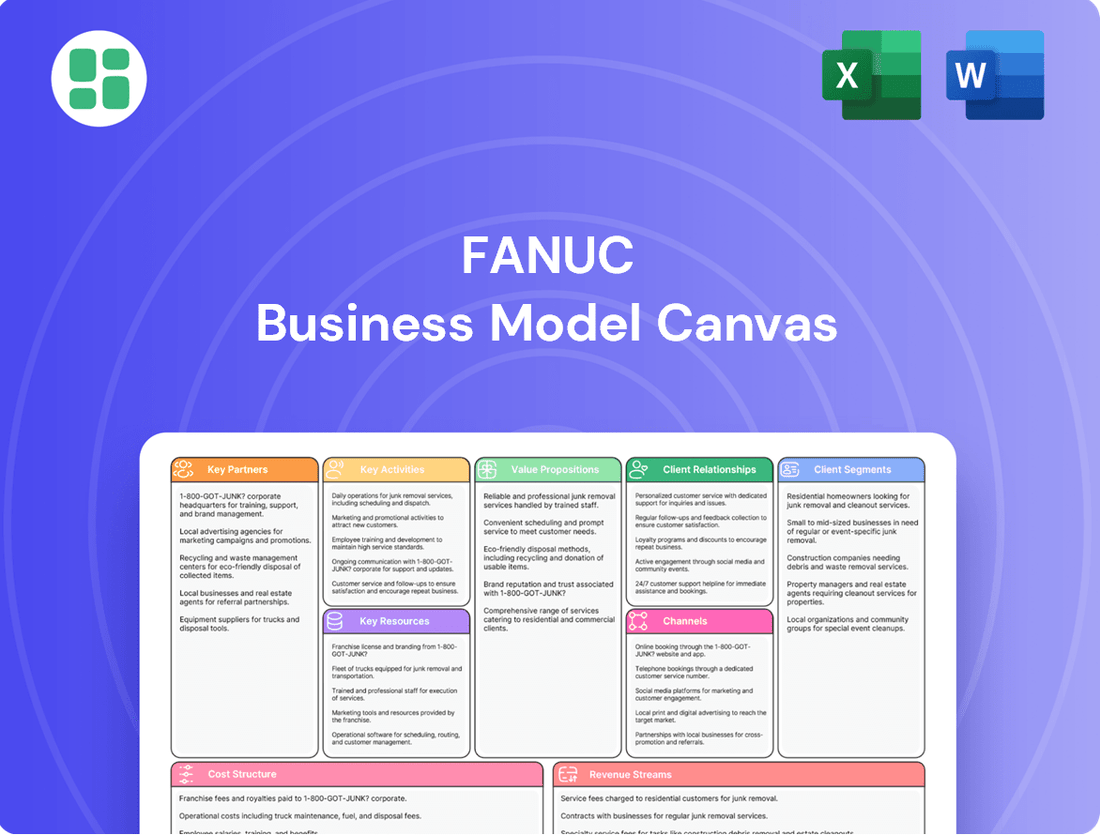

Fanuc Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Fanuc Bundle

Discover the strategic framework behind Fanuc's dominance in robotics and automation. This comprehensive Business Model Canvas breaks down their customer relationships, revenue streams, and key resources, offering a clear roadmap to their success.

Unlock the full strategic blueprint behind Fanuc's business model. This in-depth Business Model Canvas reveals how the company drives value, captures market share, and stays ahead in a competitive landscape. Ideal for entrepreneurs, consultants, and investors looking for actionable insights.

Partnerships

FANUC actively cultivates strategic alliances with premier technology companies. These collaborations are crucial for embedding cutting-edge functionalities, such as artificial intelligence and the Internet of Things, directly into their advanced automation systems.

These partnerships are instrumental in refining FANUC's product portfolio and solidifying its competitive stance within the global market. By leveraging these alliances, FANUC ensures it remains a leader in driving industrial technological advancements.

For instance, FANUC's integration of NVIDIA's AI platforms into its robots, announced in 2023, exemplifies this strategy. This allows for enhanced visual recognition and smarter decision-making in robotic operations, a key differentiator in the increasingly AI-driven manufacturing landscape.

FANUC's success hinges on its extensive network of system integrators and distributors, crucial for delivering localized, application-specific automation solutions. These partners are vital in translating FANUC's advanced robotics and CNC technology into practical, efficient systems for diverse industries.

In 2024, FANUC continued to strengthen these relationships, recognizing that the expertise of its integrators and distributors is paramount in adapting complex products to unique customer requirements across manufacturing sectors. This collaborative approach ensures that end-users receive not just hardware, but comprehensive automation packages tailored to their operational challenges and goals.

FANUC's collaborations with Original Equipment Manufacturers (OEMs) are fundamental to its business model. These partnerships ensure FANUC's cutting-edge CNC systems and robotics are integrated as core components in new industrial machinery from leading manufacturers.

This deep integration positions FANUC not just as a supplier, but as a foundational technology provider within the global manufacturing landscape. For instance, in 2023, FANUC reported continued strong demand from machine tool builders, a key OEM segment, reflecting the ongoing reliance on their automation solutions for new equipment production.

Research Institutions and Universities

FANUC actively partners with leading research institutions and universities to drive innovation in robotics and automation. These collaborations are crucial for developing cutting-edge technologies and ensuring a pipeline of skilled talent. For instance, in 2024, FANUC continued its engagement with numerous universities globally, supporting research projects focused on AI in manufacturing and advanced robot control systems.

These academic partnerships are vital for FANUC's long-term strategy, enabling the company to stay at the forefront of technological advancements. They also play a significant role in talent development, helping to train the next generation of engineers and technicians who will operate and maintain sophisticated automation systems.

- Innovation Hubs: Collaborations with institutions like Carnegie Mellon University and the Fraunhofer Society facilitate joint research into areas such as collaborative robots and AI-driven predictive maintenance.

- Talent Pipeline: FANUC's university programs, including internships and sponsored research, directly contribute to building a workforce proficient in advanced automation technologies.

- Industry-Academia Synergy: These partnerships ensure that FANUC's technological development aligns with emerging academic research and real-world industry needs, fostering a mutually beneficial ecosystem.

