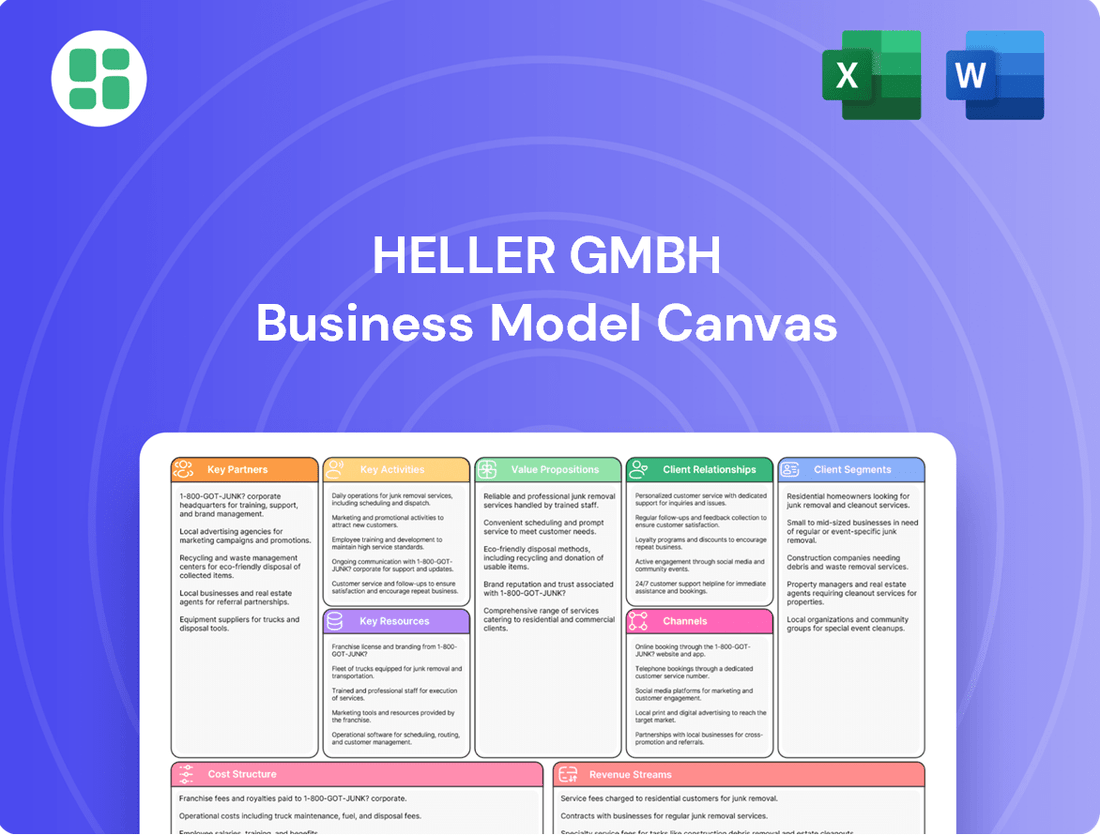

Heller GmbH Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Heller GmbH Bundle

Unlock the core strategies behind Heller GmbH's success with their comprehensive Business Model Canvas. This detailed breakdown reveals their customer relationships, revenue streams, and key resources, offering a clear roadmap for their operations. Discover how Heller GmbH effectively delivers value and captures market share, providing invaluable insights for your own business planning.

Partnerships

Heller GmbH has solidified a crucial strategic partnership with H.I.G. Capital, a prominent global alternative investment firm, as announced in February 2025. This alliance is designed to fast-track Heller's strategic objectives, encompassing investments in cutting-edge technologies, operational enhancements, and global market expansion.

The infusion of H.I.G. Capital's substantial financial backing and extensive international network is poised to significantly accelerate Heller's ongoing transformation program. This collaboration is anticipated to reinforce Heller's position as a leader in innovation within its sector.

Heller GmbH actively pursues strategic development and technology partnerships to drive innovation. A prime example is the collaboration announced with Seco Tools AB in July 2025, aimed at revolutionizing machining technology.

