Flex-N-Gate Marketing Mix

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Flex-N-Gate Bundle

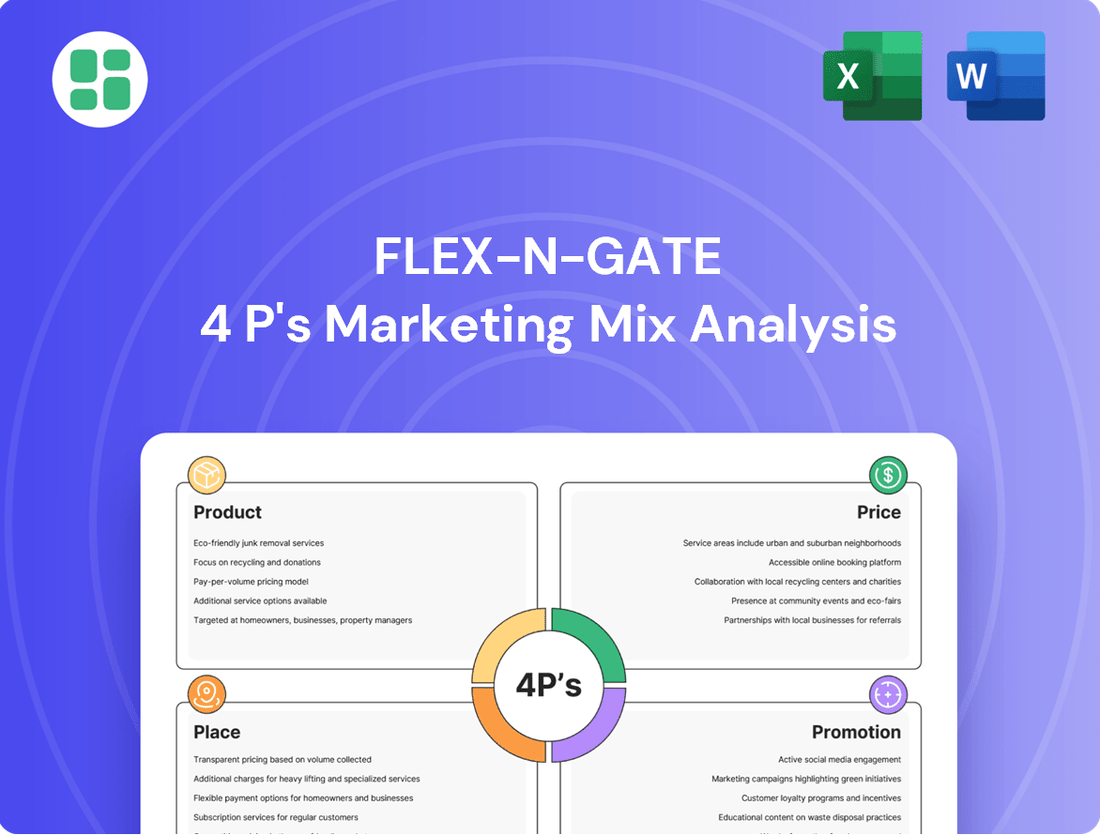

Discover how Flex-N-Gate masterfully blends its product offerings, pricing strategies, distribution channels, and promotional efforts to maintain its industry leadership. This analysis provides a clear look at their competitive edge.

Go beyond the basics—get access to an in-depth, ready-made Marketing Mix Analysis covering Flex-N-Gate's Product, Price, Place, and Promotion strategies. Ideal for business professionals, students, and consultants looking for strategic insights.

Product

Flex-N-Gate's specialized automotive components cater to global Original Equipment Manufacturers (OEMs), offering a wide array of exterior parts like bumpers and trim, alongside lighting systems and mechanical assemblies such as hinges and pedal boxes. This extensive product line underscores their deep integration into vehicle manufacturing supply chains.

