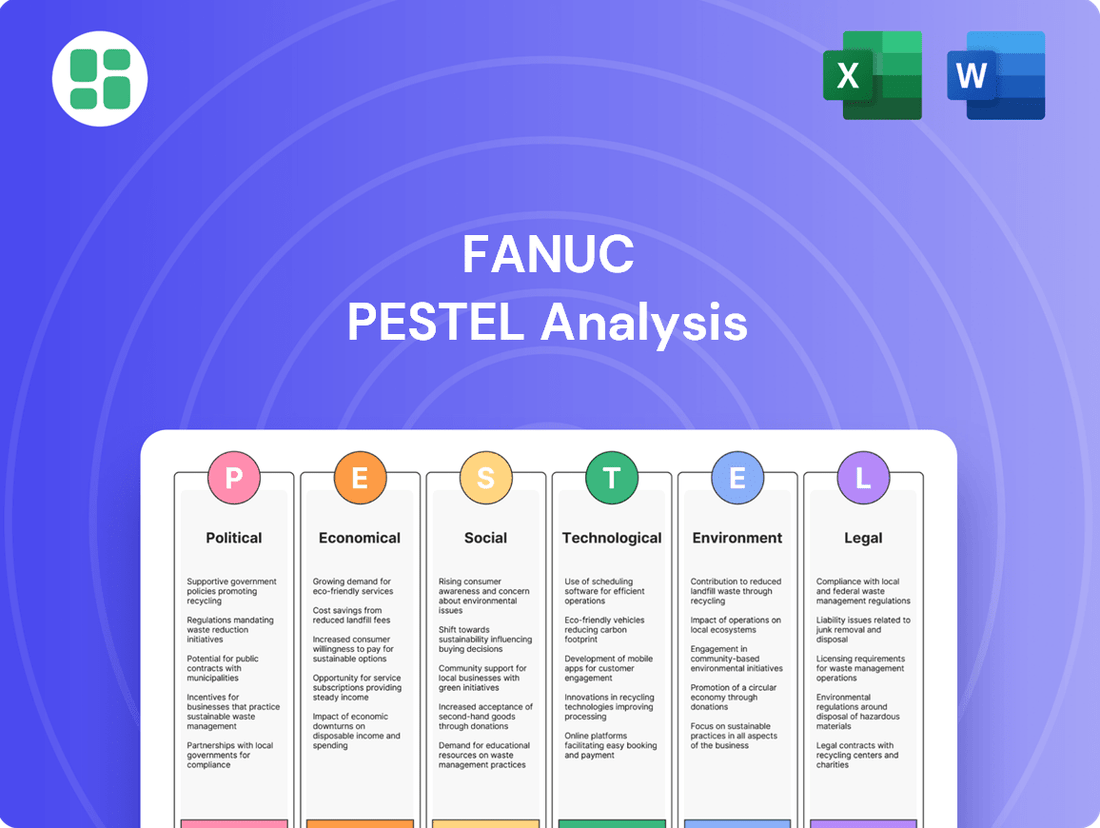

Fanuc PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Fanuc Bundle

Uncover the critical political, economic, social, technological, environmental, and legal factors shaping Fanuc's trajectory. Our expertly crafted PESTLE analysis provides actionable insights to help you anticipate market shifts and capitalize on emerging opportunities. Download the full version for a strategic advantage.

Political factors

Global trade policies, especially tariffs, introduce considerable uncertainty for the industrial automation sector. For instance, ongoing trade disputes, such as those involving the U.S. and China, can disrupt supply chains and increase the cost of components for automation equipment manufacturers like FANUC.

Recent U.S. tariffs have already sparked concerns among manufacturers, leading to the postponement of significant capital investments in automation. This hesitancy could impede the anticipated recovery of industrial production in 2025, directly impacting demand for FANUC's products.

This unpredictable trade landscape complicates long-term strategic planning for companies operating in the industrial automation space. Navigating these shifting policy environments requires agility and robust risk management strategies.

Governments globally are prioritizing factory automation to boost economic competitiveness and supply chain resilience. For instance, the United States' CHIPS and Science Act of 2022, with its significant funding for semiconductor manufacturing, implicitly supports automation adoption. This trend creates a more receptive market for companies like FANUC, as policy tailwinds encourage investment in advanced manufacturing technologies.

Escalating geopolitical tensions, such as those seen in Eastern Europe and the Middle East, significantly disrupt global supply chains. This impacts FANUC's ability to import critical components and export its advanced automation products, potentially delaying production and deliveries. For instance, the ongoing conflicts have led to increased shipping costs and lead times, affecting the predictability of FANUC's supply chain operations.

