Sia Abrasives Holding AG PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Sia Abrasives Holding AG Bundle

Unlock the strategic landscape for Sia Abrasives Holding AG with our comprehensive PESTLE analysis. Understand how political stability, economic fluctuations, and evolving social attitudes are shaping the abrasives market, presenting both challenges and opportunities. Gain the foresight needed to navigate these external forces effectively.

Our PESTLE analysis delves into the technological advancements and environmental regulations impacting Sia Abrasives Holding AG, offering critical insights for your business planning. Equip yourself with actionable intelligence to anticipate market shifts and secure a competitive advantage. Download the full report now for immediate strategic clarity.

Political factors

Changes in global trade policies, including the imposition or removal of import/export tariffs, directly affect Sia Abrasives Holding AG's operational costs and market pricing. For instance, the ongoing adjustments to trade agreements between major economic blocs in 2024 and 2025 could alter the landed cost of raw materials like aluminum oxide and silicon carbide, impacting overall manufacturing expenses.

Geopolitical tensions can exacerbate these trade uncertainties, potentially leading to increased protectionist measures that restrict market access or create competitive disadvantages for Sia Abrasives' finished goods. Companies like Sia Abrasives must remain agile, adapting sourcing strategies to mitigate risks associated with trade barriers, as seen with the fluctuating trade relationships impacting key Asian manufacturing hubs.

Governments worldwide, including key markets for Sia Abrasives, implement a range of regulations affecting manufacturing. These cover aspects from worker safety standards, such as those mandated by OSHA in the United States, to product quality certifications like CE marking in Europe. Sia Abrasives must navigate these varying legal landscapes, potentially investing in updated machinery or training to ensure compliance. For instance, in 2024, the EU's updated chemical regulations (REACH) could impact the raw materials used in abrasive production, requiring reformulation or new supplier vetting.

Adherence to these diverse governmental rules necessitates ongoing investment in compliance infrastructure and process adaptation. For example, stricter environmental regulations, such as those targeting emissions or waste disposal, could lead to increased operational costs for Sia Abrasives. However, these pressures can also spur innovation, driving the development of more sustainable manufacturing techniques and potentially creating a competitive advantage in environmentally conscious markets.

Government support for sectors like automotive and aerospace can boost demand for Sia Abrasives' products. For instance, in 2024, the EU's Strategic Technologies for Europe (STEP) program allocated €3.3 billion to foster innovation in areas that heavily rely on advanced surface finishing, potentially benefiting Sia Abrasives.

Conversely, a lack of government incentives in Sia Abrasives' key markets could dampen growth. If policies don't favor manufacturing or technological upgrades in customer industries, the need for high-performance abrasives might stagnate.

Sia Abrasives needs to closely monitor industrial policy shifts. For example, the US Inflation Reduction Act, with its significant clean energy and manufacturing incentives, could indirectly spur demand for abrasives used in renewable energy component production through 2025.

Political Stability in Key Markets

Political instability, including civil unrest or abrupt government changes in major markets, poses a significant risk to global operations. Such events can severely disrupt supply chains, manufacturing processes, and ultimately impact consumer purchasing power and demand for abrasive products. For Sia Abrasives, which has a global footprint, understanding and mitigating these political risks is paramount.

Sia Abrasives must closely monitor the political climate in countries where it has substantial manufacturing facilities or significant sales volumes. For instance, potential political turbulence in a key European market could directly affect production output and distribution efficiency. This proactive assessment enables better strategic planning, including the diversification of manufacturing and sales operations to reduce reliance on any single volatile region.

- Geopolitical Risk Monitoring: Sia Abrasives should maintain robust systems for tracking political developments in its top 10 markets, which historically include Germany, France, and the United States, alongside emerging economies.

- Supply Chain Resilience: In 2024, global supply chains faced ongoing disruptions; political instability in countries like those in parts of Eastern Europe or the Middle East could further exacerbate these issues for raw material sourcing.

- Market Diversification Strategy: To counter political risks, Sia Abrasives may consider expanding its presence in regions with more stable political environments, potentially increasing investment in markets in Southeast Asia or North America.

- Scenario Planning: Developing contingency plans for various political scenarios, such as trade policy shifts or localized conflicts, is crucial for business continuity and maintaining market share.

International Relations and Sanctions

Geopolitical shifts and international sanctions significantly impact Sia Abrasives' global operations. For instance, the ongoing geopolitical tensions in Eastern Europe and the subsequent sanctions imposed by various nations on Russia and Belarus could limit Sia Abrasives' market access and supply chain activities in these regions. In 2023, global trade disruptions due to geopolitical instability affected numerous manufacturing sectors, with some analysts projecting a continued impact on international trade volumes through 2024 and into 2025.

