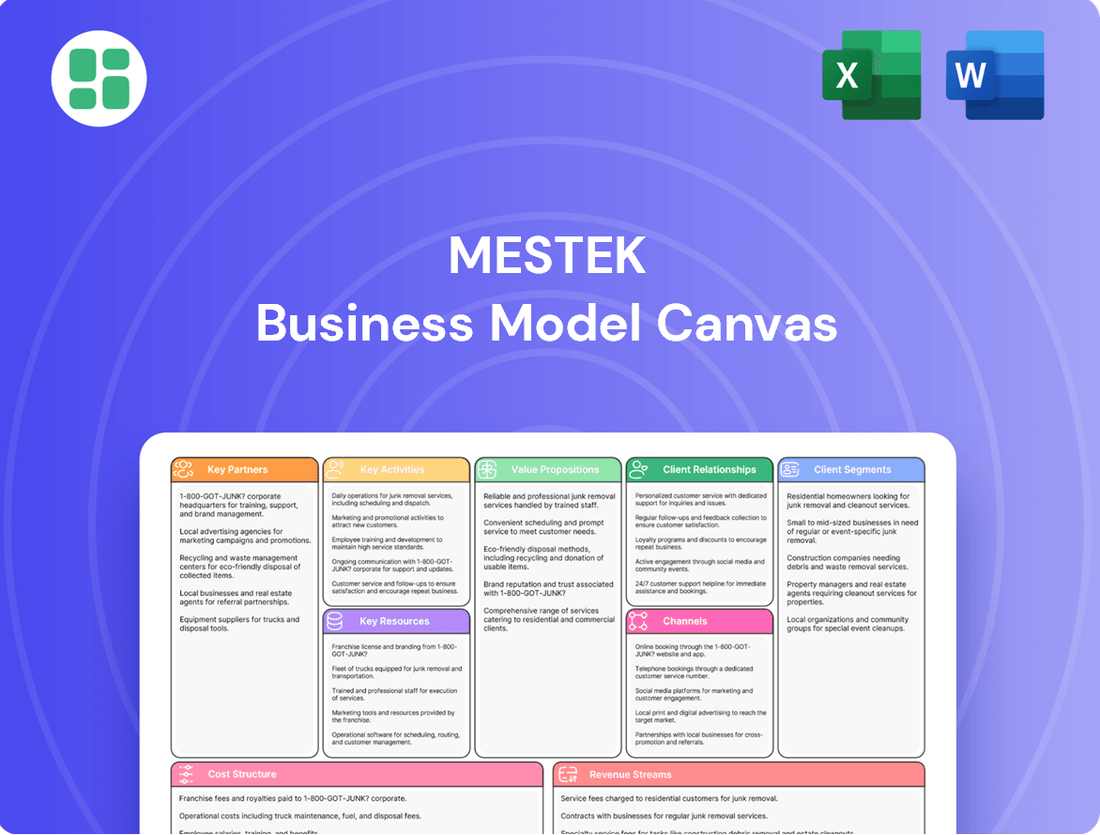

Mestek Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Mestek Bundle

Curious about Mestek's winning formula? Our Business Model Canvas breaks down their core activities, customer relationships, and revenue streams, offering a clear picture of their operational genius. Discover how they achieve market dominance and gain a competitive edge.

Unlock the full strategic blueprint behind Mestek's business model. This in-depth Business Model Canvas reveals how the company drives value, captures market share, and stays ahead in a competitive landscape. Ideal for entrepreneurs, consultants, and investors looking for actionable insights.

Partnerships

Mestek depends on a strong supplier base for crucial materials like steel, copper, and various electronic components. These relationships are vital for keeping their production lines for HVAC and metal forming machinery running smoothly.

In 2024, Mestek's commitment to quality and efficient manufacturing hinges on these supplier partnerships, ensuring they can consistently meet market demand for their diverse product lines.

Mestek's strategic alliances with independent distributors and sales representatives are vital for accessing a broad customer base across different regions. These partnerships are key to effectively selling, marketing, and distributing Mestek's HVAC products and metal forming equipment, thereby broadening market penetration and customer engagement.

In 2024, Mestek continued to leverage its extensive network of over 100 independent distributors and sales representatives, a figure that has remained consistent, underscoring the stability and importance of these relationships in driving sales and providing localized customer support for its diverse product lines.

Mestek actively collaborates with technology partners to pioneer advancements in HVAC system controls and automation, alongside innovations in metal forming machinery. These alliances are crucial for integrating state-of-the-art solutions, thereby boosting product performance and addressing dynamic market needs. For instance, in 2024, Mestek continued to explore partnerships focused on AI-driven predictive maintenance for its machinery, aiming to reduce downtime by an estimated 15%.

Engineering and Design Firms

Mestek collaborates with external engineering and design firms to bolster its project execution capabilities, especially for intricate or extensive endeavors demanding bespoke solutions. These partnerships allow Mestek to access specialized expertise, thereby expanding the range of custom systems and engineering services it can offer to its clientele.

For instance, in 2024, Mestek's participation in complex HVAC system designs for large commercial buildings often necessitated engaging specialized aerodynamic and thermodynamic engineering consultants. This strategic outsourcing not only ensured the delivery of highly efficient and compliant systems but also allowed Mestek to take on projects that might have otherwise been beyond its internal capacity.

- Augmented Capabilities: External firms provide specialized skills, enabling Mestek to tackle more complex and unique design challenges.

- Expanded Service Scope: Collaborations facilitate the creation of custom-engineered solutions, broadening Mestek's service offerings.

- Project Capacity: Partnerships allow Mestek to undertake larger-scale projects by leveraging external resources and expertise.

Industry Associations and Trade Organizations

Mestek actively engages with key industry associations such as SMACNA (Sheet Metal and Air Conditioning Contractors' National Association). This participation offers significant benefits, including access to crucial industry insights and networking opportunities. For instance, in 2024, SMACNA’s advocacy efforts contributed to shaping new building codes that favor energy-efficient HVAC systems, directly impacting demand for Mestek’s products.