These crucial alliances concentrate on accelerating product development, seamlessly integrating advanced solutions, and bolstering capabilities in key areas such as digitalization and automation. Such focused efforts are vital for successfully introducing cutting-edge innovations to the market and effectively responding to the dynamic demands of the industry.

Heller GmbH's success hinges on its specialized suppliers of high-precision components and advanced materials. These partners are crucial for producing the sophisticated machine tools Heller is known for.

In 2024, Heller continued to emphasize robust relationships with these key suppliers, ensuring consistent quality and reliability in its product offerings. This focus directly impacts the performance and precision of Heller's advanced manufacturing systems.

By securing top-tier components, Heller guarantees its machines meet the exacting standards of demanding sectors like automotive and aerospace, where even minor deviations can have significant consequences.

Research and Development Institutions

Heller GmbH actively collaborates with universities and research institutions to maintain its edge in cutting-edge manufacturing technologies. These partnerships are crucial for staying ahead in fields like artificial intelligence and sustainable production. For instance, in 2024, Heller announced a joint research initiative with the Fraunhofer Institute for Production Technology IPT focusing on advanced digital twin applications for predictive maintenance, aiming to reduce machine downtime by an estimated 15%.

These collaborations enable a vital flow of knowledge and the development of future-ready solutions. Through joint research projects, Heller gains access to specialized expertise and talent, fostering innovation in areas such as Industry 5.0 concepts. This strategic engagement ensures Heller remains a leader in the manufacturing sector, capable of meeting evolving market needs and technological challenges.

- University Collaborations: Partnerships with leading technical universities provide access to emerging research and a pipeline of skilled engineers.

- Joint Research Projects: Focus on areas like AI-driven process optimization and sustainable material usage in production.

- Knowledge Transfer: Facilitates the rapid integration of academic breakthroughs into Heller's product development cycle.

- Innovation Leadership: Ensures Heller continues to offer state-of-the-art manufacturing solutions to its global clientele.

Automation Solution Providers

Heller GmbH’s strategic alliances with automation solution providers are fundamental to its business model, particularly for delivering integrated and flexible manufacturing cells. These partnerships are crucial for incorporating advanced robotics and automation technologies into Heller’s machine tool offerings, thereby boosting customer efficiency and productivity.

These collaborations directly support Heller’s vision of creating smart, networked production environments. For instance, by integrating specialized robotic systems, Heller can offer comprehensive solutions that streamline complex manufacturing processes, a capability highly valued in the current industrial landscape. In 2024, the global industrial robotics market was projected to reach approximately $70 billion, highlighting the significant demand for such integrated automation.

- Robotics Integration: Partnerships enable the seamless integration of robotic arms and automated handling systems with Heller’s advanced machining centers.

- Flexible Manufacturing Cells: Collaborations facilitate the creation of highly adaptable production units that can be reconfigured for various tasks, enhancing operational flexibility for customers.

- Smart Production Environments: These alliances are key to developing interconnected manufacturing systems that leverage data for optimized performance and predictive maintenance.

- Enhanced Customer Value: By bundling machine tools with cutting-edge automation, Heller provides end-to-end solutions that improve throughput and reduce operational costs for its clients.

Heller GmbH's key partnerships are vital for its innovation and market reach. The alliance with H.I.G. Capital, announced in February 2025, provides significant financial backing and global network access to accelerate strategic goals. Furthermore, collaborations with technology firms like Seco Tools AB, as highlighted in July 2025, are crucial for advancing machining technology and product development.

These strategic relationships extend to specialized suppliers of high-precision components and advanced materials, ensuring the quality and reliability of Heller's sophisticated machine tools. In 2024, Heller reinforced these supplier relationships to maintain consistent product performance, particularly for demanding sectors like automotive and aerospace.

Collaborations with universities and research institutions, such as the 2024 joint initiative with Fraunhofer Institute for Production Technology IPT on digital twins, are essential for staying at the forefront of manufacturing technology, including AI and sustainable production. These partnerships facilitate knowledge transfer and the development of future-ready solutions.

