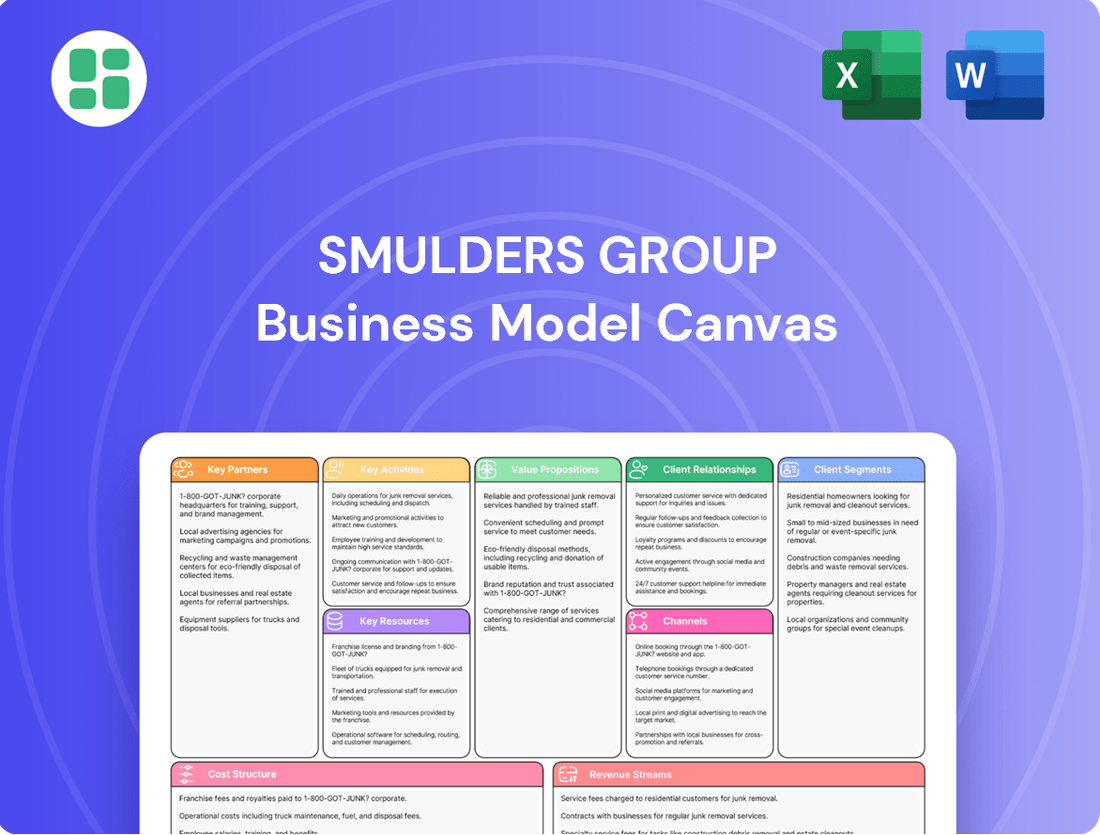

Smulders Group Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Smulders Group Bundle

Discover the strategic core of Smulders Group with our comprehensive Business Model Canvas. This detailed breakdown illuminates their customer relationships, revenue streams, and key resources, offering a clear view of their operational success. Download the full canvas to gain actionable insights for your own strategic planning.

Partnerships

Smulders Group's strategic alignment with its parent company, Eiffage Metal, is a cornerstone of its business model. This relationship allows Smulders to tap into the vast resources, extensive network, and comprehensive capabilities of the wider Eiffage Group.

This integration is crucial for securing robust financial backing and accessing a wealth of shared expertise. It also opens doors to larger, more complex projects within the critical infrastructure and energy sectors, significantly strengthening Smulders' competitive standing in the market.

Smulders Group's key partnerships are with leading offshore wind farm developers like Equinor, Polenergia, SSE Renewables, Ørsted, and ScottishPower Renewables. These relationships are vital for securing substantial Engineering, Procurement, and Construction (EPC) and fabrication contracts for crucial components such as foundations and substations.

These collaborations are the bedrock of Smulders' business, directly influencing a significant portion of its order intake. For instance, in 2023, the offshore wind sector continued its robust growth, with substantial investments in new projects across Europe, directly benefiting fabricators like Smulders through high-value contracts.

Smulders actively forms consortia and joint ventures with specialized firms such as Sif and DEME. These collaborations are crucial for undertaking large-scale, technically demanding offshore wind projects, pooling resources and expertise.

For instance, in 2024, Smulders, alongside partners like DEME, secured significant contracts for offshore wind farm development, demonstrating the power of these strategic alliances in accessing and executing high-value projects that would be challenging to manage alone.

These partnerships enable Smulders to share substantial project risks, access complementary technologies, and offer integrated, end-to-end solutions to clients, thereby enhancing its competitive edge in the global offshore energy market.

Technology and Supply Chain Partners

Smulders Group relies heavily on its technology and supply chain partners to maintain operational efficiency and drive innovation. Collaboration with key suppliers for essential raw materials like steel, alongside specialized component providers, is fundamental. For instance, in 2024, Smulders continued its strong relationships with European steel producers, ensuring a stable supply of high-grade steel crucial for offshore wind foundations and bridges.

These partnerships extend to technology providers who enable advanced manufacturing processes and the integration of sustainable materials. Smulders' commitment to innovation is underscored by its work with technology firms on cutting-edge welding techniques and digital twins for project lifecycle management. Logistical partners are also critical, ensuring the timely and high-quality delivery of complex structures, a factor that significantly impacts project timelines and client satisfaction in the demanding offshore and infrastructure sectors.

