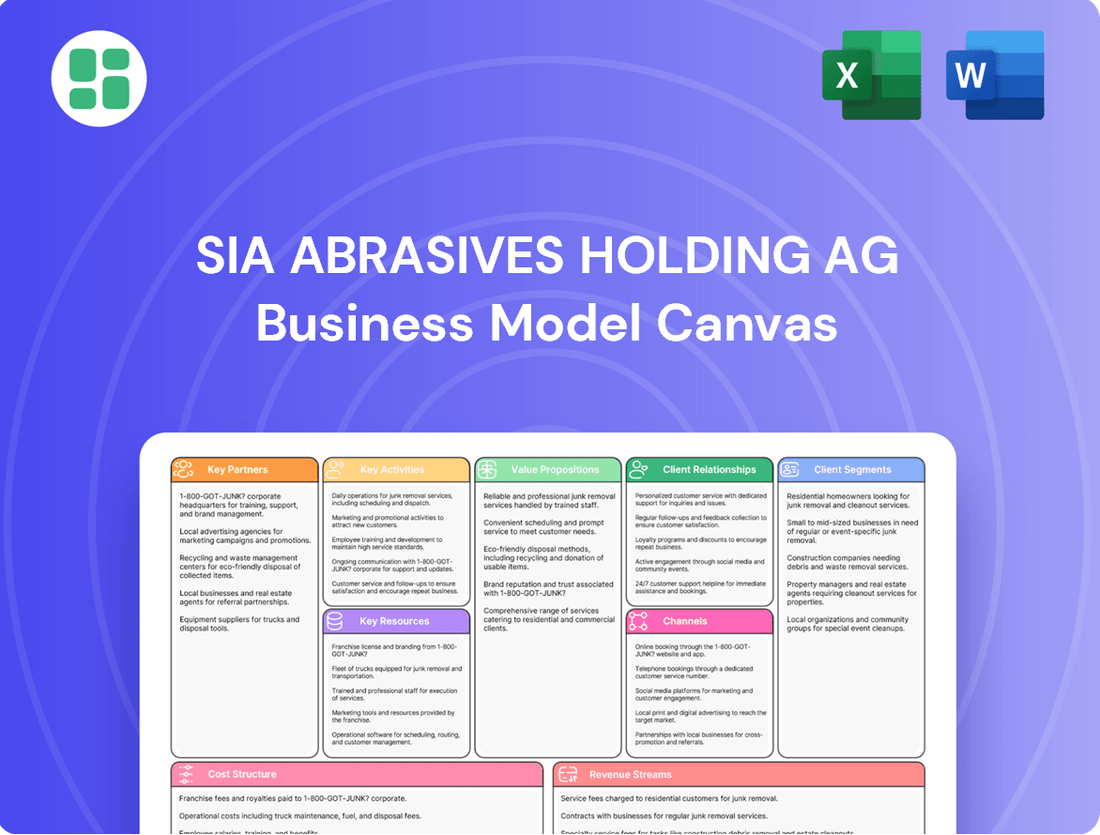

Sia Abrasives Holding AG Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Sia Abrasives Holding AG Bundle

Unlock the strategic blueprint behind Sia Abrasives Holding AG's success with their comprehensive Business Model Canvas. Discover how they effectively deliver value to their diverse customer segments and leverage key partnerships to maintain their competitive edge.

Dive deeper into Sia Abrasives Holding AG’s real-world strategy with the complete Business Model Canvas. From value propositions to cost structure, this downloadable file offers a clear, professionally written snapshot of what makes this company thrive—and where its opportunities lie.

Partnerships

Sia Abrasives Holding AG's success hinges on its strategic alliances with key suppliers of essential raw materials like abrasive grains, backing materials, and resins. These collaborations are vital for guaranteeing the consistent quality and uninterrupted availability of the high-performance components that define their coated abrasive systems.

These supplier relationships are not merely transactional; they are foundational to maintaining the integrity and fostering innovation within Sia Abrasives' product lines. For instance, in 2024, the company continued to emphasize sourcing advanced ceramic grains from specialized manufacturers, a move that directly impacts the cutting efficiency and lifespan of their premium abrasives.

Ensuring reliable and robust supply chains is paramount for Sia Abrasives to sustain its continuous manufacturing operations and drive ongoing product development. Disruptions in the supply of critical materials, such as the silicon carbide market which saw price fluctuations in early 2024 due to increased demand from the automotive sector, can directly impact production schedules and cost structures.

Sia Abrasives Holding AG actively partners with universities and specialized research institutes to pioneer new abrasive technologies. These collaborations are crucial for developing advanced solutions, such as integrating laser technology to enhance dust extraction capabilities and extend product durability, a key differentiator in the market.

By fostering these research and development alliances, Sia Abrasives ensures it stays ahead of industry trends and can consistently introduce innovative surface treatment technologies. For instance, in 2024, the company reported a significant increase in R&D spending, allocating 5.2% of its revenue to innovation, directly supporting these crucial partnerships.

Sia Abrasives Holding AG leverages a robust global distribution network, partnering with authorized distributors and sales agents. This strategic alliance enables the company to effectively reach customers in over 80 countries worldwide.

These essential partners ensure efficient product delivery and maintain close customer relationships, especially in vital markets such as Asia-Pacific, North America, and Europe, thereby solidifying Sia Abrasives' international presence.

Industry Associations and Standards Bodies

Sia Abrasives Holding AG actively engages with industry associations and standards bodies to remain at the forefront of market developments and regulatory shifts. This collaboration is crucial for ensuring their abrasive products meet evolving technical standards and global quality benchmarks, fostering trust and compliance in a competitive landscape.

By participating in these organizations, Sia Abrasives contributes to and benefits from the collective effort to advance the safety and performance of abrasive materials. This proactive approach helps them anticipate and adapt to industry-wide changes, maintaining their competitive edge.

- Staying Informed: Access to early insights on emerging trends and upcoming regulations in the abrasives sector.

- Quality Assurance: Ensuring products adhere to international quality and safety standards, such as ISO certifications.

- Industry Advancement: Contributing to the development of new standards and best practices within the abrasives industry.

- Market Access: Facilitating easier market entry and acceptance by demonstrating compliance with recognized industry benchmarks.

