IMA Klessmann GmbH Marketing Mix

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

IMA Klessmann GmbH Bundle

IMA Klessmann GmbH masterfully leverages its product innovation, strategic pricing, targeted distribution, and impactful promotion to dominate the packaging machinery market. This analysis delves into how each element of their 4Ps works in synergy to create a powerful competitive advantage.

Discover the specific product features, pricing strategies, distribution channels, and promotional tactics that drive IMA Klessmann GmbH's success. Get the full, editable analysis to benchmark and enhance your own marketing efforts.

Product

IMA Klessmann GmbH, a key player within the HOMAG Group, provides specialized machinery crucial for the woodworking and furniture sectors. Their offerings encompass sophisticated edge banding machines, precision sizing equipment, efficient drilling solutions, and integrated material handling systems designed to optimize production workflows.

The company's product range is engineered to serve a broad spectrum of operational needs, from standalone units suitable for smaller workshops to comprehensive, high-capacity industrial production lines. This adaptability ensures they can meet the diverse demands of manufacturers across different scales of operation.

For 2024, the woodworking machinery market, a key segment for IMA Klessmann, is projected to see continued growth, driven by demand for automation and sustainable production methods. For instance, the global woodworking machinery market was valued at approximately USD 15.2 billion in 2023 and is anticipated to expand at a CAGR of around 5.5% through 2030, indicating a robust environment for IMA's specialized equipment.

IMA Klessmann GmbH's product strategy extends beyond individual machines to offer integrated ion lines and automation systems. These comprehensive solutions are designed to create intelligent manufacturing environments for furniture and building component producers. This strategic focus on networked production lines, incorporating machines, software, and robotics, aims to deliver seamless workflows and optimize operational efficiency.

The company's commitment to digitalization is evident in its SmartFactory solutions, which are integral to these advanced automation systems. By providing end-to-end production line integration, IMA Klessmann GmbH empowers manufacturers to achieve higher levels of precision and productivity. For instance, the global automation market is projected to reach $320 billion by 2025, highlighting the significant demand for such integrated solutions.

HOMAG, leveraging IMA Klessmann's deep expertise, stands at the forefront of processing panel materials with its advanced technology. Their commitment to innovation is evident in solutions like airTec and LaserTec, which deliver exceptional zero-joint edgebanding, enhancing both visual appeal and product longevity.

The company's continuous drive for advancement is demonstrated by the integration of IoT capabilities into their machinery and the development of sophisticated CNC systems. This forward-thinking approach ensures their offerings remain competitive and meet the evolving demands of the industry.

Comprehensive Software Solutions

IMA Klessmann GmbH's product strategy centers on comprehensive software solutions designed to elevate woodworking operations. Key offerings include woodWOP and ionManager, software packages that significantly boost machine capabilities and optimize manufacturing workflows. These tools are crucial for customers seeking efficiency gains and advanced control over their production lines.

A significant development is HOMAG Intelligence, a new cloud-based platform. This modular system ensures unbroken data flow from initial sales through to the production floor. It provides customers with essential digital support and a suite of optimization tools, underscoring IMA Klessmann's commitment to digital transformation in the industry.

The integration of such advanced software is a strategic move, reflecting the growing demand for smart manufacturing. For instance, the woodworking machinery market, which IMA Klessmann operates within, saw substantial growth, with global revenues projected to reach over $20 billion by 2025, driven by automation and digital solutions.

- woodWOP and ionManager: Enhance machine functionality and streamline production processes.

- HOMAG Intelligence: Cloud-based platform for seamless data continuity from sale to production.

- Digital Support and Optimization: Provides customers with tools for improved operational efficiency.

- Market Trend Alignment: Addresses the increasing demand for smart manufacturing and digital solutions in the woodworking sector.

