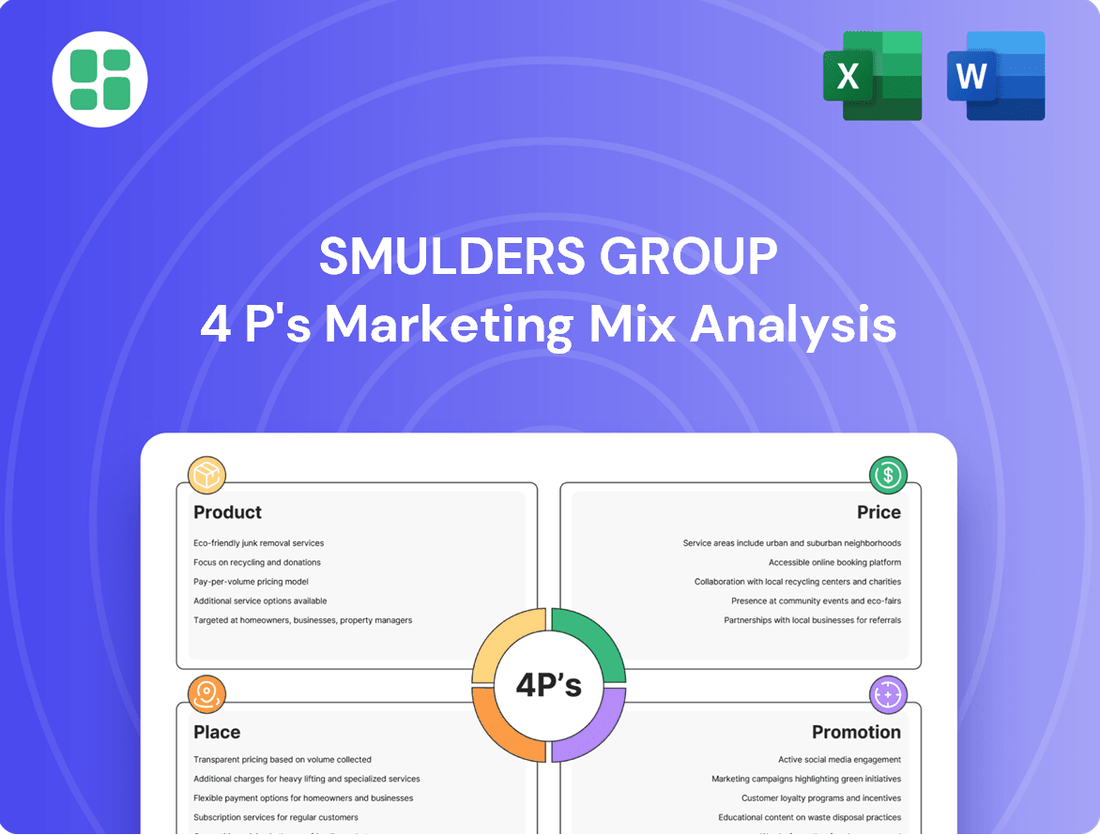

Smulders Group Marketing Mix

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Smulders Group Bundle

Discover how Smulders Group leverages its product offerings, strategic pricing, efficient distribution, and impactful promotion to dominate the market. This analysis unpacks their winning formula.

Ready to understand the core of Smulders Group's marketing success? Get the full, in-depth 4Ps analysis, complete with actionable insights and ready-to-use formatting.

Product

Complex Steel Structures, a key product offering from Smulders Group, encompasses the design, building, and assembly of substantial, technically demanding steel frameworks. This specialization is crucial for sectors requiring robust and precise engineering, such as offshore wind energy and infrastructure development.

Smulders Group's expertise in these complex structures is evident in their successful delivery of projects with challenging specifications. For instance, in 2023, Smulders was a significant contributor to the construction of offshore wind farms, fabricating and installing numerous foundations and transition pieces, showcasing their capacity for large-scale, intricate fabrication.

