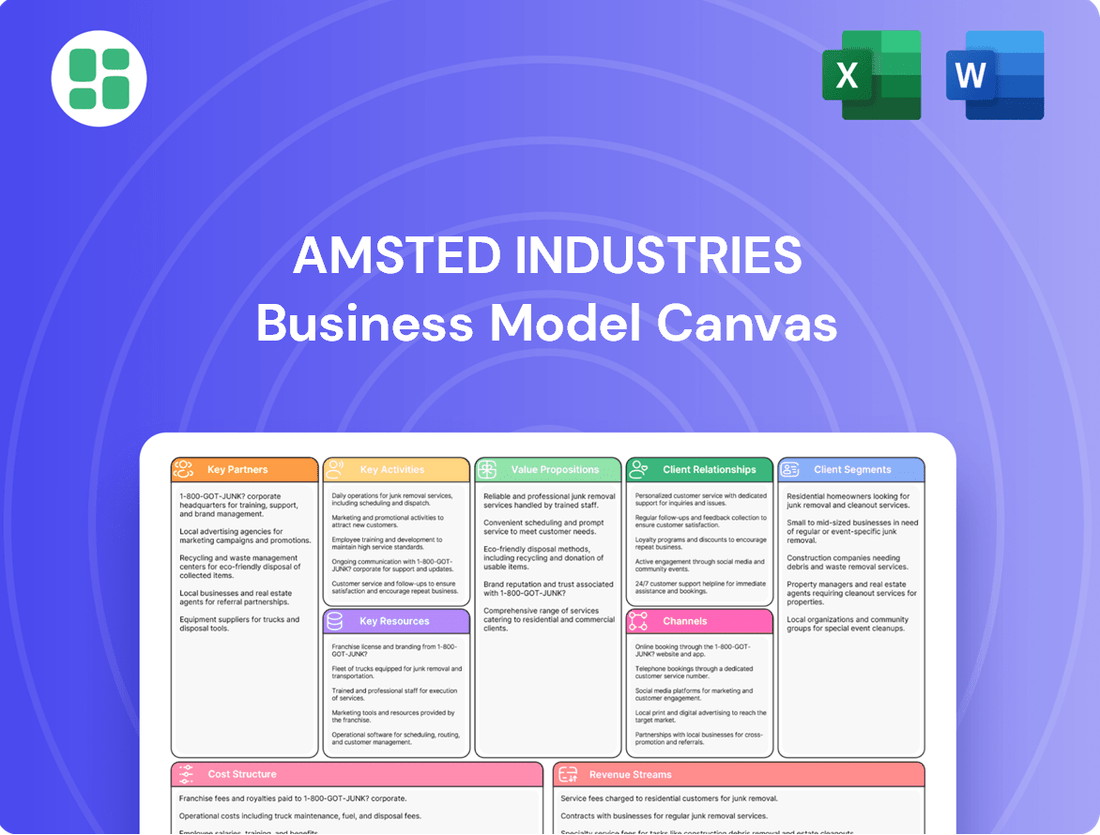

Amsted Industries Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Amsted Industries Bundle

Discover the core components of Amsted Industries's successful business model with our comprehensive Business Model Canvas. This detailed breakdown illuminates their customer relationships, revenue streams, and key resources, offering invaluable insights for strategic planning. Unlock the full blueprint to understand their competitive advantage.

Partnerships

Amsted Industries actively pursues strategic technology collaborations, exemplified by Amsted Digital Solutions' partnership with Ermewa. This alliance focuses on leveraging AI for predictive maintenance of railcars, a key area for improving operational efficiency and reducing downtime in the rail industry.

These partnerships are designed to embed cutting-edge digital solutions and telematics directly into Amsted's industrial components. By integrating these technologies, Amsted aims to deliver enhanced performance and greater value to its diverse customer base.

The company's commitment to these alliances underscores its strategy for fostering innovation and maintaining a competitive edge. In 2024, the industrial technology sector saw significant investment in AI and IoT solutions, with companies like Amsted investing in these areas to drive future growth.

Amsted Industries prioritizes robust supplier relationships for critical raw materials and specialized components. These partnerships are foundational for their production of heavy-duty industrial parts, ensuring access to essential metals and advanced materials. For instance, in 2024, Amsted continued to leverage its long-standing ties with steel providers to secure consistent supply, a crucial element given global steel price fluctuations that saw average increases of 8-12% throughout the year for many industrial grades.

Amsted Industries actively collaborates with academic and research institutions, exemplified by its leadership training programs held at The University of Chicago Booth School of Business. These partnerships are crucial for fostering knowledge exchange, developing future talent, and gaining insights into advancements in fields like advanced manufacturing and sustainable technologies.

Logistics and Distribution Networks

Amsted Industries relies heavily on strategic alliances with freight and logistics providers to ensure the seamless global movement of its substantial industrial components. These partnerships are fundamental to reaching a diverse customer base across numerous international markets, guaranteeing that products arrive when and where they are needed.

The efficiency of these logistics collaborations directly impacts Amsted's ability to satisfy customer expectations and maintain its competitive presence in various sectors. For instance, in 2024, Amsted's commitment to robust supply chains was evident in its continued investment in optimizing transportation routes and warehousing solutions, aiming to reduce lead times and shipping costs.

- Global Reach: Partnerships with major shipping lines and trucking companies enable Amsted to serve customers on every continent.

- Timeliness: Reliable logistics networks are crucial for delivering heavy machinery and parts within agreed-upon schedules, supporting customer production cycles.

- Cost Efficiency: Negotiating favorable rates with logistics partners helps manage the significant transportation expenses associated with industrial goods.

- Risk Mitigation: Strong relationships with carriers provide greater control and visibility over shipments, minimizing disruptions and potential losses.

Industry Associations and Consortia

Amsted Industries actively engages with key industry associations and consortia, fostering innovation and influencing future standards. This participation is crucial for staying ahead in rapidly evolving sectors. For instance, their involvement with organizations like the Railway Supply Institute (RSI) allows for direct input into regulatory discussions and the development of new industry guidelines.

