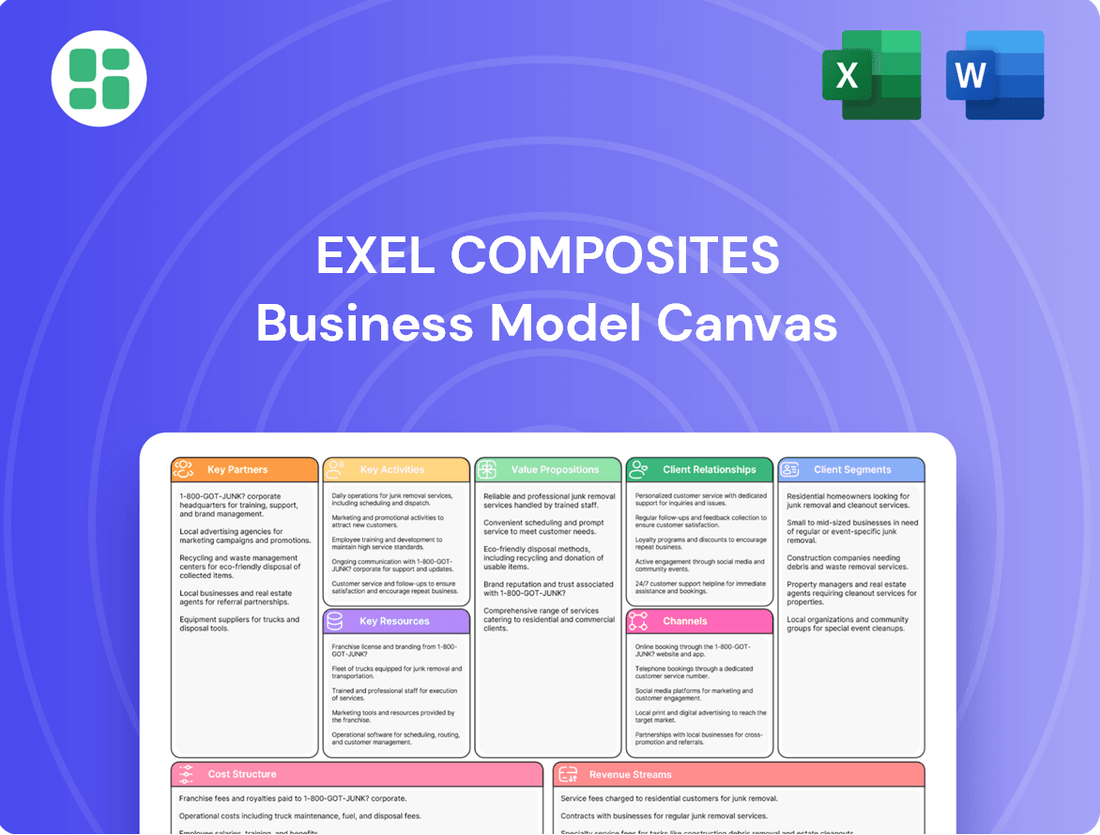

Exel Composites Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Exel Composites Bundle

Unlock the strategic blueprint behind Exel Composites's success with our comprehensive Business Model Canvas. Discover their key partners, value propositions, and revenue streams that drive their market leadership. This detailed analysis is essential for anyone looking to understand how Exel Composites thrives.

Ready to dissect Exel Composites's winning formula? Our full Business Model Canvas provides an in-depth look at their customer relationships, cost structure, and key resources. Gain actionable insights to inform your own strategic planning. Download now!

Partnerships

Exel Composites relies on a network of trusted raw material suppliers to source critical components like resins and various fibers, including carbon and glass. These collaborations are fundamental to maintaining the high standards of their pultrusion and continuous lamination products. For instance, in 2024, Exel Composites continued to emphasize long-term agreements with key suppliers to ensure supply chain resilience and competitive pricing for these essential inputs.

Exel Composites actively collaborates with key technology and equipment providers, securing access to state-of-the-art machinery and sophisticated manufacturing solutions. These partnerships are crucial for their pultrusion and pull-winding processes.

Through these alliances, Exel Composites continuously enhances its production efficiency and drives the development of novel composite profiles. This ensures they remain at the forefront of technological advancement in the global composite market.

In 2023, Exel Composites reported a significant investment in manufacturing technology, underscoring the importance of these partnerships for maintaining their competitive edge and fostering ongoing innovation. This focus on advanced equipment is vital for their long-term growth strategy.

Exel Composites actively pursues research and development collaborations with a diverse range of partners. These include key customers and esteemed research institutions, all focused on the joint development of novel composite materials and their innovative applications.

A prime illustration of this strategy is Exel's R&D partnership with Flying Whales, specifically for the development of airship components. This collaboration not only showcased their joint innovation capabilities but also successfully evolved into a substantial supply agreement, demonstrating the tangible commercial benefits of such partnerships.

These strategic alliances are designed to harness Exel's extensive R&D expertise. By working closely with partners, they aim to accelerate innovation and engineer highly customized solutions that precisely address the unique requirements and challenges faced by their clients.

Industry Associations and Standardization Bodies

Exel Composites’ engagement with industry associations and standardization bodies is crucial for shaping the future of composite materials. This collaboration ensures their products align with evolving industry demands and certifications, opening new market avenues.