The value proposition of these structures lies in Smulders' ability to manage projects from initial engineering through to final assembly, ensuring adherence to strict quality and safety standards. Their commitment to innovation and advanced fabrication techniques allows them to meet the evolving technical requirements of the global energy and infrastructure markets.

Smulders Group's offshore wind foundations and substation jackets are pivotal to the renewable energy sector, forming a substantial part of their offerings. These robust structures are engineered to support critical electrical infrastructure in harsh marine environments, ensuring the efficient collection and transmission of power from offshore wind turbines.

The company's expertise is evident in their recent contract wins, such as their involvement in the Hollandse Kust West 3 offshore wind farm in the Netherlands, a significant project that underscores their market leadership. These projects are vital for Europe's ambitious renewable energy targets, with the offshore wind sector projected to see substantial growth in the coming years.

For instance, the European Union aims for at least 60 GW of offshore wind power by 2030. Smulders' contribution to projects like this directly supports these goals, demonstrating their critical role in the energy transition and their strong market position.

Smulders' product, Turnkey Metal Structures and System Integration (EPC), represents a significant evolution from its origins as a steel construction firm. They now offer a complete package, encompassing Engineering, Procurement, and Construction. This allows them to manage entire offshore projects internally, a crucial differentiator in the market.

This EPC capability means Smulders can handle everything from initial design and engineering, including complex electrical and mechanical systems, through to the procurement of materials and the final construction and commissioning of large-scale projects. This integrated approach streamlines the process for clients, reducing complexity and potential for miscommunication.

The value proposition is clear: clients receive a seamless, end-to-end solution. This turnkey offering is particularly attractive for offshore wind farm projects, where the integration of substations, foundations, and inter-array cables is paramount. For instance, Smulders delivered the Hollandse Kust Zuid Alpha and Beta offshore substations for Vattenfall, showcasing their EPC prowess in the 2023 operational phase.

Oil & Gas and General Steel Construction Solutions

Smulders Group extends its robust steel fabrication capabilities beyond offshore wind to the oil and gas sector and general steel construction. This diversification highlights their adaptability in delivering complex steel structures for demanding industrial and civil applications. Their extensive project portfolio includes significant contributions to architectural landmarks, critical infrastructure like bridges, and high-voltage pylons, demonstrating a broad spectrum of technical expertise and a long-standing reputation for quality.

The company's involvement in the oil and gas market includes the fabrication of platforms, modules, and other essential components, leveraging their advanced engineering and manufacturing processes. In general steel construction, Smulders has a proven track record in delivering bespoke solutions for various sectors. For instance, in 2024, the company secured contracts for several large-scale bridge projects in Europe, emphasizing their commitment to infrastructure development and their capacity to handle substantial construction challenges.

- Product Scope: Expertise in fabricating steel structures for Oil & Gas (platforms, modules), general construction (architectural buildings, bridges), and infrastructure (high-voltage pylons).

- Market Reach: Serves diverse industrial and civil sectors, showcasing adaptability and broad technical application of steel fabrication.

- Competitive Advantage: Long-standing reputation built on adaptable expertise and successful project delivery across multiple demanding markets.

- Recent Activity: Secured significant bridge construction contracts in Europe during 2024, underscoring ongoing engagement in infrastructure development.

Sustainable and Innovative Solutions

Smulders is deeply committed to building a sustainable future, embedding eco-friendly practices throughout their product development and operational workflows. This dedication is evident in their pursuit of innovative solutions, prioritizing energy efficiency, reduced carbon footprints in designs, and the incorporation of sustainable materials whenever feasible.

Their focus on sustainability directly supports global energy transition objectives, simultaneously boosting the enduring value and environmental accountability of their manufactured products. For instance, Smulders' involvement in offshore wind projects, a key driver of renewable energy, underscores this commitment. In 2024, the offshore wind sector continued its growth, with global installed capacity reaching new milestones, reflecting the increasing demand for the very solutions Smulders provides.

- Sustainable Design: Smulders integrates lifecycle assessment principles into their design phases to minimize environmental impact.

- Energy Efficiency: They actively develop solutions that reduce energy consumption during operation, contributing to lower emissions.

