HMS PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

HMS Bundle

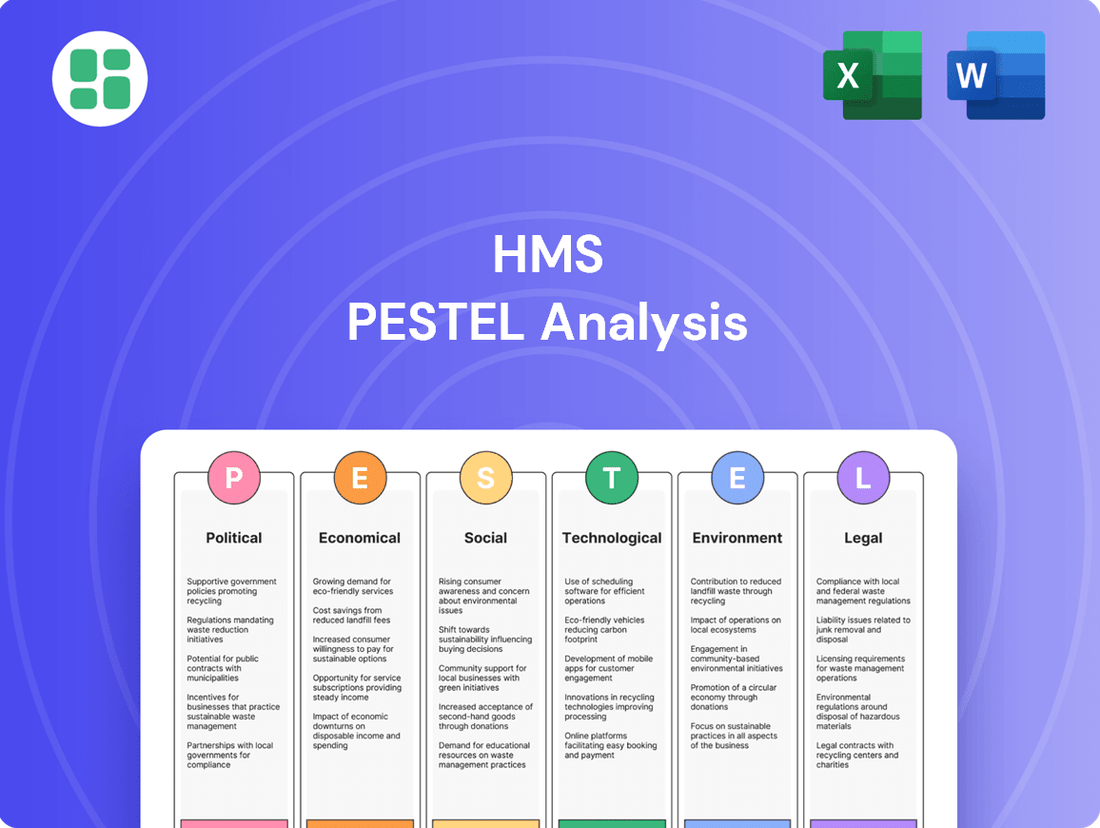

Unlock the hidden forces shaping HMS's destiny with our meticulously crafted PESTLE analysis. Understand the political, economic, social, technological, legal, and environmental factors that will dictate its future success. Equip yourself with actionable intelligence to anticipate challenges and seize emerging opportunities. Download the full PESTLE analysis now and gain the strategic foresight you need to thrive.

Political factors

Governments globally are heavily investing in Industry 4.0, with initiatives like Germany's Industrie 4.0 strategy and the US's Manufacturing USA network driving digital transformation in factories. These programs, often including substantial grants and tax incentives, aim to boost national manufacturing output and technological adoption. For instance, the European Union's Digital Europe Programme allocated €9.2 billion for 2021-2027 to foster digital skills and technologies, directly benefiting companies like HMS Networks that supply critical connectivity hardware for smart manufacturing environments.

Global geopolitical shifts and evolving trade policies, including protectionist measures, significantly impact international supply chains and market access for companies like HMS Networks. For instance, the ongoing trade tensions between major economic blocs continue to create uncertainty. In 2024, the World Trade Organization (WTO) reported that trade restrictions, including tariffs and non-tariff barriers, affected a notable portion of global trade, increasing operational costs for multinational corporations.

Trade disputes and tariffs can directly increase the cost of components or restrict the sale of products across borders, impacting profitability and market reach. As of early 2025, several key industries, including electronics where HMS Networks operates, are still navigating the repercussions of past tariff impositions, leading to adjustments in sourcing strategies and pricing models. This directly affects the cost of goods sold and the competitiveness of products in different regions.

For HMS Networks, operating globally, navigating these complexities and ensuring supply chain resilience becomes a critical political consideration. The company's ability to adapt to changing trade agreements and mitigate the impact of geopolitical instability is paramount. For example, diversifying manufacturing locations and supplier bases, a strategy often employed to counter political risks, was a key focus for many technology firms throughout 2024, aiming to reduce reliance on single-source or politically sensitive regions.