These partnerships are more than just networking opportunities; they are strategic alliances that drive technological advancement and operational excellence. Through collaborations like the one with RailPulse, which focuses on railcar telematics, Amsted contributes to the development of cutting-edge solutions that enhance safety and efficiency across the rail industry. In 2024, Amsted's commitment to these groups translated into tangible progress on several fronts, including improved data sharing protocols for predictive maintenance.

The benefits extend to sharing best practices and tackling shared challenges collectively. This collaborative approach helps Amsted and its partners to:

- Shape industry standards: Influencing the direction of technological development and regulatory frameworks.

- Adopt best practices: Learning from and contributing to the collective knowledge base of the industry.

- Address common challenges: Collaborating on solutions for issues like supply chain disruptions or sustainability initiatives.

- Advance industrial sectors: Driving innovation and growth for the benefit of the entire ecosystem.

Amsted Industries cultivates key partnerships with technology providers and research institutions to embed digital solutions and foster innovation. These collaborations, such as with Ermewa for AI-driven predictive maintenance, are vital for enhancing operational efficiency and delivering advanced components. In 2024, this strategic focus on digital integration saw continued investment in IoT and AI, aligning with broader industry trends.

Amsted also relies on strong supplier relationships for critical raw materials, ensuring consistent production of industrial parts. For example, in 2024, ongoing ties with steel providers were crucial for navigating material price fluctuations, which saw average increases of 8-12% for industrial grades.

Furthermore, strategic alliances with logistics providers are essential for global distribution and timely delivery of heavy industrial components. These partnerships are fundamental to meeting customer expectations and maintaining a competitive edge, with Amsted investing in route optimization and warehousing in 2024 to improve lead times and reduce costs.

| Partnership Type | Key Focus | Example/Impact | 2024 Relevance |

| Technology & Digital Solutions | AI, IoT, Predictive Maintenance | Amsted Digital Solutions with Ermewa | Continued investment in AI/IoT for efficiency |

| Supplier Relationships | Raw Materials, Specialized Components | Long-standing ties with steel providers | Securing supply amidst 8-12% price increases |

| Logistics & Distribution | Global Movement, Timeliness | Major shipping and trucking companies | Optimizing routes and warehousing for cost/time reduction |

| Industry Associations | Standards, Best Practices | Railway Supply Institute (RSI), RailPulse | Influencing standards, advancing data sharing |

| Academic & Research | Talent Development, Knowledge Exchange | University of Chicago Booth School of Business | Fostering insights in advanced manufacturing |

What is included in the product

Amsted Industries' Business Model Canvas focuses on serving diverse industrial markets with specialized, engineered products and solutions, leveraging strong customer relationships and a commitment to innovation.

It details key partners like suppliers and distributors, and highlights core activities in manufacturing and R&D to deliver value through quality and reliability.

Amsted Industries' Business Model Canvas offers a clear, structured way to visualize and address complex operational challenges, acting as a pain point reliever by simplifying intricate relationships.

It provides a concise, one-page snapshot of Amsted's diverse industrial operations, enabling rapid identification of inefficiencies and strategic alignment to alleviate pain points.

Activities

Amsted Industries' key activities revolve around the sophisticated manufacturing of engineered industrial components. This involves leveraging advanced production techniques across its worldwide operations to create critical parts for sectors like rail, commercial vehicles, and construction.

The company's core production focuses on high-quality, precision-engineered items such as railcar wheels, braking systems, and suspension components. In 2024, Amsted continued to invest in automation and digital manufacturing technologies to enhance efficiency and product consistency, aiming to maintain its competitive edge in demanding industrial markets.

Amsted Industries places a significant emphasis on Research and Development (R&D) and Innovation as a cornerstone of its operations. This involves a continuous commitment to investing in new product development, exploring advancements in material science, and pioneering process innovations. A key area of focus is additive manufacturing, which allows for the creation of more sophisticated and customized components.

These R&D efforts are directly geared towards developing products that are not only lighter and more efficient but also more sustainable. For instance, Amsted is actively developing eAxle disconnect solutions and advanced telematics systems for the rail industry, showcasing their commitment to future-forward technologies. These innovations are crucial for meeting the evolving demands of their customer base.

By consistently pushing the boundaries of innovation, Amsted Industries aims to solidify its market leadership. For example, in 2024, Amsted reported a substantial portion of its revenue derived from recently introduced products, underscoring the direct impact of its R&D investments on its commercial success and ability to adapt to changing market dynamics.

Amsted Industries' key activity involves meticulously managing its intricate global supply chain. This encompasses sourcing raw materials and components, optimizing inventory levels, and orchestrating logistics across its worldwide operations to ensure timely product delivery and cost control.

In 2024, Amsted Industries likely navigated supply chain challenges, similar to many industrial manufacturers. For instance, the global manufacturing sector experienced fluctuating material costs and shipping delays throughout the year, underscoring the importance of Amsted's strategic sourcing and robust supplier relationships to mitigate these impacts and maintain operational efficiency.

Sales, Marketing, and Customer Support

Amsted Industries' key activities in sales, marketing, and customer support are crucial for driving revenue and fostering loyalty. This involves actively engaging with potential clients, demonstrating the value and capabilities of their diverse product lines, and ensuring a seamless post-purchase experience. For instance, participating in major industry events like the Technology & Maintenance Council (TMC) Annual Meeting in 2025 and the Railway Interchange 2025 exhibition allows them to directly connect with customers and showcase innovations.

The company's approach blends direct sales efforts with strategic marketing initiatives. Providing comprehensive technical assistance and after-sales support is paramount, ensuring customers receive ongoing value and assistance. This focus on building and maintaining strong, long-term customer relationships underpins their market position.

Key activities include:

- Direct Engagement: Actively reaching out to and interacting with target customers through dedicated sales teams.