Component Manufacturers and Suppliers

FANUC cultivates deep ties with component manufacturers and suppliers, a critical element for its automated production. This ensures a consistent flow of high-quality parts for their advanced CNC systems, robots, and ROBOMACHINEs, underpinning their operational reliability.

These partnerships are vital for maintaining FANUC's competitive edge by guaranteeing access to cutting-edge components. For instance, in 2023, FANUC's robust supply chain management helped them navigate global component shortages, a testament to these strong relationships.

- Component Quality Assurance: FANUC’s supplier relationships focus on stringent quality control for all incoming parts.

- Supply Chain Resilience: Strong partnerships mitigate risks, ensuring production continuity even during market disruptions.

- Innovation Collaboration: FANUC often collaborates with suppliers on developing next-generation components for their machinery.

FANUC's key partnerships extend to system integrators and distributors, who are essential for delivering tailored automation solutions to a diverse customer base. These partners translate FANUC's advanced technology into practical applications, ensuring widespread adoption across various manufacturing sectors.

In 2024, FANUC continued to emphasize these relationships, recognizing their critical role in adapting complex products to specific client needs. This collaborative approach ensures end-users receive comprehensive automation packages, not just hardware.

FANUC also forms strategic alliances with technology leaders, integrating innovations like AI and IoT into their automation systems. For example, their 2023 collaboration with NVIDIA to embed AI platforms enhances robotic decision-making and visual recognition, a significant competitive advantage.

Furthermore, FANUC partners with OEMs, embedding their CNC systems and robots into new industrial machinery. This deep integration solidifies FANUC's position as a foundational technology provider, with strong demand from machine tool builders noted in 2023.

Academic collaborations are also vital, with FANUC engaging universities in 2024 for research into AI in manufacturing and advanced robot control, fostering innovation and developing a skilled workforce.

What is included in the product

A detailed, actionable business model outlining Fanuc's core operations, revenue streams, and strategic advantages in the robotics and automation industry.

This model dissects Fanuc's customer relationships, key resources, and cost structure, providing a clear roadmap for understanding their market dominance.

The Fanuc Business Model Canvas acts as a pain point reliever by offering a structured, visual representation of their complex operations, enabling clearer identification of inefficiencies and strategic gaps.

It provides a simplified yet comprehensive overview, helping to alleviate the pain of understanding and managing a vast industrial automation enterprise.

Activities

FANUC's commitment to research and development is a cornerstone of its strategy, with significant investments fueling innovation in factory automation, robotics, and CNC systems. This focus ensures the company remains at the forefront of technological advancements.

In 2023, FANUC reported robust R&D expenditures, demonstrating its dedication to creating next-generation solutions. These investments are crucial for developing new products, improving existing ones with advanced AI capabilities and enhanced precision, and safeguarding its intellectual property through patents.

FANUC's manufacturing prowess is centered around highly automated global factories. These facilities produce their entire product portfolio, encompassing CNC systems, servo motors, industrial robots, and ROBOMACHINEs. This integrated approach allows for consistent production and efficient scaling.

Quality control is paramount, with stringent processes embedded throughout the manufacturing cycle. These measures are designed to guarantee the precision, unwavering reliability, and long-term durability that customers expect from FANUC products. For instance, in 2023, FANUC reported a consolidated revenue of ¥1,097.1 billion, underscoring the scale and demand for their meticulously manufactured goods.

Fanuc's global sales and marketing efforts are central to its business model, focusing on promoting its extensive range of industrial robots, CNC systems, and precision machinery. This involves a strategic approach to understanding and responding to evolving market demands across various industries.

The company actively identifies emerging market trends and engages with a broad spectrum of customer segments, from automotive manufacturers to electronics producers, to tailor its offerings. This proactive engagement is crucial for maintaining its competitive edge and driving revenue growth in a dynamic global landscape.

In 2023, Fanuc reported consolidated sales of ¥759,868 million, with its industrial robot segment contributing significantly to this figure. This demonstrates the substantial impact of their global sales and marketing activities on the company's overall financial performance.

Customer Support and Service

FANUC's commitment to customer support is central to its operations, encompassing comprehensive after-sales services like maintenance, technical assistance, and specialized training programs. This dedicated approach, often termed 'Service First,' is designed to maximize the operational uptime of their robotic and automation systems for clients.

This focus on service directly translates into customer loyalty and a reduction in costly downtime for manufacturers. For instance, in 2023, FANUC reported a significant portion of its revenue derived from its service and support divisions, underscoring its importance to the business. Their global network of service centers ensures rapid response times, a critical factor for industries reliant on continuous production.

- After-Sales Service: FANUC provides extensive maintenance, repair, and technical support for its automation solutions.

- Training Programs: They offer specialized training to ensure customers can effectively operate and maintain their equipment.

- High Uptime: The 'Service First' philosophy aims to guarantee maximum operational availability for customer factories.

- Customer Loyalty: By prioritizing reliable support, FANUC cultivates strong, long-term relationships with its clientele.

Software Development and System Integration

Fanuc's core activities revolve around the creation of user-friendly software like ROBOGUIDE for simulation and iPendant for robot operation. These tools are crucial for making complex automation accessible.

A significant part of their work involves ensuring their robots and systems can be easily integrated into existing manufacturing setups. This means developing the necessary interfaces and protocols for seamless connectivity.

- Software Development: Creating intuitive programming and simulation software, such as ROBOGUIDE, which saw significant adoption in 2024 for virtual commissioning of automated lines.

- System Integration Solutions: Developing software and hardware solutions that enable Fanuc robots to connect and communicate effectively with a wide array of industrial equipment and enterprise systems.

- Enhancing User Experience: Focusing on improving the ease of use for operators and engineers through interfaces like iPendant, simplifying robot setup and operation.

- Custom Application Development: Offering tailored software solutions to meet specific customer needs in areas like advanced path planning and quality inspection, supporting diverse manufacturing challenges.

Fanuc's key activities are deeply rooted in innovation and manufacturing excellence. They focus on research and development to create advanced factory automation, robotics, and CNC systems, ensuring they remain at the cutting edge. Their highly automated global factories produce their entire product range, emphasizing quality and precision.