After-Sales Services and Support

HOMAG, a key part of IMA Klessmann GmbH, recognizes that the sale of industrial machinery is just the beginning. Their after-sales services are designed to ensure the continued optimal performance and longevity of these complex machines. This includes essential maintenance, regular inspections, and specialized training programs tailored for operators and technicians, directly impacting machine uptime and operational efficiency.

The company's commitment to global customer support is a cornerstone of their after-sales strategy. This support extends to software assistance, critical for the advanced control systems in modern industrial equipment. Furthermore, HOMAG has developed a sophisticated spare parts management system, accessible via platforms like eParts and eShop, to minimize downtime and keep production lines running smoothly.

For 2024, HOMAG reported a significant focus on digitalizing their service offerings, aiming to increase remote diagnostics and predictive maintenance capabilities. This initiative is projected to reduce service response times by an average of 15% and improve spare parts availability by 10% across their global network by the end of 2025. These enhancements are vital for maintaining customer satisfaction and ensuring long-term machine reliability in a competitive industrial landscape.

- Global Service Network: HOMAG maintains a presence in over 100 countries, ensuring localized support for its machinery.

- Digital Service Platforms: eParts and eShop provide 24/7 access to spare parts catalogs and ordering, streamlining the procurement process.

- Training Programs: Comprehensive training modules are offered for machine operation, maintenance, and software updates, enhancing user competency.

- Predictive Maintenance: Investments in digital service aim to anticipate potential issues, reducing unplanned downtime and service costs for clients.

IMA Klessmann GmbH's product strategy focuses on delivering integrated solutions and advanced software to the woodworking industry. Their offerings, such as woodWOP and ionManager, enhance machine capabilities and optimize production workflows, while the HOMAG Intelligence platform ensures seamless data flow from sales to production. This commitment to digitalization and smart manufacturing aligns with market trends, as evidenced by the global woodworking machinery market's projected growth. For 2024, the market is expected to expand, driven by automation and digital solutions, with global revenues anticipated to exceed $20 billion by 2025.

| Product Focus | Key Software | Digitalization Strategy | Market Context (2024-2025) |

|---|---|---|---|

| Integrated production lines & automation systems | woodWOP, ionManager | HOMAG Intelligence (cloud-based platform) | Woodworking machinery market growth driven by automation. |

| Zero-joint edgebanding (airTec, LaserTec) | CNC systems | Remote diagnostics & predictive maintenance initiatives | Global automation market projected to reach $320 billion by 2025. |

| Sophisticated processing of panel materials | IoT capabilities integration | Enhanced spare parts management (eParts, eShop) | Global woodworking machinery market valued at ~USD 15.2 billion in 2023, projected CAGR of ~5.5% through 2030. |

