Akzo Nobel PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Akzo Nobel Bundle

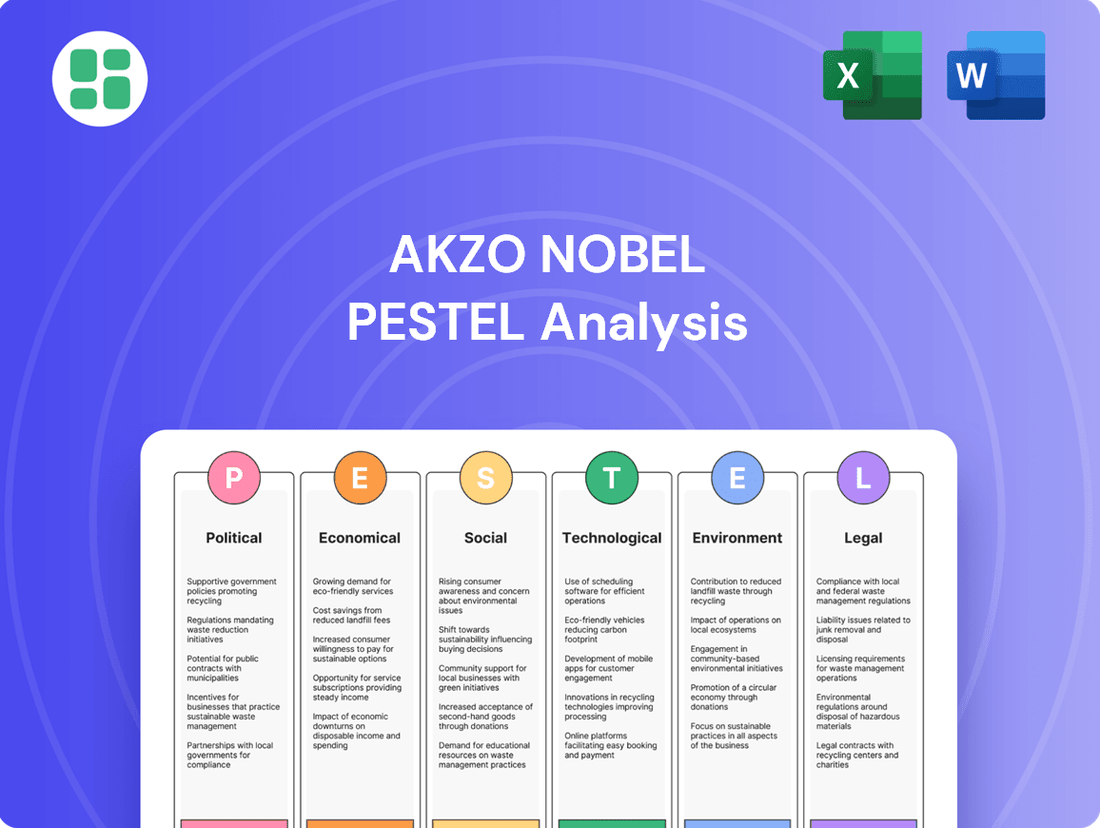

Navigate the complex global landscape affecting Akzo Nobel with our comprehensive PESTLE analysis. Understand the political, economic, social, technological, legal, and environmental factors shaping the paints and coatings giant. Gain a strategic advantage by anticipating market shifts and identifying opportunities. Download the full PESTLE analysis now for actionable intelligence.

Political factors

AkzoNobel navigates a complex web of global government regulations impacting product safety, chemical usage, and environmental standards. Compliance is paramount, with initiatives like Europe's Corporate Sustainability Reporting Directive (CSRD) influencing disclosures, a directive AkzoNobel began voluntarily transitioning to in 2024. These evolving legal landscapes demand continuous investment in research and development, alongside operational adaptations to ensure adherence.

Global trade policies and the imposition of tariffs, particularly ongoing tensions between major economies like the U.S. and China, directly impact AkzoNobel's operational costs and the stability of its supply chains. These trade disputes can lead to increased prices for raw materials and finished goods, affecting profitability.

AkzoNobel actively manages these risks through strategies like 'local-for-local' production, aiming to source and manufacture within specific regions to minimize exposure to international trade barriers. Procurement de-risking further bolsters this by diversifying supply sources.