These restrictions can manifest as direct limitations on sales, difficulties in processing financial transactions, or hindrances to the movement of essential goods and personnel. Companies like Sia Abrasives must maintain rigorous compliance protocols to navigate the complex web of international sanctions, ensuring adherence to all relevant regulations to avoid penalties and operational disruptions.

- Geopolitical Risk: Increased geopolitical instability can lead to sudden market access restrictions.

- Sanctions Compliance: Strict adherence to evolving international sanctions is critical for Sia Abrasives.

- Trade Disruptions: Global trade slowdowns, partly driven by geopolitical factors, can affect supply chains and sales volumes.

- Market Access: Sanctions may directly prohibit or complicate business dealings in specific countries.

Governmental industrial policies and trade agreements directly influence Sia Abrasives Holding AG's market access and operational costs. Fluctuations in import/export tariffs, as seen in ongoing adjustments between major economic blocs in 2024-2025, can alter the cost of raw materials like aluminum oxide.

Geopolitical tensions can amplify trade uncertainties, potentially leading to protectionist measures that restrict market access or create competitive disadvantages for Sia Abrasives' finished goods. For example, global trade disruptions due to geopolitical instability in 2023 were projected to continue impacting international trade volumes through 2024 and 2025.

Regulatory compliance, from worker safety standards to product quality certifications, requires ongoing investment. In 2024, the EU's updated chemical regulations (REACH) could affect raw materials used in abrasive production, necessitating reformulation or new supplier vetting.

Government support for key customer sectors, such as automotive and aerospace, can boost demand. The EU's STEP program, allocating €3.3 billion in 2024 to foster innovation in advanced surface finishing, could benefit Sia Abrasives.

| Political Factor | Impact on Sia Abrasives | 2024/2025 Relevance |

|---|---|---|

| Trade Policies & Tariffs | Affects raw material costs and market pricing. | Ongoing adjustments between major economic blocs. |

| Geopolitical Tensions | Creates trade uncertainty and potential protectionism. | Projected continued impact on trade volumes. |

| Regulatory Compliance | Requires investment in updated machinery and training. | EU REACH regulations impacting raw materials. |

| Government Support/Incentives | Can boost demand in customer sectors. | EU STEP program for advanced surface finishing. |

| Political Instability | Disrupts supply chains and impacts purchasing power. | Monitoring key European markets for production efficiency. |

What is included in the product

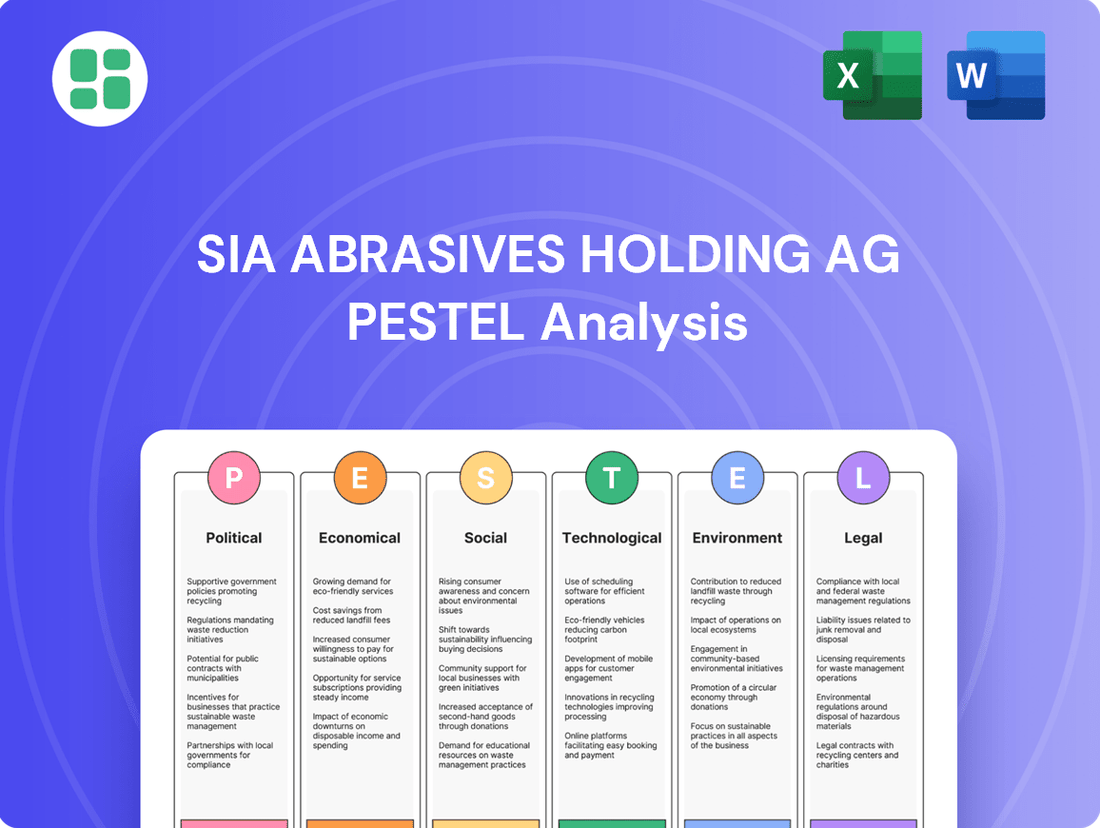

This PESTLE analysis of Sia Abrasives Holding AG examines the influence of political, economic, social, technological, environmental, and legal factors on its operations and strategy.

