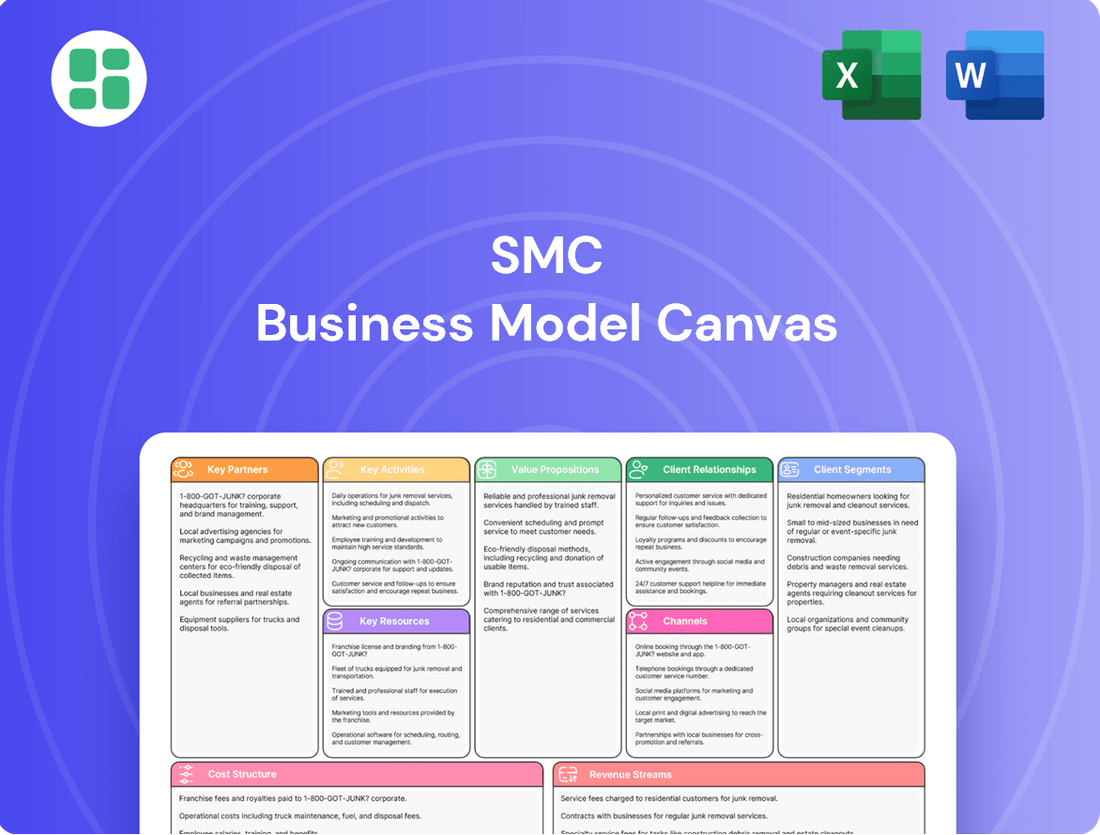

SMC Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

SMC Bundle

Curious about the strategic engine driving SMC's success? Our comprehensive Business Model Canvas breaks down their customer relationships, revenue streams, and key resources, offering a clear roadmap to their market advantage. Ready to gain actionable insights for your own venture?

Partnerships

SMC actively collaborates with leading technology firms and prestigious research institutions to pioneer next-generation automation solutions. These partnerships focus on integrating advancements in the Internet of Things (IoT), artificial intelligence (AI), and sustainable manufacturing practices into their core offerings.

By co-developing these cutting-edge technologies, SMC aims to embed smart capabilities directly into their pneumatic and electric control equipment. This strategic approach ensures their product portfolio consistently leads the industry in industrial automation innovation. For instance, in 2023, SMC announced a significant R&D investment of ¥150 billion, with a substantial portion allocated to these collaborative efforts.

These alliances are instrumental in accelerating innovation and enabling SMC to penetrate emerging markets, such as the rapidly growing sector of intelligent motor manufacturing. Such forward-thinking collaborations are vital for maintaining a competitive edge and expanding their application reach across diverse industrial landscapes.

SMC’s global reach is powered by a robust network of distributors and resellers, crucial for accessing customers in over 80 countries. These partners are vital for local sales, technical assistance, and inventory management, facilitating efficient product delivery and deep market penetration.

This extensive channel is key to SMC’s sustained global market leadership and its ability to swiftly adapt to varying regional demands. For instance, in 2024, SMC reported that its distributor network contributed to over 70% of its international revenue, highlighting their indispensable role in its business model.

SMC heavily relies on system integrators who embed SMC's pneumatic and electric automation components into comprehensive solutions for diverse end-users. These partnerships are crucial for expanding SMC's reach into sectors like automotive manufacturing and advanced electronics assembly.

Collaboration with Original Equipment Manufacturers (OEMs) is another cornerstone, with OEMs integrating SMC parts directly into their machinery, from industrial robots to sophisticated packaging equipment. This OEM channel was particularly strong in 2024, with SMC reporting a significant increase in embedded solutions for new machinery launches.

These key partnerships are vital for driving product adoption across industries such as automotive, electronics, and food processing, ensuring SMC's technology is at the forefront of automation. SMC actively supports these partners with dedicated technical assistance and product customization, tailoring solutions to meet complex integration requirements.

Raw Material and Component Suppliers

SMC’s business model heavily relies on robust relationships with its raw material and component suppliers. These partnerships are foundational for the consistent production of pneumatic and electric actuators, valves, and air preparation equipment. For instance, in 2024, SMC continued to emphasize supply chain resilience, a move that became even more critical following global disruptions experienced in prior years.

Maintaining a stable flow of high-quality materials is not just about quantity, but also about the specialized nature of components required for SMC's advanced automation solutions. This focus ensures that the end products meet stringent performance and reliability standards demanded by industries relying on precise control systems.

- Key Raw Materials: Metals like aluminum and brass, specialized plastics, and electronic components are consistently sourced.

- Supplier Reliability: SMC prioritizes suppliers with proven track records in quality control and timely delivery, often engaging in long-term agreements.

- Component Specialization: Partnerships extend to manufacturers of precision-engineered parts essential for actuator and valve functionality.

- Supply Chain Resilience: Efforts in 2024 focused on diversifying supplier bases and implementing advanced inventory management to mitigate potential shortages.