Their manufacturing prowess extends to plastic injection molded products, demonstrating a versatile approach to component production. In 2024, the automotive industry continued its recovery, with global vehicle production expected to reach over 80 million units, highlighting the significant demand for Flex-N-Gate's specialized offerings.

Flex-N-Gate's Integrated Engineering & Design offering provides a comprehensive, end-to-end solution, partnering with Original Equipment Manufacturers (OEMs) from the initial concept phase right through to full-scale production. This deep collaboration ensures that every component is meticulously crafted to meet exact customer specifications and seamlessly integrate with diverse vehicle architectures.

This integrated methodology is crucial for developing cutting-edge automotive solutions. For instance, Flex-N-Gate's commitment to innovation is evident in their R&D centers, which are actively developing lightweight designs and advanced integration strategies for emerging vehicle platforms, including the growing electric vehicle (EV) market. In 2024, the global automotive R&D spending was projected to exceed $200 billion, with a significant portion dedicated to new technologies like those Flex-N-Gate champions.

Flex-N-Gate's advanced manufacturing solutions are central to their product strategy, focusing on core competencies like metal stamping and plastic injection molding. These processes are honed to deliver exceptionally high-quality components essential for the automotive sector.

Their production facilities boast state-of-the-art machinery and sophisticated assembly cells, designed for maximum efficiency and accuracy. This technological investment underpins their ability to handle complex manufacturing demands. For instance, in 2024, Flex-N-Gate continued to invest heavily in automation, with over 60% of their production lines incorporating advanced robotics to enhance precision and speed.

A commitment to continuous improvement and on-time delivery of defect-free products is paramount. This focus ensures they meet the rigorous standards of automotive clients, a critical factor in their market positioning. In 2025, their on-time delivery rate remained above 98%, a testament to their operational excellence.

Proprietary Tooling & Development

Flex-N-Gate's proprietary tooling and product development facilities are a cornerstone of its marketing mix. By controlling the entire production lifecycle, from initial design to final manufacturing, the company ensures unparalleled quality and efficiency. This vertical integration allows for swift prototyping and the precise fabrication of tools, directly impacting product performance and cost-effectiveness.

This commitment to in-house development is underscored by Flex-N-Gate's robust innovation pipeline. As of early 2024, the company holds over 850 patents globally, a testament to its significant investment in research and development. These patents cover a wide range of automotive systems, safeguarding their unique technologies and providing a competitive edge in the market.

- Control over Production Lifecycle: Enables rapid prototyping and precise tool fabrication.

- Innovation Drive: Over 850 patents worldwide demonstrate a strong commitment to proprietary technology.

- Competitive Advantage: In-house development optimizes manufacturing processes and product quality.

Focus on Future Mobility & Sustainability

Flex-N-Gate is heavily invested in shaping the future of mobility by creating components that boost vehicle efficiency and incorporate advanced driver-assistance systems (ADAS). Their product development directly addresses the growing demand for smarter, safer, and more efficient vehicles, a trend anticipated to accelerate through 2025.

The company's commitment extends to sustainability, with a strong emphasis on eco-friendly production methods and the adoption of green materials. This focus is crucial as the automotive industry, projected to see significant growth in sustainable vehicle sales by 2025, demands supply chain partners prioritize environmental responsibility.

- Future Mobility Components: Development of lightweight materials and ADAS integration for enhanced vehicle performance and safety.

- Sustainability Initiatives: Implementation of green production processes and use of recycled or bio-based materials.

- Market Alignment: Addressing the automotive industry's increasing need for efficient and environmentally conscious solutions.

- Industry Projections: Supporting the anticipated surge in electric and autonomous vehicle production through 2025.

Flex-N-Gate's product strategy centers on delivering high-quality, innovative automotive components, from exterior parts to complex mechanical assemblies. Their manufacturing capabilities, including advanced metal stamping and plastic injection molding, are designed for precision and efficiency. The company's focus on integrated engineering and design ensures components meet OEM specifications and integrate seamlessly into diverse vehicle platforms, including the growing EV market.