It provides a comprehensive overview of the external landscape, highlighting key drivers of change and potential impacts for informed decision-making.

A concise PESTLE analysis for Sia Abrasives Holding AG that can be easily dropped into PowerPoints or used in group planning sessions, highlighting key external factors impacting the business.

Economic factors

Global economic growth is a key driver for Sia Abrasives. When the world economy is expanding, industries that use abrasives, such as automotive manufacturing and metalworking, tend to ramp up production. This increased industrial activity directly translates into higher demand for Sia Abrasives' products.

For instance, the International Monetary Fund (IMF) projected global growth to be around 3.1% in 2024, a slight uptick from previous estimates, indicating a generally supportive environment for industrial output. Stronger growth in major economies like the United States and the Eurozone, where automotive and heavy machinery sectors are significant, would likely bolster Sia Abrasives' sales volumes.

Conversely, a global economic slowdown or recession would dampen industrial output and, consequently, reduce the demand for abrasives. If major markets experience contraction, such as a projected 0.5% decline in industrial production in a specific region during a downturn, Sia Abrasives would likely see a direct negative impact on its revenue and profitability.

The cost and availability of essential raw materials like abrasive grains, resins, and backing materials directly influence Sia Abrasives' production expenses and profitability. For instance, the price of aluminum oxide, a primary abrasive grain, saw a notable increase in early 2024, impacting manufacturers across the sector.

Supply chain disruptions, such as those experienced in 2023 due to geopolitical tensions affecting shipping and logistics, can lead to material shortages and price volatility. Sia Abrasives needs robust procurement strategies to secure stable supplies and manage these economic risks effectively.

As a global entity, Sia Abrasives Holding AG operates across various currency markets. Fluctuations in exchange rates directly impact the cost of raw materials and finished goods imported into different regions, as well as the price competitiveness of its exported abrasives. For instance, a stronger Swiss Franc (CHF), Sia Abrasives' reporting currency, could make its products more expensive for international buyers in 2024-2025, potentially dampening sales volume.

These currency shifts also affect the translation of overseas earnings and expenditures into Sia Abrasives' consolidated financial statements. For example, if the Euro weakens against the Swiss Franc in 2024, revenue generated in Euros by its European subsidiaries would translate into fewer Swiss Francs, impacting reported profitability. Effective foreign exchange risk management strategies are therefore essential for maintaining financial predictability and operational stability for Sia Abrasives.

Inflation and Interest Rates

High inflation in 2024 and early 2025 directly impacts Sia Abrasives' operational costs. For instance, the Producer Price Index (PPI) in key manufacturing regions saw significant increases through 2024, affecting raw material and energy prices. If Sia Abrasives cannot fully pass these higher costs onto its customers through price adjustments, its profit margins could face considerable pressure.

Rising interest rates, a trend observed globally in 2024, also pose a challenge. Central banks have maintained or increased benchmark rates to combat inflation, making it more expensive for Sia Abrasives to finance new capital expenditures or expansion projects. This could necessitate a re-evaluation of investment strategies and potentially slow down growth initiatives.

- Increased Input Costs: Global supply chain disruptions and energy price volatility in 2024 contributed to a rise in raw material and transportation costs for manufacturing firms like Sia Abrasives.

- Cost of Capital: As of late 2024, average corporate borrowing costs have risen by approximately 1.5-2.0% compared to early 2023 due to central bank monetary policy tightening.

- Pricing Power: The ability of Sia Abrasives to implement price increases is crucial. In competitive markets, this can be challenging, potentially eroding profitability if cost increases are substantial.

- Investment Decisions: Higher interest rates make debt financing less attractive, potentially leading to a more cautious approach to large-scale investments and acquisitions.

Industry-Specific Investment Cycles

The capital expenditure cycles in Sia Abrasives' core customer sectors, including automotive, woodworking, and metalworking, significantly influence demand for its abrasive products. When these industries ramp up investment in new manufacturing equipment or facility upgrades, it typically boosts sales for abrasive systems.

For instance, the automotive sector's investment in electric vehicle (EV) production lines, a trend accelerating through 2024 and projected to continue, requires advanced manufacturing processes that often rely on specialized abrasives for battery casing and lightweight material finishing. Similarly, the global woodworking industry saw a rebound in construction and furniture demand in late 2023 and early 2024, leading to increased capital spending on advanced machinery for precision cutting and finishing.

