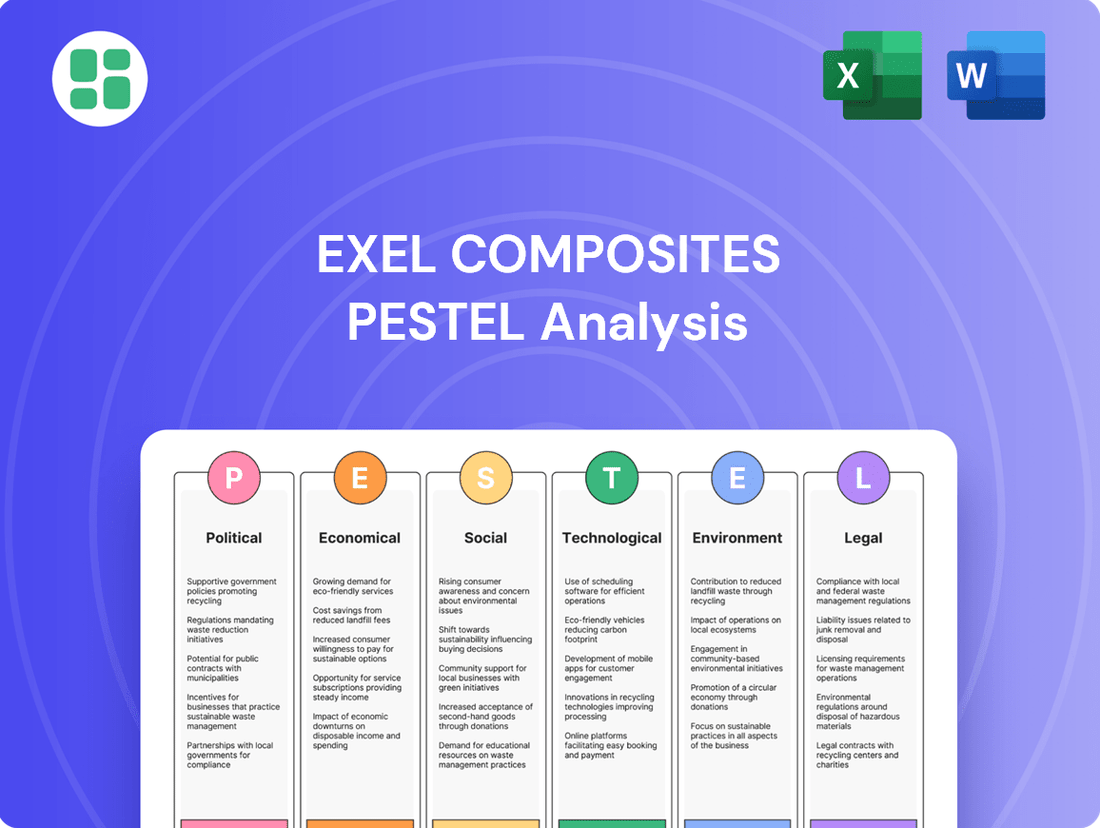

Exel Composites PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Exel Composites Bundle

Navigate the complex external environment impacting Exel Composites with our comprehensive PESTLE analysis. Understand how political stability, economic fluctuations, technological advancements, environmental regulations, and social trends are shaping the company's strategic landscape. Gain a competitive edge by leveraging these critical insights. Download the full PESTLE analysis now for actionable intelligence to inform your business decisions.

Political factors

Government regulations on manufacturing and materials are becoming more stringent globally, directly impacting companies like Exel Composites. For instance, the European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation continues to evolve, influencing the types of chemicals and materials that can be used in manufacturing processes. In 2024, there's a growing focus on sustainable materials and circular economy principles, with new directives expected to mandate higher recycled content in manufactured goods, potentially affecting Exel Composites' sourcing strategies and product design.

These evolving rules necessitate continuous adaptation in production methods and material sourcing for Exel Composites. For example, stricter emissions standards, such as those being implemented in North America and Asia in 2024-2025, might require investments in new abatement technologies or a shift towards lower-emission materials. Failure to comply can lead to significant fines and reputational damage, underscoring the critical need for proactive regulatory monitoring and strategic adjustments.

International trade policies, such as tariffs and trade agreements, significantly impact the cost of raw materials and the market competitiveness of Exel Composites' products. For instance, the European Union's carbon border adjustment mechanism (CBAM), which began its transitional phase in October 2023, could indirectly affect material costs for companies importing goods into the EU, potentially influencing Exel Composites' sourcing strategies.

Shifts in these policies present both avenues for growth and potential hurdles for Exel Composites' global operations. For example, the USMCA (United States-Mexico-Canada Agreement) continues to shape trade dynamics in North America, offering a stable framework but also specific rules of origin that Exel Composites must navigate for its composite materials.

