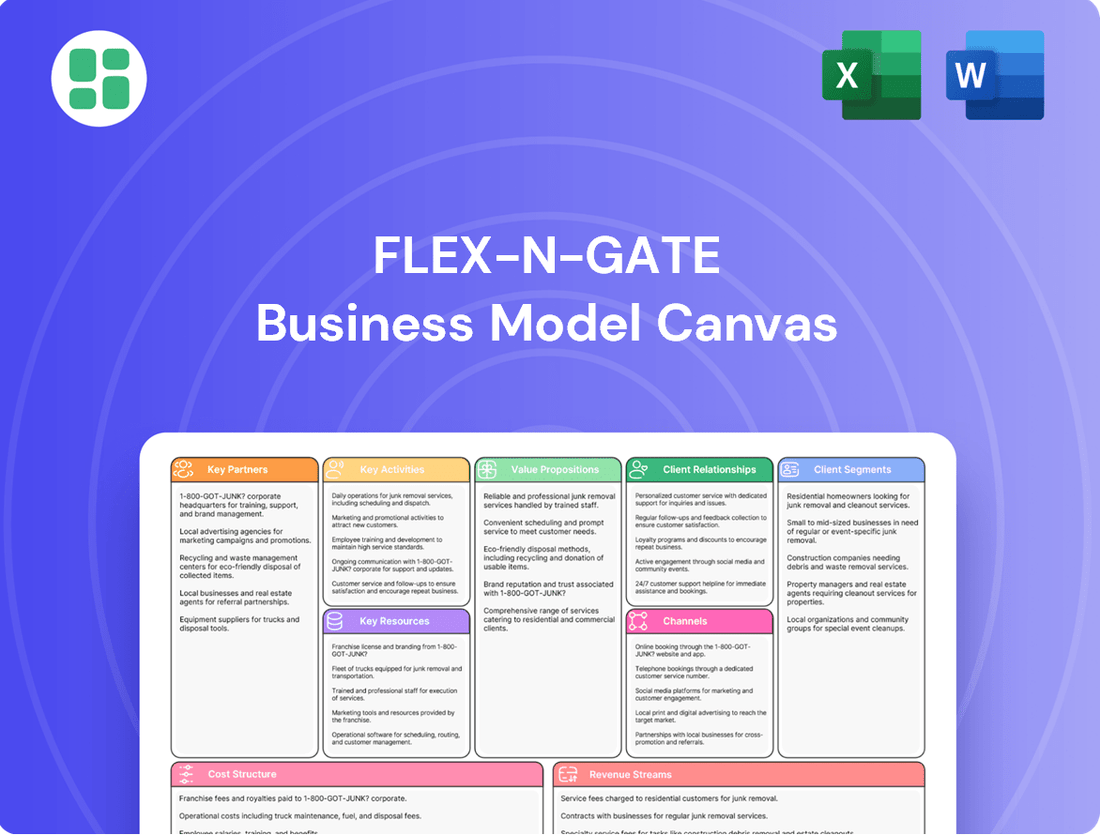

Flex-N-Gate Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Flex-N-Gate Bundle

Uncover the strategic genius behind Flex-N-Gate's operational success with our comprehensive Business Model Canvas. This detailed breakdown illuminates their customer relationships, revenue streams, and key resources, offering a clear roadmap to their market dominance.

Want to dissect Flex-N-Gate's winning formula? Our full Business Model Canvas provides an in-depth, section-by-section analysis, revealing their core activities and cost structure. Download it now to gain actionable insights for your own business strategy.

Partnerships

Flex-N-Gate's core strength lies in its deep relationships with major automotive Original Equipment Manufacturers (OEMs) globally. These collaborations are essential for their business, as Flex-N-Gate provides a full spectrum of engineering, design, and manufacturing services tailored to OEM needs.

Securing long-term contracts with these automotive giants is paramount. It allows Flex-N-Gate to embed its components into the development cycles of new vehicle platforms, ensuring consistent business and market presence. For instance, in 2024, Flex-N-Gate highlighted its role in supplying critical components for several new model year vehicle launches from prominent OEMs, underscoring the ongoing nature of these vital partnerships.

Flex-N-Gate relies heavily on a diverse network of suppliers for critical raw materials like steel, aluminum, and various plastics, as well as specialized components such as lighting systems and electronic modules. In 2024, the automotive industry continued to navigate supply chain volatility, making strong supplier relationships paramount for ensuring consistent production. For instance, disruptions in global steel markets directly impact the cost of automotive body components, a core product for Flex-N-Gate.

Flex-N-Gate’s collaborations with technology and innovation partners are crucial, particularly as the automotive sector embraces electric vehicles and sophisticated systems. These alliances allow the company to embed advanced technologies into its product lines, ensuring it remains competitive.

A prime example is Flex-N-Gate's strategic partnership with StoreDot. This collaboration focuses on the mass production of extreme fast-charging battery cells, with a target for readiness by 2025. This initiative directly addresses the growing demand for faster EV charging solutions.

Tooling and Equipment Providers

Flex-N-Gate's reliance on its internal tooling and product development capabilities necessitates robust alliances with specialized tooling and equipment suppliers. These partnerships are fundamental for securing cutting-edge manufacturing technologies and machinery, vital for achieving the high precision and efficiency required in producing intricate automotive parts. In 2024, the global industrial automation market, which includes advanced tooling and machinery, was projected to reach over $200 billion, highlighting the critical nature of these supplier relationships for companies like Flex-N-Gate.

These collaborations ensure Flex-N-Gate can consistently access state-of-the-art equipment, which directly impacts their capacity to innovate and deliver complex components. This access to advanced manufacturing solutions allows them to maintain a competitive edge and offer integrated solutions to original equipment manufacturers (OEMs).

- Access to Advanced Technology: Partnerships provide Flex-N-Gate with the latest in tooling and machinery, enabling the production of highly complex and precise automotive components.

- Efficiency and Precision: Reliable equipment suppliers are key to optimizing manufacturing processes, reducing lead times, and ensuring the high quality demanded by OEMs.

- Innovation Support: Collaboration with equipment providers fosters innovation, allowing Flex-N-Gate to adopt new manufacturing techniques and develop next-generation automotive parts.

- Comprehensive Solutions: By leveraging strong supplier relationships, Flex-N-Gate can offer end-to-end product development and manufacturing services to their automotive clients.