Governments worldwide are tightening regulations on critical infrastructure, particularly focusing on cybersecurity and operational resilience. For instance, the NIS2 directive in Europe, effective from January 2023 with a transposition period, requires significantly enhanced security measures for operational technology (OT) and industrial control systems (ICS). This regulatory push directly translates into a growing market for secure industrial communication solutions.

HMS Networks is well-positioned to capitalize on this trend by offering products that meet these stringent compliance requirements. The increasing demand for secure-by-design solutions for industrial networks, driven by mandates like NIS2, presents a clear opportunity for HMS to provide compliant and robust communication technologies, thereby supporting the enhanced security posture of critical infrastructure operators.

International Standards and Harmonization

The push for international standards in industrial communication, particularly for the Industrial Internet of Things (IIoT), directly impacts market expansion and ensures devices can seamlessly connect. Political initiatives aimed at aligning these standards globally simplify the integration of IIoT technologies and encourage wider adoption.

HMS Networks, a significant player in this space, actively participates in and benefits from these standardization efforts, which underpins the global compatibility of its product portfolio. For instance, the ongoing work within bodies like the International Electrotechnical Commission (IEC) on standards such as IEC 62443 for industrial cybersecurity is vital for building trust and enabling secure IIoT deployments.

- Global Interoperability: Harmonized standards reduce fragmentation, allowing HMS products to function across diverse international industrial environments.

- Market Access: Adherence to recognized international standards facilitates market entry and compliance for HMS solutions in new regions.

- Reduced Integration Costs: Standardized communication protocols lower the complexity and cost of integrating HMS technology with other systems.

- IIoT Growth Driver: Political support for standardization directly fuels the growth of the IIoT market, creating more opportunities for HMS.

Public Sector Investment in Digitalization

Governments worldwide are channeling substantial funds into digital transformation initiatives, aiming to modernize public services and infrastructure. These investments, particularly in areas like smart cities and intelligent transportation, directly fuel the demand for Industrial Internet of Things (IIoT) solutions and robust industrial communication technologies. For instance, the European Union's Digital Decade targets aim to significantly increase public investment in digital infrastructure and skills, creating a fertile ground for companies like HMS Networks.

These government-backed projects, from upgrading energy grids to enhancing public safety networks, necessitate advanced connectivity and data management capabilities. The push for more efficient and responsive public utilities means a greater need for secure, reliable industrial communication hardware and software. This trend is evident in national digital strategies, such as the United States' focus on modernizing critical infrastructure through initiatives like the Infrastructure Investment and Jobs Act, which allocates significant resources towards broadband expansion and smart grid technologies.

- Increased Government Spending: Global public sector spending on digital transformation projects, particularly in infrastructure, is projected to grow, with estimates suggesting a compound annual growth rate of over 15% in the coming years.

- Smart City Initiatives: Over 1,000 smart city projects were underway globally as of late 2024, many of which involve substantial investments in IIoT and connected infrastructure.

- Energy Grid Modernization: Investments in smart grids are a key component of national energy policies, with billions allocated in regions like North America and Europe for grid resilience and digitalization.

- Transportation Infrastructure: Governments are prioritizing the digitalization of transportation networks, including smart traffic management systems and connected vehicle infrastructure, driving demand for specialized communication solutions.

Government investments in Industry 4.0 and digital transformation, such as the EU's €9.2 billion Digital Europe Programme, directly benefit companies like HMS Networks by creating demand for their connectivity solutions in smart manufacturing. Geopolitical shifts and trade policies, exemplified by WTO data on trade restrictions in 2024, impact supply chains and market access, necessitating strategies for resilience and diversification.

Heightened government regulations on cybersecurity for critical infrastructure, like the NIS2 directive, create a market opportunity for secure industrial communication solutions. Furthermore, political support for international IIoT standards, such as IEC 62443, fosters global interoperability and market expansion for HMS Networks.

| Factor | Impact on HMS Networks | Supporting Data (2024/2025) |

| Government Digitalization Investments | Increased demand for IIoT and connectivity solutions | EU Digital Europe Programme: €9.2 billion (2021-2027); >1,000 global smart city projects (late 2024) |

| Trade Policies & Geopolitics | Supply chain disruption, market access challenges | WTO: Notable portion of global trade affected by restrictions (2024); ongoing navigation of tariff repercussions (early 2025) |

| Cybersecurity Regulations | Opportunity for secure communication hardware | NIS2 Directive (effective Jan 2023) driving demand for OT/ICS security |

| Standardization Efforts | Enhanced global interoperability and market access | IEC 62443 for industrial cybersecurity vital for IIoT deployments |

What is included in the product

The HMS PESTLE Analysis provides a comprehensive understanding of the external forces impacting the business, meticulously examining Political, Economic, Social, Technological, Environmental, and Legal factors.