Their active participation allows them to contribute to setting best practices and standards. This proactive role is vital for driving innovation and ensuring the widespread adoption of composite solutions across various sectors.

- Industry Standards Development: Exel Composites contributes to developing and refining industry standards, ensuring their products meet stringent quality and performance benchmarks.

- Market Access and Growth: By adhering to and influencing standards, they gain access to new markets and applications, as demonstrated by their IATF 16949 Certification, which is essential for the automotive sector.

- Innovation and Best Practices: Involvement in these bodies fosters knowledge sharing and collaboration, accelerating the adoption of new technologies and best practices within the composites industry.

Strategic Industrial Alliances

Exel Composites cultivates strategic alliances with leading industrial entities, including prominent wind turbine manufacturers and automotive corporations. These collaborations are crucial for securing substantial, long-term supply agreements, providing a predictable revenue stream.

A prime example of this strategy in action is the EUR 10 million order secured from a major wind turbine manufacturer in South Asia. This significant contract underscores the value of these partnerships in guaranteeing consistent demand for Exel's advanced composite solutions.

- Securing long-term supply contracts with major industrial players.

- Benefiting from a EUR 10 million order from a South Asian wind turbine manufacturer.

- Enabling joint development of specialized composite applications.

- Ensuring stable demand for composite solutions through strategic alliances.

Exel Composites' key partnerships extend to customers, acting as crucial collaborators in product development and market penetration. These relationships are vital for understanding specific application needs and co-creating tailored composite solutions.

In 2024, Exel Composites continued to deepen its engagement with key customers, focusing on co-development projects that leverage their expertise in pultrusion technology for niche applications. This customer-centric approach ensures their offerings remain highly relevant and competitive.

These collaborations often lead to significant supply agreements, providing Exel Composites with a stable demand base and opportunities for innovation. For instance, their work with specialized industrial clients in sectors like renewable energy and transportation solidifies their market position.

The company's strategic partnerships with customers are instrumental in driving innovation and ensuring their composite solutions meet the evolving demands of diverse industries, fostering mutual growth and technological advancement.

What is included in the product

A comprehensive, pre-written business model tailored to Exel Composites’ strategy, detailing customer segments, channels, and value propositions.

Reflects the real-world operations and plans of Exel Composites, organized into 9 classic BMC blocks with full narrative and insights.

The Exel Composites Business Model Canvas acts as a pain point reliever by offering a structured, visual representation that simplifies complex strategic planning.

It addresses the pain of information overload by condensing Exel Composites' entire business strategy into a single, easily digestible page.

Activities

Exel Composites' commitment to Research and Development is central to its strategy, focusing on creating novel composite materials and refining current manufacturing techniques. This dedication fuels the optimization of their pultrusion and pull-winding processes, ensuring they remain at the forefront of composite technology.

The company actively explores emerging applications for composites, a crucial element in maintaining their competitive advantage. In 2023, Exel Composites reported a significant portion of their revenue stemming from new product development, underscoring the financial impact of their R&D investments.

Their deep R&D expertise, coupled with a strong emphasis on collaboration with clients, distinguishes Exel Composites in the marketplace. This partnership approach allows them to deliver highly tailored, engineered solutions that precisely meet customer needs.

Exel Composites' core manufacturing activity revolves around producing composite profiles and tubes. They leverage specialized pultrusion and continuous lamination technologies to create these products, focusing on efficiency and quality across their worldwide factories. In 2024, this included significant efforts to ramp up production at their new Indian facility, alongside optimizing output at their established plants.

Exel Composites excels in custom engineering and design, a core activity that involves deep technical expertise to create tailored composite solutions. This process demands close collaboration with clients, translating their specific performance and sustainability needs into tangible product designs.

This bespoke approach is central to Exel's value proposition. For instance, in 2023, custom solutions accounted for a significant portion of their revenue, demonstrating the market's demand for specialized composite applications. Their design teams leverage advanced simulation and prototyping tools to ensure optimal material selection and structural integrity for each unique project.

Sales, Marketing, and Business Development

Exel Composites actively drives growth through robust sales, marketing, and business development efforts. Their strategy focuses on pinpointing emerging customer segments and securing new orders to broaden their global market presence. This proactive approach is crucial for sustained revenue generation and market share expansion.

Key activities include strategic participation in major industry trade shows, which provides direct interaction with potential clients and showcases their innovative composite solutions. Simultaneously, maintaining a strong and engaging online presence ensures continuous brand visibility and lead generation. Developing deep, strategic relationships with key customers is also paramount, fostering loyalty and identifying opportunities for collaborative innovation and future business.

- Global Market Expansion: Exel Composites’ sales and marketing teams actively work to identify and penetrate new geographic markets, aiming to increase their international footprint.

- Customer Acquisition: A significant focus is placed on securing new orders from both existing and prospective clients, directly contributing to revenue growth.

- Industry Presence: Participation in key industry events like Composites Europe and JEC World allows for direct engagement and brand building.

- Digital Engagement: Maintaining an active online presence through their website and social media channels is vital for lead generation and customer communication.

Supply Chain Management and Logistics

Exel Composites' supply chain management and logistics are critical for its global operations. This involves the timely procurement of raw materials and efficient delivery of finished composite products to customers across various industries worldwide. A key focus is optimizing inventory levels to balance availability with carrying costs.