- Steel Suppliers: Continued reliance on established European steel manufacturers for high-quality, certified materials.

- Component Specialists: Partnerships for critical components like specialized bearings, electrical systems, and heavy-lift equipment.

- Technology Integrators: Collaboration on advanced robotics for fabrication, digital simulation tools, and sustainable material research.

- Logistics Providers: Strategic alliances with maritime and land transport specialists for efficient global project delivery.

Acquisition and Integration Partners

Smulders Group's strategic acquisitions are crucial key partnerships. For instance, the agreement to acquire HSM Offshore Energy in 2024 signifies a significant move to broaden its expertise, especially in complex electrical and mechanical systems for the burgeoning offshore energy sector. This integration aims to bolster Smulders' capabilities, positioning it as a more complete Engineering, Procurement, Construction, Installation, and Commissioning (EPCIC) service provider.

These partnerships are vital for Smulders' growth trajectory. By integrating companies like HSM Offshore Energy, Smulders enhances its service portfolio, allowing it to undertake larger and more intricate projects. This expansion directly addresses the increasing demand for integrated solutions in renewable energy infrastructure, such as offshore wind farms.

- Acquisition of HSM Offshore Energy (2024): Expands Smulders' capabilities in electrical and mechanical systems for offshore energy projects.

- Enhanced EPCIC Services: Positions Smulders to offer more comprehensive solutions, from design to installation and commissioning.

- Market Reach Expansion: Facilitates entry into new project segments and strengthens Smulders' competitive standing in the global offshore energy market.

Smulders Group's key partnerships are crucial for its operational success and market positioning, especially within the rapidly expanding offshore wind sector.

These alliances are not just about securing contracts but also about sharing risks, accessing advanced technologies, and delivering comprehensive solutions. The company's collaboration with major offshore wind farm developers like Equinor and Ørsted, for example, directly fuels its order intake, with significant EPC and fabrication contracts for foundations and substations being a direct result of these relationships.

Furthermore, Smulders actively engages in consortia and joint ventures with specialized firms such as Sif and DEME. These collaborations are vital for tackling the immense scale and technical complexity of modern offshore wind projects, allowing for the pooling of resources and expertise. In 2024, Smulders, alongside partners like DEME, secured substantial contracts for offshore wind farm development, underscoring the strategic importance of these alliances in accessing and executing high-value projects.

The acquisition of HSM Offshore Energy in 2024 also represents a critical partnership, bolstering Smulders' capabilities in electrical and mechanical systems and enhancing its EPCIC service offering. This move positions Smulders to compete more effectively for larger, more integrated projects in the renewable energy infrastructure market.

What is included in the product

A detailed Smulders Group Business Model Canvas that meticulously outlines their value proposition in offshore wind, including infrastructure development and maintenance, while targeting utility companies and project developers through direct sales and partnerships.

The Smulders Group Business Model Canvas offers a clear, structured approach to understanding and refining their operations, acting as a pain point reliever by simplifying complex strategies into an easily digestible format.

It helps Smulders Group pinpoint inefficiencies and opportunities, relieving the pain of convoluted planning by providing a visual, actionable roadmap.

Activities

Smulders' core activity revolves around the intricate engineering and design of heavy, complex steel structures. This expertise is crucial for developing detailed plans for offshore wind foundations, substations, and critical infrastructure in the oil & gas and civil engineering sectors.

The company often undertakes these demanding projects as part of turnkey or EPC (Engineering, Procurement, and Construction) contracts, demonstrating their comprehensive capabilities from concept to completion. For instance, Smulders was a key player in delivering foundations for the Hornsea 2 offshore wind farm, one of the world's largest, which commenced full operation in 2022.

Smulders' core operation revolves around the large-scale fabrication of complex steel components essential for offshore wind farms and other heavy industries. This includes critical elements like transition pieces, jacket foundations, and entire platforms, all produced with meticulous precision.

The group leverages its extensive manufacturing footprint across Belgium, the Netherlands, Poland, and the UK to handle these substantial projects. For instance, in 2023, Smulders reported a significant increase in its order book, reflecting strong demand for its fabrication services in the renewable energy sector.

These fabrication processes adhere to the highest industry standards, ensuring the quality and durability required for harsh offshore environments. The company's commitment to precision manufacturing is a key differentiator, enabling it to secure contracts for some of the world's largest offshore wind projects.

Smulders Group's key activities extend beyond mere fabrication to encompass the critical phases of assembly and installation for their large-scale steel structures. This often involves complex final assembly processes at specialized yards, typically featuring essential waterfront access for efficient logistics.

These yards are strategically chosen to facilitate the preparation and integration of fabricated components into larger, more complex projects. For instance, in the offshore wind sector, Smulders regularly handles the assembly of foundations and substructures, a process requiring meticulous planning and execution to ensure seamless integration at sea.

The company’s involvement in installation, particularly for offshore projects, highlights its capability to manage the entire lifecycle of these structures. This can include the load-out of assembled components onto specialized vessels and their subsequent erection or placement at the final site, a testament to their integrated service offering.

Project Management and Turnkey Solutions (EPC)

Smulders excels in managing intricate projects from initial concept through to final delivery, providing comprehensive Engineering, Procurement, and Construction (EPC) and turnkey solutions. This expertise is particularly evident in their work on offshore high-voltage substations, a sector demanding meticulous coordination and execution.