This in-depth review equips stakeholders with actionable insights to navigate the macro-environment and strategically position the HMS for success.

A clean, summarized version of the full analysis for easy referencing during meetings or presentations, reducing the time spent deciphering complex external factors.

Helps support discussions on external risk and market positioning during planning sessions by providing a structured framework to identify and address potential challenges.

Economic factors

The global industrial automation market is on a significant upward trend, with projections indicating it could reach between USD 420.49 billion and USD 569.27 billion by 2033-2034. This growth is expected to occur at a compound annual growth rate (CAGR) of 9.1% to 9.31% starting from 2025.

Key drivers for this expansion include the escalating need for improved operational efficiency, greater precision, and higher productivity across a variety of industries. Sectors like manufacturing, healthcare, and food and beverages are particularly pushing this demand.

As a supplier of industrial communication solutions, HMS Networks is strategically placed to capitalize on this robust market growth. The company's offerings are integral to the very systems that are fueling this automation surge.

The Industrial Internet of Things (IIoT) market is experiencing robust expansion, with forecasts suggesting a valuation of $286.3 billion by 2029. This growth is driven by the increasing adoption of IIoT for operational efficiency and productivity gains.

The market's trajectory is impressive, with some projections estimating it could reach $500 billion by 2025, up from $194.4 billion in 2024. This highlights the critical role IIoT plays in modern industrial transformation.

HMS Networks' strategic alignment with IIoT solutions positions it to capitalize on this significant market growth, presenting substantial revenue opportunities. The company's offerings are well-suited to meet the escalating demand for connected industrial technologies.

Manufacturing firms are significantly boosting capital expenditure on digital upgrades and smart factory technologies. This trend, evident through 2024 and projected into 2025, is fueled by the pursuit of enhanced production efficiency and lower operational costs via automation. For instance, global spending on industrial automation, a key component of smart factories, is expected to reach over $200 billion by 2025, indicating a strong commitment to capital investment in this area.

These investments are strategically aimed at optimizing production workflows, minimizing equipment downtime, and realizing substantial cost reductions. By leveraging automation and data analytics, manufacturers are transforming their operations. The adoption of Industrial Internet of Things (IIoT) solutions, crucial for smart factories, saw a robust growth rate of 15% in 2024, reflecting this capital allocation.

HMS Networks' solutions are vital enablers for these capital-intensive modernization projects, facilitating smooth data flow and remote operational oversight. As companies deploy more connected devices and advanced analytics, the demand for reliable industrial communication technology, like that offered by HMS, continues to climb, supporting the core objectives of these capital expenditure initiatives.

Impact of Inflation and Cost Pressures

Persistent inflation and rising costs for raw materials and labor worldwide are forcing manufacturers to find ways to be more efficient and cut expenses, often through automation. This economic reality is a significant push for companies to invest in industrial communication and automation technologies. HMS Networks' solutions are designed to help businesses improve their operations, minimize waste, and use their resources more effectively, directly tackling these cost pressures.

For instance, in 2024, many industrial sectors are reporting substantial increases in input costs. According to industry surveys, the average cost of key manufacturing components saw an increase of 8-12% year-over-year. This environment makes the efficiency gains offered by automation particularly attractive. HMS Networks' products, such as their Anybus and Ewon solutions, enable seamless data exchange and remote monitoring, which are crucial for optimizing production lines and reducing operational overhead.

- Increased Material Costs: Global supply chain disruptions and geopolitical events have led to an average 10% rise in the cost of metals and electronic components for manufacturers in 2024.

- Labor Shortages and Wage Inflation: Many regions are experiencing a shortage of skilled labor, driving up wages by an estimated 5-7% in manufacturing roles during 2024, further incentivizing automation.

- Demand for Efficiency: Companies are actively seeking solutions that can reduce energy consumption and improve throughput, with automation technologies projected to boost productivity by up to 15% in well-implemented scenarios.

- HMS Networks' Role: By providing robust industrial communication, HMS enables the data collection and analysis necessary for identifying and implementing cost-saving automation strategies.

Supply Chain Disruptions and Resilience Investment

The ongoing global supply chain disruptions, highlighted by events in 2024, are forcing companies to prioritize resilience. This means substantial investment in technologies that offer real-time visibility and control over industrial operations. For instance, a report from McKinsey in late 2024 indicated that over 60% of companies were actively redesigning their supply chains to be more agile and less vulnerable to shocks.

Companies are increasingly adopting advanced technologies like the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and digital twins. These tools are essential for monitoring operations, predicting potential bottlenecks, and proactively mitigating disruptions. The adoption rate of IIoT devices in manufacturing alone saw a projected 20% year-over-year increase in 2024, according to Gartner.