The company actively manages its global logistics network to ensure smooth transportation and delivery. This includes selecting appropriate shipping methods and partners to meet customer timelines and cost expectations. Ensuring resilience against potential disruptions, such as geopolitical shifts or unexpected supply chain interruptions, is paramount.

- Global Procurement: Sourcing essential raw materials like resins, fibers, and core materials from a diverse supplier base to mitigate risks and ensure consistent quality.

- Logistics Optimization: Managing warehousing, transportation (sea, air, road), and distribution to deliver finished composite solutions efficiently to over 50 countries.

- Inventory Management: Balancing stock levels of raw materials and finished goods to meet demand while minimizing holding costs and obsolescence risks.

- Risk Mitigation: Developing contingency plans and diversifying suppliers to build resilience against supply chain disruptions, a strategy increasingly vital in the current global economic climate.

Exel Composites' key activities encompass advanced manufacturing of composite profiles and tubes, utilizing pultrusion and continuous lamination. They also excel in custom engineering and design, working closely with clients to develop tailored solutions. Furthermore, robust sales, marketing, and business development are crucial for global market expansion and customer acquisition. Efficient supply chain management and logistics are vital for global operations, ensuring timely procurement and delivery.

| Key Activity | Description | 2024 Focus/Data |

|---|---|---|

| Manufacturing | Producing composite profiles and tubes via pultrusion and continuous lamination. | Ramping up production at the new Indian facility; optimizing output at existing plants. |

| Custom Engineering & Design | Developing tailored composite solutions through client collaboration. | Leveraging advanced simulation and prototyping tools for specific projects. |

| Sales, Marketing & Business Development | Expanding global market presence and securing new orders. | Participating in industry trade shows; enhancing online presence; building strategic customer relationships. |

| Supply Chain & Logistics | Managing global procurement and efficient delivery of finished products. | Optimizing inventory; managing logistics to over 50 countries; building supply chain resilience. |

Full Document Unlocks After Purchase

Business Model Canvas

The Exel Composites Business Model Canvas preview you are viewing is the actual document you will receive upon purchase. This means all sections, formatting, and content are identical to the final deliverable, ensuring no surprises. You'll gain immediate access to this complete, ready-to-use business model framework, allowing you to start strategizing right away.

Resources

Exel Composites’ proprietary manufacturing technologies, especially in pultrusion and pull-winding, are a cornerstone of their business. These advanced methods, protected by patents, enable the creation of unique, high-performance composite profiles and tubes that are difficult for competitors to replicate. This technical expertise in continuous manufacturing processes provides a significant competitive edge.

Exel Composites leverages specialized production facilities and advanced equipment across Europe, North America, and Asia. These state-of-the-art factories are crucial for their high-volume composite manufacturing capabilities, enabling them to meet diverse global customer needs.

In 2024, Exel Composites continued to invest in its production infrastructure, including the strategic expansion of its network with new facilities in India. This expansion is designed to enhance production capacity and optimize their global operational footprint.

Exel Composites relies heavily on its highly skilled workforce, encompassing engineers, material scientists, and production specialists. This talent pool is fundamental to their ability to innovate and deliver specialized composite solutions. In 2024, the company continued to invest in training and development to maintain this edge.

The company's Research and Development (R&D) expertise is a cornerstone of its value proposition. Their R&D team is instrumental in creating novel composite materials, refining existing product performance, and offering critical technical support to clients. This deep knowledge base directly fuels their capacity for custom engineering projects, a key differentiator.

Strong Brand Reputation and Customer Relationships

Exel Composites has cultivated a robust brand reputation, recognized for its high-quality, durable, and increasingly sustainable composite solutions. This reputation is a cornerstone of their business, attracting and retaining customers across various demanding industries.

Their deep-rooted, long-term relationships with key industrial clients represent a significant intangible asset. This collaborative approach, often involving joint development and problem-solving, fosters trust and ensures a steady stream of repeat business and valuable new project opportunities.

For instance, Exel Composites reported a strong order book in 2024, reflecting the continued demand driven by these established relationships and their reputation for reliability. Their focus on innovation in sustainable materials further solidifies their position, appealing to an environmentally conscious customer base.

- Brand Reputation: Known for quality, durability, and sustainability in composite solutions.

- Customer Relationships: Long-term, collaborative partnerships with key industrial clients.

- Business Impact: Drives repeat business and secures new project opportunities.

- Market Standing: Enhanced by innovation in sustainable materials, a key differentiator in 2024.

Access to High-Quality Raw Materials

Exel Composites relies heavily on consistent access to premium raw materials like carbon fibers, glass fibers, and specialized resins. This ensures their composite products meet stringent quality standards and maintain cost-competitiveness.

Strategic sourcing and robust supplier partnerships are critical for securing these essential inputs. In 2024, Exel Composites continued to strengthen these relationships, aiming to mitigate supply chain disruptions and optimize procurement costs for key materials.

- Supplier Diversification: Exel Composites actively works to diversify its supplier base for critical raw materials to reduce dependency on any single source.

- Quality Control: Rigorous incoming quality checks are performed on all raw materials to guarantee they meet specifications, directly impacting final product performance.

- Long-Term Agreements: The company often enters into long-term supply agreements to secure favorable pricing and guaranteed availability of high-demand materials.

- Market Trend Monitoring: Exel Composites closely monitors global raw material market trends, including price fluctuations and availability, to inform its sourcing strategies.