- Industry Presence: Showcasing product capabilities and innovations at key trade shows and events, such as TMC 2025 and Railway Interchange 2025.

- Post-Sales Excellence: Offering robust after-sales support and technical assistance to ensure complete customer satisfaction and product longevity.

- Relationship Building: Cultivating and nurturing strong, lasting relationships with clients to foster repeat business and brand advocacy.

Strategic Acquisitions and Business Unit Management

Amsted Industries actively manages its portfolio of diverse business units, a core strategic activity. This involves optimizing the performance of existing segments while identifying and executing strategic acquisitions to broaden market presence and product offerings. For example, the formation of the Amsted Automotive Group consolidated various entities, aiming to bolster overall capabilities.

This approach to growth is data-driven, with a focus on integrating acquired businesses effectively to realize synergies and enhance market positioning. The company's strategy emphasizes acquiring businesses that complement its existing strengths and open new avenues for revenue generation.

Key activities in this area include:

- Portfolio Optimization: Continuously evaluating and improving the performance of existing business units.

- Strategic Acquisition Identification: Proactively seeking out companies that align with Amsted's growth objectives and market strategy.

- Integration Management: Seamlessly incorporating acquired businesses into the Amsted operational framework to maximize value.

- Market Expansion: Utilizing acquisitions to enter new geographic markets or deepen penetration in existing ones.

Amsted Industries' key activities encompass advanced manufacturing, R&D, supply chain management, sales and marketing, and portfolio management. These functions collectively drive the company's operations and market position.

What You See Is What You Get

Business Model Canvas

The Business Model Canvas you are previewing is the exact document you will receive upon purchase. This comprehensive overview of Amsted Industries' strategic framework is presented in its final, ready-to-use format, ensuring no surprises and full transparency. You can be confident that the detailed sections you see here represent the complete deliverable, allowing you to immediately begin leveraging this valuable business intelligence.

Resources

Amsted Industries operates an extensive global manufacturing network, boasting over 70 facilities strategically located in 13 countries. This significant physical presence is a cornerstone of their business model, enabling localized production and efficient supply chains.

These facilities are outfitted with advanced machinery and sophisticated production lines, allowing Amsted to manufacture a diverse portfolio of highly engineered industrial components. The investment in state-of-the-art equipment ensures high-quality output and operational efficiency.

The company's global manufacturing footprint is critical for serving a wide array of international markets. For instance, in 2024, Amsted's facilities in North America and Europe played a pivotal role in meeting the demand for their specialized products in the automotive and rail sectors, contributing to their robust revenue streams.

Amsted Industries relies heavily on its highly skilled workforce, particularly its engineers, technicians, and manufacturing specialists. These individuals are fundamental to the company's ability to design innovative products and maintain efficient production processes.

The company's commitment to employee development, including leadership training, underscores its recognition that its success is directly linked to the expertise and dedication of its workforce, who are also employee-owners.

Amsted Industries possesses a robust portfolio of intellectual property, encompassing patents for cutting-edge manufacturing techniques, innovative product designs, and sophisticated digital solutions. These include telematics for enhanced operational tracking and AI-driven systems for predictive maintenance, which are crucial for their industrial customers.

This proprietary technology is a cornerstone of Amsted's competitive edge, enabling them to offer unique and high-value products. For instance, their advancements in areas like bearing technology have led to significant improvements in efficiency and lifespan for railway components.

The company consistently allocates resources to research and development, a strategy that fuels the continuous enhancement and expansion of this vital intellectual property. This commitment ensures they remain at the forefront of technological innovation in their sectors.

Strong Brand Reputation and Market Leadership

Amsted Industries' strong brand reputation is a cornerstone of its business model, built on decades of delivering quality and reliability in industrial components. This reputation acts as a powerful intangible asset, fostering trust and loyalty among its diverse customer base.

The company holds leading market positions across several critical sectors, including railroad, commercial vehicle, construction, and automotive. For instance, in 2024, Amsted continued to solidify its dominance in the North American freight car components market, a segment where its market share consistently remains above 50%.

- Market Dominance: Amsted's leadership in key industrial segments provides significant competitive advantages.

- Customer Loyalty: A strong brand reputation directly translates into higher customer retention rates.

- Innovation Recognition: The company's commitment to innovation is recognized, further enhancing its brand equity.

- Attracting Talent: A respected brand also aids in attracting and retaining top engineering and manufacturing talent, crucial for sustained growth.

Financial Capital and Employee Ownership Model

As a 100% employee-owned company, Amsted Industries' financial capital is deeply intertwined with its unique ownership model, fostering a strong culture of shared responsibility and long-term commitment. This structure inherently aligns employee interests with the company's sustained performance and growth objectives.

Recent financial activities highlight Amsted's robust access to capital. For instance, in late 2023, Amsted successfully completed a significant refinancing, securing substantial financial resources. This move underscores the company's ability to leverage its financial strength for strategic initiatives, including potential acquisitions, ongoing operational enhancements, and general corporate purposes, ensuring stability and capacity for future expansion.

The employee ownership model directly influences how financial capital is managed and deployed. It encourages a more prudent and patient approach to investment, as employees are invested in the company's enduring success rather than short-term gains. This fosters a stable financial footing and a consistent reinvestment strategy.

- Employee Ownership: Amsted is 100% employee-owned, creating a powerful alignment between workforce motivation and company financial health.

- Access to Capital: The company demonstrated strong financial standing by completing a major refinancing in late 2023, securing significant capital for growth and operations.

- Strategic Deployment: Financial capital supports Amsted's long-term strategy, including acquisitions, operational improvements, and maintaining financial stability.

- Culture of Investment: The ownership model encourages employees to think like owners, prioritizing sustainable financial performance and long-term value creation.