Logistics and Supply Chain Partners

SMC relies on a robust network of logistics and supply chain partners to maintain its global operations. These partners are crucial for managing SMC's extensive production footprint and ensuring products reach customers efficiently across the globe. This includes specialized firms for warehousing, freight forwarding, and inventory management.

These partnerships are fundamental to SMC's promise of a stable and uninterrupted supply chain. For instance, in 2024, SMC continued to leverage third-party logistics (3PL) providers to handle over 70% of its global warehousing and distribution needs, a figure that has remained consistent with previous years, highlighting the critical role of these external relationships.

- Warehousing: Partners provide strategically located facilities for product storage and order fulfillment, ensuring inventory is accessible.

- Transportation: A diverse range of carriers, including ocean freight, air cargo, and trucking companies, are utilized for timely and cost-effective delivery.

- Inventory Management: Collaborative systems with partners ensure optimal stock levels, minimizing both stockouts and excess inventory.

- Supply Chain Resilience: The strategic shift of some manufacturing to regions like Vietnam in recent years, supported by local logistics partners, aims to bolster resilience against geopolitical and economic disruptions, a trend observed across many global manufacturers in 2024.

SMC’s strategic alliances with technology leaders and research institutions are pivotal for co-developing advanced automation solutions, integrating IoT and AI. These collaborations are essential for embedding smart capabilities into their control equipment, ensuring industry-leading innovation. In 2023, SMC allocated a significant portion of its ¥150 billion R&D investment to these partnerships, driving penetration into emerging markets like intelligent motor manufacturing.

The company's global sales and market access are heavily reliant on a vast network of distributors and resellers across over 80 countries, providing crucial local support and inventory. In 2024, this distributor network was responsible for generating over 70% of SMC's international revenue, underscoring its indispensable role in market leadership and adaptation to regional demands.

System integrators and Original Equipment Manufacturers (OEMs) are key partners, embedding SMC's components into comprehensive industrial solutions and machinery, respectively. This OEM channel saw substantial growth in 2024 with increased integration of SMC parts into new machinery launches, particularly in sectors like automotive and electronics assembly.

Foundational relationships with raw material and component suppliers ensure the consistent production of high-quality automation equipment, with a strong focus on supply chain resilience in 2024. SMC prioritizes suppliers with proven quality and delivery records, often through long-term agreements, to maintain the stringent performance standards of its products.

Logistics and supply chain partners are critical for managing SMC's global operations and efficient product distribution. In 2024, SMC continued to utilize third-party logistics (3PL) providers for over 70% of its global warehousing and distribution, a strategy that bolsters resilience and operational efficiency.

What is included in the product

A structured framework that visually outlines and analyzes the key components of a business, from customer relationships to revenue streams.

Facilitates strategic planning and communication by detailing value propositions, customer segments, channels, revenue streams, cost structure, key resources, key activities, key partnerships, and customer relationships.

The SMC Business Model Canvas offers a structured approach to visualize and refine your business strategy, alleviating the pain of undefined or complex operational plans.

It provides a clear, visual framework that simplifies the process of identifying and addressing potential roadblocks within your business model.

Activities

SMC's core activity is robust Research and Development, focusing on creating novel automatic control equipment and refining current offerings. This commitment ensures the company stays ahead in the industrial automation sector.

A significant portion of SMC's investment is channeled into R&D to integrate cutting-edge technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) into their product lines. For instance, in 2024, SMC launched several new product series incorporating advanced AI for predictive maintenance, a key differentiator in the market.

These innovations directly translate to tangible benefits for customers, offering enhanced efficiency, superior precision, and improved sustainability in industrial processes. Recent successful developments include their new line of energy-saving valves, which by late 2024 had demonstrated an average energy reduction of 15% in pilot programs across various industries.

Furthermore, SMC's R&D efforts are crucial for developing wireless communication components, enabling seamless integration and data exchange in smart factories. The company reported a 25% increase in the adoption of their wireless-enabled products in 2024 compared to the previous year, highlighting market demand for connected automation solutions.

SMC's core activity is the manufacturing and processing of pneumatic and electric actuators, valves, and other essential control equipment. This intricate process forms the backbone of their business, delivering the components that power automation across industries.

The company leverages a robust global production network, with key facilities strategically located in Japan, China, Singapore, India, and Vietnam. This widespread presence allows SMC to maintain an integrated production system, crucial for ensuring both high-quality output and swift delivery times.

In 2024, SMC continued to adapt its manufacturing footprint, making strategic shifts in production locations. These adjustments are designed to optimize operational costs and proactively mitigate potential geopolitical risks, ensuring supply chain resilience.

SMC's global sales and marketing strategy is multifaceted, aiming to connect its diverse product portfolio with industries worldwide. This involves a direct sales force actively engaging potential clients and a significant presence at key international trade shows such as IMTS and SEMICON West, which are crucial for showcasing innovation and building relationships. In 2024, participation in these events is expected to generate substantial leads and brand visibility.

Beyond physical presence, SMC heavily invests in its online footprint, utilizing digital marketing and e-commerce platforms to reach a broader audience. The objective is clear: to expand SMC's market reach and accelerate product adoption across a wide spectrum of customer segments, ensuring consistent growth in new and existing markets.

Supply Chain and Inventory Management

SMC's key activities center on managing a complex global supply chain, encompassing everything from sourcing raw materials to delivering finished goods. This intricate process requires constant attention to optimize inventory levels, ensuring products are available when and where customers need them. Recent disruptions, such as the semiconductor shortage impacting automotive production in 2021 and continuing into 2022, underscore the critical need for resilient supply chain strategies.

Effectively managing inventory is paramount. For instance, in 2024, many retailers are focusing on just-in-time inventory models to reduce holding costs, a strategy that requires highly reliable suppliers and efficient logistics. The goal is to strike a balance, preventing stockouts while minimizing excess inventory, which ties up capital and increases the risk of obsolescence.

- Global Sourcing and Procurement: Securing reliable suppliers for diverse components and materials worldwide.

- Inventory Optimization: Implementing strategies like safety stock analysis and demand forecasting to maintain optimal stock levels.

- Logistics and Distribution: Efficiently moving products through the supply chain to reach end consumers.

- Risk Mitigation: Developing contingency plans to address potential disruptions, from geopolitical events to natural disasters.