Logistics and Distribution Partners

Flex-N-Gate relies heavily on a robust network of logistics and distribution partners to ensure critical automotive components reach Original Equipment Manufacturer (OEM) assembly lines worldwide, often adhering to strict just-in-time delivery schedules. These collaborations are essential for managing the complex, cross-border movement of goods efficiently and cost-effectively, underpinning Flex-N-Gate's global operational capabilities. A prime example of this is their extensive use of third-party logistics providers (3PLs) who manage warehousing and transportation, ensuring parts are available precisely when needed on the production floor.

The effectiveness of these partnerships directly impacts Flex-N-Gate's ability to maintain seamless production flows and meet fluctuating customer demands. For instance, in 2024, the automotive industry saw continued emphasis on supply chain resilience, with companies like Flex-N-Gate leveraging advanced tracking and inventory management systems integrated with their logistics partners to mitigate potential disruptions. The timely delivery of components, such as stamped metal parts and plastic molded assemblies, is paramount to avoiding costly line stoppages for OEMs.

- Global Reach: Partnerships with carriers like FedEx, UPS, and specialized freight forwarders facilitate international shipments, connecting Flex-N-Gate’s manufacturing facilities with OEM plants across North America, Europe, and Asia.

- Just-in-Time (JIT) Execution: Collaboration with logistics providers enables the precise scheduling and delivery of components, minimizing inventory holding costs for both Flex-N-Gate and its automotive clients.

- Supply Chain Visibility: Integration of real-time tracking and data sharing with logistics partners provides crucial visibility into shipment status, allowing for proactive management of potential delays.

- Cost Optimization: Strategic selection of logistics partners based on route density, service levels, and pricing models helps to control transportation expenses, a significant factor in overall production costs.

Flex-N-Gate's key partnerships are foundational to its operational success and market position. These include deep, long-standing relationships with major automotive OEMs, ensuring consistent business through embedded component supply. The company also relies on a robust network of suppliers for raw materials and specialized parts, a crucial element given the 2024 automotive industry's focus on supply chain resilience.

Strategic alliances with technology innovators, such as the collaboration with StoreDot for extreme fast-charging battery cells, are vital for staying ahead in the EV market. Furthermore, partnerships with specialized tooling and equipment suppliers are essential for maintaining manufacturing precision and adopting advanced production techniques, a sector projected to exceed $200 billion in 2024.

Finally, strong ties with logistics and distribution providers are critical for efficient, just-in-time global delivery, enabling Flex-N-Gate to meet the demanding schedules of its OEM clients and navigate supply chain complexities effectively.

What is included in the product

This Flex-N-Gate Business Model Canvas provides a detailed, 9-block overview of their operations, focusing on their value proposition as a global automotive supplier and their extensive customer relationships.

It outlines Flex-N-Gate's strategy for manufacturing and supplying automotive components, detailing key partners, resources, and revenue streams to support their growth in the automotive industry.

Flex-N-Gate's Business Model Canvas acts as a pain point reliever by providing a clear, one-page snapshot of their complex operations, allowing for rapid identification of inefficiencies and areas for improvement.

It streamlines strategic planning by condensing Flex-N-Gate's intricate business model into an easily digestible format, facilitating quicker decision-making and adaptation to market changes.

Activities

Flex-N-Gate's core activities revolve around intensive research and development, driving innovation in automotive components and systems. This commitment to R&D is crucial for staying ahead in a rapidly evolving industry.

The company excels in advanced product engineering, design, and prototyping, often working hand-in-hand with Original Equipment Manufacturers (OEMs). This collaborative approach ensures their solutions meet specific customer needs and industry standards.

A significant focus is placed on developing solutions for future mobility trends, such as lightweighting materials and integrating multiple functions into single components. For instance, in 2024, Flex-N-Gate continued to invest heavily in materials science to reduce vehicle weight, contributing to improved fuel efficiency and electric vehicle range.

Flex-N-Gate's manufacturing prowess is the engine of its business, focusing on the high-volume production of critical automotive components like bumpers, exterior trim, lighting, and intricate plastic injection molded parts. This global network of production facilities is designed for efficiency and quality, meeting the rigorous demands of the automotive sector.

The company's diverse manufacturing capabilities span plastics, metals, lighting systems, and complex mechanical assemblies, enabling them to serve a broad spectrum of automotive needs. In 2024, Flex-N-Gate continued to invest in advanced manufacturing technologies to enhance production speed and precision across its extensive global footprint.

Flex-N-Gate's commitment to tooling and product development is central to its operations. The company maintains its own specialized facilities for creating the unique molds and equipment essential for manufacturing automotive components. This in-house approach ensures meticulous quality control and accelerates the design refinement process.

This direct control over tooling development allows Flex-N-Gate to rapidly iterate on product designs and craft bespoke solutions that precisely meet the specific needs of Original Equipment Manufacturers (OEMs). For instance, in 2024, their investment in advanced prototyping equipment enabled them to reduce the lead time for new component tooling by an average of 15% compared to previous years, directly supporting their ability to offer comprehensive, tailored solutions.

Supply Chain Management

Flex-N-Gate's key activity of supply chain management is crucial for its operations. This involves the intricate process of procuring raw materials, meticulously managing inventory levels, and coordinating global logistics to ensure a seamless flow of components to manufacturing facilities. In 2024, the automotive supply chain faced significant challenges, including ongoing semiconductor shortages and increased raw material costs, making efficient management even more vital.

Effective supply chain management directly impacts Flex-N-Gate's ability to meet Original Equipment Manufacturer (OEM) demands. This includes not only the timely delivery of finished automotive parts but also the strategic sourcing of materials and the cultivation of strong supplier relationships. For instance, the company's reliance on global suppliers means navigating diverse regulatory environments and transportation networks, a complexity amplified by geopolitical events that can disrupt shipping routes.

- Procurement: Sourcing high-quality raw materials like steel and aluminum from a global network of suppliers.

- Inventory Management: Optimizing stock levels to minimize holding costs while preventing production stoppages.

- Logistics Coordination: Managing the transportation of raw materials and finished goods across international borders, ensuring timely delivery to customers.

- Supplier Relationship Management: Building and maintaining strong partnerships with key suppliers to ensure reliability and competitive pricing.

Quality Control and Assurance

Flex-N-Gate’s commitment to quality control and assurance is deeply embedded in its operations, ensuring that every component meets rigorous automotive standards. This focus is critical for maintaining customer trust and loyalty in a highly competitive market.

The company employs comprehensive checks at every stage of production, from raw material inspection to final product testing. This meticulous approach aims to deliver defect-free components consistently, supporting Flex-N-Gate’s reputation for reliability.

- Zero Defects Goal: Flex-N-Gate actively pursues a zero-defects philosophy, striving for perfection in all manufactured parts.