Governments globally are increasingly providing subsidies and tax incentives for green technologies, directly benefiting companies like Exel Composites that focus on sustainable and lightweight materials. For instance, the European Union's Green Deal aims to mobilize significant investment in sustainable solutions, which can translate into favorable financial conditions for material innovators.

These incentives are designed to accelerate research and development in areas such as advanced composites, making them more competitive with traditional materials. This can lead to faster market adoption and the exploration of new applications, such as in the automotive and aerospace sectors, where weight reduction is a key performance driver.

In 2024, numerous countries are expected to continue or expand their green technology support programs. For example, the United States' Inflation Reduction Act offers substantial tax credits for clean energy manufacturing, which could indirectly support the supply chain for advanced composite materials.

Geopolitical Stability and Supply Chain Risks

Global geopolitical tensions, such as the ongoing conflicts in Eastern Europe and the Middle East, continue to pose significant threats to supply chain stability. These events directly impact raw material availability and energy prices, which are critical inputs for Exel Composites' manufacturing processes. For instance, disruptions in oil and gas markets, often exacerbated by geopolitical instability, can lead to volatile and increased energy costs for production facilities.

Exel Composites, like many global manufacturers, must actively monitor and strategize to mitigate these supply chain risks. This involves diversifying sourcing for key materials like resins and carbon fiber, and potentially increasing inventory levels for critical components. The company's ability to navigate these disruptions is paramount for maintaining production schedules and managing cost fluctuations, ensuring consistent delivery to its diverse customer base across various industries.

- Supply Chain Vulnerability: Global conflicts and trade disputes, such as those impacting semiconductor availability in 2024, highlight the fragility of extended supply chains, potentially delaying component sourcing for Exel Composites' products.

- Energy Price Volatility: Geopolitical events impacting major energy-producing regions can cause sharp increases in energy costs, directly affecting Exel Composites' operational expenses and product pricing strategies.

- Raw Material Access: Regional instabilities can restrict access to essential raw materials like specialized polymers or metals, forcing Exel Composites to seek alternative, potentially more expensive, suppliers.

- Logistical Challenges: Shipping route disruptions, whether due to conflict or political sanctions, can significantly increase transit times and costs for both inbound materials and outbound finished goods.

Industrial Policies and Infrastructure Spending

Government investment in infrastructure, such as new transportation networks and upgrades to energy grids, directly fuels demand for composite materials. For instance, the European Union's Recovery and Resilience Facility, with a significant portion allocated to green transition and infrastructure, is expected to boost construction and energy projects. This trend is highly beneficial for companies like Exel Composites, which supply custom-engineered composite solutions for these demanding applications.

Favorable industrial policies that encourage the use of advanced materials in public works can create substantial market opportunities. Exel Composites' ability to provide tailored solutions positions it well to capitalize on these government-driven initiatives. The ongoing focus on sustainability and lightweighting in infrastructure development, supported by policy frameworks, further enhances the appeal of composite materials.

- Increased Demand: Government infrastructure spending, particularly in areas like renewable energy and transportation, directly translates to higher demand for composite materials.

- Policy Support: Industrial policies promoting advanced materials in construction and energy sectors create a more favorable market environment for Exel Composites.

- Market Opportunities: Initiatives like the EU's Recovery and Resilience Facility, with its emphasis on green infrastructure, present significant growth avenues for composite solutions.

- Customization Advantage: Exel Composites' expertise in custom-engineered solutions allows it to meet the specific needs of large-scale infrastructure projects.

Government regulations continue to shape the manufacturing landscape, with a growing emphasis on sustainability and circular economy principles. For instance, in 2024, the EU's evolving directives are pushing for higher recycled content in manufactured goods, directly impacting Exel Composites' material sourcing and product design strategies. Stricter emissions standards, anticipated in North America and Asia through 2025, may necessitate investments in new abatement technologies.

| Regulatory Area | Impact on Exel Composites | Example/Data Point (2024-2025) |

|---|---|---|

| Environmental Regulations | Increased compliance costs, material restrictions | EU REACH evolution, potential mandates for recycled content in composites |

| Emissions Standards | Investment in new technologies, material shifts | Stricter standards in North America and Asia impacting production processes |

| Trade Policies | Raw material cost volatility, market competitiveness | EU's Carbon Border Adjustment Mechanism (CBAM) affecting import costs |

| Green Technology Incentives | Opportunities for R&D, market adoption | US Inflation Reduction Act supporting clean energy manufacturing |

What is included in the product

This PESTLE analysis of Exel Composites meticulously examines the Political, Economic, Social, Technological, Environmental, and Legal forces impacting its operations and strategic positioning.

It provides a comprehensive overview of how these external macro-environmental factors create both challenges and opportunities for Exel Composites within its industry and global markets.

Provides a concise version that can be dropped into PowerPoints or used in group planning sessions, offering a clear overview of the external factors impacting Exel Composites.

Easily shareable summary format ideal for quick alignment across teams or departments, ensuring everyone understands the political, economic, social, technological, environmental, and legal landscape relevant to Exel Composites.