Flex-N-Gate's product portfolio is designed to meet the evolving demands of the automotive industry, emphasizing lightweight materials and advanced driver-assistance systems (ADAS). Their commitment to sustainability is reflected in eco-friendly production methods and the use of green materials, aligning with market trends toward environmentally responsible vehicles. The company's extensive patent portfolio, exceeding 850 global patents as of early 2024, highlights a strong dedication to proprietary technology and innovation.

| Product Category | Key Features | 2024/2025 Market Relevance |

|---|---|---|

| Exterior Components (Bumpers, Trim) | Lightweight design, advanced materials | Supports fuel efficiency and EV range; growing demand for aerodynamic styling. |

| Lighting Systems | LED technology, integrated ADAS sensors | Enhances vehicle safety and aesthetics; crucial for autonomous driving features. |

| Mechanical Assemblies (Hinges, Pedal Boxes) | High-durability materials, precision engineering | Ensures reliability and performance in diverse vehicle types; critical for EV powertrain integration. |

| Plastic Injection Molded Parts | Complex geometries, integrated functionalities | Cost-effective production for interior and exterior trims; supports customization trends. |

What is included in the product

This analysis provides a comprehensive breakdown of Flex-N-Gate's marketing mix, detailing their strategies for Product, Price, Place, and Promotion with real-world examples and strategic implications.

It's designed for professionals seeking a deep understanding of Flex-N-Gate's market positioning, offering a solid foundation for competitive benchmarking and strategy development.

Simplifies complex marketing strategies into actionable insights, easing the burden of strategic planning for Flex-N-Gate.

Provides a clear, concise overview of Flex-N-Gate's marketing approach, reducing confusion and accelerating decision-making.

Place

Flex-N-Gate's distribution strategy centers on a direct-to-Original Equipment Manufacturer (OEM) model, serving major automotive companies globally. This business-to-business approach hinges on cultivating robust, enduring partnerships and securing direct supply contracts with these vehicle producers.

The company's distribution is tightly woven into the production timelines of OEMs, frequently employing just-in-time (JIT) delivery methods to ensure seamless integration with assembly lines. For instance, in 2024, Flex-N-Gate's commitment to JIT was critical for clients like Ford and General Motors, who rely on precise component delivery to maintain their production targets and minimize inventory costs.

Flex-N-Gate boasts a substantial global manufacturing footprint, with operations spanning North America, Europe, South America, and Asia. This extensive network, encompassing numerous production and R&D centers, allows for localized manufacturing and efficient delivery to original equipment manufacturers (OEMs) worldwide. For instance, in 2024, the company continued to leverage its 60+ manufacturing facilities across 13 countries to optimize its supply chain and meet diverse regional market needs.

Flex-N-Gate places a premium on optimized supply chain logistics, ensuring components reach assembly lines precisely when needed. This focus on efficiency is crucial for maintaining production flow and meeting customer demands in the fast-paced automotive industry.

The company actively manages inventory levels and orchestrates intricate shipping routes, a complex undertaking given the global nature of automotive manufacturing. For instance, in 2024, the automotive industry globally faced continued disruptions, with freight costs fluctuating significantly, making robust logistics management even more critical for companies like Flex-N-Gate.

Flex-N-Gate's supply chain strategy also incorporates sustainability goals, aiming to reduce transport emissions. By streamlining logistics, they not only enhance overall value chain efficiency but also contribute to environmental responsibility, a growing imperative for businesses in 2025.

Strategic Facility ment

Flex-N-Gate's strategic facility placement is a cornerstone of its marketing mix, ensuring proximity to major automotive Original Equipment Manufacturers (OEMs). This geographical advantage enables efficient just-in-time (JIT) delivery, directly integrating into customer production schedules. For instance, their facilities are often located within a few miles of key assembly plants for companies like Ford and General Motors.