Industrial Policy and Reshoring

Many nations are actively pursuing industrial policies focused on bringing manufacturing back home, a trend known as reshoring or nearshoring. This strategic shift is driven by a desire to strengthen supply chains and bolster national security, especially in light of recent global disruptions. For instance, the US CHIPS and Science Act, passed in 2022, allocates over $52 billion to boost domestic semiconductor manufacturing, encouraging companies to build plants within the United States.

This push for localized production is expected to fuel greater demand for factory automation solutions. As businesses invest in setting up or expanding domestic manufacturing facilities, they will likely turn to advanced robotics and automation systems to improve efficiency and competitiveness. FANUC, a leader in industrial automation, stands to gain significantly from this trend.

FANUC could see increased orders as companies build out their automated production lines within these incentivized or protected domestic markets. The company’s expertise in robotics, CNC systems, and factory automation solutions directly aligns with the needs of manufacturers seeking to enhance their capabilities. For example, reports in late 2023 indicated a surge in investment in automation technology by German manufacturers, partly driven by government support programs aimed at increasing domestic production capacity.

- Reshoring Initiatives: Governments globally are implementing policies to encourage domestic manufacturing, aiming to secure supply chains.

- Increased Automation Demand: This trend is projected to drive higher adoption of factory automation and robotics as companies invest in local production.

- FANUC's Opportunity: FANUC is well-positioned to benefit from increased investment in automated manufacturing within these reshoring-focused economies.

- Market Growth: The global industrial robotics market was valued at approximately $50 billion in 2023 and is expected to grow substantially in the coming years, partly due to these industrial policies.

Regulatory Stability and Predictability

Regulatory stability is paramount for companies like FANUC, especially in the capital-intensive factory automation sector. Unforeseen shifts in trade policies or environmental regulations, for instance, can significantly impact manufacturing costs and market access. FANUC's strategic planning relies on predictable frameworks to make informed, long-term investments in research and development and global expansion.

For example, in 2024, the global industrial automation market is projected to reach approximately $240 billion, a figure heavily influenced by regulatory landscapes in key manufacturing hubs. Changes in data privacy laws or cybersecurity mandates, such as those being refined in the EU and US, can necessitate costly system upgrades and affect how FANUC's connected technologies are deployed.

- Predictable regulations foster investor confidence, crucial for FANUC's capital-intensive R&D.

- Sudden policy changes, like tariffs or export controls, can disrupt supply chains and market access.

- Compliance with evolving standards for AI and robotics safety is a key consideration for FANUC's product development.

Governmental focus on reshoring and nearshoring initiatives, spurred by geopolitical instability and supply chain vulnerabilities, is a significant political factor. Policies like the US CHIPS and Science Act of 2022, allocating over $52 billion to domestic semiconductor manufacturing, directly encourage automation adoption. This trend is expected to boost demand for FANUC's advanced robotics and automation systems as companies invest in local production capabilities.

Trade policies and tariffs, such as those impacting U.S.-China trade, create market uncertainty and can disrupt supply chains for industrial automation. For instance, recent tariffs have led to hesitations in capital investments, potentially slowing the anticipated recovery of industrial production in 2025 and impacting demand for FANUC's offerings.

Geopolitical tensions, like those in Eastern Europe, disrupt global logistics, increasing shipping costs and lead times for critical components and finished goods. This directly affects FANUC's ability to maintain predictable production schedules and timely deliveries to its international customer base.

Regulatory stability is crucial for capital-intensive sectors like industrial automation. Unforeseen changes in trade or environmental regulations can impact manufacturing costs and market access, making predictable frameworks essential for FANUC's long-term investment and expansion strategies.

| Policy/Initiative | Objective | Impact on FANUC | Key Year |

|---|---|---|---|

| US CHIPS and Science Act | Boost domestic semiconductor manufacturing | Increased demand for automation in US plants | 2022 |

| Reshoring/Nearshoring Trends | Strengthen supply chains, national security | Higher adoption of robotics and automation | Ongoing (2023-2025) |

| Tariffs (e.g., US-China) | Trade balance, national interests | Supply chain disruption, cost increases, market uncertainty | Ongoing (2023-2025) |

| Industrial Automation Market Growth | Economic competitiveness | Projected market value of ~$240 billion in 2024 | 2024 |

What is included in the product

This Fanuc PESTLE analysis examines the influence of Political, Economic, Social, Technological, Environmental, and Legal factors on the company's operations and strategic positioning.