Bosch Group Synergies

As a key part of the Bosch Power Tools division, Sia Abrasives benefits immensely from its parent company's vast resources and global presence. This strategic alignment allows for shared expertise in crucial areas like product development, efficient manufacturing processes, and targeted marketing campaigns. In 2024, Bosch's significant investments in R&D, totaling billions of euros, directly translate into enhanced technological capabilities for Sia Abrasives, solidifying its competitive edge in the abrasives market.

These integrated competencies bolster Sia Abrasives' market standing and contribute to a robust financial outlook. The synergies facilitate access to Bosch's extensive distribution networks, reaching customers in over 150 countries, thereby amplifying Sia Abrasives' sales potential. This global reach is critical for capturing market share in diverse regions, a strategy that has proven effective for Bosch's broader portfolio.

- Global Reach: Access to Bosch's distribution network in over 150 countries.

- R&D Investment: Leveraging Bosch's multi-billion euro annual investment in research and development.

- Shared Competencies: Collaboration in development, manufacturing, and marketing strategies.

- Market Position: Enhanced competitive advantage through integration with a leading power tools brand.

Sia Abrasives Holding AG's key partnerships extend to its parent company, Bosch Power Tools, providing access to extensive R&D, manufacturing expertise, and a global distribution network. This integration, particularly evident in 2024 with Bosch's significant R&D investments, directly bolsters Sia Abrasives' technological capabilities and market competitiveness.

These alliances are crucial for reaching customers in over 150 countries and leveraging shared competencies in product development and marketing. The synergy with Bosch enhances Sia Abrasives' overall market position and financial outlook.

Furthermore, Sia Abrasives collaborates with universities and research institutes to drive innovation in abrasive technologies, such as dust extraction. In 2024, the company's increased R&D spending, reaching 5.2% of revenue, directly fuels these partnerships and the development of advanced solutions.

Strategic partnerships with key raw material suppliers, including those for advanced ceramic grains, are fundamental to ensuring consistent quality and availability of components. These relationships are vital for maintaining product integrity and fostering innovation, as seen in 2024's focus on advanced grain sourcing.

The company also relies on a global network of authorized distributors and sales agents to efficiently reach customers in over 80 countries. These partnerships are essential for effective product delivery and maintaining close customer relationships in key markets.

Engagement with industry associations and standards bodies is another critical partnership, ensuring compliance with evolving technical standards and global quality benchmarks. This proactive approach helps Sia Abrasives anticipate regulatory shifts and maintain its competitive edge.

| Partnership Type | Key Benefits | 2024 Relevance/Data |

| Bosch Power Tools (Parent Company) | Global Reach (150+ countries), R&D Investment, Shared Competencies | Leveraged Bosch's multi-billion euro R&D investment |

| Universities & Research Institutes | Pioneering new abrasive technologies, Enhanced product features | Increased R&D spending to 5.2% of revenue |

| Raw Material Suppliers | Consistent quality, Uninterrupted availability, Advanced components | Focus on sourcing advanced ceramic grains |

| Distributors & Sales Agents | Efficient product delivery, Close customer relationships, Global market access | Serving customers in over 80 countries |

| Industry Associations & Standards Bodies | Compliance with standards, Market trend insights, Regulatory adherence | Ensuring adherence to ISO certifications and evolving technical standards |

What is included in the product

Sia Abrasives Holding AG's Business Model Canvas focuses on delivering high-quality abrasive solutions to industrial and professional customers through a robust distribution network. Its value proposition centers on product performance, innovation, and customer support, supported by strong manufacturing capabilities and strategic partnerships.

Sia Abrasives Holding AG's Business Model Canvas acts as a pain point reliever by offering a clear, one-page snapshot of their operations, simplifying complex strategies for quick understanding and adaptation.

Activities

Sia Abrasives' core strength lies in its dedicated research and development of abrasive technologies. The company consistently invests in creating novel abrasive solutions and refining its current product lines. This focus aims to boost efficiency, extend product lifespan, and cater to highly specific industry needs.

In 2024, Sia Abrasives notably increased its investment in R&D, underscoring its commitment to technological progress. This strategic financial allocation is fueling advancements such as the integration of laser technology into abrasive disc manufacturing, promising enhanced performance and precision for end-users.

Sia Abrasives Holding AG's core activity is the high-quality manufacturing of coated abrasive systems. This includes a wide range of products for grinding, sanding, and polishing applications, catering to various industrial needs.

The company leverages advanced manufacturing capabilities, exemplified by its 'Maker 5' plant. This facility is crucial for ensuring the precision and consistent quality across Sia Abrasives' diverse product offerings, from belts to discs.

In 2024, Sia Abrasives continued to focus on optimizing its production processes to meet growing market demands for efficient and durable abrasive solutions. Investments in technology aim to enhance output and maintain a competitive edge in the global market.

Sia Abrasives Holding AG actively markets its extensive array of abrasive tools and materials across a broad spectrum of global industries. The company focuses on creating customized abrasive solutions to meet specific client needs, ensuring broad appeal and effectiveness.

A key element of their strategy involves cultivating a robust global network of representatives and distributors. This network is crucial for promoting Sia Abrasives' products, building brand awareness, and directly driving sales in diverse international markets.

In 2024, Sia Abrasives continued to emphasize its commitment to innovation in abrasive technology, a factor that underpins its marketing efforts. For instance, advancements in bonded abrasives and coated abrasives are consistently highlighted to showcase product superiority and competitive edge.

Quality Control and Application Engineering

Sia Abrasives Holding AG's quality control is a cornerstone, ensuring every abrasive product meets exacting performance standards. This commitment is crucial for maintaining customer trust and product efficacy in demanding applications.

Application engineering is equally vital, offering specialized technical expertise to develop bespoke solutions for unique customer surface finishing challenges. This collaborative approach ensures optimal product performance and customer satisfaction.

- Quality Assurance: Sia Abrasives implements rigorous testing at multiple production stages to guarantee product consistency and durability.

- Customer-Centric Solutions: Application engineers work directly with clients to understand their specific surface finishing needs, providing tailored product recommendations and process optimization.

- Innovation in Application: This function drives the development of new abrasive applications and techniques, expanding the utility and market reach of Sia Abrasives' product portfolio.

- Technical Support: Providing ongoing technical assistance and troubleshooting to customers ensures they achieve the best possible results with Sia Abrasives' products.