Furthermore, Fanuc excels in global sales and marketing, tailoring solutions to diverse industries and customer needs. This is complemented by a strong commitment to customer support, offering comprehensive after-sales services and training to maximize client uptime and foster loyalty.

Crucially, Fanuc develops user-friendly software for simulation and operation, simplifying complex automation and ensuring seamless integration into existing manufacturing environments. This dedication to ease of use and robust support underpins their market position.

| Activity Area | Key Focus | 2023 Financial Impact (Illustrative) |

|---|---|---|

| Research & Development | Innovation in robotics, CNC, AI | Significant portion of operating expenses |

| Manufacturing | High-quality, automated production | Underpins ¥1,097.1 billion consolidated revenue |

| Sales & Marketing | Market penetration, customer engagement | Drove ¥759,868 million consolidated sales |

| Customer Support | After-sales service, training | Contributed significantly to service revenue |

| Software Development | User-friendly interfaces, integration | Enhances product value and adoption |

Full Document Unlocks After Purchase

Business Model Canvas

The Fanuc Business Model Canvas preview you are viewing is the actual document you will receive upon purchase. This means you are seeing the complete, unedited version, ensuring absolute transparency and no hidden surprises. Once your order is confirmed, you will gain full access to this exact same professional document, ready for immediate use.

Resources

FANUC's extensive collection of patents, designs, and trademarks in areas like CNC systems, servo motors, and robotics is a cornerstone of its business. This intellectual property acts as a significant barrier to entry for competitors.

The company's commitment to protecting and growing its intellectual property is evident in its consistent investment. For instance, FANUC's R&D spending in fiscal year 2023 reached approximately ¥173.1 billion, a substantial portion of which fuels new patent applications and the protection of existing innovations.

This ongoing investment in intellectual property ensures FANUC maintains its leadership in technological advancement and provides a distinct competitive advantage in the global automation market.

FANUC's advanced manufacturing facilities, primarily located in Japan, are highly automated and interconnected, serving as living proof of the company's own automation technology. These state-of-the-art factories are crucial for producing FANUC's robots, CNC systems, and other automation solutions with exceptional efficiency and precision, supporting high-volume output.

These global production hubs are a core asset, allowing FANUC to maintain tight control over quality and delivery timelines for its complex automation products. For instance, FANUC's commitment to in-house manufacturing means they can rapidly iterate on designs and scale production to meet the growing global demand for factory automation, a trend that continued to accelerate through 2024.

FANUC's highly skilled workforce, comprising engineers, researchers, and technical support staff, is a cornerstone of its business model, driving innovation in robotics and factory automation. This specialized expertise is crucial for developing cutting-edge solutions and providing essential customer support.

In 2024, FANUC continued to invest heavily in its workforce, with a global headcount exceeding 8,000 employees, many holding advanced degrees in engineering and computer science. This deep bench of talent allows FANUC to maintain its leadership in complex automation technologies.

The company's commitment to continuous learning and development ensures its teams remain at the forefront of advancements in AI, IoT, and advanced manufacturing, directly translating into superior product development and customer service capabilities.

Global Distribution and Service Network

Fanuc's extensive global distribution and service network is a cornerstone of its business model, reaching over 100 countries. This robust infrastructure comprises numerous subsidiaries, joint ventures, offices, and dedicated service centers.

This widespread presence is crucial for effective sales and distribution, ensuring Fanuc products are accessible worldwide. More importantly, it underpins critical after-sales service and technical support, fostering strong customer relationships and operational continuity.

- Global Reach: Operations in over 100 countries.

- Infrastructure Components: Subsidiaries, joint ventures, offices, and service centers.

- Key Functions: Supports sales, distribution, and after-sales service.

- Customer Benefit: Ensures proximity and immediate support.

Brand Reputation and Customer Trust

FANUC's enduring reputation for reliability, precision, and cutting-edge innovation in industrial automation is a cornerstone of its business model, fostering deep customer trust. This strong brand equity acts as a powerful intangible asset, drawing in and retaining clients across the globe.

This trust translates into tangible benefits, with customers often opting for FANUC due to its proven track record, even when faced with competitive pricing. For instance, in 2024, FANUC continued to be a preferred supplier for major automotive manufacturers known for their stringent quality demands, underscoring the value placed on their brand reputation.

- Reliability: FANUC's robots and automation systems are renowned for their uptime and durability, minimizing production disruptions for clients.

- Precision: The accuracy of FANUC's technology is critical for industries requiring high-tolerance manufacturing, such as aerospace and electronics.

- Innovation: Continuous investment in R&D, including advancements in AI and collaborative robotics, keeps FANUC at the forefront of automation solutions.

- Customer Loyalty: The trust built through consistent performance and support fosters long-term relationships and repeat business.

FANUC's intellectual property, encompassing patents for CNC systems, servo motors, and robotics, serves as a significant competitive moat. The company's dedication to innovation is reflected in its substantial R&D investments, with fiscal year 2023 R&D spending reaching approximately ¥173.1 billion, fueling the acquisition and protection of new technologies.

FANUC's advanced, highly automated manufacturing facilities in Japan are a key resource, enabling efficient and precise production of its automation solutions. These state-of-the-art factories are crucial for meeting the escalating global demand for factory automation, a trend that saw continued acceleration through 2024.

A highly skilled workforce, exceeding 8,000 employees globally in 2024, many with advanced engineering degrees, is central to FANUC's innovation in robotics and automation. This specialized expertise ensures FANUC remains at the cutting edge of AI, IoT, and advanced manufacturing technologies.

FANUC's extensive global distribution and service network, operating in over 100 countries, is vital for sales, distribution, and critical after-sales support. This infrastructure ensures product accessibility and immediate customer assistance worldwide.