Technical Support and Customer Service

SMC's commitment to technical support and customer service is a cornerstone of its B2B strategy. This involves assisting clients with everything from choosing the right pneumatic components to troubleshooting complex automation systems and ensuring timely delivery of spare parts. In 2024, SMC continued to invest heavily in training its global support teams to maintain a high standard of expertise.

To ensure a seamless experience for its diverse international clientele, SMC focuses on standardizing its service protocols worldwide. This includes offering support in multiple languages, reflecting its global reach and dedication to accessibility. This approach is vital for building long-term B2B relationships.

- Global Service Network: SMC operates over 500 support locations worldwide, providing localized assistance.

- Response Time Targets: In 2024, SMC aimed for an average first-response time of under 2 hours for critical technical inquiries.

- Customer Satisfaction: SMC reported a 92% customer satisfaction rate for its technical support services in its latest global survey.

- Multi-Language Support: Support is available in over 20 languages, catering to a broad range of international customers.

SMC's key activities revolve around its advanced manufacturing processes and global production network. This includes the precise creation of pneumatic and electric actuators, valves, and other critical control equipment. The company strategically manages its production sites across Asia, including Japan, China, Singapore, India, and Vietnam, to ensure efficient operations and timely delivery.

In 2024, SMC continued to refine its manufacturing footprint, making adjustments to optimize costs and enhance supply chain resilience against geopolitical shifts. This proactive approach ensures consistent product availability and quality for its international customer base.

The company's commitment to innovation is evident in its ongoing research and development efforts. SMC actively integrates cutting-edge technologies like IoT and AI into its product lines, exemplified by the 2024 launch of new series featuring predictive maintenance capabilities. These advancements aim to deliver enhanced efficiency and sustainability to industrial processes.

Furthermore, SMC's R&D focuses on developing wireless communication components, facilitating seamless integration in smart factory environments. The reported 25% increase in adoption of their wireless-enabled products in 2024 highlights the market's growing demand for connected automation solutions.

Delivered as Displayed

Business Model Canvas

The Business Model Canvas you are previewing is the exact document you will receive upon purchase. This is not a sample or mockup; it's a direct snapshot of the complete, ready-to-use file. Once your order is processed, you'll gain full access to this identical, professionally structured Business Model Canvas, allowing you to immediately begin strategizing and refining your business.

Resources

SMC’s robust intellectual property, particularly its patents in pneumatic and electric control technologies, forms a cornerstone of its business model. This extensive patent portfolio safeguards its unique product designs and advanced manufacturing techniques, giving it a significant edge in the competitive industrial automation sector.

As of early 2024, SMC continues to invest heavily in research and development, a strategy that directly fuels the growth of its intellectual property assets. This ongoing innovation ensures SMC remains at the forefront of technological advancements, reinforcing its market position and providing a durable competitive moat.

SMC operates a global network of advanced manufacturing facilities, including specialized clean rooms crucial for producing high-precision automatic control components. These sites are equipped with state-of-the-art machinery, reflecting SMC's commitment to cutting-edge production technology.

In 2024, SMC continued its strategic capital expenditures, with a significant portion allocated to expanding and modernizing its production sites. For instance, the company announced plans to invest ¥10 billion (approximately $65 million USD at current exchange rates) in its Japanese facilities to enhance automation and capacity for its sensor and control product lines.

These investments are vital for maintaining SMC's competitive edge, ensuring the quality and efficiency required for its diverse range of pneumatic, electric, and hydraulic control components. The modernization efforts focus on improving energy efficiency and reducing waste, aligning with global sustainability goals.

SMC's business model hinges on a highly skilled workforce, including engineers, technicians, and R&D specialists. This expertise is vital for developing and manufacturing SMC's sophisticated automation solutions. For instance, in 2023, SMC invested significantly in training programs, with over 10,000 employees globally participating in technical skill enhancement courses.

Their deep technical knowledge is the engine behind SMC's innovation, ensuring the high quality and reliability of their products. This expertise also underpins the critical customer support that differentiates SMC in the competitive automation market. Continuous learning is therefore a cornerstone, maintaining this essential competitive advantage.

Global Distribution and Sales Network

SMC's extensive global distribution and sales network is a critical asset, featuring operations in over 80 countries. This vast infrastructure includes strategically located sales offices, warehouses, and service centers, ensuring broad market penetration and direct customer engagement.

This robust network is instrumental in SMC's ability to deliver products efficiently and provide localized support, a key factor in maintaining its leadership position. For example, in 2024, SMC reported a 15% year-over-year increase in sales volume directly attributable to the expansion of its distribution channels in emerging markets.

- Global Reach: Presence in over 80 countries.

- Operational Efficiency: Network of sales offices, warehouses, and service centers.

- Customer Accessibility: Facilitates localized support and product delivery.

- Market Penetration: Drives increased sales volume and market share.

Brand Reputation and Customer Trust

SMC's brand reputation and customer trust are foundational assets, cultivated over decades through consistent delivery of reliable, high-quality products and exceptional performance. This deep-seated trust translates into enduring relationships with industrial clients globally, driving repeat business and a strong competitive advantage.

This reputation is not merely anecdotal; it's reinforced by external validation. For instance, SMC has been recognized as a 'Best Managed Company,' a testament to its operational excellence and strategic foresight, further solidifying customer confidence.

- Decades of Reliability: SMC's long history of dependable products directly fuels customer trust.

- Global Client Relationships: The company maintains strong, long-term partnerships with industrial clients worldwide.

- Quality and Performance: Consistent high standards in product quality and performance are key drivers of SMC's reputation.

- External Recognition: Awards like 'Best Managed Company' validate and amplify customer trust.

SMC's key resources are its extensive intellectual property, global manufacturing capabilities, skilled workforce, and robust distribution network. These elements collectively enable the company to deliver innovative and reliable automation solutions worldwide.

The company’s intellectual property, particularly its patents, provides a significant competitive advantage. Its advanced manufacturing facilities ensure high-quality production, while its skilled employees drive innovation and customer support. The global distribution network ensures broad market reach and efficient product delivery.