A clear, actionable breakdown of Fanuc's external environment, transforming complex PESTLE factors into manageable insights for strategic decision-making.

Economic factors

The global economy's well-being is a significant factor for factory automation demand, as manufacturing output directly drives investment in new equipment. While industrial automation markets experienced a dip in 2024 due to inventory adjustments, a gradual recovery is expected in 2025, though order volumes might not match the highs of 2022-2023.

FANUC's financial projections for fiscal year 2024/25 reflect this improving outlook, with anticipated increases in operating profit and net income, signaling a positive trend for the company.

Persistent inflation is a significant tailwind for FANUC. Manufacturers are facing escalating costs for labor, energy, and essential raw materials. This economic pressure is pushing them to find ways to boost efficiency and cut expenses, making automation solutions like FANUC's robots increasingly attractive.

The rising cost of human labor, in particular, makes the one-time investment in automation a more compelling proposition. For instance, average hourly wages in manufacturing saw a notable increase throughout 2024, making the long-term cost savings from robotics even more pronounced.

The prevailing interest rate environment significantly influences capital expenditure decisions for FANUC's potential clients. For the past three years, elevated interest rates have increased borrowing costs, making substantial automation investments less appealing for many businesses. This sustained higher cost of capital acts as a headwind, potentially slowing the adoption rate of FANUC's advanced robotics and automation solutions, even with strong underlying demand for improved operational efficiency.

Investment in Manufacturing Automation

Investment in manufacturing automation continues its upward trajectory, fueled by the drive for efficiency and competitiveness. The global market for AI in industrial automation is anticipated to experience substantial expansion. For instance, it was valued at approximately USD 11.5 billion in 2023 and is projected to reach USD 31.5 billion by 2028, growing at a CAGR of over 22% during this period.

This sustained global investment creates a robust and favorable market environment for companies like FANUC, whose core business revolves around robotics and automation solutions. The demand for automated systems is particularly pronounced in rapidly developing economies, underscoring the long-term potential for growth.

- Asia-Pacific Dominance: Regions like Asia-Pacific, with China and India at the forefront, are leading the charge in robotics adoption, showcasing a significant appetite for advanced automation technologies.

- AI Integration: The integration of Artificial Intelligence within industrial automation is a key growth driver, enhancing capabilities and expanding the application of automated systems.

- Market Growth Projections: The AI in industrial automation market is expected to see a compound annual growth rate (CAGR) exceeding 22% between 2023 and 2028, indicating strong future demand.

- FANUC's Position: This overall positive trend in automation investment directly benefits FANUC, as it aligns with their strategic focus on providing cutting-edge robotic and automation solutions to a growing global market.

Currency Exchange Rate Fluctuations

As a global manufacturing giant, FANUC's financial health is significantly influenced by the ebb and flow of currency exchange rates, especially concerning the Japanese Yen (JPY) against major trading currencies like the US Dollar (USD) and the Euro (EUR). When the Yen weakens, FANUC's overseas earnings translate into more Yen, positively impacting its reported revenues and profits. Conversely, a stronger Yen can diminish the value of its international sales when converted back into its home currency.

For instance, FANUC's financial results for the fiscal year ending March 2024 highlighted this sensitivity. The company reported that favorable foreign exchange movements contributed positively to its operating income. Specifically, the average USD/JPY rate during FY2024 was approximately 145 JPY per USD, a level that generally benefits Japanese exporters like FANUC compared to a stronger Yen environment.

The impact of these fluctuations is evident in FANUC's financial statements. For the fiscal year 2024, the company noted that currency translation effects provided a tailwind. While specific figures vary, the general trend for Japanese manufacturers in 2024 often showed a benefit from a weaker Yen, boosting the Yen-denominated earnings from their substantial international operations.

FANUC's strategic approach often involves managing currency risk through hedging activities, but the underlying exposure remains. This makes monitoring global economic trends and central bank policies crucial for understanding FANUC's future financial performance.

The global economic landscape presents a mixed but generally improving outlook for FANUC. While 2024 saw some inventory adjustments impacting industrial automation demand, a recovery is anticipated for 2025, albeit with order volumes potentially not reaching 2022-2023 peaks. FANUC's own financial projections for fiscal year 2024/25 reflect this optimism with expected increases in operating profit and net income.

Inflationary pressures are a significant positive for FANUC, as rising labor, energy, and material costs compel manufacturers to seek efficiency through automation. The increasing cost of human labor, in particular, makes the initial investment in robotic solutions more financially viable. For example, average manufacturing hourly wages saw a steady climb through 2024, amplifying the long-term cost-saving benefits of automation.