What is included in the product

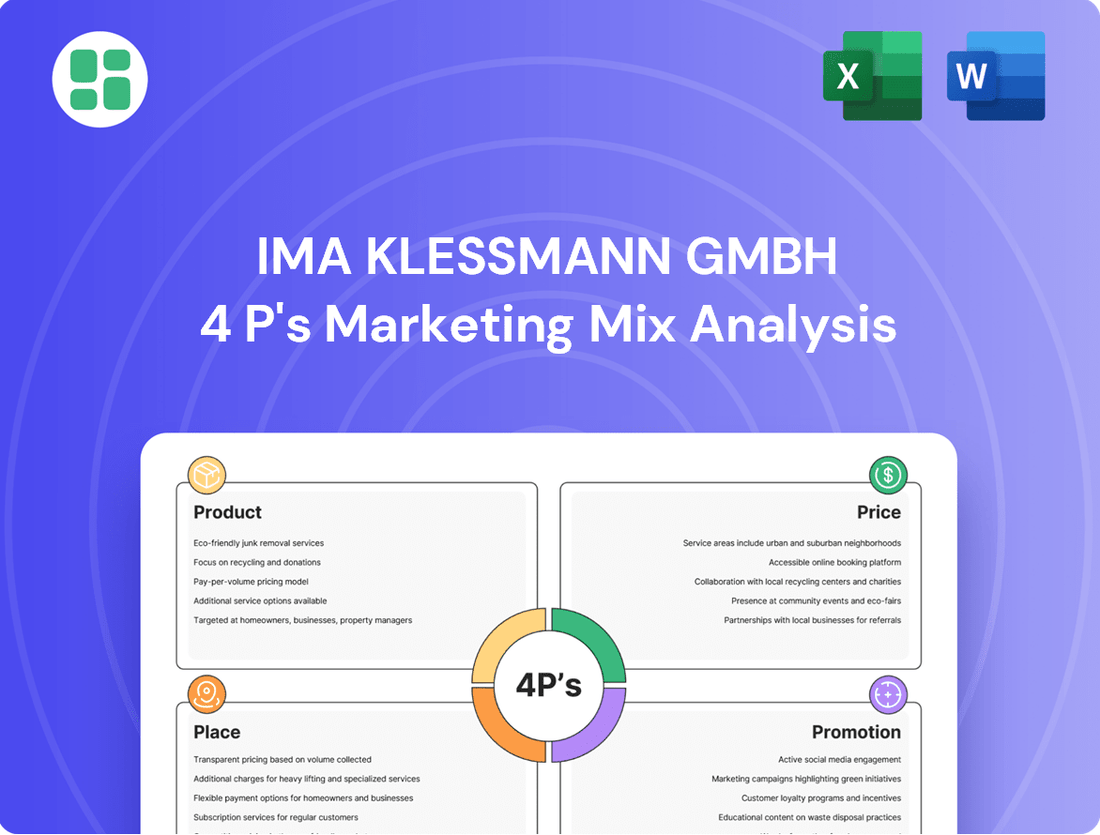

This analysis provides a comprehensive examination of IMA Klessmann GmbH's marketing mix, detailing their strategies for Product, Price, Place, and Promotion to understand their market positioning.

It offers a deep dive into IMA Klessmann GmbH's actual marketing practices, providing actionable insights for strategic decision-making and competitive benchmarking.

Simplifies complex marketing strategies by clearly outlining IMA Klessmann GmbH's Product, Price, Place, and Promotion, alleviating the pain of strategic ambiguity.

Provides a clear, actionable framework for understanding and improving IMA Klessmann GmbH's marketing efforts, addressing the challenge of ineffective campaign execution.

Place

IMA Klessmann, as part of the HOMAG Group, leverages a substantial global distribution network to ensure its woodworking machinery is accessible across the globe. This expansive infrastructure is crucial for serving a diverse international clientele.

The HOMAG Group's commitment to global reach is evident in its approximately 14 specialized production plants, strategically located to optimize manufacturing and supply chains. This foundation allows for efficient production and distribution of their advanced machinery.

Further strengthening this global presence, the Group operates around 20 group-owned sales and service companies, complemented by approximately 60 exclusive sales partners. This network, spanning over 100 countries, guarantees localized support, timely delivery, and expert maintenance for customers worldwide.

For major industrial clients and intricate, integrated solutions, IMA Klessmann, a key player within the HOMAG Group, frequently utilizes dedicated direct sales teams. This strategy is crucial for fostering deep relationships and understanding the specific needs of high-value customers. In 2024, HOMAG reported a significant portion of its revenue derived from its industrial solutions segment, underscoring the importance of these direct sales efforts.

Key account management is central to this direct sales approach, enabling tailored consultations and the development of project-specific solutions. This personalized engagement ensures that IMA Klessmann can effectively address the unique production demands of its most important clients. The company's focus on customized solutions, supported by direct client interaction, is a core differentiator in the competitive industrial machinery market.