- Continuous Improvement: The company invests in advanced technologies and employee training to foster a culture of ongoing quality enhancement.

- Customer Satisfaction: By consistently delivering high-quality, on-time products, Flex-N-Gate strengthens its relationships with major automotive manufacturers, contributing to their production efficiency.

Flex-N-Gate's key activities are centered on innovation, manufacturing excellence, and robust supply chain management. The company dedicates significant resources to research and development, focusing on advanced materials and future mobility solutions, such as lightweighting. Its manufacturing operations are extensive, producing a wide array of automotive components globally, supported by in-house tooling development for rapid prototyping and customization.

Quality control is paramount, with a commitment to zero defects and continuous improvement across all production stages. This comprehensive approach ensures that Flex-N-Gate consistently delivers high-quality parts, meeting the stringent demands of Original Equipment Manufacturers (OEMs) and fostering strong customer relationships. In 2024, the company continued its strategic investments in advanced manufacturing technologies to maintain its competitive edge.

| Key Activity | Description | 2024 Focus/Data |

| Research & Development | Innovation in automotive components and systems. | Continued investment in materials science for lightweighting and future mobility solutions. |

| Manufacturing | High-volume production of automotive components (bumpers, lighting, etc.). | Investment in advanced manufacturing technologies across global facilities. |

| Tooling & Product Development | In-house creation of molds and equipment for component manufacturing. | 15% average reduction in lead time for new component tooling. |

| Supply Chain Management | Procurement, inventory, and logistics coordination. | Navigating semiconductor shortages and raw material cost increases. |

| Quality Control & Assurance | Ensuring components meet rigorous automotive standards. | Pursuit of zero defects and continuous improvement initiatives. |

Full Document Unlocks After Purchase

Business Model Canvas

The Flex-N-Gate Business Model Canvas preview you are viewing is the actual document you will receive upon purchase. This means you are seeing the exact structure, content, and formatting that will be yours to use. There are no altered samples or mockups; what you see is precisely what you get, ready for your strategic planning.

Resources

Flex-N-Gate's global manufacturing facilities form a critical backbone, with a vast network spanning North America, Europe, and beyond. These integrated sites handle everything from plastics and metals to lighting and mechanical assembly, ensuring a comprehensive production capability.

This extensive footprint, comprising numerous sites worldwide, empowers Flex-N-Gate to deliver just-in-time to automotive original equipment manufacturers (OEMs) globally. For instance, in 2024, the company continued to leverage this network to meet the dynamic demands of the automotive sector, facilitating efficient supply chains.

Flex-N-Gate relies heavily on a highly skilled workforce, encompassing engineers, designers, manufacturing specialists, and technical staff. This expertise is fundamental to their operations, particularly in areas like automotive systems, materials science, and efficient production processes. Their knowledge directly fuels innovation and maintains the high quality and efficiency expected in the automotive sector.

The company's commitment to its employees is underscored by recent labor agreements, which acknowledge the vital role this skilled workforce plays. For instance, in 2024, significant agreements were reached with various unions, ensuring competitive wages and benefits, which are crucial for retaining top talent in a demanding industry. These agreements reflect the substantial human capital investment required to maintain Flex-N-Gate's competitive edge.

Flex-N-Gate's intellectual property, encompassing numerous patents and proprietary manufacturing techniques for automotive components, forms a crucial pillar of its business model. This IP allows them to differentiate their offerings, providing advanced and unique solutions that set them apart in the competitive automotive supply chain.

The company's commitment to continuous innovation directly fuels the growth of this valuable asset base. For instance, in 2024, Flex-N-Gate continued to invest heavily in research and development, securing new patents related to lightweight materials and advanced assembly processes, further solidifying their competitive edge.

Advanced Machinery and Tooling

Flex-N-Gate's commitment to advanced machinery and tooling is a cornerstone of its business model, directly impacting its ability to deliver complex automotive components at scale. This investment ensures they can meet the rigorous demands of the automotive industry for precision and efficiency.

The company operates its own tooling facilities, a significant advantage that enables the design and production of highly specialized and intricate parts. This vertical integration allows for greater control over quality and faster adaptation to evolving vehicle designs. In 2024, Flex-N-Gate continued to invest in upgrading its manufacturing lines, with a focus on automation and Industry 4.0 technologies to enhance throughput and reduce waste.

- State-of-the-art machinery: Essential for high-volume, precision manufacturing.

- In-house tooling facilities: Enables creation of complex parts and maintains competitive edge.

- Investment in automation: Driving production efficiency and quality improvements in 2024.

- Adaptability to new designs: Facilitated by advanced tooling capabilities.

Financial Capital

Flex-N-Gate's business model hinges on substantial financial capital to fuel its global operations. This capital is crucial for funding extensive research and development, ensuring the company stays at the forefront of automotive manufacturing innovation. In 2024, significant investments were channeled into advanced robotics and automation for its manufacturing plants.

Maintaining and expanding a vast network of global manufacturing facilities demands considerable financial resources. Flex-N-Gate operates numerous plants worldwide, requiring ongoing capital for upgrades, new equipment, and capacity expansion to meet market demand. The company’s commitment to investing in new technologies, such as advanced materials and sustainable manufacturing processes, also draws heavily on its financial reserves.

Managing working capital effectively is another critical area where financial capital plays a vital role. This includes financing inventory, accounts receivable, and day-to-day operational expenses. As a large private company, Flex-N-Gate reported substantial revenue figures in 2024, underscoring its robust financial capacity to support these ongoing and strategic initiatives.

- Research and Development: Funding for advanced materials, process engineering, and new product development.

- Manufacturing Infrastructure: Capital for plant expansion, equipment acquisition, and technology upgrades.

- Technology Investment: Allocations for automation, AI in manufacturing, and sustainable production methods.

- Working Capital Management: Financing for inventory, receivables, and operational liquidity.

Flex-N-Gate's key resources are its extensive global manufacturing footprint, a highly skilled workforce, valuable intellectual property, advanced machinery and tooling, and significant financial capital. These elements collectively enable the company to design, engineer, and produce a wide range of automotive components and systems for major original equipment manufacturers worldwide.

The company's commitment to innovation is evident in its continuous investment in research and development, leading to the acquisition of new patents and the refinement of manufacturing processes. This dedication to technological advancement, coupled with substantial financial backing, allows Flex-N-Gate to maintain its competitive edge and adapt to the evolving demands of the automotive industry.