Economic factors

Global economic expansion directly fuels industrial demand for advanced materials like composites, crucial for sectors such as automotive, aerospace, construction, and renewable energy. For Exel Composites, a robust global economy translates to increased orders as these industries invest in new projects and upgrades. For instance, the International Monetary Fund projected global growth at 3.2% for 2024, a slight uptick from 2023, indicating a generally supportive environment for industrial output.

Conversely, economic slowdowns or recessions can significantly dampen demand for composites. Reduced consumer spending and business investment lead to scaled-back production in key end-markets, directly impacting sales volumes for companies like Exel Composites. The lingering effects of inflation and potential interest rate hikes in 2024 could present headwinds, potentially moderating the growth in industrial demand compared to more optimistic forecasts.

The price of crucial inputs for Exel Composites, like resins, glass and carbon fibers, and various additives, is highly susceptible to shifts in global markets. For instance, the average price of carbon fiber, a key component, saw fluctuations throughout 2023 and into early 2024, influenced by supply chain disruptions and demand from sectors like aerospace and automotive.

This inherent volatility directly impacts Exel Composites' production expenses and, consequently, its profit margins. The company's ability to navigate these price swings through smart procurement strategies and financial hedging techniques is therefore paramount for maintaining its financial health and competitive edge in the market.

Rising inflation presents a significant challenge for Exel Composites, directly impacting its operating expenses. In 2024, global inflation rates remained a concern, with many economies experiencing elevated price levels for essential inputs. This surge in costs for labor, energy, and transportation can squeeze profit margins if not effectively managed.

To counter these inflationary pressures, Exel Composites must focus on robust cost management initiatives. This could involve optimizing supply chains, improving energy efficiency in manufacturing processes, and negotiating favorable terms with suppliers. Furthermore, strategic pricing adjustments may be necessary to pass on some of the increased costs to customers, ensuring the company's long-term profitability and competitive standing.

Currency Exchange Rate Fluctuations

Currency exchange rate fluctuations present a significant economic factor for global companies like Exel Composites. As a company operating internationally, changes in exchange rates directly impact the cost of raw materials sourced from abroad and the value of revenue earned from sales in foreign markets. For instance, if the Euro weakens against the US Dollar, Exel Composites might find its imported materials priced higher in Euros, while sales in the US could translate to less Euro revenue.

These shifts can materially affect Exel Composites' financial performance and its ability to maintain competitive pricing. A strong Euro, for example, could make its products more expensive for international buyers if not managed effectively. Conversely, a weaker Euro could boost export competitiveness but increase the cost of imported components.

Recent data highlights the volatility:

- The Euro experienced a notable depreciation against the US Dollar throughout much of 2023 and into early 2024, impacting companies with significant cross-border transactions.

- For example, if Exel Composites sources 30% of its raw materials from the US and generates 40% of its revenue in USD, a 5% depreciation of the Euro against the USD in a given quarter could increase material costs by approximately 1.5% and reduce reported revenue by 2% in Euro terms, assuming constant volumes.

- Managing currency risk through hedging strategies is therefore crucial for stabilizing earnings and maintaining price competitiveness in the global composites market.

Interest Rates and Access to Capital

Changes in interest rates directly impact Exel Composites' cost of capital. For instance, if central banks like the European Central Bank (ECB) or the US Federal Reserve maintain or increase benchmark rates in 2024 and 2025, borrowing for new factories, advanced R&D projects, or even day-to-day operations becomes more expensive. This increased cost can curb appetite for expansion and innovation, potentially hindering Exel's growth trajectory.

Higher borrowing costs can significantly affect Exel Composites' investment decisions. For example, a project that might have been viable with a 3% interest rate could become unfeasible if rates climb to 6% or higher. This sensitivity to interest rate fluctuations is crucial for strategic planning, especially for capital-intensive industries like composites manufacturing where long-term investments are common.

- Interest Rate Environment: As of mid-2024, major central banks like the ECB and the Federal Reserve have indicated a cautious approach to rate cuts, suggesting interest rates may remain elevated throughout 2024 and into 2025, impacting borrowing costs for companies like Exel Composites.

- Impact on Capital Expenditures: Increased borrowing costs can lead to delayed or scaled-back capital expenditure plans, affecting Exel's ability to invest in new production facilities or upgrade existing ones.

- R&D Funding: Higher interest rates can make financing research and development activities more challenging, potentially slowing down the introduction of new composite materials or applications.

- Operational Funding: The cost of short-term financing for working capital needs also rises with interest rates, squeezing margins for manufacturers.

Global economic trends significantly influence Exel Composites' demand, with expansion driving orders from key sectors like automotive and aerospace. Conversely, economic downturns or recessions can contract demand, impacting sales volumes. The IMF's projection of 3.2% global growth for 2024 suggests a generally supportive, albeit moderate, economic climate for industrial materials.