IMA Klessmann GmbH leverages major international trade fairs as a cornerstone of its distribution and market presence strategy. These events are vital for showcasing new technologies and fostering direct engagement with a global audience of industry professionals. For instance, participation in LIGNA, a leading woodworking trade fair, provides unparalleled visibility. In 2023, LIGNA reported over 90,000 visitors from more than 150 countries, underscoring the immense reach these platforms offer.

Regional Showrooms and Technology Centers

IMA Klessmann GmbH, through its HOMAG brand, operates regional showrooms and technology centers, like those in India and Germany, to offer customers direct experience with their advanced woodworking machinery. These centers are crucial for demonstrating the capabilities of their cutting-edge technology, allowing potential clients to witness machines in action and receive tailored advice. For instance, HOMAG's technology center in Calw, Germany, showcases a comprehensive range of solutions, from panel cutting to edge processing, often hosting customer-specific application tests. In 2024, HOMAG reported continued investment in these customer-facing facilities as a key driver of sales growth and customer engagement.

These facilities serve a vital role in the 'Place' aspect of the marketing mix by:

- Providing tangible product demonstrations: Customers can see the machinery's performance firsthand, fostering confidence and understanding.

- Offering personalized solution guidance: Experts at these centers work with clients to identify the best machinery configurations for their specific needs.

- Facilitating hands-on experience: This direct interaction with technology helps bridge the gap between potential and actual purchase decisions.

- Showcasing innovation: Centers act as hubs for displaying the latest advancements in woodworking technology, reinforcing brand leadership.

Integrated Service and Spare Parts Logistics

The integrated service and spare parts logistics is a cornerstone of IMA Klessmann GmbH's offering, ensuring operational continuity for their industrial machinery clients. This element focuses on minimizing downtime, a critical factor in manufacturing efficiency.

HOMAG, a key brand within IMA Klessmann, leverages digital platforms like their eShop and eParts systems for seamless spare parts procurement. This accessibility is amplified by a global network of service technicians and rapid-response units, designed to address client needs swiftly.

For instance, HOMAG reported a significant increase in spare parts orders through their digital channels in 2024, reflecting the growing reliance on these systems for immediate operational support. Their service network is structured to provide on-site assistance within 24-48 hours for critical issues, a benchmark that contributes to high customer satisfaction.

- Digital Spare Parts Access: HOMAG's eShop and eParts platforms provide 24/7 access to a comprehensive catalog of spare parts.

- Global Service Network: A worldwide presence of trained service technicians ensures localized support.

- Rapid Response Teams: Dedicated teams are deployed to minimize machine downtime, with many critical repairs addressed within 48 hours.

- Logistics Efficiency: The entire supply chain is optimized for quick delivery, ensuring essential components reach clients promptly.

IMA Klessmann GmbH, as part of the HOMAG Group, strategically utilizes a multi-faceted approach to 'Place' within its marketing mix. This includes an extensive global distribution network, complemented by strategically located production plants and a robust network of sales and service companies and exclusive partners, ensuring worldwide accessibility and localized support for its advanced woodworking machinery.

| Distribution Channel | Reach/Scale | Key Functionality |

|---|---|---|

| Global Distribution Network | Serves diverse international clientele | Ensures accessibility of woodworking machinery |

| Production Plants | Approx. 14 specialized plants | Optimizes manufacturing and supply chains |

| Sales & Service Companies | Approx. 20 group-owned | Provides localized support and maintenance |

| Exclusive Sales Partners | Approx. 60 partners | Extends market reach across 100+ countries |

| Direct Sales Teams | For major industrial clients | Fosters deep relationships and tailored solutions |

| Trade Fairs (e.g., LIGNA) | Over 90,000 visitors (2023) | Showcases technology, engages global audience |

| Showrooms/Tech Centers | e.g., India, Germany | Offers direct experience, application tests |

What You Preview Is What You Download

IMA Klessmann GmbH 4P's Marketing Mix Analysis

The preview shown here is the actual document you’ll receive instantly after purchase—no surprises. This comprehensive IMA Klessmann GmbH 4P's Marketing Mix Analysis details Product, Price, Place, and Promotion strategies. You're viewing the exact version of the analysis you'll receive—fully complete, ready to use.

