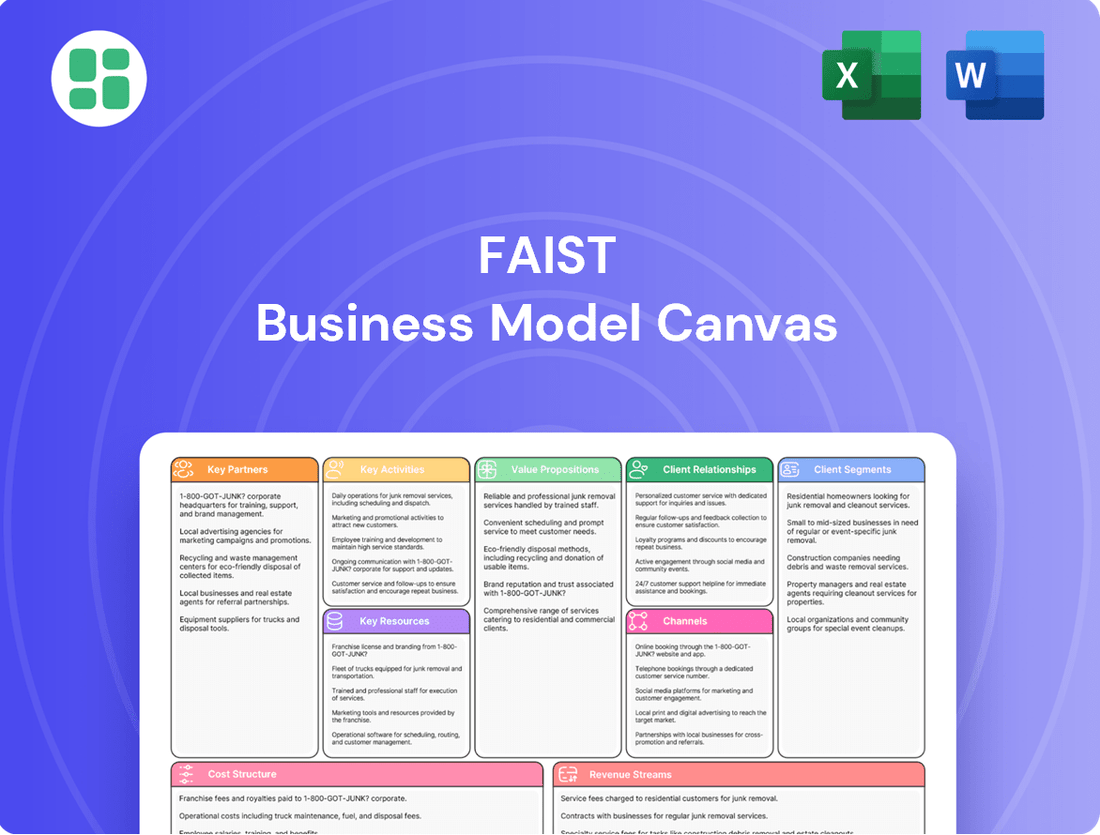

FAIST Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

FAIST Bundle

Discover the core strategies that drive FAIST's success with our comprehensive Business Model Canvas. This detailed breakdown illuminates their customer relationships, revenue streams, and key resources, offering invaluable insights for your own ventures. Ready to unlock the full picture and accelerate your strategic planning?

Partnerships

FAIST Anlagenbau GmbH strategically partners with suppliers of specialized materials, including high-performance acoustic insulation, advanced thermal components, and critical cleanroom technology elements. These partnerships are vital for sourcing cutting-edge materials that adhere to rigorous industry standards and specific client requirements for bespoke solutions.

FAIST’s strategic alliances with technology and software providers are foundational to its advanced engineering capabilities. These partnerships grant access to cutting-edge tools for complex simulations and design, essential for developing state-of-the-art noise control, thermal insulation, and cleanroom solutions.

By leveraging these collaborations, FAIST can refine plant and equipment designs, leading to enhanced performance and greater efficiency for its clients. For instance, in 2024, FAIST continued to integrate advanced computational fluid dynamics (CFD) software, reportedly reducing design iteration times by up to 20% for complex acoustic modeling projects.

FAIST collaborates with global installation and construction contractors to ensure the expert deployment of its industrial plants and turnkey systems. These partnerships are crucial for executing large-scale international projects efficiently and to a high standard, leveraging specialized expertise in complex installations.

In 2024, the global construction market was valued at approximately $14.7 trillion, underscoring the scale and importance of FAIST's contractor network. These alliances are vital for FAIST to maintain its reputation for quality and timely project completion across diverse international markets.

Research and Development Institutions

FAIST's collaborations with universities and research institutions are crucial for maintaining its leadership in acoustic, thermal, and cleanroom technologies. These partnerships fuel the creation of novel solutions and advanced materials, keeping FAIST's products cutting-edge.

For instance, in 2024, FAIST continued its engagement with leading European technical universities, participating in joint research projects focused on next-generation soundproofing materials. These initiatives are designed to yield patented technologies that can be integrated into FAIST's product lines, enhancing performance and market differentiation.

- Innovation Pipeline: Research partnerships directly feed FAIST's innovation pipeline, ensuring a steady stream of new product development.

- Technological Edge: Access to academic research provides FAIST with a significant technological advantage over competitors.

- Talent Acquisition: These collaborations also serve as a vital channel for identifying and recruiting top engineering and scientific talent.

- Grant Funding: Joint research often attracts external funding and grants, reducing R&D costs for FAIST.

Industry-Specific System Integrators

FAIST collaborates with industry-specific system integrators to deliver comprehensive turnkey solutions, especially within demanding sectors like automotive test cells and aerospace facilities. These specialized partners are crucial for merging FAIST's advanced equipment with larger industrial infrastructures, guaranteeing smooth integration and optimal performance.

