Albany International Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Albany International Bundle

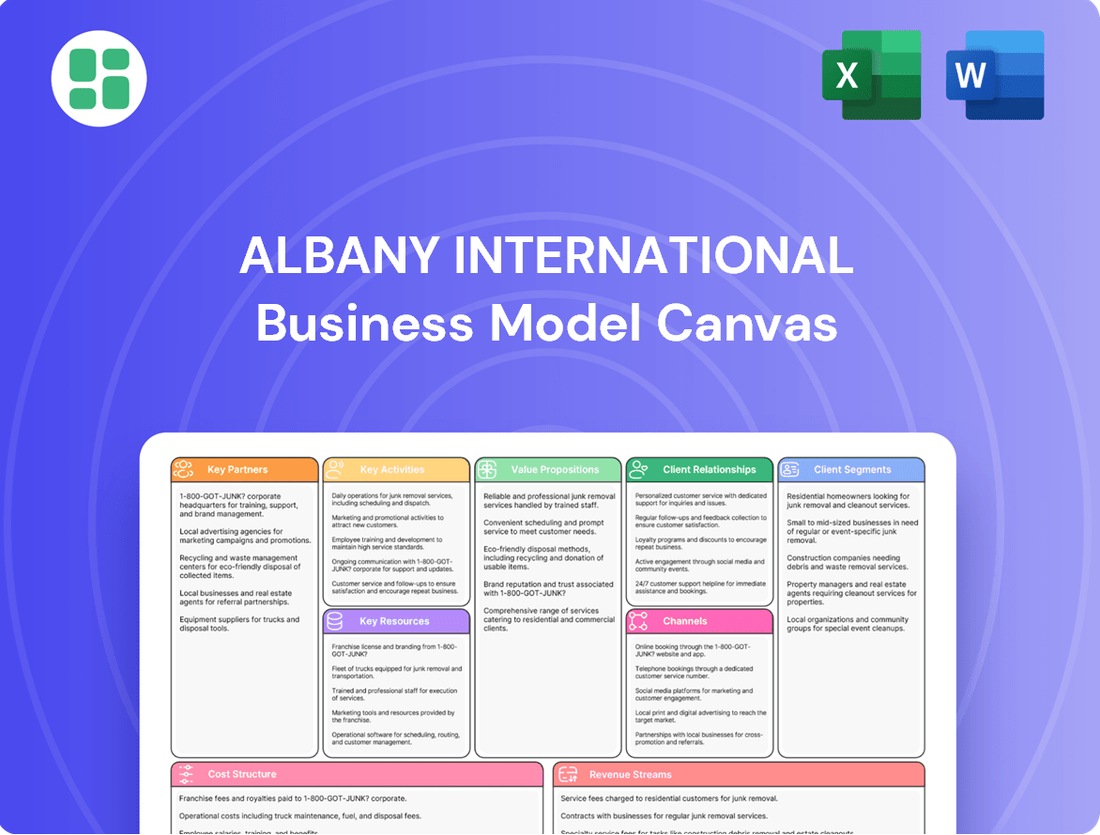

Unlock the full strategic blueprint behind Albany International's business model. This in-depth Business Model Canvas reveals how the company drives value, captures market share, and stays ahead in a competitive landscape. Ideal for entrepreneurs, consultants, and investors looking for actionable insights.

Partnerships

Albany International's strategic suppliers are the backbone of its advanced textile and composite manufacturing. These partnerships ensure the consistent quality and availability of specialized fibers, resins, and other critical materials. For instance, in 2024, the company continued to leverage these relationships to mitigate supply chain disruptions, a common challenge across many industries.

Albany Engineered Composites' key partnerships with major aerospace and defense prime contractors are absolutely crucial for their business. These aren't just casual relationships; they often involve long-term agreements to supply advanced composite parts.

For instance, collaborations with companies like Boeing and GE Aviation are vital. These partnerships focus on developing and delivering high-performance composite structures. These are used in significant programs such as the CH-53K helicopter and the widely adopted LEAP engine, showcasing the critical nature of these alliances.

Albany International actively partners with universities and research institutions. These collaborations are crucial for advancing their expertise in engineered fabrics and materials science. For example, in 2024, they continued to foster relationships with leading academic bodies to explore novel fiber technologies and advanced manufacturing techniques.

These partnerships are instrumental in driving innovation, allowing Albany International to stay at the forefront of material development. Through joint research projects, they aim to achieve breakthroughs in areas like high-performance composites and sustainable textile solutions, which directly contribute to their technological leadership in the market.

Industry Associations

Albany International actively engages with industry associations, a crucial element of its business model. This engagement allows the company to remain informed about evolving market dynamics, new regulations, and emerging technologies within its core sectors, notably paper and aerospace. These affiliations are vital for fostering connections, exchanging valuable information, and advocating for industry-wide standards that benefit all participants.

These partnerships provide Albany International with several key advantages:

- Market Intelligence: Access to up-to-date information on industry trends and best practices. For example, participation in associations like the Technical Association of the Pulp and Paper Industry (TAPPI) provides insights into sustainable manufacturing processes and material innovations.

- Regulatory Awareness: Staying ahead of legislative changes that could impact operations, such as environmental regulations or material certifications required in aerospace.

- Networking and Collaboration: Building relationships with peers, suppliers, and customers, which can lead to new business opportunities and collaborative research initiatives.

- Advocacy and Standards: Contributing to the development and promotion of industry standards, ensuring a level playing field and fostering innovation.