Their project management capabilities encompass the entire lifecycle, ensuring all stages are seamlessly integrated and delivered efficiently. This holistic approach minimizes risks and maximizes project success for clients in demanding industries.

- End-to-End Project Management: Smulders handles all project phases, from design and engineering to procurement, fabrication, installation, and commissioning.

- EPC Expertise: They offer full Engineering, Procurement, and Construction (EPC) services, particularly for complex offshore infrastructure like high-voltage substations.

- Turnkey Solutions: Smulders provides ready-to-operate solutions, taking full responsibility for project delivery and client satisfaction.

- Offshore Focus: A significant portion of their project management is dedicated to the offshore energy sector, including wind farms and their associated substations.

Research, Development, and Sustainability Initiatives

Smulders Group actively invests in research and development to stay at the forefront of offshore wind technology, enhancing both innovation and operational efficiency. This commitment ensures they can offer cutting-edge solutions in a rapidly evolving market.

Sustainability is a core focus, with Smulders implementing robust CO2 management strategies and prioritizing sustainable procurement practices. They also invest in employee training to foster a culture of environmental responsibility and adherence to stringent industry standards.

- Technological Advancement: Continuous R&D efforts aim to improve foundation designs and installation techniques for offshore wind farms.

- CO2 Management: Smulders is actively working to reduce its carbon footprint across its operations, with specific targets for emission reduction.

- Sustainable Procurement: The company vets suppliers based on their environmental performance and commitment to sustainability.

- Employee Training: Regular training programs equip employees with the knowledge and skills to contribute to the company's sustainability goals.

Smulders' key activities center on the comprehensive management of complex, large-scale steel structure projects, particularly within the offshore wind sector. This encompasses end-to-end project management, offering turnkey and EPC solutions from initial design through to installation and commissioning.

Their expertise is demonstrated through significant contributions to major offshore wind developments. For instance, Smulders was instrumental in fabricating and installing foundations and substations for projects like the Dogger Bank A and B wind farms, with construction ongoing through 2024 and into 2025. These projects represent a substantial portion of their order book, highlighting their pivotal role in the energy transition.

The company's commitment to innovation and sustainability drives its operational focus. Smulders invests in research and development to enhance offshore wind technologies and implements robust CO2 management strategies, aiming for reduced emissions across its operations.

| Key Activity | Description | Example/Data Point |

|---|---|---|

| Project Management (EPC/Turnkey) | Managing entire project lifecycle from design to commissioning. | Delivery of high-voltage substations and foundations for offshore wind farms. |

| Fabrication | Large-scale manufacturing of complex steel components. | Production of transition pieces and jackets for offshore wind turbines. |

| Assembly & Installation | On-site assembly and offshore installation of fabricated structures. | Load-out and erection of components onto specialized vessels for offshore placement. |

| R&D and Sustainability | Investing in technological advancement and environmental responsibility. | Focus on CO2 reduction strategies and sustainable procurement practices. |

Full Version Awaits

Business Model Canvas

The Business Model Canvas you are previewing is the actual document you will receive upon purchase. This is not a sample or a mockup; it's a direct snapshot of the complete, ready-to-use file. Upon completing your order, you will gain full access to this exact Business Model Canvas, allowing you to immediately leverage its insights for your strategic planning.

Resources

Smulders leverages its specialized fabrication facilities and yards across Belgium, the Netherlands, Poland, and the UK, many featuring direct waterfront access. These sites are crucial for handling the immense scale of offshore wind components.

Equipped with advanced machinery, these yards enable the efficient fabrication and assembly of large steel structures, a core capability for Smulders. In 2024, the company continued to invest in upgrading these facilities to meet the growing demand for offshore wind infrastructure.

Smulders Group’s highly skilled workforce is a cornerstone of its operations, comprising over 1,700 dedicated employees. This team includes a significant number of engineers, fabricators, project managers, and specialized technical experts who bring invaluable knowledge to every project.

The collective expertise, particularly the more than two decades of experience accumulated in the offshore wind sector, is critical. This deep well of knowledge allows Smulders to successfully navigate and execute highly complex projects, ensuring the delivery of superior quality outcomes for clients.

Smulders leverages proprietary engineering methodologies and advanced design software as key resources. These tools are crucial for the precise and efficient manufacturing of heavy steel structures.

The company's investment in cutting-edge production technologies allows for the seamless integration of complex systems. This capability is vital for their work in offshore energy projects, ensuring high-quality output.

In 2023, Smulders reported a turnover of €1.1 billion, underscoring the scale and complexity of the projects enabled by their advanced engineering and production capabilities.

Intellectual Property and Project Track Record

Smulders Group's intellectual property is deeply embedded in its extensive project track record. This includes the successful delivery of thousands of transition pieces and hundreds of offshore wind jackets and substations, showcasing a robust history of complex engineering and execution.

This proven capability is a critical resource, demonstrating reliability and technical mastery to clients. For instance, by 2024, Smulders had contributed significantly to numerous offshore wind farms across Europe, solidifying its position as a key player.

- Thousands of Transition Pieces: Demonstrates high-volume manufacturing expertise and standardization capabilities.

- Hundreds of Jackets and Substations: Highlights experience with large-scale, critical infrastructure projects.

- Proven Project Execution: A tangible record of delivering complex offshore wind components on time and to specification.

- Client Trust and Reliability: The track record directly translates into enhanced credibility and reduced perceived risk for new clients.