This heightened demand for supply chain resilience directly benefits companies like HMS Networks, which provide critical connectivity and remote access solutions. These solutions are fundamental for enabling the robust and adaptable digital infrastructure required for modern, resilient supply chains. The market for industrial communication and IIoT connectivity is expected to grow by approximately 15% annually through 2025, driven by these very needs.

- Increased Investment in Supply Chain Resilience: Global supply chain disruptions have spurred significant investment in building more robust and adaptable operational frameworks.

- Adoption of Advanced Technologies: Companies are heavily investing in IIoT, AI, and digital twins to enhance visibility, prediction, and mitigation of supply chain issues.

- Demand for Connectivity Solutions: The need for real-time monitoring and control directly fuels demand for HMS Networks' connectivity and remote access products, crucial for supply chain agility.

- Market Growth in Industrial Connectivity: The industrial communication and IIoT connectivity sector is projected for substantial growth, driven by the imperative for resilient and digitally integrated supply chains.

Economic factors are significantly shaping the industrial automation landscape. Persistent inflation and rising input costs, with key manufacturing components seeing an average 10% increase in 2024, are compelling companies to seek efficiency through automation. Labor shortages and wage inflation, estimated at 5-7% in manufacturing roles during 2024, further incentivize the adoption of automated solutions. These economic pressures directly drive demand for technologies that enhance productivity and reduce operational overhead.

HMS Networks is well-positioned to benefit from these economic trends. Their industrial communication solutions enable the data collection and analysis necessary for identifying and implementing cost-saving automation strategies. By facilitating seamless data exchange and remote monitoring, HMS products help businesses optimize production and reduce operational costs, directly addressing the challenges posed by increasing material and labor expenses.

| Economic Factor | Impact on Industrial Automation | HMS Networks' Relevance |

|---|---|---|

| Inflation & Rising Input Costs | Drives demand for efficiency and cost reduction via automation. | Enables operational optimization and resource management. |

| Labor Shortages & Wage Inflation | Incentivizes automation to offset labor costs and skill gaps. | Provides connectivity for automated systems and remote oversight. |

| Supply Chain Disruptions | Promotes investment in resilient, visible, and controlled operations. | Offers critical connectivity for real-time monitoring and agile supply chains. |

Preview Before You Purchase

HMS PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use.

Our HMS PESTLE Analysis is a comprehensive tool designed to help you understand the external factors influencing your business.

You'll gain insights into Political, Economic, Social, Technological, Legal, and Environmental aspects, all presented in a clear and actionable format.

Sociological factors

The manufacturing sector is grappling with a significant shortage of skilled workers, a challenge that's pushing companies to embrace automation. This isn't just about replacing people; it's about maintaining and boosting production capacity while reducing dependence on manual tasks. For instance, in 2024, the U.S. manufacturing sector reported a deficit of over 770,000 workers, highlighting the urgency for technological solutions.

This drive towards industrial automation directly plays into the hands of companies like HMS Networks. Their solutions are crucial for seamlessly integrating these automated systems, enabling businesses to enhance productivity and operational efficiency amidst labor constraints. The adoption of Industry 4.0 technologies, which HMS supports, is expected to grow significantly, with the global industrial automation market projected to reach over $300 billion by 2025, up from an estimated $220 billion in 2023.

The widespread adoption of remote and hybrid work, significantly boosted since 2020, has fundamentally reshaped how businesses operate. This shift necessitates robust remote access and management capabilities, especially within industrial settings where operational continuity is paramount. Companies are increasingly investing in solutions that allow for real-time monitoring and control of machinery and systems, regardless of physical location.

HMS Networks' remote access solutions are instrumental in facilitating this transition. Their technology enables secure and reliable connections to industrial equipment, ensuring that operations can be managed effectively from anywhere. This capability is crucial for maintaining flexibility and resilience in today's dynamic business landscape.

By 2024, it's estimated that over 30% of the global workforce will be working remotely at least part-time. This trend directly fuels the demand for industrial IoT (IIoT) solutions that support remote management, with the IIoT market projected to reach over $1 trillion by 2026, highlighting the significant economic impact of these sociological changes.

Societal acceptance of AI and automation is rapidly increasing, with a growing number of people recognizing their potential to improve efficiency and safety in various sectors. This trend is particularly evident in the workplace, where businesses are increasingly adopting AI-powered tools to streamline operations. For instance, a 2024 survey indicated that over 65% of businesses are exploring or actively implementing AI solutions to enhance productivity.

This evolving acceptance directly impacts how industries integrate advanced technologies. As more companies witness the tangible benefits of human-machine collaboration, the willingness to invest in and deploy these systems grows. HMS Networks' solutions play a crucial role here, facilitating the seamless communication and interaction necessary for these intelligent systems to function effectively, driving this societal shift forward.

Demand for Upskilling and Reskilling

The accelerating pace of technological change, particularly in industrial automation and the Industrial Internet of Things (IIoT), is creating a substantial need for workers to acquire new skills or update existing ones. This shift is driven by the increasing integration of smart technologies across industries.