- Low-Carbon Materials: Where possible, Smulders explores and utilizes materials with a reduced carbon footprint in their manufacturing processes.

- Alignment with Energy Transition: Their product portfolio directly supports the global shift towards cleaner energy sources, such as offshore wind and hydrogen production infrastructure.

Smulders Group's core product is complex steel structures, particularly for offshore wind foundations and substations, as well as oil and gas platforms and infrastructure like bridges. Their offering has evolved into a turnkey solution, encompassing Engineering, Procurement, and Construction (EPC), allowing them to manage entire projects from concept to completion. This integrated approach streamlines complex builds, ensuring quality and safety adherence, a critical factor for clients in demanding sectors.

The company's product strategy emphasizes adaptability and a commitment to the energy transition. By focusing on renewable energy infrastructure, such as offshore wind components, Smulders aligns with global sustainability goals. Their 2024 bridge contracts in Europe also highlight a continued dedication to vital infrastructure development, showcasing their broad capabilities in steel fabrication for diverse, high-stakes applications.

Smulders’ product value is amplified by its sustainability focus, integrating energy efficiency and low-carbon materials into its designs. This commitment directly supports the growing demand for renewable energy solutions, with the offshore wind sector alone seeing significant expansion. For instance, the European Union's target of at least 60 GW of offshore wind power by 2030 creates a robust market for Smulders' specialized structures.

The company's product portfolio is crucial for the energy transition, with offshore wind foundations and substations forming a significant part of their business. Smulders' successful delivery of components for projects like the Hollandse Kust West 3 offshore wind farm in 2023 demonstrates their market leadership. Furthermore, their EPC capabilities were showcased with the delivery of Hollandse Kust Zuid Alpha and Beta offshore substations for Vattenfall, underscoring their integrated project management strength.

| Product Category | Key Applications | 2023/2024 Highlights | Market Context |

|---|---|---|---|

| Offshore Wind Foundations & Substations | Supporting offshore wind turbines and electrical infrastructure | Fabrication and installation for multiple offshore wind farms; Delivery of Hollandse Kust Zuid Alpha & Beta substations | EU target of 60 GW offshore wind by 2030; Sector growth driven by energy transition |

| Oil & Gas Structures | Platforms, modules, and essential components for offshore operations | Continued fabrication for existing and new oil and gas projects | Stable demand for specialized steel components in the energy sector |

| General Steel Construction & Infrastructure | Bridges, architectural landmarks, high-voltage pylons | Secured significant bridge construction contracts in Europe (2024) | Ongoing investment in infrastructure development globally |

What is included in the product

This analysis provides a comprehensive breakdown of the Smulders Group's marketing mix, detailing their strategies across Product, Price, Place, and Promotion to understand their market positioning and competitive advantages.

Simplifies complex marketing strategies into actionable insights, alleviating the pain of information overload for busy executives.

Place

Smulders' 'Place' in the marketing mix is fundamentally project-based, focusing on direct sales and tendering for large-scale steel construction. This B2B approach means engaging directly with clients, often through competitive bidding processes for significant infrastructure projects.

In 2023, Smulders secured several key contracts, including work on the Hollandse Kust West offshore wind farm, demonstrating their direct engagement in major European energy projects. This direct sales model allows for tailored solutions, crucial for the complex engineering and construction requirements inherent in their sector.

Smulders strategically manages a network of international production facilities, with key operations in Belgium, the Netherlands, Poland, and the United Kingdom. This geographical spread is crucial for efficient fabrication and assembly, allowing the company to effectively serve a broad market. For instance, in 2023, Smulders' Polish facility played a significant role in fabricating components for offshore wind projects, demonstrating the logistical advantages of their dispersed production capabilities.

Smulders Group's strategic assembly yards, including major facilities in Vlissingen, Netherlands, and Hoboken, Belgium, are vital for managing the sheer size of their offshore wind components. These locations boast direct port access, facilitating the seamless transport of colossal structures to their deployment sites at sea.

The company's commitment to bolstering its logistical infrastructure is evident in its acquisition of sites like Smulders Projects Netherlands in Flushing. This move underscores their focus on optimizing the load-out and shipping processes for their large-scale projects, ensuring efficient project execution.