However, elevated interest rates over the past few years have increased borrowing costs for FANUC's clients, potentially slowing the adoption of new automation technologies despite the underlying demand for efficiency. This higher cost of capital acts as a constraint on significant capital expenditure projects for many businesses.

The global investment in manufacturing automation, especially in AI-driven solutions, continues to grow robustly. The AI in industrial automation market, valued at approximately USD 11.5 billion in 2023, is projected to reach USD 31.5 billion by 2028, with a compound annual growth rate exceeding 22%. This trend, particularly strong in regions like Asia-Pacific, creates a favorable market for FANUC's offerings.

Preview the Actual Deliverable

Fanuc PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This comprehensive PESTLE analysis of Fanuc covers all key political, economic, social, technological, legal, and environmental factors impacting the company. You'll gain valuable insights into the strategic landscape for Fanuc.

Sociological factors

Global manufacturing sectors are grappling with significant labor shortages and a widening skills gap, pushing companies towards automation. This trend is particularly pronounced as experienced workers retire, creating a deficit in specialized manufacturing expertise. For instance, in the US, the Bureau of Labor Statistics projected a need for over 4.6 million manufacturing jobs by 2030, with a significant portion expected to remain unfilled due to the skills gap.

This scarcity of skilled labor directly fuels demand for advanced automation solutions, such as those offered by Fanuc. Companies are investing in industrial robots and AI-powered systems to compensate for the lack of human workers and to enhance productivity. The International Federation of Robotics reported that the installation of robots in manufacturing reached a new record in 2023, highlighting this shift.

Public perception of industrial automation is shifting, with a growing appreciation for robots as partners that enhance human capabilities rather than solely replacing workers. This evolving view is crucial for FANUC's market expansion.

Collaborative robots, or cobots, are at the forefront of this change, taking on repetitive and physically demanding jobs. This not only boosts productivity but also contributes to a safer work environment, as evidenced by a significant reduction in workplace injuries in sectors adopting these technologies. For instance, in 2023, manufacturing facilities utilizing cobots reported an average decrease of 15% in ergonomic-related injuries.

This positive acceptance, driven by tangible benefits like improved worker well-being and efficiency, directly fuels market penetration for FANUC's automation solutions. As more businesses and their employees recognize the collaborative potential, demand for FANUC's advanced robotics is expected to climb, with the global cobot market projected to reach $12 billion by 2025.

The manufacturing sector is undergoing a significant shift, with automation becoming increasingly common. This means the workforce needs new skills to handle and manage these advanced technologies. Think operating, maintaining, and even programming robots and automated machinery. This transformation highlights a critical need for robust training programs to equip workers for this evolving landscape.

To bridge this skills gap, substantial investment in upskilling and reskilling initiatives is essential. Workers need to learn how to effectively collaborate with automated systems, not just be replaced by them. FANUC recognizes this, actively supporting the development of a skilled workforce through programs like scholarship funds, aiming to cultivate the next generation of talent in advanced manufacturing.

Demand for Customized Products and Flexibility

Consumers increasingly want products tailored to their specific needs, pushing manufacturers toward more agile production. This shift means businesses need systems that can adapt quickly, rather than relying on rigid, mass-production lines. For instance, the global market for personalized goods is projected to reach hundreds of billions of dollars by 2025, highlighting this powerful trend.

Advanced automation, including FANUC's robotics and AI-driven solutions, is key to meeting this demand for customization. These technologies allow factories to retool production rapidly, handling a wider variety of product configurations without significant downtime. FANUC's ROBOMACHINEs and robotic arms are designed for this flexibility, enabling efficient production of diverse product runs.

- Growing Demand for Personalization: The market for customized products is expanding rapidly, with projections indicating significant growth through 2025.

- Automation as an Enabler: Robotics and AI are crucial for manufacturers to achieve the flexibility needed for mass customization.

- FANUC's Role: FANUC's versatile machinery and robotic solutions are well-positioned to support this trend towards personalized manufacturing.

Occupational Health and Safety

Fanuc's automation solutions significantly enhance occupational health and safety. By deploying robots in hazardous environments, like those involving heavy lifting or exposure to dangerous chemicals, companies can drastically reduce the risk of workplace injuries. For instance, the International Federation of Robotics reported that the density of robots in manufacturing globally reached 151 units per 10,000 employees in 2022, a clear indicator of the trend towards safer, automated workplaces.