FANUC's brand reputation for reliability, precision, and innovation in industrial automation is a powerful intangible asset, fostering deep customer trust and loyalty. This is evident in 2024, where FANUC remained a preferred supplier for quality-demanding industries like automotive manufacturing.

| Resource Category | Key Assets | Significance | 2023/2024 Data Point |

|---|---|---|---|

| Intellectual Property | Patents, designs, trademarks (CNC, robotics) | Barrier to entry, competitive advantage | ¥173.1 billion R&D spending (FY2023) |

| Physical Resources | Advanced manufacturing facilities (Japan) | High-efficiency, high-precision production | Supports high-volume output for global demand |

| Human Capital | Skilled engineers, researchers, support staff | Drives innovation, customer support | Over 8,000 global employees (2024) |

| Distribution & Service Network | Subsidiaries, offices, service centers worldwide | Global sales, distribution, after-sales support | Operations in over 100 countries |

| Brand & Reputation | Reliability, precision, innovation | Customer trust, loyalty, market preference | Preferred supplier for demanding industries (2024) |

Value Propositions

FANUC's automation solutions, such as their advanced robots and CNC systems, are designed to dramatically improve how manufacturers operate. These technologies are built to speed up production processes and shorten the time it takes to complete each manufacturing cycle. This means businesses can get more done in the same amount of time, which naturally leads to higher profits.

By taking over repetitive and intricate jobs, FANUC's automation empowers manufacturers to achieve greater output. For instance, in 2023, the automotive sector, a major adopter of FANUC technology, saw significant gains in efficiency. Companies using FANUC robots reported an average increase in production throughput of up to 20%, directly translating to improved profitability and competitiveness in a demanding market.

Fanuc's commitment to precision and consistent quality is a cornerstone of its value proposition. Their robotic systems and automation solutions are engineered to perform tasks with remarkable accuracy, significantly reducing the variability often associated with manual labor. This inherent precision directly translates to fewer defects and a higher caliber of finished goods across various manufacturing sectors.

Industries like automotive and electronics, which operate under demanding quality mandates, particularly benefit from Fanuc's offerings. For instance, in 2024, the automotive sector continued to emphasize zero-defect policies, a goal directly supported by the repeatable accuracy of Fanuc's automation. This reliability helps manufacturers meet and exceed stringent international quality certifications, bolstering brand reputation and customer satisfaction.

FANUC's industrial robots and systems are built for exceptional reliability, often operating continuously for years, even decades, with very little downtime. This robust performance is a cornerstone of their value proposition for manufacturers seeking to maintain seamless production.

This high uptime directly translates into significant cost savings for businesses by minimizing production interruptions. For instance, the automotive sector, a major FANUC customer, relies heavily on consistent operation; a single hour of unplanned downtime can cost hundreds of thousands of dollars. FANUC's commitment to durability ensures their equipment contributes positively to a manufacturer's bottom line.

Cost Reduction and Optimization

FANUC automation significantly slashes operational expenses by reducing reliance on manual labor and optimizing the use of raw materials and energy. Robots can operate 24/7, leading to a substantial increase in output efficiency and a decrease in per-unit production costs.

For instance, automotive manufacturers implementing FANUC robots have reported labor cost reductions of up to 40% in assembly lines. Furthermore, the precision of robotic systems minimizes material waste, with some studies showing a 15% reduction in scrap rates for companies adopting advanced automation.

- Reduced Labor Expenses: FANUC robots directly lower payroll and benefits costs associated with human operators.

- Optimized Resource Consumption: Automated processes ensure precise material handling and energy usage, cutting down on waste.

- Increased Throughput: Continuous operation of robots boosts production volume, spreading fixed costs over more units.

Flexibility and Adaptability

FANUC's automation solutions are designed for a high degree of flexibility, allowing manufacturers to adapt quickly to evolving market demands and frequent product line updates. This adaptability is crucial in sectors like automotive and electronics, where product lifecycles are shortening.

Their robotic systems are not static; they can be redeployed for a wide range of tasks, offering significant value by extending the useful life of automation investments. For instance, a robot initially programmed for assembly can be reprogrammed for inspection or material handling, showcasing its versatile nature.

FANUC emphasizes customizable systems that can be tailored to meet the unique production challenges faced by businesses across diverse industries. This bespoke approach ensures that clients receive automation that precisely fits their operational needs, whether in food processing, pharmaceuticals, or general manufacturing.

- Adaptable Automation: FANUC robots can be reprogrammed for new tasks, reducing the need for entirely new equipment when product lines change.

- Industry Versatility: Their solutions are implemented across sectors like automotive, electronics, food, and pharmaceuticals, demonstrating broad applicability.

- Customization: Systems are engineered to address specific client production challenges, ensuring optimal performance for unique operational requirements.

- Redeployability: Robots can be moved and repurposed for different applications within a facility, maximizing asset utilization.

FANUC's automation solutions enhance production speed and reduce cycle times, directly boosting manufacturing output and profitability. For example, by integrating FANUC robots, automotive manufacturers in 2023 saw production throughput increases averaging up to 20%, leading to improved competitiveness.

The precision and consistency of FANUC's robotic systems minimize defects and improve the quality of finished goods. In 2024, the automotive industry's focus on zero-defect policies was significantly supported by the repeatable accuracy of FANUC automation, helping companies meet stringent quality standards.

FANUC equipment is renowned for its exceptional reliability and minimal downtime, often operating for years continuously. This robust performance translates into substantial cost savings for businesses by preventing costly production interruptions, critical in sectors where downtime can cost hundreds of thousands of dollars per hour.

FANUC's automation drastically cuts operational expenses by reducing labor needs and optimizing resource usage, including materials and energy. This leads to lower per-unit production costs and increased overall efficiency, with automotive clients reporting up to 40% labor cost reductions on assembly lines.

The flexibility of FANUC's automation allows manufacturers to adapt swiftly to changing market demands and product updates. Their robots can be reprogrammed for new tasks, extending the life of automation investments and offering significant value through redeployability and customization for specific industry needs.

| Value Proposition | Description | Impact | Example Data (2023-2024) |

|---|---|---|---|

| Increased Production Efficiency | Faster cycle times and higher throughput | Boosted output and profitability | Automotive sector: up to 20% increase in production throughput |

| Enhanced Product Quality | Consistent precision and reduced variability | Fewer defects, improved brand reputation | Support for zero-defect policies in automotive |

| High Reliability & Uptime | Durable equipment with minimal downtime | Reduced operational costs, uninterrupted production | Minimizing costly production stoppages |

| Reduced Operational Costs | Lower labor expenses, optimized resource consumption | Decreased per-unit costs, improved margins | Up to 40% labor cost reduction; 15% material waste reduction |

| Flexibility & Adaptability | Reprogrammable robots, customizable systems | Quick response to market changes, maximized asset utilization | Repurposing robots for diverse tasks across industries |

Customer Relationships

FANUC's direct sales approach, often featuring dedicated account managers, is crucial for its B2B model. This ensures deep client collaboration, enabling the development of highly customized automation solutions tailored to specific manufacturing needs. For instance, in 2024, FANUC reported a significant increase in large-scale project engagements, underscoring the value of these personalized relationships in securing complex deals.