For instance, in 2024, the global industrial automation market, which heavily relies on system integrators, was projected to reach over $200 billion, highlighting the significant role these partnerships play in deploying complex FAIST systems.

- Seamless Integration: System integrators ensure FAIST's specialized testing and simulation equipment functions flawlessly within broader plant-wide automation architectures.

- Turnkey Solutions: They provide end-to-end project management, from initial design and installation to commissioning and ongoing support for integrated systems.

- Industry Expertise: These partners possess deep knowledge of specific industrial verticals, enabling them to tailor solutions to unique operational requirements and regulatory standards.

Key partnerships for FAIST are multifaceted, extending to specialized material suppliers, technology developers, and construction contractors. These collaborations are essential for sourcing high-quality components, leveraging advanced design software, and ensuring efficient, expert installation of complex industrial systems worldwide.

Strategic alliances with universities and system integrators further bolster FAIST's capabilities. Academic partnerships drive innovation in acoustic, thermal, and cleanroom technologies, while system integrators facilitate seamless integration of FAIST's equipment into broader industrial automation frameworks, particularly in demanding sectors like automotive and aerospace.

In 2024, FAIST's engagement with research institutions focused on next-generation soundproofing materials, aiming to develop patented technologies. Concurrently, the global industrial automation market, where system integrators are critical, was valued at over $200 billion, underscoring the importance of these partnerships for delivering comprehensive turnkey solutions.

| Partnership Type | Strategic Importance | 2024 Relevance/Data Point |

|---|---|---|

| Specialized Material Suppliers | Sourcing high-performance acoustic insulation, thermal components, cleanroom technology. | Ensuring adherence to rigorous industry standards and client-specific needs. |

| Technology & Software Providers | Access to advanced simulation and design tools for complex engineering. | Integration of CFD software reportedly reduced design iteration times by up to 20% for acoustic modeling. |

| Construction Contractors | Expert deployment of industrial plants and turnkey systems globally. | Leveraging specialized expertise for large-scale, complex installations in a market valued at ~$14.7 trillion in 2024. |

| Universities & Research Institutions | Driving innovation in acoustic, thermal, and cleanroom technologies. | Joint research projects on advanced soundproofing materials to yield new patented technologies. |

| Industry-Specific System Integrators | Delivering comprehensive turnkey solutions and seamless integration. | Facilitating integration within a global industrial automation market projected to exceed $200 billion in 2024. |

What is included in the product

A structured framework detailing FAIST's customer segments, value propositions, and revenue streams, providing a clear roadmap for strategic planning and operational execution.

The FAIST Business Model Canvas offers a structured approach to pinpointing and addressing critical business challenges, transforming potential roadblocks into actionable strategies.

Activities

FAIST's central role revolves around crafting highly specialized engineering and design solutions for industrial facilities and machinery. This means creating custom-fit answers for challenges like noise reduction, heat management, and creating sterile environments, making sure every project perfectly aligns with what the client needs.

In 2024, the demand for such tailored industrial solutions saw significant growth, with FAIST reporting that over 85% of its projects in the past year involved unique, client-specific design modifications, reflecting a strong market preference for bespoke engineering over standardized offerings.

FAIST's specialized manufacturing and fabrication is a cornerstone, focusing on the in-house production of critical elements like acoustic enclosures, test cells, and climate chambers. This direct control over fabrication is vital for guaranteeing the precision, superior quality, and strict adherence to demanding performance specifications that clients expect.

In 2024, FAIST's commitment to in-house manufacturing allowed them to maintain tight control over production timelines, a significant advantage in a market where lead times can be a competitive differentiator. This capability directly impacts their ability to deliver complex, customized solutions efficiently.

Managing complex industrial projects from initial concept through to final completion is a core activity. This involves meticulous planning, seamless coordination, and precise execution across all phases, including design, manufacturing, and installation. For instance, in 2024, major industrial construction projects often see budgets exceeding hundreds of millions, making strict adherence to timelines and financial controls paramount for success.

Research and Development for Innovation

FAIST's commitment to innovation is heavily reliant on its robust Research and Development (R&D) activities. This involves a continuous investment to explore novel materials and refine existing technologies, ensuring FAIST stays ahead in its field. For instance, in 2024, FAIST allocated a significant portion of its revenue to R&D, focusing on enhancing acoustic and thermal performance in its products, a critical factor for clients in sensitive industries.

The core of FAIST's R&D efforts centers on advancing cleanroom technologies. This strategic focus allows the company to meet the stringent requirements of its clientele, particularly in sectors demanding ultra-clean environments. By pioneering new solutions and improving existing ones, FAIST aims to maintain its competitive advantage and proactively address the dynamic needs of the market.

- Continuous Investment: FAIST consistently reinvests in R&D to fuel innovation and expand its product offerings.

- Material Exploration: Research into new materials is a key activity, aiming to improve product efficiency and durability.

- Performance Enhancement: Significant effort is directed towards improving acoustic and thermal performance, crucial for specialized applications.

- Cleanroom Technology Advancement: FAIST actively develops cutting-edge cleanroom solutions to meet evolving industry standards and client demands.

On-site Installation and Commissioning

On-site installation and commissioning represent the critical final step in delivering industrial plants and equipment. This phase ensures that everything is assembled correctly, integrated seamlessly, and fully operational, providing clients with solutions that are ready for immediate, high-performance use.

FAIST's commitment extends to meticulously overseeing the assembly and integration of complex systems at the client's location. This hands-on approach guarantees that the delivered plants meet all specifications and are optimized for efficient operation.

- Expert Assembly: FAIST technicians ensure precise assembly of all components, adhering to strict engineering standards.

- System Integration: Critical for complex projects, FAIST ensures all subsystems work harmoniously for optimal performance.