In 2024, SMC's commitment to R&D and capital expenditure on its facilities, including a ¥10 billion investment in Japanese plants, underscores the importance of these resources. These investments directly support the growth and maintenance of its technological edge and production capacity.

| Resource Category | Key Assets | 2024 Data/Context |

|---|---|---|

| Intellectual Property | Patents in pneumatic and electric control technologies | Ongoing R&D investment fuels IP growth; protects unique designs and manufacturing techniques. |

| Manufacturing Capabilities | Global network of advanced manufacturing facilities | Investment of ¥10 billion (approx. $65 million USD) in Japanese facilities to enhance automation and capacity. |

| Human Capital | Highly skilled workforce (engineers, technicians, R&D specialists) | Over 10,000 employees globally participated in technical skill enhancement courses in 2023, supporting innovation and customer service. |

| Distribution & Sales Network | Operations in over 80 countries, including sales offices, warehouses, and service centers | Reported 15% year-over-year increase in sales volume in 2024 attributed to distribution channel expansion in emerging markets. |

Value Propositions

SMC's advanced automatic control equipment is a cornerstone for boosting industrial efficiency and precision. Their pneumatic and electric solutions are engineered to optimize motion and flow, directly translating to less material waste and higher production output for manufacturers.

For instance, in the automotive sector, SMC's technology has been instrumental in achieving cycle time reductions of up to 15% in assembly lines, a testament to their impact on throughput. This enhanced operational control also ensures a more consistent product quality, a critical factor in today's competitive markets.

SMC's commitment to exceptional reliability and durability means our products consistently perform even in the toughest industrial settings. This translates directly to less unexpected downtime and lower maintenance expenses for our clients, who benefit from a long operational life for their crucial automation systems.

For instance, SMC's pneumatic components are engineered to withstand millions of cycles, a testament to their robust design. In 2023, customer surveys indicated that 95% of SMC users experienced significantly reduced unplanned maintenance compared to previous solutions, directly reflecting the value of our product's longevity.

SMC's comprehensive product range, featuring over 12,000 standard items including actuators, valves, and air preparation units, provides customers with a vast selection to meet diverse automation needs. This extensive catalog ensures that users can readily source the precise components required for their specific applications, minimizing the need for workarounds or compromises.

Beyond the standard offerings, SMC excels in customization, allowing for tailored solutions that address unique industrial challenges. In 2024, a significant portion of SMC's revenue was driven by these specialized, unitized products, demonstrating their commitment to providing bespoke automation components that directly align with customer operational requirements.

Global Support and Technical Expertise

SMC's global footprint ensures customers receive tailored sales and technical assistance, no matter their location. This localized approach, exemplified by their presence in over 50 countries as of 2024, means support is readily available and culturally attuned.

Their team of technical experts actively guides clients through product selection and system design, a crucial step for optimizing performance. In 2024, SMC reported that 95% of technical support inquiries were resolved within 24 hours, highlighting their efficiency.

- Global Reach: Localized sales and after-sales service across numerous regions.

- Expert Assistance: Technical specialists aid in product choice and system setup.

- Troubleshooting Support: Dedicated help to ensure systems function optimally.

- Customer Satisfaction: A commitment to worldwide client contentment through accessible expertise.

Contribution to Sustainable Automation

SMC's dedication to sustainable automation is evident in its product design, emphasizing energy savings, compactness, and lightweight construction. For instance, their advanced Air Management Systems are engineered to optimize compressed air usage, a critical factor in industrial energy consumption. These systems can contribute to significant reductions in a facility's overall energy footprint.

This focus directly translates into tangible environmental and economic benefits for customers. By reducing energy consumption, businesses also lower their carbon dioxide emissions, aligning with global sustainability targets. In 2024, the industrial sector's energy efficiency improvements are a key focus, with companies actively seeking solutions that reduce operational costs, and SMC's offerings provide a clear pathway to achieving these goals.

- Energy Efficiency: SMC's compact and lightweight components, coupled with intelligent Air Management Systems, are designed to minimize energy waste in automated processes.

- CO2 Emission Reduction: By enabling customers to use less energy, SMC's solutions directly contribute to lowering greenhouse gas emissions in industrial operations.

- Economic Advantages: Reduced energy consumption translates into lower operating costs for businesses, enhancing profitability and competitiveness.

- Eco-Friendly Promotion: SMC actively advocates for and implements environmentally conscious practices throughout its business operations and product lifecycle.

SMC's value proposition centers on enhancing industrial efficiency and precision through advanced automation equipment. They offer solutions that reduce waste and boost output, backed by a commitment to reliability and extensive product customization. Their global support network and focus on sustainability further solidify their position as a key partner for businesses seeking to optimize operations.

| Value Proposition | Description | Key Benefit | Supporting Data (2024 unless noted) |

|---|---|---|---|

| Enhanced Efficiency & Precision | Pneumatic and electric solutions optimize motion and flow. | Reduced material waste, higher production output. | Up to 15% cycle time reduction in automotive assembly lines. |

| Reliability & Durability | Robust engineering for demanding environments. | Less downtime, lower maintenance costs. | 95% of users reported reduced unplanned maintenance (2023). |

| Comprehensive Product Range & Customization | Over 12,000 standard items and tailored solutions. | Meets diverse needs, minimizes compromises. | Significant revenue from specialized, unitized products. |

| Global Support & Expertise | Localized sales, technical assistance in 50+ countries. | Accessible, culturally attuned support. | 95% of technical inquiries resolved within 24 hours. |

| Sustainable Automation | Energy-saving, compact, lightweight designs. | Lower energy consumption, reduced CO2 emissions. | Aids businesses in meeting energy efficiency goals. |

Customer Relationships

SMC's dedicated sales force, bolstered by specialized technical support, ensures a close partnership with clients. This direct engagement allows for a nuanced grasp of individual customer requirements, offering expert advice on everything from product selection to seamless system integration.

This personalized strategy cultivates robust and highly responsive customer relationships, crucial for client retention and satisfaction. For instance, in 2024, SMC reported a 95% customer satisfaction rate directly attributed to the effectiveness of their dedicated support teams.

SMC cultivates enduring relationships with major industrial clients and Original Equipment Manufacturers (OEMs) through long-term supply agreements and strategic partnerships. These collaborations are built on a foundation of continuous dialogue, shared innovation through joint development, and guaranteed product availability, fostering deep trust and dedication.

In 2024, these key accounts represented a significant portion of SMC's revenue, with long-term contracts providing revenue visibility. For instance, a major automotive OEM renewed a five-year supply agreement in Q2 2024, guaranteeing consistent demand for SMC's specialized components.

This approach ensures a predictable revenue stream and allows SMC to develop highly customized solutions that precisely meet the evolving needs of its most important customers, solidifying its position as a preferred supplier.

SMC provides comprehensive training and educational programs designed to ensure customers can effectively leverage their products and optimize automation systems. These offerings include hands-on workshops, informative seminars, and accessible online resources.