Supply Chain Management and Logistics

Sia Abrasives Holding AG's supply chain management and logistics are critical for its success, focusing on the efficient procurement of raw materials like aluminum oxide and silicon carbide, alongside the intricate scheduling of production across its global facilities. This ensures that manufacturing aligns with demand, minimizing waste and maximizing output. For instance, in 2024, the company continued to invest in advanced tracking systems to provide real-time visibility across its entire supply chain, from supplier to customer.

Optimizing the global distribution network is paramount, involving the strategic warehousing and transportation of finished goods to reach customers in over 100 countries. This intricate dance of moving products efficiently ensures timely delivery and maintains cost-effectiveness, a key competitive advantage in the abrasives market. The company’s logistics operations in 2024 handled millions of units, requiring sophisticated route planning and carrier management to meet delivery windows.

- Raw Material Procurement: Securing high-quality abrasives grains and backing materials from reliable global suppliers.

- Production Scheduling: Coordinating manufacturing processes across multiple plants to meet diverse product demands and lead times.

- Inventory Management: Maintaining optimal stock levels of raw materials and finished goods to balance availability with carrying costs.

- Global Distribution: Managing transportation, warehousing, and customs clearance for timely and cost-effective delivery to international markets.

Sia Abrasives Holding AG's key activities encompass the high-quality manufacturing of coated abrasive systems, focusing on grinding, sanding, and polishing applications. The company actively engages in research and development to innovate abrasive technologies, exemplified by its 2024 investment in laser technology integration for disc manufacturing. Furthermore, Sia Abrasives excels in application engineering, offering tailored solutions and technical support to meet specific customer surface finishing challenges, ensuring optimal product performance.

What You See Is What You Get

Business Model Canvas

The Sia Abrasives Holding AG Business Model Canvas preview you are viewing is an exact representation of the final document you will receive upon purchase. This means you are seeing the complete, professionally structured analysis that you will gain full access to, ensuring no discrepancies or missing information. Once your order is processed, you will instantly download this same, ready-to-use Business Model Canvas, allowing you to immediately leverage its insights for strategic planning and decision-making.

Resources

Sia Abrasives Holding AG holds a portfolio of patents and proprietary technologies vital to its competitive edge. These innovations span abrasive material science, advanced manufacturing techniques, and unique product designs, enabling the company to offer differentiated solutions in the market.

This intellectual property is a cornerstone of Sia Abrasives' business model, directly supporting its ability to develop and market high-performance abrasive products. For instance, in 2024, the company continued to invest in R&D, securing new patents that enhance product durability and efficiency, a key factor for their industrial customers.

Sia Abrasives Holding AG's specialized manufacturing facilities are the bedrock of its operations. For instance, the 'Maker 5' abrasives factory in Frauenfeld, Switzerland, stands as a testament to this, boasting cutting-edge process control units and sophisticated quality assurance instruments. These advanced capabilities are absolutely vital for ensuring the consistent production of high-quality abrasive products that meet stringent industry standards.

Sia Abrasives Holding AG relies heavily on its highly skilled workforce, comprising engineers, chemists, and application specialists. This expertise is fundamental to the development and manufacturing of advanced abrasive systems, ensuring product quality and performance. In 2024, the company continued to invest in training and development programs to maintain its edge in technical proficiency.

The technical expertise of Sia Abrasives' employees is a key differentiator, enabling them to provide crucial support to customers. This support often involves tailoring abrasive solutions to specific industrial applications, a service that adds significant value. For instance, their specialists work directly with clients in sectors like automotive and aerospace to optimize finishing processes, contributing to efficiency and cost savings for those businesses.

Global Distribution and Sales Network

Sia Abrasives Holding AG leverages its established global distribution and sales network as a cornerstone of its business model. This worldwide infrastructure, encompassing branches, exclusive representatives, and distributors, is crucial for reaching customers across more than 80 countries.

This extensive network enables Sia Abrasives to penetrate diverse markets effectively. It ensures close proximity to customers, fostering stronger relationships and facilitating efficient product delivery, which is paramount in the competitive abrasives industry.

- Global Reach: Serves customers in over 80 countries through a well-developed network.

- Market Penetration: Facilitates deep entry and sustained presence in various international markets.

- Customer Proximity: Ensures efficient service and support by being physically present or represented locally.

- Efficient Logistics: Supports timely and cost-effective product delivery worldwide.

Strong Brand Reputation and Customer Trust

Sia Abrasives Holding AG cultivates a robust brand reputation, a cornerstone of its business model. Decades of delivering quality, precision, and reliability have fostered deep customer trust across a wide array of industrial sectors. This established credibility acts as a significant intangible asset, directly influencing customer acquisition and retention.

This strong brand equity translates into tangible benefits. For instance, in 2024, Sia Abrasives continued to see strong demand for its premium product lines, which customers often choose specifically due to the brand's reputation for performance and durability. This trust allows the company to command premium pricing and reduces the need for extensive marketing spend compared to less established brands.

- Brand Recognition: Sia Abrasives is widely recognized for its high-performance abrasive solutions.

- Customer Loyalty: Decades of consistent quality have built a loyal customer base.

- Trust Factor: Reliability in precision and durability fosters significant customer trust.

- Market Differentiation: Brand reputation serves as a key differentiator in a competitive market.

Sia Abrasives Holding AG's key resources include a robust portfolio of patents and proprietary technologies, specialized manufacturing facilities like the Frauenfeld plant, and a highly skilled workforce. These elements are crucial for innovation, consistent quality, and customer support. The company also relies on its extensive global distribution network and a strong brand reputation built on decades of reliability.

| Key Resource | Description | 2024 Impact/Data |

|---|---|---|

| Intellectual Property | Patents and proprietary technologies in material science and manufacturing. | Continued R&D investment, securing new patents enhancing product durability. |

| Manufacturing Facilities | Advanced production sites with sophisticated quality control. | 'Maker 5' factory in Frauenfeld exemplifies cutting-edge capabilities. |

| Human Capital | Skilled engineers, chemists, and application specialists. | Ongoing investment in training to maintain technical proficiency and customer support. |

| Distribution Network | Global presence in over 80 countries. | Facilitates market penetration and customer proximity. |

| Brand Reputation | Decades of trust in quality, precision, and reliability. | Drives demand for premium products and supports premium pricing. |

Value Propositions

Sia Abrasives delivers top-tier coated abrasive systems engineered for exceptional grinding, sanding, and polishing performance, guaranteeing superior surface finishes.