While these localized strategies mitigate direct tariff impacts, indirect consequences remain. Slower global economic growth, often a byproduct of trade friction, can dampen customer demand for AkzoNobel's products, presenting a more pervasive challenge for the company's sales volumes in 2024 and 2025.

AkzoNobel's operations are significantly influenced by geopolitical stability in its key markets. For instance, the ongoing conflicts and political tensions in Eastern Europe, a region where AkzoNobel has a notable presence, can directly impact demand for its coatings and chemicals due to economic disruptions and reduced consumer spending. This instability also contributes to persistent inflation, as seen in the broader European economic landscape throughout 2023 and into 2024, increasing raw material and operational costs for the company.

Macroeconomic uncertainties, often fueled by geopolitical events, heighten competitive intensity across the paints and coatings industry. AkzoNobel, facing rivals like PPG Industries and Sherwin-Williams, must navigate fluctuating currency exchange rates and trade policies that can affect market access and profitability. In 2024, the company continues to monitor global trade agreements and potential tariffs, which could alter the cost-effectiveness of its supply chain and product pricing strategies in various international markets.

Government Support for Green Initiatives

Government support for green initiatives presents significant market opportunities for AkzoNobel. In 2024, the EU's Green Deal continues to drive demand for sustainable building materials and eco-friendly coatings. This aligns directly with AkzoNobel's focus on developing innovative, low-VOC (Volatile Organic Compound) products and circular economy solutions, potentially leading to favorable market conditions and strategic partnerships.

- EU Green Deal: Continued implementation in 2024-2025 incentivizes sustainable construction and product innovation.

- Circular Economy Push: Government policies promoting resource efficiency and waste reduction create demand for AkzoNobel's recyclable and bio-based coating solutions.

- Carbon Emission Targets: National and international climate goals encourage the adoption of energy-efficient building materials, benefiting AkzoNobel's performance coatings.

Restructuring and Labor Policies

Government labor policies significantly shape AkzoNobel's restructuring initiatives. For instance, the company announced plans in 2024 to reduce its global workforce by approximately 2,000 employees by the end of 2025, a move directly influenced by evolving labor regulations and the need for operational efficiency.

These workforce adjustments are critical for streamlining AkzoNobel's organizational structure and enhancing its overall competitiveness in the global market. Such policies can impact the feasibility and timeline of plant closures and consolidations, requiring careful navigation of legal and social considerations.

- Workforce Reduction: AkzoNobel's 2024 announcement of 2,000 job cuts by end-2025 highlights the impact of labor policies on restructuring.

- Efficiency Drive: These measures are designed to streamline operations and improve the company's competitive standing.

- Regulatory Compliance: Navigating governmental labor regulations is crucial for the successful implementation of such organizational changes.

Government regulations in 2024-2025 continue to shape AkzoNobel's operations, particularly concerning environmental standards and product safety, with directives like the EU's CSRD influencing reporting. Geopolitical instability, especially in Eastern Europe, impacts demand and increases operational costs due to inflation, a trend observed throughout 2023 and into 2024. Government support for green initiatives, like the EU Green Deal, presents opportunities for AkzoNobel's sustainable product lines.

| Factor | Impact on AkzoNobel | 2024-2025 Data/Trends |

|---|---|---|

| Environmental Regulations | Compliance costs, R&D investment for eco-friendly products | EU Green Deal driving demand for sustainable coatings; CSRD implementation impacting disclosures. |

| Trade Policies & Tariffs | Supply chain disruption, increased raw material costs | Ongoing U.S.-China trade tensions; AkzoNobel employing 'local-for-local' production to mitigate. |

| Geopolitical Stability | Demand fluctuations, economic disruptions, inflation | Conflicts in Eastern Europe affecting regional demand; persistent inflation increasing operational costs. |

| Labor Policies | Workforce restructuring, operational efficiency | 2,000 job cuts announced by end-2025 to streamline operations. |

What is included in the product

This PESTLE analysis provides a comprehensive examination of the external macro-environmental forces impacting Akzo Nobel, covering Political, Economic, Social, Technological, Environmental, and Legal factors.

It offers actionable insights into how these global trends create both challenges and strategic advantages for Akzo Nobel's operations and future growth.

Provides a concise version that can be dropped into PowerPoints or used in group planning sessions, simplifying complex external factors impacting Akzo Nobel.