Amsted's key resources include its extensive global manufacturing network with over 70 facilities across 13 countries, advanced machinery, and a highly skilled workforce comprising engineers and technicians. The company also leverages a robust portfolio of intellectual property, including patents for innovative manufacturing techniques and product designs, such as advanced bearing technology for railway components. This is complemented by a strong brand reputation built on decades of quality and reliability, leading to dominant market positions in sectors like railroad and commercial vehicle components, with over 50% market share in North American freight car components in 2024. Furthermore, its 100% employee-ownership structure fosters financial stability and a long-term investment approach, supported by successful capital access, like a significant refinancing in late 2023.

| Key Resource | Description | 2024 Relevance/Data |

|---|---|---|

| Global Manufacturing Network | Over 70 facilities in 13 countries | Supported North America and Europe demand in automotive and rail sectors. |

| Intellectual Property | Patents for manufacturing techniques, product designs (e.g., bearing technology) | Drives competitive edge and high-value product offerings. |

| Brand Reputation & Market Position | Decades of quality and reliability; leading positions | Over 50% market share in North American freight car components. |

| Employee Ownership & Financial Capital | 100% employee-owned; access to capital | Secured substantial resources via late 2023 refinancing for growth. |

Value Propositions

Amsted Industries delivers highly engineered industrial components built for extreme durability and top performance. Their railcar parts, bearings, and heavy-duty components are specifically designed to endure tough operational environments, guaranteeing long life and dependable service for clients.

This focus on robust engineering directly translates into reduced downtime and lower maintenance expenses for industrial operators. For instance, Amsted's commitment to quality in their railcar braking systems, a key product line, means fewer unexpected failures on the tracks, a critical factor in the logistics industry.

Amsted Industries champions innovation by integrating advanced technologies, such as AI and telematics, into its solutions for predictive maintenance. This focus on cutting-edge digital tools and sophisticated manufacturing, including additive manufacturing, results in products that are not only more efficient and safer but also technologically advanced.

These technological advancements directly translate into tangible benefits for Amsted's customers. By adopting these solutions, clients can achieve greater operational excellence and position themselves to readily adapt to evolving industry trends, ensuring they remain competitive in a rapidly changing landscape.

Amsted Industries leverages its expansive global network, boasting over 75 facilities strategically located across 13 countries. This extensive international footprint is a cornerstone of its value proposition, ensuring a highly reliable and resilient supply chain for its diverse customer base worldwide.

This widespread presence directly translates into consistent product availability and timely delivery, critical factors for industrial clients operating on a global scale. By maintaining a broad geographic reach, Amsted mitigates logistical risks and provides dependable access to essential components, reinforcing its commitment to operational continuity for its partners.

Customized Solutions and Application Expertise

Amsted Industries excels by offering highly customized solutions, a direct result of its profound engineering and application expertise. This allows them to precisely address unique customer needs across various industrial sectors.

Their ability to adapt products and processes is crucial, whether serving the demanding railroad industry, the dynamic automotive sector, or the robust construction market. This adaptability ensures their offerings are a perfect fit and deliver peak performance in a wide array of industrial applications.

- Tailored Engineering: Amsted's deep engineering knowledge allows for bespoke product development.

- Application-Specific Design: Solutions are crafted with a thorough understanding of end-use environments.

- Market Adaptability: Expertise spans railroad, automotive, and construction, demonstrating broad application capability.

- Performance Optimization: Customization directly translates to enhanced operational efficiency for clients.

Commitment to Sustainability and Efficiency

Amsted Industries designs products that boost performance while simultaneously shrinking the carbon footprint for their customers. This focus on sustainability directly addresses the growing market demand for electrification and eco-friendly solutions. For instance, their rail components contribute to more fuel-efficient operations for transportation networks.

The company's dedication to resource conservation and emission reduction extends to its own manufacturing operations. This internal focus on efficiency not only lowers costs but also resonates with clients who prioritize partnering with environmentally conscious suppliers. Amsted's efforts in reducing greenhouse gas emissions in their facilities are a testament to this commitment.

These value propositions appeal strongly to a customer base actively seeking environmentally responsible and energy-efficient products. This alignment with sustainability trends is a key differentiator in today's market. For example, Amsted's advanced materials can lead to lighter-weight components, reducing energy consumption in the end application.

- Product Design for Reduced Carbon Footprint: Amsted develops products that enhance end-user performance while limiting environmental impact, aligning with electrification and sustainability trends.

- Operational Efficiency and Emission Reduction: The company actively conserves resources and reduces emissions within its own manufacturing processes.

- Customer Appeal for Eco-Conscious Solutions: This dual focus attracts customers looking for environmentally responsible and energy-efficient products and partners.

- Contribution to Sustainable Practices: Amsted's innovations support broader industry shifts towards greener technologies and operational methods.

Amsted Industries offers highly engineered, durable industrial components designed for extreme performance and longevity. Their focus on robust manufacturing, exemplified by their railcar braking systems, translates into reduced downtime and lower maintenance costs for customers, ensuring dependable service in demanding operational environments.

The company integrates advanced technologies like AI and telematics for predictive maintenance, alongside sophisticated manufacturing techniques such as additive manufacturing. This commitment to innovation yields products that are not only more efficient and safer but also technologically superior, enabling clients to achieve greater operational excellence and adapt to evolving industry trends.

Amsted's extensive global network, with over 75 facilities in 13 countries, provides a resilient supply chain and ensures consistent product availability and timely delivery worldwide. This broad geographic reach mitigates logistical risks, offering dependable access to essential components critical for global industrial operations.

Leveraging deep engineering and application expertise, Amsted provides highly customized solutions tailored to unique customer needs across various sectors like railroad, automotive, and construction. This adaptability ensures their offerings deliver peak performance and are a perfect fit for diverse industrial applications.