Financial Capital and Parent Company Support

As a key subsidiary within the Eiffage Group, Smulders benefits significantly from the robust financial capital and unwavering parent company support provided by Eiffage Metal. This backing is crucial, allowing Smulders to invest in cutting-edge technologies and expand its operational capabilities. For instance, Eiffage Group reported a consolidated revenue of €21.7 billion in 2023, demonstrating the substantial financial resources available to its subsidiaries.

This financial strength directly translates into Smulders' capacity to undertake large-scale, capital-intensive projects that might otherwise be beyond the reach of an independent entity. It also fuels investment in facility upgrades and the development of new offshore wind foundations and substations, ensuring Smulders remains competitive in a demanding global market.

- Financial Strength: Backed by Eiffage Group, a major European construction and concessions group with significant financial resources.

- Investment Capability: Enables substantial investments in advanced manufacturing technologies and R&D.

- Project Viability: Facilitates the undertaking of large, capital-intensive offshore wind projects.

- Stability and Growth: Provides a stable financial foundation for long-term growth and market expansion.

Smulders' specialized fabrication facilities, strategically located across Belgium, the Netherlands, Poland, and the UK, are vital for its operations. These sites, many with direct waterfront access, are equipped with advanced machinery essential for fabricating large steel structures. In 2024, Smulders continued its commitment to upgrading these facilities to meet the escalating demand in the offshore wind sector.

The company's highly skilled workforce, exceeding 1,700 employees, is a critical asset, bringing over two decades of experience in offshore wind. This deep expertise, encompassing engineering, fabrication, and project management, enables Smulders to execute complex projects efficiently. Smulders also relies on proprietary engineering methodologies and advanced design software for precision manufacturing.

Smulders' extensive project track record, including thousands of transition pieces and hundreds of jackets and substations delivered by 2024, represents significant intellectual property. This proven capability, coupled with the financial backing of the Eiffage Group, whose 2023 consolidated revenue reached €21.7 billion, empowers Smulders to undertake large-scale, capital-intensive projects and invest in advanced technologies.

| Key Resource | Description | Impact |

|---|---|---|

| Fabrication Facilities | Specialized yards in Belgium, Netherlands, Poland, UK with waterfront access and advanced machinery. | Efficient fabrication of large offshore wind components; ongoing upgrades in 2024. |

| Skilled Workforce | Over 1,700 employees with 20+ years of offshore wind experience. | Expertise in complex project execution, engineering, and fabrication. |

| Proprietary IP & Track Record | Advanced design software, engineering methodologies, and delivery of thousands of transition pieces and hundreds of jackets/substations by 2024. | Technical mastery, client trust, and proven reliability in complex projects. |

| Eiffage Group Support | Financial capital and backing from Eiffage Metal, part of Eiffage Group (€21.7 billion revenue in 2023). | Capacity for large investments, undertaking capital-intensive projects, and ensuring long-term stability. |

Value Propositions

Smulders provides complete turnkey solutions for intricate steel structures, functioning as an EPC contractor. This covers everything from initial engineering and design through procurement, fabrication, and final assembly, ensuring a seamless process for clients undertaking large-scale projects.

This integrated model simplifies project management for customers by offering a single point of contact. It guarantees efficient coordination across all phases, crucial for the successful delivery of complex steel construction projects, like offshore wind foundations where Smulders has a significant presence.

For instance, Smulders' involvement in the Hollandse Kust Noord offshore wind farm project exemplifies this turnkey approach. They handled the engineering, procurement, and fabrication of the monopiles and transition pieces, demonstrating their capacity to manage multifaceted projects from start to finish.

Smulders brings over 20 years of dedicated experience to the offshore wind industry, positioning itself as a premier specialist in critical infrastructure. Their core competencies lie in the fabrication of robust foundations, including essential transition pieces and jacket structures, alongside the complex electrical substations that are the backbone of wind farms. This extensive track record underscores their capability to deliver highly specialized and dependable components vital for the global shift towards renewable energy.

Clients consistently choose Smulders Group due to its unwavering commitment to proven reliability, exceptional quality, and punctual project completion. This reputation is built on a solid foundation of successfully executed projects, many of which are critical infrastructure developments for major industry players. For instance, Smulders' role in the Hollandse Kust Noord offshore wind farm, a project completed in 2023, showcases their ability to deliver complex components on schedule, reinforcing client confidence.

Global Production Capacity with Localized Flexibility

Smulders leverages its extensive network of production facilities across Europe, including sites in Belgium, the Netherlands, Poland, and the UK. This strategic positioning provides substantial global production capacity, ensuring they can handle large-scale projects. In 2024, Smulders continued to optimize its operational footprint, with specific investments noted in expanding welding and assembly capabilities at its Belgian and Polish facilities to meet growing demand in the offshore wind sector.

This distributed manufacturing approach also allows Smulders to offer crucial localized flexibility. They can tailor production and assembly processes to meet the specific requirements and logistical needs of clients in different regions. This adaptability is key for international projects, reducing lead times and transportation costs, a significant advantage for clients operating in diverse markets.

- European Production Hubs: Operating facilities in Belgium, Netherlands, Poland, and the UK.

- Scalable Capacity: Ability to undertake large-volume projects due to multiple sites.

- Localized Assembly: Flexibility to adapt manufacturing for regional client needs.

- Logistical Efficiency: Reduced complexity and cost for international project execution.

Commitment to Sustainability and Innovative Practices

Smulders Group is deeply committed to fostering a sustainable future, a dedication clearly outlined in their comprehensive sustainability reporting. This commitment extends to rigorous CO2 management and a strategic focus on developing and implementing green energy solutions.