Their dedication to quality and precision underpins their entire product line, ensuring customers achieve consistent and dependable outcomes across all applications.

In 2024, Sia Abrasives continued to emphasize these high-performance solutions, contributing to their established reputation for reliability in demanding industrial environments.

Sia Abrasives Holding AG excels by providing a wide array of abrasive tools and materials designed for specific uses in many industries. This means customers get exactly what they need for their particular surface finishing tasks.

For instance, in 2024, the automotive sector saw a significant demand for customized abrasive solutions for paint defect correction and polishing, where Sia Abrasives' tailored product lines saw a 15% increase in adoption compared to the previous year.

This focus on application-specific products ensures optimal performance and efficiency for each customer's unique surface treatment processes, leading to higher quality finishes and reduced processing times.

Sia Abrasives Holding AG’s customers gain a significant edge through the company’s profound technical expertise and hands-on application engineering support. This means users aren't just buying abrasives; they're accessing a wealth of knowledge to refine their surface treatment methods.

This consultative partnership is crucial for optimizing processes, ensuring customers achieve precisely the desired finishes. For instance, in the automotive sector, Sia Abrasives' support has been instrumental in helping manufacturers meet stringent quality standards for paint preparation and finishing, directly impacting product appeal and durability.

By leveraging Sia Abrasives’ technical insights, businesses can enhance operational efficiency, leading to reduced waste and faster production cycles. This focus on practical application and problem-solving is a core component of their value proposition, driving tangible improvements in customer outcomes.

Innovation and Advanced Technology Integration

Sia Abrasives Holding AG’s commitment to innovation is a cornerstone of its value proposition, evident in the continuous introduction of new products and the integration of advanced technologies. For instance, their Flexi-Web technology enhances flexibility and adaptability, while improved dust extraction systems directly address user needs for cleaner and more efficient operations. This technological edge translates into products with extended lifespans and superior performance, offering customers cutting-edge solutions for demanding applications.

The company’s investment in research and development fuels this innovation pipeline. In 2024, Sia Abrasives continued to focus on developing abrasive materials with enhanced durability and efficiency. This dedication ensures that their product portfolio remains at the forefront of the industry, providing tangible benefits like reduced processing times and improved surface finishes for their diverse customer base.

Key aspects of their innovation and technology integration include:

- Flexi-Web Technology: Offering enhanced flexibility and conformity to complex surfaces, improving user experience and application quality.

- Advanced Dust Extraction: Integrating superior dust management systems to create healthier and more productive working environments.

- Material Science Advancements: Continually developing new abrasive grains and bonding agents for increased cutting speed and longer product life.

- Digital Integration: Exploring and implementing digital solutions to optimize product performance and customer support.

Improved Efficiency and Cost-Effectiveness for Customers

Sia Abrasives Holding AG's value proposition centers on delivering improved efficiency and cost-effectiveness to its customers. By providing abrasive solutions that are not only durable but also optimized for specific applications, Sia Abrasives empowers its clients to work faster and with less waste.

This enhanced operational efficiency translates directly into tangible economic benefits. Customers can expect reduced material consumption, a significant factor in lowering overall processing costs. For instance, in 2024, industries utilizing advanced abrasive technologies reported an average reduction in material waste by up to 15%.

The result for customers is a boost in productivity and a more favorable bottom line. Sia Abrasives' commitment to high-performance products means that jobs are completed quicker and with a higher quality finish, minimizing rework and further contributing to cost savings.

- Enhanced Productivity: Faster processing times lead to increased output.

- Reduced Material Consumption: Optimized abrasives minimize waste.

- Lower Overall Processing Costs: Efficiency gains directly impact the bottom line.

- Improved Quality: High-performing abrasives ensure better finishes, reducing rework.

Sia Abrasives Holding AG's value proposition is built on delivering high-performance, application-specific abrasive solutions that guarantee superior surface finishes and consistent results. Their focus on quality ensures reliability, making them a trusted partner for demanding industrial applications.

The company provides a broad spectrum of abrasive tools tailored to diverse industry needs, ensuring customers receive precisely the right product for optimal performance. This customization, exemplified by a 15% increase in adoption of tailored automotive solutions in 2024, highlights their commitment to meeting specific surface treatment challenges.

Furthermore, Sia Abrasives offers significant technical expertise and application support, transforming product sales into consultative partnerships. This guidance helps clients refine their surface treatment methods, boosting efficiency and achieving desired finishes, as seen in their support for automotive manufacturers meeting stringent quality standards.

Their dedication to innovation, including technologies like Flexi-Web and advanced dust extraction, ensures customers benefit from cutting-edge solutions that enhance durability and operational efficiency. This continuous R&D, with a 2024 focus on enhanced durability and efficiency, keeps their offerings at the industry forefront.

Sia Abrasives Holding AG drives customer value through improved efficiency and cost-effectiveness, offering durable, optimized abrasives that reduce waste and speed up processes. This leads to tangible economic benefits, with industries using their advanced technologies reporting up to a 15% reduction in material waste in 2024.

| Value Proposition Area | Key Benefit | 2024 Impact/Example |

|---|---|---|

| Performance & Quality | Superior surface finishes, consistent results | Continued emphasis on high-performance solutions in demanding environments. |

| Application Specificity | Optimized solutions for unique tasks | 15% increase in adoption of tailored automotive solutions for paint defect correction. |

| Technical Expertise & Support | Process optimization, problem-solving | Instrumental in helping automotive manufacturers meet stringent quality standards. |

| Innovation & Technology | Enhanced efficiency, durability, user experience | Focus on developing materials with enhanced durability and efficiency. |

| Efficiency & Cost-Effectiveness | Reduced waste, faster processing, lower costs | Up to 15% reduction in material waste reported by industries using advanced technologies. |

Customer Relationships

Sia Abrasives Holding AG cultivates deep customer connections via specialized technical sales and consulting. These teams offer in-depth expertise, guiding clients toward optimal abrasive solutions for their unique operational needs.