In 2024, Flex-N-Gate continued to prioritize investments in automation and advanced manufacturing technologies, aiming to enhance production efficiency, reduce costs, and improve product quality. Strategic labor agreements were also a focus, ensuring the retention of its skilled workforce through competitive compensation and benefits.

| Key Resource | Description | 2024 Focus/Data Points |

| Global Manufacturing Facilities | Vast network of integrated sites for plastics, metals, lighting, and mechanical assembly. | Continued leveraging of network for just-in-time delivery to OEMs globally. |

| Skilled Workforce | Engineers, designers, manufacturing specialists, technical staff. | Significant labor agreements reached to ensure competitive wages and benefits, crucial for talent retention. |

| Intellectual Property | Patents and proprietary manufacturing techniques for automotive components. | Continued heavy investment in R&D, securing new patents for lightweight materials and advanced assembly. |

| Machinery & Tooling | Advanced machinery, in-house tooling facilities, and investment in automation. | Upgrading manufacturing lines with focus on automation and Industry 4.0 technologies to enhance throughput. |

| Financial Capital | Funding for R&D, global operations, infrastructure, and working capital. | Substantial investments channeled into advanced robotics and automation; robust financial capacity to support initiatives. |

Value Propositions

Flex-N-Gate's value proposition centers on providing OEMs with a comprehensive, end-to-end engineering and manufacturing solution. This integrated approach covers everything from initial design and prototyping to high-volume production and global delivery, streamlining the automotive supply chain for their clients.

By acting as a single source for complex automotive components, Flex-N-Gate simplifies product development and integration for original equipment manufacturers. This allows OEMs to focus on their core competencies while relying on Flex-N-Gate's expertise for critical parts. In 2024, the automotive industry continued to emphasize supply chain efficiency, making such integrated solutions highly valuable.

The company leverages its collective engineering and manufacturing resources to deliver these comprehensive solutions. This pooled expertise ensures that Flex-N-Gate can handle intricate projects and adapt to evolving OEM needs, a crucial factor in the fast-paced automotive sector. Their ability to manage the entire process from concept to completion offers significant advantages in terms of quality control and time-to-market.

Flex-N-Gate prioritizes delivering top-tier components for the automotive sector. This commitment translates to a relentless pursuit of excellence, aiming for defect-free parts and punctual delivery to major original equipment manufacturers (OEMs).

Their dedication to quality and dependability serves as a significant competitive edge. This ensures that Flex-N-Gate's offerings consistently meet the rigorous specifications demanded by automotive giants, reinforcing trust and partnership.

In 2024, the automotive industry faced ongoing supply chain challenges, making reliable component sourcing paramount. Flex-N-Gate's established reputation for high-quality, on-time delivery positions them favorably amidst these complexities, supporting their OEM partners' production schedules.

Flex-N-Gate's commitment to innovation in automotive systems is a core value proposition, driving their focus on lightweighting solutions and function integration. This forward-thinking approach is evident in their significant contributions to new electric vehicle platforms and the development of advanced lighting systems, positioning them at the forefront of automotive technology.

Global Manufacturing and Supply Chain Capabilities

Flex-N-Gate's global manufacturing and supply chain capabilities provide Original Equipment Manufacturers (OEMs) with a significant competitive edge. This extensive network of production and development facilities across the globe enables localized manufacturing, which is crucial for meeting regional market demands and ensuring efficient global supply chain management.

This localized approach facilitates just-in-time delivery, a critical component for modern automotive production, and allows for greater responsiveness to evolving market needs. In 2024, Flex-N-Gate continued to leverage its strategically located facilities to support the complex needs of global vehicle platforms, optimizing logistics and reducing lead times for its OEM partners.

- Global Footprint: Operates manufacturing and product development facilities in North America, South America, Europe, and Asia.

- Supply Chain Efficiency: Enables just-in-time delivery and responsive management of global automotive supply chains.

- Regional Market Support: Facilitates localized production to meet specific regional demands and regulations.

- Platform Integration: Supports the efficient rollout and adaptation of global vehicle platforms across diverse markets.

Cost-Efficiency and Production Optimization

Flex-N-Gate's commitment to cost-efficiency is evident in their advanced industrialization solutions. By optimizing manufacturing processes and leveraging expertise across materials like plastics and metals, they deliver high-quality components at competitive prices. This focus on lean operations is crucial in the automotive sector, where cost control directly impacts vehicle affordability and market competitiveness.

Their ability to propose weight-saving designs further enhances cost-effectiveness for their customers. In 2024, lightweighting initiatives are a major trend in the automotive industry, driven by fuel efficiency regulations and consumer demand for better mileage. For instance, a reduction of just 10% in vehicle weight can lead to a 5-7% improvement in fuel economy. Flex-N-Gate's engineering capabilities in this area directly translate to tangible savings for automakers.

- Optimized Production: Flex-N-Gate employs advanced automation and lean manufacturing principles to reduce waste and increase throughput, driving down per-unit costs.

- Material Expertise: Deep knowledge in processing diverse materials, from high-strength plastics to specialized metals, allows for the selection of the most cost-effective solutions without sacrificing performance.

- Weight Reduction Solutions: Designing lighter components contributes to overall vehicle fuel efficiency, a key selling point and regulatory requirement in 2024.

- Integrated Supply Chain: Streamlined logistics and a focus on vertical integration help manage supply chain costs, ensuring competitive pricing for their automotive clients.

Flex-N-Gate offers OEMs a singular point of contact for the entire lifecycle of complex automotive components, from initial design through to high-volume manufacturing and global distribution. This end-to-end solution simplifies the supply chain for their clients.

The company acts as a single provider for intricate automotive parts, which streamlines product development and integration for original equipment manufacturers. This allows OEMs to concentrate on their core business while relying on Flex-N-Gate's specialized knowledge for critical components. In 2024, the automotive sector's continued focus on supply chain efficiency made such integrated solutions exceptionally valuable.

Flex-N-Gate's value proposition is built on delivering high-quality, dependable automotive components. This unwavering commitment to excellence aims for defect-free parts and punctual delivery to major original equipment manufacturers (OEMs). Their reputation for quality and reliability provides a significant competitive advantage, ensuring Flex-N-Gate's offerings consistently meet the stringent requirements of automotive leaders, fostering trust and strong partnerships.