- Automotive Sector Capital Expenditure: Global automotive capital expenditure was projected to reach over $300 billion in 2024, with a substantial portion directed towards EV and autonomous driving technologies, directly benefiting suppliers of precision manufacturing components like abrasives.

- Woodworking Industry Investment: The woodworking sector's capital expenditure saw an estimated 5-7% increase in 2024 compared to 2023, driven by demand for sustainable building materials and automated production.

- Metalworking Machinery Sales: Orders for metalworking machinery globally experienced a modest uptick in the latter half of 2023 and into early 2024, signaling renewed investment in manufacturing capacity.

Global economic health directly impacts Sia Abrasives by influencing demand in key customer sectors. A projected 3.1% global growth for 2024, as estimated by the IMF, suggests a generally favorable environment for industrial output. However, rising inflation and interest rates, with corporate borrowing costs up 1.5-2.0% by late 2024, increase operational expenses and the cost of capital, potentially pressuring profit margins and investment decisions.

Currency fluctuations also play a significant role, with a stronger Swiss Franc potentially making Sia Abrasives' products more expensive internationally. For example, revenue generated in weaker currencies would translate into fewer Swiss Francs, impacting reported profitability. These economic factors necessitate robust risk management and strategic pricing to navigate cost pressures and maintain competitiveness.

Preview Before You Purchase

Sia Abrasives Holding AG PESTLE Analysis

The preview shown here is the exact Sia Abrasives Holding AG PESTLE Analysis document you’ll receive after purchase—fully formatted and ready to use. This comprehensive analysis delves into the Political, Economic, Social, Technological, Legal, and Environmental factors impacting Sia Abrasives.

This is a real screenshot of the product you’re buying—delivered exactly as shown, no surprises. You’ll gain valuable insights into the market dynamics and strategic considerations for Sia Abrasives Holding AG.

Sociological factors

Consumers are increasingly seeking finished products that not only look good but also last longer and are produced with the environment in mind. This shift, evident across sectors like automotive and furniture, means manufacturers using abrasives need materials that deliver superior surface finishes and enhanced durability.

For instance, the automotive industry's push for lighter, more fuel-efficient vehicles often requires advanced surface treatments and coatings, directly impacting the types of abrasive products needed. By 2024, the global automotive refinish coatings market was valued at approximately $28.5 billion, with sustainability and aesthetic appeal being key growth drivers, highlighting the demand for high-performance abrasive solutions.

Sia Abrasives must therefore innovate its abrasive technologies to meet these evolving specifications, focusing on solutions that enable finer finishes, greater material efficiency, and reduced waste, thereby aligning with the sustainability goals of its downstream customers.

Changes in workforce demographics, like an aging industrial workforce or a scarcity of skilled manufacturing labor, directly affect Sia Abrasives' operations and its customers' production capabilities. For instance, a 2024 report indicated a 15% decline in the availability of experienced machinists in key European markets, a challenge Sia Abrasives must navigate.

The company must assess labor availability for its manufacturing sites and the necessary technical expertise for product application and customer support. In 2025, the demand for specialized abrasive application technicians is projected to grow by 8%, highlighting the need for targeted training and recruitment efforts.

The increasing global focus on worker health and safety directly impacts abrasive product design and application. Sia Abrasives Holding AG must ensure its offerings, including abrasive papers and tools, meet evolving safety standards, potentially necessitating innovation in dust suppression or ergonomic features. For instance, the European Agency for Safety and Health at Work (EU-OSHA) consistently highlights the importance of minimizing exposure to airborne particles in industrial settings, a key concern for abrasive processes.

Compliance with these stringent regulations, such as those governed by OSHA in the United States or similar bodies internationally, influences customer purchasing decisions. Companies are increasingly prioritizing suppliers who demonstrate a commitment to safety, driving demand for products that reduce health risks. This trend is further underscored by rising occupational health insurance costs for businesses that fail to adequately protect their workforce.

Public Perception and Corporate Social Responsibility (CSR)

Public perception of corporate social responsibility (CSR) significantly shapes how Sia Abrasives Holding AG is viewed by stakeholders. Growing awareness means consumers, employees, and investors increasingly expect companies to act ethically. For instance, a 2024 survey by Edelman found that 60% of consumers globally choose brands based on their values and beliefs, highlighting the direct link between CSR and brand loyalty.

Sia Abrasives' dedication to responsible practices, such as fair labor standards and community involvement, can bolster its brand image and attract top talent. Companies that actively report on their sustainability efforts, like those participating in the Global Reporting Initiative (GRI) framework, often see improved investor confidence. In 2023, companies with strong ESG (Environmental, Social, and Governance) scores outperformed their peers in the S&P 500 by an average of 3.5% in total return, demonstrating the financial benefits of CSR.

- Consumer Preference: A significant portion of consumers prioritize brands with strong ethical and sustainable practices.