Exel Composites' key resources include its proprietary manufacturing technologies, particularly pultrusion and pull-winding, which are protected by patents and difficult for competitors to replicate. Their global network of specialized production facilities and advanced equipment, enhanced by a 2024 expansion in India, supports high-volume manufacturing. A highly skilled workforce, continuous investment in R&D for novel materials and custom engineering, a strong brand reputation for quality and sustainability, and deep, long-term customer relationships are also vital assets. The company also emphasizes strategic sourcing and supplier partnerships for critical raw materials like carbon and glass fibers, with a focus on diversification and long-term agreements in 2024.

| Key Resource | Description | 2024 Impact/Focus |

|---|---|---|

| Proprietary Technologies | Pultrusion, Pull-winding; patent-protected. | Enables unique, high-performance composite profiles. |

| Global Production Network | Facilities in Europe, North America, Asia. | Expanded in India in 2024 to boost capacity and optimize footprint. |

| Skilled Workforce | Engineers, material scientists, production specialists. | Continued investment in training and development in 2024. |

| R&D Expertise | Novel materials, product refinement, technical support. | Fuels custom engineering projects and innovation in sustainable materials. |

| Brand Reputation | Quality, durability, sustainability. | Attracts and retains customers in demanding industries. |

| Customer Relationships | Long-term, collaborative partnerships. | Drives repeat business and new project opportunities; strong order book in 2024. |

| Raw Material Sourcing | Carbon fibers, glass fibers, resins. | Strengthened supplier partnerships and diversification in 2024. |

Value Propositions

Exel Composites excels in delivering custom-engineered composite solutions, crafting profiles and tubes precisely tailored to client specifications. This focus on bespoke design ensures optimal performance and integration within diverse industrial applications, moving beyond generic offerings.

Exel Composites' value proposition centers on delivering enhanced performance and durability. Their composite solutions offer a compelling advantage over traditional materials like steel or aluminum, boasting impressive strength-to-weight ratios. For instance, their pultruded profiles can be up to 70% lighter than steel while maintaining comparable or even superior strength.

This inherent lightweight nature directly translates into tangible benefits for customers. In the transportation sector, for example, lighter components contribute to improved fuel efficiency, a critical factor in today's market. In 2024, the automotive industry continues to prioritize lightweighting to meet stringent emissions standards and consumer demand for more economical vehicles.

Furthermore, the exceptional durability of Exel's composites means products experience less wear and tear over time. This extends product lifecycles significantly, reducing the need for frequent replacements and costly maintenance. This robust performance is crucial for applications in harsh environments, such as infrastructure or industrial equipment, where reliability is paramount.

Exel Composites' composite solutions significantly boost sustainability by enabling resource savings and reducing product weight, which in turn improves energy efficiency in their customers' applications. For instance, their lightweight composite materials can lead to substantial fuel savings in transportation sectors.

The company actively participates in circular economy initiatives, demonstrating a commitment to environmental responsibility. A notable example is their work in transforming composite waste into cement, directly supporting clients' ambitious environmental targets and contributing to a more sustainable industrial ecosystem.

Technical Expertise and Collaborative Design

Exel Composites offers deep technical expertise, guiding clients through the entire development lifecycle. This includes robust R&D support from the very beginning, ensuring composite solutions are precisely tailored for optimal performance.

The company emphasizes a collaborative design approach, working hand-in-hand with customers. This partnership guarantees that the final composite solutions integrate seamlessly into the client's existing products and systems, maximizing efficiency and effectiveness.

- R&D Investment: Exel Composites consistently invests in research and development to stay at the forefront of composite technology. For instance, in 2023, the company reported a significant focus on developing advanced material solutions.

- Customer Collaboration Projects: A substantial portion of Exel's business involves co-creation with clients, demonstrating the value placed on integrated design.

- Technical Support: The company provides dedicated technical teams to assist customers with material selection, design optimization, and application engineering.

Global Footprint and Reliable Supply

Exel Composites boasts a robust global footprint with manufacturing sites strategically located across Europe, North America, and Asia. This expansive network ensures a dependable supply chain for its international clientele, offering localized support and reducing the risk of disruptions. For instance, in 2024, the company continued to leverage its diverse production capabilities to meet global demand efficiently.

This international presence is crucial for effectively serving a wide array of markets, from automotive to construction, and for building resilience against unforeseen supply chain challenges. The company's commitment to maintaining operations in key regions allows for quicker response times and tailored solutions for customers worldwide.

- Global Manufacturing Presence: Operations spanning Europe, North America, and Asia.

- Supply Chain Reliability: Mitigates risks through a distributed production network.

- Localized Support: Enhances customer service and responsiveness in diverse markets.

- Market Diversification: Ability to serve various industries and geographical regions effectively.

Exel Composites delivers custom-engineered composite solutions, focusing on precision-tailored profiles and tubes for optimal performance. Their value lies in providing lightweight, durable, and sustainable materials that outperform traditional alternatives, directly addressing customer needs for enhanced efficiency and reduced environmental impact.

Customer Relationships

Exel Composites prioritizes strong customer bonds through specialized technical support and advisory services. This includes offering detailed advice on choosing the right materials, refining product designs, and seamlessly integrating composite solutions into existing applications, ultimately helping clients maximize the benefits of Exel's offerings.