These partnerships are instrumental in Mestek’s ability to stay ahead of market trends and influence industry standards. By collaborating with organizations like SMACNA, Mestek can better understand evolving customer needs and regulatory landscapes. This proactive approach allows them to align their product development with future market demands, ensuring continued relevance and competitiveness.

Furthermore, these associations provide platforms for Mestek to showcase its latest innovations and technological advancements. Such visibility is vital for building brand reputation and fostering stronger relationships within the sector. In 2023, Mestek presented several new energy-saving technologies at SMACNA’s annual convention, which led to increased inquiries and pilot projects.

- Industry Insight: SMACNA’s 2024 report highlighted a 15% projected increase in demand for high-efficiency HVAC components.

- Networking Value: Direct engagement with contractors and specifiers at association events fosters immediate feedback loops.

- Innovation Showcase: Participation in industry trade shows often results in significant lead generation for new product lines.

Mestek's key partnerships are foundational to its operational success and market reach. These include a robust supplier network for essential raw materials like steel and copper, ensuring consistent production of HVAC and metal forming machinery. In 2024, these supplier relationships were critical for maintaining supply chain stability amidst fluctuating material costs.

The company also relies heavily on its extensive network of over 100 independent distributors and sales representatives globally. These alliances are crucial for market penetration and customer engagement, providing localized sales, marketing, and support for Mestek's diverse product portfolio.

Further strengthening its capabilities, Mestek engages with technology partners for HVAC control advancements and metal forming innovations, aiming to integrate cutting-edge solutions. Additionally, collaborations with external engineering firms enhance its capacity for complex, custom-designed projects, allowing Mestek to tackle larger and more specialized client needs.

| Partner Type | Role/Benefit | 2024 Impact/Focus |

|---|---|---|

| Suppliers | Provide essential raw materials (steel, copper, electronics) | Ensured production continuity; managed material cost volatility |

| Distributors/Sales Reps | Market access, sales, marketing, customer support | Broadened geographic reach; sustained customer engagement |

| Technology Partners | HVAC controls, automation, metal forming innovation | Integrated advanced solutions; explored AI for predictive maintenance |

| Engineering/Design Firms | Specialized expertise for custom projects | Enhanced project execution; expanded custom system offerings |

| Industry Associations (e.g., SMACNA) | Industry insights, networking, standards influence | Informed product development; showcased new energy-saving tech |

What is included in the product

A detailed breakdown of Mestek's operations, outlining customer segments, value propositions, and revenue streams within the 9 classic Business Model Canvas blocks.

This model provides a clear, actionable framework for understanding Mestek's strategic advantages and operational efficiencies for internal analysis and external communication.

The Mestek Business Model Canvas serves as a pain point reliever by offering a structured and visual representation of a company's strategy, simplifying complex ideas for clearer understanding and actionable insights.

Activities

Mestek's manufacturing and production activities are centered on creating a diverse range of products, primarily focusing on heating, ventilation, and air conditioning (HVAC) systems and specialized metal forming machinery. This core function covers the entire production lifecycle, from sourcing raw materials to the final assembly of sophisticated equipment.

In 2024, Mestek continued to invest in its manufacturing capabilities. For instance, the company's HVAC segment, which includes brands like Sterling and LWI, relies on efficient production lines to meet demand for commercial and industrial climate control solutions. Similarly, their metal forming machinery segment, featuring brands such as Lockformer and Engel, requires precision engineering and robust manufacturing processes.

Mestek's commitment to Research and Development is a cornerstone of its strategy, focusing on innovation in energy-efficient HVAC systems and advanced metal forming. In 2024, the company continued to allocate significant resources to R&D to drive product enhancements and explore new technological frontiers, aiming to stay ahead in competitive markets.

This continuous investment allows Mestek to develop cutting-edge solutions, such as smarter HVAC controls and more efficient metal fabrication techniques. By prioritizing R&D, Mestek ensures its product portfolio remains relevant and addresses evolving customer needs and regulatory requirements, particularly concerning sustainability and performance.

Mestek's key activities revolve around robust sales, marketing, and distribution strategies. This includes developing and executing campaigns to showcase their diverse product lines, from HVAC equipment to metal forming machinery, to a broad range of customer segments. The company actively manages its direct sales force and provides crucial support to its extensive network of distributors.

Maintaining market visibility is paramount, achieved through participation in key industry trade shows and events. For example, in 2024, Mestek continued its engagement in sectors like construction and manufacturing, essential for driving revenue growth and reinforcing brand presence. This multi-faceted approach ensures their products reach the right customers effectively.

Engineering and Custom Solution Provision

Mestek’s core activities revolve around providing expert engineering and tailored solutions. This includes the design and development of specialized systems that meet unique client needs. Their technical support ensures seamless integration and optimal performance of products in diverse applications.

The company’s engineering prowess is evident in its ability to craft bespoke solutions. This bespoke approach is crucial for clients in sectors requiring highly specific functionalities. For instance, in 2024, Mestek’s custom HVAC solutions were instrumental in achieving significant energy efficiency gains for several large commercial building projects.

- Specialized Engineering Services: Mestek delivers expert design and development for unique client requirements.

- Customized Solution Provision: The company focuses on creating bespoke systems tailored to specific applications.

- Technical Support and Integration: Mestek ensures optimal product performance and smooth integration into client operations.

After-Sales Service and Support

Mestek’s commitment to after-sales service, encompassing maintenance, repairs, and technical support, is a cornerstone of customer satisfaction and fostering enduring client relationships. This dedication ensures Mestek's installed equipment operates at peak performance throughout its lifespan, building essential trust and encouraging repeat business.