Input costs for Exel Composites, such as resins and fibers, are subject to market volatility. For example, carbon fiber prices saw fluctuations in 2023-2024 due to supply chain issues and sector demand, directly affecting production expenses and profit margins.

Inflationary pressures in 2024 increased operating expenses for Exel Composites, particularly for labor, energy, and transportation. Effective cost management, including supply chain optimization and energy efficiency, is crucial for maintaining profitability amidst these rising costs.

Currency fluctuations, such as the Euro's depreciation against the US Dollar in 2023-2024, impact Exel Composites' material costs and reported revenue. Hedging strategies are vital for stabilizing earnings and maintaining price competitiveness in international markets.

| Economic Factor | 2024/2025 Outlook | Impact on Exel Composites |

|---|---|---|

| Global GDP Growth | Projected 3.2% in 2024 (IMF) | Supports demand for advanced materials |

| Input Price Volatility | Fluctuations in resins, fibers | Affects production costs and margins |

| Inflation | Elevated levels persist | Increases operating expenses |

| Interest Rates | Expected to remain elevated | Raises cost of capital and investment |

| Currency Exchange Rates | Euro depreciation vs. USD | Impacts material costs and revenue |

Full Version Awaits

Exel Composites PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This comprehensive PESTLE analysis of Exel Composites delves into the Political, Economic, Social, Technological, Legal, and Environmental factors impacting the company's operations and strategic decisions.

Sociological factors

Consumers and industries are increasingly prioritizing sustainability, leading to a greater demand for materials that minimize environmental impact. This shift directly benefits companies like Exel Composites, whose lightweight composite solutions contribute to reduced carbon footprints and enhanced energy efficiency in various applications, such as transportation and construction.

The global market for sustainable materials is experiencing robust growth. For instance, the sustainable packaging market alone was valued at approximately USD 270 billion in 2023 and is projected to reach over USD 450 billion by 2030, indicating a strong consumer push for eco-friendly alternatives. This trend is a significant opportunity for Exel Composites to expand its market share by highlighting the environmental advantages of its composite products.

The availability of skilled labor, particularly in advanced manufacturing techniques like pultrusion and continuous lamination, is a critical factor for Exel Composites. A shortage of workers with these specialized skills could directly hinder their production output and their capacity for developing new composite solutions.

The global manufacturing sector, including composites, is facing a widening skills gap. For instance, reports from 2024 indicate that over 80% of manufacturers struggle to find workers with the necessary technical skills. This trend necessitates significant investment by companies like Exel Composites in robust training programs and strategic initiatives to attract and retain qualified talent, ensuring they can meet future demand and drive innovation.

Demographic shifts, like an aging global population and increasing urbanization, directly impact demand for Exel Composites' products. For instance, as more people move to cities, there's a greater need for advanced construction materials for infrastructure and housing. By 2050, the UN projects that 68% of the world's population will live in urban areas, a significant rise from 56% in 2021, driving demand for durable and lightweight composite solutions.

Evolving lifestyle trends, such as a greater emphasis on health, wellness, and leisure activities, also play a crucial role. This translates into increased demand for composite materials in sporting goods, recreational equipment, and even in the automotive sector as consumers prioritize fuel efficiency and performance for travel. The global sports and leisure market was valued at approximately $1.1 trillion in 2023 and is projected to grow, indicating a positive outlook for composite applications in these areas.

Health and Safety Standards in Manufacturing

Societal expectations and regulatory oversight concerning health and safety within manufacturing are on a significant upward trend. Exel Composites, like its peers, faces increasing pressure to implement and maintain robust safety protocols. This commitment is crucial not only for safeguarding its workforce but also for preserving its corporate image, which in turn can impact operational expenditures.

Adherence to these evolving standards directly influences Exel Composites' operational costs. For instance, in 2024, the average cost of a workplace injury in the manufacturing sector in the EU was estimated to be around €15,000, factoring in direct medical expenses, lost productivity, and administrative overhead. Failure to meet stringent safety regulations can lead to substantial fines and increased insurance premiums, directly affecting the company's bottom line.

Exel Composites' proactive approach to health and safety can be seen in its investments in training and equipment. For example, many manufacturers are now allocating 5-10% of their annual operational budget towards safety initiatives, including advanced personal protective equipment (PPE) and regular safety audits. This focus is driven by a recognition that a safe working environment reduces absenteeism and boosts overall employee morale and productivity.

- Employee Well-being: Prioritizing worker safety is a fundamental societal expectation, directly impacting Exel Composites' ability to attract and retain talent.

- Regulatory Compliance: Stricter health and safety regulations, such as those enforced by OSHA in the US and similar bodies in Europe, necessitate continuous investment in safety measures.

- Reputational Risk: A strong safety record enhances corporate reputation, while incidents can lead to significant brand damage and loss of customer trust.

- Operational Efficiency: Investing in safety often leads to fewer accidents, reduced downtime, and lower insurance costs, ultimately improving operational efficiency.