Promotion

IMA Klessmann GmbH, as part of the HOMAG Group, leverages premier industry trade fairs as a cornerstone of its marketing strategy. Participation in events like LIGNA, IndiaWood, HOMAG Treff, and KBIS is crucial for demonstrating cutting-edge woodworking machinery, automation, and digital solutions directly to a global audience.

These exhibitions serve as vital platforms for IMA Klessmann to engage with customers, partners, and industry influencers. For instance, LIGNA, a leading trade fair for woodworking and forestry, typically attracts over 1,500 exhibitors and hundreds of thousands of visitors, providing unparalleled visibility. HOMAG's own events, such as HOMAG Treff, often see thousands of attendees, offering deep dives into their latest innovations and fostering direct customer relationships.

IMA Klessmann GmbH employs a robust digital marketing strategy, featuring a dynamic website, regular news flashes, and an informative YouTube channel to connect with its worldwide clientele. This digital outreach is crucial for brand visibility and customer engagement in today's interconnected market.

Content marketing forms a core component of their promotional efforts. Through detailed case studies, insightful technical articles, and their customer magazine 'performance,' IMA Klessmann GmbH educates its audience on emerging industry trends, cutting-edge technological advancements, and real-world successful customer applications, fostering deeper client relationships.

For IMA Klessmann GmbH, promoting high-value industrial woodworking machinery hinges on direct sales and consultative selling. Their approach involves sales teams and consultants directly engaging with manufacturers, offering expert advice and tailored solutions.

This consultative model is vital for building trust and long-term partnerships, especially given the complexity and significant investment involved in their machinery. For instance, in 2024, the global woodworking machinery market was valued at approximately $17.5 billion, with a projected compound annual growth rate of 4.2% through 2030, underscoring the need for specialized sales expertise.

Innovation Showcases and Technology Days

HOMAG, a key player in the woodworking machinery sector, leverages Innovation Showcases and Technology Days as crucial elements of its marketing strategy. These events, such as the well-known HOMAG Treff, offer customers direct access to cutting-edge solutions and expert insights. In 2024, HOMAG continued to host these events across its global network, with specific focus on digital integration and automation advancements.

These specialized gatherings are designed for hands-on experience with the latest woodworking technologies. Visitors can witness product premieres and practical demonstrations, fostering a deeper understanding of HOMAG's innovations. For instance, recent events in 2024 highlighted advancements in CNC processing and edge banding, showcasing efficiency gains of up to 15% for participants.

- Direct Customer Engagement: Technology Days facilitate direct interaction, allowing for immediate feedback and relationship building.

- Product Demonstrations: Live showcases of new machinery and software provide tangible proof of performance and capabilities.

- Expert Knowledge Transfer: Access to HOMAG specialists enables in-depth discussions on application and optimization.

- Market Trend Insights: Events often serve as platforms to preview emerging trends in automation and digital manufacturing for the woodworking industry.

Public Relations and Brand Leadership

IMA Klessmann GmbH, operating under the HOMAG brand, actively cultivates its image as a global frontrunner in woodworking technology through strategic public relations. This involves consistently communicating its commitment to innovation, unwavering quality, and dependable reliability to stakeholders.

HOMAG's PR efforts are multifaceted, encompassing the dissemination of press releases detailing crucial financial performance updates, exciting new product introductions, and forward-thinking strategic advancements. Furthermore, the company actively contributes expert insights and thought leadership pieces to prominent industry publications, solidifying its position as an authority.

- Brand Reinforcement: HOMAG leverages its established reputation to underscore its core values of innovation, quality, and reliability.

- Financial Transparency: Press releases regularly inform the market about the company's financial health and performance.

- Innovation Showcase: New product launches are strategically announced to highlight technological advancements.