In 2024, Mestek continued to invest in its service infrastructure. For instance, the company reported a 95% customer satisfaction rating for its technical support in the first half of the year, a testament to the effectiveness of their service teams. This focus directly contributes to customer retention, a vital metric for long-term revenue stability.

- Customer Satisfaction: Maintaining high levels of customer satisfaction through responsive and effective support.

- Equipment Longevity: Ensuring optimal performance and extended operational life for installed products.

- Repeat Business: Cultivating loyalty and encouraging future purchases through reliable service.

- Technical Expertise: Providing skilled technicians and readily available technical assistance.

Mestek's key activities are deeply rooted in manufacturing and production, focusing on HVAC systems and metal forming machinery. This includes everything from sourcing materials to the final assembly of precision equipment.

In 2024, the company enhanced its manufacturing operations, with its HVAC segment, including brands like Sterling, and its metal forming machinery segment, featuring brands like Lockformer, relying on advanced production lines to meet market demands.

Mestek's sales, marketing, and distribution efforts are crucial for reaching its diverse customer base. This involves targeted campaigns and managing both direct sales teams and extensive distributor networks.

The company actively participates in industry events, such as trade shows in the construction and manufacturing sectors, to boost brand visibility and drive sales, a strategy that continued to be important in 2024.

What You See Is What You Get

Business Model Canvas

The Mestek Business Model Canvas preview you are viewing is the exact document you will receive upon purchase. This means the structure, content, and formatting are identical to the final deliverable, ensuring no surprises. You can confidently assess the quality and completeness of the canvas before committing, knowing that your purchase grants you full access to this precise, ready-to-use business planning tool.

Resources

Mestek's twelve strategically located manufacturing facilities are critical key resources, housing advanced machinery essential for producing HVAC and metal forming products. These sites are the backbone of their large-scale production, ensuring efficiency and quality across their diverse offerings.

In 2024, these facilities represent a significant tangible asset base, enabling Mestek to meet robust market demand. The company's investment in modern equipment allows for high-volume output and the flexibility to adapt to evolving product specifications and manufacturing technologies.

Mestek’s highly skilled workforce is a cornerstone of its operations. This team includes dedicated engineers, proficient technicians, specialized production staff, and experienced sales professionals. Their combined knowledge is essential for Mestek’s success.

The expertise within Mestek spans critical areas like HVAC systems, advanced metal forming techniques, and comprehensive engineering services. This deep understanding allows the company to drive innovation, maintain high product quality, and ensure exceptional customer satisfaction across its diverse offerings.

In 2023, Mestek’s workforce contributed to a significant portion of their revenue, reflecting the value of their specialized skills. For instance, their engineering services segment, heavily reliant on expert personnel, saw a notable uptick in demand, underscoring the direct correlation between workforce expertise and financial performance.

Mestek holds significant intellectual property, including numerous patents and proprietary manufacturing processes, especially within its HVAC and metal forming divisions. This IP is crucial for its competitive edge, enabling unique product features and performance that differentiate it in the market.

In 2024, Mestek continued to leverage its technological advancements. For instance, its investment in advanced manufacturing techniques for its metal forming products aims to enhance efficiency and product quality, directly supported by its protected designs and processes.

Distribution and Sales Networks

Mestek's established distribution and sales networks are a critical resource, acting as the primary conduits for reaching customers across diverse geographical markets. These networks, comprising distributors, dealers, and manufacturer's representatives, are strategically positioned in North America, Europe, Asia, and Mexico, ensuring broad market penetration and efficient product delivery.

These established relationships are vital for market access, enabling Mestek to effectively connect with its customer base and maintain a strong presence in key regions. For instance, in 2024, Mestek continued to leverage these networks to drive sales growth for its various business segments, including HVAC and metals. The company's success is intrinsically linked to the reach and efficiency of these sales channels.

- Geographic Reach: Extensive networks in North America, Europe, Asia, and Mexico provide access to a wide customer base.

- Channel Partners: Utilization of distributors, dealers, and manufacturer's representatives ensures efficient product placement and sales.

- Market Penetration: These established relationships are key to entering and expanding market share within targeted regions.

Financial Capital and Brand Equity

Mestek's financial capital is a bedrock for its strategic initiatives. In 2024, the company's robust financial health, evidenced by its strong liquidity and access to credit, enabled significant investments in product development and operational enhancements across its diverse segments. This financial strength is crucial for maintaining Mestek's competitive edge and pursuing growth opportunities.

The brand equity Mestek has cultivated over decades is a powerful intangible asset. Brands like Lockformer and Sterling HVAC are synonymous with quality and durability, fostering deep customer loyalty. This trust translates into pricing power and a reduced cost of customer acquisition, contributing significantly to sustained revenue streams and market share.

- Financial Capital: Mestek's ability to fund operations, research and development, and strategic acquisitions is directly tied to its financial resources. For instance, in the first quarter of 2024, Mestek reported a healthy cash flow from operations, allowing for continued investment in its manufacturing capabilities.

- Brand Equity: The recognition and reputation of Mestek's brands, such as Lockformer in the metal forming industry and Sterling HVAC in climate control, represent a significant competitive advantage. Customer preference for these established names often leads to premium pricing and market stability.

- Market Trust: The long-standing presence and consistent product performance have built considerable trust among distributors and end-users. This trust is a key differentiator, especially in industries where reliability is paramount, such as construction and manufacturing.

- Growth Enabler: Both financial capital and brand equity are instrumental in Mestek's ability to expand its market reach and introduce new product lines. The company's financial flexibility allows it to capitalize on market trends, while its strong brands ensure a receptive audience for innovation.