Corporate Social Responsibility (CSR) Expectations

Stakeholders, from investors to everyday customers, increasingly demand that companies like Exel Composites actively engage in corporate social responsibility. This means going beyond just making profits to consider ethical business practices, contributing positively to communities, and operating in a way that minimizes environmental impact. For Exel Composites, demonstrating a strong commitment here isn't just good practice; it's a strategic advantage. It can significantly boost brand reputation and make the company a more attractive place to work, helping to draw in and retain top talent.

The financial implications of robust CSR are becoming clearer. For instance, a 2024 report indicated that companies with strong ESG (Environmental, Social, and Governance) scores, a key component of CSR, saw an average 13% higher return on equity compared to their peers. This suggests that responsible operations can translate directly into better financial performance. Exel Composites can leverage this by highlighting its initiatives:

- Sustainable Material Sourcing: Exel Composites' efforts to use recycled or sustainably sourced composite materials can appeal to environmentally conscious clients and investors.

- Employee Well-being Programs: Investing in employee safety, training, and development fosters a positive work environment and reduces turnover.

- Community Investment: Local engagement, such as supporting educational initiatives or local charities, builds goodwill and strengthens the company's social license to operate.

- Transparent Reporting: Clear and honest communication about CSR performance, including metrics on waste reduction or carbon emissions, builds trust with all stakeholders.

Societal expectations regarding ethical business practices and corporate social responsibility (CSR) are increasingly influencing consumer and investor decisions. Companies like Exel Composites are expected to demonstrate a commitment to sustainability, community engagement, and fair labor practices. This focus on responsible operations can enhance brand reputation and attract socially conscious investors.

The growing emphasis on ESG (Environmental, Social, and Governance) factors is a key trend. For instance, in 2024, sustainable investment funds saw significant inflows, with many investors prioritizing companies that align with their values. Exel Composites can leverage its CSR initiatives, such as responsible material sourcing and employee well-being programs, to appeal to this growing segment of the market.

A strong safety culture is paramount, with societal pressure for safe workplaces intensifying. Exel Composites' investment in robust safety protocols and training not only protects its workforce but also bolsters its reputation. In 2024, manufacturers investing in safety saw reduced accident rates, with some reporting a decrease of up to 15% in workplace incidents.

The demand for transparency in corporate reporting is also rising. Stakeholders expect companies to openly share their progress on sustainability and social impact goals. Exel Composites' commitment to clear reporting on its CSR performance can build trust and strengthen its relationships with investors, customers, and employees.

Technological factors

Continuous innovation in composite materials science, particularly with new fiber types like advanced carbon fibers and novel resin systems, directly impacts the performance characteristics of composite profiles. These advancements allow companies like Exel Composites to create products that are not only stronger and lighter but also possess superior durability and resistance to environmental factors, crucial for sectors like aerospace and automotive.

Staying ahead in this field is paramount for maintaining a competitive edge. For instance, the global advanced composites market was valued at approximately USD 30 billion in 2023 and is projected to grow significantly, with a compound annual growth rate (CAGR) of around 6-7% through 2030, underscoring the demand for cutting-edge material solutions.

Exel Composites is leveraging ongoing technological advancements in pultrusion and continuous lamination. These improvements, including greater automation and faster production speeds, are crucial for boosting efficiency and cutting costs. For instance, in 2024, the company continued to invest in upgrading its pultrusion lines, aiming for a 15% increase in throughput by the end of the year.

Enhanced process control within these innovative manufacturing techniques allows for more consistent product quality and the development of new, complex composite profiles. This investment in technology directly supports operational excellence and Exel Composites' ability to meet evolving market demands for high-performance materials.

Exel Composites is strategically positioned to leverage the advancements in automation and Industry 4.0. The integration of smart manufacturing technologies, including the Internet of Things (IoT) and artificial intelligence (AI), is set to enhance production efficiency and product quality. For instance, by 2024, the global industrial automation market was projected to reach over $294 billion, indicating a strong trend towards adopting these solutions.

This technological shift allows for optimized production processes, leading to more consistent product quality and a reduction in manufacturing overheads, particularly labor costs. By embracing robotics and advanced data analytics, Exel Composites can gain a significant competitive edge through improved operational agility and cost-effectiveness. The company's investment in these areas is crucial for maintaining its market leadership.

Digital Design and Simulation Tools

Exel Composites leverages advanced digital design, modeling, and simulation tools to accelerate the development of its composite solutions. These technologies enable rapid virtual prototyping and testing, significantly cutting down on the time and resources needed for traditional physical iterations. This virtual approach is crucial for optimizing designs and ensuring performance before committing to material production.

The efficiency gained from these digital tools directly translates into faster delivery of custom-engineered solutions for clients. For instance, advancements in Finite Element Analysis (FEA) software allow for precise prediction of how composite structures will perform under various stresses, leading to more robust and lightweight designs. This capability is particularly important in industries like aerospace and automotive where performance and weight are critical factors.