Helps support discussions on external risk and market positioning during planning sessions by clearly outlining the Political, Economic, Social, Technological, Legal, and Environmental influences on Akzo Nobel.

Economic factors

AkzoNobel's fortunes are intrinsically linked to the pulse of the global economy. When economic growth falters, so too does customer demand for their paints and coatings. For instance, a projected global GDP growth of around 2.7% for 2025, according to the IMF, suggests a cautious outlook, which translates to less robust spending on construction and industrial goods, key markets for AkzoNobel.

The company itself anticipates a subdued market environment, with no significant rebound expected in 2025. This means navigating continued mixed market conditions, where certain regions or sectors might perform better than others, but overall demand remains tempered.

Given this backdrop, AkzoNobel's strategy must heavily rely on internal efficiencies and cost management. The emphasis shifts to 'self-help' measures, such as optimizing operations and driving innovation, to maintain and improve profitability amidst a less buoyant economic landscape.

Persistent inflation and fluctuating raw material costs have a significant impact on AkzoNobel's profitability. For instance, in 2023, the company faced considerable cost inflation, which it countered through strategic pricing adjustments and rigorous cost-saving initiatives. Managing these input costs remains a critical challenge for AkzoNobel in its ongoing efforts to maintain healthy adjusted EBITDA margins.

Currency fluctuations, especially the strength of the Euro, have presented a consistent challenge for AkzoNobel, impacting its reported revenue and adjusted EBITDA. For instance, in the first quarter of 2024, the company cited adverse currency movements as a significant headwind.

Despite implementing strategies like operational efficiencies and price adjustments, AkzoNobel continues to navigate these currency headwinds. The company's financial performance in 2024 has been notably affected by these external currency pressures, underscoring the ongoing need for robust currency risk management.

Consumer Spending and Market Segments

Consumer confidence and spending power are critical drivers for AkzoNobel's decorative paints segment. Conversely, industrial and infrastructure investment significantly shapes the performance coatings business.

While the marine and protective coatings sectors have demonstrated notable resilience, the decorative paint market has experienced some softening, particularly in regions like China. This regional weakness is, however, being counterbalanced by expansion in other geographical areas, showcasing a dynamic global demand landscape.

- Decorative Paints: Influenced by consumer confidence and disposable income.

- Performance Coatings: Driven by industrial production and infrastructure projects.

- Market Dynamics: Marine and protective coatings show resilience, while decorative paint volumes can vary significantly by region. For instance, while China saw some decorative paint volume weakness in early 2024, other markets continued to grow.

Company Financial Performance and Outlook

AkzoNobel is targeting an adjusted EBITDA exceeding €1.55 billion for 2025. This goal is underpinned by ongoing efficiency initiatives and a disciplined approach to pricing. The company demonstrated resilience in Q1 2025, maintaining its adjusted EBITDA despite a minor dip in revenue, highlighting its capacity to navigate challenging market conditions.

Looking ahead, AkzoNobel has set ambitious mid-term objectives. These include boosting profitability to achieve an adjusted EBITDA margin above 16%. This strategic focus on margin expansion aims to drive long-term value creation for shareholders.

- 2025 Target: Adjusted EBITDA above €1.55 billion.

- Q1 2025 Performance: Adjusted EBITDA held steady despite slight revenue decline.

- Mid-term Goal: Adjusted EBITDA margin above 16%.

The global economic climate significantly impacts AkzoNobel's demand for paints and coatings. With projected global GDP growth around 2.7% for 2025, the company anticipates continued mixed market conditions and a subdued overall demand environment, necessitating a focus on internal efficiencies and cost management.

Persistent inflation and raw material cost volatility remain key challenges, as seen in 2023's cost pressures which AkzoNobel addressed through pricing and cost-saving measures to protect its adjusted EBITDA margins.

Currency fluctuations, particularly the Euro's strength, have negatively affected AkzoNobel's reported revenues and adjusted EBITDA, as noted in Q1 2024, underscoring the ongoing need for robust currency risk management strategies.

| Economic Factor | Impact on AkzoNobel | 2024/2025 Data/Trend |

|---|---|---|

| Global GDP Growth | Affects demand for construction and industrial goods | IMF projects ~2.7% global GDP growth for 2025; AkzoNobel anticipates subdued demand. |

| Inflation & Raw Material Costs | Pressures profitability and margins | AkzoNobel focused on pricing and cost savings in 2023 to manage inflation; ongoing challenge. |

| Currency Exchange Rates | Impacts reported revenue and adjusted EBITDA | Adverse currency movements cited as a headwind in Q1 2024; ongoing management focus. |

Full Version Awaits

Akzo Nobel PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This comprehensive PESTLE analysis of Akzo Nobel delves into the Political, Economic, Social, Technological, Legal, and Environmental factors impacting the company's operations and strategic decisions.