Technology Development Partners

Albany International collaborates with technology development partners to embed advanced automation and digital solutions, such as SAP S/4HANA, into its manufacturing processes. This strategic alignment enhances operational efficiency and data analytics capabilities. For instance, in 2024, the company continued its focus on digital transformation initiatives, aiming to streamline supply chain management and improve real-time decision-making across its global facilities.

These partnerships are crucial for staying at the forefront of industry innovation.

- Integration of Advanced Automation: Facilitates the adoption of next-generation manufacturing technologies.

- Digital Solutions Implementation: Drives efficiency through platforms like SAP S/4HANA.

- Enhanced Analytics: Improves data-driven insights for better business agility.

- Streamlined Operations: Optimizes supply chain and global facility management.

Albany International's key partnerships extend to academic and research institutions, fostering crucial advancements in materials science and textile engineering. These collaborations are vital for their innovation pipeline, allowing them to explore novel fiber technologies and cutting-edge manufacturing processes. In 2024, the company continued to invest in these relationships to maintain its technological edge.

What is included in the product

A detailed, pre-written business model canvas for Albany International, outlining its customer segments, value propositions, and channels with real-world operational insights.

This canvas is structured around the 9 classic BMC blocks, offering a comprehensive narrative and analysis of Albany International's competitive advantages, strengths, weaknesses, opportunities, and threats.

Albany International's Business Model Canvas provides a clear, structured framework that alleviates the pain of complex strategy development by condensing intricate business elements into a single, easily digestible page.

It acts as a pain point reliever by offering a visual roadmap that simplifies strategic planning and communication, making it easier to identify and address potential challenges.

Activities

Albany International's commitment to advanced material research and development is central to its strategy. The company consistently invests in R&D to pioneer novel materials and refine existing ones, with a keen eye on attributes such as superior strength-to-weight ratios and enhanced durability.

A significant focus area for Albany International involves exploring cutting-edge manufacturing techniques like 3D weaving and resin transfer molding. These advanced processes are particularly crucial for applications in demanding sectors such as defense and aerospace, ensuring the company maintains its technological edge and competitive advantage in these high-growth markets.

Albany International's key activities revolve around the intricate design and production of specialized materials. This includes crafting custom-engineered fabrics and process belts vital for their Machine Clothing segment, alongside developing advanced high-performance composite structures for their Albany Engineered Composites segment.

These operations demand highly specialized manufacturing processes and rigorous quality assurance protocols to meet the exacting standards of their diverse clientele. For instance, in 2023, Albany International reported that their Machine Clothing segment generated approximately $765 million in revenue, underscoring the significance of their fabric manufacturing capabilities.

Albany International's key activity involves meticulously managing a complex global supply chain. This encompasses sourcing raw materials and essential components from various international suppliers to fuel its manufacturing operations. Efficiently orchestrating these inbound logistics is paramount for maintaining production continuity and meeting customer demand across its extensive network.

The company operates 30 facilities spread across 13 countries, underscoring the intricate nature of its supply chain management. This global footprint necessitates robust strategies for optimizing transportation routes and ensuring timely delivery of finished goods. Strong supplier relationships are a cornerstone of this process, enabling better negotiation, quality control, and risk mitigation.

In 2024, companies like Albany International faced persistent supply chain challenges, including geopolitical disruptions and fluctuating freight costs. Effective management of these dynamics, by maintaining diversified supplier bases and investing in advanced logistics technology, was critical for operational resilience and cost control. For instance, a 2024 report indicated that companies with proactive supply chain visibility experienced an average of 15% lower logistics costs.

Sales, Marketing, and Technical Support

Albany International’s sales, marketing, and technical support are crucial for its success. They directly engage customers to understand unique needs and offer customized solutions, which is vital for winning new business and fostering lasting partnerships. For instance, in 2023, the company reported a backlog of $1.3 billion, indicating strong demand driven by effective sales and marketing efforts.

These activities are not just about selling products; they involve deep technical expertise. Providing comprehensive support ensures customers can effectively utilize Albany’s advanced materials, leading to higher satisfaction and repeat business. This focus on customer success is a cornerstone of their strategy to maintain a competitive edge in specialized markets.

- Direct Sales Engagement: Building relationships and understanding client needs for tailored solutions.

- Strategic Marketing: Communicating value proposition and reaching target markets effectively.

- Technical Support Excellence: Ensuring customer success through expert assistance and problem-solving.

- Contract Acquisition: Leveraging sales and support to secure new and recurring business.

Operational Efficiency and Restructuring

Albany International's key activities include a relentless focus on operational efficiency. This involves ongoing efforts to boost manufacturing productivity across its global facilities. For instance, in 2024, the company continued its strategic initiatives to optimize its production footprint, aiming to consolidate manufacturing capacity where feasible to reduce overhead and improve throughput.

Cost controls are also paramount. Albany International actively implements measures to manage expenses, from raw material sourcing to supply chain logistics. These cost-saving initiatives are crucial for maintaining competitiveness and enhancing profitability in a dynamic market environment. The company's commitment to streamlining operations directly impacts its ability to deliver value.

- Manufacturing Productivity: Continuous improvement programs to increase output per unit of input.

- Cost Management: Implementing strict controls on operational expenses and supply chain costs.

- Strategic Restructuring: Actions like consolidating manufacturing capacity to optimize the global operational footprint.