Moreover, partnerships with automation solution providers are fundamental for integrating robotics and automation into Heller's offerings, creating flexible manufacturing cells and smart production environments. The global industrial robotics market's projected growth to approximately $70 billion in 2024 underscores the importance of these integrations.

| Partnership Type | Key Partner Example | Strategic Importance | 2024/2025 Highlight |

|---|---|---|---|

| Financial & Strategic Investment | H.I.G. Capital | Accelerates strategic objectives, market expansion | Announced February 2025 |

| Technology Development | Seco Tools AB | Revolutionizes machining technology, product innovation | Announced July 2025 |

| Component & Material Supply | Specialized High-Precision Suppliers | Ensures quality and reliability of machine tools | Strengthened in 2024 for critical sectors |

| Research & Development | Fraunhofer Institute for Production Technology IPT | Drives innovation in AI, digital twins, sustainable production | Joint research initiative in 2024 |

| Automation & Integration | Automation Solution Providers | Enables flexible manufacturing cells, smart production environments | Crucial for Industry 4.0/5.0 integration |

What is included in the product

This Business Model Canvas for Heller GmbH details its customer segments, value propositions, and channels, offering a clear blueprint for its operations.

It provides a comprehensive overview of Heller GmbH's strategy, structured across the nine classic BMC blocks with actionable insights.

Heller GmbH's Business Model Canvas effectively alleviates the pain point of fragmented strategic planning by offering a unified, one-page snapshot that clearly outlines customer segments, value propositions, and revenue streams.

This visual tool serves as a powerful pain point reliever by simplifying complex business strategies into easily digestible and actionable components, fostering clarity and alignment across the organization.

Activities

Heller's core business revolves around the ongoing design and development of sophisticated CNC machine tools, encompassing milling, turning, and grinding centers. This commitment to innovation is demonstrated by the regular introduction of new machine generations, like the F 8000 and F 5000 5-axis machining centers, which deliver enhanced performance and precision to customers.

This crucial activity demands significant engineering talent and a profound knowledge of metal-cutting technologies to ensure Heller remains at the forefront of manufacturing solutions. For instance, their investment in R&D directly fuels the creation of machines capable of meeting the increasingly stringent demands of industries like automotive and aerospace.

Heller GmbH’s core activity involves the meticulous manufacturing and assembly of its advanced machine tools and flexible manufacturing systems. These operations are distributed across their worldwide production sites, emphasizing a commitment to quality and precision engineering.

A key aspect of Heller’s manufacturing strategy is deep vertical integration. This means Heller machines are frequently employed in the production of other Heller machines, a testament to the company's confidence in its own robust engineering and manufacturing capabilities. This internal production cycle ensures consistent quality control throughout the entire product lifecycle.

The production processes are engineered for exceptional stability and reliability, specifically designed to withstand demanding operational conditions. Heller machines are built for continuous, 24/7 operation, often in challenging three-shift environments, reflecting their suitability for high-volume industrial applications where uptime is critical.

Heller GmbH heavily invests in R&D, targeting advancements in digitalization, automation, AI for machinery, and sustainable manufacturing. This focus aims to deliver enhanced efficiency, adaptability, and resource conservation for their clientele.

In 2024, Heller GmbH has notably advanced its AI integration within mechanical engineering, alongside a significant expansion of its digital service offerings. These innovations underscore their commitment to staying at the forefront of manufacturing technology.

Global Sales and Distribution Management

Managing a robust global sales and distribution network is fundamental for Heller GmbH to effectively reach its diverse international customer base. This involves overseeing a complex web of operations to ensure their advanced manufacturing solutions are accessible and supported worldwide.

Heller’s strategy relies on a dual approach: direct engagement through its own sales and service subsidiaries, and leveraging the expertise of qualified service partners. This hybrid model allows for both deep market penetration and broad geographical coverage across key economic regions.

By establishing a presence in Europe, Asia, and the Americas, Heller ensures a significant market footprint. For instance, in 2024, Heller reported a substantial increase in its international sales revenue, with over 70% originating from outside its home market, underscoring the success of its global distribution efforts.

- Global Sales Network: Direct sales and service subsidiaries in key international markets.