This is a real screenshot of the product you’re buying—delivered exactly as shown, no surprises. You'll gain a clear understanding of the external forces shaping Akzo Nobel's industry landscape.

The content and structure shown in the preview is the same document you’ll download after payment. It provides a detailed examination of each PESTLE element, offering valuable insights for stakeholders.

Sociological factors

Consumers are increasingly prioritizing sustainability, with a significant portion of global consumers willing to pay more for eco-friendly products. This shift directly impacts AkzoNobel's product development, pushing for innovation in environmentally conscious coatings and paints. For instance, a 2024 survey indicated that over 60% of consumers consider sustainability a key factor in their purchasing decisions.

Global demographic shifts, including an aging population in developed nations and a growing youth demographic in emerging markets, directly impact housing demand and renovation cycles, influencing AkzoNobel's sales. For example, the United Nations projects that by 2050, 68% of the world's population will live in urban areas, a significant increase from 56% in 2021. This trend fuels construction and infrastructure projects, creating a strong market for AkzoNobel's coatings.

Urbanization drives the need for new buildings and infrastructure, from residential housing to commercial spaces and transportation networks, all of which require paints and coatings. AkzoNobel's presence in key urbanizing regions, such as Southeast Asia and Africa, positions it to capitalize on this growth. The company's focus on sustainable and durable coatings also aligns with the increasing demand for eco-friendly solutions in urban development.

Societal emphasis on health and well-being directly influences AkzoNobel's product development, driving demand for paints with low Volatile Organic Compounds (VOCs) and no formaldehyde. This trend means consumers are actively seeking healthier options for their homes and workplaces.

AkzoNobel is responding to this by significantly investing in research and development to create safer, more sustainable products. For instance, their Dulux brand in Europe has been actively promoting low-VOC formulations, with many products achieving EPD (Environmental Product Declaration) certifications, reflecting a commitment to transparency and environmental responsibility.

Aesthetic and Design Trends

AkzoNobel actively engages in researching and establishing aesthetic and design trends, notably through initiatives like its 'Color of the Year 2025,' named True Joy. This selection is a direct reflection of evolving societal aspirations for optimism, enhanced creativity, and greater avenues for self-expression. These curated color palettes significantly influence product development across AkzoNobel's diverse market segments.

The impact of these trends extends across various industries, shaping the visual appeal of everything from decorative paints for homes to the finishes on automobiles and consumer electronics. Consequently, these design directions play a crucial role in guiding and influencing consumer purchasing decisions in a highly competitive marketplace.

- Color Trend Influence: AkzoNobel's 'Color of the Year 2025' (True Joy) signals a societal shift towards optimism and creativity.

- Market Reach: These aesthetic trends impact product palettes in decorative paints, automotive, and consumer electronics sectors.

- Consumer Choice: Design trends directly shape consumer preferences and purchasing behavior.

Workforce Dynamics and Employee Engagement

AkzoNobel recognizes that a highly engaged and diverse workforce is crucial for its success. The company actively pursues initiatives to foster employee engagement and cultivate an inclusive environment where all individuals feel valued and can contribute their best. This focus is not just philosophical; it directly impacts operational efficiency and innovation.

In 2023, AkzoNobel reported a global employee engagement score of 73%, a slight increase from the previous year, indicating positive progress in its efforts. The company's commitment to talent development is evident in its investment in training programs, with employees completing an average of 25 hours of learning and development in 2023. Furthermore, AkzoNobel aims to achieve 40% female representation in leadership positions by 2025, underscoring its dedication to diversity.

- Employee Engagement: AkzoNobel's 2023 engagement score stood at 73%.

- Talent Development: Employees averaged 25 hours of training in 2023.

- Diversity Goals: The company targets 40% female leadership by 2025.

- Safety Focus: Maintaining a safe work environment remains a top priority, with a lost-time injury frequency rate of 0.34 per million hours worked in 2023.