- Profitability Enhancement: Direct correlation between operational efficiency and improved financial performance.

Albany International's key activities center on the design, development, and manufacturing of specialized engineered materials and components. This involves intricate fabric creation for their Machine Clothing segment and advanced composite structures for their Engineered Composites segment, demanding precise engineering and rigorous quality control.

The company actively manages a complex global supply chain, sourcing materials internationally and optimizing logistics across its 30 facilities in 13 countries. This global reach requires robust strategies for supplier relations, transportation, and ensuring product delivery, especially amidst 2024's supply chain volatility.

Sales, marketing, and technical support are critical for understanding customer needs and providing tailored solutions, fostering strong client partnerships. This customer-centric approach, backed by deep technical expertise, drives new business acquisition and ensures customer satisfaction, as evidenced by their substantial backlog.

Operational efficiency and cost management are paramount, with ongoing initiatives to boost manufacturing productivity and control expenses. Strategic actions, such as optimizing the production footprint, aim to enhance throughput and profitability, directly impacting the company's competitive standing.

| Key Activity Area | Description | Example Data/Impact |

|---|---|---|

| Material Design & Manufacturing | Creating specialized fabrics and composite structures. | Machine Clothing revenue in 2023: ~$765 million. |

| Supply Chain Management | Sourcing, logistics, and supplier relations across global facilities. | Operates 30 facilities in 13 countries. Proactive visibility can lower logistics costs by ~15% (2024 trend). |

| Sales, Marketing & Support | Customer engagement, technical assistance, and contract acquisition. | 2023 backlog: $1.3 billion, reflecting strong demand. |

| Operational Efficiency & Cost Control | Improving productivity and managing expenses. | Ongoing optimization of production footprint in 2024. |

Full Version Awaits

Business Model Canvas

The Albany International Business Model Canvas you are previewing is the exact document you will receive upon purchase. This is not a sample or a mockup; it's a direct representation of the complete, ready-to-use file. You'll gain full access to this professionally structured and formatted Business Model Canvas, allowing you to immediately leverage its insights for your strategic planning.

Resources

Albany International holds a robust portfolio of intellectual property, particularly patents safeguarding its innovative textile and composite technologies. This proprietary knowledge is a critical differentiator, especially in its specialized market segments.

In 2023, Albany International reported approximately $1.3 billion in revenue, with a significant portion stemming from its advanced materials and engineered fabrics, underscoring the commercial value of its intellectual property.

These patents are not just legal protections; they represent a tangible competitive advantage, enabling the company to offer unique solutions and maintain leadership in high-performance applications.

Albany International's global network of specialized manufacturing facilities is a cornerstone of its business model. These sites are outfitted with cutting-edge machinery and sophisticated processes, enabling the precise engineering and large-scale production of intricate materials vital to their customer base.

In 2024, the company continued to leverage these facilities to serve diverse markets, including aerospace and defense, where the demand for high-performance, custom-engineered materials remains robust. The strategic placement of these manufacturing hubs allows for efficient global supply chain management and responsiveness to client needs.

Albany International’s success hinges on its highly skilled workforce, comprising engineers, material scientists, and technical specialists. This deep expertise is critical for their advanced research and development initiatives, ensuring the company remains at the forefront of filtration and engineered fabrics technology.

In 2024, Albany International continued to invest in its human capital, recognizing that this talent pool is the engine driving both innovation and operational excellence. Their technical staff's ability to develop and manufacture complex, high-performance materials directly translates into superior product offerings and the capacity to provide intricate technical support to a global customer base.

Proprietary Materials and Formulations

Albany International's proprietary materials and unique formulations are central to its business model, especially in advanced composites. These specialized materials are meticulously developed to deliver exceptional performance, meeting the stringent requirements of high-stakes industries like aerospace and advanced manufacturing. For instance, their expertise in creating materials with enhanced strength-to-weight ratios and superior thermal resistance directly translates into competitive advantages for their clients.

These advanced materials are not merely components; they are enablers of innovation for their customers. The ability to tailor material properties for specific, demanding applications, such as in jet engine components or high-performance industrial machinery, is a critical differentiator. This focus on unique formulations allows Albany International to command premium pricing and build strong, long-term relationships.

- Proprietary Formulations: Albany International invests heavily in research and development to create and refine unique material compositions.

- Superior Performance: These materials offer enhanced durability, lighter weight, and greater resistance to extreme conditions compared to standard alternatives.

- Aerospace and Industrial Focus: Key applications include critical components in aircraft engines, industrial filtration, and other demanding environments.

- Competitive Advantage: The exclusivity and performance of these materials provide a significant edge in niche, high-value markets.

Financial Capital and Strong Balance Sheet

Albany International's robust financial capital and strong balance sheet are cornerstones of its operational strategy. This financial strength allows the company to consistently invest in crucial areas like research and development, ensuring innovation in its advanced materials and engineered components. For instance, in 2024, Albany International reported a healthy liquidity position, enabling them to navigate potential market downturns without compromising long-term growth initiatives.

Furthermore, sufficient financial resources are vital for Albany International to undertake significant capital expenditures. These investments are often directed towards upgrading manufacturing facilities and adopting new technologies, which is essential for maintaining a competitive edge in the aerospace and defense sectors. The company's commitment to maintaining a strong balance sheet also positions it favorably for pursuing strategic acquisitions that could expand its market reach or technological capabilities.

- Financial Capital: Enables sustained investment in R&D and capital expenditures.