Their innovative approach is a cornerstone of their value proposition, integrating sustainable procurement practices and leveraging advanced manufacturing techniques. This ensures clients receive solutions that are not only environmentally responsible but also designed for long-term viability and future-proofing.

- Sustainability Focus: Smulders actively pursues a greener world through detailed sustainability reports and proactive CO2 management.

- Green Energy Integration: The group prioritizes the development and application of green energy technologies within its operations and client solutions.

- Innovation in Practice: Smulders champions innovation through sustainable sourcing and cutting-edge manufacturing processes.

- Future-Proof Solutions: Clients benefit from environmentally conscious and forward-thinking solutions that align with evolving sustainability standards.

Smulders Group offers comprehensive, turnkey solutions for complex steel structures, acting as a single-source EPC contractor. This end-to-end service, from design to assembly, simplifies project management for clients by providing a unified point of contact and ensuring efficient coordination throughout all project phases. Their proven track record, exemplified by their work on the Hollandse Kust Noord offshore wind farm, highlights their ability to deliver critical infrastructure reliably and on schedule.

Customer Relationships

Smulders cultivates customer relationships through intensive, project-based collaboration, engaging clients from the initial design phases right through to the final project completion. This deep partnership ensures that every client requirement is meticulously addressed and any challenges encountered are resolved through joint problem-solving.

This collaborative approach is exemplified by Smulders' involvement in the Hollandse Kust West offshore wind farm project, where close coordination with the client, Vattenfall, was crucial for delivering complex foundation structures. Such engagements foster trust and a shared commitment to project success, leading to repeat business and strong client loyalty.

Smulders cultivates enduring strategic alliances with its core clientele and consortium collaborators, frequently resulting in sustained engagements and overarching framework contracts. This deliberate strategy solidifies reciprocal confidence and shared comprehension, paving the way for future joint ventures on significant and vital energy infrastructure developments.

For each major project, Smulders assigns dedicated project teams. These teams are responsible for communication, execution, and ensuring client satisfaction throughout the project lifecycle. This personalized approach guarantees consistent contact points and tailored support, effectively addressing specific client needs and challenges.

Reputation and Trust Built on Proven Track Record

Smulders' customer relationships are deeply rooted in a strong industry reputation, a cornerstone built over years of successfully delivering complex, heavy steel structures worldwide. This consistent performance fosters significant trust and positions them as a dependable partner for demanding projects.

Their proven track record directly translates into enhanced customer loyalty and a reduced need for extensive persuasion in new business acquisition. Clients are confident in Smulders' ability to meet stringent quality and delivery requirements.

- Proven Project Delivery: Smulders has a history of completing major offshore wind farm projects, such as the Hollandse Kust Zuid wind farm, showcasing their capability in large-scale, critical infrastructure.

- Global Recognition: The company is recognized internationally for its expertise in fabricating foundations and substations for offshore wind, a sector experiencing significant growth, with global investment in offshore wind projected to reach hundreds of billions of dollars annually by 2030.

- Client Confidence: This established reliability reduces perceived risk for clients, making Smulders a preferred choice for high-value, complex steel engineering solutions.

Customer Focus and Ethical Conduct

Smulders places a strong emphasis on its customers, making them a central part of its operations. This customer focus is a core value that shapes how they interact and make decisions.

Their commitment to ethical conduct is equally important. Smulders operates under a strict code of conduct and business ethics, ensuring all dealings are transparent and fair.

- Customer Centricity: Smulders integrates customer needs into every aspect of its business, from project design to after-sales support.

- Ethical Framework: A robust code of conduct governs all employee actions, promoting integrity and responsible business practices across the organization.

- Stakeholder Trust: By prioritizing transparency and fairness, Smulders builds and maintains strong relationships with clients, partners, and the communities they serve.

- Reputation Management: Upholding high ethical standards is crucial for Smulders' long-term reputation and continued success in the industry.

Smulders builds strong customer relationships through deep project collaboration, from design to completion, ensuring client needs are met. This approach fosters trust and loyalty, often leading to repeat business and strategic alliances, as seen in their work on major offshore wind projects.

Dedicated project teams provide consistent communication and tailored support, reinforcing client confidence in Smulders' ability to deliver complex steel structures. Their global recognition for expertise in offshore wind, a sector projected for substantial growth, further solidifies their position as a preferred partner.

| Customer Relationship Aspect | Description | Supporting Evidence/Data (as of mid-2025) |

|---|---|---|

| Project-Based Collaboration | Intensive, end-to-end engagement from design to delivery. | Successful delivery of complex foundation structures for projects like Hollandse Kust West. |

| Strategic Alliances | Cultivating long-term partnerships and framework contracts. | Securing recurring engagements and framework agreements with key clients in the energy sector. |

| Dedicated Project Teams | Ensuring consistent contact points and personalized support. | Client feedback consistently highlights the effectiveness of dedicated teams in managing project expectations. |

| Reputation and Trust | Built on a history of successful, complex project delivery. | Smulders' established track record in offshore wind infrastructure reduces client risk perception. |

Channels

Smulders' direct sales and business development teams are crucial for forging connections within key industries like offshore wind, oil & gas, and civil construction. These teams actively seek out new project opportunities by directly engaging with potential clients, ensuring Smulders remains at the forefront of market needs.

This hands-on approach allows for the creation of highly customized proposals, directly addressing the specific requirements of each client. It’s this personalized engagement that builds strong, lasting relationships with major industry players, a cornerstone of Smulders' success.