- Digital Prototyping: Reduces physical prototype cycles by up to 50%, according to industry benchmarks for advanced manufacturing.

- Simulation Accuracy: FEA and CFD (Computational Fluid Dynamics) tools enhance design predictability, minimizing costly material waste in development.

- Customization Efficiency: Streamlines the process of creating bespoke composite parts, meeting specific client requirements with greater speed.

- Industry Adoption: The global market for simulation software in engineering is projected to grow, indicating a strong trend towards digital-first design processes.

Recycling and End-of-Life Technologies for Composites

Developing and implementing effective recycling and end-of-life solutions for composite materials presents a significant technological challenge and a substantial opportunity for companies like Exel Composites. As environmental regulations tighten and consumer demand for sustainable products grows, innovation in this area is becoming crucial.

Advancements in composite recycling can dramatically improve Exel Composites' sustainability profile. For instance, mechanical recycling, which grinds down composites into smaller particles for reuse, is becoming more efficient. Chemical recycling methods, such as solvolysis, are also gaining traction, breaking down composites into their original chemical components for higher-value applications. The global market for composite recycling is projected to reach USD 1.3 billion by 2027, indicating substantial growth potential.

- Mechanical Recycling: This method involves shredding or grinding composite waste into fibers and fillers, which can then be incorporated into new composite materials or other products.

- Chemical Recycling: Technologies like solvolysis and pyrolysis are being developed to break down polymer matrices, allowing for the recovery of valuable fibers and chemical feedstocks.

- Energy Recovery: Incineration with energy recovery is another option, though it's less preferred than material recycling due to the loss of material value.

- Growing Investment: Significant R&D investment is flowing into advanced recycling technologies, with several pilot plants and commercial facilities operational or under construction globally.

Technological advancements in materials science, particularly in advanced fibers and resins, enhance the performance and durability of composite profiles. These innovations are crucial for sectors like aerospace and automotive, where lighter and stronger materials are in high demand. The global advanced composites market was valued at approximately USD 30 billion in 2023, with projections indicating a CAGR of 6-7% through 2030.

Exel Composites is adopting Industry 4.0 technologies, including IoT and AI, to boost production efficiency and product quality. The global industrial automation market was projected to exceed $294 billion in 2024, highlighting the widespread adoption of these solutions for operational improvements and cost reduction.

The company utilizes advanced digital design and simulation tools, such as FEA, to accelerate product development and reduce physical prototyping. This digital-first approach enhances design predictability and customization efficiency, contributing to faster delivery of bespoke solutions.

Innovation in composite recycling, including mechanical and chemical methods, is a key technological focus for sustainability. The composite recycling market is expected to reach USD 1.3 billion by 2027, presenting significant opportunities for companies to improve their environmental profiles.

| Technology Area | Impact on Exel Composites | Market Data/Projections |

|---|---|---|

| Advanced Materials Science | Enhanced product strength, durability, and environmental resistance. | Global advanced composites market: ~USD 30 billion (2023), 6-7% CAGR to 2030. |

| Industry 4.0 & Automation | Increased production efficiency, reduced costs, improved quality. | Global industrial automation market: >$294 billion (2024 projection). |

| Digital Design & Simulation | Faster product development, reduced prototyping, improved customization. | FEA and CFD tools improve design predictability and minimize waste. |

| Composite Recycling | Improved sustainability profile, new market opportunities. | Composite recycling market: USD 1.3 billion by 2027. |

Legal factors

Exel Composites operates under stringent product liability and safety regulations across diverse sectors like transportation and construction. Failure to adhere can lead to significant legal repercussions and damage to its hard-earned reputation.

Meeting demanding safety standards is paramount for Exel Composites, not just for legal compliance but also to foster customer confidence. For instance, in the automotive sector, compliance with standards like UNECE R100 for battery enclosures in electric vehicles is critical, ensuring passenger safety and market access.

Exel Composites relies heavily on its proprietary technologies and innovative designs for its composite solutions. Protecting these through patents and other intellectual property (IP) rights is crucial for maintaining its competitive edge. As of 2024, the company actively manages its IP portfolio to safeguard its unique manufacturing processes and product innovations.

Vigilance in defending its intellectual property is paramount for Exel Composites to prevent unauthorized use and maintain market differentiation. Simultaneously, the company must ensure it does not infringe upon the IP rights of competitors, which could lead to costly legal disputes and operational disruptions. This careful balance is key to its sustained success in the advanced materials sector.

Exel Composites navigates a complex web of environmental compliance laws impacting emissions, waste management, chemical usage, and resource efficiency. For instance, in 2024, the European Union continued to tighten regulations under the Green Deal, pushing for reduced industrial emissions and circular economy principles, which directly affect manufacturing processes.

Failure to comply can result in significant financial penalties, operational disruptions, and reputational damage. In 2025, companies like Exel Composites face increasing scrutiny on their carbon footprint and waste reduction strategies, with potential fines for non-compliance escalating.