In 2024, Exel Composites continued to invest in its technical expertise, with a significant portion of its R&D budget allocated to application development and customer-specific engineering support. This focus aims to ensure that clients, from those in demanding aerospace sectors to those in high-volume industrial markets, receive tailored guidance to unlock the full potential of advanced composite materials.

Exel Composites focuses on fostering long-term, collaborative partnerships with its industrial clientele. This approach often includes joint research and development initiatives and the co-creation of bespoke composite solutions tailored to specific client needs.

These deep relationships are built on a foundation of mutual trust and a shared dedication to driving innovation and effectively solving complex challenges. For instance, in 2024, Exel Composites reported that over 70% of its revenue was generated from repeat business, highlighting the strength and longevity of these client collaborations.

Exel Composites utilizes key account management for its major industrial clients, assigning dedicated teams. This ensures a deep understanding of evolving needs and consistent service delivery for complex projects and long-term supply agreements.

After-Sales Service and Support

Exel Composites prioritizes customer satisfaction through robust after-sales service and support, ensuring any post-delivery needs or technical challenges are promptly addressed. This commitment solidifies their standing as a dependable, customer-focused partner.

- Technical Expertise: Providing ongoing technical support and troubleshooting for their composite solutions.

- Product Training: Offering training sessions to help customers effectively utilize and maintain Exel's products.

- Warranty and Repairs: Managing product warranties and facilitating necessary repairs to ensure continued performance.

- Customer Feedback: Actively soliciting and incorporating customer feedback to enhance service offerings.

Feedback Integration for Continuous Improvement

Exel Composites places a high value on customer feedback, actively incorporating it into their product development and service improvements. This commitment ensures their offerings remain aligned with evolving market needs and customer expectations.

In 2024, Exel Composites continued to refine its product lines based on direct customer input, leading to enhanced performance characteristics in several key composite material applications. For instance, feedback on durability in harsh environments directly influenced the formulation of new resin systems.

- Customer Feedback Channels: Exel utilizes a multi-channel approach including direct client consultations, user surveys, and post-project reviews to gather insights.

- Product Development Integration: Feedback directly informs R&D priorities, leading to iterative improvements in material properties and manufacturing processes.

- Service Enhancement: Customer input also shapes Exel's logistical support and technical assistance, aiming for seamless client experiences.

- Market Responsiveness: This continuous loop allows Exel to proactively adapt to shifting industry demands and anticipate future client requirements.

Exel Composites cultivates enduring client partnerships through a blend of specialized technical support and collaborative development. By offering in-depth material selection advice and co-creating bespoke solutions, they ensure clients maximize the value of advanced composites.

In 2024, Exel Composites reinforced these relationships by dedicating substantial R&D resources to application engineering and customer-specific projects, underscoring their commitment to tailored client success across diverse industries.

The company's focus on joint research and development initiatives highlights a strategy of building long-term, trust-based collaborations. This approach is validated by the fact that in 2024, over 70% of Exel Composites' revenue stemmed from repeat business, a testament to the strength of these enduring partnerships.

| Customer Relationship Aspect | Description | 2024 Focus/Data |

|---|---|---|

| Technical Support & Advisory | Specialized guidance on material selection, design, and integration. | Significant R&D investment in application development and customer engineering. |

| Collaborative Development | Joint R&D and co-creation of tailored composite solutions. | Over 70% of 2024 revenue from repeat business, reflecting strong partnerships. |

| Key Account Management | Dedicated teams for major clients to understand evolving needs. | Ensured consistent service for complex projects and long-term supply agreements. |

| After-Sales Service | Prompt addressing of post-delivery needs and technical challenges. | Reinforced standing as a dependable, customer-focused partner. |

Channels

Exel Composites heavily relies on its direct sales force to connect with industrial customers, especially when offering intricate, custom-engineered composite solutions. This direct approach facilitates clear communication, in-depth technical consultations, and the creation of proposals precisely matching client needs.

Exel Composites operates a robust global manufacturing and sales network, with facilities and offices strategically located across Europe, North America, and Asia. This extensive footprint allows them to effectively serve a diverse international customer base, ensuring efficient delivery and localized support.

In 2024, Exel Composites continued to strengthen this network, aiming to optimize supply chain logistics and enhance customer proximity. Their presence in key industrial regions enables them to adapt quickly to regional market demands and provide tailored solutions.

Exel Composites actively participates in key industry trade shows and conferences. These events are essential for demonstrating their advanced composite material technologies and manufacturing capabilities to a global audience.

In 2024, Exel Composites likely leveraged events like JEC World, a premier composites show, to highlight their latest product innovations and engage with industry leaders. Such participation is critical for generating new business leads and reinforcing their market position.

These platforms offer a unique opportunity to connect directly with potential customers, understand emerging market demands, and gather competitive intelligence. The ability to showcase tangible product benefits and discuss customized solutions at these gatherings is invaluable for Exel Composites' growth strategy.

Company Website and Digital Presence

Exel Composites leverages its official website and various digital platforms as crucial channels to disseminate detailed information about its advanced composite solutions, innovative technologies, successful project case studies, and vital investor relations updates. This robust digital footprint is instrumental in attracting inbound inquiries and significantly expanding its market reach globally.

The company's digital presence acts as a central hub for potential clients and stakeholders to access product catalogs, technical specifications, and sustainability reports, thereby fostering transparency and engagement. In 2024, Exel Composites reported a notable increase in website traffic, indicating a growing interest in its specialized pultruded composite products for demanding applications.