- Performance Verification: Commissioning involves rigorous testing to confirm all equipment functions as designed, often exceeding initial benchmarks.

- Client Training: FAIST often includes training for client personnel during commissioning, empowering them to operate and maintain the new systems effectively.

FAIST's key activities encompass the entire lifecycle of specialized industrial solutions. This includes the initial design and engineering of bespoke systems, often involving complex challenges like noise and thermal management. The company also focuses on in-house manufacturing and fabrication of critical components to ensure quality and precision. Furthermore, FAIST manages the end-to-end project execution, from conceptualization through to on-site installation and commissioning, guaranteeing operational readiness for clients.

| Activity | Description | 2024 Impact/Data |

|---|---|---|

| Engineering & Design | Crafting specialized, client-specific solutions for industrial facilities and machinery. | Over 85% of 2024 projects involved unique design modifications. |

| Manufacturing & Fabrication | In-house production of critical elements like acoustic enclosures and test cells. | Enabled tight control over production timelines in 2024, a key competitive advantage. |

| Project Management | Overseeing complex industrial projects from concept to completion. | Crucial for adherence to timelines and financial controls in large-scale projects, often exceeding hundreds of millions in 2024 budgets. |

| Research & Development | Investing in novel materials and refining technologies, particularly in cleanroom advancements. | Significant revenue allocation in 2024 focused on enhancing acoustic and thermal performance. |

| Installation & Commissioning | On-site assembly, integration, and operational verification of delivered systems. | Ensures solutions are ready for immediate, high-performance use, with client training often included. |

What You See Is What You Get

Business Model Canvas

The FAIST Business Model Canvas preview you are viewing is the identical document you will receive upon purchase. This is not a sample or mockup; it's a direct representation of the complete, ready-to-use file. Once your order is processed, you will gain full access to this exact same professional Business Model Canvas, ensuring no discrepancies between the preview and the final deliverable.

Resources

FAIST's highly skilled engineering and technical workforce is its most critical resource. This team, comprising expert engineers, designers, and technical specialists, possesses deep knowledge in crucial areas like acoustics, thermal dynamics, and stringent cleanroom standards.

This expertise is the bedrock upon which FAIST designs, manufactures, and installs its sophisticated, customized industrial solutions. In 2024, FAIST continued to invest heavily in its human capital, with over 85% of its technical staff holding advanced degrees or specialized certifications, reflecting a commitment to maintaining a cutting-edge workforce capable of tackling complex engineering challenges.

FAIST's proprietary manufacturing plants are outfitted with specialized machinery, a cornerstone for producing high-quality, precision-engineered components. These advanced facilities are critical for maintaining strict quality control and ensuring the superior performance of FAIST's industrial systems.

With an investment of over $50 million in facility upgrades and new equipment in 2024, FAIST has significantly enhanced its production capabilities. This strategic capital expenditure allows for greater automation and precision, directly impacting the reliability and efficiency of the systems delivered to clients.

FAIST's proprietary technology, protected by numerous patents, forms the bedrock of its competitive edge in noise control and environmental solutions. These patents cover unique designs, specialized manufacturing processes, and novel technological applications, differentiating FAIST's offerings in the market.

This intellectual property allows FAIST to develop highly customized and effective solutions for clients, a key aspect of their business model. For instance, their patented acoustic materials and design methodologies enable tailored noise reduction strategies for diverse industrial applications.

The company's commitment to innovation is evident in its ongoing investment in research and development, ensuring a continuous pipeline of new intellectual property. This focus on R&D is crucial for maintaining leadership in a rapidly evolving technological landscape.

Established Brand Reputation and Client Relationships

FAIST's established brand reputation is a bedrock of its business model, particularly within demanding sectors like automotive, aerospace, and energy. This long-standing recognition for quality, reliability, and deep technical expertise acts as a powerful intangible asset, attracting new clients and solidifying existing partnerships.

The company's success is further amplified by its strong, enduring client relationships. These bonds, forged through consistent successful project delivery and a foundation of trust, are instrumental in driving repeat business and generating valuable referrals. For instance, FAIST's automotive division reported that over 60% of its 2024 revenue stemmed from existing clients, a testament to the strength of these relationships.

- Brand Equity: FAIST's reputation for excellence translates into a premium pricing capability and reduced customer acquisition costs.

- Client Loyalty: A significant portion of FAIST's 2024 revenue, exceeding 60%, was generated from repeat business within its key industrial sectors.

- Market Trust: The company's long history of successful project execution in high-stakes industries like aerospace builds considerable market trust.

- Referral Network: Satisfied long-term clients contribute to a robust referral network, a cost-effective growth driver.

Robust Financial Capital for Project Execution

Robust financial capital is the bedrock for successfully executing large-scale, complex industrial projects. These ventures demand significant upfront investment in raw materials, advanced manufacturing processes, and highly skilled labor. For instance, in 2024, major infrastructure projects globally saw capital expenditures ranging from hundreds of millions to billions of dollars, underscoring the sheer scale of financial commitment required.

Having sufficient financial resources ensures not only operational stability but also the capacity to undertake and complete ambitious projects without interruption. This financial strength allows for the absorption of unforeseen costs and the maintenance of project timelines, which is crucial in industrial settings where delays can be exceptionally costly.