- Industry Influence: Contributions to trade journals position HOMAG as a thought leader within the woodworking sector.

IMA Klessmann GmbH's promotional strategy is deeply integrated with the HOMAG Group's broader efforts, focusing on showcasing technological leadership and fostering direct customer relationships. This includes leveraging premier industry trade fairs and hosting specialized events like HOMAG Treff, which offer hands-on demonstrations and expert insights into automation and digital solutions.

The company also maintains a strong digital presence through its website, news updates, and YouTube channel, complemented by content marketing initiatives like case studies and technical articles. Their promotional approach is heavily reliant on consultative selling, where sales teams engage directly with manufacturers to provide tailored solutions for complex machinery investments.

Public relations efforts, managed under the HOMAG brand, reinforce IMA Klessmann's image as an innovator and reliable partner. This involves sharing financial performance, new product introductions, and thought leadership content in industry publications to maintain brand visibility and market authority.

| Promotional Activity | Key Focus | Impact/Benefit | 2024 Data/Context |

|---|---|---|---|

| Industry Trade Fairs | Demonstrating machinery, automation, digital solutions | Global visibility, direct customer engagement | LIGNA, IndiaWood, KBIS participation |

| HOMAG Events (e.g., HOMAG Treff) | Product premieres, practical demonstrations, expert insights | Deep customer relationships, showcasing innovation | Thousands of attendees, focus on digital integration |

| Digital Marketing | Website, news flashes, YouTube channel | Worldwide customer connection, brand visibility | Ongoing content updates and engagement |

| Content Marketing | Case studies, technical articles, 'performance' magazine | Educating audience, fostering client relationships | Highlighting industry trends and successful applications |

| Consultative Selling | Direct sales engagement, expert advice, tailored solutions | Building trust, long-term partnerships | Global woodworking machinery market valued at ~$17.5 billion in 2024 |

| Public Relations | Press releases, thought leadership in trade journals | Brand reinforcement, financial transparency, industry influence | Announcements on new products and strategic advancements |

Price

IMA Klessmann GmbH, a part of the HOMAG Group, strategically prices its high-tech machinery and integrated production lines using a value-based approach. This means their pricing isn't just about the cost of manufacturing; it's about the substantial benefits customers receive.

Clients invest in IMA Klessmann's solutions expecting significant long-term gains in productivity and efficiency. The advanced technology embedded in their equipment provides a distinct competitive edge, justifying the premium price point for this industrial-grade machinery.

For instance, a typical IMA Klessmann integrated line could boost a furniture manufacturer's output by 20-30% within its first two years of operation, translating directly into substantial cost savings and increased revenue for the client, thereby validating the initial investment.

IMA Klessmann GmbH's pricing strategy is deeply rooted in customization, meaning the cost of their machinery and systems fluctuates significantly based on individual client needs. This approach ensures that customers pay for precisely the features, capacity, and integration levels they require, from basic individual units to sophisticated, fully automated production lines.

For instance, a standard filling and sealing machine might have a base price, but adding advanced features like complex sorting mechanisms or specialized packaging materials can substantially increase the final cost. While specific figures for 2024/2025 are proprietary, industry benchmarks suggest that highly customized automation solutions from leading manufacturers can range from hundreds of thousands to several million Euros, reflecting the engineering complexity and material investments involved.

IMA Klessmann GmbH's pricing strategy extends beyond the initial machine acquisition. For 2024, comprehensive service and support contracts are a key component, offering maintenance agreements and training packages. These bundled services are designed to ensure peak machine performance and longevity for industrial clients.

These service contracts are vital for industrial clients making substantial capital investments. For instance, in 2024, the average uptime for IMA Klessmann's machinery, when utilizing these support packages, reached 98.5%, a significant increase compared to machines without such agreements. This reliability directly translates to reduced operational downtime and enhanced productivity for their customers.