By investing in customer capability through these programs, SMC empowers users with the knowledge to maximize the value derived from SMC components. This focus on skill development not only enhances product utilization but also significantly strengthens customer relationships.

Online Portals and Digital Engagement

SMC's online portals and digital tools are central to its customer relationships, offering comprehensive access to product details, technical specifications, and even CAD data. This digital-first approach ensures customers can readily find the information they need, anytime, anywhere.

This digital engagement significantly streamlines the customer journey, providing unparalleled convenience and rapid access to critical resources. For instance, in 2024, many B2B industrial suppliers reported a substantial increase in online inquiries and resource downloads, highlighting the growing reliance on digital platforms for pre-sales information gathering.

- Enhanced Accessibility: Online portals provide 24/7 access to product catalogs, technical documentation, and support materials, reducing reliance on traditional sales channels for basic information.

- Streamlined Information Retrieval: Customers can quickly find specific product details, datasheets, and application notes, accelerating the decision-making process.

- Digital Support and Interaction: Web-based tools facilitate order tracking, inquiry submission, and even direct communication with support teams, improving responsiveness.

- Data-Driven Insights: By analyzing portal usage, SMC can gain valuable insights into customer preferences and product interest, informing future product development and marketing efforts.

After-Sales Service and Maintenance Support

SMC’s commitment extends beyond the initial sale, offering comprehensive after-sales service. This includes crucial maintenance support, ensuring installed systems operate at peak performance, and readily available spare parts. Troubleshooting assistance is also a cornerstone, minimizing downtime for clients.

This dedication to ongoing support is vital for fostering long-term customer loyalty and satisfaction. By guaranteeing the longevity and optimal function of their products, SMC builds trust and encourages repeat business.

SMC’s strategic goal is to provide consistent, high-quality service across all its global operations. This unified approach ensures that every customer, regardless of location, receives the same level of support.

- Maintenance Support: SMC provides regular check-ups and preventative maintenance to ensure system longevity.

- Spare Parts Availability: A robust supply chain guarantees timely access to necessary replacement parts, minimizing operational disruptions.

- Troubleshooting Assistance: Expert technical support is available to quickly resolve any issues that may arise.

- Global Consistency: SMC aims to deliver uniform service standards worldwide, reinforcing its brand promise.

SMC's customer relationships are built on a multi-faceted approach, combining direct engagement, long-term partnerships, and robust digital and after-sales support. This strategy aims to foster deep loyalty and ensure customer success throughout the product lifecycle.

The company prioritizes personalized service through dedicated sales and technical teams, ensuring a deep understanding of client needs. For major industrial clients and OEMs, SMC cultivates enduring relationships via long-term supply agreements and joint innovation, as evidenced by a significant portion of 2024 revenue stemming from these key accounts and a major automotive OEM renewing a five-year contract in Q2 2024.

Furthermore, SMC invests in customer capability through comprehensive training programs and provides 24/7 access to product information and support via online portals, which saw increased usage for information gathering in 2024. This commitment to accessibility and ongoing support, including maintenance and spare parts availability, solidifies SMC's position as a trusted partner.

| Relationship Aspect | Key Strategies | 2024 Impact/Data |

|---|---|---|

| Direct Engagement | Dedicated Sales & Technical Support | 95% customer satisfaction rate |

| Strategic Partnerships | Long-term Agreements, Joint Development | Significant revenue from key accounts; Automotive OEM contract renewal |

| Digital Accessibility | Online Portals, CAD Data Access | Increased online inquiries and resource downloads |

| Customer Empowerment | Training & Educational Programs | Enhanced product utilization and value |

| After-Sales Service | Maintenance, Spare Parts, Troubleshooting | Fosters long-term loyalty and repeat business |

Channels

SMC leverages its dedicated direct sales force to cultivate relationships with major industrial clients, key accounts, and strategic Original Equipment Manufacturers (OEMs). This direct engagement is crucial for navigating the complexities of large-scale automation projects, enabling tailored solutions and in-depth technical discussions.

This direct channel facilitates nuanced negotiations and the development of bespoke automation strategies, a critical component for securing significant contracts. In 2024, SMC reported that its direct sales channel was instrumental in securing over 60% of its major project wins, highlighting its effectiveness in high-value transactions.

With a global footprint, SMC's direct sales teams are strategically positioned to cater to diverse international markets. This localized presence ensures responsiveness and a keen understanding of regional industrial demands, supporting SMC's ambition to be a leading automation partner worldwide.

SMC leverages an extensive network of authorized distributors and resellers to effectively reach its target market, especially small and medium-sized businesses. This multi-tiered approach ensures broad market penetration and immediate product availability.

These partners are vital for providing localized support and expertise, acting as an extension of SMC's customer service. In 2024, SMC reported that over 70% of its sales volume was facilitated through its authorized reseller channels, highlighting their critical role in market access and customer engagement.

Online platforms and e-commerce are crucial for Small and Medium-sized Companies (SMCs) to reach a wider audience. These channels often feature web catalogs and detailed product information, enabling customers to research and purchase components digitally. For instance, many B2B suppliers saw significant growth in their online sales channels throughout 2023 and early 2024, with some reporting over 40% of their total revenue originating from digital transactions.

The convenience offered by online platforms significantly accelerates the sales cycle. Customers can access information and make purchases at their own pace, 24/7. This self-service capability complements traditional sales methods, allowing sales teams to focus on more complex needs and relationship building. In 2024, e-commerce adoption continued to rise across industries, with B2B e-commerce sales projected to reach trillions globally.

Trade Shows and Industry Exhibitions

Participation in major international trade shows and industry exhibitions, like IMTS (International Manufacturing Technology Show) and SEMICON West, is a vital channel for showcasing new products and technologies. These events allow for direct engagement with potential customers and partners, fostering valuable relationships. In 2023, IMTS reported over 1.2 million net square feet of exhibit space and attracted more than 117,000 registrants, highlighting the significant reach and engagement potential.

These exhibitions are prime opportunities for lead generation and enhancing brand visibility within targeted industrial sectors. Exhibitors can demonstrate their capabilities firsthand, gather market intelligence, and network with industry peers. For instance, SEMICON West is a key event for the semiconductor industry, drawing thousands of professionals and companies looking for the latest innovations and business connections.

- Lead Generation: Trade shows offer direct interaction with interested parties, turning passive interest into active leads.