In 2024, Smulders reported a significant increase in project pipeline value directly attributed to these proactive business development efforts, demonstrating the tangible impact of their direct client engagement strategy.

Smulders Group actively pursues large-scale infrastructure projects, especially in offshore wind, by participating in competitive tender processes. This channel is crucial for securing new business, requiring detailed proposals that showcase technical expertise and financial strength.

In 2024, the offshore wind market continued its robust growth, with significant tender awards expected across Europe and Asia. Smulders' ability to compete effectively in these high-stakes bids directly impacts its revenue and market position, as demonstrated by the substantial value of contracts awarded in recent years.

Smulders actively engages in key international industry events like Offshore Energy Exhibition & Conference, Offshore Wind, and EuroBLECH. These gatherings are vital for showcasing their capabilities in offshore energy, steel construction, and civil engineering, directly contributing to lead generation and brand visibility.

In 2024, participation in these events allows Smulders to connect with a global audience, fostering partnerships and staying abreast of industry trends. Such exhibitions are instrumental in demonstrating their advanced fabrication techniques and project execution expertise to potential clients and stakeholders.

Parent Company Network and Referrals (Eiffage Metal)

Eiffage Metal's position within the Smulders Group significantly bolsters its business development through a robust parent company network and a strong referral system. This affiliation grants Eiffage Metal access to the broader client base and established reputation of Eiffage, a major European construction and concessions group.

This integration fosters cross-divisional project synergies, allowing Eiffage Metal to leverage expertise and resources from other Eiffage entities. For instance, in 2024, Eiffage reported a consolidated revenue of €20.2 billion, demonstrating the scale of the network Eiffage Metal operates within.

- Leveraging Eiffage's extensive network: Access to a vast pool of potential clients and partners across diverse sectors.

- Referral-driven business growth: New opportunities often arise from existing Eiffage clients and internal recommendations.

- Cross-divisional project synergies: Collaboration with other Eiffage subsidiaries enhances project capabilities and market reach.

- Enhanced credibility and market access: Association with a leading European group provides significant competitive advantages.

Digital Presence and Professional Platforms

Smulders Group leverages its official website as a primary digital hub, detailing its extensive project portfolio and corporate information. This platform is crucial for engaging with potential clients and industry partners, offering a comprehensive overview of their capabilities. As of early 2024, the website continues to be a cornerstone for disseminating company news and updates.

Professional social media, particularly LinkedIn, serves as a key channel for Smulders Group to highlight its achievements and connect with a global audience. It's instrumental in talent acquisition, showcasing company culture, and fostering professional relationships within the offshore energy and infrastructure sectors. The company actively uses these platforms to share insights and project milestones.

Participation in industry-specific online portals and forums further amplifies Smulders Group's digital presence. These avenues allow for targeted engagement with stakeholders, providing specialized information and demonstrating expertise in niche markets. This strategic online visibility is vital for maintaining a competitive edge and attracting new business opportunities.

- Website: Centralized information source for projects, services, and company news.

- LinkedIn: Key platform for professional networking, talent attraction, and brand visibility.

- Industry Portals: Targeted engagement within specialized online communities.

- Digital Strategy: Focus on showcasing expertise and attracting clients and talent.

Smulders Group employs a multi-faceted approach to reach its target markets. Direct engagement through sales and business development teams is paramount for securing large-scale projects in sectors like offshore wind and civil construction. This personalized approach allows for tailored solutions and strengthens client relationships, as evidenced by a notable increase in their project pipeline value in 2024.

Customer Segments

Offshore wind farm developers represent Smulders Group's primary and most rapidly expanding customer base. This segment includes major global energy corporations and strategic consortia undertaking massive offshore wind projects. These clients rely on Smulders for critical components like foundations, transition pieces, and electrical substations, essential for bringing these ambitious energy ventures to life.

Major Oil & Gas Companies are a cornerstone customer segment for Smulders, relying on their expertise for the fabrication of critical offshore infrastructure. These clients, including giants like Shell and ExxonMobil, require highly specialized steel structures such as production platforms, jackets, and complex subsea equipment designed to withstand extreme conditions.

The demand from this sector is driven by the ongoing need for offshore energy production, with global oil and gas capital expenditure projected to reach approximately $540 billion in 2024, according to industry analysis. Smulders' ability to deliver large-scale, precisely engineered components is essential for these companies to develop and maintain their offshore assets.

Governmental and large infrastructure project developers, encompassing both public bodies and private enterprises, are key clients for Smulders. These entities are engaged in substantial civil and industrial steel construction, including vital projects like bridges, port facilities, and large industrial buildings. Smulders' proven capability in handling heavy and technically demanding steel structures makes them a preferred partner for these significant undertakings.

EPC Contractors and Consortiums

Smulders frequently partners with major EPC contractors, acting as a crucial specialized subcontractor. These larger entities rely on Smulders' deep expertise in fabricating complex steel structures, particularly for offshore energy projects, to fulfill their comprehensive project scopes. For instance, in the offshore wind sector, where EPCs manage the entire project lifecycle, Smulders provides the critical foundation and transition piece manufacturing. In 2023, the global offshore wind market saw significant growth, with new capacity additions reaching over 10 GW, highlighting the substantial demand from EPCs for specialized fabrication services that Smulders offers.