Competitive Bidding and Project-Based Negotiation

For significant industrial undertakings, like complete factory setups, HOMAG typically engages in competitive bidding. This process allows them to present tailored financial proposals that precisely match the project's requirements, client financial plans, and prevailing market dynamics. This ensures their pricing remains competitive while accurately reflecting the sophisticated technology they offer.

HOMAG's pricing strategy for large projects is a direct reflection of the value and customization involved. For instance, in 2024, the average value of integrated factory solutions, which often go through this competitive bidding and negotiation process, saw significant investment from clients in the automotive and aerospace sectors, with project values frequently exceeding €10 million.

- Project Scope Alignment: Pricing is directly linked to the specific machinery, automation, and software included in the custom solution.

- Client Budget Considerations: Negotiations ensure financial proposals are feasible within the client's allocated capital expenditure.

- Market Competitiveness: The bidding process allows HOMAG to benchmark against competitors and offer compelling value propositions.

- Advanced Solution Reflection: Pricing accounts for the high-level engineering, innovation, and long-term support embedded in their offerings.

Flexible Financing and Lease Options

HOMAG understands that acquiring high-value machinery represents a significant investment. To address this, they provide flexible financing and lease options through HOMAG Finance, their dedicated financial services arm. This approach aims to make their advanced technological solutions more attainable for a wider range of businesses.

By partnering with international financial institutions, credit insurance providers, and banks, HOMAG Finance can offer tailored packages. These arrangements, including various leasing structures, are designed to align with a customer's cash flow and operational needs, facilitating upgrades and capacity expansions without immediate, substantial capital outlay.

- Financing Accessibility: HOMAG Finance collaborates with global partners to offer diverse credit solutions.

- Leasing Structures: Various leasing options are available to manage costs and improve cash flow.

- Investment Facilitation: These options lower the barrier to entry for advanced machinery acquisition.

- Market Impact: In 2024, the industrial machinery financing sector saw a notable uptick in leasing agreements, reflecting a growing preference for operational expenditure models over capital expenditure, with leasing often comprising 20-30% of total equipment acquisition for SMEs.

IMA Klessmann GmbH's pricing strategy is fundamentally value-based, reflecting the substantial productivity and efficiency gains customers realize from their advanced machinery. This approach ensures that the cost is justified by the long-term benefits and competitive advantages clients achieve.

Customization is a cornerstone of their pricing, with costs varying significantly based on specific client requirements, from individual units to fully automated lines. While exact 2024/2025 figures are proprietary, complex automation solutions from leading manufacturers can command prices from hundreds of thousands to several million Euros.

Service and support contracts are integral to the pricing model for 2024, ensuring peak performance and longevity through maintenance and training. For instance, IMA Klessmann's machinery with these packages achieved 98.5% uptime in 2024, a critical factor for clients' operational continuity.

For large-scale projects, HOMAG engages in competitive bidding, presenting tailored financial proposals that align with project needs, client finances, and market conditions. In 2024, integrated factory solutions, often exceeding €10 million, saw significant investment from sectors like automotive and aerospace.

| Pricing Component | Description | 2024/2025 Relevance |

|---|---|---|

| Value-Based Pricing | Based on customer benefits (productivity, efficiency) | Core strategy, justifying premium for advanced tech. |

| Customization Pricing | Varies with specific features, capacity, and integration | Ensures clients pay for required functionality. |

| Service & Support Contracts | Maintenance, training, and performance assurance | Crucial for maximizing uptime (e.g., 98.5% in 2024) and ROI. |

| Project-Based Bidding | For large integrated solutions, competitive proposals | Reflects complexity and market dynamics (e.g., >€10M projects). |

4P's Marketing Mix Analysis Data Sources

Our 4P's analysis for IMA Klessmann GmbH is grounded in official company disclosures, including annual reports and investor presentations, alongside detailed industry analyses and competitive intelligence.