This shift directly addresses societal expectations for businesses to prioritize employee well-being and adopt responsible corporate practices. A commitment to safety not only protects workers but also bolsters a company's reputation, contributing to a more sustainable and resilient workforce. In 2023, workplace safety regulations continued to evolve, with many regions strengthening requirements for hazard mitigation, further driving the demand for automated safety solutions.

- Reduced Risk: Robots handle tasks in dangerous conditions, preventing human accidents.

- Societal Alignment: Automation meets growing public demand for corporate responsibility in safety.

- Workforce Sustainability: Safer environments lead to a more stable and healthier labor pool.

- Regulatory Compliance: Advanced automation helps businesses meet increasingly stringent safety standards.

Societal expectations are increasingly focused on worker well-being and safety, driving demand for automation that minimizes human exposure to hazardous tasks. This aligns with growing regulatory pressures to enhance workplace safety standards. For example, the adoption of industrial robots in manufacturing has been linked to a reduction in workplace accidents, with some sectors reporting a significant decrease in injury rates.

The global workforce is also undergoing a transformation, with a growing emphasis on upskilling and reskilling to adapt to new technologies. This necessitates training programs that equip workers to collaborate with automated systems. FANUC actively supports these initiatives, recognizing the importance of a skilled workforce for the future of manufacturing.

Consumers' desire for personalized products is pushing manufacturers towards more agile and flexible production methods. Automation, including FANUC's robotics, is essential for enabling this mass customization. The market for personalized goods is projected for substantial growth through 2025, underscoring this trend.

Technological factors

Advancements in AI and Machine Learning are fundamentally reshaping industrial automation, allowing machinery to learn, adapt, and operate autonomously. These sophisticated technologies are key drivers behind predictive maintenance, improving quality control through advanced inspection, streamlining supply chains, and facilitating the development of self-healing operational systems.

The global AI in industrial automation market is experiencing robust expansion, with projections indicating substantial growth. For instance, the market was valued at approximately USD 4.2 billion in 2022 and is anticipated to reach around USD 23.5 billion by 2030, demonstrating a compound annual growth rate (CAGR) of over 24% during this period, underscoring the transformative influence of AI on manufacturing processes.

The Industrial Internet of Things (IIoT) is rapidly becoming a foundational element in manufacturing, connecting machinery for real-time data analysis and optimized workflows. This digital transformation is a key driver for robotic advancements, fostering greater agility and responsiveness in industrial settings.

FANUC's commitment to this interconnected environment is evident in its solutions, which facilitate seamless data exchange and enhanced operational efficiency. For instance, by 2024, the global IIoT market was projected to reach hundreds of billions of dollars, underscoring the widespread adoption and impact of these technologies on productivity.

Collaborative robots, or cobots, are rapidly advancing, making it easier and safer for them to work directly with people on factory floors. These machines are getting smarter with better sensors and software, allowing for more complex tasks to be automated. This means human workers can focus on more important, strategic jobs, boosting overall efficiency and job satisfaction.

The increasing sophistication of cobots is significantly lowering the cost and complexity of implementing automation. For instance, by the end of 2024, the global cobot market was projected to reach approximately $10 billion, with an expected compound annual growth rate (CAGR) of over 30% through 2030. This growth is fueled by their ability to enhance productivity and improve the working environment by taking over repetitive or strenuous tasks.

Digital Twin Technology Adoption

Digital twin technology is rapidly transforming industrial automation, offering virtual replicas of physical assets and processes for real-time simulation, monitoring, and optimization. This allows manufacturers to gain deep insights, facilitate predictive maintenance, and make proactive adjustments to production. FANUC's integration with these digital frameworks is key to unlocking enhanced control and operational efficiency.

The global digital twin market is projected to reach significant growth, with some estimates suggesting it could expand from approximately $6.7 billion in 2023 to over $56 billion by 2028, reflecting a compound annual growth rate (CAGR) of over 50%. This surge is driven by the increasing demand for IoT integration, AI, and advanced analytics in manufacturing sectors.

- Enhanced Operational Efficiency: Digital twins enable manufacturers to identify bottlenecks and optimize workflows, leading to improved throughput.

- Predictive Maintenance: By simulating wear and tear, digital twins allow for the scheduling of maintenance before failures occur, reducing downtime.

- Cost Reduction: Real-time monitoring and simulation can minimize material waste and energy consumption, contributing to lower operational costs.

- Improved Product Design: Virtual testing and iteration using digital twins can accelerate product development cycles and enhance quality.