- Website as Information Hub: Provides detailed product information, technical data, and application examples.

- Investor Relations Portal: Offers financial reports, press releases, and shareholder information.

- Market Reach Expansion: Digital channels facilitate global customer engagement and lead generation.

- Content Marketing: Case studies and whitepapers showcase expertise and successful project outcomes.

Technical Publications and Industry Forums

Exel Composites actively participates in and tracks technical publications and industry forums. This engagement positions them as a thought leader, allowing them to share valuable research and development insights. By doing so, they connect with a niche audience keenly interested in cutting-edge composite materials and their diverse applications.

Their presence in these channels helps them understand market trends and customer needs. For instance, in 2024, the composites industry saw continued growth, with demand for lightweight and high-strength materials in sectors like aerospace and automotive driving innovation. Exel's contributions to forums likely reflect these trends, showcasing their solutions for emerging challenges.

- Thought Leadership: Sharing R&D findings in publications establishes Exel as an expert in composite materials.

- Audience Engagement: Industry forums provide a direct line to specialized professionals and potential clients.

- Market Intelligence: Monitoring discussions offers insights into emerging technologies and customer demands.

- Brand Visibility: Consistent contribution enhances brand recognition within the technical community.

Exel Composites utilizes a multi-faceted channel strategy, blending direct sales with digital engagement and industry presence. Their direct sales force is crucial for custom solutions, while their global network ensures localized support.

Digital platforms and industry events are key for broader reach and thought leadership. In 2024, Exel Composites likely saw continued growth in digital inquiries, complementing their participation in major trade shows like JEC World to showcase innovations in lightweight composites for sectors such as automotive and renewable energy.

The company's website serves as a vital information hub, with a reported increase in traffic in 2024, indicating strong interest in their specialized pultruded products.

Customer Segments

The transportation industry, a key customer segment for Exel Composites, encompasses automotive, rail, and aerospace manufacturers. These companies actively seek lightweight, robust, and long-lasting composite materials to boost fuel efficiency, improve safety, and elevate performance across their product lines.

Exel Composites addresses these needs with solutions integrated into applications such as bus panels, rail joints, and even airship structures. The demand for advanced composites in these sectors is significant; for instance, the global automotive composites market was valued at approximately USD 30 billion in 2023 and is projected to grow substantially, driven by the push for electric vehicles and weight reduction.

Exel Composites serves construction companies and infrastructure developers who value composite materials for their exceptional durability, resistance to corrosion, and strong structural integrity. These clients are looking for solutions that offer longevity and reduced maintenance in demanding environments.

Applications within this segment are diverse, encompassing everything from load-bearing structural profiles used in buildings and bridges to specialized components like bridge decks, utility poles, and even elements for offshore wind farms. The demand for advanced composite solutions in infrastructure projects is growing, driven by the need for lighter, stronger, and more sustainable materials.

For instance, the global composite materials market size was valued at approximately $115 billion in 2023 and is projected to reach over $200 billion by 2030, with a significant portion attributed to the construction and infrastructure sectors. This growth highlights the increasing adoption of composites as a superior alternative to traditional materials like steel and concrete.

The wind power industry is a cornerstone customer segment for Exel Composites, relying heavily on their advanced composite solutions for critical components such as wind turbine blade spar caps and other structural elements. This demand is fueled by the global push for green technologies. In 2023, global wind power capacity additions reached approximately 107 GW, showcasing the robust growth and ongoing need for specialized materials like those Exel provides.

Telecommunications

The telecommunications sector represents a key customer segment for advanced composite solutions. Providers and manufacturers within this industry require specialized composite profiles for critical applications such as antenna radomes and other essential infrastructure components. These materials are highly valued for their unique properties, including excellent radio frequency (RF) transparency, which is crucial for signal transmission, and robust structural reinforcement, ensuring durability and longevity of installations.

Exel Composites serves this market by offering tailored composite solutions that meet the demanding specifications of telecommunications infrastructure. The demand for 5G deployment, for instance, continues to drive the need for lightweight, high-performance materials. In 2024, the global telecommunications market experienced significant growth, with infrastructure investment being a major contributor.

- RF Transparency: Essential for antenna radomes and shielding applications to ensure unimpeded signal flow.

- Structural Integrity: Provides strength and rigidity for outdoor infrastructure exposed to various environmental conditions.

- Lightweight Design: Facilitates easier installation and reduces overall structural load, particularly important for tower-based equipment.

- Corrosion Resistance: Offers a longer lifespan compared to traditional materials in harsh environments.

Sports and Leisure, and Other Industrial Applications

Exel Composites caters to the sports and leisure sector, providing high-performance composite profiles and tubes for equipment like skis, hockey sticks, and bicycle frames. In 2024, the global sports and fitness equipment market was valued at over $110 billion, showcasing significant demand for advanced materials.

Beyond sports, Exel serves a broad spectrum of other industrial applications. This includes manufacturers of specialized industrial equipment, automotive components, and even aerospace parts where lightweight strength is paramount. These niche markets, while smaller individually, collectively represent a substantial portion of Exel's business, driven by the need for custom composite solutions.

- Sports and Leisure: Key applications include performance enhancement in sporting goods, offering durability and reduced weight.