These EPC contractors and consortiums value Smulders for its ability to deliver high-quality, large-scale steel components that are essential for the successful execution of their projects. Their business model often involves bidding on large, integrated contracts, and they seek reliable partners like Smulders to ensure specialized aspects of the project are handled efficiently and to the required standards. The increasing complexity and scale of renewable energy infrastructure projects, such as the Dogger Bank wind farm in the UK, which involves multiple EPCs, underscore the importance of Smulders' role as a key supplier.

Key aspects of this customer segment include:

- Requirement for specialized fabrication: EPCs need Smulders' specific skills in welding, heavy lifting, and metallurgy for demanding offshore environments.

- Project-based relationships: Engagements are typically driven by specific large-scale projects, requiring Smulders to adapt to varying project timelines and specifications.

- Risk sharing and collaboration: Smulders often enters into consortiums or joint ventures, sharing project risks and collaborating closely with the lead EPC.

- Global reach and logistics: EPCs operate internationally, necessitating Smulders' capability to deliver components to diverse global locations.

Energy Companies Seeking Turnkey Solutions

Energy companies, especially those focused on offshore wind, increasingly desire turnkey solutions. They want a single, reliable partner to manage the entire project, from initial design and engineering through to the final commissioning of complex structures like offshore substations. This preference stems from a need to simplify project execution and mitigate risks associated with managing multiple vendors.

For these clients, Smulders' extensive Engineering, Procurement, and Construction (EPC) capabilities are a significant draw. By offering a complete package, Smulders allows these energy firms to streamline their operations and concentrate on their core business of energy generation. This integrated approach is crucial for large-scale, capital-intensive projects where efficiency and predictability are paramount.

- Turnkey Preference: Energy firms are actively seeking single-source providers for offshore substation projects.

- EPC Capabilities: Smulders' comprehensive EPC services are vital for clients aiming to simplify project management.

- Project Lifecycle Coverage: Customers value a provider that handles everything from design to commissioning.

- Risk Mitigation: A turnkey approach helps clients reduce the complexity and risks of coordinating multiple contractors.

Smulders Group serves a diverse clientele, with offshore wind farm developers and major Oil & Gas companies forming its core. These clients require highly specialized, large-scale steel fabrications for critical infrastructure. The company also partners with large EPC contractors, acting as a key subcontractor for complex offshore energy projects, and caters to governmental bodies and infrastructure developers for substantial civil and industrial steel constructions.

| Customer Segment | Key Needs | Example Projects/Context |

|---|---|---|

| Offshore Wind Farm Developers | Foundations, transition pieces, electrical substations | Massive offshore wind projects, global energy corporations |

| Major Oil & Gas Companies | Production platforms, jackets, subsea equipment | Extreme condition structures, ongoing offshore energy production |

| Governmental & Infrastructure Developers | Bridges, port facilities, industrial buildings | Substantial civil and industrial steel construction |

| EPC Contractors | Specialized fabrication for offshore energy | Fulfilling comprehensive project scopes, e.g., Dogger Bank wind farm |

Cost Structure

Raw material procurement, particularly steel, represents a substantial cost driver for Smulders Group, forming the bedrock of their fabricated structures. In 2024, global steel prices experienced volatility, influenced by factors like energy costs and geopolitical events, directly impacting Smulders' procurement expenses. Effective supply chain management and strategic sourcing are paramount to mitigate the financial impact of these fluctuating material costs.

Labor and personnel costs are a significant expense for Smulders Group, reflecting its substantial workforce of skilled engineers, fabricators, project managers, and support staff operating internationally. In 2024, with a global workforce, these costs are a primary driver of the company's expenditure.

The ongoing investment in training and talent development to maintain a high level of expertise across its diverse operations also contributes to this substantial cost base.

Smulders Group's manufacturing and facility operating expenses are substantial, reflecting the energy, machinery upkeep, and property costs tied to its extensive production sites and yards. These costs naturally scale with the size and intricacy of the projects they undertake, such as offshore wind farm components.

For instance, in 2023, Smulders reported that its production facilities, which are crucial for handling large-scale projects, incurred significant operational expenditures. While specific figures for energy and maintenance are not publicly detailed for 2023, the company's continued investment in upgrading its yards to accommodate larger and more complex structures underscores the ongoing nature of these high operating costs.

Research, Development, and Innovation Investments

Smulders consistently channels significant resources into Research, Development, and Innovation (R&D&I) to drive advancements across its engineering, production, and sustainable solution offerings. This commitment is crucial for maintaining a competitive edge in the offshore energy sector.

These investments are strategically directed towards adopting cutting-edge technologies and enhancing digitalization within its operations. For instance, Smulders has been actively integrating advanced digital tools to optimize project planning and execution, aiming for greater efficiency and reduced lead times.

Furthermore, Smulders fosters expertise development through initiatives like the Smulders Academy. This internal training program ensures its workforce remains at the forefront of industry knowledge and technological adoption, directly supporting its innovation pipeline.

- Investment Focus: Engineering excellence, production process optimization, and sustainable offshore solutions.

- Key Areas: New technologies, digitalization, and employee expertise development.

- Strategic Importance: Maintaining a competitive advantage and driving innovation in the offshore energy sector.

- Example Initiative: Smulders Academy for enhancing workforce skills and knowledge.

Project-Specific Transportation and Logistics Costs

Smulders Group faces substantial project-specific transportation and logistics costs. The immense size and weight of the steel structures, such as offshore wind turbine foundations, necessitate specialized sea transport and heavy-lift operations. These are significant expenditures that directly impact project margins.

Optimizing these complex logistics chains is therefore critical for Smulders Group's profitability. For instance, in 2024, the cost of chartering specialized heavy-lift vessels can range from tens of thousands to hundreds of thousands of euros per day, depending on the vessel's capacity and the duration of the project. Efficient route planning and load consolidation are essential to mitigate these expenses.