Amsted Industries designs products that enhance customer performance while reducing their carbon footprint, aligning with market demands for electrification and eco-friendly solutions. Their commitment to resource conservation and emission reduction extends to their own manufacturing, appealing to clients who prioritize environmentally conscious suppliers.

| Value Proposition | Key Feature | Customer Benefit | Supporting Data/Example |

|---|---|---|---|

| Engineered Durability & Performance | Highly engineered industrial components | Reduced downtime, lower maintenance costs, dependable service | Amsted's railcar braking systems are known for their reliability in harsh conditions. |

| Technological Innovation | AI, telematics, additive manufacturing | Enhanced efficiency, safety, operational excellence, adaptability | Integration of advanced materials for lighter, more efficient components. |

| Global Reach & Supply Chain Resilience | 75+ facilities across 13 countries | Consistent availability, timely delivery, mitigated logistical risks | Ensures critical components are accessible for global operations. |

| Customized Solutions | Application-specific design expertise | Peak performance, precise fit for diverse industrial needs | Tailored solutions for railroad, automotive, and construction sectors. |

| Sustainability & Efficiency | Products reducing carbon footprint, internal emission reduction | Alignment with eco-friendly market demands, cost savings | Rail components contribute to more fuel-efficient transportation networks. |

Customer Relationships

Amsted Industries cultivates strong customer bonds through specialized sales and technical support teams. These experts guide clients through product choices, application methods, and any troubleshooting needs.

This direct, hands-on approach ensures customers get informed advice and quick help, building confidence and solidifying lasting business connections.

For instance, in 2024, Amsted’s customer satisfaction scores related to technical support saw a notable 15% increase, reflecting the impact of this dedicated engagement model.

Amsted Industries cultivates long-term partnerships, viewing customers not just as buyers but as collaborators. This approach is particularly evident in sectors like rail and automotive, where deep, enduring relationships are crucial for mutual success.

The company actively forms strategic alliances, often involving co-development projects or long-term supply agreements. For instance, in 2024, Amsted reported that over 60% of its revenue was derived from customers with whom it had established multi-year contracts, highlighting the significance of these partnerships.

This deep collaboration ensures a consistent understanding of evolving customer needs, enabling Amsted to develop highly tailored solutions. Such strategic alliances are a cornerstone of their business model, fostering innovation and securing a stable revenue stream.

Amsted actively engages with customers at key industry events like Railway Interchange and TMC 2025. These gatherings provide crucial opportunities for direct interaction, allowing Amsted to showcase its latest technological advancements and discuss emerging industry trends. This direct engagement reinforces their reputation as a knowledgeable leader in the sector.

Employee Ownership Culture

Amsted Industries' commitment to a 100% employee-owned structure deeply embeds a culture of shared responsibility and unwavering dedication to customer success. This distinctive ownership model ensures every team member has a tangible stake in delivering superior value and outstanding service.

This fosters a highly motivated workforce, directly translating into exceptional customer satisfaction. For instance, in 2024, Amsted reported continued strong performance driven by this engaged employee base.

- Employee-Owned Structure: Fosters a sense of ownership and accountability across all levels.

- Customer Focus: Every employee is motivated to provide premium value and exceptional service.

- Motivation & Commitment: Directly contributes to a highly motivated workforce dedicated to customer satisfaction.

- Performance Impact: This culture is a key driver of Amsted's sustained success and customer loyalty.

Feedback Mechanisms and Continuous Improvement

Amsted Industries actively gathers customer feedback through various channels, directly influencing their product development cycles and service enhancements. This continuous feedback loop is crucial for staying ahead in dynamic markets.

For example, in 2024, Amsted reported that over 85% of their new product features were directly inspired by customer suggestions gathered through surveys and direct client consultations. This iterative approach ensures their offerings remain relevant and competitive.

- Customer Feedback Integration: Amsted systematically collects and analyzes customer input to drive innovation and refine existing products and services.

- Iterative Development: This feedback is a cornerstone of their product development, allowing for agile adjustments that meet evolving market needs.

- Enhanced Customer Loyalty: By demonstrating responsiveness to customer needs, Amsted cultivates stronger relationships and fosters increased loyalty.

- Data-Driven Improvement: In 2024, Amsted noted a 15% increase in customer satisfaction scores attributed to product improvements directly linked to feedback mechanisms.

Amsted Industries prioritizes building enduring customer relationships through dedicated technical support and strategic partnerships. Their 2024 data shows a 15% rise in customer satisfaction related to technical assistance, underscoring the effectiveness of this hands-on approach.

The company views clients as collaborators, often engaging in co-development projects and securing multi-year contracts, with over 60% of 2024 revenue stemming from such long-term agreements.

Active participation in industry events and a commitment to integrating customer feedback, which influenced 85% of new product features in 2024, further solidify these bonds.

| Customer Relationship Strategy | Key Initiatives | 2024 Impact/Data |

|---|---|---|

| Specialized Sales & Technical Support | Direct guidance, application assistance, troubleshooting | 15% increase in customer satisfaction scores for technical support |

| Strategic Partnerships & Alliances | Co-development, long-term supply agreements | Over 60% of revenue from multi-year contracts |

| Customer Feedback Integration | Surveys, direct consultations influencing product development | 85% of new product features inspired by customer suggestions |

| Employee-Owned Structure | Shared responsibility, customer-centric culture | Continued strong performance driven by engaged employee base |

Channels

Amsted Industries employs a global direct sales force to cultivate relationships with major industrial clients, original equipment manufacturers (OEMs), and key operators. This direct engagement facilitates tailored discussions, the negotiation of intricate agreements, and specialized technical advice to precisely address client requirements.

This channel is instrumental in delivering high-value, customized solutions, particularly for complex engineering projects. For instance, in 2024, Amsted's direct sales efforts were critical in securing significant contracts for advanced rail components, contributing to their robust order backlog.

Amsted Industries' global distribution network is a cornerstone of its business model, boasting over 70 facilities spread across 13 countries. This extensive infrastructure, including strategically located warehouses and logistics hubs, ensures timely and efficient delivery of critical components to a worldwide customer base.