Educational bodies and businesses are actively collaborating to equip employees with the competencies required to manage and operate these advanced systems. For instance, by 2025, it's projected that over 149 million jobs globally will need to adapt to new technological demands, highlighting the urgency of reskilling initiatives.

This growing demand for adaptable skills translates into a market preference for solutions that are intuitive and easy to implement. Companies are seeking technologies that simplify complex industrial communication, a trend that aligns well with HMS Networks' strategic focus on user-friendly integration.

- Workforce Adaptability: Industries are prioritizing employees who can manage AI, IoT, and automation systems.

- Skill Gap: A significant portion of the global workforce will require reskilling by 2025 to meet new technological demands.

- Demand for Simplicity: User-friendly and easily integrable solutions are becoming critical for technology adoption.

ESG and Corporate Social Responsibility Expectations

Consumer and investor demand for strong Environmental, Social, and Governance (ESG) performance is increasingly shaping manufacturing operations. Businesses are feeling more pressure to showcase their dedication to social matters, such as fair labor and positive community engagement. For instance, in 2024, the global ESG investing market reached an estimated $37.1 trillion, highlighting its significant influence.

Even though HMS Networks is primarily a technology company, its offerings can indirectly bolster clients' ESG objectives. Their solutions can foster safer workplaces and enhance resource efficiency, aligning with broader corporate social responsibility goals. For example, improved operational visibility through HMS Networks' technology can reduce waste and energy consumption in manufacturing processes.

- Growing ESG Investment: The global ESG investing market was valued at approximately $37.1 trillion in 2024, indicating a strong market preference for sustainable businesses.

- Labor Practice Scrutiny: Companies face increased scrutiny regarding their labor practices, supply chain ethics, and overall community impact.

- Resource Efficiency Support: HMS Networks' technology can contribute to resource efficiency and safer work environments for their clients, indirectly aiding ESG compliance.

Societal acceptance of AI and automation is climbing, with more people seeing their benefits for efficiency and safety. This trend is particularly strong in workplaces, where AI tools are increasingly used to streamline operations. A 2024 survey found over 65% of businesses are exploring or implementing AI for productivity gains.

This growing acceptance directly influences how industries adopt advanced technologies. As businesses see the advantages of human-machine collaboration, their willingness to invest in and deploy these systems increases. HMS Networks' solutions are key in enabling the smooth communication needed for these intelligent systems to work, driving this societal shift.

The global workforce's adaptability to new technologies is paramount, with a significant demand for skills in AI, IoT, and automation. By 2025, an estimated 149 million jobs worldwide will need to adapt to technological advancements, underscoring the critical need for reskilling. This necessitates intuitive and easily integrated solutions, a focus for HMS Networks.

Consumer and investor focus on Environmental, Social, and Governance (ESG) performance is significantly influencing manufacturing. Companies are under pressure to demonstrate commitment to social issues like fair labor and community engagement. The global ESG investing market reached approximately $37.1 trillion in 2024, showing its substantial market influence.

Technological factors

Industrial Ethernet is solidifying its grip on the industrial networking landscape, with projections showing it will account for 76% of all new installations in 2025, a notable increase from 71% in 2024. This surge highlights a decisive move away from older fieldbus systems, driven by the escalating demand for greater bandwidth, faster communication speeds, and enhanced scalability in modern industrial environments.

HMS Networks is strategically positioned to benefit from this market trend, thanks to its comprehensive range of Industrial Ethernet solutions. The company's ability to offer robust and high-performance networking products aligns perfectly with the industry's evolving needs, allowing it to capture a significant share of this expanding market.

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing industrial automation. These technologies are key to enabling predictive maintenance, improving quality control, and optimizing production processes. For example, AI can analyze vast amounts of data from factory equipment to forecast potential breakdowns, thereby minimizing costly downtime and enhancing operational efficiency.

HMS Networks plays a crucial role by providing the essential data infrastructure that underpins these AI-driven advancements. Their solutions ensure that the data needed for AI algorithms to generate valuable insights and power new applications is reliably collected and transmitted. This connectivity is vital for realizing the full potential of AI in industrial settings.

Edge computing is rapidly becoming a cornerstone for industrial IoT, allowing for immediate data analysis right where it's generated. This significantly cuts down on delays, which is vital for many operational processes.

The rollout of 5G is a major enabler here, offering the super-fast and reliable wireless connections needed for sophisticated industrial uses. For example, by the end of 2024, it's projected that over 30% of global mobile connections will be 5G, a figure expected to climb further into 2025, supporting this trend.

HMS Networks' communication modules and gateways are key to harnessing these advancements. They facilitate distributed data processing and ensure smooth wireless communication, allowing businesses to fully benefit from the power of edge computing and 5G.