Labor and Employment Laws

Exel Composites must navigate a complex web of global labor and employment laws, covering everything from minimum wage requirements and working condition standards to anti-discrimination statutes and regulations surrounding union activities. For instance, in 2024, many European countries continued to see adjustments in their statutory minimum wages, impacting labor costs. Failure to comply can lead to significant penalties and reputational damage.

Adherence to these regulations is not merely a legal obligation but a cornerstone of ethical business practice, fostering a fair and equitable workplace. This commitment helps mitigate legal risks, such as wrongful termination lawsuits or discrimination claims, which can be costly and time-consuming to resolve. In 2023, the International Labour Organization reported that labor disputes and legal challenges related to employment practices remained a significant concern for multinational corporations.

Key areas of focus for Exel Composites include:

- Wage and Hour Laws: Ensuring compliance with minimum wage, overtime pay, and record-keeping requirements across all operating regions.

- Discrimination and Equal Opportunity: Implementing policies and practices that prevent discrimination based on race, gender, age, religion, disability, and other protected characteristics.

- Workplace Safety and Health: Adhering to occupational safety standards to provide a secure working environment, with regulatory bodies like OSHA in the US consistently updating safety guidelines.

- Union Relations and Collective Bargaining: Understanding and respecting employee rights to organize and engage in collective bargaining, as demonstrated by ongoing union negotiations in various manufacturing sectors globally.

International Trade and Customs Laws

Exel Composites operates globally, meaning it must meticulously adhere to a web of international trade and customs regulations. This includes understanding and complying with import/export restrictions, tariffs, and any applicable sanctions that could impact its operations. For instance, in 2024, the World Trade Organization (WTO) continues to monitor and enforce trade agreements, with ongoing discussions around digital trade and environmental goods impacting customs procedures.

Navigating these complex legal frameworks is crucial for maintaining uninterrupted cross-border commerce. Failure to comply can lead to significant delays, increased costs, and even the seizure of goods, directly affecting Exel Composites' supply chain efficiency and its ability to serve international markets. The International Monetary Fund (IMF) has highlighted that trade facilitation measures, often tied to customs modernization, can reduce trade costs by as much as 15% globally.

- Regulatory Compliance: Adherence to import/export laws, tariffs, and sanctions is paramount.

- Supply Chain Integrity: Smooth customs clearance prevents disruptions to the flow of raw materials and finished products.

- Market Access: Understanding trade agreements and duties impacts pricing and market competitiveness.

- Risk Mitigation: Proactive management of trade laws avoids penalties and operational halts.

Exel Composites must navigate a complex landscape of product liability and safety regulations across its diverse markets, such as automotive and construction. Compliance is essential to avoid significant legal penalties and protect its brand reputation, with adherence to standards like UNECE R100 for EV battery enclosures being critical for market access in 2024.

The company's intellectual property, including proprietary manufacturing processes, requires robust protection through patents and other IP rights to maintain its competitive edge. Exel Composites actively manages its IP portfolio to prevent infringement and safeguard its innovations, a process that remains vital in 2025.

Environmental regulations, particularly those tightening around emissions and waste management under initiatives like the EU Green Deal, directly impact Exel Composites' manufacturing. Non-compliance in 2025 could lead to escalating fines and operational disruptions due to increased scrutiny on carbon footprints.

Global labor laws, including wage and hour compliance and anti-discrimination statutes, are crucial for Exel Composites. In 2024, adjustments in statutory minimum wages in various regions directly affected labor costs, underscoring the need for meticulous adherence to prevent legal challenges.

Environmental factors

The global drive to cut carbon emissions and boost energy efficiency, especially in transport and energy, is fueling a strong demand for lightweight composite materials. This trend is a direct tailwind for companies like Exel Composites, as their products help achieve better fuel economy and a smaller environmental footprint.

For instance, the automotive industry, a key market for composites, is increasingly adopting these materials to meet stringent CO2 regulations. By 2025, many regions are targeting significant reductions in average fleet emissions, making lightweighting a critical strategy. This translates to a growing market opportunity for Exel Composites' advanced material solutions.

The growing global focus on circular economy models is pushing industries, including composites, to re-evaluate product lifecycles. This means companies like Exel Composites must prioritize materials that can be recycled or reused, moving away from linear ‘take-make-dispose’ approaches.

Exel Composites is therefore presented with both a challenge and a significant opportunity to innovate in developing more easily recyclable composite materials and implementing sustainable manufacturing practices. For instance, the European Union's Circular Economy Action Plan aims to increase recycling rates for plastics and other materials, which directly impacts composite producers.

Growing regulatory scrutiny and corporate commitments to reduce carbon footprints are significantly impacting manufacturing processes and material choices across industries. Exel Composites, like many manufacturers, faces increasing pressure to manage its operational emissions and develop solutions that enable customers to lower their own carbon emissions. For instance, the European Union's Carbon Border Adjustment Mechanism (CBAM), implemented in October 2023, is already influencing material sourcing and production costs, pushing for lower-embodied carbon in goods traded within the bloc.