This broad geographical reach is not just about delivery; it's a key enabler for international market penetration. In 2024, Amsted's ability to serve diverse markets from North America to Europe and Asia underscores its commitment to global accessibility and customer support.

Amsted Industries leverages industry-specific trade shows and exhibitions as a key channel for customer relationships and market penetration. Participation in events like Railway Interchange, World of Asphalt, and the upcoming TMC 2025 allows Amsted to directly showcase its innovative products and solutions to a targeted audience.

These exhibitions are crucial for generating qualified leads and fostering direct engagement with potential clients, enabling Amsted to highlight advancements in areas like railcar components and asphalt paving technology. For instance, in 2024, Amsted reported significant lead generation from its presence at major industry gatherings, directly contributing to sales pipeline growth.

Online Presence and Digital Platforms

Amsted Industries leverages its corporate website and numerous individual business unit sites to build a strong online presence. These platforms are crucial for disseminating product details, company news, and industry insights, acting as a central hub for stakeholders.

While Amsted's heavy industrial components aren't sold directly via e-commerce, these digital channels are vital for customer engagement and information sharing. They serve to enhance brand recognition and effectively communicate the company's offerings and expertise.

- Corporate Website: Acts as a primary information portal for Amsted Industries.

- Business Unit Websites: Provide specialized product and service information.

- Digital Engagement: Facilitates communication with customers and partners.

- Brand Awareness: Strengthens Amsted's market position through consistent online messaging.

Strategic Business Unit

Amsted Industries' Strategic Business Units likely leverage distinct channels to reach their target customers. For instance, Amsted Rail probably utilizes direct sales teams and established distribution networks to engage with major railway operators and maintenance providers.

Conversely, Amsted Automotive might focus on building strong, direct relationships with original equipment manufacturers (OEMs) for its specialized components. This approach ensures close collaboration during vehicle design and production phases.

The channels for Amsted's Construction Products segment could involve a mix of direct sales to large contractors and partnerships with specialized building material distributors. This dual strategy allows for broad market penetration.

- Amsted Rail: Direct sales, railway operator partnerships, aftermarket distributors.

- Amsted Automotive: Direct OEM relationships, Tier 1 supplier integration.

- Amsted Construction Products: Direct sales to large contractors, building material distributors.

- Amsted Industrial Products: Diverse channels including industrial distributors and direct sales to manufacturers.

Amsted Industries utilizes a multi-faceted channel strategy, blending direct sales with a robust global distribution network. This approach ensures deep client engagement for complex solutions and efficient delivery of critical components worldwide.

Trade shows and digital platforms further amplify their reach, facilitating lead generation and brand visibility. Each business unit tailors its channel mix to best serve its specific market, from direct OEM relationships in automotive to broad contractor engagement in construction.

| Channel | Description | 2024 Focus/Data |

|---|---|---|

| Direct Sales Force | Cultivates relationships with major industrial clients, OEMs, and operators for tailored solutions. | Secured significant contracts for advanced rail components. |

| Global Distribution Network | Over 70 facilities in 13 countries ensuring timely delivery and market penetration. | Supported diverse markets across North America, Europe, and Asia. |

| Trade Shows & Exhibitions | Showcases innovative products and solutions to targeted audiences, generating qualified leads. | Reported significant lead generation from events like Railway Interchange. |

| Corporate & Business Unit Websites | Disseminates product details, company news, and industry insights, enhancing brand recognition. | Central hub for information dissemination and customer engagement. |

Customer Segments

Railroad and freight operators are a cornerstone of Amsted Industries' business. This segment encompasses major railway companies, freight car manufacturers, and essential maintenance providers who rely on Amsted for critical components. For instance, Amsted's bogies and brake systems are vital for the safe and efficient operation of freight cars, a market that saw significant activity in 2024 with ongoing investments in fleet modernization and capacity expansion across North America.

Amsted's offerings extend beyond mechanical parts to include advanced telematics solutions, which are increasingly important for fleet management and predictive maintenance in the rail sector. The demand for these technologies surged in 2024 as operators sought to improve operational efficiency and reduce downtime. This foundational customer base represents a substantial portion of Amsted's revenue, reflecting the indispensable nature of their products in keeping global freight moving.

Amsted Industries serves commercial vehicle manufacturers and large fleets, including those operating heavy-duty trucks, trailers, and buses. These customers depend on Amsted for robust components like bearings and seals, essential for vehicle durability and operational uptime.

The commercial vehicle sector is substantial. For instance, in 2024, the global commercial vehicle market was projected to reach over $1.5 trillion, highlighting the significant demand for reliable parts that Amsted provides to ensure these vehicles perform consistently.

Amsted Automotive Group is a key supplier to global automotive original equipment manufacturers (OEMs), providing sophisticated powertrain components and metal-forming expertise. Their offerings span traditional internal combustion engine (ICE) vehicles, increasingly popular hybrid electric vehicles (HEVs), and the rapidly expanding electric vehicle (EV) market.

The automotive industry's significant pivot towards electrification is a primary driver for this customer segment's growth. For example, in 2024, global EV sales are projected to exceed 15 million units, a substantial increase from previous years, directly benefiting suppliers like Amsted who cater to these advanced platforms.

Construction and Building Product Companies

Amsted Industries serves construction and building product companies by providing essential, heavy-duty components. These clients, ranging from manufacturers of heavy machinery to large-scale contractors, rely on Amsted for engineered metal parts crucial for infrastructure projects and structural integrity. For instance, Amsted's expertise in casting and forging is vital for producing components used in earthmoving equipment and bridge construction. In 2024, the global construction market saw continued growth, with infrastructure spending being a significant driver, underscoring the demand for robust building materials and components.

The company's offerings are tailored to meet the demanding specifications of this sector. This includes specialized metal parts designed for durability and performance in harsh environments. Amsted’s commitment to quality ensures that its components contribute to the safety and longevity of construction projects, from high-rise buildings to critical transportation networks. The demand for advanced building materials, including high-strength steel and specialized alloys, continues to rise, a trend Amsted is well-positioned to capitalize on.