In 2024, the automotive industry navigated persistent supply chain disruptions, making the reliable sourcing of components a top priority. Flex-N-Gate's established track record for superior quality and on-time delivery positions them advantageously amidst these challenges, effectively supporting their OEM partners' production schedules.

| Value Proposition | Key Benefit | 2024 Relevance |

|---|---|---|

| End-to-End Engineering & Manufacturing | Streamlined supply chain, focus on core competencies for OEMs | Critical for efficiency amidst supply chain volatility |

| High-Quality, Dependable Components | Reduced risk, consistent performance, strong OEM partnerships | Essential for meeting rigorous automotive standards |

| Innovation in Lightweighting & Integration | Improved fuel efficiency, advanced EV platforms, enhanced lighting systems | Key trend driven by regulations and consumer demand |

Customer Relationships

Flex-N-Gate cultivates deep, strategic alliances with leading Original Equipment Manufacturers (OEMs), extending beyond mere supply agreements to encompass co-development and innovation. This collaborative approach means they are involved in new vehicle programs right from the initial design stages through to full production.

A prime example of this is their work on the new IVECO range, showcasing a commitment to integrated product development. Furthermore, Flex-N-Gate's ongoing partnerships with automotive giants like Renault and Nissan highlight their role in shaping multiple vehicle platforms, demonstrating a consistent and valued relationship within the industry.

Flex-N-Gate typically assigns dedicated account management teams to its major Original Equipment Manufacturer (OEM) clients. This ensures prompt service and customized assistance, crucial for maintaining strong relationships.

These specialized teams oversee particular projects, resolve technical issues, and streamline communication channels. This proactive engagement is particularly important for the complex, long-term agreements common in the automotive supply chain, fostering loyalty and repeat business.

Flex-N-Gate fosters deep customer relationships through collaborative design and engineering. Their R&D centers actively partner with Original Equipment Manufacturer (OEM) engineering teams. This ensures customized solutions are developed, meeting precise performance, aesthetic, and integration needs for new vehicle components.

Problem Solving and Technical Support

Flex-N-Gate prioritizes ongoing technical support and proactive problem-solving as a cornerstone of its customer relationships. This commitment ensures that any challenges encountered during production or after the integration of their components are resolved quickly and efficiently, safeguarding the operational continuity for Original Equipment Manufacturers (OEMs).

Their deep expertise across a diverse range of materials and complex systems allows them to offer comprehensive support, addressing intricate issues that may arise. This technical prowess is a key differentiator in maintaining strong partnerships.

- Proactive Issue Resolution: Addressing potential problems before they impact OEM production lines.

- Technical Expertise: Leveraging deep knowledge of materials and systems to solve complex challenges.

- Operational Continuity: Ensuring seamless integration and ongoing performance of supplied components.

- OEM Partnership: Building trust through reliable and responsive technical assistance.

Long-Term Contractual Agreements

Flex-N-Gate's customer relationships are largely built on long-term contractual agreements with Original Equipment Manufacturers (OEMs). These multi-year deals, often spanning the lifecycle of specific vehicle models, ensure a steady demand for Flex-N-Gate's components, like stamped metal parts and plastic components.

These contracts are crucial for stability, offering predictability in revenue streams for Flex-N-Gate and a reliable supply chain for automakers. For instance, in 2024, many automotive supply contracts were renewed or extended, reflecting the ongoing need for established supplier partnerships. These agreements typically cover the supply of critical parts such as:

- Chassis and structural components

- Exterior trim and body panels

- Interior plastic parts and assemblies

- Exhaust systems and related components

Flex-N-Gate's customer relationships are anchored in deep, collaborative partnerships with Original Equipment Manufacturers (OEMs), extending to joint development and innovation from concept to production. This approach is exemplified by their involvement in new vehicle programs, ensuring components are perfectly integrated.

Dedicated account management teams provide tailored support, addressing technical challenges and streamlining communication for long-term contracts. Their 2024 activities saw continued renewals of multi-year supply agreements, underscoring the stability and trust built with key automotive players.

This deep integration and proactive support solidify Flex-N-Gate's role as a critical partner, ensuring operational continuity and fostering loyalty through reliable technical expertise and problem-solving.

| Customer Relationship Aspect | Description | Example/Impact |

|---|---|---|

| Collaborative Development | Joint design and engineering with OEM teams. | Customized solutions for new vehicle components, ensuring precise performance and aesthetic integration. |

| Dedicated Account Management | Specialized teams for major OEM clients. | Prompt service, customized assistance, and streamlined communication for complex projects. |

| Long-Term Contracts | Multi-year supply agreements covering vehicle lifecycles. | Ensures steady demand and revenue predictability; 2024 saw significant contract renewals. |

| Technical Support & Problem Solving | Proactive issue resolution and deep material/system expertise. | Maintains operational continuity for OEMs and addresses intricate challenges, building trust. |

Channels

Flex-N-Gate's direct sales and business development teams are crucial for forging strong relationships with major automotive original equipment manufacturers (OEMs). These dedicated professionals actively seek out new business avenues and showcase Flex-N-Gate's extensive manufacturing and engineering expertise.

These teams are the frontline for customer engagement, managing everything from initial contact to the finalization of complex supply agreements. For instance, in 2024, these teams were instrumental in securing significant contracts with key players in the automotive industry, contributing to Flex-N-Gate's robust order book.

Flex-N-Gate's global manufacturing and engineering footprint is a key channel, enabling direct proximity to Original Equipment Manufacturer (OEM) assembly plants and research and development centers worldwide. This extensive network, encompassing numerous facilities across North America, Europe, and Asia, facilitates localized production and just-in-time delivery, critical for the automotive industry's lean manufacturing principles.

Their strategically located plants, such as those in key automotive production hubs like Mexico, Germany, and China, allow for close technical collaboration with customers. This geographical advantage supports rapid prototyping and problem-solving, ensuring Flex-N-Gate remains a responsive partner in the fast-paced automotive supply chain. For instance, in 2024, the company continued to optimize its supply chain by investing in advanced manufacturing capabilities at several of its European facilities to better serve the region's premium automotive manufacturers.

Flex-N-Gate leverages industry trade shows and conferences as a crucial channel to display its cutting-edge automotive components and advanced manufacturing technologies. These events are vital for demonstrating product innovation and capabilities directly to potential and existing Original Equipment Manufacturer (OEM) clients.

Participation in key automotive gatherings allows Flex-N-Gate to foster direct engagement with industry leaders and potential partners. For instance, major shows like the North American International Auto Show (NAIAS) or the Consumer Electronics Show (CES) automotive sections provide unparalleled networking opportunities, facilitating relationship building and business development within the sector.

These platforms are essential for staying abreast of market trends and competitor activities, enabling Flex-N-Gate to refine its strategic positioning. The insights gained from observing industry advancements and client feedback at these events directly inform product development and business strategy, ensuring continued relevance and competitive advantage.