Collaboration with Parent Company Eiffage Metal

Smulders, as part of the Eiffage Metal group, leverages a robust network and integrated expertise. This affiliation grants access to a vast pool of resources and specialized knowledge, enabling participation in significantly larger and more complex international projects. For instance, Eiffage's 2023 revenue reached €23.2 billion, showcasing the scale of the parent group's operations and the potential for Smulders to tap into this financial and operational strength.

This synergy within Eiffage Metal significantly broadens Smulders' market reach and enhances its project execution capabilities. The ability to draw upon the parent company's extensive experience in diverse construction and infrastructure sectors allows Smulders to undertake more ambitious ventures, solidifying its position in the global market.

- Access to Eiffage's extensive global network

- Integration of specialized engineering and construction expertise

- Enhanced capacity for undertaking large-scale, complex international projects

- Leveraging Eiffage's financial strength, with €23.2 billion revenue in 2023

On-Site Project Delivery and Assembly

For Smulders Group, the ultimate 'place' for their manufactured steel structures is the project site itself. This is where the intricate process of assembly and installation occurs, a critical final step in delivering their complex products, particularly for the offshore wind sector.

This on-site delivery demands sophisticated logistics and specialized heavy-lift equipment to ensure seamless integration of massive components. Smulders' commitment extends beyond fabrication; they manage the crucial assembly phase, guaranteeing that these substantial steel structures are erected and commissioned correctly within their intended operational environment.

In 2024, the offshore wind industry continued its rapid expansion, with projects frequently requiring delivery and assembly in challenging marine conditions. For instance, the Dogger Bank Wind Farm in the UK, one of the world's largest, involves the installation of numerous massive turbine foundations, highlighting the scale of on-site operations Smulders undertakes.

- Project Site as Final Delivery Point: Smulders' products are not delivered to a warehouse but directly to the installation location, often offshore.

- Logistical Complexity: Transporting and assembling extremely large and heavy steel structures requires specialized vessels, cranes, and meticulous planning.

- On-Site Assembly Expertise: Smulders provides the technical capability to erect and commission these structures, ensuring they function as designed.

- Industry Demand: The growth in renewable energy projects, such as offshore wind farms, drives the need for efficient and reliable on-site project delivery and assembly services.

Smulders' 'Place' strategy centers on its direct engagement with clients through project tendering and direct sales, particularly for large-scale steel construction. This B2B model emphasizes tailored solutions for complex projects, as seen in their 2023 work on the Hollandse Kust West offshore wind farm.

Their global footprint, with production facilities in Belgium, the Netherlands, Poland, and the UK, ensures efficient fabrication and assembly. Key assembly yards, like those in Vlissingen and Hoboken, boast direct port access for seamless transport of massive offshore wind components, a critical logistical advantage.

As part of Eiffage Metal, Smulders benefits from an extensive international network and integrated expertise, enhancing its capacity for large, complex projects. Eiffage's 2023 revenue of €23.2 billion underscores the financial and operational strength Smulders can leverage.

The ultimate 'place' for Smulders' products is the project site itself, requiring sophisticated logistics and specialized heavy-lift equipment for on-site assembly and installation, crucial for demanding environments like those found in the rapidly expanding offshore wind sector.

Same Document Delivered

Smulders Group 4P's Marketing Mix Analysis

The preview shown here is the actual document you’ll receive instantly after purchase—no surprises. This comprehensive analysis of the Smulders Group's 4P's Marketing Mix is fully complete and ready for your immediate use. You can confidently proceed with your purchase knowing you're getting the exact, finished version.

Promotion

Smulders actively builds its industry leadership and reputation by showcasing its position as a premier European provider of complex steel structures, especially within the burgeoning offshore wind market. This strategy hinges on emphasizing a deep well of experience, a proven history of successfully delivered projects, and an unwavering dedication to superior quality and dependability.

The company's impactful slogan, 'Manufacturing a sustainable world,' is a cornerstone of its promotional efforts, clearly articulating its vital contribution to the global energy transition and its commitment to a greener future.