Enhanced Cybersecurity for Operational Technology (OT)

The increasing connectivity of manufacturing systems, a hallmark of Industry 4.0 and the convergence of Information Technology (IT) with Operational Technology (OT), has unfortunately amplified cybersecurity risks. These risks include sophisticated ransomware attacks and the theft of valuable intellectual property, directly impacting production continuity and safety.

Protecting these critical OT systems is no longer optional; it's essential for maintaining the integrity and security of manufacturing operations. For FANUC, a key player in connected automation, this translates to a non-negotiable requirement to embed robust cybersecurity features and promote best practices across its entire product ecosystem.

- Increased Connectivity Risks: By 2024, the global OT cybersecurity market was projected to reach $33.3 billion, highlighting the growing vulnerability of connected industrial systems.

- FANUC's Role: As a provider of interconnected automation solutions, FANUC's commitment to cybersecurity directly impacts its customers' ability to safeguard their production lines against evolving threats.

- Mitigation Strategies: Implementing multi-layered security approaches, including secure network design, regular software updates, and employee training, is crucial for defending OT environments.

Advancements in AI and machine learning are driving autonomous operations and predictive maintenance in industrial settings. The global AI in industrial automation market, valued at approximately USD 4.2 billion in 2022, is projected to reach USD 23.5 billion by 2030, with a CAGR exceeding 24%.

The Industrial Internet of Things (IIoT) connects machinery for real-time data analysis, enhancing robotic agility. By 2024, the global IIoT market was expected to reach hundreds of billions of dollars, signifying its broad impact on productivity.

Collaborative robots (cobots) are becoming more intelligent and accessible, with the global cobot market projected to reach around $10 billion by the end of 2024, growing at a CAGR over 30% through 2030.

Digital twin technology creates virtual replicas for simulation and optimization, with the market expected to surge from USD 6.7 billion in 2023 to over USD 56 billion by 2028, a CAGR above 50%.

| Technology | 2022/2023 Valuation | Projected 2028/2030 Valuation | Estimated CAGR | Impact on FANUC |

|---|---|---|---|---|

| AI in Industrial Automation | USD 4.2 billion (2022) | USD 23.5 billion (2030) | >24% | Enhanced automation, predictive maintenance |

| IIoT | Hundreds of billions (2024 projection) | N/A | N/A | Real-time data, improved workflows |

| Cobots | N/A | ~USD 10 billion (end of 2024) | >30% (through 2030) | Safer human-robot collaboration, increased efficiency |

| Digital Twins | USD 6.7 billion (2023) | >USD 56 billion (2028) | >50% | Simulation, monitoring, optimization |

Legal factors

FANUC's innovation, particularly in CNC systems and robotics, is underpinned by robust intellectual property (IP) protection laws. These laws are crucial for safeguarding patents covering their advanced technologies and maintaining a competitive edge in the global market.

The manufacturing sector faces escalating risks of IP theft, making stringent legal frameworks and effective enforcement essential for companies like FANUC. This protection is vital to prevent the unauthorized use of proprietary technologies and preserve FANUC's market position.

FANUC's global operations expose it to a complex web of international trade laws and sanctions. These regulations, including tariffs and export controls, directly influence its ability to source components and sell products across different regions. For instance, the imposition of U.S. tariffs in recent years has been a significant factor affecting global trade dynamics, and FANUC has acknowledged their impact on its business outlook.

The imposition of economic sanctions by various nations can create substantial hurdles for companies like FANUC. These sanctions can restrict market access, disrupt supply chains, and increase the cost of compliance, potentially impacting FANUC's revenue streams and operational efficiency. The company’s decision to refrain from providing certain future forecasts in its financial reports has been partly attributed to the uncertainty surrounding global economic conditions and trade policies.

FANUC operates under stringent product liability and safety regulations, a critical legal factor for industrial machinery and robotics. Compliance with these global standards is paramount for minimizing legal exposure and ensuring the safety of users interacting with automation solutions.

Failure to adhere to these regulations, which cover design, manufacturing, and deployment, could lead to significant financial penalties and reputational damage. For instance, in 2023, the European Union continued to strengthen its machinery safety directives, impacting the integration of AI and collaborative robots, areas where FANUC is a major player.

FANUC's commitment to human-robot interaction safety, a key component of these regulations, is essential. This focus helps prevent accidents and reinforces the company's image as a provider of dependable and advanced automation technology, crucial for maintaining market trust.