Customer Referrals and Reputation

Flex-N-Gate's reputation for quality, innovation, and reliability in the automotive sector is a powerful driver of customer referrals. This organic channel brings in new business as satisfied Original Equipment Manufacturers (OEMs) often recommend Flex-N-Gate to other divisions or for new vehicle programs. For instance, in 2024, the company continued to solidify its standing by securing significant contracts with major automotive players, underscoring the trust placed in its capabilities.

This trust translates directly into tangible growth. A strong track record means existing clients are more likely to advocate for Flex-N-Gate, reducing customer acquisition costs. The company's commitment to meeting stringent OEM quality standards, evidenced by its numerous industry awards and certifications, reinforces this positive perception and fuels ongoing referrals.

- Reputation as a Key Asset: Flex-N-Gate's established name in the automotive industry acts as a powerful, low-cost customer acquisition channel.

- OEM Advocacy: Satisfied Original Equipment Manufacturers (OEMs) frequently recommend Flex-N-Gate to their peers and for new projects.

- Quality and Reliability Drive Referrals: The company's consistent delivery of high-quality, innovative, and reliable automotive components is the bedrock of its referral-based growth.

Digital Presence and Corporate Website

Flex-N-Gate leverages its corporate website and various digital platforms as key channels to disseminate information about its extensive product portfolio, engineering capabilities, company news, and available career paths. These digital touchpoints are crucial for building brand awareness and establishing an initial connection with potential clients, suppliers, and future employees.

While not a direct sales conduit for their intricate B2B dealings, the digital presence acts as a vital information hub. It supports the company's visibility in the market and serves as a primary point of contact for inquiries, fostering early engagement for strategic partnerships and talent acquisition.

- Website Functionality: Provides detailed product specifications, technological expertise, and corporate updates.

- Brand Visibility: Enhances market presence and brand recognition within the automotive supply chain.

- Talent Acquisition: Serves as a platform for showcasing company culture and career opportunities, attracting skilled professionals.

- Initial Contact: Facilitates initial inquiries from potential business partners and stakeholders.

Flex-N-Gate's direct sales and business development teams are critical for engaging major automotive OEMs, serving as the primary interface for securing new contracts and showcasing expertise. These teams are instrumental in managing client relationships from initial contact through to complex supply agreements, as demonstrated by their success in securing significant orders in 2024.

Customer Segments

Flex-N-Gate's primary customer base consists of major global automotive Original Equipment Manufacturers (OEMs). These include giants like Ford, General Motors, Stellantis, Nissan, Renault, BMW, and Toyota, who are the backbone of the automotive industry.

These OEMs demand a consistent supply of high-volume, superior-quality, and innovative automotive components. Their needs span across various vehicle types, from light commercial vehicles to passenger cars, requiring specialized solutions for each segment.

In 2024, the global automotive market saw significant activity, with major OEMs continuing to invest in new technologies and vehicle platforms. For instance, the transition towards electric vehicles (EVs) is driving demand for new types of components, a trend Flex-N-Gate is positioned to address.

Electric Vehicle (EV) Manufacturers are a crucial and expanding customer base for Flex-N-Gate. As the automotive sector pivots to electrification, companies producing EVs require specialized components, and Flex-N-Gate is delivering. For instance, the global EV market was projected to reach over $800 billion by 2024, highlighting the significant demand for such suppliers.

Flex-N-Gate is actively supplying these manufacturers with critical parts for electric models. This includes advanced solutions like battery charge indicator modules, essential for EV functionality, and unique plastic exterior components specifically engineered for the aerodynamic and structural needs of electric vehicles. This focus aligns with the growing trend, with EV sales in 2024 showing continued strong growth globally.

Flex-N-Gate's influence extends beyond passenger cars to the robust commercial vehicle sector. They supply critical components for both light commercial vehicles and heavy-duty trucks, demonstrating a comprehensive approach to the automotive industry.

A prime example of this commitment is their collaboration with IVECO, a significant player in commercial vehicles. Flex-N-Gate provides components for IVECO's well-regarded Daily and S-WAY truck ranges, showcasing their capability to meet the demanding specifications of this market. In 2024, the global commercial vehicle market is projected to see continued growth, with sales of heavy-duty trucks expected to remain strong, underscoring the strategic importance of this segment for suppliers like Flex-N-Gate.

Tier 1 Automotive Suppliers (for sub-assemblies)

Flex-N-Gate's customer segment of Tier 1 automotive suppliers for sub-assemblies represents a strategic niche. While their primary focus remains direct supply to Original Equipment Manufacturers (OEMs), they also cater to other major Tier 1 players who require specialized or modular components. This B2B relationship involves integrating Flex-N-Gate's parts into larger systems, such as advanced seating mechanisms or complex exhaust systems, which are then supplied to vehicle manufacturers. This diversification allows Flex-N-Gate to leverage its manufacturing expertise across a broader automotive value chain.

In 2024, the automotive industry saw continued demand for sophisticated sub-assemblies, driven by trends in vehicle electrification and advanced driver-assistance systems (ADAS). For instance, suppliers of integrated battery pack components or sensor housings often rely on specialized manufacturers like Flex-N-Gate. This segment is characterized by rigorous quality standards and the need for highly reliable, precisely engineered parts. The market for automotive sub-assemblies is substantial, with global sales projected to reach hundreds of billions of dollars annually, underscoring the importance of this customer base.

- Specialized Component Supply: Providing modular parts for integration into larger systems by other Tier 1 suppliers.

- Quality and Precision: Meeting stringent OEM-level quality and engineering standards for critical sub-assemblies.

- Market Demand: Capitalizing on the growing need for advanced components in electrified and ADAS-equipped vehicles.

- Value Chain Integration: Deepening relationships within the automotive supply network beyond direct OEM relationships.

Aftermarket and Replacement Parts Market

Flex-N-Gate's vast product range, encompassing lighting, exhaust systems, and body and trim components, positions it to potentially serve the automotive aftermarket. This segment would target vehicle owners and independent repair facilities seeking reliable replacement parts for maintenance and repairs. While Flex-N-Gate's primary focus remains on Original Equipment Manufacturer (OEM) supply, the aftermarket presents a secondary revenue stream. For instance, the global automotive aftermarket was valued at approximately $450 billion in 2023 and is projected to grow, offering a significant opportunity for established suppliers like Flex-N-Gate to leverage their manufacturing expertise.