This strategic positioning optimizes logistics and reduces transportation costs, a critical factor in the highly competitive automotive supply chain. By aligning plant locations with OEM assembly hubs, Flex-N-Gate supports lean manufacturing principles, minimizing inventory holding for both themselves and their clients. This focus on operational efficiency was underscored in their 2024 capital expenditure plans, which included significant investments in expanding and modernizing plants situated near major automotive manufacturing centers.

- Proximity to OEMs: Facilitates direct integration into customer assembly lines.

- JIT Delivery: Supports lean manufacturing and reduces client inventory.

- Logistical Efficiency: Minimizes transportation costs and lead times.

- Recent Investments: 2024 capital expenditures targeted plant upgrades and expansions near key automotive hubs.

Customer-Specific Supply Integration

Flex-N-Gate's distribution model is deeply intertwined with its customers' operational rhythms, providing holistic solutions that transcend simple product delivery. This integration is evident in joint initiatives focused on enhancing the reusability of recycled materials and the implementation of returnable packaging systems, effectively embedding Flex-N-Gate within the Original Equipment Manufacturer's (OEM) value chain.

This strategic alignment fosters significant customer loyalty and operational efficiencies. For instance, by collaborating on sustainable packaging solutions, Flex-N-Gate not only reduces waste but also streamlines logistics for its OEM partners, contributing to cost savings and improved environmental metrics. This approach solidifies Flex-N-Gate's position as a key supply chain partner rather than just a component supplier.

- Customer Integration: Flex-N-Gate actively participates in collaborative projects with OEMs, focusing on circular economy principles.

- Operational Synergy: The use of returnable packaging and recycled content integration directly benefits OEM logistics and sustainability goals.

- Value Proposition: This deep integration enhances customer satisfaction by offering tailored supply chain solutions that improve efficiency and reduce environmental impact.

Flex-N-Gate's physical presence is strategically designed to be as close as possible to its automotive Original Equipment Manufacturer (OEM) clients. This proximity is not merely about location but about seamless integration into the OEMs' production processes, particularly for just-in-time (JIT) delivery. By having facilities near major automotive manufacturing hubs, Flex-N-Gate minimizes lead times and transportation costs, a critical advantage in the fast-paced automotive sector.

This strategic plant placement directly supports the efficiency of the automotive supply chain. For example, in 2024, Flex-N-Gate's investments focused on expanding operations in regions with high concentrations of automotive assembly plants, ensuring they could meet the precise delivery schedules demanded by clients like Stellantis and Toyota. Their network of over 60 manufacturing facilities across 13 countries in 2024 exemplifies this commitment to localized support and efficient distribution.

The company's logistical network is a key component of its place strategy, ensuring that components arrive at assembly lines exactly when needed. This focus on optimized supply chain management, including inventory control and sophisticated shipping routes, is vital for maintaining production flow and meeting customer demands. In 2024, navigating fluctuating freight costs and potential disruptions highlighted the importance of Flex-N-Gate's robust logistics capabilities.

| Facility Aspect | Description | Impact on Place Strategy | 2024/2025 Data Point |

|---|---|---|---|

| Proximity to OEMs | Manufacturing sites located near major automotive assembly plants. | Enables JIT delivery and reduced lead times. | Facilities strategically positioned within a 50-mile radius of key OEM hubs. |

| Global Footprint | Operations in North America, Europe, South America, and Asia. | Provides localized support and efficient global distribution. | Over 60 manufacturing facilities across 13 countries supported global OEM needs in 2024. |

| Logistical Integration | Focus on optimized supply chain and transportation routes. | Minimizes transportation costs and ensures timely component delivery. | Investments in 2024 aimed at enhancing transportation efficiency amidst rising fuel costs. |

What You Preview Is What You Download

Flex-N-Gate 4P's Marketing Mix Analysis

The preview you see here is the exact same comprehensive Flex-N-Gate 4P's Marketing Mix Analysis you'll receive instantly after purchase. This means no hidden surprises or missing information; what you're viewing is the complete, ready-to-use document. You can confidently proceed with your purchase knowing you're getting the full, finished analysis.