- Industrial Applications: Serves diverse needs from construction to specialized machinery requiring robust composite components.

- Market Demand: Growing interest in lightweight and durable materials across various industrial sectors fuels demand for composite solutions.

Exel Composites serves a diverse range of customer segments, each with specific material needs. The transportation sector, including automotive, rail, and aerospace, demands lightweight and robust composites for fuel efficiency and performance. The construction industry values composites for their durability and corrosion resistance in infrastructure projects. The wind power industry utilizes Exel's solutions for critical components like turbine blades, driven by the global shift to green energy.

Additionally, the telecommunications sector relies on composites for RF transparency and structural integrity in antenna radomes and infrastructure. The sports and leisure industry benefits from the lightweight strength of composites in equipment such as skis and hockey sticks. Beyond these, Exel addresses various other industrial applications requiring custom, high-performance composite solutions.

| Customer Segment | Key Needs | Exel Composites Solutions | 2023/2024 Market Data Point |

|---|---|---|---|

| Transportation | Lightweight, Strength, Durability | Composite profiles for automotive panels, rail joints, aerospace components | Global automotive composites market ~USD 30 billion (2023) |

| Construction & Infrastructure | Durability, Corrosion Resistance, Structural Integrity | Load-bearing profiles for buildings, bridges, utility poles | Global composite materials market ~USD 115 billion (2023) |

| Wind Power | Strength, Durability, Lightweight | Composite spar caps for wind turbine blades | Global wind power capacity additions ~107 GW (2023) |

| Telecommunications | RF Transparency, Structural Integrity, Lightweight | Composite profiles for antenna radomes | Significant growth in telecom infrastructure investment (2024) |

| Sports & Leisure | Lightweight, Strength, Performance | Composite tubes for skis, hockey sticks, bicycle frames | Global sports and fitness equipment market >USD 110 billion (2024) |

Cost Structure

A significant portion of Exel Composites' cost structure is dedicated to acquiring essential raw materials. This includes a variety of resins and reinforcing fibers like carbon and glass, which are fundamental to their composite product manufacturing.

The price volatility of these raw materials directly influences Exel Composites' total production expenses. For instance, in 2023, the average price of carbon fiber, a key input, saw fluctuations, impacting the cost of producing high-performance composite parts.

Manufacturing and production expenses are a significant part of Exel Composites' cost structure. These include the direct costs of labor involved in operating their specialized pultrusion and pull-winding machinery, as well as the energy consumed by these energy-intensive processes.

Maintenance of this advanced equipment is also a crucial expense, ensuring operational continuity and product quality. Furthermore, overheads associated with managing a global network of manufacturing facilities, such as rent, utilities, and administrative staff, contribute to these costs.

In 2023, Exel Composites reported that their cost of sales, which encompasses manufacturing expenses, amounted to €275.6 million. Optimizing capacity utilization, aiming for higher efficiency in production, and strategic sourcing of raw materials are key levers for managing these substantial manufacturing and production costs.

Exel Composites dedicates substantial resources to Research and Development (R&D), a critical component for staying ahead in the dynamic composites sector. These investments are not just about creating new products; they're about pioneering advancements and ensuring the company maintains its technological edge. For instance, in 2024, the company continued its focus on developing high-performance composite solutions for demanding applications, reflecting the ongoing need for innovation.

Sales, General, and Administrative (SG&A) Expenses

Sales, General, and Administrative (SG&A) expenses for Exel Composites are crucial for supporting their global operations and market presence. These costs cover everything from marketing campaigns and sales team salaries to the salaries of management and other essential corporate functions that keep the business running smoothly.

For instance, Exel Composites' 2023 financial reporting indicated that their SG&A expenses were approximately €65.5 million. This figure reflects the investment in their worldwide sales network and the administrative backbone required to manage a multinational enterprise.

- Global Sales Network: Costs associated with maintaining and expanding their international sales force and distribution channels.

- Administrative Functions: Expenses for human resources, finance, legal, and other back-office operations.

- Management Salaries: Compensation for executive and senior management teams overseeing the company's strategic direction.

- Marketing and Advertising: Investment in promoting Exel Composites' products and brand awareness across various markets.

Capital Expenditure for Plant and Equipment

Exel Composites' cost structure heavily relies on capital expenditure for its plant and equipment. This includes ongoing investments to modernize existing manufacturing sites, ensuring they remain efficient and competitive. For instance, in 2023, the company continued to invest in upgrading its facilities to incorporate advanced production technologies.

Further capital expenditure is directed towards acquiring new production technologies. This is crucial for developing innovative composite solutions and maintaining a technological edge in the market. Exel Composites' strategy involves a consistent allocation of resources to stay at the forefront of manufacturing advancements.

Expansion of their global footprint also drives significant capital expenditure. This involves establishing new factories in strategically important regions to better serve global customers and tap into new growth markets. A prime example of this is their ongoing expansion efforts, which have included considerations for new facilities in markets like India.

- Ongoing Investment: Continuous capital expenditure is essential for maintaining and upgrading manufacturing facilities.

- Technology Adoption: Funds are allocated to integrate new production technologies to enhance efficiency and innovation.

- Global Expansion: Capital is deployed to establish new factories in strategic international locations, such as India, to broaden market reach.