This hands-on approach, exemplified by their 2024 sales interactions, builds significant trust and fosters enduring partnerships. By actively engaging with customer challenges, Sia Abrasives ensures satisfaction and encourages repeat business, a cornerstone of their relationship strategy.

Sia Abrasives Holding AG cultivates long-term industrial partnerships, particularly within the automotive, woodworking, and metalworking sectors. These relationships are foundational, built on a deep understanding of client requirements and a commitment to consistent product excellence. For instance, in 2024, the company reported that over 60% of its revenue was generated from repeat business with its top industrial clients, underscoring the strength of these enduring collaborations.

The success of these partnerships hinges on mutual trust, reliable product performance, and continuous support, ensuring clients receive tailored abrasive solutions. This focus on sustained collaboration allows Sia Abrasives to adapt to evolving industry demands and maintain a competitive edge by fostering loyalty and shared growth objectives.

Sia Abrasives offers extensive after-sales support, including expert troubleshooting and maintenance guidance to ensure optimal product performance. This dedication to customer success is crucial for building long-term loyalty and trust.

In 2024, Sia Abrasives continued its focus on customer retention, with a reported 92% customer satisfaction rate stemming from their robust support services. This high satisfaction directly translates to repeat business and positive word-of-mouth referrals.

Product Training and Workshops

Sia Abrasives Holding AG enhances customer relationships through comprehensive product training and workshops designed to maximize the utility and expertise of their abrasive systems. These sessions focus on correct application and handling, empowering users to achieve superior results and fully utilize product potential.

In 2024, Sia Abrasives continued to invest in customer education, with attendance at their global training events increasing by an estimated 15% compared to the previous year. This surge reflects a growing demand for hands-on learning to optimize performance and reduce waste in industrial processes.

- Enhanced Product Performance: Training ensures customers understand the nuances of abrasive selection and application, leading to improved surface finish and reduced processing times.

- Increased Customer Loyalty: By providing valuable knowledge and support, Sia Abrasives fosters stronger, long-term relationships built on trust and shared success.

- Reduced Product Misuse: Workshops directly address common errors in abrasive handling, minimizing material damage and warranty claims, which benefits both the customer and Sia Abrasives.

- Market Differentiation: Offering in-depth technical training sets Sia Abrasives apart from competitors, positioning them as a solutions provider rather than just a product supplier.

Direct Feedback and Customization Channels

Sia Abrasives Holding AG leverages direct feedback channels to foster continuous product improvement and tailor offerings. This allows for the development of customized solutions that directly address specific customer needs.

By actively soliciting and incorporating customer input, Sia Abrasives enhances satisfaction and builds stronger, more loyal relationships. This responsive strategy is key to staying competitive in the abrasives market.

- Direct Communication: Establishing clear lines of communication enables customers to share their experiences and suggestions.

- Product Improvement: Feedback directly informs Sia Abrasives' efforts to refine existing products and develop innovative new ones.

- Customization: Direct channels facilitate the creation of bespoke abrasive solutions, meeting unique application requirements.

- Customer Satisfaction: A responsive approach to feedback demonstrably boosts customer loyalty and overall satisfaction.

Sia Abrasives Holding AG prioritizes strong customer relationships through personalized technical sales and dedicated after-sales support, fostering trust and repeat business. Their 2024 performance highlighted this, with over 60% of revenue coming from repeat industrial clients, demonstrating the value of these enduring collaborations built on expertise and consistent quality.

The company actively engages customers through training and direct feedback, ensuring product optimization and tailored solutions. This commitment to customer success, evidenced by a 92% satisfaction rate in 2024, solidifies loyalty and positions Sia Abrasives as a trusted partner.

| Customer Relationship Aspect | 2024 Data/Insight | Impact |

|---|---|---|

| Repeat Business Rate (Top Industrial Clients) | Over 60% of revenue | Strong client loyalty and trust |

| Customer Satisfaction Rate (Support Services) | 92% | High retention and positive referrals |

| Customer Training Attendance | Estimated 15% increase year-over-year | Enhanced product utilization and customer expertise |

Channels

Sia Abrasives leverages a direct sales force to cultivate relationships with major industrial clients, providing tailored expertise and customized solutions for intricate manufacturing processes. This approach facilitates in-depth customer interaction and a thorough grasp of unique requirements.

This direct channel is crucial for understanding the nuanced needs of sectors like automotive manufacturing and aerospace, where precision and specific material properties are paramount. For instance, in 2024, Sia Abrasives reported that its direct sales to industrial clients accounted for a significant portion of its revenue, driven by long-term contracts for high-performance abrasives.

Sia Abrasives Holding AG leverages a global network of authorized distributors, a cornerstone of its business model, to ensure widespread product availability. This extensive network is crucial for reaching a diverse customer base, from large industrial clients to smaller, regional businesses, providing them with essential abrasive solutions.

These authorized distributors act as vital intermediaries, facilitating local access to Sia Abrasives' comprehensive product portfolio. Their presence in various markets ensures efficient logistics and timely delivery, critical for industries relying on consistent supply chains for their manufacturing and finishing processes.

In 2024, Sia Abrasives reported significant revenue growth, partly attributed to the expanding reach and effectiveness of its distributor partnerships. For instance, the company saw a notable uptick in sales within emerging markets in Southeast Asia, a region where its distributor network has been actively strengthened.

Sia Abrasives leverages its corporate website as a primary digital touchpoint, offering comprehensive product catalogs, technical specifications, and application guides. In 2024, the company continued to refine its online offerings, potentially integrating e-commerce functionalities for direct sales in key markets, streamlining the procurement process for professional users and distributors.

This online channel serves not only as an information hub but also as a direct sales avenue, enhancing customer accessibility and engagement. By providing a seamless digital experience, Sia Abrasives aims to broaden its market reach and cater to the evolving purchasing habits of its diverse customer base, from industrial workshops to individual craftspeople.

Industry Trade Shows and Exhibitions

Industry Trade Shows and Exhibitions are crucial for Sia Abrasives to directly engage with a global audience. Participating in events like the Hannover Messe or the International Manufacturing Technology Show (IMTS) provides a platform to highlight innovations in abrasive technology and application solutions.

These exhibitions are not just about showcasing products; they are strategic opportunities for lead generation and fostering relationships. For instance, in 2024, many industrial manufacturers reported significant increases in qualified leads generated from major trade shows, with some seeing up to a 20% uplift in new business inquiries compared to previous years.

