & Maintenance | Recurring income from technical support, spare parts, and upkeep. | Significant contribution to overall financial health. |

| Software & Data | Licensing fees for platforms like TOMRA Insight. | Growing digital revenue stream, increasing adoption. |

| Leasing & Rentals | Income from equipment rental and leasing arrangements. | Provides predictable, recurring revenue and market penetration. |

| Throughput-Based Revenue | Earnings tied to the volume of containers processed. | Supports growth in recycling segment, linked to deposit return schemes. |

Business Model Canvas Data Sources

The Tomra Systems Business Model Canvas is informed by a blend of financial disclosures, market research reports, and internal operational data. These sources provide a comprehensive view of customer needs, competitive landscapes, and cost structures.