Data Privacy and Security Regulations

FANUC's operations, deeply integrated into industrial IoT and connected factories, necessitate stringent adherence to data privacy and security regulations. As these systems gather vast operational data, compliance with frameworks like the EU's General Data Protection Regulation (GDPR) and similar regional laws is paramount. Failure to protect sensitive manufacturing data and maintain customer trust can lead to significant penalties and reputational damage, especially as cyber threats to manufacturing environments continue to escalate. For instance, the global cybersecurity market for operational technology (OT) was projected to reach USD 21.5 billion in 2024, highlighting the increasing focus on securing industrial data.

Labor and Employment Laws related to Automation

Labor and employment laws are a critical consideration as automation reshapes the workforce. While FANUC's technology can help address labor shortages, the legal frameworks governing job displacement and worker retraining are still developing. For instance, in the US, the Worker Adjustment and Retraining Notification (WARN) Act requires employers with 100 or more employees to provide 60 days' notice before plant closings or mass layoffs, a provision that becomes increasingly relevant with widespread automation.

Navigating these evolving legal and ethical considerations is crucial for FANUC and its clients to maintain their social license to operate. Ensuring fair labor practices during this transition, such as providing adequate retraining opportunities for workers whose roles are automated, is paramount. This proactive approach helps mitigate potential legal challenges and fosters a positive relationship with employees and the broader community.

The International Labour Organization (ILO) has also highlighted the need for policies that support workers through automation, emphasizing social dialogue and the protection of fundamental rights. As of 2024, many countries are actively reviewing their labor laws to adapt to these technological shifts, with a focus on lifelong learning and social safety nets to cushion the impact of automation-driven job changes.

- Job Displacement & Retraining Laws: Evolving regulations require companies to consider worker displacement and invest in retraining programs, impacting operational costs and workforce planning.

- Worker Rights in Automation: Ensuring fair labor practices, including fair wages and safe working conditions for humans working alongside automated systems, is a growing legal focus.

- Social License to Operate: Proactive engagement with labor laws and ethical considerations is vital for maintaining public trust and regulatory approval for automation deployments.

- International Labor Standards: Global bodies like the ILO are influencing national policies, pushing for worker protections and social dialogue in the face of automation.

FANUC's global footprint means navigating a complex landscape of international trade laws, sanctions, and tariffs, which directly affect its ability to source components and sell products. For example, ongoing geopolitical tensions and trade disputes continue to create uncertainty, impacting supply chain stability and market access for advanced manufacturing technologies. The company's financial reports have acknowledged these external factors as key considerations influencing its business outlook.

Compliance with stringent product liability and safety regulations is paramount for FANUC, especially given the nature of industrial machinery and robotics. Adherence to global standards, such as updated EU machinery safety directives in 2023 concerning collaborative robots and AI integration, is crucial to avoid legal repercussions and maintain user trust. This focus on safety is vital for FANUC's reputation as a provider of reliable automation solutions.

The increasing integration of industrial IoT and connected factories necessitates strict adherence to data privacy and security regulations, like the EU's GDPR. As manufacturing environments collect substantial operational data, protecting this information and ensuring customer trust is critical, particularly with escalating cyber threats. The global cybersecurity market for operational technology was projected to reach USD 21.5 billion in 2024, underscoring the importance of data security.

Evolving labor and employment laws present significant considerations as automation transforms the workforce. Regulations concerning job displacement and worker retraining, such as the US WARN Act, are becoming more relevant. FANUC must navigate these laws while also considering ethical implications and the need for fair labor practices, including retraining initiatives, to maintain its social license to operate.

Environmental factors

FANUC is actively pursuing carbon neutrality by 2050 for its Scope 1 and 2 emissions. This commitment is further reinforced by aggressive greenhouse gas (GHG) reduction targets, aiming for a 42% decrease in Scope 1 and 2 emissions by fiscal year 2030. They also plan a 12.3% reduction in Scope 3 emissions by the same year.

These ambitious environmental goals are actively shaping FANUC's internal operations, encouraging more sustainable practices. Furthermore, this focus drives the creation of energy-efficient products designed to assist their customers in lowering their own carbon footprints.

The push for energy efficiency in industrial machinery is intensifying, fueled by global sustainability targets and the increasing expense of energy. This trend directly impacts demand for automation solutions like those offered by FANUC, as businesses seek to reduce their operational carbon footprints and energy bills.

FANUC is actively addressing this by designing products that minimize power consumption, thereby aiding customers in their decarbonization efforts and boosting factory productivity. For instance, their commitment to developing more energy-efficient robots and CNC systems is a key part of their strategy to meet evolving market needs.

Beyond product design, FANUC is also implementing significant energy-saving measures within its own manufacturing facilities. A notable example is their transition to renewable electricity sources, a move that not only reduces their direct environmental impact but also demonstrates their dedication to sustainable operations, aligning with the broader industry shift towards greener practices.