- Talent Acquisition: A positive CSR reputation makes companies more attractive to potential employees.

- Investor Confidence: Strong ESG performance can lead to better access to capital and higher valuations.

- Reputational Risk: Neglecting CSR can result in substantial damage to a company's public image and financial standing.

Education and Training in Industrial Skills

The availability and quality of technical education significantly impact industrial efficiency. For instance, in Germany, a strong vocational training system, as exemplified by the dual education model, ensures a skilled workforce for manufacturing sectors. This directly influences how effectively companies like Sia Abrasives' customers can utilize advanced grinding and polishing technologies. A well-trained workforce can lead to better product application, reduced waste, and increased productivity, ultimately boosting demand for high-performance abrasives.

Sia Abrasives may need to proactively address skill gaps. This could involve developing customer training programs or enhancing technical support services. For example, if a new, highly efficient abrasive technology is introduced, but end-users lack the necessary skills to operate it optimally, adoption will be slow. Providing training on best practices for grinding and polishing can ensure customers achieve the intended benefits, fostering loyalty and driving sales. The global shortage of skilled manufacturing labor, a trend observed across many developed economies in 2024, further emphasizes the need for such initiatives.

- Skilled Workforce Impact: A highly skilled workforce, often a result of robust technical education, improves the efficiency of abrasive product usage.

- Technology Adoption: The level of technical training directly influences the speed and success of adopting new abrasive technologies by end-users.

- Sia Abrasives' Role: The company may need to invest in customer training or technical support to ensure optimal performance of its products.

- Market Trend: Global shortages in skilled manufacturing labor in 2024 highlight the growing importance of training and upskilling initiatives.

Societal attitudes towards health and safety directly influence product development and market acceptance. As awareness of occupational hazards in manufacturing increases, there's a growing demand for abrasive products that minimize dust generation and offer ergonomic benefits, a trend reinforced by a 2024 EU-OSHA report highlighting the need for safer industrial practices.

Consumer demand for ethically produced goods is also on the rise, with a 2024 Edelman survey indicating that 60% of consumers choose brands based on their values, impacting Sia Abrasives' reputation and market position.

Furthermore, the availability of a skilled workforce, often a product of strong vocational training systems like Germany's dual education model, directly affects how effectively customers can utilize advanced abrasive technologies, with a 2024 report noting a 15% decline in experienced machinists in key European markets.

| Sociological Factor | Impact on Sia Abrasives | Supporting Data (2024/2025) |

| Health & Safety Awareness | Demand for safer, low-dust, ergonomic abrasives | EU-OSHA reports emphasize safer industrial practices. |

| Ethical Consumerism | Need for strong Corporate Social Responsibility (CSR) | 60% of consumers choose brands based on values (Edelman, 2024). |

| Workforce Skills | Influence on adoption of advanced abrasive technologies | 15% decline in experienced machinists in Europe (2024). |

Technological factors

Continuous innovation in abrasive grain technology, bonding systems, and backing materials is crucial for Sia Abrasives to develop more efficient and durable products. For instance, advancements in ceramic grain technology have significantly improved cutting performance and lifespan compared to traditional aluminum oxide.

Sia Abrasives must prioritize research and development to maintain a competitive edge, focusing on novel material compositions and production methods. This investment allows them to offer cutting-edge solutions that deliver superior surface finishes or accelerate processing times, a key differentiator in the market.

The manufacturing sector's embrace of automation and robotics, particularly in tasks like grinding, sanding, and polishing, directly influences the demand for specific abrasive products. Sia Abrasives must innovate to create abrasives designed for seamless integration with automated systems and robotic arms, potentially necessitating novel product formats or specialized attachment mechanisms.

This technological shift presents Sia Abrasives with a significant opportunity to offer integrated solutions, moving beyond just supplying abrasives to providing comprehensive packages that enhance the efficiency and precision of automated surface treatment processes.

The increasing integration of digital technologies, often referred to as Industry 4.0, presents significant opportunities for Sia Abrasives. By embedding sensors and leveraging advanced data analytics, Sia Abrasives can optimize abrasive usage in real-time, predict maintenance needs for machinery, and enhance overall quality control. This digital transformation allows for the development of smart abrasive solutions, providing customers with valuable data-driven insights that boost their operational efficiency and product performance.

New Surface Treatment Techniques

New surface treatment techniques, like laser finishing and advanced chemical processes, are emerging as potential alternatives to traditional abrasive methods. For instance, the global laser surface texturing market was valued at approximately USD 1.1 billion in 2023 and is projected to grow significantly, indicating a shift in how surfaces are treated across various industries. This trend could impact demand for abrasive products.

Sia Abrasives needs to stay ahead of these technological shifts. By closely monitoring advancements and investing in research and development, the company can identify opportunities to integrate these new methods or develop complementary solutions. This proactive approach is crucial for maintaining market share and relevance in a rapidly evolving landscape.