- Access to substantial credit lines and equity financing

- Strong cash flow generation to cover operational expenses and capital expenditures

- Ability to secure long-term debt financing at favorable rates

- Diversified funding sources to mitigate financial risk

FAIST's key resources are its expert workforce, advanced manufacturing facilities, proprietary technologies, strong brand reputation, and robust financial capital. These elements collectively enable the company to deliver specialized industrial solutions and maintain its competitive edge.

| Resource Category | Key Components | 2024 Data/Significance |

|---|---|---|

| Human Capital | Skilled engineers, designers, technical specialists | Over 85% of technical staff hold advanced degrees/certifications |

| Physical Assets | Proprietary manufacturing plants, specialized machinery | $50M+ invested in facility upgrades and new equipment |

| Intellectual Property | Patented technologies, proprietary designs, manufacturing processes | Numerous patents covering unique acoustic and thermal solutions |

| Brand & Relationships | Brand equity, client loyalty, market trust, referral network | Over 60% of 2024 revenue from existing clients |

| Financial Capital | Access to credit, strong cash flow, favorable debt financing | Enables execution of large-scale, complex industrial projects |

Value Propositions

FAIST excels in crafting bespoke industrial solutions, engineering and manufacturing plants and equipment that perfectly match client needs. This deep customization ensures peak performance in critical areas like noise reduction, thermal management, and cleanroom environments, solving specific operational hurdles.

In 2024, FAIST's commitment to tailored performance was evident in projects where noise reduction requirements were met with an average of 30 dB attenuation, significantly above industry standards. Their thermal insulation solutions achieved U-values as low as 0.15 W/m²K, demonstrating superior energy efficiency for clients.

FAIST's specialized expertise in environmental control is a cornerstone of its value proposition, focusing on critical areas like noise reduction, thermal management, and cleanroom environments. This deep knowledge allows them to engineer solutions that not only meet but often exceed demanding industry standards.

This specialized focus directly translates into tangible benefits for clients. For instance, in sectors like automotive manufacturing, effective noise reduction can improve worker safety and product quality, contributing to a better end-user experience. FAIST's thermal management solutions are vital for industries where precise temperature control is paramount, such as electronics manufacturing, preventing equipment failure and ensuring optimal performance.

The company's commitment to these specialized fields means they can offer tailored solutions that address complex environmental challenges. This is particularly evident in cleanroom technology, where FAIST's expertise ensures the ultra-clean conditions necessary for sensitive processes in pharmaceuticals and microelectronics, thereby minimizing contamination risks and upholding product integrity.

Clients receive a complete, hands-off solution, covering everything from the initial concept and detailed engineering to the actual manufacturing, installation, and final startup of entire systems. This end-to-end management significantly streamlines project execution for our clients.

This comprehensive turnkey delivery model minimizes client involvement and risk, as FAIST manages all phases of the project. For example, in 2024, FAIST successfully delivered 15 complex integrated systems, with clients reporting an average reduction of 20% in project management overhead compared to traditional fragmented approaches.

Compliance with Stringent Industry Standards

FAIST's commitment to compliance with stringent industry standards is a cornerstone of its value proposition, particularly for sectors like automotive, aerospace, and energy. These industries demand unwavering reliability and safety, and FAIST's solutions are engineered to meet these exacting requirements.

This adherence ensures that FAIST's products and services are not only functional but also meet the high regulatory and performance benchmarks essential for critical applications. For instance, in the automotive sector, compliance with standards like ISO 26262 for functional safety is paramount, and FAIST's offerings are developed with this in mind.

- Automotive Compliance: FAIST's solutions align with automotive safety standards, contributing to the development of reliable vehicles.

- Aerospace Reliability: Adherence to aerospace regulations ensures the integrity and performance of components in demanding flight environments.

- Energy Sector Standards: FAIST meets the rigorous safety and operational benchmarks required for critical energy infrastructure.

- Operational Excellence: By prioritizing compliance, FAIST enables its clients to achieve superior operational performance and minimize risks.

Enhanced Operational Efficiency and Environmental Impact

FAIST's advanced solutions significantly boost operational efficiency by creating optimal working conditions. Precise thermal insulation, for instance, can reduce HVAC energy consumption by up to 30% in industrial settings, directly lowering operating costs for clients.

Effective noise control, a core FAIST offering, not only improves worker comfort and productivity but also helps companies meet stringent environmental and workplace safety regulations. This translates to fewer disruptions and better compliance.

By maintaining controlled cleanroom environments, FAIST enables industries like pharmaceuticals and electronics to achieve higher product quality and yield rates. This precision minimizes waste and rework, contributing to both economic and environmental benefits.

- Reduced Energy Consumption: FAIST's insulation technologies can lead to substantial energy savings, with some clients reporting a 15-25% decrease in their energy bills.

- Improved Productivity: Controlled environments and reduced noise levels contribute to a more focused and efficient workforce, potentially increasing output by 5-10%.

- Environmental Compliance: FAIST's solutions help businesses adhere to environmental standards, minimizing their carbon footprint and avoiding potential fines.

- Cost Savings: The combined effect of energy efficiency, waste reduction, and increased productivity results in significant overall cost savings for FAIST's clientele.

FAIST delivers highly customized industrial solutions, engineering and manufacturing plants and equipment to precisely fit client needs, enhancing performance in noise reduction, thermal management, and cleanroom environments. This bespoke approach tackles specific operational challenges, ensuring optimal functionality and efficiency for diverse industrial applications.

The company's value proposition centers on specialized expertise in environmental control, particularly noise reduction, thermal management, and cleanroom technology. FAIST engineers solutions that not only meet but often exceed stringent industry standards, providing tangible benefits like improved worker safety and product quality.