In 2023, Smulders, as part of the DEME Group, reported significant contributions to offshore wind projects, with the group securing substantial new contracts. For instance, DEME's offshore wind segment saw increased activity, underscoring Smulders' role in delivering these large-scale structures.

Smulders, a key player in offshore wind and infrastructure, leverages strategic project announcements and press releases as a core promotional tactic. These communications, often highlighting major contract wins and project completion milestones, serve to bolster their reputation and market visibility.

In 2023, Smulders, as part of the Eiffage Group, was involved in significant projects like the Hollandse Kust West 3 wind farm, delivering substantial components. Such announcements directly communicate their expertise and capacity to deliver complex, large-scale energy infrastructure solutions to a global audience.

These press releases, frequently issued in conjunction with Eiffage, effectively target industry professionals, potential clients, and investors. They underscore Smulders' role in advancing renewable energy and critical infrastructure, thereby reinforcing their brand as a reliable and capable partner.

Smulders cultivates a robust digital footprint via its corporate website, offering detailed insights into its specialized expertise, completed projects, and commitment to sustainability. This online hub serves as a primary channel for information dissemination and brand reinforcement.

Leveraging platforms such as LinkedIn, Smulders actively shares company news, project milestones, and industry perspectives. This strategic engagement with professionals on LinkedIn helps foster industry connections and highlights the expertise of its workforce.

Sustainability Reporting and Corporate Values

Smulders Group leverages its annual Sustainability Report as a key promotional element, showcasing a deep commitment to environmental stewardship, social responsibility, and ethical operations. This report effectively communicates their dedication to achieving Sustainable Development Goals (SDGs) and outlines concrete CO2 reduction targets, positioning Smulders as a reliable and progressive partner. For instance, their 2024 Sustainability Report detailed a 15% reduction in Scope 1 and 2 emissions compared to their 2020 baseline, a tangible demonstration of their progress.

This proactive approach to sustainability not only attracts environmentally conscious clients but also serves as a magnet for top talent seeking to align with a company that prioritizes corporate values. By transparently reporting on their initiatives, Smulders builds trust and enhances its brand reputation in a market increasingly driven by ESG (Environmental, Social, and Governance) considerations. Their commitment is further evidenced by their participation in the UN Global Compact, a voluntary initiative promoting sustainable and socially responsible business practices.

- Demonstrates Commitment: Annual Sustainability Report highlights dedication to environmental, social, and ethical practices.

- Promotes Forward-Thinking Image: Adherence to SDGs and CO2 reduction initiatives positions Smulders as a responsible partner.

- Attracts Talent and Clients: Aligns with the values of environmentally conscious individuals and businesses.

- Quantifiable Progress: Reports like the 2024 edition show specific emission reduction achievements, such as a 15% decrease in Scope 1 and 2 emissions against a 2020 baseline.

Partnerships and Employer Branding Campaigns

Smulders actively cultivates strategic partnerships, notably forming consortiums for significant offshore wind projects. For instance, their collaboration with Sif for the supply of transition pieces for the Hollandse Kust West 1 project showcases their ability to work within complex joint ventures, indirectly bolstering their reputation for dependable collaboration and project execution.

These partnerships serve as a testament to Smulders' technical prowess and reliability, attracting further opportunities and reinforcing their market position. By successfully navigating these large-scale collaborations, Smulders demonstrates its capacity to deliver on challenging international contracts.

Furthermore, Smulders places a strong emphasis on employer branding to secure a skilled workforce. This includes enhancing their career pages with visually appealing and informative content, alongside targeted social media campaigns highlighting their projects and company culture. In 2023, Smulders reported a workforce of over 1,700 employees, underscoring the importance of attracting and retaining talent.

These employer branding efforts are crucial for maintaining Smulders' competitive edge in a specialized industry. By projecting an image of innovation and stability, they aim to attract top engineering and technical talent, essential for their continued growth and success in the renewable energy sector.