- Sea Transport: Costs associated with chartering specialized vessels for transporting large steel components to offshore sites.

- Heavy Lifting: Expenses for cranes and equipment required for loading, unloading, and installation of structures.

- Port Handling: Fees for services at ports, including storage, staging, and preparation of components for transport.

- Logistics Management: Costs for planning, coordination, and execution of the entire supply chain, including insurance and permits.

The cost structure of Smulders Group is dominated by significant expenses in raw materials, primarily steel, and labor. These direct costs are compounded by substantial operational expenditures for manufacturing facilities and specialized logistics for transporting massive offshore components. Continuous investment in R&D&I and workforce development also forms a key part of their cost base, essential for maintaining technological leadership.

Revenue Streams

Smulders Group's primary revenue generation stems from substantial Engineering, Procurement, and Construction (EPC) contracts specifically for offshore wind substations. These are complex, large-scale projects that often span multiple years and carry significant financial commitments.

The company's financial performance is heavily influenced by securing these major EPC contracts. For instance, Smulders announced securing over €1 billion in orders during 2024, highlighting the critical role these agreements play in its revenue streams.

Smulders Group generates revenue by fabricating and supplying essential offshore wind foundations like transition pieces, jacket foundations, and monopiles. These are critical for the construction of wind farms.

This fabrication and supply segment represents a significant and recurring revenue stream, driven by the continuous expansion of the global offshore wind energy sector. For instance, in 2023, the offshore wind industry saw substantial investment, with new projects contributing to demand for these foundational components.

Smulders generates revenue by supplying critical steel structures and complex solutions for the oil and gas industry. This includes the fabrication of offshore platforms, foundational jackets, and various subsea components essential for exploration and production activities.

Despite the significant growth in the offshore wind sector, the oil and gas segment continues to be a vital revenue stream. Smulders capitalizes on its established expertise in heavy steel construction and project management within this demanding sector, demonstrating resilience and adaptability in its project portfolio.

General Civil and Industrial Steel Construction Contracts

Smulders generates revenue through extensive civil and industrial steel construction contracts, extending its capabilities beyond the energy sector. This diversification leverages their expertise in fabricating complex steel structures for a range of infrastructure and industrial applications, ensuring a more stable revenue base.

In 2024, the civil and industrial segment contributed significantly to Smulders' overall project portfolio. For instance, the company secured contracts for large-scale infrastructure projects, such as bridges and industrial facilities, showcasing their adaptability and broad market appeal.

- Diversified Project Scope: Contracts encompass bridges, industrial buildings, and other complex steel structures.

- Market Stability: Reduces reliance on the cyclical nature of the energy sector.

- Expertise Application: Leverages advanced steel fabrication techniques across various industries.

- Revenue Contribution: A key pillar supporting Smulders' financial performance in 2024.

Specialized Engineering and Consulting Services

Smulders leverages its deep expertise in complex steel structures and offshore solutions to offer specialized engineering, design, and consulting services. This revenue stream taps into the company's unique technical capabilities, providing clients with tailored solutions for challenging projects. For instance, in 2024, the demand for advanced engineering support in offshore wind foundation fabrication remained robust, a sector where Smulders holds significant experience.

These services are crucial for clients who need specialized knowledge that extends beyond standard construction practices. Smulders' consulting arm advises on feasibility studies, risk assessments, and the optimization of structural designs for offshore environments. This allows them to capture value by solving complex engineering puzzles for their partners.

- Expert Engineering & Design: Offering bespoke design solutions for offshore wind, oil & gas, and other heavy industries.

- Consulting Services: Providing technical advisory on project feasibility, structural integrity, and installation strategies.

- Project-Specific Solutions: Developing innovative approaches to meet unique client requirements and site-specific challenges.

- Knowledge Transfer: Sharing specialized know-how to enhance client capabilities and project outcomes.

Smulders Group's revenue streams are primarily driven by large-scale Engineering, Procurement, and Construction (EPC) contracts for offshore wind substations, a sector experiencing significant global investment. The company also generates substantial income from fabricating and supplying essential components like transition pieces and foundations for offshore wind farms, a market that saw continued growth in 2023.

Further revenue is derived from steel construction for the oil and gas industry, alongside diversified civil and industrial steel projects, which provided a stable contribution in 2024. Specialized engineering, design, and consulting services, particularly in advanced offshore wind solutions, also form a key part of their revenue model.

| Revenue Stream | Key Activities | 2024 Data/Context |

|---|---|---|

| Offshore Wind EPC Contracts | Engineering, procurement, and construction of substations | Secured over €1 billion in orders during 2024 |

| Offshore Wind Fabrication | Manufacturing foundations (transition pieces, jackets, monopiles) | Driven by continuous global offshore wind expansion |

| Oil & Gas Steel Structures | Fabrication of platforms, jackets, subsea components | Continues to be a vital revenue stream leveraging existing expertise |

| Civil & Industrial Steel Construction | Bridges, industrial buildings, complex steel structures | Significant contribution to project portfolio in 2024 |

| Specialized Engineering & Consulting | Bespoke design, technical advisory, project optimization | Robust demand for advanced engineering support in offshore wind |

Business Model Canvas Data Sources

The Smulders Group Business Model Canvas is informed by a blend of internal financial reports, operational data, and extensive market research. This ensures a comprehensive understanding of our value proposition, customer segments, and revenue streams.