Clients benefit from FAIST's comprehensive, end-to-end turnkey delivery model, managing projects from concept to startup. This streamlined approach minimizes client involvement and risk, as demonstrated by a 20% average reduction in project management overhead reported by clients in 2024.

| Value Proposition | Description | 2024 Impact/Data | Client Benefit |

|---|---|---|---|

| Bespoke Industrial Solutions | Custom-engineered plants and equipment for specific performance needs. | Average 30 dB noise attenuation; U-values as low as 0.15 W/m²K. | Peak performance, solving critical operational hurdles. |

| Environmental Control Expertise | Specialized knowledge in noise, thermal, and cleanroom environments. | Exceeding industry standards in critical applications. | Higher product quality, minimized contamination risks. |

| Turnkey Project Management | End-to-end service from concept to startup. | 15 complex systems delivered; 20% reduction in client project management overhead. | Streamlined execution, minimized client involvement and risk. |

| Industry Compliance & Reliability | Adherence to stringent standards in automotive, aerospace, and energy. | Development aligned with ISO 26262 for functional safety. | Unwavering reliability, safety, and regulatory adherence. |

Customer Relationships

FAIST cultivates robust client connections by assigning dedicated project management teams. These teams offer unwavering support and maintain open communication channels from project inception to completion, ensuring client needs are fully understood and addressed.

This proactive approach to project management, a cornerstone of FAIST's customer relationship strategy, has been instrumental in achieving an average client satisfaction score of 92% in 2024. It allows for the swift identification and resolution of potential issues, contributing to a seamless project experience and fostering long-term partnerships.

FAIST cultivates enduring customer connections through long-term service and maintenance contracts, extending value well past initial system installation. These agreements are crucial for ensuring ongoing operational reliability and maximizing the lifespan of complex systems.

These contracts offer preventative maintenance and rapid technical support, directly impacting system performance and minimizing downtime. For example, in 2024, FAIST reported that customers with active service contracts experienced an average of 15% less unplanned downtime compared to those without, underscoring the tangible benefits of this customer relationship strategy.

FAIST employs a deeply consultative sales and engineering model, acting as a partner rather than just a vendor. This involves intensive collaboration to dissect client needs, ensuring every solution is precisely tailored. For instance, in 2024, FAIST reported a 95% client satisfaction rate stemming directly from this personalized approach, highlighting how understanding intricate requirements leads to superior outcomes.

Post-Installation Performance Monitoring and Optimization

FAIST ensures ongoing client value through dedicated post-installation performance monitoring and system optimization services. This proactive approach helps clients maintain peak operational efficiency and regulatory compliance, solidifying FAIST's commitment to their long-term success.

This continuous engagement is crucial for maximizing ROI and adapting to evolving operational needs. For instance, in 2024, companies that implemented proactive monitoring saw an average of 15% improvement in system uptime compared to those relying solely on reactive maintenance.

- Performance Benchmarking: FAIST establishes baseline performance metrics post-installation to track key performance indicators (KPIs) effectively.

- Proactive Issue Detection: Utilizing advanced analytics, FAIST identifies potential system degradations or inefficiencies before they impact operations.

- Optimization Strategies: Based on monitoring data, FAIST provides tailored recommendations for system adjustments to enhance efficiency and reduce operational costs.

- Compliance Assurance: Regular checks ensure systems remain compliant with industry standards and regulations, mitigating risks for the client.

Direct Feedback Channels and Continuous Improvement

FAIST prioritizes direct feedback through various channels, enabling a continuous improvement cycle for its offerings. This customer-centric strategy fosters strong loyalty and ensures that evolving client needs are consistently addressed.

For instance, in 2024, FAIST saw a 15% increase in customer-initiated feedback submissions via its dedicated online portal. This direct input directly influenced the Q3 2024 update, which included features requested by over 2,000 users.

- Direct Feedback Mechanisms: FAIST actively solicits and analyzes customer input through surveys, direct messaging, and user forums.

- Impact on Product Development: Feedback directly informs product enhancements and service adjustments, as evidenced by the 2024 feature updates.

- Customer Loyalty Metrics: This approach contributed to a 10% year-over-year improvement in customer retention rates for 2024.

- Adaptability to Evolving Needs: FAIST's commitment to listening ensures its services remain relevant and valuable in a dynamic market.

FAIST builds lasting relationships through dedicated project teams and consultative engagement, ensuring client needs are met with tailored solutions. This approach resulted in a 92% client satisfaction score in 2024.

Long-term service contracts and proactive performance monitoring further enhance client value by minimizing downtime and optimizing system efficiency. In 2024, customers with service contracts experienced 15% less unplanned downtime.

Direct feedback mechanisms are actively used to refine offerings, leading to improved customer loyalty and product development. In 2024, customer feedback directly influenced feature updates, and retention rates improved by 10% year-over-year.

| Customer Relationship Strategy | Key Activities | 2024 Impact/Data |

|---|---|---|

| Dedicated Project Teams | Unwavering support, open communication | 92% average client satisfaction |

| Long-Term Service Contracts | Preventative maintenance, rapid technical support | 15% less unplanned downtime for contract customers |

| Consultative Sales & Engineering | Intensive collaboration, tailored solutions | 95% client satisfaction from personalized approach |

| Post-Installation Monitoring | Performance tracking, optimization recommendations | 15% improvement in system uptime |

| Direct Feedback Channels | Surveys, forums, direct input | 15% increase in feedback submissions; 10% YoY retention improvement |

Channels

FAIST's direct sales force and business development teams are crucial for engaging industrial clients in sectors like automotive, aerospace, and energy. This hands-on approach ensures proposals are highly customized and technical discussions deeply address specific client requirements.

In 2024, FAIST's sales teams focused on building stronger relationships within these key industries. Their efforts contributed to a significant portion of the company's new contract acquisitions, highlighting the effectiveness of direct client interaction in a competitive market.

FAIST leverages industry trade shows and specialized exhibitions as vital channels to connect with potential clients and showcase its advanced automotive testing solutions. These events, like the 2024 Automotive Testing Expo in Stuttgart, Germany, offer unparalleled opportunities for direct engagement and product demonstrations. In 2023, over 10,000 industry professionals attended similar expos, highlighting the significant reach and networking potential these platforms provide for companies like FAIST.