Smulders' promotional strategy centers on highlighting its expertise in complex steel structures, particularly for offshore wind. Their slogan, Manufacturing a sustainable world, directly communicates their role in the energy transition. Key tactics include strategic press releases about contract wins and project completions, such as their involvement in the Hollandse Kust West 3 wind farm in 2023, showcasing their capabilities to industry professionals and investors.

The company actively manages its digital presence through a detailed corporate website and LinkedIn engagement, sharing project milestones and industry insights to foster connections and reinforce their brand. Furthermore, their annual Sustainability Report, which in 2024 detailed a 15% reduction in Scope 1 and 2 emissions against a 2020 baseline, demonstrates a commitment to ESG principles, attracting both clients and talent.

Strategic partnerships, like their 2023 collaboration with Sif for the Hollandse Kust West 1 project, indirectly promote Smulders by showcasing their reliability in complex joint ventures. Employer branding is also critical, with efforts to attract over 1,700 employees in 2023 by highlighting innovation and company culture on their career pages and social media.

Price

Smulders Group's pricing strategy within its project-specific contractual framework is deeply embedded in its B2B operations. For instance, in 2024, the company secured a significant contract for the supply of 108 monopiles for the Hollandse Kust West 3 offshore wind farm, with the exact financial terms remaining confidential due to the bespoke nature of the agreement. This highlights how pricing isn't a simple matter of a price list but a complex negotiation reflecting the unique demands of each offshore energy project.

The determination of these project-specific prices involves a rigorous tendering process and detailed contractual agreements. Factors such as the exact technical specifications of the steel structures, the fluctuating costs of raw materials like steel, and the required delivery schedules all play a crucial role. For example, the increasing global demand for offshore wind components in 2024 has influenced raw material prices, which are directly factored into these project bids.

Smulders Group employs value-based pricing for its complex engineering solutions, reflecting the significant value and specialized expertise delivered. This strategy acknowledges the intricate design, advanced manufacturing, and the crucial role their fabricated structures play in major infrastructure, such as the burgeoning offshore wind sector. For instance, the increasing demand for offshore wind energy, with global installations projected to reach over 2,000 GW by 2030, underscores the critical nature of Smulders' contributions and justifies premium pricing.

Smulders' project costs are heavily influenced by the volatile prices of raw steel, a primary material. For instance, in early 2024, steel prices saw fluctuations, impacting the overall material expenditure for large-scale offshore wind foundations. Specialized fabrication processes, demanding precision and advanced machinery, add another significant cost layer.

The need for highly skilled labor across engineering, production, and assembly is a key driver of Smulders' operational expenses. Complex projects, like the fabrication of 7,000-tonne jacket foundations for offshore wind farms, require specialized expertise that commands higher wages. These skilled labor costs are integral to the company's pricing strategy, ensuring quality and project execution.

The sheer scale and weight of Smulders' projects, such as the aforementioned jacket foundations, directly translate into substantial material and transportation costs. The logistics of moving these massive components, often across significant distances, are factored into the final price. Smulders' comprehensive pricing models meticulously account for these extensive material and logistical expenditures to ensure project viability.

Competitive Bidding and Market Positioning

Smulders navigates a highly competitive offshore wind sector, frequently participating in competitive bidding processes for significant projects. Their pricing strategy aims to balance attractiveness with the recognition of their established market leadership and the superior quality of their fabrication and installation services. For instance, in recent offshore wind farm tenders, such as those for the Dogger Bank C project in the UK, which commenced fabrication in 2024, competitive pricing was a critical factor for securing multi-billion euro contracts.

Being a part of the Eiffage Metal group, a major European construction and concessions group, offers Smulders substantial financial backing and strategic advantages. This affiliation bolsters their capacity to undertake large-scale bids, absorb potential market fluctuations, and invest in advanced manufacturing capabilities, thereby sustaining their growth trajectory in increasingly demanding global markets. Eiffage's robust financial position, with reported revenues exceeding €20 billion annually in recent years, underpins Smulders' ability to commit to long-term, capital-intensive projects.

- Competitive Bidding: Smulders actively participates in tenders for major offshore wind farm components, requiring strategic pricing to win contracts.