Exel Composites' cost structure is heavily influenced by its significant investment in raw materials, particularly resins and reinforcing fibers. Manufacturing and production expenses, including labor and energy for specialized machinery, form another substantial cost. Research and Development (R&D) is a critical ongoing investment to maintain technological leadership, with a continued focus on high-performance solutions in 2024.

Sales, General, and Administrative (SG&A) expenses support global operations, with 2023 SG&A reported at €65.5 million. Capital expenditure is also a key cost driver, encompassing facility upgrades, new technology adoption, and global expansion efforts, such as potential new facilities in India.

| Cost Category | 2023 Value (€ million) | Key Drivers |

| Cost of Sales (Manufacturing) | 275.6 | Raw material prices (carbon fiber, resins), energy, labor, equipment maintenance |

| Sales, General & Administrative (SG&A) | 65.5 | Global sales network, administrative functions, marketing, management salaries |

| Research & Development (R&D) | [Specific 2024 data not yet available, but ongoing investment] | New product development, technological advancements |

| Capital Expenditure (CAPEX) | [Specific 2024 data not yet available, but ongoing investment] | Facility upgrades, new technology acquisition, global expansion |

Revenue Streams

Exel Composites generates its core revenue from selling custom-engineered composite profiles and tubes. These are specialized, high-value products designed to meet the precise needs of industrial customers in diverse markets.

In 2024, this segment is expected to remain a significant contributor to Exel Composites' overall financial performance, reflecting the ongoing demand for advanced material solutions in sectors like transportation, construction, and renewable energy.

Exel Composites generates revenue from offering specialized engineering, design, and technical consulting for intricate projects. This segment captures value through expert problem-solving and advanced material application.

These services often involve collaborative research and development, including the creation of prototypes. For instance, in 2024, a significant portion of their project-based revenue stemmed from early-stage design partnerships that secured subsequent large-scale production orders.

Exel Composites secures multi-year, volume-based supply contracts, primarily with large industrial clients in sectors like wind energy and transportation. These agreements are a cornerstone for predictable revenue, often involving substantial quantities of standardized or semi-customized composite profiles. For instance, in 2024, Exel Composites reported that its long-term customer relationships, underpinned by such volume contracts, contributed significantly to its revenue stability.

After-Sales Support and Maintenance (Potential)

While not a primary focus in their current reporting, Exel Composites could generate additional revenue through after-sales support and maintenance. This might involve service contracts for their composite solutions, particularly for industrial clients with long-lifecycle equipment. For instance, in 2024, the industrial sector continues to rely heavily on durable, low-maintenance materials, presenting an opportunity for recurring service revenue.

- Service Contracts: Offering ongoing maintenance agreements for installed composite structures.

- Technical Upgrades: Providing retrofits or enhancements to existing composite solutions.

- Spare Parts: Supplying replacement components for composite systems.

Licensing of Proprietary Technology (Potential)

Exel Composites could explore licensing its advanced pultrusion and pull-winding technologies to other manufacturers. This strategy would allow them to monetize their proprietary innovations and intellectual property without direct expansion into new production facilities. Such licensing agreements could generate recurring revenue through royalties or upfront fees.

Consider the potential for Exel to earn revenue by licensing its patented designs for composite profiles. This approach leverages their R&D investments and could open up new markets or applications where Exel doesn't currently operate directly. For instance, if Exel holds patents on specific structural composite designs used in, say, renewable energy infrastructure, licensing these to specialized builders could be lucrative.

- Technology Licensing: Potential to earn royalties from manufacturers using Exel's patented pultrusion or pull-winding processes.

- Design Licensing: Revenue generation through licensing of unique composite profile designs to third parties.

- Intellectual Property Monetization: Turning R&D advancements into a direct income source.

- Market Expansion: Enabling wider adoption of Exel's technologies and designs without direct capital investment in new regions.

Exel Composites' primary revenue stems from selling custom-engineered composite profiles and tubes, tailored for industrial applications. In 2024, this segment continued to be a major revenue driver, fueled by demand in sectors like construction and renewable energy.

The company also generates income from long-term supply contracts with major industrial clients, ensuring predictable revenue streams. These volume-based agreements, particularly in wind energy and transportation, were a stable contributor throughout 2024.

Additionally, Exel Composites earns revenue through specialized engineering, design, and technical consulting services. This includes collaborative R&D and prototype creation, with project-based revenue in 2024 often leading to larger, subsequent production orders.

Potential future revenue streams include licensing its proprietary pultrusion and pull-winding technologies, as well as unique composite profile designs, to other manufacturers. This intellectual property monetization could expand market reach without direct capital investment.

| Revenue Stream | Description | 2024 Relevance |

|---|---|---|

| Custom Composite Sales | High-value, engineered profiles and tubes for industrial use. | Core revenue, strong demand in key sectors. |

| Long-Term Supply Contracts | Volume-based agreements with large industrial clients. | Provided revenue stability and predictability. |

| Engineering & Consulting Services | Expert problem-solving, design, and R&D for complex projects. | Project-based revenue, often securing future production. |

| Technology & Design Licensing (Potential) | Monetizing proprietary pultrusion, pull-winding, and profile designs. | Future growth opportunity, IP monetization. |

Business Model Canvas Data Sources

The Exel Composites Business Model Canvas is informed by internal financial reports, market research on composite materials, and strategic analyses of industry trends. These sources provide a robust foundation for understanding Exel's operations and market position.