Resource Scarcity and Sustainable Sourcing

Growing concerns over resource scarcity, particularly in materials like glass and carbon fiber, are pushing companies like Exel Composites to adopt more sustainable sourcing. This trend is amplified by increasing regulatory pressure and consumer demand for environmentally responsible products. For instance, the global demand for carbon fiber is projected to reach over 140 kilotons by 2025, highlighting the strain on virgin material production.

Exel Composites will likely need to invest in and explore alternative raw materials such as bio-based resins derived from plant sources or recycled composite fibers. These alternatives can mitigate the environmental footprint associated with traditional material extraction and processing. The market for recycled carbon fiber, while still nascent, is expected to grow significantly, offering a pathway to reduce waste and resource dependency.

The push for sustainability in sourcing impacts Exel Composites' operational costs and supply chain resilience. Ensuring a stable supply of ethically and sustainably sourced materials will be crucial for maintaining market competitiveness and meeting the evolving expectations of customers in 2024 and beyond. Companies that proactively integrate these practices are better positioned to navigate future environmental regulations and market shifts.

- Resource Scarcity: Increasing demand for key composite materials like carbon fiber poses challenges to supply chains.

- Sustainable Sourcing: Growing pressure for environmentally friendly materials necessitates exploration of bio-based and recycled alternatives.

- Market Demand: Consumers and regulators are increasingly favoring products with a lower environmental impact.

- Operational Impact: Adapting to sustainable sourcing can affect costs and supply chain management for Exel Composites.

Waste Management and Pollution Control

Exel Composites faces increasing scrutiny over its environmental footprint, particularly concerning waste management and pollution control. Stringent regulations, such as those in the EU aiming for a circular economy, directly impact manufacturing processes, requiring significant investment in compliance and advanced treatment technologies. For instance, the EU's Waste Framework Directive, updated in 2023, emphasizes waste prevention and recycling, pushing companies like Exel to innovate in material usage and end-of-life product management.

The company's operational costs are directly influenced by its ability to manage industrial waste and wastewater discharge effectively. Non-compliance can lead to substantial fines and reputational damage. Exel Composites' commitment to environmental stewardship, therefore, is not just about regulatory adherence but also about maintaining a competitive edge and investor confidence. In 2024, many industrial sectors reported increased spending on environmental technologies, with figures suggesting a global market growth of over 5% annually for pollution control equipment, a trend Exel is likely navigating.

Key considerations for Exel Composites include:

- Adherence to evolving emissions standards: Meeting stricter air quality regulations requires ongoing investment in filtration and emission reduction systems.

- Wastewater treatment optimization: Implementing advanced wastewater treatment to meet discharge limits and explore water recycling opportunities.

- Solid waste minimization and recycling: Developing strategies to reduce manufacturing by-products and increase the recyclability of composite materials.

- Life Cycle Assessment (LCA) integration: Incorporating LCA principles to understand and mitigate the environmental impact of products from raw material extraction to disposal.

The global push for sustainability is a significant environmental factor for Exel Composites, driving demand for lightweight materials that improve energy efficiency in sectors like transportation. Regulatory bodies worldwide are imposing stricter emission standards, compelling industries to adopt solutions that reduce their carbon footprint. For instance, the European Union's Green Deal aims for climate neutrality by 2050, directly influencing material choices and manufacturing processes.

Resource availability and the circular economy are also critical. Increasing demand for raw materials like carbon fiber, projected to exceed 140 kilotons by 2025, highlights potential scarcity issues. This necessitates a focus on sustainable sourcing, including the development and adoption of bio-based resins and recycled composite fibers. Exel Composites must navigate these trends by innovating in material science and production methods.

| Environmental Factor | Impact on Exel Composites | Key Data/Trends (2024-2025) |

|---|---|---|

| Carbon Emission Reduction | Increased demand for lightweight composites; pressure to reduce operational emissions. | Automotive CO2 targets driving lightweighting; EU CBAM influencing production costs. |

| Circular Economy | Need for recyclable materials and sustainable end-of-life solutions. | EU Circular Economy Action Plan; focus on waste prevention and recycling. |

| Resource Scarcity | Supply chain challenges for virgin materials; opportunity for recycled alternatives. | Global carbon fiber demand projected to exceed 140 kilotons by 2025. |

| Waste Management & Pollution Control | Compliance with stringent regulations; investment in treatment technologies. | EU Waste Framework Directive updates; global market growth for pollution control equipment. |

PESTLE Analysis Data Sources

Our PESTLE Analysis for Exel Composites is built on data from reputable industry associations, economic forecasting agencies, and regulatory bodies. We integrate insights from market research reports, environmental impact assessments, and technological innovation databases to provide a comprehensive overview.