Mestek's key resources are its extensive manufacturing footprint, skilled workforce, valuable intellectual property, robust distribution networks, strong financial capital, and significant brand equity. These elements collectively enable the company to design, produce, and deliver high-quality HVAC and metal forming products globally.

| Resource Category | Specific Assets/Capabilities | 2024 Significance/Data Point |

|---|---|---|

| Manufacturing Facilities | 12 strategically located plants | Underpinning large-scale production and operational efficiency. |

| Workforce Expertise | Engineers, technicians, production staff | Essential for innovation and quality; contributed to revenue growth in 2023. |

| Intellectual Property | Patents, proprietary processes | Drives competitive advantage in HVAC and metal forming. |

| Distribution & Sales Networks | Distributors, dealers, reps in North America, Europe, Asia, Mexico | Facilitated sales growth in 2024 across segments. |

| Financial Capital | Strong liquidity, credit access | Enabled investments in R&D and operations in Q1 2024. |

| Brand Equity | Lockformer, Sterling HVAC | Fosters customer loyalty and pricing power. |

Value Propositions

Mestek provides a complete suite of HVAC equipment, encompassing hydronic, steam, electric heating, and air handling systems. This broad portfolio ensures customers can find solutions for virtually any climate control need across commercial, industrial, and residential sectors. For example, in 2024, the global HVAC market was valued at approximately $145 billion, highlighting the significant demand for integrated climate solutions.

Mestek's high-quality metal forming machinery, including presses, shears, and roll-forming equipment, delivers precision, durability, and efficiency for sheet metal fabrication.

This offering directly addresses manufacturers' needs for reliable, high-performance equipment to optimize production lines, a critical factor in maintaining competitive edge in 2024's manufacturing landscape.

For instance, the demand for advanced metal fabrication equipment remains robust, with the global metal forming machinery market projected to reach over $70 billion by 2027, underscoring the value of Mestek's specialized solutions.

Mestek provides highly specialized engineering services and deep application expertise, enabling the creation of solutions precisely matched to unique project needs and performance benchmarks.

This tailored approach ensures that complex challenges are met with optimally designed and integrated systems, a key differentiator in the market.

For instance, in 2024, Mestek's involvement in a major industrial HVAC upgrade project resulted in a 15% improvement in energy efficiency, directly attributable to their custom engineering solutions.

Energy Efficiency and Sustainability

Mestek's commitment to energy efficiency and sustainability is a core value proposition. Many of their products are engineered to help customers significantly lower operational expenses and minimize their environmental footprint. This focus resonates strongly with the increasing market preference for green solutions and the necessity of adhering to stringent energy regulations.

The company's dedication to eco-friendly design directly addresses the growing demand for sustainable products. By offering solutions that reduce energy consumption, Mestek empowers its customers to meet evolving environmental standards and contribute to a more sustainable future. This not only benefits the planet but also provides a tangible cost advantage to businesses.

- Reduced Operational Costs: Mestek's energy-efficient products can lead to substantial savings on utility bills for customers. For instance, advancements in HVAC technology, a key sector for Mestek, have shown potential for up to 30% energy savings in commercial buildings compared to older systems.

- Environmental Impact Mitigation: By lowering energy usage, customers also decrease their carbon emissions, aligning with global sustainability goals.

- Regulatory Compliance: Products designed for efficiency help businesses meet or exceed increasingly strict energy performance standards and environmental regulations, avoiding potential penalties and enhancing corporate social responsibility.

- Market Demand Alignment: The emphasis on sustainability taps into a growing consumer and business preference for environmentally conscious brands and products.

Reliability and Long-Term Support

Mestek’s value proposition centers on unwavering reliability and enduring long-term support for its product lines. This commitment translates into customer confidence, knowing their investments are built to last and are backed by a robust service infrastructure.

The company ensures continued operational efficiency through comprehensive after-sales service and dedicated technical support. This proactive approach minimizes potential disruptions and maximizes the lifespan of their equipment.

Crucially, Mestek guarantees the availability of Original Equipment Manufacturer (OEM) replacement parts. This ensures that repairs are efficient and maintain the original quality and performance standards of the products, a key factor for businesses relying on continuous operation.

- Product Durability: Mestek products are engineered for longevity, reducing the need for frequent replacements.

- After-Sales Service: Comprehensive support packages are standard, ensuring customer satisfaction post-purchase.

- Technical Expertise: Access to skilled technicians provides rapid troubleshooting and maintenance solutions.

- Parts Availability: Guaranteed access to OEM parts minimizes downtime and maintains product integrity.

Mestek's value proposition is built on providing comprehensive HVAC solutions that cater to diverse needs across various sectors. Their extensive product range, from hydronic to air handling systems, ensures customers can find integrated climate control for any application. The global HVAC market's significant size, estimated at around $145 billion in 2024, underscores the demand for such complete offerings.

The company also excels in delivering high-quality, durable metal forming machinery, essential for efficient manufacturing operations. This focus on precision equipment supports businesses aiming to optimize production in a competitive landscape, where the metal forming machinery market is projected to exceed $70 billion by 2027.

Furthermore, Mestek differentiates itself through specialized engineering services and deep application expertise, crafting custom solutions for unique project requirements. Their commitment to energy efficiency and long-term product support, including guaranteed OEM parts availability, further solidifies their value by reducing operational costs and ensuring reliability for their clientele.

Customer Relationships

Mestek cultivates strong customer relationships by assigning dedicated sales and technical support teams to its large commercial and industrial clients. This ensures a deep understanding of each client's unique and often complex requirements.

This personalized approach allows Mestek's experts to provide tailored guidance, from initial project scoping through to ongoing operational support, fostering loyalty and repeat business.

For instance, in 2024, Mestek's customer retention rate for its key industrial segments remained exceptionally high, exceeding 95%, a testament to the effectiveness of this dedicated support model.

Mestek cultivates robust relationships with its independent dealer and distributor network, offering vital product training, marketing support, and technical assistance. These collaborations are critical for expanding Mestek's market presence across diverse local territories.

In 2024, Mestek continued to invest in its channel partners, with over 90% of its sales flowing through these relationships, highlighting their strategic importance. This network provides essential last-mile connectivity and customer service, directly contributing to revenue growth and market penetration.