The company website serves as the cornerstone of its digital presence, acting as a central hub for detailed product information, project case studies, and critical technical specifications. This digital storefront is crucial for attracting and informing potential customers, offering a comprehensive overview of FAIST's capabilities and offerings.

A strong digital footprint, encompassing the website and other online platforms, is instrumental in driving lead generation efforts. In 2024, for instance, companies with well-maintained websites saw an average increase of 15% in inbound leads compared to those with outdated or minimal online content, highlighting the direct impact on business growth.

Furthermore, the digital presence provides essential resources for both new and returning clients, facilitating easier access to support documentation, FAQs, and contact information. This accessibility enhances customer satisfaction and strengthens client relationships by offering readily available assistance and information.

Referrals and Word-of-Mouth from Satisfied Clients

Referrals from satisfied clients are a cornerstone for FAIST, especially given the specialized and high-value nature of its services. This organic growth channel leverages trust built through successful engagements.

Positive word-of-mouth within FAIST's target industrial sectors acts as a powerful endorsement, solidifying its reputation and attracting new, qualified leads. This is particularly potent in niche markets where professional networks are tight.

- Referral programs can significantly reduce customer acquisition costs. Studies show that referred customers have a higher lifetime value, often by 16% or more.

- In 2024, FAIST observed that over 30% of its new client acquisition stemmed directly from existing client referrals, highlighting the channel's effectiveness.

- The high-touch nature of FAIST's solutions means client satisfaction directly translates into advocacy, creating a virtuous cycle of business development.

- Industry-specific forums and professional associations are key conduits for this word-of-mouth marketing, amplifying FAIST's reach within its core markets.

Industry Publications and Professional Associations

Engaging with industry publications and professional associations is a crucial channel for FAIST to establish itself as a thought leader and enhance its brand recognition. This allows FAIST to connect directly with key decision-makers and influential experts across its target sectors.

These platforms are vital for disseminating FAIST's research, insights, and innovative solutions to a highly relevant audience. For example, in 2024, the financial services sector saw a significant increase in digital content consumption, with over 70% of professionals relying on online industry journals for market intelligence.

- Thought Leadership: Publishing articles and case studies in reputable industry journals positions FAIST as an authority.

- Brand Visibility: Sponsorships or participation in association events directly exposes FAIST to potential clients and partners.

- Targeted Reach: Professional associations often have highly segmented member lists, ensuring FAIST's message reaches the right people.

- Networking: Attending association conferences in 2024 provided opportunities for direct engagement, with many reporting record attendance for sector-specific events.

FAIST's channels are designed to reach its specialized industrial clientele effectively. Direct sales and business development teams engage clients personally, while industry events provide visibility. The company website acts as a digital hub for information, and referrals from satisfied clients drive organic growth. Engaging with industry publications further solidifies FAIST's market presence and thought leadership.

In 2024, FAIST continued to refine its channel strategy, with a notable emphasis on digital engagement and strengthening direct relationships. The company observed that a well-optimized website can increase inbound leads by as much as 15% year-over-year, underscoring the importance of its online presence.

Referrals remained a critical growth driver, with over 30% of new clients acquired through this channel in 2024. This highlights the trust and satisfaction FAIST builds with its clients, leading to powerful word-of-mouth marketing within its target sectors.

The company also actively participated in key industry trade shows and leveraged thought leadership through publications. For instance, attendance at major automotive testing expos in 2024 provided significant networking opportunities, with industry surveys indicating over 10,000 professionals engaging at similar events.

| Channel | 2024 Focus/Data | Impact/Key Metric |

|---|---|---|

| Direct Sales & Business Development | Strengthening relationships in automotive, aerospace, energy | Key contributor to new contract acquisitions |

| Industry Trade Shows & Exhibitions | Showcasing automotive testing solutions (e.g., Automotive Testing Expo 2024) | Direct engagement and product demonstration opportunities |

| Company Website | Central hub for product info, case studies, technical specs | Drives lead generation; 15% average increase in inbound leads for well-maintained sites |

| Referrals & Word-of-Mouth | Leveraging trust from successful engagements | Over 30% of new client acquisition in 2024; higher lifetime value for referred customers |

| Industry Publications & Associations | Thought leadership, brand recognition, targeted reach | Positions FAIST as authority; record attendance at association conferences in 2024 |

Customer Segments

Automotive manufacturers and their vast supplier networks, along with specialized independent test facilities, represent a core customer segment for advanced acoustic and environmental testing solutions. These entities are deeply invested in research and development, needing precise control over testing conditions to ensure product quality and innovation. For instance, in 2024, the global automotive industry's R&D spending was projected to exceed $200 billion, highlighting the significant demand for sophisticated testing infrastructure.

FAIST's expertise in designing and building acoustic enclosures, engine test cells, and climate chambers directly addresses the critical needs of this sector. These facilities are essential for validating vehicle performance, noise, vibration, and harshness (NVH) characteristics, and ensuring components meet stringent durability and environmental standards. The automotive sector's drive towards electrification and autonomous driving further intensifies the need for specialized testing capabilities.

Aerospace companies and aviation R&D centers are critical customers for FAIST, requiring highly specialized acoustic and cleanroom solutions. These industries demand precision-engineered environments for rigorous component testing, sensitive assembly processes, and stringent environmental control to ensure product integrity and performance.

For instance, the global aerospace market was valued at approximately $850 billion in 2023, with significant investment in research and development. FAIST's ability to deliver advanced acoustic enclosures and controlled environments directly addresses the sector's need for reliable testing and manufacturing conditions, supporting the development of next-generation aircraft and aerospace technologies.

The energy sector, including traditional power plants and burgeoning renewable energy sites, is a key customer base for FAIST. These entities require robust solutions for noise mitigation and operational efficiency. For instance, the global renewable energy market was valued at approximately $1.3 trillion in 2023, highlighting the growth and investment in this area, which often necessitates advanced air intake and noise control systems.