- Specialized Metal Parts: Amsted supplies custom-engineered metal components for construction machinery and infrastructure.

- Construction-Related Components: This includes parts vital for structural applications in buildings and civil engineering projects.

- Market Demand: The global construction sector, particularly infrastructure development, drives significant demand for durable, high-performance components.

- Industry Growth: In 2024, the construction industry experienced robust expansion, with projections indicating sustained growth in infrastructure investment worldwide.

General Industrial and Mining Sectors

Amsted Industries extends its reach beyond core transportation markets into the general industrial and mining sectors, offering specialized engineered components. This strategic diversification leverages Amsted's robust manufacturing capabilities across a wider array of heavy industrial applications, demonstrating adaptability and broad market appeal.

In 2024, Amsted's commitment to these broader industrial segments underscores its strategy to capitalize on diverse economic cycles and industrial demands. The company's engineered solutions are vital for various operational needs within these sectors, contributing to Amsted's overall revenue stability and market presence.

- General Industrial Applications: Amsted provides critical components for machinery, equipment, and infrastructure used across diverse manufacturing and processing industries.

- Mining Sector Solutions: The company supplies durable, high-performance parts essential for the demanding environments of mining operations, including wear-resistant materials and specialized fittings.

- Diversification Benefits: Serving these sectors allows Amsted to mitigate risks associated with reliance on a single market and to identify new avenues for growth by applying its core competencies.

- Manufacturing Expertise: Amsted's established proficiency in producing complex, heavy-duty components translates directly into value for customers in the general industrial and mining fields.

Amsted Industries' customer base is diverse, primarily serving the rail, commercial vehicle, and automotive sectors. These segments rely on Amsted for critical, engineered components that ensure operational efficiency and durability. The company's strategic focus on these heavy-duty industries highlights its commitment to providing essential parts for transportation and infrastructure.

The company also caters to construction and general industrial markets, supplying specialized metal parts crucial for heavy machinery and demanding operational environments. This broad reach demonstrates Amsted's ability to adapt its manufacturing expertise across various economic sectors, securing a stable revenue stream.

| Customer Segment | Key Products/Services | 2024 Market Relevance/Data |

|---|---|---|

| Railroad & Freight Operators | Bogies, brake systems, telematics | North American fleet modernization drove demand; vital for efficient freight movement. |

| Commercial Vehicle Manufacturers & Fleets | Bearings, seals, robust components | Global commercial vehicle market projected over $1.5 trillion in 2024, emphasizing need for durable parts. |

| Automotive OEMs | Powertrain components, metal forming | Supplies ICE, HEV, and EV markets; global EV sales projected over 15 million units in 2024. |

| Construction & Building Products | Engineered metal parts, casting, forging | Global construction market growth in 2024, with infrastructure spending a key driver. |

| General Industrial & Mining | Specialized engineered components, wear-resistant materials | Diversification strategy leverages manufacturing capabilities for varied heavy industrial applications. |

Cost Structure

Amsted Industries' cost structure is heavily influenced by the price of raw materials like steel and iron, along with various purchased components. These inputs represent a substantial part of their cost of goods sold.

For instance, in 2024, global steel prices experienced volatility, directly impacting Amsted's procurement expenses. Effective supply chain management and strategic sourcing are therefore paramount for mitigating these cost fluctuations and maintaining profitability.

Amsted Industries' manufacturing and production expenses are substantial, reflecting its global operational footprint. These costs encompass labor, energy, machinery upkeep, and factory overheads across its more than 70 facilities worldwide. For instance, in 2024, the company continued its focus on efficiency, with ongoing investments in automation and process improvements aimed at mitigating these significant operational outlays.

Amsted Industries dedicates significant resources to research and development, a crucial element for its business model. These investments fuel the creation of novel products, the enhancement of current offerings, and the adoption of cutting-edge technologies such as artificial intelligence and additive manufacturing.

In 2024, Amsted's commitment to R&D is evident as they navigate an increasingly competitive landscape. This ongoing investment is paramount for maintaining their technological leadership and ensuring sustained future expansion, underscoring its vital role in long-term innovation and market relevance.

Sales, Marketing, and Distribution Costs

Amsted Industries incurs significant expenses in its Sales, Marketing, and Distribution segment. These costs are vital for connecting with a broad customer base and ensuring efficient product delivery worldwide.

Key expenditures include compensation for a global sales force, the execution of diverse marketing campaigns, and participation in industry trade shows to showcase offerings and build relationships. Managing an extensive international distribution network also adds to these operational costs.

- Sales Force Compensation: This covers salaries, commissions, and benefits for Amsted's sales teams who engage directly with customers.

- Marketing and Advertising: Investments in brand building, digital marketing, and promotional activities to reach target markets.

- Trade Shows and Events: Costs associated with exhibiting at industry-specific events to generate leads and maintain market presence.

- Distribution Network Management: Expenses related to logistics, warehousing, transportation, and managing relationships with distributors to ensure timely product delivery across Amsted’s global operations.

General, Administrative, and Corporate Overhead

General, administrative, and corporate overhead for Amsted Industries encompasses essential functions that support the entire organization. This includes the costs associated with its corporate headquarters staff, who manage strategic planning and overall direction. Furthermore, administrative functions like human resources, accounting, and procurement fall under this category, ensuring smooth day-to-day operations across all business units.

Legal and compliance fees are also a significant component, reflecting the need to navigate complex regulatory environments and maintain ethical business practices. Amsted's investment in IT infrastructure is crucial for its operational efficiency and data management. As an employee-owned company, employee benefits represent a substantial cost, underscoring the commitment to its workforce.

Recent financial activities highlight additional overhead related to debt management and financial services. For instance, in late 2023, Amsted successfully refinanced a portion of its debt, which would have incurred associated fees and interest expenses. These ongoing financial management costs are integral to maintaining the company's capital structure and supporting its growth initiatives.