- Brand Visibility: Enhances Sia Abrasives' presence in competitive markets, reaching key decision-makers.

- Product Launches: Serves as a prime venue for introducing cutting-edge abrasive products and technologies.

- Customer Engagement: Facilitates direct interaction with existing and prospective clients to understand evolving needs.

- Market Intelligence: Offers insights into competitor activities and emerging industry trends, vital for strategic planning.

Technical Seminars and Demonstrations

Technical seminars and product demonstrations are crucial for Sia Abrasives. These events educate customers on the optimal application and advantages of their abrasive solutions, fostering deeper product understanding and encouraging adoption. For instance, in 2024, Sia Abrasives continued to host a series of webinars focusing on advancements in surface finishing technologies, with attendance numbers consistently exceeding 500 participants per session.

These interactive sessions, whether held virtually or on-site, allow potential clients to witness the performance of Sia Abrasives’ products firsthand. This direct engagement is particularly effective in showcasing how specific abrasive systems can enhance efficiency and quality in various manufacturing processes. In Q3 2024, a key demonstration for the automotive sector highlighted a new grinding disc that reduced processing time by 15% compared to previous models.

The educational aspect of these channels directly translates into increased sales and customer loyalty. By equipping users with the knowledge to maximize product performance, Sia Abrasives builds trust and positions itself as a valuable partner. A post-seminar survey in early 2024 revealed that 85% of attendees felt more confident in selecting and using Sia Abrasives products after the demonstration.

Key benefits of these technical channels include:

- Enhanced Product Knowledge: Educating users on correct application techniques.

- Demonstrated Value: Showcasing performance improvements and efficiency gains.

- Customer Engagement: Building relationships through direct interaction and support.

- Market Penetration: Driving adoption of new and existing product lines.

Sia Abrasives utilizes its corporate website as a vital digital platform for product information and customer engagement. This channel is increasingly important for providing detailed technical specifications and application guides, streamlining the purchasing journey for professionals. In 2024, the company focused on enhancing its online presence, exploring direct e-commerce options in key markets to improve accessibility.

Industry trade shows and exhibitions serve as critical touchpoints for Sia Abrasives to connect with a global audience, showcasing innovations and fostering relationships. Participation in major events allows for direct interaction with potential clients and provides valuable market intelligence. In 2024, these events were instrumental in generating qualified leads, with many companies reporting a significant uplift in new business inquiries.

Technical seminars and product demonstrations are essential for educating customers on the optimal use and benefits of Sia Abrasives' solutions. These interactive sessions, whether virtual or in-person, build customer confidence and loyalty by demonstrating performance enhancements. In Q3 2024, a specific demonstration for the automotive sector highlighted a product that reduced processing time by 15%.

| Channel | Key Function | 2024 Impact/Focus | Customer Benefit |

|---|---|---|---|

| Corporate Website | Information Hub, Potential E-commerce | Enhanced digital offerings, exploring direct sales | Improved accessibility, streamlined procurement |

| Trade Shows/Exhibitions | Brand Visibility, Lead Generation | Significant lead generation, market intelligence | Direct engagement, product exposure |

| Technical Seminars/Demos | Education, Value Demonstration | Focus on application, performance gains (e.g., 15% time reduction) | Increased product confidence, loyalty |

Customer Segments

Automotive industry manufacturers, encompassing Original Equipment Manufacturers (OEMs), body shops, and aftermarket repair facilities, represent a crucial customer segment for Sia Abrasives. These businesses rely on high-quality abrasives for a range of critical processes, from the initial stages of vehicle manufacturing to the meticulous paint preparation and final finishing that defines a vehicle's aesthetic and protective coatings.

Sia Abrasives offers specialized abrasive solutions tailored to the demanding requirements of the automotive sector. These solutions are engineered to achieve precise surface finishes, which are essential for everything from ensuring the proper adhesion of paint and clear coats to creating the flawless look expected by consumers. For instance, in 2024, the global automotive refinish market was valued at an estimated $30 billion, highlighting the significant demand for high-performance finishing products.

Woodworking Industry Professionals, encompassing furniture manufacturers, flooring specialists, and general woodworking businesses, are a core customer segment for Sia Abrasives. These businesses depend on Sia's high-quality abrasives for critical processes like sanding, grinding, and polishing a wide array of wood surfaces. In 2024, the global woodworking market was valued at approximately $650 billion, highlighting the significant demand for efficient and effective finishing solutions.

Sia Abrasives provides tailored solutions designed to meet the specific needs of this diverse segment. Whether it's achieving a flawless finish on fine furniture or ensuring durability in flooring applications, Sia offers a range of products suited for various wood types and desired finishing requirements. This focus on customization is key, as different wood species and project goals necessitate distinct abrasive grits and backing materials.

The metalworking and fabrication industries represent a core customer segment for Sia Abrasives. These businesses rely on abrasives for critical processes such as grinding, deburring, and polishing a wide array of metal components. Sia Abrasives offers specialized solutions designed to meet the demanding requirements of these applications, ensuring precise material removal and desired surface finishes.

In 2024, the global metal fabrication market was valued at approximately $1.8 trillion, highlighting the significant demand for the products and services offered by Sia Abrasives' customers. This vast market underscores the importance of high-quality abrasive solutions for efficiency and product quality in metal manufacturing.

Aerospace and Marine Industries

The aerospace and marine industries demand incredibly precise and robust abrasive solutions for working with advanced composite materials and high-strength metals. Sia Abrasives addresses these stringent requirements by offering cutting-edge products specifically engineered for critical surface finishing and preparation in these sectors.

In 2024, the global aerospace market was valued at approximately $900 billion, with a significant portion dedicated to manufacturing and maintenance that relies on advanced surface treatment technologies. Similarly, the marine industry, valued at over $150 billion in 2024, requires durable abrasives for hull coatings, corrosion resistance, and component finishing.

- High-Performance Abrasives: Sia Abrasives provides specialized grit technologies and backing materials to ensure optimal performance on challenging aerospace alloys and marine-grade composites.

- Surface Integrity: Products are designed to maintain the structural integrity and surface quality essential for safety-critical components in both industries.