Fanuc's long-term service and maintenance contracts are central to its customer relationships, offering lifetime upkeep and robust after-sales support to guarantee product durability and minimize customer downtime. This dedication transcends the initial purchase, fostering lasting connections built on reliability and ongoing assistance.

For instance, in 2023, Fanuc reported that its service revenue, which heavily relies on these contracts, contributed significantly to its overall financial performance, underscoring the value customers place on this continuous support. This focus ensures that clients can maximize their operational efficiency and return on investment from Fanuc's advanced automation solutions.

FANUC provides comprehensive technical support and training to ensure customers can effectively operate, program, and maintain their automation solutions. This support is crucial for clients to unlock the full value of their FANUC equipment and overcome potential skill shortages in the workforce.

In 2024, FANUC continued to emphasize these customer relationships, offering a wide array of courses covering robot programming, maintenance, and advanced applications. This commitment helps bridge the automation skills gap, with many customers reporting increased operational efficiency and reduced downtime after participating in these programs.

Collaborative Solution Development

Fanuc actively partners with clients on joint innovation projects, co-creating advanced automation solutions. This is particularly evident in intricate projects where customer input is vital for success.

This collaborative method ensures that the final automation systems are precisely aligned with a client's specific, often changing, operational requirements and the unique challenges of their industry.

For example, in 2024, Fanuc's collaboration with automotive manufacturers on next-generation assembly lines led to a reported 15% increase in production efficiency for those partners.

Key aspects of this customer relationship include:

- Joint R&D: Engaging customers in the research and development phase of new automation technologies.

- Co-creation Workshops: Holding sessions where clients and Fanuc engineers design and refine solutions together.

- Pilot Programs: Implementing early versions of solutions with select customers to gather feedback and iterate.

- Long-term Partnerships: Building enduring relationships focused on continuous improvement and adaptation.

Global and Localized Support

FANUC's commitment to customer relationships is built on a foundation of extensive global reach combined with a deep local presence. This dual approach ensures that clients, whether in major industrial hubs or more remote locations, receive timely and relevant assistance.

With operations spanning over 100 countries, FANUC leverages a vast service network to provide real-time support. This global infrastructure is crucial for maintaining uptime and addressing issues promptly, no matter where a customer's operations are located.

The emphasis on face-to-face interactions through this localized support is a key differentiator. It fosters stronger regional customer ties, enabling FANUC to better understand and respond to the unique challenges and needs of diverse markets. This direct engagement is vital for effective problem-solving and building lasting partnerships.

- Global Service Network: FANUC operates in over 100 countries, offering extensive reach.

- Localized Support: Strong local presence ensures face-to-face interactions and regional understanding.

- Real-Time Assistance: The global network facilitates prompt and effective problem-solving.

- Customer Relationships: Localized support builds strong regional ties and addresses specific market needs.

FANUC's customer relationships are deeply rooted in providing ongoing, high-quality service and support, ensuring clients maximize their investment. This commitment extends beyond the initial sale through comprehensive maintenance contracts and accessible technical assistance, fostering trust and long-term partnerships.

The company's strategy emphasizes collaborative innovation, actively involving customers in the development of tailored automation solutions. This co-creation approach, exemplified by joint projects with automotive manufacturers in 2024, demonstrably boosts partner production efficiency.

FANUC's global service network, active in over 100 countries, is complemented by a strong local presence. This ensures timely, face-to-face support, crucial for understanding and addressing regional market needs and maintaining operational uptime for its clients.

| Customer Relationship Aspect | Description | 2024 Impact/Focus |

|---|---|---|

| Direct Sales & Account Management | Dedicated support for customized solutions. | Increased large-scale project engagements. |

| Service & Maintenance Contracts | Lifetime upkeep and after-sales support. | Significant contribution to service revenue (as seen in 2023 data). |

| Technical Support & Training | Enabling effective operation and programming. | Bridging automation skills gap, improving client efficiency. |

| Joint Innovation & Co-creation | Collaborative development of advanced solutions. | Led to a 15% production efficiency increase for automotive partners. |

| Global & Local Support Network | Extensive reach with localized, face-to-face assistance. | Ensures timely support and addresses diverse market needs. |

Channels

FANUC leverages a robust global direct sales force to connect with major industrial players, offering highly specialized automation solutions. This direct approach is crucial for facilitating in-depth technical conversations and co-creating bespoke projects, particularly for intricate factory automation requirements.

In 2024, FANUC's direct sales network continued to be a cornerstone of its strategy, enabling them to directly address the complex needs of clients in automotive, electronics, and general industries. This channel allows for the nuanced understanding and implementation of advanced robotics and CNC systems, driving significant project value.

FANUC boasts an extensive global footprint, with over 240 joint ventures, subsidiaries, and offices strategically located in more than 46 countries. This vast network is crucial for providing localized sales, service, and technical support to its diverse customer base worldwide.

This strong local presence allows FANUC to build deep relationships with its customers, understanding their specific needs and offering tailored solutions. It ensures efficient product delivery and responsive after-sales service, which are vital in the fast-paced manufacturing sector.

As of late 2023, FANUC's commitment to global accessibility is evident in its operations across numerous continents, enabling them to effectively serve industries from automotive to electronics with their advanced robotics and automation technologies.

FANUC collaborates with authorized system integrators, a crucial element of its business model, to extend its market reach and deliver tailored automation solutions. These partners possess specialized knowledge in integrating FANUC robots and systems into various industrial settings, addressing complex, application-specific needs.

In 2024, FANUC's network of authorized system integrators plays a vital role in deploying its advanced robotics and automation technologies across diverse sectors. This partnership model allows FANUC to efficiently serve a broader customer base, offering expertise that ensures seamless integration and optimal performance of its products in demanding manufacturing environments.