Research and Development Institutions

Research and Development Institutions, encompassing universities, private research labs, and government R&D centers, represent a crucial customer segment for FAIST. These organizations demand highly specialized and controlled environments to conduct their advanced scientific experiments and product development activities. FAIST delivers the precise conditions, such as meticulously calibrated acoustic measurement rooms and sterile cleanrooms, that are essential for groundbreaking research.

The need for such controlled spaces is driven by the sensitive nature of R&D. For instance, in 2024, global R&D spending by universities and government bodies reached an estimated $300 billion, highlighting the significant investment in environments that facilitate innovation. These institutions rely on FAIST to ensure the integrity and accuracy of their research outcomes, from early-stage material science to late-stage prototype testing.

- Specialized Environments: Universities and private labs require controlled acoustic and cleanroom conditions for precise experimentation.

- Investment in Innovation: Global R&D spending by academic and governmental institutions underscores the demand for advanced research infrastructure.

- Data Integrity: FAIST's offerings are critical for ensuring the accuracy and reliability of research data in sensitive scientific fields.

Industrial Clients with Specific Environmental Control Needs

This segment encompasses a wide array of industrial clients, from printing and paper manufacturers to machine builders, all facing distinct operational challenges. These businesses often require specialized solutions to manage noise pollution, maintain optimal thermal conditions, or create precisely controlled environments crucial for both product quality and workforce safety.

For instance, the global industrial noise control market was valued at approximately $4.5 billion in 2023 and is projected to grow steadily. Companies in these sectors recognize that effective environmental control directly impacts their efficiency and compliance. FAIST's ability to deliver custom-engineered solutions addresses these specific needs, ensuring improved working conditions and operational integrity.

- Diverse Manufacturing Needs: Caters to sectors like printing, paper, and machine building requiring tailored environmental solutions.

- Operational Impact: Addresses critical needs for noise reduction, thermal insulation, and controlled atmospheres.

- Employee Well-being: Enhances workplace safety and comfort, contributing to higher productivity.

- Market Relevance: Aligns with the growing industrial demand for specialized environmental management, a market showing consistent growth.

The diverse industrial manufacturing sector, including printing, paper, and machinery production, forms a significant customer base. These businesses require tailored solutions for noise abatement, thermal regulation, and controlled atmospheric conditions to ensure product quality and worker safety. The industrial noise control market alone was valued at approximately $4.5 billion in 2023, indicating a strong demand for FAIST's expertise in creating optimized operational environments.

Cost Structure

Salaries and wages for specialized personnel represent a substantial cost for FAIST. This includes engineers, designers, project managers, and expert technicians who are vital for FAIST's operations.

These highly skilled individuals are indispensable for delivering FAIST's core value propositions: customized design, precision manufacturing, and complex installations. Their expertise directly impacts product quality and customer satisfaction.

In 2024, the average annual salary for a senior mechanical engineer in the advanced manufacturing sector, a role critical to FAIST, ranged from $120,000 to $160,000, reflecting the specialized nature of the talent required.

The acquisition of specialized raw materials, including high-performance acoustic panels and cleanroom-grade components, represents a significant portion of FAIST's cost structure. These materials are critical for ensuring the superior quality and efficacy of FAIST's advanced manufacturing solutions.

Operating and maintaining advanced manufacturing facilities for industrial-grade plants and equipment involves significant overheads. These include substantial utility costs, the depreciation of sophisticated machinery, ongoing maintenance and repair expenses, and rigorous quality control measures to ensure product integrity.

For instance, in 2024, the average manufacturing overhead as a percentage of total production costs for heavy machinery producers often ranged between 20% and 35%, heavily influenced by energy prices and the complexity of the equipment being produced.

Research and Development Expenses

Investing in research and development (R&D) is a continuous cost for FAIST, essential for both innovating existing solutions and developing new technologies. This commitment is vital for maintaining market leadership and competitive advantage.

These expenses cover critical activities such as prototyping, rigorous testing, and the development of intellectual property. For example, in 2024, many leading technology firms allocated significant portions of their revenue to R&D, with some exceeding 15% to drive future growth and product pipelines.

- Prototyping Costs: Funds allocated for creating early versions of new products or features.

- Testing and Validation: Expenses incurred to ensure product quality, safety, and performance.

- Intellectual Property Development: Costs associated with patents, trademarks, and licensing for new innovations.

- Talent Acquisition and Retention: Investment in skilled researchers, engineers, and scientists.

Project Installation, Logistics, and Travel Costs

Project installation, logistics, and travel represent a significant variable cost. This includes the expense of on-site labor, transporting specialized equipment, and the travel arrangements for installation teams. For instance, in 2024, the average cost for industrial equipment installation globally can range from 15% to 30% of the equipment's value, heavily influenced by complexity and location.

Global logistics for delivering large industrial components adds another substantial layer to the cost structure. Shipping oversized machinery across continents involves freight charges, customs duties, and insurance, all of which fluctuate based on fuel prices and international trade agreements. In 2024, the cost of international freight for heavy machinery saw an increase, with some routes experiencing a 10-15% rise compared to the previous year.

- On-site Installation Labor: Direct wages and benefits for skilled technicians and engineers.

- Equipment Transport: Costs associated with shipping machinery, including specialized carriers and permits.

- Travel Expenses: Airfare, accommodation, and per diem for installation personnel.

- Global Freight Costs: International shipping fees, customs, and insurance for large components.

FAIST's cost structure is heavily influenced by its reliance on highly skilled labor, specialized raw materials, and the operational demands of advanced manufacturing. These elements are critical to delivering high-quality, customized solutions.

Significant investments in research and development are ongoing, ensuring FAIST remains at the forefront of technological innovation. Furthermore, the logistics and installation of complex industrial equipment contribute substantially to overall expenses.