This aftermarket segment would cater to the need for genuine or equivalent components, ensuring vehicle performance and safety. The company's established manufacturing capabilities and quality control processes, honed through OEM contracts, would be a key differentiator. In 2024, the demand for aftermarket parts is expected to remain robust, driven by an aging vehicle parc and increasing consumer interest in DIY repairs and vehicle customization.

- Aftermarket Potential: Flex-N-Gate's broad product portfolio is well-suited for supplying replacement parts to the automotive aftermarket.

- Target Customers: This segment includes individual vehicle owners and professional repair shops requiring maintenance and repair components.

- Competitive Advantage: Leveraging existing manufacturing expertise and quality standards from OEM supply provides a strong foundation for aftermarket success.

- Market Opportunity: The global automotive aftermarket's consistent growth, projected to continue through 2024, offers a substantial revenue expansion avenue.

Flex-N-Gate's customer segments are primarily major global automotive Original Equipment Manufacturers (OEMs) and a growing base of Electric Vehicle (EV) manufacturers. They also serve the commercial vehicle sector and act as a supplier of sub-assemblies to other Tier 1 suppliers. The company also has potential in the automotive aftermarket.

| Customer Segment | Key Characteristics | 2024 Market Context/Opportunity |

|---|---|---|

| Major Global OEMs | Demand high-volume, quality, innovative components for diverse vehicle types. | Continued investment in new platforms, especially EVs, driving demand for specialized parts. |

| Electric Vehicle (EV) Manufacturers | Require specialized components for electric models, such as battery charge modules. | Global EV market projected over $800 billion in 2024; strong sales growth continues. |

| Commercial Vehicle Sector | Need robust components for light commercial vehicles and heavy-duty trucks. | Global commercial vehicle market projected for continued growth in 2024, with strong heavy-duty truck sales. |

| Tier 1 Suppliers (Sub-assemblies) | Require specialized or modular components for integration into larger systems. | Growing need for advanced components in EVs and ADAS; market for sub-assemblies is substantial. |

| Automotive Aftermarket | Seek reliable replacement parts for maintenance and repairs. | Global aftermarket valued at ~$450 billion in 2023, with consistent growth projected through 2024. |

Cost Structure

Raw material costs represent a substantial part of Flex-N-Gate's expenses. They rely heavily on materials like steel, aluminum, plastics, and electronic components for their automotive parts. In 2024, global steel prices saw volatility, with benchmarks like the TSI US Hot-Rolled Coil Index experiencing fluctuations, directly impacting Flex-N-Gate's procurement budget.

The company's significant production volume means they purchase these materials in large quantities. This scale allows for potential volume discounts but also amplifies the impact of any price changes. Efficient global sourcing and robust hedging strategies are crucial to mitigate the financial risk associated with these fluctuating commodity prices.

Manufacturing and production costs are a significant component for Flex-N-Gate, encompassing direct labor wages for its workforce, substantial energy consumption to power its machinery, and the ongoing expenses of factory overheads. Maintaining its global network of manufacturing facilities, including essential upkeep and repairs, also falls under this umbrella.

Investments in cutting-edge manufacturing technologies and automation represent a considerable capital expenditure, aimed at enhancing efficiency and output. For instance, the automotive industry, where Flex-N-Gate is a major player, saw significant investment in automation in 2024, with companies spending billions to integrate robotics and AI on production lines.

Recent labor agreements can directly impact direct labor costs. For example, new collective bargaining agreements in the automotive sector in late 2023 and early 2024 have led to increased wage and benefit packages for many manufacturing employees, a trend likely to affect companies like Flex-N-Gate.

Flex-N-Gate's commitment to continuous innovation is reflected in significant Research and Development (R&D) expenses. These costs encompass everything from engineering talent and rigorous testing to the creation of prototypes and the protection of intellectual property.

In 2024, the automotive industry, including companies like Flex-N-Gate, continued to pour resources into R&D, particularly for electric vehicle (EV) technology and advanced driver-assistance systems (ADAS). For instance, major automotive suppliers reported R&D spending in the billions, underscoring the high investment needed to remain competitive and develop next-generation vehicle components.

These R&D investments are critical for Flex-N-Gate to maintain its competitive edge by offering cutting-edge solutions. Developing advanced materials, improving manufacturing processes, and integrating new technologies are essential for future vehicle generations, especially as the industry rapidly transitions towards electrification and autonomous driving.

Labor and Personnel Costs

Flex-N-Gate's cost structure is heavily influenced by its substantial global workforce. Salaries, wages, and comprehensive benefits for its employees represent a significant expenditure. Furthermore, ongoing investment in training and development programs to maintain a skilled workforce adds to these personnel costs.

Recent labor agreements, particularly those with unions like Unifor and the UAW, directly impact these expenses. For instance, in late 2023 and early 2024, negotiations resulted in new contracts that included phased wage increases and enhanced benefit packages for thousands of Flex-N-Gate employees across North America, adding to the overall labor cost burden.

- Salaries and Wages: A primary driver of cost, reflecting the compensation for a large, geographically dispersed workforce.

- Employee Benefits: Includes health insurance, retirement plans, and other benefits, contributing significantly to overall personnel expenses.

- Training and Development: Investment in upskilling and reskilling employees to adapt to evolving manufacturing technologies and processes.

- Union Contract Impacts: Wage hikes and improved benefits negotiated in recent agreements with major unions directly increase labor expenditure.

Logistics and Distribution Costs

Flex-N-Gate's logistics and distribution costs are substantial, covering the global movement of raw materials to manufacturing plants and finished components to Original Equipment Manufacturer (OEM) assembly lines. These expenses encompass freight charges, warehousing, and meticulous inventory management, particularly crucial for their just-in-time delivery strategies. For instance, in 2024, the global logistics market saw continued pressure on shipping rates due to capacity constraints and geopolitical events, directly impacting companies like Flex-N-Gate that rely on extensive international transport.

Optimizing supply chain efficiency is paramount to controlling these significant expenditures. This involves strategic route planning, carrier negotiation, and leveraging technology for real-time tracking and inventory visibility. The company's commitment to lean manufacturing principles extends to its logistics operations, aiming to minimize waste and transit times. In 2023, the average cost of shipping a 40-foot container globally fluctuated, with significant increases seen at various points, underscoring the volatility and cost-sensitivity of this segment for manufacturers.

- Freight Expenses: Costs associated with ocean, air, and ground transportation of materials and finished goods.

- Warehousing Costs: Expenses related to storing raw materials, work-in-progress, and finished components.

- Inventory Management: Costs tied to holding inventory, including carrying costs, insurance, and potential obsolescence, especially critical for just-in-time models.