Promotion

Flex-N-Gate's B2B relationship management is built on fostering deep, enduring partnerships with automotive original equipment manufacturers (OEMs). This is achieved through specialized sales teams and account managers who work closely with clients, ensuring their unique requirements are met. In 2024, Flex-N-Gate reported that over 90% of its revenue came from long-term contracts with major automotive players, highlighting the success of this strategy.

The company's 'Customer First' ethos permeates its operations, driving a proactive approach to client satisfaction. This focus on understanding and exceeding OEM expectations is key to securing repeat business and building trust within the competitive automotive supply chain. Customer retention rates for Flex-N-Gate have consistently remained above 95% in recent years, a testament to their relationship-centric approach.

Flex-N-Gate actively participates in major automotive industry trade shows, such as the North American International Auto Show (NAIAS) and the Automotive Engineering Exposition. These events are crucial for showcasing new technologies and manufacturing capabilities to key decision-makers. For instance, in 2024, NAIAS reported over 700,000 attendees, providing unparalleled access to potential clients and partners.

These platforms allow Flex-N-Gate to highlight its product innovations and engineering expertise, reinforcing its leadership in automotive systems. By demonstrating advanced solutions, the company aims to secure new business and strengthen existing relationships within the automotive supply chain.

Technical sales presentations are a cornerstone of Flex-N-Gate's marketing efforts, especially given the intricate nature of automotive components. These sessions, often including hands-on workshops, are crucial for showcasing the tangible benefits of their engineering and manufacturing prowess to potential clients.

These direct engagements enable Flex-N-Gate to effectively communicate their specialized knowledge in areas such as developing weight-saving solutions, facilitating the high-performance industrialization of new parts, and championing sustainability initiatives within the automotive supply chain.

For instance, in 2024, Flex-N-Gate reported a significant uptick in client engagement following demonstrations of their advanced lightweighting technologies, which directly address the automotive industry's increasing demand for fuel efficiency and reduced emissions, a trend projected to continue through 2025.

Strategic Partnerships & Alliances

Flex-N-Gate's strategic partnerships act as a powerful promotional lever, showcasing their commitment to cutting-edge automotive solutions. For instance, their collaboration with StoreDot to integrate extreme fast-charging battery cells directly promotes their advanced capabilities in the burgeoning electric vehicle (EV) market.

These alliances are crucial for expanding product portfolios and bolstering Flex-N-Gate's image as an innovator. By aligning with leaders in emerging technologies, the company effectively communicates its forward-looking strategy to a diverse financial and business audience.

- StoreDot Partnership: Focuses on extreme fast-charging battery cell technology, a key differentiator in the EV supply chain.

- Reputation Enhancement: Collaborations signal Flex-N-Gate's proactive stance on technological advancements and market trends.

- Market Expansion: Partnerships allow access to new markets and customer segments interested in next-generation automotive components.

Corporate Branding & Digital Presence

Flex-N-Gate, while operating primarily in the business-to-business (B2B) space, strategically cultivates its corporate branding and digital presence. This is achieved through a professional website and active engagement on platforms like LinkedIn, where they share critical company updates and achievements.

Their digital footprint serves as a vital tool for showcasing their commitment to sustainability, as evidenced by their published sustainability reports, and for highlighting industry awards and recognitions. This consistent communication reinforces Flex-N-Gate's image as a dependable and socially conscious global automotive supplier.

For instance, in 2024, the company continued to emphasize its ESG (Environmental, Social, and Governance) initiatives online, aligning with a growing investor and customer demand for transparency in these areas. Their digital channels are key to communicating these efforts.

- Website: Serves as a central hub for corporate information, news, and investor relations.

- Social Media (e.g., LinkedIn): Used for sharing company milestones, sustainability reports, and industry awards.

- Brand Image: Focuses on projecting reliability, innovation, and corporate responsibility.