The company's strategy should involve continuous market intelligence gathering to understand the adoption rates and effectiveness of these new technologies. For example, in the automotive sector, laser welding and finishing are increasingly being adopted for lightweight materials, potentially reducing reliance on abrasive finishing for certain components. Sia Abrasives must explore potential synergies or diversification avenues to adapt.

- Market Shift: The rise of laser finishing and advanced chemical treatments poses a potential threat to traditional abrasive methods in specific applications.

- R&D Imperative: Continuous investment in research and development is essential for Sia Abrasives to understand and potentially integrate or counter these new technologies.

- Diversification Strategy: Exploring opportunities for synergy or diversification into complementary surface treatment areas will be key to long-term market relevance.

Sustainability-Driven Technological Innovations

Technological advancements are increasingly steering towards sustainability, a trend Sia Abrasives can leverage. Innovations like abrasives made with recycled materials, those boasting extended lifespans, or products designed to minimize dust emissions are gaining significant traction. For instance, the global market for sustainable abrasives is projected to grow substantially, with some estimates suggesting a compound annual growth rate (CAGR) of over 5% between 2023 and 2030, driven by these eco-friendly attributes.

By focusing on developing and marketing these eco-friendly product lines and refining its manufacturing processes to be more sustainable, Sia Abrasives can carve out a distinct competitive advantage. This strategic direction not only addresses growing global environmental consciousness but also anticipates and aligns with escalating regulatory pressures worldwide, which are increasingly favoring greener industrial practices.

Key areas for technological innovation in sustainability for Sia Abrasives include:

- Development of abrasives utilizing a higher percentage of post-consumer recycled content.

- Research into advanced bonding agents and substrate materials to significantly extend product lifespan, reducing replacement frequency.

- Implementation of dust suppression technologies and the creation of low-dust emitting abrasive formulations.

- Investment in energy-efficient manufacturing processes, potentially powered by renewable energy sources, to reduce the carbon footprint of production.

Technological advancements in abrasive materials, such as enhanced ceramic grains, significantly boost product efficiency and durability, offering a competitive edge. The increasing adoption of automation and robotics in manufacturing necessitates abrasives designed for seamless integration, driving demand for specialized solutions.

Industry 4.0 principles, including sensor technology and data analytics, enable smart abrasives that optimize usage and predict maintenance, enhancing customer operational efficiency. Emerging alternative surface treatments like laser finishing, with a global market valued at approximately USD 1.1 billion in 2023, present both challenges and opportunities for adaptation.

Sustainability is a key technological driver, with a growing market for abrasives made from recycled materials and those with extended lifespans, projected to grow at a CAGR exceeding 5% from 2023 to 2030. Innovations focusing on reduced dust emissions and energy-efficient manufacturing processes align with environmental consciousness and regulatory trends.

| Technological Factor | Impact on Sia Abrasives | Example/Data Point |

|---|---|---|

| Advanced Grain Technology | Improved product performance (cutting, lifespan) | Ceramic grains offer superior performance over aluminum oxide. |

| Automation & Robotics Integration | Demand for specialized abrasives for automated systems | Need for novel product formats and attachment mechanisms for robotic arms. |

| Industry 4.0 / Digitalization | Development of smart, data-driven abrasive solutions | Real-time optimization of abrasive usage and predictive maintenance. |

| Emerging Surface Treatments | Potential threat to traditional abrasive methods | Laser finishing market valued at ~USD 1.1 billion in 2023. |

| Sustainable Technologies | Opportunity for competitive advantage and market growth | Sustainable abrasives market CAGR >5% (2023-2030), driven by recycled content and longevity. |

Legal factors

Sia Abrasives must navigate a complex web of product liability and safety regulations across its global operations. This means rigorously ensuring its abrasive products are safe for their intended applications, providing comprehensive usage instructions, and having robust processes to manage any product defect claims or customer injuries. For instance, in the European Union, the General Product Safety Regulation (GPSR) sets out stringent requirements for product safety, and non-compliance can result in recalls and substantial penalties.

Failure to adhere to these legal mandates can have severe financial and reputational consequences. Companies like Sia Abrasives can face significant legal fees, substantial fines, and costly product recalls. For example, in 2023, several companies across various industries faced multi-million dollar settlements due to product liability claims, highlighting the critical importance of proactive safety management and regulatory compliance in the abrasives sector.

Intellectual property, particularly patents for its innovative abrasive technologies and manufacturing methods, forms a cornerstone of Sia Abrasives' competitive advantage. Protecting these assets is paramount to maintaining its market position.

The company must actively monitor for and defend against any patent infringements by rivals, while also ensuring its own product portfolio respects existing patents. This necessitates a proactive and rigorous legal approach to safeguard its innovations.