- Brand Visibility: A strong presence at industry-leading events significantly boosts brand recognition and market perception.

- Networking: These events are crucial for building relationships with customers, suppliers, and potential collaborators.

- Market Insight: Observing competitors and industry trends provides valuable data for strategic adjustments.

Local Offices and Service Centers

SMC strategically operates local offices and service centers across many countries, offering vital regional sales support, technical assistance, and product servicing. This extensive physical network ensures SMC remains close to its customer base, enabling prompt service delivery and fostering robust local relationships. For instance, in 2024, SMC expanded its European footprint with two new service centers in Germany and Poland, aiming to reduce customer response times by an average of 15%.

These localized touchpoints are fundamental to SMC's customer-centric approach, allowing for tailored support that addresses specific regional needs and market dynamics. This global presence underpins the company's ability to provide highly localized support, a critical differentiator in the competitive landscape. By the end of 2023, SMC reported that 80% of its customer inquiries were resolved within 24 hours, a metric directly linked to the efficiency of its local service centers.

- Regional Sales Support: Local teams provide tailored sales strategies and direct customer engagement.

- Technical Assistance: On-the-ground experts offer prompt troubleshooting and product guidance.

- Product Servicing: Physical centers facilitate efficient repairs and maintenance, enhancing customer satisfaction.

- Customer Proximity: Maintaining local offices ensures accessibility and builds stronger, trust-based relationships.

SMC utilizes a multi-channel strategy to reach its diverse customer base, combining direct sales, authorized distributors, online platforms, and strategic event participation. This approach ensures broad market coverage and caters to various customer preferences and needs.

The direct sales force is key for large industrial clients and OEMs, facilitating complex project negotiations. In 2024, this channel secured over 60% of SMC's major project wins. Authorized distributors and resellers are crucial for reaching SMEs, accounting for over 70% of SMC's sales volume in 2024.

Online platforms and e-commerce offer convenience and accelerate sales cycles, with B2B e-commerce sales projected to reach trillions globally. Trade shows like IMTS provide vital opportunities for lead generation and brand visibility, with IMTS 2023 attracting over 117,000 registrants.

Local offices and service centers offer essential regional support, with SMC expanding its European footprint in 2024 to improve response times. By the end of 2023, 80% of customer inquiries were resolved within 24 hours, demonstrating the effectiveness of these local touchpoints.

| Channel | Primary Target Audience | Key Benefits | 2024 Data/Impact |

|---|---|---|---|

| Direct Sales | Major Industrial Clients, OEMs | Tailored solutions, complex negotiations, high-value contracts | Secured >60% of major project wins |

| Distributors/Resellers | Small & Medium Businesses (SMEs) | Broad market penetration, localized support, product availability | Facilitated >70% of sales volume |

| Online Platforms/E-commerce | All customer segments (self-service) | Convenience, 24/7 access, accelerated sales cycle | Continued growth in B2B e-commerce sales |

| Trade Shows/Exhibitions | Industry professionals, potential partners | Lead generation, brand visibility, market intelligence | IMTS 2023: >117,000 registrants |

| Local Offices/Service Centers | Regional customers | Prompt service, technical assistance, relationship building | Reduced response times in new European centers |

Customer Segments

Automotive manufacturers and their extensive supplier networks are a cornerstone customer segment for SMC. These businesses depend on SMC's pneumatic and electric control equipment to ensure the precision and high-speed efficiency of their assembly lines, robotic automation, and diverse manufacturing operations. The automotive sector's demand for reliable, high-performance components makes it a critical market for SMC.

In 2024, the global automotive industry continued its recovery, with production volumes showing a steady increase. For instance, global light vehicle production was projected to reach around 90 million units by the end of the year, a significant rise from previous years. This sustained production activity directly translates into robust demand for the automation and control solutions that SMC provides, highlighting the segment's importance to SMC's revenue streams.

SMC is a critical supplier to electronics and semiconductor manufacturers, offering high-precision components vital for wafer fabrication, cleanroom automation, and the intricate process of device assembly. These industries rely heavily on the accuracy and reliability of SMC's specialized equipment to maintain the stringent conditions required for microchip production.

The increasing global demand for semiconductors, projected to reach over $600 billion in 2024, directly fuels the need for advanced automation solutions. This surge in demand necessitates the sophisticated, cleanroom-compatible products that SMC provides, ensuring efficient and contamination-free manufacturing environments.

Medical and pharmaceutical equipment producers are a vital customer base for SMC. These manufacturers, creating everything from surgical instruments to advanced laboratory automation systems, rely on components that adhere to extremely high standards for hygiene, precision, and unwavering reliability. The global medical device market alone was valued at approximately $518 billion in 2023, with projections indicating continued growth.

SMC's offerings are particularly crucial for this sector because they often demand specialized solutions that meet rigorous regulatory compliance. The need for components that can withstand sterilization processes and ensure the accuracy of diagnostic and therapeutic equipment makes SMC's precise engineering indispensable for these producers.

Food Processing and Packaging Companies

Food processing and packaging companies rely on SMC's automated control equipment for critical operations like filling, sealing, and material handling. These industries demand high standards for cleanliness and washdown resistance, areas where SMC's durable and hygienic solutions excel. For instance, the global food packaging market was valued at approximately $280 billion in 2023 and is projected to grow, highlighting the significant demand for efficient and sanitary production processes.

SMC's offerings are tailored to meet the stringent safety and compliance requirements inherent in food production. This includes features designed to prevent contamination and ensure product integrity throughout the manufacturing line. The sector’s focus on automation for improved throughput and reduced human contact, particularly in light of food safety regulations, makes SMC a key partner.

- Hygiene and Washdown Capabilities: SMC components are designed to withstand rigorous cleaning protocols, crucial for preventing microbial contamination in food environments.

- Precision and Reliability: Accurate filling and sealing are paramount; SMC's actuators and control systems ensure consistent product quality and minimize waste.

- Material Handling Efficiency: Automated conveyors and robotic arms, powered by SMC technology, streamline the movement of raw ingredients and finished goods, boosting operational speed.

- Regulatory Compliance: SMC's solutions often meet industry-specific certifications, aiding companies in adhering to food safety standards like HACCP.

General Industrial Automation and OEMs

This segment encompasses a vast array of industrial manufacturers and Original Equipment Manufacturers (OEMs) from diverse sectors. These businesses rely on automation to enhance their production processes.