Societal values continue to shape consumer preferences, with a growing emphasis on ethical sourcing and corporate responsibility influencing purchasing decisions. AkzoNobel's commitment to sustainability, including its focus on reducing its environmental footprint and promoting circular economy principles, resonates with these evolving values.

The company’s proactive approach to social issues, such as promoting diversity and inclusion within its workforce and supply chain, further aligns with societal expectations. For instance, AkzoNobel reported that 73% of its employees felt engaged in 2023, and the company aims for 40% female representation in leadership roles by 2025, demonstrating a tangible commitment to these social factors.

Furthermore, AkzoNobel's 'Color of the Year 2025,' True Joy, reflects a societal desire for optimism and enhanced self-expression, directly impacting product design and consumer appeal across various sectors. This focus on human well-being and positive societal trends is a key driver for innovation in their product offerings.

Technological factors

AkzoNobel is channeling significant investment into developing cutting-edge coating technologies that prioritize sustainability. This includes a focus on UV-curable coatings that are incorporating a higher percentage of bio-based materials, a key trend in the chemical industry as companies seek to reduce their reliance on fossil fuels. For instance, their efforts in this area are directly addressing the growing consumer and regulatory demand for greener product formulations.

Further demonstrating this commitment, AkzoNobel is advancing internal coatings for food cans that are free from Polyvinyl Chloride (PVC) and Bisphenol A (BPA). These innovations are crucial for meeting stringent food safety standards and catering to market preferences for healthier packaging solutions. The company's R&D in this segment directly supports the global push for safer and more environmentally responsible food packaging, with market growth for sustainable packaging expected to continue its upward trajectory through 2025.

AkzoNobel is significantly boosting manufacturing efficiency through the integration of advanced technologies. For instance, their use of AI-powered software like coatingAI and automated mixing systems streamlines production, leading to faster and more precise application processes.

Digital monitoring capabilities are a key component of this transformation, allowing AkzoNobel to make real-time adjustments on the factory floor. This enhanced control directly translates to a reduction in production defects and the costly rework associated with them.

AkzoNobel's commitment to research and development is a cornerstone of its strategy for enhanced product functionality. The company consistently invests in innovation, aiming to create coatings that offer superior durability and versatility across demanding sectors such as automotive, aerospace, and marine industries. This focus ensures their products meet evolving customer needs and regulatory standards.

A key area of R&D involves developing specialized coatings, like 'sunscreen' systems designed to combat urban heat island effects by reflecting solar radiation. Furthermore, AkzoNobel is advancing finishing solutions for the wood industry, improving aesthetics and protection. These innovations highlight a forward-thinking approach to material science and application.

Advancements in Material Science

Progress in material science is a significant technological driver for AkzoNobel. Developments in areas like polymer chemistry are enabling the creation of novel formulations for their coatings. For example, advancements in thermoplastic materials are directly contributing to the innovation of their powder coatings portfolio.

These material science breakthroughs translate into tangible product benefits. AkzoNobel can now offer coatings with enhanced properties such as superior flexibility and improved impact resistance. This is crucial for applications where durability and performance under stress are paramount, thereby expanding their market reach.

The ability to engineer materials with specific characteristics, like better adhesion, further solidifies AkzoNobel's competitive edge. This allows them to cater to a wider range of customer needs across various industries, from automotive to consumer electronics. In 2024, AkzoNobel reported that their powder coatings segment, heavily influenced by material innovation, continued to see strong demand.

Key benefits derived from material science advancements include:

- Development of eco-friendlier coating formulations

- Enhanced durability and performance characteristics

- Creation of coatings for new and demanding applications

- Improved application efficiency and reduced waste

Supply Chain Technology and Efficiency

Technological advancements are significantly boosting supply chain efficiency and resilience. AkzoNobel's commitment to industrial excellence and efficiency initiatives, which include optimizing its operational footprint, directly benefits from these technological leaps. By leveraging cutting-edge supply chain technologies, the company aims to streamline its global operations and achieve cost reductions.

In 2023, AkzoNobel reported significant progress in its efficiency programs, contributing to a €124 million positive impact on operational costs. This progress is underpinned by investments in digital tools and automation across its supply chain. For instance, the company is implementing advanced analytics for demand forecasting and inventory management, aiming to reduce waste and improve delivery times. These technologies are crucial for navigating the complexities of a globalized market and ensuring a robust supply of paints and coatings to its customers.