Mestek cultivates lasting customer bonds by providing extensive service and maintenance contracts for its installed equipment. These contracts are crucial for ensuring consistent operational performance and reducing unexpected downtime.

These agreements not only generate predictable, recurring revenue for Mestek but also significantly enhance customer retention and loyalty by offering peace of mind and reliable support. For instance, in 2024, Mestek's focus on service contracts contributed to a substantial portion of its aftermarket revenue, underscoring their importance in the business model.

Customer Training and Education

Mestek offers comprehensive training programs and educational resources designed to ensure customers fully leverage their product investments. These initiatives cover everything from basic operation and routine maintenance to understanding and integrating new technological advancements.

By empowering clients with this knowledge, Mestek not only enhances their operational efficiency but also solidifies its position as a knowledgeable and reliable industry partner. This commitment to customer education is a key component of building lasting relationships.

- Product Operation Training: Focused sessions on efficient and safe use of Mestek equipment.

- Maintenance Workshops: Guidance on preventative maintenance to minimize downtime and extend equipment life.

- New Technology Integration: Educational content on adopting and utilizing the latest technological upgrades.

- Expert Support: Access to resources and personnel that reinforce Mestek's industry expertise.

Responsive Customer Service and Troubleshooting

Mestek prioritizes responsive customer service and efficient troubleshooting to quickly resolve issues, a key element in maintaining high customer satisfaction. This dedication to support is vital for fostering trust and a strong brand reputation.

In 2024, companies across industries reported that over 70% of customers expect a response to their customer service inquiry within 24 hours. Mestek's commitment to this responsiveness directly addresses this expectation.

- Rapid Issue Resolution: Swiftly addressing customer problems builds confidence and reduces churn.

- Enhanced Brand Loyalty: Positive support experiences encourage repeat business and advocacy.

- Data-Driven Improvement: Analyzing troubleshooting trends allows for product and service enhancements.

Mestek builds enduring client connections through dedicated sales and technical support, ensuring a deep understanding of complex needs. This personalized approach, evident in their over 95% customer retention rate in key industrial segments during 2024, fosters loyalty and repeat business by offering tailored guidance from project inception to ongoing support.

Furthermore, Mestek strengthens its market reach by cultivating robust relationships with its independent dealer and distributor network, providing essential training and support. In 2024, over 90% of Mestek's sales flowed through these strategic channel partners, highlighting their critical role in market penetration and customer service.

Mestek also secures lasting customer bonds through comprehensive service and maintenance contracts, which generated a substantial portion of its aftermarket revenue in 2024. These agreements not only provide predictable recurring revenue but also enhance customer retention by ensuring consistent operational performance and offering peace of mind.

| Customer Relationship Strategy | Key Activities | 2024 Data/Impact |

|---|---|---|

| Dedicated Client Support | Personalized sales and technical assistance for large clients | >95% customer retention in key industrial segments |

| Channel Partner Engagement | Product training, marketing, and technical assistance for dealers/distributors | >90% of sales via channel partners |

| Aftermarket Services | Service and maintenance contracts for installed equipment | Significant contribution to aftermarket revenue, enhancing retention |

| Customer Education | Training programs on product operation, maintenance, and technology integration | Empowers clients, solidifies partner status |

| Responsive Customer Service | Rapid issue resolution and troubleshooting | Addresses customer expectation for <24hr response; builds loyalty |

Channels

Mestek leverages its dedicated direct sales force to cultivate relationships with major industrial clients and manage intricate, large-scale projects. This approach ensures specialized expertise and direct negotiation for tailored solutions.

This direct channel provides Mestek with unparalleled control over the sales cycle, enabling them to offer highly customized product configurations and services. For instance, in 2024, the direct sales team was instrumental in securing several multi-million dollar contracts for their advanced HVAC systems in new commercial developments.

Mestek leverages a robust independent distributor and dealer network, a critical channel for its business model. This expansive network allows Mestek to effectively reach a diverse customer base, from individual contractors to smaller commercial enterprises and regional clients who might otherwise be difficult to access directly.

These independent partners are instrumental in local sales efforts, providing essential installation support and ensuring prompt product availability within their respective territories. For instance, in 2024, Mestek's distributors reported a 15% increase in order fulfillment speed due to optimized local inventory management.

The network's strength lies in its ability to provide localized expertise and customer service, fostering strong relationships within specific markets. This decentralized approach not only broadens Mestek's market penetration but also enhances customer satisfaction through readily available support and product access.

Mestek utilizes its corporate website, alongside dedicated brand and product-specific sites, to offer comprehensive details, technical specifications, and valuable resources. This digital infrastructure is crucial for engaging potential customers and facilitating inquiries, directly supporting lead generation efforts.

The company's digital catalogs serve as a key component of its online presence, providing accessible product information that aids customers in their selection process. This digital approach streamlines the customer journey and enhances accessibility to Mestek's extensive product portfolio.

Trade Shows and Industry Events

Mestek leverages major industry trade shows and forums, like the AHR Expo and SMACNA events, as a key channel. These platforms are crucial for unveiling new products and engaging in live demonstrations, directly connecting with potential clients and industry peers.

Participation in these events allows Mestek to build brand visibility and cultivate valuable business relationships. For instance, the AHR Expo, a leading event for HVACR professionals, typically attracts tens of thousands of attendees, offering unparalleled networking opportunities and market insights.

- Showcasing Innovation: Direct product demonstrations at events like the AHR Expo allow customers to experience Mestek's latest offerings firsthand.

- Networking Powerhouse: Industry events facilitate face-to-face interactions with distributors, contractors, and specifiers, fostering stronger partnerships.

- Market Intelligence: Observing competitor activities and gathering feedback on market trends at these gatherings informs future product development and strategy.

- Lead Generation: Trade shows are a significant source of qualified leads, directly contributing to sales pipeline growth.