- Strong Balance Sheet: Supports strategic acquisitions and provides liquidity during market volatility.

- 2024 Performance: Demonstrated a solid financial footing, reflecting effective financial management.

- Operational Resilience: Underpins the ability to fund facility upgrades and technological advancements.

Albany International's key resources include its intellectual property, particularly patents on textile and composite technologies, its global network of specialized manufacturing facilities, its highly skilled workforce of engineers and material scientists, its proprietary advanced materials and unique formulations, and its strong financial capital. These resources collectively enable the company to innovate, produce high-performance products, and maintain a competitive edge in demanding markets.

| Key Resource | Description | 2024 Relevance/Data Point |

|---|---|---|

| Intellectual Property | Patents on textile and composite technologies | Differentiator in high-performance applications, underpinning unique solutions. |

| Manufacturing Facilities | Global network of specialized sites with advanced machinery | Facilitated production for diverse markets, including aerospace and defense, in 2024. |

| Skilled Workforce | Engineers, material scientists, technical specialists | Drove innovation and operational excellence in 2024, crucial for complex material development. |

| Proprietary Materials | Unique formulations for advanced composites | Enabled tailored solutions for aerospace and industrial applications, commanding premium pricing. |

| Financial Capital | Strong balance sheet and liquidity | Supported R&D investment and operational resilience in 2024, enabling growth initiatives. |

Value Propositions

Albany International's Machine Clothing segment delivers custom-engineered fabrics and belts specifically for the paper, tissue, and paperboard industries. These advanced materials are crucial for boosting production line efficiency, increasing operational speeds, and elevating the quality of the final paper products.

For instance, in 2023, the company's innovative solutions contributed to paper manufacturers achieving up to a 5% increase in machine uptime, a direct result of the enhanced durability and performance of Albany's clothing. This translates to significant cost savings and higher output volumes for their clients.

Albany Engineered Composites delivers advanced composite structures for aerospace, boasting exceptional strength-to-weight ratios that significantly outperform traditional metals like titanium. This translates directly into enhanced fuel efficiency for aircraft and enables more innovative designs for both aviation and space exploration.

For instance, in 2024, the aerospace sector continued its push for lighter, stronger materials to meet stringent emissions targets and performance demands. Albany's composites are crucial in this evolution, contributing to the development of next-generation aircraft components where every kilogram saved directly impacts operational costs and environmental footprint.

Albany International excels by crafting highly customized solutions, meticulously engineered to meet the distinct and rigorous demands of its industrial and aerospace clientele. This deep level of personalization ensures products are optimized for specific machine types or integrated seamlessly into complex aerospace programs, a key differentiator in a competitive market.

For instance, in 2024, the company continued its focus on application-specific engineering, a strategy that has historically driven strong customer loyalty and premium pricing. This approach allows Albany International to address niche requirements that off-the-shelf solutions cannot, thereby cementing its value proposition.

Reliability and Durability in Demanding Environments

Albany International's offerings are built to last, ensuring consistent performance even in tough industrial settings and critical aerospace uses. This robust engineering translates directly into fewer interruptions and lower upkeep expenses for clients.

Their commitment to reliability means customers can depend on Albany's products to function flawlessly, minimizing costly downtime. For instance, in 2023, the company's focus on quality contributed to its strong performance in key markets, reflecting the value placed on durable solutions.

- Engineered for Harsh Conditions: Products designed to withstand extreme industrial and aerospace demands.

- Reduced Downtime: High reliability minimizes operational interruptions for customers.

- Lower Maintenance Costs: Durability leads to less frequent repairs and replacements.

- Consistent Performance: Dependable operation in critical applications.

Innovation and Technological Leadership

Albany International's commitment to innovation and technological leadership is a cornerstone of its value proposition. Through dedicated research and development, the company consistently introduces advanced manufacturing technologies and materials. This focus ensures that customers receive solutions designed to enhance their own competitive edge and operational efficiency.

In 2024, Albany International continued to invest heavily in its innovation pipeline, aiming to deliver next-generation products. For instance, their work in advanced textiles for aerospace applications directly addresses the industry's demand for lighter, stronger, and more fuel-efficient components. This forward-thinking approach allows clients to achieve superior performance and sustainability goals.

- Cutting-Edge Solutions: Albany International provides advanced manufacturing technologies and materials that give customers a competitive advantage.

- Customer-Centric Innovation: R&D efforts are directed towards developing solutions that meet evolving industry needs and drive customer success.

- Sustainability and Performance: Innovations are designed to improve both the environmental footprint and the operational performance of customer products.

- Technological Advancement: The company maintains a leading position through continuous investment in and adoption of state-of-the-art manufacturing processes.

Albany International's value proposition centers on delivering highly customized, engineered solutions that enhance customer efficiency and performance. Their advanced fabrics for the paper industry, for example, improve machine uptime and product quality, while their composite structures for aerospace offer superior strength-to-weight ratios, leading to better fuel efficiency. This dedication to tailored, high-performance products ensures clients gain a competitive edge.

The company's focus on durability and reliability minimizes downtime and maintenance costs for its customers. This commitment to robust engineering means clients can depend on consistent operational performance, even in demanding environments. For instance, Albany's products are designed for longevity, reducing the need for frequent replacements and contributing to overall cost savings.