- Digitalization of Warehousing: AkzoNobel is investing in automated warehousing solutions to improve inventory accuracy and speed up order fulfillment.

- Advanced Analytics for Logistics: The company utilizes data analytics to optimize transportation routes and modes, reducing fuel consumption and delivery costs.

- Supply Chain Visibility Tools: Implementing real-time tracking and monitoring systems enhances transparency and allows for proactive management of potential disruptions.

Technological advancements are central to AkzoNobel's strategy, driving innovation in sustainable coatings and manufacturing efficiency. Their focus on UV-curable coatings with bio-based materials and PVC/BPA-free solutions for food packaging highlights a commitment to greener formulations, aligning with market demands through 2025.

AI-powered software and automation are streamlining production, enhancing precision and reducing defects, while digital monitoring enables real-time factory floor adjustments. These technological integrations are crucial for maintaining a competitive edge in demanding sectors like automotive and aerospace.

Material science breakthroughs, particularly in polymer chemistry, are enabling AkzoNobel to develop coatings with superior flexibility and impact resistance. This innovation fuels growth in their powder coatings segment, which saw strong demand in 2024, and allows them to cater to diverse industry needs.

Supply chain efficiency is also being boosted through digitalization, with investments in automated warehousing and advanced analytics for logistics. These efforts contributed to a €124 million positive impact on operational costs in 2023, underscoring the financial benefits of technological adoption.

| Area of Technology | Impact on AkzoNobel | Key Data/Example |

|---|---|---|

| Sustainable Coatings R&D | Development of eco-friendly products | Focus on UV-curable, bio-based, and PVC/BPA-free formulations |

| Manufacturing Automation & AI | Increased efficiency and reduced defects | Use of coatingAI, automated mixing systems |

| Material Science Advancements | Enhanced product performance and new applications | Improved flexibility, impact resistance in powder coatings |

| Supply Chain Digitalization | Improved efficiency and cost reduction | €124 million positive impact on operational costs in 2023 |

Legal factors

AkzoNobel navigates a complex web of global environmental regulations, impacting everything from volatile organic compound (VOC) emissions to the handling of hazardous chemicals and waste disposal. These rules are becoming increasingly strict, requiring significant investment in compliance and innovation.

The company is actively adapting to evolving reporting standards, moving to Corporate Sustainability Reporting Directive (CSRD) aligned reporting starting in 2024. This shift emphasizes transparency and accountability in environmental performance.

A key focus for AkzoNobel is the phase-out of persistent chemicals, notably PFAS substances. This strategic move is directly influenced by tightening regulatory frameworks worldwide and growing public demand for safer, more sustainable products. For example, in 2023, the EU proposed further restrictions on PFAS, aiming to ban thousands of these chemicals.

AkzoNobel navigates a complex web of legal requirements for product safety and health, particularly crucial given its broad range of paints, coatings, and specialty chemicals. For instance, regulations concerning volatile organic compounds (VOCs) in architectural coatings are a constant focus, with many regions, including the European Union and California, implementing increasingly stringent limits. AkzoNobel's commitment to compliance often involves proactive reformulation to meet or exceed these standards.

The company actively monitors and adapts to evolving legislation regarding specific chemical substances. For example, regulations around substances like formaldehyde and bisphenols, which can be found in certain adhesives or resins, require careful management. AkzoNobel has demonstrated a strategy of preempting potential bans by developing and introducing safer alternatives, a move that not only ensures continued market access but also reinforces consumer trust and its reputation for responsible product development.

AkzoNobel navigates a complex web of labor laws across its operations in more than 150 countries, directly influencing its HR practices from recruitment to workforce reductions. These regulations dictate hiring procedures, dismissal protocols, and the legal framework for any restructuring efforts, demanding meticulous adherence to local statutes.

The company's announced plans to cut jobs by the end of 2025 are particularly sensitive to these labor laws. Each country's specific regulations regarding notice periods, severance pay, and consultation processes with employee representatives must be carefully managed to ensure compliance and mitigate employee impact.

Intellectual Property Rights and Patents

Protecting its vast array of innovative paints and coatings through intellectual property rights, including patents and trademarks, is a crucial legal consideration for AkzoNobel. This legal framework is vital for maintaining its competitive edge and recouping substantial research and development expenditures. For instance, in 2023, AkzoNobel continued to file new patents, reinforcing its commitment to innovation in areas like sustainable coatings and advanced material science.