Manufacturers are increasingly embracing green manufacturing, focusing on waste reduction and efficient material use, key tenets of the circular economy. This shift is driven by regulatory pressures and growing consumer demand for sustainable products.

FANUC is actively implementing strategies to minimize single-use packaging, favoring recyclable and reusable options. This initiative directly contributes to reducing both FANUC's and its customers' environmental impact.

For instance, in 2023, the packaging industry saw a significant push towards sustainable materials, with global investments in recycled plastics reaching billions, signaling a strong market trend FANUC is aligning with.

Environmental Regulations and Reporting Standards

Global environmental regulations are becoming increasingly stringent, with initiatives like the EU Green Deal and the International Sustainability Standards Board (ISSB) setting new benchmarks for corporate sustainability. These evolving standards compel manufacturers like FANUC to invest in greener technologies and improve their environmental footprint, impacting operational costs and strategic planning.

FANUC actively addresses these pressures by transparently reporting its sustainability performance. The company publishes detailed Sustainability Reports and ESG Data Books, aligning with international reporting frameworks. For instance, FANUC's 2023 Sustainability Report highlights efforts in reducing greenhouse gas emissions and promoting circular economy principles within its operations.

- Increased Scrutiny: Investors and consumers are demanding greater transparency on environmental impact, driving companies to adopt robust sustainability reporting.

- Regulatory Compliance: Adherence to evolving standards like the ISSB's climate-related disclosures is becoming a prerequisite for market access and investor confidence.

- Operational Efficiency: Investing in energy-efficient technologies and waste reduction, often driven by environmental regulations, can lead to significant cost savings.

- Innovation Driver: The push for sustainability fosters innovation in product design, manufacturing processes, and supply chain management.

Resource Conservation and Biodiversity Initiatives

FANUC's commitment extends beyond just energy and waste management, encompassing significant efforts in resource conservation. The company actively works to reduce its freshwater consumption and implements water reuse programs within its manufacturing facilities, a crucial step given global water scarcity concerns. This focus on efficient water management is vital for sustainable operations, particularly as industrial demand for water continues to rise.

A standout initiative is FANUC's long-term 100-Year Tree Restoration Plan at its headquarters. This ambitious project underscores a deep commitment to biodiversity and the regeneration of natural ecosystems. By investing in such long-term environmental stewardship, FANUC aims to contribute positively to ecological balance and natural resource preservation for future generations.

These initiatives align with growing global expectations for corporate environmental responsibility. For instance, in 2023, companies with robust environmental, social, and governance (ESG) strategies saw an average of 25% higher stock performance compared to those with weaker ESG integration, highlighting the financial benefits of such conservation efforts.

Key aspects of FANUC's resource conservation and biodiversity efforts include:

- Reduced Freshwater Usage: Implementing technologies and processes to minimize water consumption in manufacturing operations.

- Water Reuse Programs: Recycling and reusing production water to lessen reliance on fresh water sources.

- 100-Year Tree Restoration Plan: A long-term commitment to reforestation and ecological regeneration at their headquarters.

- Biodiversity Focus: Actively working to support and enhance local natural ecosystems.

FANUC's environmental strategy is deeply integrated into its operations and product development. The company is committed to achieving carbon neutrality for Scope 1 and 2 emissions by 2050, with interim goals including a 42% reduction in Scope 1 and 2 GHG emissions by fiscal year 2030, alongside a 12.3% reduction in Scope 3 emissions by the same year.

This focus on sustainability drives innovation in energy-efficient products, such as robots and CNC systems, helping customers reduce their own carbon footprints and operational costs. FANUC is also actively transitioning to renewable electricity sources for its facilities, demonstrating a commitment to greener manufacturing practices.

The company is also prioritizing resource conservation, implementing water reuse programs and working to minimize freshwater consumption. Its long-term 100-Year Tree Restoration Plan at its headquarters further highlights a dedication to biodiversity and ecological regeneration.

These efforts are crucial as global environmental regulations, like the EU Green Deal and ISSB standards, become more stringent, compelling companies to invest in sustainable technologies and transparently report their environmental performance, as exemplified by FANUC's detailed Sustainability Reports.

PESTLE Analysis Data Sources

Our Fanuc PESTLE analysis is meticulously constructed using data from leading global economic indicators, official government policy documents, and reputable industry research firms. This ensures a comprehensive understanding of the political, economic, social, technological, legal, and environmental factors influencing Fanuc's operations and future growth.