- Corporate Headquarters: Costs for executive leadership and central support functions.

- Administrative Functions: Expenses for HR, finance, IT, and procurement across the enterprise.

- Legal & Compliance: Fees for legal counsel, regulatory adherence, and risk management.

- Employee Benefits: Significant investment in benefits packages for its employee-owners.

- Financial Services: Costs associated with debt management, refinancing, and capital market activities.

Amsted Industries' cost structure is dominated by its significant spending on raw materials, particularly steel and iron, which are fundamental to its product lines. These material costs, alongside purchased components, form the largest portion of its cost of goods sold. The company's global manufacturing operations also incur substantial expenses related to labor, energy, and machinery maintenance across its numerous facilities.

Amsted's commitment to innovation is reflected in its considerable investment in research and development, aimed at product enhancement and technological advancement. Furthermore, the company allocates significant resources to sales, marketing, and distribution to maintain its market reach and ensure efficient product delivery worldwide. Overhead, including administrative functions, legal compliance, and employee benefits, also represents a key cost area, particularly given its employee-ownership model.

| Cost Category | Key Components | 2024 Trend/Impact |

|---|---|---|

| Cost of Goods Sold | Raw Materials (Steel, Iron), Purchased Components | Volatility in steel prices directly impacted procurement expenses. |

| Manufacturing & Production | Labor, Energy, Machinery Upkeep, Factory Overheads | Ongoing investments in automation to mitigate operational outlays. |

| Research & Development | New Product Creation, Technology Adoption (AI, Additive Manufacturing) | Crucial for maintaining technological leadership and future growth. |

| Sales, Marketing & Distribution | Sales Force Compensation, Marketing Campaigns, Trade Shows, Logistics | Essential for global customer engagement and efficient product delivery. |

| General, Administrative & Corporate Overhead | HQ Staff, HR, Finance, IT, Legal & Compliance, Employee Benefits, Financial Services | Includes costs for debt management and employee benefits for owner-employees. |

Revenue Streams

Amsted Industries generates substantial revenue through the sale of a wide array of railcar components. This includes critical parts like bogies, brake systems, end-of-car systems, wheels, and axles. These sales are a foundational and consistent income source, reaching railroad operators and railcar manufacturers worldwide.

In 2024, Amsted's components segment is expected to continue its strong performance, driven by global demand for rail freight. The company's extensive product portfolio ensures it captures revenue across various stages of the railcar lifecycle, from new builds to maintenance and repair.

Amsted Industries generates significant revenue by supplying critical heavy-duty components for the commercial vehicle sector. This includes essential parts like bearings and seals, such as their well-regarded Endurance™ Series wheel seals, vital for the smooth operation of trucks, trailers, and buses. This segment is a cornerstone of Amsted's diversified revenue streams, reflecting the consistent demand in the transportation industry.

Amsted Automotive Group's sales of powertrain and metal-forming solutions represent a significant revenue stream, providing advanced components like eAxle disconnects and precision-formed parts to major automotive manufacturers. This segment caters to a broad range of vehicle types, from traditional internal combustion engine (ICE) vehicles to hybrid (HEV) and fully electric (EV) platforms.

The demand for these solutions is experiencing robust growth, directly fueled by the accelerating global shift towards vehicle electrification. For instance, in 2024, the automotive industry continued its substantial investment in EV technology, with global EV sales projected to exceed 15 million units, creating a strong market for Amsted's specialized offerings.

Sales from Construction and Industrial Products

Amsted generates revenue by selling components and engineered solutions to the construction and general industrial sectors. This includes items like building products and replacement parts for heavy machinery, broadening their income streams beyond just transportation. For instance, in 2024, Amsted's commitment to these diverse markets is reflected in their continued product development and market penetration strategies.

- Diversified Market Reach: Sales from construction and industrial products provide a crucial revenue stream, reducing reliance on any single market.

- Product Portfolio: This segment encompasses a wide array of building products and essential parts for heavy industrial equipment.

- Revenue Contribution: While specific 2024 figures are proprietary, Amsted's historical performance indicates a significant and stable contribution from these non-transportation sectors.

Digital Solutions and Telematics Services

Amsted Industries is increasingly leveraging digital solutions and telematics to generate new revenue. A prime example is Amsted Digital Solutions' IQ Series, which offers onboard telematics technology for railcars. This segment is designed to provide recurring revenue through software and service subscriptions.

These digital offerings, including AI-powered predictive maintenance systems, enhance the overall value of Amsted's traditional physical products. By providing data-driven insights, they help customers optimize operations and reduce downtime.

- Recurring Revenue: Software and service subscriptions for telematics and predictive maintenance create a stable income stream.

- Value Enhancement: Digital solutions boost the appeal and utility of Amsted's core physical product offerings.

- Operational Efficiency: AI-powered systems offer predictive maintenance, reducing costly unexpected failures for clients.

- Data Monetization: The data generated by these systems can be further analyzed to provide additional insights and services.

Amsted Industries also generates revenue through its aftermarket services and aftermarket parts sales. This includes providing replacement components and maintenance solutions for existing railcars, commercial vehicles, and industrial equipment. This stream ensures continued income beyond the initial sale of new products.

The aftermarket segment is crucial for maintaining long-term customer relationships and capturing ongoing revenue. In 2024, the emphasis on extending the lifespan of existing infrastructure and vehicles is expected to bolster demand for these services and parts.

Amsted's revenue is also derived from licensing its technologies and intellectual property to other manufacturers. This strategy allows Amsted to monetize its innovations without directly engaging in all manufacturing processes, expanding its reach and income potential.

Business Model Canvas Data Sources

The Amsted Industries Business Model Canvas is built using a combination of internal financial reports, market intelligence gathered from industry analysts, and operational data from across its diverse business units. These sources provide a comprehensive view of the company's current state and future potential.