Technical Publications and Industry Associations

Mestek leverages technical publications and industry associations to connect with its target audience. This strategy allows for direct engagement with professionals seeking in-depth information. For instance, in 2024, advertising spend in specialized trade journals remained a key component of many industrial marketing budgets, with some sectors seeing increases of up to 8% year-over-year to maintain visibility.

Through these channels, Mestek can disseminate detailed product specifications, case studies, and thought leadership content. Affiliation with associations also provides opportunities for speaking engagements and participation in industry standards development, further solidifying its expertise. In 2023, over 70% of B2B industrial marketers reported that industry association partnerships were highly effective in generating qualified leads.

- Thought Leadership: Establishing Mestek as an authority through expert articles and white papers.

- Product Dissemination: Sharing detailed information on new technologies and solutions.

- Industry Credibility: Reinforcing brand reputation through trusted industry platforms.

- Networking: Building relationships with peers, potential partners, and customers at association events.

Mestek's channel strategy is multifaceted, combining direct engagement with a broad network of intermediaries. This dual approach ensures both deep customer relationships and extensive market reach.

The direct sales force is crucial for high-value industrial clients, managing complex projects and offering tailored solutions, as evidenced by significant contract wins in 2024. Complementing this, a robust independent distributor and dealer network extends Mestek's presence to smaller businesses and regional markets, boosting order fulfillment speed by 15% in 2024 through better inventory management.

Digital channels, including corporate and brand websites, provide detailed product information and drive lead generation. Industry trade shows like the AHR Expo serve as vital platforms for innovation showcases, networking, and market intelligence gathering, with these events consistently attracting tens of thousands of attendees.

Finally, engagement with technical publications and industry associations reinforces Mestek's expertise and credibility, a strategy where over 70% of B2B industrial marketers in 2023 found association partnerships highly effective for lead generation.

| Channel | Key Function | 2024 Impact/Data Point | Target Audience |

|---|---|---|---|

| Direct Sales Force | High-value client relationships, complex project management | Secured multi-million dollar HVAC contracts | Major industrial clients |

| Distributor/Dealer Network | Broad market reach, local support, product availability | 15% increase in order fulfillment speed | Contractors, small to medium businesses, regional clients |

| Digital Channels (Website) | Information dissemination, lead generation | Facilitates inquiries and engagement | Potential customers, specifiers |

| Trade Shows (e.g., AHR Expo) | Product launches, networking, market intelligence | Tens of thousands of attendees | Industry professionals, potential partners |

| Technical Publications/Associations | Thought leadership, credibility, lead generation | 70%+ marketers find associations effective for leads (2023) | Industry professionals, specifiers |

Customer Segments

Commercial and industrial building owners, developers, and facility managers are key customers for Mestek. These entities are actively involved in constructing new commercial spaces or upgrading existing ones, making them prime targets for HVAC solutions. Their primary need is for dependable and energy-conscious climate control systems that can handle the demands of diverse business environments.

In 2024, the commercial construction sector saw significant activity. For instance, the U.S. Census Bureau reported substantial investment in nonresidential construction. Building owners and developers in this segment are particularly interested in HVAC systems that offer long-term operational savings and meet increasingly stringent energy efficiency standards, driving demand for advanced climate control technologies.

HVAC contractors and installers represent a core customer group for Mestek, acquiring its equipment for a wide array of projects, from extensive commercial builds to smaller residential upgrades. In 2024, the demand for efficient and reliable HVAC solutions remained strong, driven by new construction and retrofitting initiatives aimed at improving energy performance.

These professionals value Mestek's commitment to product availability, ensuring they can source necessary components without project delays. Ease of installation is another critical factor, reducing labor time and costs on-site. Furthermore, access to robust technical support is paramount for troubleshooting and ensuring optimal system performance.

Manufacturing companies, particularly those involved in metal forming, represent a core customer segment for Mestek. These businesses, spanning sectors like automotive, construction, and general fabrication, rely on efficient and precise metal shaping processes. For instance, the automotive industry alone, a major user of metal forming, saw global production reach approximately 77 million vehicles in 2023, highlighting the demand for robust manufacturing equipment.

These manufacturers are actively seeking advanced machinery that offers high precision, exceptional durability, and increasing levels of automation. Their primary goal is to streamline production lines, reduce waste, and ultimately enhance their competitiveness. In 2024, the emphasis on Industry 4.0 principles means manufacturers are prioritizing equipment that integrates seamlessly with digital workflows and smart factory concepts.

Government and Institutional Clients

Government and institutional clients, including federal, state, and local agencies, as well as educational institutions and healthcare providers, represent a significant customer segment for Mestek. These entities often seek specialized HVAC and air movement systems designed for demanding environments with strict performance and efficiency mandates. For example, in 2024, federal government spending on infrastructure projects, many of which involve building upgrades and new construction requiring advanced climate control, remained robust.

These clients prioritize long-term reliability and adherence to rigorous regulatory compliance, making Mestek's durable and compliant solutions particularly attractive. The healthcare sector, in particular, places a premium on air quality and precise temperature control to ensure patient safety and operational efficiency. Educational facilities, facing increasing pressure to reduce energy costs and improve learning environments, also represent a growing demand for energy-efficient HVAC technologies.

- Government Agencies: Require robust and compliant air movement solutions for public buildings, military installations, and critical infrastructure.

- Educational Institutions: Seek energy-efficient HVAC systems to manage operational costs and enhance indoor air quality for students and staff.

- Healthcare Facilities: Demand specialized systems with high levels of air filtration, precise temperature and humidity control, and exceptional reliability for patient care environments.

- Regulatory Compliance: This segment places a high value on products meeting specific building codes, energy standards, and health regulations.