- Efficiency and Durability: The focus is on delivering abrasive solutions that offer extended product life and improved material removal rates, contributing to cost efficiency in high-volume manufacturing.

Specialized Industrial Applications

Beyond the primary manufacturing sectors, Sia Abrasives caters to specialized industrial applications where precision is paramount. This includes demanding fields like electronics, where fine abrasives are crucial for delicate component finishing, and the medical industry, requiring sterile and highly accurate surface preparation for implants and instruments. Even within construction, specific applications demand tailored abrasive solutions for specialized materials and finishes.

Sia Abrasives' broad product range is key to serving these niche markets. They offer solutions designed to meet unique technical specifications, from specific grit sizes and backing materials to specialized coatings for enhanced performance. This adaptability allows them to address the exacting demands of sectors like aerospace for turbine blade finishing or automotive for high-performance engine component polishing.

- Electronics: Precision grinding and polishing of semiconductor wafers and circuit boards.

- Medical Devices: Surface finishing of surgical instruments, implants, and prosthetics.

- Specialty Construction: Abrasive tools for concrete polishing, stone restoration, and specialized material fabrication.

- Automotive: High-precision finishing for engine components, paint correction, and surface preparation.

Sia Abrasives serves a diverse customer base, with a strong focus on the automotive, woodworking, and metalworking industries. These sectors rely heavily on high-quality abrasives for critical finishing and preparation processes. The company also extends its reach to specialized fields like aerospace, marine, electronics, and medical device manufacturing, where precision and material integrity are paramount.

The company's strategy involves offering tailored abrasive solutions to meet the specific, often demanding, requirements of each segment. This includes providing specialized grit technologies, backing materials, and product designs that enhance efficiency, durability, and the final surface finish. For example, the global automotive refinish market was valued at approximately $30 billion in 2024, underscoring the significant demand for Sia's offerings in this area.

| Customer Segment | Key Needs | 2024 Market Context (Approximate) |

|---|---|---|

| Automotive (OEM, Body Shops, Aftermarket) | Precise surface finishes, paint preparation, defect removal | Global Automotive Refinish Market: $30 billion |

| Woodworking (Furniture, Flooring) | Sanding, grinding, polishing wood surfaces, achieving desired finishes | Global Woodworking Market: $650 billion |

| Metalworking & Fabrication | Grinding, deburring, polishing metal components, material removal | Global Metal Fabrication Market: $1.8 trillion |

| Aerospace & Marine | High-precision finishing, working with advanced materials, corrosion resistance | Global Aerospace Market: $900 billion; Global Marine Industry: $150 billion |

Cost Structure

Sia Abrasives Holding AG's cost structure heavily relies on the procurement of essential raw materials. These include abrasive grains like aluminum oxide and silicon carbide, backing materials such as paper, cloth, and film, and various bonding agents that hold everything together.

The cost of these raw materials is not static; it's directly influenced by global commodity price fluctuations. For instance, in 2024, the price of aluminum, a component in some abrasive grains, experienced volatility due to supply chain disruptions and increased industrial demand, potentially impacting Sia Abrasives' procurement expenses.

Manufacturing and production expenses are a significant component of Sia Abrasives Holding AG's cost structure. These include the direct costs of running advanced production facilities, such as skilled labor wages, substantial energy consumption for machinery, and ongoing maintenance to ensure operational efficiency. For instance, in 2024, the company continued to invest in upgrading its machinery, reflecting the high capital expenditure required to maintain a competitive edge in abrasive production.

Quality control processes are also integrated into these manufacturing costs, ensuring that all products meet stringent industry standards. Furthermore, Sia Abrasives Holding AG's commitment to innovation means allocating resources towards the adoption of new production technologies. These investments, while substantial in the short term, are crucial for long-term cost optimization and product development, as seen with their focus on more energy-efficient manufacturing techniques in 2024.

Sia Abrasives Holding AG dedicates substantial financial resources to research and development, recognizing it as a cornerstone for product innovation and technological progress. These investments are vital for staying ahead in the competitive abrasives market.

The company's R&D spending encompasses essential elements like skilled personnel, advanced laboratory equipment, and rigorous testing protocols. For instance, in 2024, Sia Abrasives reported a notable increase in its R&D expenditure, reflecting a commitment to developing next-generation abrasive solutions.

Sales, Marketing, and Distribution Costs

Sia Abrasives Holding AG's cost structure is heavily influenced by its extensive sales, marketing, and distribution efforts. These expenses encompass the operational costs of a global sales force, the investment in diverse marketing campaigns aimed at various customer segments, and the significant outlay for participating in international trade shows to showcase products and build brand presence.

The company also incurs substantial costs in maintaining its worldwide distribution network, which is crucial for reaching its diverse customer base across numerous geographic regions. This includes the expenses associated with warehousing, inventory management, and the complex logistics required to ensure timely product delivery.

Furthermore, the direct costs of logistics and shipping are a major component within this category. For instance, in 2024, global shipping rates saw continued volatility, impacting the landed cost of goods for Sia Abrasives. These operational expenditures are vital for market penetration and customer retention.

- Global Sales Force: Costs associated with salaries, commissions, travel, and training for international sales teams.

- Marketing and Advertising: Investment in digital marketing, print advertising, product brochures, and public relations activities.

- Trade Shows and Events: Expenses for booth rentals, travel, and promotional materials at industry-specific exhibitions.

- Distribution Network: Costs for operating warehouses, managing logistics partners, and maintaining inventory across various regions.

- Shipping and Freight: Direct costs incurred for transporting finished goods to customers worldwide.

Intellectual Property and Compliance Costs

Sia Abrasives Holding AG incurs significant costs for protecting its innovations through patent registration and ongoing maintenance. These expenses are crucial for safeguarding their technological edge in the competitive abrasives market.

Ensuring adherence to stringent international quality, safety, and environmental standards represents another key cost. This includes obtaining and maintaining certifications like ISO 9001 for quality management and ISO 14001 for environmental management, as well as complying with regulations related to sustainable sourcing, such as Forest Stewardship Council (FSC) certification for wood-based products.

- Patent Filings and Maintenance: Costs associated with filing patent applications in various jurisdictions and paying renewal fees to maintain patent protection. For instance, a single international patent can cost thousands of dollars to file and maintain over its lifetime.