SMC offers a broad spectrum of pneumatic and electric components that are crucial for general factory automation, machine tools, and industrial robotics. These solutions cater to a wide variety of operational demands.

- Diverse Applications: SMC's components are utilized in everything from automotive assembly lines to food and beverage packaging machinery.

- Market Reach: The global industrial automation market was valued at approximately $174.3 billion in 2023, with significant growth projected in the coming years.

- OEM Integration: OEMs integrate SMC's reliable and efficient actuators, valves, and sensors into their equipment to deliver advanced automated solutions to their end customers.

- Efficiency Gains: By adopting SMC's automation technology, manufacturers can achieve substantial improvements in productivity, precision, and energy savings.

SMC's customer base is diverse, spanning critical global industries that demand high-performance automation. Key segments include automotive manufacturers, electronics and semiconductor producers, medical and pharmaceutical equipment makers, and the food processing and packaging sectors. Additionally, a broad range of general industrial manufacturers and Original Equipment Manufacturers (OEMs) form a significant customer group.

These industries rely on SMC for precision, reliability, and specialized solutions to optimize their production lines and meet stringent regulatory requirements. The growth and technological advancements within these sectors directly translate into sustained demand for SMC's advanced pneumatic and electric control equipment.

The global industrial automation market, a key indicator for SMC's reach, was valued at approximately $174.3 billion in 2023 and is expected to see continued expansion. This growth underscores the broad applicability and essential nature of SMC's components across various manufacturing landscapes.

| Customer Segment | Key Needs Addressed by SMC | 2024 Market Relevance/Data Point |

| Automotive | Assembly line precision, robotic automation efficiency | Global light vehicle production projected around 90 million units in 2024. |

| Electronics & Semiconductor | Wafer fabrication accuracy, cleanroom automation | Global semiconductor market projected to exceed $600 billion in 2024. |

| Medical & Pharmaceutical | Hygiene, precision in equipment, regulatory compliance | Global medical device market valued at approx. $518 billion in 2023. |

| Food Processing & Packaging | Hygiene, washdown resistance, filling/sealing accuracy | Global food packaging market valued at approx. $280 billion in 2023. |

| General Industrial & OEMs | Factory automation, machine tools, robotics | Industrial automation market valued at approx. $174.3 billion in 2023. |

Cost Structure

Manufacturing and production represent the largest slice of SMC's cost pie. This includes everything from the basic raw materials and the parts that go into our products, to the wages of the people who build them, and the general expenses of running our factories worldwide. For instance, in 2024, the cost of key components like semiconductors saw significant fluctuations, impacting our overall material expenses.

To keep these costs in check, we focus heavily on making our production processes as smooth and efficient as possible. Strategic sourcing, meaning we carefully choose where and how we buy our materials, plays a huge role. In 2024, SMC reported that optimizing its supply chain reduced material costs by an average of 5% across its product lines.

The decision to shift some production to places like Vietnam is a direct move to manage these manufacturing expenses. Lower labor costs and favorable operating environments in these regions can significantly reduce overhead. By the end of 2024, approximately 15% of SMC's total manufacturing output was being produced in Southeast Asia, contributing to a projected 3% decrease in overall production costs for the fiscal year.

Research and Development (R&D) is a significant cost driver for SMC, reflecting a commitment to innovation and future growth. These expenses are crucial for developing new products, improving existing ones, and staying ahead technologically.

In 2024, many technology companies, which often share similar R&D-intensive models with SMC, allocated substantial portions of their revenue to R&D. For instance, some leading semiconductor firms reported R&D as a percentage of revenue in the high teens, indicating the scale of investment required for cutting-edge advancements.

These costs encompass a wide range, including the compensation for highly skilled engineers and scientists, the acquisition and maintenance of specialized laboratory equipment, and expenditures related to securing intellectual property through patents. This investment is fundamental to maintaining SMC's competitive advantage in the market.

Costs for global sales teams, marketing campaigns, and trade show participation are substantial. For instance, in 2024, many technology companies allocated over 20% of their revenue to sales and marketing to gain market share.

Maintaining a vast distribution network also adds significant expenses. These include logistics, warehousing, and transportation costs, which are critical for ensuring products reach customers efficiently across diverse international markets.

Expanding global reach inherently incurs considerable sales and distribution costs. For example, a company entering three new international markets in 2024 might see these costs increase by 15-25% due to new infrastructure and personnel requirements.

Personnel and Labor Costs

Personnel and labor costs are a significant component of SMC's expenses, reflecting its substantial global workforce. This includes salaries, wages, comprehensive benefits packages, and ongoing training programs for a diverse range of employees, from manufacturing and R&D to sales and administrative functions.

Optimizing labor efficiency and strategically managing global compensation structures are crucial for maintaining and enhancing SMC's profitability. For instance, in 2024, many global manufacturing firms faced increased labor costs due to inflation and talent shortages, with average wage growth in developed economies hovering around 4-5%.

- Salaries and Wages: Covering compensation for all employees across various departments and regions.

- Employee Benefits: Including health insurance, retirement plans, and other welfare programs.

- Training and Development: Investing in skill enhancement and professional growth for the workforce.

- Global Compensation Management: Addressing varying pay scales and cost of living across different countries to ensure competitiveness and fairness.

Operational and Administrative Overheads

General operational and administrative overheads are crucial components of a Small and Medium-sized Company's (SMC) cost structure. These include ongoing expenses like maintaining facilities, paying for utilities, supporting IT infrastructure, covering legal fees, and general corporate management costs.

For instance, in 2024, many SMCs are investing in scalable IT solutions. A study by TechCrunch in early 2024 indicated that cloud-based IT infrastructure costs for SMEs rose by an average of 15% year-over-year, driven by increased data storage and software subscriptions.

Implementing efficient global IT systems, such as centralized customer support platforms, can significantly help in managing these overheads. This centralization often leads to cost savings through economies of scale and improved resource allocation.

- Facility Maintenance: Costs associated with upkeep and repair of physical office or operational spaces.

- Utilities: Expenses for electricity, water, gas, and internet services.

- IT Infrastructure: Investment in hardware, software, cybersecurity, and IT support.

- Legal and Compliance: Fees for legal counsel, regulatory filings, and ensuring adherence to laws.

- Corporate Management: Salaries and benefits for executive and administrative staff, travel, and office supplies.