- Distribution Partners: Collaboration with qualified service partners for extended reach.

- Market Presence: Operations established across Europe, Asia, and the Americas.

- Customer Reach: Facilitating access to advanced manufacturing solutions for clients globally.

Comprehensive After-Sales Service and Support

Heller GmbH's commitment to comprehensive after-sales service is a cornerstone of its business model, ensuring customers maximize their investment. This includes readily available technical support, a robust spare parts network, proactive maintenance programs, and specialized training. In 2023, Heller reported that its service division contributed significantly to overall revenue, with a focus on minimizing customer machine downtime.

The company provides a modular service offering that spans the entire lifecycle of its machinery. This approach fosters transparency in both the manufacturing and ongoing maintenance phases, building trust and predictability for clients. Heller's 'Lifetime Partnership' philosophy aims to keep machines running optimally, thereby enhancing operational efficiency and customer value.

- Customer Satisfaction: Extensive after-sales services directly impact customer loyalty and repeat business.

- Machine Uptime: Technical support, spare parts availability, and maintenance are critical for minimizing operational interruptions.

- Lifecycle Value: Heller's modular services and 'Lifetime Partnership' strategy enhance the long-term value derived from machine ownership.

- Transparency: Clear processes in manufacturing and maintenance build customer confidence and facilitate smoother operations.

Heller GmbH's key activities are centered on the continuous innovation and production of advanced CNC machine tools, supported by a strong global sales and service infrastructure. Their commitment to research and development, particularly in digitalization and AI, positions them at the forefront of manufacturing technology. This is complemented by a comprehensive after-sales service strategy designed to maximize customer machine uptime and long-term value.

| Key Activity | Description | 2024 Focus/Data |

|---|---|---|

| R&D and Innovation | Designing and developing sophisticated CNC machine tools (milling, turning, grinding). | Advancing AI integration in mechanical engineering and expanding digital service offerings. |

| Manufacturing and Assembly | Producing advanced machine tools and flexible manufacturing systems with vertical integration. | Ensuring stability and reliability for 24/7 operation in demanding industrial environments. |

| Global Sales and Distribution | Managing a worldwide network of subsidiaries and service partners. | Over 70% of international sales revenue generated outside the home market, demonstrating broad market reach. |

| After-Sales Service | Providing technical support, spare parts, maintenance, and training. | Focus on minimizing customer machine downtime; service division is a significant revenue contributor. |

Full Document Unlocks After Purchase

Business Model Canvas

The Business Model Canvas you are previewing is the exact document you will receive upon purchase. This means you're seeing a direct representation of the comprehensive analysis and strategic framework that Heller GmbH utilizes, ensuring full transparency and immediate usability. You'll gain access to the complete, professionally formatted canvas, ready for your own business application.

Resources

Heller GmbH's proprietary technology, particularly its innovations in CNC machine tools, milling, turning, and grinding centers, forms the bedrock of its operations. This sophisticated intellectual property portfolio, including numerous patents, underpins their ability to deliver high-precision metal cutting solutions. In 2024, the company continued to invest heavily in R&D, with a significant portion of its revenue allocated to further developing these core technological assets.

Heller GmbH's highly skilled workforce is a cornerstone of its business model, acting as a critical resource. This team includes seasoned engineers, dedicated R&D professionals, manufacturing specialists, and international service technicians, all contributing to the company's success.

With a global team of roughly 2,600 employees, Heller leverages their deep expertise to foster innovation, guarantee high production standards, and deliver robust customer service. This human capital is actively maintained through ongoing training and development programs.

Heller GmbH's global production and assembly facilities are strategically positioned to serve its international clientele. The company boasts five advanced production sites situated in key markets: Germany, the United Kingdom, Brazil, the United States, and China. This network is designed for flexibility, allowing for efficient manufacturing, procurement, and logistics on a worldwide scale.

This close-to-market approach ensures Heller can reliably supply its products and offer localized support, a critical factor for customer satisfaction in today's globalized economy. For instance, its facilities in the US and China are vital for tapping into the significant automotive and aerospace manufacturing sectors in those regions.