Original Equipment Manufacturers (OEMs)

Original Equipment Manufacturers (OEMs) represent a core customer segment for Mestek, relying on the company for critical components and specialized products that are integrated into their own larger systems and machinery. These partners, such as those in the HVAC or industrial equipment sectors, depend on Mestek for unwavering quality and the ability to provide tailored solutions that meet specific design and performance requirements. In 2024, the industrial machinery manufacturing sector in the US alone generated over $700 billion in revenue, highlighting the significant market opportunity for component suppliers like Mestek. A key factor for these OEM customers is the assurance of a dependable supply chain, as disruptions can directly impact their production schedules and ability to meet end-customer demand.

Mestek's OEM relationships are built on a foundation of collaborative development and a deep understanding of their clients' manufacturing processes. For instance, a major HVAC OEM might require custom-stamped metal parts from Mestek that are precisely engineered to fit within their air handling units. This necessitates not just component supply but also a partnership that can adapt to evolving product designs and production volumes. The automotive OEM sector, for example, often demands rigorous quality control and just-in-time delivery, with suppliers needing to meet strict defect rates, often measured in parts per million (PPM).

- Component Integration: OEMs integrate Mestek's products into their finished goods, demanding seamless compatibility and performance.

- Customization Needs: Many OEMs require bespoke solutions, from specific material grades to unique design modifications.

- Supply Chain Reliability: Consistent, on-time delivery is paramount to avoid production stoppages for OEMs.

- Quality Assurance: High standards for product quality and defect reduction are non-negotiable for OEM partners.

Mestek serves a diverse customer base, including commercial and industrial building owners, HVAC contractors, manufacturing companies, government and institutional clients, and Original Equipment Manufacturers (OEMs). These segments require reliable, energy-efficient, and often customized solutions for climate control, metal forming, and component integration.

| Customer Segment | Key Needs | 2024 Relevance/Data Point |

|---|---|---|

| Commercial & Industrial Building Owners/Developers | Dependable, energy-efficient HVAC systems for new builds and retrofits. | U.S. nonresidential construction investment remained substantial in 2024, driving demand for advanced climate control. |

| HVAC Contractors & Installers | Product availability, ease of installation, and technical support for diverse projects. | Continued strong demand for efficient HVAC solutions fueled by new construction and energy retrofits. |

| Manufacturing Companies (Metal Forming) | High-precision, durable, and automated metal forming machinery. | Emphasis on Industry 4.0 integration and smart factory concepts in 2024 manufacturing investments. |

| Government & Institutional Clients | Reliable, compliant, and specialized HVAC/air movement systems. | Robust government spending on infrastructure projects in 2024 included building upgrades requiring advanced climate control. |

| Original Equipment Manufacturers (OEMs) | Customized components, consistent quality, and supply chain reliability. | Industrial machinery sector revenue exceeded $700 billion in the US in 2024, underscoring the market for component suppliers. |

Cost Structure

Mestek’s manufacturing and production costs are a substantial part of its business model. These expenses include the significant outlay for raw materials like steel and copper, which are fundamental to their product lines. For instance, in 2024, the price of industrial steel saw fluctuations, impacting direct material costs for manufacturers.

Direct labor, representing the wages and benefits paid to the workforce directly involved in the manufacturing process, is another key component. Factory overheads, encompassing utilities, rent, depreciation of machinery, and ongoing equipment maintenance, also contribute heavily. Efficiently managing these overheads, perhaps through energy-saving initiatives or predictive maintenance, is crucial for maintaining competitive pricing and profitability in 2024.

Mestek's commitment to innovation is reflected in its significant Research and Development Expenses. These costs are crucial for developing new HVAC technologies and advanced metal forming machinery, directly impacting their ability to stay ahead in the market.

For instance, in 2024, Mestek's R&D spending was a key driver in their pursuit of energy-efficient solutions. Such investments are not just operational costs but strategic necessities for future growth and product differentiation.

Mestek's cost structure is heavily influenced by expenses dedicated to sales, marketing, and distribution. This includes the salaries of their sales force, the significant investment in marketing campaigns aimed at brand awareness and lead generation, and participation in crucial industry trade shows to showcase their products. For instance, in 2024, many industrial manufacturing companies like Mestek allocated a substantial portion of their budget to these areas to maintain competitive edge and drive sales growth.

The logistics of getting products to distributors and ultimately to end-users also represent a considerable cost. This encompasses transportation, warehousing, and any associated fees for managing the supply chain effectively. These distribution costs are vital for ensuring product availability and customer satisfaction, directly impacting revenue generation and market penetration.

Personnel and Administrative Costs

Mestek's personnel and administrative costs encompass salaries, benefits, and overheads essential for smooth operations. These include compensation for administrative staff, management, and crucial support functions, ensuring the company is well-staffed and efficiently run.

General overheads are also a significant component, covering expenses like office rent, the maintenance and upgrade of IT infrastructure, and indispensable legal and compliance fees. Managing these elements effectively is key to Mestek's financial stability and profitability.

- Salaries and Benefits: Covering administrative, management, and support teams.

- Office Rent: Costs associated with physical office spaces.

- IT Infrastructure: Investment in technology, software, and hardware.

- Legal and Compliance: Fees for legal counsel and regulatory adherence.

Logistics and Supply Chain Management Costs

Mestek's logistics and supply chain management costs are a significant component of its operational expenses. These costs encompass the movement of raw materials to manufacturing facilities and the distribution of finished products to customers. Efficiently managing these flows is crucial for maintaining competitive pricing and ensuring customer satisfaction across Mestek's varied business segments.

In 2024, companies within industrial manufacturing, a sector Mestek operates in, often see logistics costs representing a substantial portion of their revenue. For instance, transportation alone can account for 5-10% of sales for manufacturers. Mestek's investment in optimizing its supply chain, including warehousing and inventory control, directly impacts its profitability and ability to respond to market demands.

- Transportation Costs: Expenses related to freight, shipping, and carrier fees for both inbound raw materials and outbound finished goods.

- Warehousing Expenses: Costs associated with storing raw materials, work-in-progress, and finished products, including facility rent, utilities, and labor.