AkzoNobel's legal strategy also involves robust enforcement of these rights to prevent infringement and unauthorized use of its proprietary technologies and brand names. This diligent approach ensures that the company can capitalize on its unique product offerings and technological advancements in the global market.

The company's patent portfolio is a significant asset, underpinning its market position. As of early 2024, AkzoNobel holds thousands of active patents worldwide, covering a wide spectrum of its product lines and manufacturing processes, demonstrating the legal framework's importance to its business model.

Key aspects of AkzoNobel's legal protection include:

- Patent Protection: Safeguarding novel formulations, application methods, and performance-enhancing additives in paints and coatings.

- Trademark Enforcement: Protecting brand recognition and consumer trust associated with its well-known product names and logos.

- Trade Secret Management: Implementing measures to protect confidential manufacturing processes and proprietary know-how.

- Licensing Agreements: Strategically licensing its intellectual property to partners where mutually beneficial, while maintaining control.

Competition Law and Anti-Trust Compliance

AkzoNobel, as a significant player in the global chemicals and coatings market, operates under strict competition and anti-trust regulations worldwide. These laws are designed to ensure fair market practices and prevent any single entity from gaining undue market power. The company’s strategic moves, including divestments, are scrutinized by regulatory bodies to ensure they don't stifle competition.

A prime example of this oversight is the sale of AkzoNobel India to JSW Group, which underwent a thorough review by the Competition Commission of India (CCI). This process ensures that such transactions align with the principles of fair competition and do not create monopolies or anti-competitive effects in the Indian market. In 2023, the CCI approved numerous merger and acquisition deals, highlighting the active enforcement of competition law in India.

- Global Compliance: AkzoNobel must navigate a complex web of competition laws across all its operating regions, including the EU, US, and Asia.

- Merger & Acquisition Scrutiny: Major transactions, like the aforementioned sale of its Indian subsidiary, are subject to pre-merger notification and approval processes by relevant competition authorities.

- Anti-Competitive Practices: The company is prohibited from engaging in practices such as price-fixing, bid-rigging, and market allocation, which are strictly enforced by regulators.

AkzoNobel faces stringent regulations regarding product safety and health, particularly concerning VOCs in architectural coatings. Many regions, including the EU and California, have increasingly strict limits, prompting AkzoNobel to proactively reformulate products to meet these evolving standards.

The company also manages legislation around specific chemical substances like formaldehyde and bisphenols. By developing safer alternatives, AkzoNobel not only ensures market access but also reinforces its reputation for responsible product development, preempting potential future bans.

AkzoNobel's intellectual property, including thousands of active patents as of early 2024, is crucial for its competitive edge. Protecting these innovations through patents and trademarks is vital for recouping R&D investments and preventing infringement.

The company must also adhere to global competition and anti-trust laws, ensuring fair market practices. Major transactions, like the 2023 sale of AkzoNobel India, undergo thorough scrutiny by regulatory bodies such as the Competition Commission of India to prevent anti-competitive effects.

Environmental factors

AkzoNobel is actively pursuing ambitious carbon emission reduction targets, aiming for a 50% cut across its entire value chain by 2030, benchmarked against 2018 levels. This aligns with global climate goals, including the Paris Agreement.

The company has already demonstrated substantial progress, achieving a 41% reduction in Scope 1 and 2 emissions by the end of 2024, showcasing a strong commitment to its sustainability objectives.

AkzoNobel is making significant strides in its transition to renewable energy, a crucial environmental factor impacting its operations and strategy. The company reported that it increased its use of renewable electricity to 65% in 2024. This commitment is further underscored by a clear target to achieve 100% renewable electricity by 2030.

To meet these ambitious goals, AkzoNobel has been actively securing renewable energy sources. This includes entering into power purchase agreements for new solar parks, which directly contribute to increasing the supply of clean energy. Additionally, the company is undertaking the conversion of its manufacturing sites to run on renewable energy, a move designed to substantially reduce its overall carbon footprint.

AkzoNobel is aggressively pursuing a zero-waste future, aiming to eliminate non-reusable waste and achieve 100% water reuse at its most water-intensive facilities by 2030. This commitment is backed by tangible actions, such as refining application processes to cut down on solvent emissions, a key environmental concern in the coatings industry.