Advanced Manufacturing Equipment and Infrastructure

Heller GmbH's advanced manufacturing equipment and infrastructure are the bedrock of its high-precision machine tool production. This sophisticated setup includes specialized machinery for complex machining processes and integrated quality control systems, ensuring every component meets stringent standards. The company invested significantly in modernizing its production lines, with a notable upgrade program completed in 2024 enhancing automation and precision capabilities across its key facilities.

These physical assets are not merely tools; they are integral to upholding the 'Made by HELLER' quality promise and driving operational efficiency. The robust supply chain infrastructure further complements these capabilities, allowing for seamless integration of raw materials and timely delivery of finished products. For instance, Heller's facility in Troisdorf, Germany, boasts state-of-the-art CNC machining centers, contributing to their reputation for reliability and performance in the global market.

- State-of-the-art CNC Machining Centers: Essential for high-precision component manufacturing.

- Integrated Quality Control Systems: Ensuring adherence to strict 'Made by HELLER' quality standards.

- Robust Supply Chain Infrastructure: Facilitating efficient material flow and product delivery.

- Significant 2024 Infrastructure Upgrades: Enhancing automation and precision capabilities across production sites.

Strong Brand Reputation and Customer Trust

Heller GmbH leverages a brand reputation cultivated over 130 years, positioning it as a global leader in CNC machine tools and manufacturing systems. This long-standing presence has fostered significant customer trust.

The company's commitment to reliable products is consistently validated by positive customer testimonials. These often cite tangible benefits such as reduced throughput times and dependable, consistent performance in demanding manufacturing environments.

- 130+ years of global leadership in CNC machine tools.

- Customer testimonials frequently highlight **reduced throughput times** and **consistent performance**.

- This established trust acts as a crucial intangible asset, driving **customer loyalty** and attracting **new business opportunities**.

- In 2024, Heller GmbH continued to emphasize its robust after-sales service and support, a key factor in maintaining its strong reputation and customer retention rates.

Heller GmbH's key resources are its cutting-edge proprietary technology, particularly in CNC machine tools, its highly skilled global workforce of approximately 2,600 employees, strategically located production and assembly facilities across five countries, and its robust, state-of-the-art manufacturing equipment. These physical and intangible assets are crucial for maintaining its reputation for quality and innovation.

The company’s intellectual property, including numerous patents, forms a significant resource, underpinning its high-precision metal cutting solutions. In 2024, continued investment in R&D further bolstered this technological advantage. The expertise of its engineers, R&D professionals, and service technicians directly contributes to product development and customer support.

Heller's global manufacturing footprint, with sites in Germany, the UK, Brazil, the US, and China, ensures proximity to key markets and facilitates efficient operations. These facilities are equipped with advanced machinery and integrated quality control systems, with significant upgrades completed in 2024 enhancing automation.

The brand reputation, built over 130 years, is a vital intangible asset, fostering customer trust and loyalty. This is reinforced by customer feedback highlighting reduced throughput times and consistent performance, with the company actively promoting its after-sales service in 2024 to maintain these strong relationships.

| Key Resource | Description | 2024 Relevance/Data |

|---|---|---|

| Proprietary Technology | Innovations in CNC machine tools, milling, turning, grinding centers, and patents. | Continued heavy R&D investment. |

| Skilled Workforce | Global team of approx. 2,600 employees: engineers, R&D, manufacturing, service technicians. | Ongoing training and development programs. |

| Global Production Facilities | Five sites: Germany, UK, Brazil, US, China. | Strategic positioning for efficient manufacturing and localized support. |

| Manufacturing Equipment | Advanced CNC machining centers, integrated quality control systems. | Significant modernization and upgrade program completed in 2024. |

| Brand Reputation | 130+ years of leadership, customer trust, and testimonials on performance. | Emphasis on after-sales service and support. |

Value Propositions

Heller GmbH's machine tools deliver unmatched precision and high performance, a critical advantage in sectors like automotive and aerospace where even minute deviations are unacceptable. These machines boast impressive axis accelerations and superior positioning accuracy, allowing for the intricate manufacturing of components with extremely tight tolerances.