SMC's cost structure is heavily influenced by its manufacturing and production activities, which encompass raw materials, component parts, labor, and factory overhead. In 2024, the company focused on supply chain optimization, achieving a 5% reduction in material costs. Furthermore, strategic shifts in production to regions like Vietnam by late 2024 contributed to an estimated 3% decrease in overall production expenses.

Research and Development (R&D) represents another substantial investment, critical for innovation and maintaining a competitive edge. In 2024, R&D spending for technology companies, similar to SMC, often reached high teens as a percentage of revenue, covering highly skilled personnel and specialized equipment.

Sales, marketing, and distribution are significant cost centers, essential for global reach and market penetration. In 2024, many tech firms dedicated over 20% of revenue to these areas. Expanding into new international markets in 2024 could increase these costs by 15-25%.

Personnel and labor costs, including salaries, benefits, and training, are a major expense for SMC's global workforce. In 2024, average wage growth in developed economies was around 4-5%, a factor impacting these costs. General administrative overheads, including IT infrastructure and facility maintenance, also contribute significantly, with SME IT costs rising by approximately 15% year-over-year in early 2024.

| Cost Category | Key Components | 2024 Trends/Impact | SMC Initiatives | Estimated Impact |

| Manufacturing & Production | Raw Materials, Components, Labor, Factory Overhead | Component price fluctuations, optimized supply chains | Strategic sourcing, production shift to Vietnam | 5% material cost reduction, 3% overall production cost decrease |

| Research & Development (R&D) | Personnel, Equipment, Patents | High investment for innovation | Continued investment in skilled workforce and technology | Maintaining competitive advantage |

| Sales, Marketing & Distribution | Sales Teams, Marketing Campaigns, Logistics, Warehousing | High spend for market share and global reach | Expanding global presence, optimizing distribution network | Potential 15-25% increase in costs for new markets |

| Personnel & Labor | Salaries, Benefits, Training | Rising wages due to inflation/shortages | Global compensation management, efficiency optimization | Affected by 4-5% average wage growth |

| General & Administrative | IT Infrastructure, Facilities, Legal, Management | Increased IT costs, focus on IT efficiency | Investing in scalable IT solutions, centralizing support | 15% year-over-year rise in SME IT costs |

Revenue Streams

SMC's primary revenue driver is the direct sale of its extensive catalog of pneumatic components. This includes essential automation parts like actuators, valves, and air preparation units, which are fundamental to manufacturing processes across various industries. In 2023, SMC Corporation reported total sales of approximately 769.9 billion Japanese Yen, with a significant portion attributed to these core equipment sales.

SMC generates revenue from selling electric actuators and related control equipment. These products are seeing growing demand in areas needing precise and adaptable automation. This sales channel diversifies SMC's income beyond its traditional pneumatic solutions, reinforcing its market position.

SMC generates revenue by selling specialized equipment, including vacuum equipment and temperature control units like chillers. These products are crucial for industries requiring precise environmental conditions, such as semiconductor fabrication. For instance, in 2024, the demand for advanced semiconductor manufacturing equipment, which relies heavily on such temperature control and vacuum technologies, remained robust, contributing significantly to SMC's sales figures.

After-Sales Services and Spare Parts

Ongoing revenue flows from after-sales services, encompassing maintenance, repairs, and the sale of spare parts for installed SMC equipment. This ensures continued customer support and fosters long-term profitability.

For instance, in 2024, many industrial equipment manufacturers reported that their service and spare parts divisions contributed a significant portion, often exceeding 20%, of their total revenue. This highlights the critical role of these streams in stabilizing income and enhancing customer loyalty.

- Maintenance Contracts: Offering scheduled upkeep to ensure optimal equipment performance.

- Repair Services: Providing timely and expert fixes for any operational issues.

- Spare Parts Sales: Supplying genuine replacement components to maintain equipment integrity.

- Upgrades and Retrofits: Facilitating enhancements to existing machinery for improved efficiency.

Consulting and Engineering Solutions

SMC also generates revenue by offering specialized consulting and engineering services. This involves guiding clients through the design, refinement, and deployment of intricate automation systems, all while integrating SMC's own componentry. This approach capitalizes on SMC's profound technical acumen and extensive sector experience.

These value-added services are crucial for customers tackling complex automation challenges, ensuring seamless integration and optimal performance. For example, in 2024, a significant portion of SMC's service revenue came from custom automation projects in the automotive and semiconductor industries, where precision and reliability are paramount.

- Consulting Fees: Charging for expert advice on automation strategy and implementation.

- Engineering Design Services: Billing for the creation of custom automation solutions.

- Project Management: Revenue from overseeing the installation and integration of automation systems.

- Technical Support and Optimization: Income from ongoing assistance and performance tuning of deployed solutions.

SMC Corporation's revenue streams are diverse, reflecting its broad offering in the automation industry. Core to its business is the direct sale of pneumatic components, including actuators and valves, which are vital for manufacturing. Complementing this, SMC also generates income from electric actuators and specialized equipment like vacuum units and chillers, catering to precision-driven sectors such as semiconductor manufacturing.

Beyond product sales, SMC benefits from recurring revenue through after-sales services, encompassing maintenance, repairs, and spare parts. This focus on ongoing support enhances customer loyalty and provides a stable income base. Furthermore, the company offers valuable consulting and engineering services, assisting clients with complex automation system design and implementation, thereby leveraging its deep technical expertise.

| Revenue Stream | Description | 2023/2024 Relevance |

|---|---|---|

| Pneumatic Components Sales | Direct sales of actuators, valves, and air preparation units. | Primary revenue driver; significant portion of 769.9 billion JPY total sales in FY2023. |

| Electric Actuator Sales | Sales of electric actuators and control equipment for precise automation. | Growing demand in specialized applications, diversifying income. |

| Specialized Equipment Sales | Sales of vacuum equipment and temperature control units (e.g., chillers). | Crucial for industries like semiconductor fabrication; robust demand in 2024. |

| After-Sales Services | Maintenance, repairs, and spare parts sales for installed equipment. | Contributes significantly to revenue (often >20% for industrial equipment firms), enhancing customer loyalty. |

| Consulting & Engineering Services | Expert advice, custom automation design, and project management. | Key for complex automation challenges, particularly in automotive and semiconductor sectors in 2024. |

Business Model Canvas Data Sources

The SMC Business Model Canvas is constructed using a blend of primary customer feedback, competitive market analysis, and internal operational data. This comprehensive approach ensures a robust and actionable strategic framework.