- Supply Chain Technology: Investments in systems for tracking, visibility, and optimization to reduce transit times and improve efficiency.

Flex-N-Gate's cost structure is significantly shaped by its capital expenditures on advanced manufacturing technologies. These investments, including automation and robotics, are essential for maintaining production efficiency and quality in the competitive automotive sector. For example, the automotive industry globally saw investments in advanced manufacturing technologies reach hundreds of billions in 2024, reflecting a strong trend toward smart factories.

These capital outlays, while substantial, are designed to yield long-term operational benefits such as reduced labor costs per unit and increased throughput. The company's strategic focus on adopting Industry 4.0 principles means ongoing investment in machinery upgrades and digital integration is a key element of its cost base.

Depreciation on these significant assets also forms a recurring cost. As new, sophisticated equipment is added, the associated depreciation charges impact the company's profitability. For instance, the average lifespan of industrial machinery can range from 10 to 20 years, with depreciation calculated over this period.

| Cost Category | Description | 2024 Impact/Trend |

|---|---|---|

| Capital Expenditures | Investment in new machinery, automation, and factory upgrades. | Significant outlay driven by Industry 4.0 adoption; billions invested across the automotive supply chain. |

| Depreciation | Non-cash expense reflecting the wear and tear of manufacturing assets. | Increases as new, high-value equipment is capitalized; calculated over asset life (10-20 years typical). |

| Technology Integration | Costs associated with implementing digital systems, AI, and IoT in production. | Growing expense to enhance efficiency and data-driven decision-making. |

Revenue Streams

Flex-N-Gate's core revenue comes from selling a broad range of automotive parts to major car manufacturers worldwide. This encompasses everything from bumpers and exterior trim to lighting, hinges, and complex mechanical assemblies.

These sales are primarily driven by long-term agreements to supply components for specific vehicle production lines. In 2024, the automotive industry continued its recovery, with global light vehicle production projected to reach over 90 million units, directly impacting the volume of components Flex-N-Gate supplies.

Flex-N-Gate secures revenue through its specialized tooling and product development services, a crucial element often initiated during the early stages of new vehicle programs. Original Equipment Manufacturers (OEMs) compensate Flex-N-Gate for the intricate design, engineering, and manufacturing of bespoke tooling essential for producing their unique vehicle components.

This segment of their business model ensures a holistic approach, providing OEMs with a complete solution from concept to production. For instance, in 2024, the automotive industry saw significant investment in advanced manufacturing technologies, with companies like Flex-N-Gate playing a pivotal role in developing the specialized tooling required for next-generation vehicle platforms.

Flex-N-Gate is tapping into new revenue streams through the sale of advanced technology solutions, notably in the electric vehicle (EV) sector. A key development is its partnership with StoreDot, focusing on the creation and future production of extreme fast-charging battery cells. This move diversifies the company's offerings into a high-growth segment of the automotive market.

Aftermarket Parts Sales (Potential)

Flex-N-Gate's aftermarket parts sales represent a potential, albeit secondary, revenue stream. While the primary focus remains on supplying original equipment manufacturers (OEMs), the company can generate income by selling replacement components for vehicles already in use. This segment caters to the post-production vehicle maintenance and repair market.

This aftermarket channel would involve distributing parts directly to repair shops, dealerships, or even consumers. The global automotive aftermarket industry is substantial, with projections indicating continued growth. For instance, the automotive aftermarket in North America was valued at over $300 billion in 2023 and is expected to see a compound annual growth rate (CAGR) of around 3-4% through 2030, according to various industry analyses.

- Core Business: OEM supply remains the primary revenue driver.

- Aftermarket Potential: Revenue generation through the sale of replacement parts for post-production vehicles.

- Market Size: The global automotive aftermarket is a significant and growing sector.

- Industry Growth: North American aftermarket valued over $300 billion in 2023, with projected CAGR of 3-4% through 2030.

Design and Engineering Services

Flex-N-Gate leverages its deep design and engineering capabilities as a distinct revenue generator. Original Equipment Manufacturers (OEMs) can engage Flex-N-Gate for specialized research and development, design enhancement, and complex problem-solving, independent of large-volume component manufacturing contracts.

- Specialized R&D Contracts: OEMs may outsource specific R&D projects to Flex-N-Gate, tapping into their expertise in areas like lightweight materials or advanced manufacturing techniques.

- Design Optimization Services: Flex-N-Gate offers services to refine existing vehicle designs for improved performance, cost-efficiency, or manufacturability.

- Problem-Solving and Consulting: The company provides engineering consulting to address specific manufacturing or design challenges faced by OEMs.

This service-based revenue stream allows Flex-N-Gate to monetize its intellectual capital and engineering talent, diversifying income beyond traditional parts supply. For instance, in 2024, the automotive engineering services market was projected to reach over $70 billion globally, indicating a significant opportunity for specialized providers like Flex-N-Gate.

Flex-N-Gate's primary revenue streams stem from supplying automotive parts to major Original Equipment Manufacturers (OEMs) under long-term supply agreements. The company also generates income through specialized tooling and product development services, often initiated during the early stages of new vehicle programs.

New revenue avenues are being explored through advanced technology solutions, particularly in the electric vehicle (EV) sector, such as partnerships for battery cell development. Additionally, Flex-N-Gate can generate revenue from aftermarket parts sales, catering to the vehicle maintenance and repair market.

The company further monetizes its engineering expertise by offering specialized research and development, design optimization, and problem-solving services to OEMs, diversifying income beyond traditional component manufacturing.

| Revenue Stream | Description | 2024 Context/Data |

| OEM Component Supply | Sales of automotive parts (bumpers, lighting, etc.) to car manufacturers. | Global light vehicle production projected over 90 million units. |

| Tooling & Product Development | Revenue from designing and manufacturing bespoke tooling for new vehicle components. | Significant investment in advanced manufacturing technologies by OEMs. |

| Advanced Technology Solutions | Sales of new tech, like EV battery cells through partnerships. | Focus on high-growth EV segment. |

| Aftermarket Parts Sales | Selling replacement parts for vehicles already in use. | North American aftermarket valued over $300 billion in 2023. |

| Engineering Services | Specialized R&D, design enhancement, and problem-solving for OEMs. | Automotive engineering services market projected over $70 billion globally. |

Business Model Canvas Data Sources

The Flex-N-Gate Business Model Canvas is informed by a blend of internal financial data, extensive market research on automotive manufacturing trends, and strategic insights derived from competitor analysis. This multifaceted approach ensures each component of the canvas is data-driven and strategically sound.