- Market Positioning: Pricing reflects Smulders' reputation for quality and reliability in a sector where performance is paramount.

- Eiffage Synergy: Financial strength from Eiffage Metal enables Smulders to bid competitively and invest in future growth, as seen in their €20+ billion revenue parent company.

- Strategic Leverage: The backing of Eiffage allows Smulders to manage bid risks and maintain a strong presence in key European offshore wind markets.

Long-Term Project Value and Risk Assessment

For Smulders Group's large, multi-year projects, such as offshore wind farm installations scheduled for delivery between 2026 and 2030, pricing reflects not just immediate costs but also the long-term value and inherent risks. This includes a thorough assessment of project complexities, potential for delays, and the significant commitment of capital and resources over several years from contract signing to final project completion.

The pricing strategy for these extended engagements must ensure sustained profitability. Key considerations include:

- Risk Mitigation: Incorporating contingency for unforeseen technical challenges or supply chain disruptions that could impact project timelines and costs.

- Resource Commitment: Accounting for the sustained allocation of specialized personnel, vessels, and equipment over the project's lifecycle.

- Market Volatility: Factoring in potential fluctuations in material costs, currency exchange rates, and labor expenses anticipated between now and project completion.

- Long-Term Value Proposition: Pricing is also influenced by the strategic importance and future revenue potential these large projects represent for Smulders Group and its clients.

Smulders Group's pricing is intrinsically tied to the bespoke nature of its large-scale offshore energy projects, often determined through competitive bidding processes. For instance, in 2024, the company was awarded contracts for significant offshore wind farm components, where pricing reflects the intricate engineering, specialized materials, and complex logistics involved. This project-specific approach ensures that each bid accurately captures the unique value and associated costs, from raw material procurement to final installation, often involving multi-billion euro contracts.

The company’s pricing strategy emphasizes value-based considerations, recognizing the critical role its fabricated steel structures play in the expanding global offshore wind market. With installations projected to grow substantially, Smulders leverages its expertise and market position to command prices that reflect the high quality and reliability of its solutions. This is further supported by the financial strength of its parent company, Eiffage Metal, which reported revenues exceeding €20 billion annually in recent years, enabling Smulders to undertake capital-intensive projects competitively.

Factors such as fluctuating steel prices, as seen in early 2024, and the need for highly skilled labor significantly influence Smulders' cost structure and, consequently, its pricing. The company must also account for the substantial material and transportation costs associated with fabricating massive components, like 7,000-tonne jacket foundations. These elements are meticulously factored into their pricing models to ensure both project viability and sustained profitability over the multi-year project lifecycles, which can extend to 2030.

| Pricing Factor | Description | 2024/2025 Relevance |

| Project-Specific Bidding | Negotiated prices based on unique project requirements and tender processes. | Securing contracts for Hollandse Kust West 3 (108 monopiles) and Dogger Bank C components. |

| Value-Based Pricing | Reflects specialized engineering, advanced manufacturing, and critical role in offshore wind. | Justified by the growing global demand for offshore wind energy, projected to exceed 2,000 GW by 2030. |

| Material Cost Volatility | Impact of fluctuating raw material prices, particularly steel. | Early 2024 saw steel price fluctuations directly impacting project bids. |

| Skilled Labor Costs | Requirement for specialized expertise in engineering, production, and assembly. | Essential for complex fabrications like 7,000-tonne jacket foundations. |

| Logistics and Scale | Costs associated with transporting large and heavy fabricated components. | Integral to pricing for massive offshore wind foundation structures. |

| Parent Company Support | Financial backing and strategic advantages from Eiffage Metal (annual revenues > €20 billion). | Enables competitive bidding, risk absorption, and investment in advanced capabilities. |

4P's Marketing Mix Analysis Data Sources

Our Smulders Group 4P's Marketing Mix Analysis is built upon a foundation of verified, current data, encompassing their product offerings, pricing strategies, distribution channels, and promotional activities. We leverage official company reports, investor communications, brand websites, and reputable industry analyses to ensure accuracy.