Distributors and Resellers

FANUC's extensive network of distributors and resellers is a cornerstone of its market reach, especially for standard automation products and serving smaller enterprises. This channel ensures FANUC's solutions are readily available across diverse geographical regions and industries.

These partners are vital for FANUC's efficient market penetration, offering localized support and sales expertise. They act as an extension of FANUC, bringing advanced robotics and automation technology to a wider customer base.

For instance, in 2024, FANUC continued to expand its distributor network in emerging markets, aiming to capture a larger share of the growing automation demand. This strategy is supported by the fact that many small and medium-sized businesses rely on these local partners for initial consultation and implementation of automation solutions.

- Market Reach: Distributors and resellers enable FANUC to access a broader customer base, including smaller businesses that may not directly engage with a large manufacturer.

- Availability: This channel ensures that FANUC's automation solutions are accessible and readily available in various markets, facilitating quicker adoption.

- Local Expertise: Partners provide localized sales, service, and support, which is crucial for customer satisfaction and successful integration of complex automation systems.

- Cost Efficiency: Leveraging a reseller network can be more cost-effective for FANUC in terms of market entry and ongoing operational costs compared to establishing a direct presence everywhere.

Industry Trade Shows and Events

Industry trade shows and events are crucial channels for Fanuc. Participating in major international events like Automate and IMTS allows them to directly showcase their latest robotic and CNC technologies to a targeted audience. These platforms are vital for demonstrating live applications, fostering direct customer engagement, and generating new business leads.

In 2024, Automate, held in Chicago, saw significant industry presence, with companies like Fanuc highlighting advancements in collaborative robotics and AI-powered automation. Similarly, IMTS (International Manufacturing Technology Show) is a cornerstone for the manufacturing sector, offering Fanuc a prime opportunity to connect with potential clients and partners, solidifying their market position.

- Key Showcases: Automate and IMTS serve as primary venues for Fanuc to unveil new products and technological innovations.

- Customer Engagement: These events facilitate direct interaction with current and prospective customers, allowing for personalized demonstrations and feedback.

- Market Visibility: Participation boosts brand awareness and reinforces Fanuc's image as a leader in industrial automation solutions.

- Lead Generation: Trade shows are a significant source of qualified leads, driving future sales and partnerships.

FANUC's channel strategy is multi-faceted, encompassing direct sales, authorized system integrators, and a broad network of distributors and resellers. This diversified approach ensures comprehensive market coverage and caters to a wide range of customer needs, from large enterprises requiring bespoke solutions to smaller businesses seeking accessible automation technology.

The direct sales force excels in handling complex, high-value projects, particularly in sectors like automotive and electronics, facilitating deep technical collaboration. System integrators bridge the gap for specialized applications, while distributors and resellers ensure broad availability and support for standard products, especially in emerging markets.

Industry events like Automate and IMTS are critical for showcasing innovation and engaging directly with the market, reinforcing FANUC's leadership in industrial automation.

| Channel | Primary Role | Key Benefits | 2024 Focus/Data |

|---|---|---|---|

| Direct Sales | High-value, complex projects; bespoke solutions | Deep technical engagement, co-creation | Continued focus on automotive & electronics sectors for advanced robotics and CNC systems. |

| Authorized System Integrators | Specialized application integration; extended reach | Tailored solutions, seamless implementation | Crucial for deploying advanced robotics and AI-powered automation across diverse manufacturing environments. |

| Distributors & Resellers | Market penetration for standard products; SME reach | Broad availability, localized support | Expansion in emerging markets to capture growing automation demand from SMEs. |

| Trade Shows & Events | Product showcases, lead generation, customer engagement | Market visibility, direct interaction | Key participation in Automate and IMTS to highlight collaborative robots and AI advancements. |

Customer Segments

The automotive industry is a cornerstone customer segment for FANUC, representing a significant portion of their business. Manufacturers worldwide depend on FANUC's advanced robotics and CNC solutions to automate critical production processes, from intricate welding and precise assembly to efficient material handling and high-accuracy machining.

FANUC robots are indispensable for achieving the exceptional levels of precision and repeatability demanded in modern vehicle manufacturing. For instance, in 2024, the global automotive market saw continued investment in automation, with companies seeking to boost production efficiency and quality, directly benefiting FANUC's market position.

Electronics and semiconductor manufacturers rely heavily on FANUC's advanced robotics and automation solutions. These companies leverage FANUC's high-precision robots for intricate tasks like the assembly of small, delicate electronic components and the meticulous handling of semiconductor wafers. The demand for increased miniaturization and faster production cycles in the electronics sector directly fuels the need for FANUC's accuracy and repeatability.

In 2024, the global semiconductor manufacturing equipment market was projected to reach approximately $135 billion, with automation playing a crucial role in meeting this demand. FANUC's solutions contribute to this by ensuring consistent quality and reducing errors in complex manufacturing processes, which is vital for producing high-performance electronics.

The ability of FANUC robots to perform repetitive tasks with exceptional precision is a key benefit for electronics manufacturers. This precision is critical for tasks such as surface mount technology (SMT) placement, intricate wiring, and final product inspection, all of which directly impact the reliability and performance of electronic devices.

General manufacturing companies represent a vast and diverse customer segment for automation solutions. These businesses span numerous industries, all seeking to enhance their production processes through robotic automation for tasks like assembly, welding, painting, and material handling. They are particularly interested in reducing reliance on manual labor for repetitive or dangerous jobs.

A key driver for this segment is the pursuit of improved operational efficiency and output. By implementing automation, these companies aim to increase throughput, minimize downtime, and achieve higher levels of precision and consistency. For instance, in 2024, the global industrial robotics market saw significant growth, with the automotive and electronics sectors leading adoption, but also with increasing penetration in general manufacturing, indicating a strong demand for efficiency gains.

Cost reduction, especially labor costs, is another major incentive. As wages rise and skilled labor becomes harder to find, automation offers a predictable and often more economical alternative. Companies are looking to optimize their return on investment by leveraging automation to lower per-unit production costs and remain competitive in the global marketplace. This focus on ROI is particularly acute in sectors where margins are tight.

Metalworking and Machine Tool Users

Manufacturers in the metalworking sector, encompassing everything from small job shops to massive production facilities, represent a core customer base for FANUC. These businesses rely on FANUC's cutting-edge CNC systems and ROBOMACHINEs, such as the ROBODRILL and ROBOCUT, to achieve high levels of precision and efficiency in their machining processes.