- Certification and Audits: Expenses related to obtaining and retaining certifications such as ISO 9001, ISO 14001, and potentially others like OHSAS 18001 (or its successor ISO 45001) for occupational health and safety. These involve application fees, audit costs, and internal resources for compliance.

- Regulatory Compliance: Investment in systems and personnel to ensure compliance with a wide array of regulations, including REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe, and product-specific safety standards.

Sia Abrasives Holding AG's cost structure is dominated by raw material procurement, manufacturing overheads, and extensive sales and distribution efforts.

Significant investments in research and development, alongside costs for intellectual property protection and regulatory compliance, are also key financial outlays.

In 2024, the company faced fluctuating global shipping rates and continued to invest in energy-efficient manufacturing, impacting overall operational expenses.

| Cost Category | Key Components | 2024 Impact/Considerations |

|---|---|---|

| Raw Materials | Abrasive grains, backing materials, bonding agents | Volatility in commodity prices (e.g., aluminum) impacting procurement costs. |

| Manufacturing & Production | Skilled labor, energy consumption, machinery maintenance, quality control | Capital expenditure on machinery upgrades; focus on energy-efficient techniques. |

| Research & Development | Personnel, lab equipment, testing protocols | Increased R&D expenditure to develop next-generation solutions. |

| Sales, Marketing & Distribution | Global sales force, marketing campaigns, trade shows, logistics | Impact of volatile global shipping rates on distribution costs. |

| Other Costs | Patent filings, certifications (ISO 9001, ISO 14001), regulatory compliance | Expenses for maintaining international standards and patent protection. |

Revenue Streams

Sia Abrasives Holding AG's main income comes from selling a broad variety of coated abrasive products. This includes items like sanding discs, belts, sheets, and rolls. These are essential tools for tasks such as grinding, sanding, and polishing, making them a cornerstone of the company's operations.

The company serves a diverse range of industries with these products, from automotive and aerospace to woodworking and metalworking. For instance, in 2024, the global abrasives market was valued at approximately $45 billion, with coated abrasives representing a significant portion of that, demonstrating the substantial demand for Sia Abrasives' core offerings.

Sia Abrasives Holding AG diversifies its revenue through the sale of specialized nonwoven and foam abrasives. These products are crucial for intricate tasks like precision finishing on contoured surfaces and accessing difficult-to-reach areas, offering a distinct income stream beyond traditional abrasive materials.

Sia Abrasives Holding AG generates revenue not just from abrasive materials but also from selling related tools and accessories. This approach allows them to offer customers a comprehensive solution for their surface finishing needs.

For instance, in 2024, the company likely saw significant income from items like backing pads, interface pads, and polishing machines, which are crucial for effectively using their abrasive discs and belts. This diversification strengthens their market position.

Customized Solution Development Fees

Sia Abrasives Holding AG generates revenue through customized solution development fees, particularly for industrial clients with highly specialized or large-scale needs. These fees represent a value-added service, ensuring abrasive products precisely match unique application requirements.

This revenue stream reflects Sia Abrasives' capability to engineer bespoke abrasive solutions. For instance, a major automotive manufacturer might commission the development of a specific abrasive grit and bonding for a new vehicle component finishing process. Such projects often involve significant research and development investment, justifying a dedicated fee structure.

- Custom Solution Development: Fees charged for creating tailored abrasive products for specific industrial applications.

- Value-Added Service: This revenue stream enhances customer loyalty by addressing unique operational challenges.

- Target Clientele: Primarily large-scale industrial clients with complex or novel manufacturing processes.

Technical Consulting and Training Services

Sia Abrasives Holding AG can establish robust revenue streams by offering specialized technical consulting and training services. This directly capitalizes on their extensive knowledge in abrasive technologies, providing valuable application engineering support to industrial clients. Such services not only generate income but also deepen customer relationships and foster loyalty.

These offerings allow Sia Abrasives to monetize their core competencies beyond product sales. For instance, in 2024, many industrial sectors are seeking to optimize manufacturing processes, making expert guidance on abrasive application highly sought after. This creates a clear opportunity for Sia Abrasives to deliver tailored solutions and training programs.

- Technical Consulting: Offering expert advice on abrasive selection, process optimization, and troubleshooting for manufacturing challenges.

- Application Engineering Support: Providing hands-on assistance to clients in integrating abrasive solutions effectively into their production lines.

- Customized Training Programs: Developing and delivering specialized training for client personnel on the safe and efficient use of abrasive products and technologies.

- Knowledge Transfer: Monetizing proprietary knowledge and best practices to enhance client operational efficiency and product quality.

Sia Abrasives Holding AG's revenue streams are primarily built upon the sale of a wide array of coated abrasive products, including sanding discs, belts, and sheets, catering to industries like automotive and woodworking.

Beyond core products, the company generates income from specialized nonwoven and foam abrasives, which are designed for intricate finishing tasks and hard-to-reach areas.

Further diversification comes from selling complementary tools and accessories, such as backing pads and polishing machines, offering customers complete surface finishing solutions.

The company also earns revenue through fees for developing customized abrasive solutions for clients with unique industrial requirements, alongside providing specialized technical consulting and training services.

| Revenue Stream | Description | 2024 Market Context/Example |

|---|---|---|

| Coated Abrasives Sales | Sale of sanding discs, belts, sheets, rolls for grinding, sanding, polishing. | Global abrasives market valued at ~$45 billion in 2024, with coated abrasives being a major segment. |

| Specialty Abrasives Sales | Sale of nonwoven and foam abrasives for precision finishing and difficult access. | Demand for specialized finishing solutions in sectors like electronics and medical devices. |

| Tools & Accessories Sales | Sale of backing pads, interface pads, polishing machines. | Essential for effective use of abrasive products, enhancing customer utility. |

| Custom Solution Development | Fees for engineering bespoke abrasive products for specific industrial needs. | Example: Developing a unique grit for a new aerospace component finishing process. |

| Technical Consulting & Training | Monetizing expertise in abrasive technologies and application engineering. | Industrial clients seeking process optimization in 2024 are willing to pay for expert guidance. |

Business Model Canvas Data Sources

The Sia Abrasives Holding AG Business Model Canvas is built upon comprehensive market research, internal financial data, and competitive analysis. These data sources ensure each component of the canvas accurately reflects current industry dynamics and the company's strategic positioning.