Innovation is a core pillar, with Albany International consistently investing in R&D to introduce advanced materials and technologies. This forward-looking approach allows them to provide cutting-edge solutions that meet evolving industry demands, such as lighter, more fuel-efficient components for aerospace. Their customer-centric innovation ensures clients benefit from superior performance and sustainability.

| Value Proposition Area | Key Benefit | Example/Data Point (2023-2024) |

|---|---|---|

| Customization & Performance Enhancement | Tailored solutions for specific needs | Up to 5% increase in machine uptime for paper manufacturers (2023) |

| Durability & Reliability | Reduced downtime and maintenance costs | Strong market performance reflecting value of durable solutions (2023) |

| Innovation & Technology Leadership | Competitive advantage through advanced materials | Development of next-gen aerospace components for fuel efficiency (2024) |

Customer Relationships

Albany International leverages dedicated sales and technical support teams to foster strong customer relationships. These teams act as crucial liaisons, deeply understanding client requirements and offering expert guidance.

This personalized approach ensures seamless product integration and optimal performance, going beyond mere transactions to build lasting partnerships. For instance, in 2023, Albany International reported a significant increase in customer satisfaction scores directly attributed to the responsiveness and expertise of these support functions.

Albany International cultivates deep connections through long-term strategic partnerships, particularly within its Albany Engineered Composites segment. These aren't just transactional relationships; they're collaborative endeavors focused on co-developing advanced composite solutions for critical, ongoing programs.

These enduring partnerships are underpinned by sustained supply agreements, ensuring Albany remains a vital component supplier for its customers' key initiatives. For instance, in 2024, a significant portion of the Engineered Composites revenue was derived from these multi-year contracts, highlighting the stability and strategic importance of these customer relationships.

Albany International prioritizes robust after-sales service, offering comprehensive maintenance, troubleshooting, and performance optimization for its engineered fabrics. This commitment ensures customer satisfaction and maximizes product longevity across both its Machine Clothing and Technical Fabrics segments.

In 2024, Albany International continued to focus on these support services, recognizing their critical role in customer retention and repeat business. For instance, their technical support teams actively engage with customers to address operational challenges, contributing to the efficient performance of their specialized fabrics in demanding industrial applications.

Consultative and Collaborative Development

Albany International cultivates deep customer partnerships through a consultative and collaborative development process, especially crucial for intricate aerospace components. This approach involves actively working with clients to co-create solutions tailored to their unique operational hurdles or novel product specifications.

This close collaboration builds significant trust and ensures a high degree of integration between Albany International and its customers. For instance, in 2024, the company's advanced materials segment, which heavily relies on these relationships for custom solutions, saw continued demand driven by innovation in aircraft manufacturing.

- Co-development of solutions: Albany International partners with clients to engineer bespoke answers for complex aerospace needs.

- Addressing specific challenges: The consultative method directly tackles operational issues and new product development requirements.

- Fostering trust and integration: This close working relationship creates strong bonds and seamless operational synergy.

- Driving innovation in aerospace: The collaborative model is key to Albany's success in supplying advanced materials for evolving aircraft designs.

Global Customer Service Network

Albany International leverages its extensive global presence to provide a robust customer service network. This allows them to offer timely support and specialized knowledge tailored to their international clientele, ensuring a high level of customer satisfaction across different regions.

- Global Reach: With manufacturing facilities and sales offices spread across North America, Europe, and Asia, Albany International can serve customers in over 100 countries.

- Localized Expertise: The company employs local service teams who understand regional market nuances and customer needs, facilitating more effective problem-solving and relationship building.

- Responsive Support: Albany International's network is designed for rapid response, aiming to minimize downtime and maximize operational efficiency for their customers worldwide.

Albany International builds enduring customer connections through a combination of dedicated support, strategic partnerships, and collaborative co-development. Their approach emphasizes understanding unique client needs, providing expert technical assistance, and fostering long-term relationships built on trust and mutual benefit. This focus on partnership is particularly evident in their Engineered Composites segment, where multi-year contracts underscore the strategic importance of these relationships.

| Customer Relationship Aspect | Description | Example/Data Point |

|---|---|---|

| Dedicated Support Teams | Sales and technical teams offer expert guidance and ensure seamless product integration. | 2023 saw increased customer satisfaction scores linked to responsive support. |

| Long-Term Partnerships | Collaborative endeavors focused on co-developing advanced solutions for critical programs. | Significant 2024 Engineered Composites revenue stemmed from multi-year contracts. |

| After-Sales Service | Comprehensive maintenance, troubleshooting, and performance optimization. | 2024 focus on support services for customer retention and repeat business. |

| Co-Development Process | Working with clients to engineer bespoke solutions for complex aerospace needs. | Advanced materials segment demand in 2024 driven by collaborative innovation. |

Channels

Albany International relies heavily on its direct sales force to connect with major industrial clients and aerospace leaders worldwide. This approach enables in-depth technical conversations and the development of tailored solutions for complex needs.

In 2024, Albany International's sales and marketing expenses were $220.9 million, reflecting the investment in this direct engagement model. This dedicated sales force is crucial for understanding client requirements and positioning Albany's advanced engineered fabrics and materials effectively.

Albany International's global manufacturing and distribution network is a cornerstone of its business model. With operations spanning 13 countries, the company efficiently produces and delivers its specialized products, such as engineered fabrics for papermaking and filtration, to a diverse international customer base.

In 2023, Albany International reported net sales of $1.3 billion, underscoring the scale and reach of its global operations. This extensive network allows for localized production and quicker response times, crucial for serving industries with demanding supply chain requirements.