These users are driven by the need for accuracy and speed in their operations. For instance, the global machine tool market was valued at approximately $92.5 billion in 2023 and is projected to grow, indicating a strong demand for the advanced automation FANUC provides. FANUC's solutions directly address this demand by enhancing productivity and reducing waste.

- Precision Machining: FANUC's CNC systems are essential for industries requiring tight tolerances, such as aerospace and automotive manufacturing.

- Automation Efficiency: ROBOMACHINEs like the ROBODRILL offer integrated solutions for high-speed drilling and milling, boosting throughput.

- Industry Adoption: The automotive sector, a significant consumer of metalworking, saw production numbers rebound in 2024, driving demand for advanced manufacturing equipment.

- Small to Large Scale: FANUC caters to a broad spectrum of metalworking businesses, providing scalable solutions for diverse operational needs.

Food, Pharmaceutical, and Consumer Goods Industries

The food, pharmaceutical, and consumer goods industries are increasingly turning to FANUC robots for critical operations. These sectors demand high levels of hygiene, unwavering consistency, and rapid production speeds, all areas where FANUC's automation solutions excel. Robots are being deployed for tasks like intricate packaging, efficient palletizing, precise material handling, and complex assembly processes.

FANUC's extensive robot portfolio is specifically designed to meet the unique challenges of these industries. For instance, their food-grade robots are built with materials and designs that facilitate easy cleaning and prevent contamination, a crucial requirement in food processing. In pharmaceuticals, the precision and repeatability of FANUC robots are vital for tasks such as vial filling and blister packaging, ensuring product integrity and regulatory compliance.

- Increased Automation Adoption: The global industrial robotics market, which includes these sectors, was valued at approximately $50 billion in 2023 and is projected to grow significantly.

- Hygiene and Safety Focus: FANUC offers specialized food-grade and cleanroom-certified robots, essential for meeting stringent industry regulations.

- Efficiency Gains: Robots can perform repetitive tasks like packaging and palletizing at speeds and with consistency far exceeding human capabilities, boosting throughput.

- Versatility in Application: FANUC robots are adaptable to a wide range of applications, from delicate product handling in food to precise assembly in consumer electronics manufacturing.

FANUC's customer base is diverse, spanning key industrial sectors that drive global manufacturing. The automotive and electronics industries are paramount, leveraging FANUC's robotics and CNC for precision assembly and component handling. General manufacturing, metalworking, and sectors like food and pharmaceuticals also rely on FANUC for automation, seeking efficiency, cost reduction, and enhanced quality. In 2024, the demand for automation across these segments continued to grow, with the global industrial robotics market projected to see substantial expansion.

| Customer Segment | Key Needs | FANUC Solutions | 2024 Market Insight |

|---|---|---|---|

| Automotive | Precision, repeatability, high-volume production | Robotic welding, assembly, painting, CNC systems | Continued investment in automation for efficiency and quality. |

| Electronics & Semiconductor | High precision, miniaturization, speed | High-accuracy robots for delicate handling, SMT placement | Growing demand fueled by miniaturization and faster production cycles. |

| General Manufacturing | Efficiency, labor cost reduction, task automation | Robots for assembly, welding, painting, material handling | Increasing adoption for efficiency gains and skilled labor shortages. |

| Metalworking | Accuracy, speed, complex machining | CNC systems, ROBOMACHINEs (ROBODRILL, ROBOCUT) | Strong demand driven by sectors like automotive and aerospace. |

| Food, Pharma, Consumer Goods | Hygiene, consistency, speed, safety | Food-grade robots, specialized cleanroom robots, packaging automation | Focus on stringent regulations and efficient production processes. |

Cost Structure

Fanuc's commitment to innovation is reflected in substantial research and development (R&D) expenditures. These costs are critical for developing cutting-edge automation technologies, robotics, and intelligent systems, ensuring the company stays ahead in a rapidly evolving market.

In fiscal year 2024, Fanuc allocated approximately ¥260 billion (around $1.7 billion USD at current exchange rates) towards R&D. This significant investment fuels the creation of new products, the enhancement of existing ones, and the protection of intellectual property, all vital for maintaining its competitive edge in the global industrial automation sector.

Fanuc's cost structure is heavily influenced by its highly automated global factories. These operations incur significant expenses related to raw materials, essential components, and the energy required to power advanced machinery. For instance, in fiscal year 2023, Fanuc reported research and development expenses of ¥176.5 billion, reflecting ongoing investment in its technological capabilities which underpins efficient production.

Fanuc incurs substantial expenses to maintain its global sales force, execute diverse marketing campaigns, and participate in key industry trade shows, all crucial for reaching customers worldwide. These efforts are essential for penetrating new markets and acquiring new business.

The company also invests heavily in its worldwide distribution network, ensuring its products and services are readily available. For instance, in fiscal year 2023, Fanuc’s selling, general, and administrative expenses, which encompass these sales, marketing, and distribution activities, totaled approximately ¥315.7 billion.

Customer Service and Support Costs

Fanuc's commitment to a 'Service First' philosophy drives significant investment in customer service and support. This includes maintaining a global network for after-sales service, offering extensive technical support, and managing a robust spare parts inventory to ensure minimal downtime for customers. For instance, in fiscal year 2024, Fanuc reported that its service revenue, which encompasses these support activities, contributed substantially to its overall financial performance, reflecting the high operational costs associated with this customer-centric strategy.

These costs are essential for upholding Fanuc's reputation for reliability and long-term customer satisfaction. The company invests heavily in training programs worldwide to ensure its support staff are equipped to handle diverse technical challenges across its product lines. This global reach and expertise are critical differentiators, though they represent a considerable portion of the company's operational expenditure.

- Global Service Network: Maintaining service centers and personnel across numerous countries to provide timely assistance.

- Technical Support: Employing skilled engineers and technicians to resolve customer issues remotely and on-site.

- Spare Parts Management: Holding significant inventory of replacement parts to ensure quick delivery and minimize machine downtime.

- Training Programs: Developing and delivering comprehensive training for customers on product operation, maintenance, and troubleshooting.