Furthermore, the company is actively developing innovative products designed to minimize waste throughout their lifecycle, from production to end-use. For instance, their focus on high-solids coatings and waterborne alternatives directly addresses the need for reduced VOCs and waste generation, aligning with global sustainability trends and regulatory pressures.

Sustainable Product Development and Life Cycle Assessment

AkzoNobel is deeply committed to sustainable product development, aiming to create solutions that deliver environmental advantages across their entire life cycle. This includes innovations like coatings designed to lower energy usage, improve indoor air quality, or extend the lifespan of protected surfaces, thereby reducing the need for frequent replacements.

To support informed choices, AkzoNobel offers a carbon footprint calculator for its extensive product range. This tool empowers customers to understand and compare the environmental impact of different solutions, facilitating more sustainable purchasing decisions.

- Focus on Life Cycle Benefits: Developing coatings that reduce energy consumption, purify indoor air, and enhance surface durability.

- Carbon Footprint Transparency: Providing customers with a carbon footprint calculator to assess product environmental impact.

- Innovation in Sustainability: Investing in R&D for eco-friendly alternatives and processes.

- Circular Economy Principles: Exploring ways to incorporate recycled materials and design for recyclability in product portfolios.

Resource Scarcity and Sustainable Sourcing

The increasing likelihood of climate change disruptions significantly impacts AkzoNobel's supply chains and the availability of raw materials. This reality underscores the company's commitment to sustainable sourcing and maximizing resource efficiency. For instance, AkzoNobel is actively investing in innovative technologies designed to incorporate bio-based and renewable materials into its product formulations, aiming to reduce reliance on finite resources.

AkzoNobel's 2023 sustainability report highlights a target to source 50% of its raw materials from renewable or recycled sources by 2030. This strategic focus is driven by the environmental factor of resource scarcity, a challenge amplified by climate change. The company is exploring partnerships and research initiatives to secure a stable supply of these alternative materials.

- Sustainable Sourcing Targets: AkzoNobel aims for 50% renewable or recycled raw material sourcing by 2030.

- Investment in Bio-based Materials: The company is funding research and development into bio-based alternatives for its coatings.

- Supply Chain Resilience: Climate change impacts are a key driver for diversifying material sources and improving efficiency.

Environmental factors are increasingly shaping AkzoNobel's operational strategies and long-term goals. The company is aggressively pursuing emission reductions, with a target of a 50% cut in its value chain emissions by 2030 compared to 2018 levels. By the end of 2024, AkzoNobel had already achieved a 41% reduction in Scope 1 and 2 emissions, demonstrating significant progress.

A key environmental focus for AkzoNobel is the transition to renewable energy. In 2024, the company increased its use of renewable electricity to 65% and aims for 100% by 2030. This is supported by power purchase agreements for new solar parks and the conversion of manufacturing sites to renewable energy sources.

AkzoNobel is also committed to a zero-waste future, targeting 100% water reuse at water-intensive facilities by 2030 and reducing solvent emissions. Their product development emphasizes life cycle benefits, such as coatings that lower energy consumption and improve indoor air quality, with a tool available for customers to assess product carbon footprints.

Resource scarcity, exacerbated by climate change, drives AkzoNobel's goal to source 50% of its raw materials from renewable or recycled sources by 2030. The company is investing in bio-based and recycled materials to enhance supply chain resilience and reduce reliance on finite resources.

| Environmental Factor | AkzoNobel's Target/Progress | Key Initiatives |

| Carbon Emissions | 50% reduction by 2030 (vs 2018); 41% Scope 1 & 2 reduction by end of 2024 | Value chain emission cuts, renewable energy adoption |

| Renewable Energy | 65% renewable electricity use in 2024; 100% by 2030 | Power purchase agreements, site conversions |

| Waste & Water | Zero-waste future; 100% water reuse at water-intensive sites by 2030 | Reducing solvent emissions, developing waste-minimizing products |

| Sustainable Sourcing | 50% renewable/recycled raw material sourcing by 2030 | Investment in bio-based and recycled materials |

PESTLE Analysis Data Sources

Our PESTLE analysis for Akzo Nobel is built on a robust foundation of data from authoritative sources, including government economic reports, international trade organizations, and leading market research firms. We meticulously gather information on political stability, economic indicators, social trends, technological advancements, environmental regulations, and legal frameworks to provide a comprehensive overview.