Albany International leverages industry trade shows and conferences as a crucial channel for product demonstration and market outreach. These events allow the company to directly showcase its advanced engineered fabrics and materials to key decision-makers in the paper and aerospace industries, fostering valuable face-to-face interactions.

In 2024, participation in events like the TAPPICon and the Paris Air Show provided Albany International with significant opportunities. These platforms enable direct engagement with potential clients, facilitating discussions about tailored solutions and reinforcing brand presence among a targeted audience of industry professionals.

Company Website and Digital Presence

Albany International's company website and digital presence are crucial for connecting with its diverse audience. These platforms function as the primary conduit for detailed product specifications, investor relations updates, and comprehensive corporate news. This digital hub is essential for disseminating information and handling inquiries efficiently.

The company leverages its website to showcase its advanced engineered fabrics and materials, providing in-depth technical data and application examples. Furthermore, the investor relations section offers vital financial reports, SEC filings, and management commentary, supporting informed decision-making for shareholders and potential investors. In 2024, Albany International continued to enhance its digital engagement, reflecting a commitment to transparency and accessibility for all stakeholders.

- Primary Information Hub: The official website serves as the central repository for all company-related information.

- Investor Relations: A dedicated section provides crucial financial data and corporate governance information.

- Product Showcase: Detailed technical specifications and application examples for engineered fabrics are readily available.

- Digital Engagement: Albany International actively maintains its digital footprint to ensure broad accessibility and communication.

Technical Seminars and Customer Training

Albany International actively engages customers through technical seminars and dedicated training programs. These sessions are designed to impart crucial knowledge on product application, ensuring customers can maximize performance and efficiency. By focusing on optimization and proper maintenance, Albany International not only enhances the value customers receive from their products but also cultivates strong, lasting loyalty.

These educational initiatives are a cornerstone of Albany International's customer relationship strategy. For instance, in 2024, the company hosted over 50 such events globally, reaching thousands of customer personnel. This commitment to knowledge transfer directly contributes to reduced downtime and improved operational outcomes for clients.

- Knowledge Dissemination: Educating customers on optimal product usage and maintenance best practices.

- Customer Value Enhancement: Empowering clients to achieve greater efficiency and longevity from Albany International's offerings.

- Loyalty Building: Fostering strong customer relationships through expert-led training and support.

- Operational Improvement: Driving better performance and reduced operational costs for clients.

Albany International utilizes a multi-channel approach, with its direct sales force being paramount for engaging major industrial and aerospace clients. This direct interaction facilitates in-depth technical discussions and the development of bespoke solutions, supported by $220.9 million in sales and marketing expenses in 2024.

The company's global manufacturing and distribution network, spanning 13 countries, ensures efficient production and delivery of specialized engineered fabrics, contributing to $1.3 billion in net sales in 2023. Industry trade shows and conferences, such as TAPPICon and the Paris Air Show in 2024, serve as vital platforms for product demonstrations and direct engagement with industry decision-makers.

Albany International's digital presence, particularly its website, acts as a primary information hub for product specifications, investor relations, and corporate news. Furthermore, technical seminars and training programs, with over 50 events held globally in 2024, enhance customer understanding and foster strong relationships.

| Channel | Description | 2024 Data/Activity |

|---|---|---|

| Direct Sales Force | Engages major industrial and aerospace clients for tailored solutions. | $220.9 million in sales & marketing expenses. |

| Global Network | Manufacturing and distribution across 13 countries. | Supported $1.3 billion in net sales (2023). |

| Trade Shows/Conferences | Product showcases and direct client interaction. | Participation in TAPPICon and Paris Air Show. |

| Digital Presence (Website) | Information hub for products, investors, and news. | Continued enhancement of digital engagement. |

| Technical Seminars/Training | Customer education on product application and optimization. | Over 50 global events reaching thousands of personnel. |

Customer Segments

Albany International's global paper and paperboard manufacturers segment represents a cornerstone of their business, encompassing major players in the production of paper, tissue, and paperboard. These large-scale producers are heavily reliant on Albany's specialized Machine Clothing products to ensure the efficiency and quality of their operations.

This customer segment is a significant driver of Albany International's revenue. In 2024, the paper industry continued to adapt to evolving market demands, with global paper and paperboard production reaching approximately 420 million metric tons, underscoring the substantial market for Albany's essential components.

Aerospace prime contractors and Original Equipment Manufacturers (OEMs) represent a cornerstone customer segment for Albany Engineered Composites. These major players in the aviation industry rely on Albany for sophisticated composite structures essential for both commercial airliners and military aircraft. For instance, in 2023, the global aerospace market was valued at approximately $930 billion, with a significant portion driven by the demand for advanced materials.

The defense industry, encompassing government agencies and major contractors, represents a critical customer segment for Albany International. These entities rely on Albany's advanced composite materials for demanding applications in military aircraft and other platforms.

Specifically, Albany's engineered materials are integral to programs like the CH-53K heavy-lift helicopter and the F-35 fighter jet, showcasing the sector's significant demand for high-performance solutions. In 2024, defense spending globally continued to rise, with the United States alone allocating over $886 billion to national defense, underscoring the substantial market opportunity within this segment.

Industrial Process Industries

Albany International's Machine Clothing segment extends its expertise beyond paper manufacturing to serve a broader range of industrial process industries. These sectors rely on specialized fabrics and belts for critical functions in their production lines, mirroring the needs of the paper industry but with unique material and performance requirements.