Digital Twin Technology Adoption

The increasing adoption of digital twin technology is revolutionizing manufacturing by enabling virtual replicas for simulation and optimization. This allows for proactive maintenance and the identification of operational bottlenecks without physical intervention. For instance, a 2024 report indicated that the global digital twin market is projected to reach $65.5 billion by 2027, demonstrating significant growth. HMS Networks' solutions are crucial in facilitating the extensive data exchange necessary for these accurate digital twins, supporting this advanced simulation and planning trend.

HMS Networks' role is pivotal as the complexity of digital twins demands robust and reliable data connectivity. Their industrial communication and networking solutions ensure the seamless flow of real-time data from physical assets to their virtual counterparts. This capability is essential for manufacturers aiming to leverage digital twins for enhanced efficiency and predictive capabilities. The market for industrial IoT, which underpins digital twin technology, saw investments of over $150 billion in 2023, highlighting the strategic importance of this sector.

- Digital Twin Market Growth: The global digital twin market is expected to grow substantially, reaching an estimated $65.5 billion by 2027.

- Data Exchange Imperative: Accurate digital twins rely on extensive and reliable data exchange, a core competency of HMS Networks.

- Industrial IoT Investment: The industrial IoT sector, a key enabler of digital twins, attracted over $150 billion in investments in 2023.

- Operational Optimization: Digital twins enable proactive maintenance, bottleneck identification, and fine-tuning of operations, driving efficiency.

Evolving Cybersecurity Landscape for IIoT

The increasing connectivity of industrial systems places cybersecurity at the forefront of concerns. The IoT security sector is anticipated to expand significantly, moving from an estimated $8.7 billion in 2024 to $11.36 billion in 2025, highlighting the growing market for these solutions.

Industrial IoT (IIoT) environments introduce complex security challenges. Their hybrid nature, blending Information Technology (IT) and Operational Technology (OT), alongside an expanding attack surface, creates unique vulnerabilities that demand specialized attention.

To address these evolving threats, HMS Networks must prioritize continuous innovation in cybersecurity. Integrating advanced security features directly into their product offerings is crucial for safeguarding the integrity and resilience of industrial digital ecosystems.

- Market Growth: IoT security market projected to grow from $8.7 billion in 2024 to $11.36 billion in 2025.

- IIoT Challenges: Hybrid IT/OT environments and increasing attack surfaces create unique security risks.

- HMS Strategy: Continuous innovation and integration of robust security features are essential for product development.

- Ecosystem Protection: Strong cybersecurity measures are vital to protect industrial digital ecosystems from threats.

The industrial automation landscape is rapidly evolving with technological advancements. Industrial Ethernet is becoming the dominant networking standard, projected to power 76% of new installations by 2025, up from 71% in 2024, due to demands for higher bandwidth and faster speeds. AI and Machine Learning are transforming operations through predictive maintenance and process optimization, with HMS Networks providing the essential data infrastructure for these AI applications.

Edge computing, supported by the expansion of 5G connectivity, enables real-time data analysis at the source, reducing latency. By the end of 2024, over 30% of global mobile connections are expected to be 5G, a figure poised for further growth into 2025. HMS Networks' solutions facilitate this distributed processing and wireless communication.

Digital twin technology is also a significant trend, with the global market expected to reach $65.5 billion by 2027, requiring robust data exchange that HMS Networks supports. Furthermore, the increasing connectivity in industrial systems amplifies the need for cybersecurity, with the IoT security market projected to grow from $8.7 billion in 2024 to $11.36 billion in 2025.

| Technology Trend | 2024 Data/Projection | 2025 Data/Projection | HMS Networks Relevance |

|---|---|---|---|

| Industrial Ethernet Adoption | 71% of new installations | 76% of new installations | Provides comprehensive Ethernet solutions |

| 5G Mobile Connections | >30% of global connections | Further growth | Enables edge computing and wireless communication |

| Digital Twin Market | Significant growth | Projected $65.5 billion by 2027 | Facilitates data exchange for digital twins |

| IoT Security Market | $8.7 billion | $11.36 billion | Integrates security features for IIoT |

Legal factors

Strict data protection and privacy regulations, like GDPR in Europe and CCPA in California, significantly influence how industrial data is handled by companies such as HMS Networks. These laws dictate the collection, processing, and transmission of operational data, requiring robust compliance measures for their communication solutions. For instance, GDPR fines can reach up to 4% of annual global turnover or €20 million, whichever is higher, underscoring the financial risk of non-compliance.

New cybersecurity mandates, such as the EU's Cyber Resilience Act (CRA) and the revised Radio Equipment Directive (RED), are now in effect, setting strict security requirements for connected devices entering the European market. These regulations emphasize a secure-by-design approach, requiring robust vulnerability management and ongoing security updates for products throughout their operational life. For HMS Networks, this means ensuring their industrial communication devices fully comply with these rigorous standards to maintain market access within the EU.