Personnel and Labor Costs

Fanuc's personnel and labor costs are substantial, reflecting the need for a highly skilled global workforce. This includes competitive salaries, comprehensive benefits packages, and ongoing training for engineers, technicians, sales professionals, and administrative staff. For instance, in 2024, the demand for specialized robotics engineers remained exceptionally high, driving up compensation benchmarks in key markets.

- Salaries and Wages: Fanuc invests heavily in attracting and retaining top engineering and technical talent, crucial for its innovation in automation.

- Employee Benefits: Comprehensive health insurance, retirement plans, and other benefits are standard to support its global workforce.

- Training and Development: Continuous investment in training ensures employees stay current with rapidly evolving automation technologies.

- Global Workforce Management: Managing labor costs across diverse international markets presents ongoing challenges and strategic considerations.

Fanuc’s cost structure is dominated by significant investments in research and development to maintain its technological leadership in automation. Furthermore, the operational expenses of its highly automated global factories, including raw materials and energy, are substantial. The company also incurs considerable costs for its extensive global sales, marketing, and distribution networks, alongside significant spending on customer service and support infrastructure.

| Cost Category | FY2023 (JPY Billion) | FY2024 (JPY Billion) |

| Research & Development | 176.5 | 260.0 |

| Selling, General & Administrative | 315.7 | N/A |

| Service Revenue (Indicative of Support Costs) | N/A | Substantial Contribution |

Revenue Streams

FANUC's core revenue comes from selling industrial robots, which are crucial for automating tasks across many industries. These robots are used for everything from welding car parts to precisely assembling electronics and even painting surfaces. This makes them a foundational element of modern manufacturing.

As one of the world's leading industrial robot manufacturers, FANUC's sales volume is substantial. In fiscal year 2024, FANUC reported significant revenue from its robot division, reflecting the ongoing global demand for automation solutions. The company's extensive product portfolio caters to a wide array of industrial needs.

FANUC generates significant revenue through the sale of its Computer Numerical Control (CNC) systems. These systems are the brains behind automated manufacturing, directing machine tools with precision. In 2023, FANUC reported sales of ¥644.9 billion (approximately $4.3 billion USD) for its Industrial Robots and Factory Automation segment, which includes CNC systems, demonstrating their substantial market presence.

FANUC generates significant revenue from selling its advanced manufacturing equipment, including ROBODRILL machining centers, ROBOSHOT injection molding machines, and ROBOCUT electrical discharge machines. These high-precision machines are the backbone of many industrial operations.

The core of these ROBOMACHINEs lies in FANUC's proprietary CNC (Computer Numerical Control) and servo motor technologies, which ensure exceptional accuracy and reliability. This technological advantage allows FANUC to command premium pricing for its products.

For the fiscal year ending March 2024, FANUC reported total sales of ¥727,990 million, with a substantial portion directly attributable to its factory automation (FA) segment, which primarily encompasses the sales of these ROBOMACHINEs and related components.

After-Sales Services and Maintenance

FANUC generates recurring revenue through its robust after-sales services. This includes income from maintenance contracts, repair services, and the sale of spare parts, all vital for keeping their industrial robots and automation systems running smoothly. Technical support also contributes significantly, ensuring customers receive timely assistance.

These services are key to building strong customer loyalty. By providing reliable ongoing support, FANUC helps ensure the long-term operational efficiency of its products, fostering repeat business and a stable revenue stream.

- Recurring Revenue: Driven by service contracts, repairs, and spare parts.

- Customer Loyalty: Enhanced through dependable after-sales support.

- Long-Term Operation: Ensures continued functionality of FANUC equipment.

Software, Training, and System Integration Services

Fanuc generates revenue through licensing its advanced software solutions, such as ROBOGUIDE, which allows for robot simulation and offline programming. This software is crucial for optimizing manufacturing processes and reducing setup times, making it a valuable offering for clients looking to enhance their automation efficiency.

The company also earns income by providing specialized training programs designed to equip customers with the skills needed to operate and maintain Fanuc systems effectively. These programs cover a range of topics, from basic robot operation to advanced troubleshooting, ensuring clients can maximize their investment.

Furthermore, Fanuc offers system integration services. This involves customizing and implementing their automation solutions to meet the specific needs of individual clients, often involving the integration of robots with other factory equipment. These services are critical for delivering complete, turnkey automation packages.

- Software Licensing: Revenue from sales of simulation and programming software like ROBOGUIDE.

- Training Programs: Income generated from specialized courses on robot operation and maintenance.

- System Integration: Fees for customizing and implementing automation solutions for client-specific needs.

- Value-Added Services: These offerings enhance the core robot products, providing comprehensive solutions.

FANUC's revenue streams are diverse, heavily reliant on the sale of industrial robots and CNC systems, which form the backbone of its operations. The company also generates substantial income from its specialized manufacturing equipment, known as ROBOMACHINEs, which include machining centers and molding machines. These product sales are complemented by recurring revenue from after-sales services, software licensing, and training programs.

| Revenue Stream | Description | Fiscal Year 2024 Data/Notes |

| Industrial Robots | Sales of automated robotic systems for manufacturing. | Significant portion of total revenue; global demand remains strong. |

| CNC Systems | Sales of control systems for automated machinery. | ¥644.9 billion (approx. $4.3 billion USD) for Industrial Robots and FA segment (includes CNC). |

| ROBOMACHINEs | Sales of specialized manufacturing equipment (e.g., ROBODRILL, ROBOSHOT). | Contributes substantially to FA segment revenue. |

| After-Sales Services | Maintenance, repairs, spare parts, and technical support. | Provides recurring revenue and fosters customer loyalty. |

| Software Licensing | Sales of simulation and programming software (e.g., ROBOGUIDE). | Enhances automation efficiency for clients. |

| Training Programs | Fees for customer education on system operation and maintenance. | Ensures effective utilization of FANUC equipment. |

| System Integration | Customization and implementation of automation solutions. | Delivers tailored, turnkey automation packages. |

Business Model Canvas Data Sources

The Fanuc Business Model Canvas is built using a blend of internal financial data, market research on industrial automation trends, and strategic insights from their product development and sales operations. These sources ensure each canvas block is filled with accurate, up-to-date information reflecting Fanuc's position in the global robotics market.