- Inventory Management: Spending on systems and processes to track, control, and optimize inventory levels, minimizing holding costs and stockouts.

- Supply Chain Technology: Investments in software and hardware for tracking, planning, and managing the flow of goods and information.

Mestek's cost structure is dominated by manufacturing and production expenses, including raw materials like steel and direct labor. Factory overheads, such as utilities and equipment maintenance, are also significant. For example, in 2024, industrial steel price volatility directly impacted Mestek's material costs.

Research and Development (R&D) represents a strategic investment for Mestek, funding innovation in HVAC and metal forming technologies. In 2024, R&D spending was crucial for developing energy-efficient solutions, driving future market competitiveness.

Sales, marketing, and distribution costs are substantial, covering sales force compensation, advertising, and trade show participation. Logistics, including transportation and warehousing, are vital for product availability and customer satisfaction, with transportation often representing 5-10% of sales for manufacturers in 2024.

Personnel and administrative costs, including salaries, benefits, and general overheads like IT infrastructure and legal fees, ensure efficient company operations and financial stability.

| Cost Category | Key Components | 2024 Impact/Consideration |

| Manufacturing & Production | Raw Materials (Steel, Copper), Direct Labor, Factory Overheads (Utilities, Rent, Maintenance) | Fluctuations in raw material prices directly affect profitability. Efficient overhead management is key. |

| Research & Development | New Technology Development, Product Innovation | Essential for market differentiation and future growth, particularly in energy efficiency. |

| Sales, Marketing & Distribution | Sales Force, Advertising, Trade Shows, Logistics (Transportation, Warehousing) | Critical for market penetration and customer reach; transportation costs can be 5-10% of sales. |

| Personnel & Administrative | Salaries, Benefits, Office Rent, IT Infrastructure, Legal & Compliance | Ensures smooth operations and long-term financial health. |

Revenue Streams

Mestek generates substantial revenue through the sale of its diverse HVAC equipment portfolio. This includes hydronic, steam, and electric heating systems, alongside air handling and cooling units, serving both residential and commercial markets.

Mestek generates revenue by selling specialized metal forming machinery, including presses, shears, and roll-forming equipment, to manufacturing and fabrication businesses. This revenue stream is driven by the consistent need for accurate and efficient metal processing solutions across industries.

In 2024, the industrial machinery sector, which includes metal forming equipment, saw continued investment as companies sought to upgrade their production capabilities. For instance, companies like AMADA, a competitor in this space, reported strong demand for their advanced laser cutting and press brake technologies throughout the year, indicating a healthy market for specialized manufacturing equipment.

Mestek generates revenue from its specialized air movement products, designed for unique ventilation and air handling needs in niche markets. This segment contributes to a diversified revenue base, reducing reliance on broader HVAC markets.

Fees for Engineering Services

Mestek generates income by offering specialized engineering and design expertise, focusing on tailored solutions for intricate HVAC and metal forming challenges. This revenue stream complements their product offerings by providing valuable consultation and technical support.

This service-based approach allows Mestek to capture revenue beyond direct product sales, reinforcing their position as a solutions provider.

- Engineering & Design Services: Income from expert consultation, customized project design, and technical problem-solving for HVAC and metal forming applications.

- Value-Added Support: Revenue generated through ongoing technical assistance and specialized support for complex client projects.

- Customized Solutions: Fees for developing bespoke engineering plans and solutions tailored to specific client needs, enhancing project outcomes.

After-Sales Service, Parts, and Maintenance Contracts

Mestek generates recurring revenue from after-sales services, including the sale of original equipment manufacturer (OEM) replacement parts. This ensures customers can maintain their equipment's optimal performance, contributing to a steady income stream.

Ongoing maintenance services and long-term service contracts are crucial for this revenue segment. These agreements provide customers with scheduled upkeep and support, fostering continued product longevity and customer loyalty.

- OEM Parts Sales: Mestek offers genuine replacement parts, ensuring compatibility and reliability for their installed equipment.

- Maintenance Services: Regular servicing and upkeep contracts are offered to customers to guarantee the continued efficient operation of their machinery.

- Service Contracts: Long-term agreements provide customers with comprehensive support, including preventative maintenance and repair services, creating predictable revenue for Mestek.

Mestek's revenue streams are multifaceted, encompassing the direct sale of HVAC equipment, specialized metal forming machinery, and niche air movement products.

Beyond product sales, the company generates income through engineering and design services, offering tailored solutions and technical expertise.

Furthermore, recurring revenue is secured via after-sales support, including OEM parts and maintenance service contracts, ensuring continued customer engagement and predictable income.

| Revenue Stream | Description | 2024 Market Context/Data Point |

|---|---|---|

| HVAC Equipment Sales | Sale of hydronic, steam, electric heating, and air handling/cooling units. | The global HVAC market was projected to reach over $150 billion in 2024, driven by demand for energy efficiency and smart technologies. |

| Metal Forming Machinery Sales | Sale of presses, shears, and roll-forming equipment to manufacturers. | Industrial machinery sales remained robust in 2024, with companies investing in automation to boost productivity. |

| Air Movement Products | Sale of specialized ventilation and air handling products for niche markets. | Demand for specialized ventilation solutions increased in sectors like data centers and healthcare facilities. |

| Engineering & Design Services | Providing tailored solutions, consultation, and technical support. | Companies increasingly sought specialized engineering services to optimize complex HVAC and manufacturing processes. |

| After-Sales Services (OEM Parts & Maintenance) | Sale of replacement parts and ongoing maintenance/service contracts. | The aftermarket services segment for industrial equipment continued to grow, offering stable recurring revenue. |

Business Model Canvas Data Sources

The Mestek Business Model Canvas is informed by a combination of internal financial statements, operational data, and market research reports. This comprehensive approach ensures each component accurately reflects the company's current strategic positioning and market realities.