Environmental protection laws are becoming more demanding for companies like Sia Abrasives, covering everything from how they handle waste and control air emissions to their use of chemicals and energy. For instance, the European Union's directives, like the Industrial Emissions Directive, set strict limits on pollutants, requiring significant investment in abatement technologies and ongoing monitoring.

Sia Abrasives needs to ensure compliance across all its operating regions, as regulations differ. This can mean obtaining specific permits for manufacturing processes and potentially upgrading equipment to meet standards for, say, volatile organic compound (VOC) emissions. Failure to comply can lead to substantial financial penalties, impacting profitability.

Labor Laws and Employment Regulations

Sia Abrasives, like any global employer, navigates a dense web of labor laws. These regulations dictate everything from minimum wages and working hours to employee rights and the processes for collective bargaining across its operational regions. For instance, in Germany, where Sia Abrasives has a significant presence, the Works Constitution Act (Betriebsverfassungsgesetz) grants employees substantial co-determination rights, impacting decisions on working conditions and social matters.

Adherence to these labor statutes is not merely a legal obligation but a strategic imperative. Non-compliance can lead to costly litigation, hefty fines, and significant reputational damage, disrupting operations and straining employee relations. Ensuring a safe working environment, a key component of labor law, is paramount. In 2024, workplace safety remains a critical focus, with regulatory bodies worldwide emphasizing proactive risk management and accident prevention. For example, the EU's framework directive on safety and health at work sets high standards that companies like Sia Abrasives must meet.

Key aspects of labor law compliance for Sia Abrasives include:

- Wage and Hour Laws: Ensuring all employees are paid at least the statutory minimum wage and that overtime is compensated correctly according to local regulations.

- Health and Safety Regulations: Implementing robust safety protocols and providing a secure working environment to prevent accidents and occupational illnesses, aligning with standards such as those set by OSHA in the US or equivalent bodies in Europe.

- Employee Rights and Protections: Upholding rights related to fair dismissal, anti-discrimination, and data privacy, as mandated by laws like the GDPR in Europe.

- Collective Bargaining Agreements: Engaging with trade unions and employee representatives where applicable to negotiate terms and conditions of employment, fostering a collaborative industrial relations climate.

International Trade Laws and Compliance

Adherence to international trade laws, including customs regulations, import/export controls, and anti-dumping measures, is vital for Sia Abrasives' global supply chain and distribution. The company must navigate complex legal frameworks to ensure smooth cross-border movement of goods and avoid penalties or delays, especially given the global nature of abrasive material sourcing and product sales.

Navigating these regulations is critical; for instance, the World Trade Organization (WTO) reported that in 2023, over 3,000 trade restrictions were imposed globally, impacting various sectors including manufacturing inputs. Sia Abrasives must stay updated on these evolving trade policies to maintain operational efficiency.

- Customs Compliance: Ensuring all import and export documentation is accurate to avoid tariffs and delays.

- Trade Sanctions: Monitoring and adhering to international sanctions, such as those affecting trade with specific countries, to prevent legal repercussions.

- Anti-Dumping Duties: Understanding and complying with measures designed to prevent the unfair pricing of imported goods, which could affect raw material costs or finished product competitiveness.

- Regulatory Updates: Proactively tracking changes in international trade laws and agreements that could impact supply chain logistics and market access.

Sia Abrasives must meticulously adhere to consumer protection laws, ensuring product safety, accurate labeling, and fair advertising across all markets. This includes managing warranties and handling customer complaints effectively. For example, the EU's Consumer Rights Directive harmonizes certain consumer rights related to contracts, aiming to boost cross-border sales and consumer confidence.

Compliance with competition laws is also crucial, preventing anti-competitive practices like price-fixing or abuse of dominant market positions. This ensures a level playing field and fosters fair market competition, which is vital for long-term business sustainability. In 2024, regulatory bodies continue to scrutinize mergers and acquisitions to prevent market concentration that could harm consumers.

The company's operations are significantly shaped by contractual agreements, from supplier relationships to customer sales. Ensuring these contracts are legally sound and enforceable is paramount. Sia Abrasives must also navigate dispute resolution mechanisms, whether through negotiation, mediation, or litigation, to manage any breaches or disagreements effectively.

Environmental factors

The availability and sustainable sourcing of essential minerals like aluminum oxide and silicon carbide, crucial for abrasive grain production, present a growing environmental challenge. For instance, the global demand for aluminum oxide, a primary component in many abrasives, is projected to grow, potentially straining existing supply chains.

Sia Abrasives must proactively assess its supply chain for environmental risks associated with resource extraction and transportation. Exploring opportunities to integrate recycled materials or adopt more sustainably sourced inputs is vital for long-term operational viability and to mitigate potential price volatility of virgin raw materials.

The intensifying global emphasis on waste reduction and recycling directly influences Sia Abrasives' operational strategies. This includes how the company handles manufacturing byproducts and how its abrasive products are managed once they reach their end-of-life, impacting resource utilization and environmental footprint.