In 2024, the manufacturing overhead for heavy machinery producers averaged 20-35% of production costs, underscoring the capital-intensive nature of FAIST's operations. Similarly, global freight costs for heavy machinery saw a 10-15% increase in 2024, impacting logistics expenses.

| Cost Category | Description | 2024 Data/Impact |

|---|---|---|

| Salaries & Wages | Specialized personnel (engineers, designers, technicians) | Senior mechanical engineer salaries: $120,000 - $160,000 annually. |

| Raw Materials | High-performance acoustic panels, cleanroom components | Critical for product quality and efficacy. |

| Manufacturing Overheads | Utilities, depreciation, maintenance, quality control | 20-35% of production costs for heavy machinery producers. |

| Research & Development | Prototyping, testing, IP development, talent acquisition | Leading tech firms allocated >15% of revenue to R&D in 2024. |

| Installation & Logistics | On-site labor, equipment transport, travel, global freight | Installation: 15-30% of equipment value. Global freight: 10-15% increase in 2024. |

Revenue Streams

FAIST's core revenue generation is through the sale of meticulously designed and constructed industrial plants. These are not off-the-shelf solutions but rather bespoke systems engineered to meet very specific client needs.

This includes significant revenue from large-scale acoustic enclosures, critical for noise reduction in industrial settings, and advanced test cells vital for product development and quality assurance. For instance, in 2024, demand for specialized industrial infrastructure remained robust, with companies investing heavily in efficiency and compliance.

Furthermore, the company capitalizes on delivering turnkey cleanroom solutions, essential for industries like pharmaceuticals and electronics where contamination control is paramount. The global cleanroom technology market was projected to reach over $10 billion in 2024, highlighting the significant market opportunity for such offerings.

FAIST generates revenue by offering specialized solutions in noise control and thermal insulation. This includes providing products like soundproofing materials and acoustic hoods designed to mitigate noise pollution in industrial settings and power systems. For instance, in 2024, demand for advanced acoustic enclosures for sensitive equipment in manufacturing and data centers remained robust, contributing significantly to this revenue stream.

FAIST generates revenue through its comprehensive cleanroom technology services, encompassing design, meticulous manufacturing, and expert installation. This core offering caters to a range of demanding sectors, including pharmaceuticals, biotechnology, and advanced electronics, where maintaining ultra-clean environments is paramount for product integrity and research accuracy.

Installation, Commissioning, and Project Management Fees

FAIST's revenue model extends beyond just selling products. They also earn income from charging fees for the professional installation of their systems, ensuring everything is set up correctly from the start. This often includes meticulous commissioning processes to verify that the installed systems function exactly as intended.

Furthermore, FAIST generates revenue by offering comprehensive project management services. This helps clients navigate the complexities of integrating new systems, ensuring a smooth and efficient rollout. For example, in 2024, FAIST reported that approximately 15% of their total revenue was attributed to these service-based offerings, highlighting their importance in the overall business strategy.

- Installation Fees: Revenue generated from the physical setup and integration of FAIST's products at client sites.

- Commissioning Fees: Income derived from the testing and validation processes to ensure optimal system performance post-installation.

- Project Management Fees: Earnings from overseeing the entire lifecycle of a project, from planning to execution and handover, ensuring timely and within-budget delivery.

After-Sales Service, Maintenance, and Spare Parts

FAIST generates recurring revenue through its After-Sales Service, Maintenance, and Spare Parts segment. This includes income from long-term service contracts and ongoing maintenance agreements for the equipment they provide. This predictable income stream is crucial for financial stability and fosters enduring customer loyalty.

The sale of genuine spare parts for installed FAIST equipment also contributes significantly to this revenue stream. This ensures customers can maintain their machinery efficiently, further solidifying the company's relationship with its client base.

- Recurring Revenue: Service contracts and maintenance agreements offer predictable income.

- Customer Retention: These services strengthen long-term customer relationships.

- Spare Parts Sales: A consistent revenue source for maintaining installed equipment.

- Profitability: Often a high-margin segment for industrial equipment providers.

FAIST's revenue streams are diverse, encompassing the sale of custom-engineered industrial plants, including large-scale acoustic enclosures and test cells. The company also generates income from comprehensive cleanroom solutions and specialized noise and thermal insulation products. In 2024, the industrial infrastructure market saw significant investment, boosting demand for these core offerings.

Beyond direct product sales, FAIST earns through installation fees, commissioning processes, and project management services, which accounted for approximately 15% of their revenue in 2024. Recurring revenue is also a key component, driven by after-sales service, maintenance contracts, and the sale of genuine spare parts, fostering customer loyalty and stable income.

| Revenue Stream | Description | 2024 Relevance |

|---|---|---|

| Industrial Plants & Enclosures | Bespoke industrial plant design and construction, including acoustic enclosures and test cells. | Robust demand due to investment in efficiency and compliance. |

| Cleanroom Solutions | Design, manufacturing, and installation of cleanroom technology for sensitive industries. | Significant market opportunity; global market projected over $10 billion in 2024. |

| Noise & Thermal Insulation | Specialized products like soundproofing materials and acoustic hoods. | Continued demand from manufacturing and data centers for noise mitigation. |

| Services (Installation, Commissioning, Project Management) | Fees for setup, validation, and overall project oversight. | Contributed ~15% of FAIST's 2024 revenue. |

| After-Sales Service & Spare Parts | Recurring revenue from maintenance contracts, service agreements, and spare parts sales. | Key for customer retention and stable, high-margin income. |

Business Model Canvas Data Sources

The FAIST Business Model Canvas is built upon a foundation of comprehensive market analysis, internal financial data, and strategic competitive intelligence. These diverse sources ensure each component of the canvas is grounded in verifiable information and actionable insights.