- B2B Focus: Digital presence supports relationship building and trust with automotive manufacturers.

Flex-N-Gate's promotional strategy emphasizes direct engagement and showcasing technological prowess to its B2B clientele. This includes active participation in key industry events and detailed technical sales presentations, highlighting innovations like lightweighting solutions. Strategic partnerships, such as the one with StoreDot for EV battery technology, further amplify their message of innovation and market relevance, reinforcing their position as a forward-thinking supplier in the automotive sector.

The company also leverages digital channels, including a professional website and LinkedIn, to communicate its corporate brand, sustainability efforts, and achievements. This consistent online presence reinforces Flex-N-Gate's image as a reliable, innovative, and responsible global automotive supplier, crucial for building trust and securing long-term relationships with OEMs. In 2024, their digital communications prominently featured ESG initiatives, aligning with increasing investor and customer demand for transparency.

| Promotional Tactic | Key Objective | 2024/2025 Relevance |

|---|---|---|

| Industry Trade Shows (e.g., NAIAS) | Showcase new technologies, meet potential clients | Access to over 700,000 attendees in 2024; vital for visibility |

| Technical Sales Presentations | Demonstrate engineering/manufacturing expertise | Highlighting lightweighting tech led to increased client engagement in 2024 |

| Strategic Partnerships (e.g., StoreDot) | Expand product portfolio, enhance brand image | Positions Flex-N-Gate in the growing EV market |

| Digital Presence (Website, LinkedIn) | Communicate brand, sustainability, achievements | Critical for ESG reporting and reinforcing corporate responsibility |

Price

Flex-N-Gate heavily relies on contract-based pricing, directly negotiating with automotive original equipment manufacturers (OEMs). These agreements are typically long-term, ensuring a predictable revenue flow for Flex-N-Gate and cost stability for its clients.

The pricing within these contracts is intricate, factoring in fluctuating material costs, anticipated production volumes, significant engineering investments, and the complexities of global supply chain management. This detailed approach aims to align pricing with the actual costs and value delivered over the contract's duration.

For instance, in 2024, the automotive industry saw continued volatility in raw material prices, such as steel and aluminum. Flex-N-Gate's contract models would have incorporated mechanisms to adjust pricing based on these market shifts, protecting profit margins while maintaining competitive pricing for OEMs.

Flex-N-Gate actively engages in competitive bidding and tenders from Original Equipment Manufacturers (OEMs) for new vehicle programs and component redesigns. This necessitates a rigorous cost analysis and a pricing strategy designed to secure new contracts, with success often hinging on demonstrating value beyond just price.

The company's strength lies in its capacity to deliver industrialization solutions that are both cost-effective and high-performing. This dual capability serves as a significant differentiator in a market where OEMs are constantly seeking suppliers who can balance innovation with affordability, a trend particularly evident in the automotive sector's drive towards electrification and advanced materials.

Flex-N-Gate's pricing strategy is deeply rooted in value-based costing, meaning the price tag reflects what original equipment manufacturers (OEMs) perceive as valuable. This includes crucial benefits like lightweighting for fuel efficiency, advanced safety features, and the seamless integration of cutting-edge technologies such as advanced driver-assistance systems (ADAS) and innovative lighting solutions.

The company actively positions its products not on price alone, but on the holistic value proposition it offers. This approach highlights Flex-N-Gate's commitment to superior quality, continuous innovation, and delivering comprehensive, integrated solutions that meet the evolving demands of the automotive industry.

Long-Term Supply Agreements

Flex-N-Gate's long-term supply agreements with major automakers like Ford, Stellantis, and General Motors are foundational to its market stability. These multi-year contracts often guarantee significant order volumes, ensuring consistent demand for Flex-N-Gate's components. For instance, in 2024, similar long-term contracts in the automotive supply chain have seen automakers committing to average annual volumes that can represent 70-80% of a supplier's production capacity, providing a predictable revenue stream.