Stricter environmental regulations concerning industrial waste, coupled with the growing adoption of circular economy principles, are compelling Sia Abrasives to develop more innovative waste management techniques. Furthermore, there's a heightened need to explore product recyclability, aligning with sustainability goals and potential cost savings in material sourcing.

Manufacturing abrasives is inherently energy-intensive, directly impacting Sia Abrasives' carbon footprint. For instance, the production of synthetic abrasives often involves high-temperature processes like fusion in electric arc furnaces, which are significant energy consumers.

The global push to decarbonize, exemplified by the Paris Agreement's goals, intensifies pressure on companies like Sia Abrasives to reduce greenhouse gas emissions. This will likely necessitate investments in energy-efficient machinery and a potential shift towards renewable energy sources, impacting operational expenditures and capital allocation strategies through 2025.

Stakeholders, including investors and customers, are increasingly scrutinizing corporate environmental performance. By the end of 2024, many industrial companies are expected to report on their Scope 1 and Scope 2 emissions, with a growing emphasis on Scope 3. Sia Abrasives will face greater demands for transparency regarding its carbon footprint and concrete actions to mitigate it.

Water Usage and Pollution Control

Water is a critical resource for many manufacturing operations, including those at Sia Abrasives. Its use in processes like cooling or cleaning, coupled with the potential for wastewater generation, makes water management a key environmental concern. For instance, the global manufacturing sector's water footprint is substantial, with some industries consuming billions of gallons annually.

To address this, Sia Abrasives is expected to focus on water-efficient technologies and robust wastewater treatment. These measures are essential not only for meeting increasingly strict environmental regulations, such as those concerning effluent discharge limits, but also for showcasing a commitment to sustainability. Companies that proactively manage water can reduce operational costs associated with water procurement and treatment, while also bolstering their brand image among environmentally conscious stakeholders.

In 2024, water scarcity is a growing global issue, impacting industries worldwide. For example, the World Bank reported in 2023 that by 2050, over 5 billion people could face water shortages. This underscores the importance of efficient water use for long-term business resilience.

- Water Efficiency: Implementing closed-loop systems and optimizing cleaning processes to minimize freshwater intake.

- Wastewater Treatment: Employing advanced filtration and treatment technologies to ensure discharged water meets or exceeds regulatory standards.

- Regulatory Compliance: Adhering to national and international environmental laws governing water usage and pollution.

- Resource Stewardship: Demonstrating a commitment to responsible water management as part of corporate social responsibility.

Demand for Eco-Friendly and Sustainable Products

Consumer and industrial demand for environmentally friendly products is a significant environmental factor. Sia Abrasives can leverage this trend by innovating in areas like reduced volatile organic compound (VOC) emissions, extended product lifespans, and the use of sustainable raw materials in its abrasive solutions. For instance, a 2024 report indicated that over 60% of consumers consider sustainability when making purchasing decisions, a figure expected to rise.

This growing preference for eco-conscious goods presents Sia Abrasives with a clear opportunity to differentiate itself. By developing and marketing abrasive products that meet these evolving environmental standards, the company can secure a competitive edge. This strategic alignment with market demands and increasing regulatory focus on sustainability is crucial for long-term growth and market positioning.

Key areas for Sia Abrasives to focus on include:

- Development of low-VOC abrasive products: Meeting stricter air quality regulations and consumer health concerns.

- Extended product lifespan: Reducing waste and the frequency of replacement, appealing to cost-conscious and environmentally aware customers.

- Use of sustainable materials: Incorporating recycled content or bio-based components into abrasive manufacturing.

- Energy-efficient production processes: Minimizing the carbon footprint of their manufacturing operations.

The sourcing of raw materials like aluminum oxide and silicon carbide poses environmental challenges due to increasing global demand. Sia Abrasives must focus on sustainable sourcing and potentially incorporating recycled materials to mitigate supply chain risks and price volatility.

Energy-intensive production processes, such as those using electric arc furnaces, contribute significantly to Sia Abrasives' carbon footprint. The global drive towards decarbonization by 2025 will necessitate investments in energy efficiency and renewable energy sources.

Water scarcity is a growing concern, with projections suggesting widespread shortages by 2050. Sia Abrasives needs to implement water-efficient technologies and robust wastewater treatment to ensure regulatory compliance and operational resilience.

Growing consumer and industrial demand for eco-friendly products presents an opportunity for Sia Abrasives to innovate. Developing low-VOC, longer-lasting, and sustainably sourced abrasives can provide a competitive advantage, aligning with market trends and regulatory pressures.

PESTLE Analysis Data Sources

Our PESTLE analysis for Sia Abrasives Holding AG is informed by data from reputable sources including global economic databases, environmental policy updates, and industry-specific market research. We also incorporate insights from government reports and technological trend forecasts to ensure a comprehensive view.