Protecting intellectual property rights (IPR) is crucial for technology firms like HMS Networks, given their significant investment in R&D for unique industrial communication solutions. Legal structures governing patents, trademarks, and copyrights are fundamental to securing their innovations and sustaining a competitive advantage.

In 2024, global IP filings continued to show robust activity, with the World Intellectual Property Organization (WIPO) reporting a steady increase in patent applications for advanced manufacturing technologies, a sector where HMS Networks operates. Strong enforcement of these rights is vital for HMS Networks' sustained expansion and market standing.

Product Liability and Safety Standards

Manufacturers of industrial communication hardware and software, including HMS Networks, face stringent product liability laws and safety standards. These regulations are critical for ensuring that devices operate reliably and do not create hazards for personnel or disrupt industrial processes. For instance, compliance with standards like IEC 61000 for electromagnetic compatibility (EMC) is paramount in industrial settings, preventing interference that could lead to operational failures.

HMS Networks must integrate rigorous testing and quality control measures to meet these demanding safety requirements. This commitment to adherence helps them to effectively mitigate potential legal risks associated with product defects or failures. By consistently meeting and exceeding these standards, HMS can bolster customer trust and confidence in the dependability and safety of their communication solutions.

- Product Liability: HMS Networks is subject to laws holding manufacturers responsible for harm caused by defective products, necessitating robust quality assurance.

- Safety Standards: Adherence to industry-specific safety protocols, such as those related to electrical safety and data integrity, is non-negotiable.

- Risk Mitigation: Investing in comprehensive testing and certification processes is key to reducing the likelihood of costly recalls or litigation.

- Customer Confidence: Demonstrating a strong commitment to safety and reliability through compliance builds a reputation that attracts and retains customers in critical industrial sectors.

International Trade and Export Control Laws

Operating globally, HMS Networks must navigate a complex web of international trade laws, export control regulations, and sanctions. These legal structures dictate the cross-border flow of technology, directly influencing market access and the efficiency of supply chains. For instance, in 2024, the ongoing geopolitical shifts continue to place a spotlight on export controls, particularly concerning advanced networking technologies.

Compliance with these evolving frameworks is paramount for HMS Networks' international sales and distribution strategies. Failure to adhere can lead to significant penalties, including fines and restrictions on business operations.

- Export Control Enforcement: Increased scrutiny on technology exports by major economies in 2024 means stricter enforcement of existing regulations.

- Sanctions Impact: Evolving sanctions regimes can abruptly alter market access and require immediate adjustments to distribution channels.

- Trade Agreements: Changes in international trade agreements, such as potential updates to tariffs or customs procedures, can affect the cost and speed of product delivery globally.

- Data Localization Laws: Growing trends in data localization require careful consideration of how and where data is processed and stored, impacting service delivery models.

The evolving legal landscape for industrial communication, particularly concerning data protection and cybersecurity, presents significant compliance challenges. Regulations like the EU's Cyber Resilience Act (CRA) and updated data privacy laws necessitate robust security-by-design principles and continuous vulnerability management for products like those from HMS Networks.

Intellectual property rights remain a critical legal factor, safeguarding the innovations of technology firms. In 2024, WIPO data showed continued growth in patent filings for advanced manufacturing technologies, highlighting the need for strong IP protection for companies like HMS Networks to maintain their competitive edge.

Product liability and safety standards are paramount, with adherence to regulations like IEC 61000 for electromagnetic compatibility being essential. HMS Networks must integrate rigorous testing to mitigate legal risks associated with product defects and ensure customer confidence through unwavering commitment to safety and reliability.

Navigating international trade, export controls, and sanctions is crucial for global operations. In 2024, geopolitical shifts intensified scrutiny on technology exports, demanding strict compliance from companies like HMS Networks to ensure market access and efficient supply chains.

Environmental factors

The manufacturing sector is seeing a significant push towards Environmental, Social, and Governance (ESG) principles. This is fueled by demands from consumers, investors, and regulators alike. Companies are actively weaving sustainability into their fundamental operations, with a particular focus on minimizing their environmental footprint.

HMS Networks' offerings play a crucial role in supporting their clients' sustainability agendas. Their solutions empower businesses to optimize energy consumption and enhance resource efficiency across various industrial processes, directly contributing to greener operations.

Governments worldwide are tightening energy efficiency regulations, with many aiming for significant reductions in industrial energy consumption by 2030. For instance, the European Union's Energy Efficiency Directive targets a 32.5% improvement by 2030. These mandates are pushing manufacturers to invest in solutions that monitor and optimize energy usage, directly impacting operational costs.

In response, manufacturers are actively seeking technologies that provide granular insights into their energy consumption patterns. This drive is fueled by both the desire to lower expenses and the necessity to meet increasingly stringent environmental targets. The global market for industrial energy management systems was valued at over $25 billion in 2023 and is projected to grow substantially.