Key sectors include nonwovens, where Albany's engineered fabrics are vital for processes like carding, drying, and finishing. Filtration applications also represent a significant market, utilizing Albany’s permeable fabrics for efficient separation of solids and liquids across various industrial settings. The company's ability to customize material properties ensures optimal performance in these diverse, demanding environments.

- Nonwovens Manufacturing: Albany provides specialized felts and fabrics crucial for the production of nonwoven materials used in hygiene products, geotextiles, and filtration media.

- Industrial Filtration: The company supplies filter fabrics and belts essential for liquid and gas filtration in industries such as mining, chemicals, and wastewater treatment.

- Specialty Textiles: Albany's capabilities extend to other niche industrial applications requiring high-performance woven and nonwoven textiles for conveying, supporting, or separating materials.

Emerging Technology Sectors (e.g., Space, AAM)

Albany International is strategically focusing on emerging technology sectors, such as space exploration and Advanced Air Mobility (AAM). These rapidly evolving industries present significant growth opportunities for advanced composite materials.

The demand for lightweight yet exceptionally strong components in these sectors is paramount. For instance, the burgeoning AAM market, with its focus on electric Vertical Take-Off and Landing (eVTOL) aircraft, requires innovative material solutions to enhance efficiency and safety. Similarly, the space industry, including satellite construction and the development of hypersonic technologies, relies on high-performance composites to withstand extreme conditions and reduce payload weight.

- Space Sector Growth: The global space economy was valued at approximately $469 billion in 2021 and is projected to reach over $640 billion by 2030, indicating substantial demand for advanced materials.

- AAM Market Potential: Analysts project the AAM market to grow from a few billion dollars in the early 2020s to hundreds of billions by 2040, creating a strong need for specialized composite manufacturers.

- Hypersonic Development: Significant government investment in defense, particularly in hypersonic weapon systems, drives the need for materials capable of enduring extreme temperatures and stresses, a core competency for Albany Engineered Composites.

Albany International's customer base is diverse, spanning traditional industries and cutting-edge sectors. Their core business revolves around supplying essential components to global paper and paperboard manufacturers, a sector that produced around 420 million metric tons in 2024.

Beyond paper, Albany serves the aerospace and defense industries, providing advanced composite materials crucial for aircraft like the F-35 fighter jet. The defense sector alone saw over $886 billion in US spending in 2024, highlighting the significant market for these high-performance solutions.

Emerging markets like space exploration and Advanced Air Mobility (AAM) are also key targets. The space economy was valued at approximately $469 billion in 2021, with AAM projected for substantial growth, creating a strong demand for Albany's innovative materials.

Albany also caters to a variety of industrial process industries, including nonwovens and filtration, where their specialized fabrics are vital for efficient production and separation processes.

Cost Structure

Albany International's cost structure is heavily influenced by the procurement of specialized raw materials, such as advanced fibers, polymers, and resins. These components are critical for manufacturing their high-performance textiles and composite materials used in diverse industries like aerospace and automotive.

In 2024, the volatility in global supply chains and commodity prices directly impacted these procurement costs. For instance, fluctuations in the price of key polymers, essential for their engineered fabrics, could significantly alter the company's cost of goods sold, requiring careful sourcing and inventory management strategies.

Albany International's manufacturing and production expenses are substantial, reflecting the global scale of its operations. These costs encompass everything from the wages paid to factory workers and the electricity powering their machinery to the upkeep of specialized equipment and general factory overhead. For instance, in 2023, the company reported cost of sales of $1.06 billion, a significant portion of which would be directly attributable to these manufacturing activities.

The company actively pursues operational efficiency initiatives to keep these significant costs in check. By optimizing production processes, investing in more energy-efficient equipment, and streamlining maintenance schedules, Albany International aims to reduce its per-unit manufacturing cost. This focus on efficiency is crucial for maintaining competitive pricing and profitability in the demanding industries it serves.

Albany International's commitment to innovation is reflected in its substantial research and development (R&D) investments. These ongoing costs are essential for developing new advanced materials and enhancing existing technologies. For instance, in 2023, the company reported R&D expenses of $52.7 million, a key driver for maintaining its competitive edge in specialized textile solutions.

Selling, General, and Administrative (SG&A) Expenses

Selling, General, and Administrative (SG&A) expenses for Albany International encompass costs associated with their sales force, marketing initiatives, and the overall administrative functions of the company. Efficiently controlling these expenditures is crucial for maintaining strong profitability and maximizing the company's financial health.

In 2024, Albany International reported SG&A expenses that played a significant role in their operational costs. For instance, their SG&A expenses were approximately $214.3 million for the fiscal year ending December 28, 2024. This figure represents a key area where cost management directly impacts the bottom line.

- Sales and Marketing: Costs incurred to promote and sell Albany International's specialized fabric and materials.

- General and Administrative: Expenses covering executive salaries, legal, finance, and other corporate overhead.

- Profitability Impact: Effective management of SG&A is vital for ensuring healthy profit margins.

- 2024 Data: SG&A expenses totaled $214.3 million in 2024, highlighting their significance.

Capital Expenditures and Restructuring Costs

Albany International faces substantial capital expenditures, with ongoing investments in facility upgrades, new equipment, and technological advancements being a core component of their cost structure. These investments are crucial for maintaining operational efficiency and competitive edge in their manufacturing processes. For instance, in 2024, the company continued to allocate significant resources towards modernizing its production capabilities.