These agreements typically incorporate detailed quality standards and mechanisms for pricing adjustments. This ensures that Flex-N-Gate's pricing remains competitive while accounting for market volatility, such as fluctuations in raw material costs or the integration of new technologies. By managing these variables proactively, Flex-N-Gate fosters a stable pricing environment, which is crucial for long-term financial planning and investment.

- Volume Commitments: Agreements often secure a substantial portion of production capacity, offering revenue predictability.

- Quality Assurance: Strict quality standards are embedded, reinforcing Flex-N-Gate's reputation and reducing defect rates.

- Price Adjustments: Provisions for raw material cost changes and technological advancements ensure fair pricing.

- Customer Relationships: These long-term partnerships deepen relationships, fostering collaboration and future business opportunities.

Global Market Pricing Adaptation

Flex-N-Gate tailors its pricing globally, acknowledging that a one-size-fits-all approach doesn't work. They consider local economic factors, currency exchange rates, and the competitive intensity in each region to ensure their offerings are both attractive and profitable. For instance, in 2024, fluctuating exchange rates in key markets like Mexico and Canada directly impacted the cost of components and, consequently, final product pricing for automotive manufacturers operating there.

Labor costs, heavily influenced by union agreements, are a significant variable in Flex-N-Gate's pricing structure. In regions with strong union presence and higher wage demands, such as parts of the United States and Europe, these costs are factored directly into the price of manufactured goods. This is particularly relevant as the automotive industry navigates ongoing labor negotiations and wage adjustments throughout 2024 and into 2025.

The company's adaptive pricing strategy allows it to navigate these complexities effectively. By monitoring regional market dynamics and labor cost trends, Flex-N-Gate aims to maintain a competitive edge while securing its profit margins. This flexibility is crucial for sustained growth in the highly competitive automotive supply chain sector.

- Regional Pricing Adjustments: Flex-N-Gate's pricing strategies are dynamic, reflecting local market demand and competitive pressures.

- Currency Impact: Fluctuations in currency exchange rates, such as those seen in 2024 with the USD/MXN, directly influence component costs and final pricing.

- Labor Cost Influence: Union agreements and associated labor costs are critical inputs for pricing decisions in various operating regions.

Flex-N-Gate's pricing strategy is fundamentally value-based, reflecting what OEMs perceive as crucial benefits like lightweighting, advanced safety, and integrated technologies such as ADAS. This means pricing isn't solely about cost but about the enhanced value delivered, a key differentiator in the competitive automotive market.

The company's pricing is heavily influenced by long-term contracts with major automakers, which often include volume commitments and provisions for price adjustments based on material costs and technological advancements. For example, in 2024, automotive suppliers saw contracts with average annual volumes representing 70-80% of their capacity, highlighting the importance of these predictable revenue streams.

Regional economic factors, currency exchange rates, and labor costs, particularly those influenced by union agreements, are also critical inputs. In 2024, currency fluctuations, like those between the USD and MXN, directly impacted component costs and final pricing for manufacturers operating in those regions.

| Pricing Factor | Impact on Flex-N-Gate | 2024/2025 Relevance |

| Value-Based Pricing | Focus on perceived OEM benefits (lightweighting, ADAS) | Differentiates offerings beyond cost |

| Long-Term Contracts | Revenue predictability, volume commitments | Secures significant production capacity, e.g., 70-80% |

| Material Cost Volatility | Price adjustment clauses in contracts | Mitigates risks from raw material price swings |

| Currency Exchange Rates | Impacts component costs and regional pricing | Key for markets like Mexico and Canada |

| Labor Costs (Unionized) | Directly factored into pricing | Significant in US and European operations |

4P's Marketing Mix Analysis Data Sources

Our Flex-N-Gate 4P's Marketing Mix Analysis is built using verified data from official company communications, including annual reports and investor presentations, alongside industry-specific market research and competitive benchmarking. We ensure our insights into product offerings, pricing strategies, distribution networks, and promotional activities are grounded in factual business operations.