HMS Networks' technology plays a crucial role by enabling seamless data collection from diverse machinery and industrial networks. This capability allows businesses to gain a comprehensive understanding of their energy footprint, facilitating better management, compliance with new standards, and the identification of cost-saving opportunities.

The global push towards a circular economy is reshaping manufacturing, focusing on waste reduction and material reuse. This shift demands enhanced visibility across supply chains, a challenge HMS Networks' solutions are designed to address. By improving material tracking and optimizing production flows, their technology helps companies minimize waste, aligning with sustainability goals and potentially reducing disposal costs, which in 2024 are seeing increased scrutiny from regulatory bodies.

Climate Change Impact on Supply Chains

Climate change is increasingly disrupting global supply chains through extreme weather events. For instance, in 2024, a severe drought in Southeast Asia significantly impacted the availability of key electronic components, leading to production delays for many manufacturers. These disruptions translate directly into increased operational costs and reduced efficiency.

Businesses are responding by investing heavily in supply chain resilience. By 2025, global spending on supply chain visibility and risk management technologies is projected to reach $15 billion, up from $10 billion in 2023. This proactive approach aims to anticipate and mitigate environmental risks before they cripple operations.

HMS Networks' solutions play a vital role in this shift towards climate resilience. Their offerings enable real-time monitoring of environmental conditions and remote management of industrial assets, allowing businesses to adapt quickly to changing circumstances. This enhanced visibility and control are crucial for building more adaptable and climate-resilient industrial operations.

- Increased Frequency of Extreme Weather: Events like floods, heatwaves, and storms are becoming more common, directly impacting transportation routes and production facilities.

- Supply Chain Cost Increases: Disruptions due to climate events led to an estimated 10-15% increase in logistics costs for affected industries in 2023.

- Investment in Resilient Technologies: Companies are prioritizing IoT and AI-driven solutions for predictive maintenance and supply chain visibility to counter environmental risks.

- HMS Networks' Contribution: Providing connectivity and edge solutions that enable real-time data collection for better environmental monitoring and operational control.

Demand for Green Manufacturing and Eco-Friendly Products

The global push for sustainability is significantly increasing the demand for green manufacturing and eco-friendly products. Consumers and businesses alike are prioritizing products with a lower environmental impact, from reduced emissions to responsible material sourcing.

This trend is not just a consumer preference; it's becoming a regulatory and competitive imperative. Companies are investing in cleaner production methods, water conservation, and circular economy principles to meet these evolving expectations. For instance, by 2025, the global market for green building materials is projected to reach over $400 billion, highlighting the scale of this shift.

- Growing Consumer Preference: Surveys indicate a substantial majority of consumers are willing to pay more for sustainable products.

- Regulatory Drivers: Stricter environmental regulations worldwide are compelling manufacturers to adopt greener practices.

- Supply Chain Pressure: Large corporations are increasingly demanding sustainability from their suppliers, creating a ripple effect.

- Technological Advancements: Innovations in materials science and manufacturing processes are making eco-friendly options more viable and cost-effective.

Environmental factors are increasingly shaping manufacturing strategies, driven by a global commitment to sustainability and the tangible impacts of climate change.

Governments are enacting stricter regulations, pushing for energy efficiency and reduced emissions, with many targeting substantial improvements by 2030.

Extreme weather events are disrupting supply chains, leading to increased costs and a growing investment in resilient technologies.

HMS Networks' solutions facilitate this transition by enabling better data collection for environmental monitoring and operational control, thereby supporting greener manufacturing and supply chain resilience.

| Environmental Factor | Impact on Manufacturing | HMS Networks' Role | Relevant Data/Projections |

|---|---|---|---|

| Climate Change & Extreme Weather | Supply chain disruptions, increased operational costs, need for resilience | Enables real-time monitoring and remote asset management for adaptability | Global spending on supply chain visibility projected to reach $15 billion by 2025. 10-15% logistics cost increase in 2023 due to climate events. |

| Energy Efficiency Regulations | Mandates for reduced industrial energy consumption, driving investment in management systems | Provides seamless data collection for energy consumption insights and optimization | EU Energy Efficiency Directive targets 32.5% improvement by 2030. Global industrial energy management systems market over $25 billion in 2023. |

| Circular Economy Push | Focus on waste reduction and material reuse, demanding supply chain visibility | Improves material tracking and production flow optimization to minimize waste | Increased regulatory scrutiny on waste disposal costs in 2024. |

| Demand for Green Products | Growing consumer and regulatory preference for eco-friendly manufacturing and products | Supports clients' sustainability agendas by enabling greener operations | Global green building materials market projected to exceed $400 billion by 2025. |

PESTLE Analysis Data Sources

Our PESTLE analysis is built on a robust foundation of data from official government statistics, reputable financial institutions like the World Bank and IMF, and leading market research firms. This ensures that every insight into political, economic, social, technological, legal, and environmental factors is grounded in current, verifiable information.