Beyond routine capital investments, restructuring costs represent another notable expense. These arise from strategic decisions such as facility consolidations or workforce adjustments, aimed at optimizing operations and improving long-term profitability. Such initiatives, while potentially disruptive in the short term, are designed to streamline the business and enhance its overall financial health.

- Capital Expenditures: Ongoing investments in facility upgrades, new machinery, and technology are essential for operational efficiency and innovation.

- Restructuring Costs: Expenses incurred from facility consolidations and workforce adjustments impact profitability but aim for long-term operational improvements.

- 2024 Focus: The company continued its commitment to modernizing production facilities and optimizing its operational footprint throughout 2024.

Albany International's cost structure is dominated by raw material procurement, manufacturing expenses, and R&D investments. In 2024, Selling, General, and Administrative (SG&A) expenses amounted to $214.3 million, underscoring the significant operational overhead. The company also manages capital expenditures for facility modernization and potential restructuring costs.

| Cost Category | 2023 Data | 2024 Data |

|---|---|---|

| Cost of Sales | $1.06 billion | (Not specified) |

| R&D Expenses | $52.7 million | (Not specified) |

| SG&A Expenses | (Not specified) | $214.3 million |

| Capital Expenditures | (Ongoing) | (Ongoing) |

Revenue Streams

Albany International's revenue primarily flows from selling specialized fabrics and process belts. These are crucial components for manufacturers in the paper, tissue, and paperboard industries worldwide.

This segment represents a significant chunk of the company's overall income. For example, in 2023, Albany International reported net sales of $1.37 billion, with its Machine Clothing segment being a major contributor.

Albany International generates significant revenue from selling advanced composite structures and parts. These are crucial components for major aerospace companies and defense contractors, finding application in numerous aircraft and space missions.

In 2024, the aerospace and defense sector continued to see robust demand, with companies like Albany International benefiting from increased production rates and new program wins. For instance, the global commercial aircraft market is projected for strong recovery and growth, driving demand for lightweight, high-strength composite materials.

Albany International's revenue, especially from its Engineered Composites segment, is heavily reliant on long-term contracts for critical aerospace and defense programs. This structure creates a robust and predictable revenue stream, bolstered by significant order backlogs. For instance, as of the first quarter of 2024, the company reported a substantial backlog, indicating sustained future revenue visibility.

Aftermarket Sales and Service

Albany International generates significant revenue from its aftermarket segment, which includes the sale of replacement parts and consumables for its Machine Clothing and Engineered Composites products. This stream also encompasses ongoing technical services, crucial for maintaining the performance and longevity of their installed base.

In 2023, Albany International reported that its Machine Clothing segment, which heavily relies on aftermarket sales and service, generated approximately $777.9 million in revenue. This highlights the substantial contribution of ongoing customer support and part replacement to the company's overall financial performance.

- Aftermarket Revenue: Sales of replacement parts and consumables for Machine Clothing and Engineered Composites.

- Service Revenue: Ongoing technical support and maintenance services for the installed product base.

- 2023 Machine Clothing Revenue: Approximately $777.9 million, demonstrating the importance of aftermarket and service.

New Product and Technology Sales

Albany International's revenue growth is significantly fueled by the successful introduction and market adoption of its new products and advanced technologies. This innovation pipeline, a direct result of their dedicated research and development efforts, allows them to tap into emerging applications and expand their reach into new geographical or industry markets.

For instance, in 2024, the company continued to see robust demand for its next-generation engineered fabrics and composite materials, which are finding increasing utility in aerospace and defense sectors. These advanced materials offer enhanced performance characteristics, driving higher sales volumes and contributing to overall revenue expansion.

- New Product Introduction: Revenue uplift from the commercialization of recently developed engineered fabrics and composite solutions.

- Technology Adoption: Increased sales driven by customer adoption of advanced manufacturing technologies and materials developed by Albany International.

- Market Expansion: Growth achieved by successfully penetrating new application areas and geographic markets with innovative product offerings.

- R&D Impact: Direct correlation between investment in research and development and the generation of revenue from cutting-edge technologies.

Albany International's revenue streams are diversified, stemming from its core segments of Machine Clothing and Engineered Composites. The company also benefits from a robust aftermarket business, which includes replacement parts and ongoing technical services.

In 2023, the Machine Clothing segment alone generated approximately $777.9 million in revenue, underscoring the importance of both original equipment sales and recurring aftermarket support. This segment is critical for the paper and tissue manufacturing industries globally.

The Engineered Composites segment contributes significantly, particularly through long-term contracts within the aerospace and defense sectors. This provides a predictable revenue base, further strengthened by a substantial order backlog reported in early 2024, reflecting sustained demand for advanced materials in aircraft and space applications.

| Revenue Segment | Key Products/Services | 2023 Revenue (Approx.) | Key Industries Served |

|---|---|---|---|

| Machine Clothing | Specialized fabrics, process belts | $777.9 million | Paper, Tissue, Paperboard |

| Engineered Composites | Composite structures, parts | N/A (Significant contributor) | Aerospace, Defense |

| Aftermarket | Replacement parts, consumables, technical services | Included in segment revenues | Aerospace, Defense, Paper, Tissue |

Business Model Canvas Data Sources

The Albany International Business Model Canvas is informed by a blend of internal financial reports, customer feedback, and operational data. This comprehensive approach ensures each component accurately reflects the company's current state and strategic direction.