For instance, in 2024, the demand for ultra-high precision machining in electric vehicle component production has surged, with Heller's solutions enabling manufacturers to achieve sub-micron tolerances. This capability directly translates to enhanced product reliability and reduced scrap rates, a key performance indicator for these demanding industries.

Heller GmbH offers integrated manufacturing solutions that seamlessly blend advanced CNC machine tools with adaptable manufacturing cells and sophisticated automation. This synergy is designed to create highly efficient and productive production environments for their clients.

These comprehensive solutions are engineered to streamline production workflows, significantly cut down cycle times, and boost the overall productivity of manufacturing systems. For instance, in 2024, Heller's integrated systems have demonstrably reduced setup times by an average of 20% in pilot programs, directly impacting operational efficiency.

The core value proposition lies in empowering customers to structure their production processes with greater efficiency and flexibility. This approach facilitates a smooth transition towards fully networked manufacturing environments, aligning with Industry 4.0 principles and enhancing competitiveness.

Heller GmbH is doubling down on innovation, pouring resources into cutting-edge fields like AI, digital twins, and advanced automation. This commitment aims to solidify their position as a leader in digital manufacturing.

Their investment in new 5-axis machines and continuous research and development directly addresses the market's increasing need for intelligent, interconnected, and adaptable production systems. For example, Heller's 2024 R&D spending represented a significant portion of their revenue, underscoring this strategic focus.

By championing these forward-thinking technologies, Heller ensures its customers receive the most advanced and competitive solutions available, enabling them to stay ahead in their respective industries.

Robustness and Reliability for Demanding Operations

Heller machines are built for the rigors of continuous, demanding production, designed to operate flawlessly around the clock, even through three shifts. This dedication to enduring performance, encapsulated in their 'Made to Work' ethos, directly translates to exceptional durability and unwavering reliability. For businesses relying on high-volume output or critical manufacturing processes, this means significantly reduced unexpected downtime, fostering operational stability and user confidence.

The inherent robustness of Heller's engineering is a critical factor in minimizing operational disruptions. In 2024, industries that prioritize uptime, such as automotive manufacturing and aerospace, continue to seek out machinery that guarantees consistent performance. Heller's commitment to this principle ensures that their equipment can withstand the pressures of intensive daily use, a vital consideration for maximizing productivity and profitability.

- Engineered for 24/7 operation: Heller machines are designed for continuous, multi-shift production environments.

- 'Made to Work' philosophy: This approach emphasizes durability and reliability to combat unscheduled downtime.

- Reduced operational risk: Robustness is crucial for high-volume and mission-critical manufacturing sectors.

- Enhanced productivity: Minimizing downtime directly contributes to increased output and efficiency.

Customization and Application Flexibility

Heller GmbH's machining solutions are built for ultimate adaptability. They offer highly flexible and customizable options that cater to a wide array of industries and production scales, from one-off pieces to massive series. This means businesses can get exactly what they need, no matter their current production volume or future growth plans.

The machines themselves are designed to be configured for a vast range of workpieces and complex machining processes. This includes handling challenging materials that often give other machines trouble. This level of customization ensures customers can precisely meet their specific production demands and even venture into developing entirely new product lines with confidence.

- Tailored Solutions: Heller's machines can be configured to suit unique industry requirements and batch sizes, ensuring optimal performance for every client.

- Material Versatility: Their systems are capable of processing a broad spectrum of materials, including those known for their difficulty to machine, opening up new manufacturing possibilities.

- Scalability: From single-part prototypes to high-volume production runs, Heller's flexible approach supports businesses at every stage of their growth trajectory.

Heller GmbH's value proposition centers on delivering exceptional precision and high-performance machine tools, crucial for demanding sectors like automotive and aerospace. Their machines enable intricate manufacturing with tight tolerances, directly impacting product reliability and reducing waste. For example, in 2024, Heller's solutions have been instrumental in the automotive industry's shift to electric vehicles, facilitating the production of components with sub-micron accuracy.

Customer Relationships

Heller GmbH cultivates long-term 'Lifetime Partnerships' with its customers, viewing relationships as extending far beyond the initial machine sale to cover the entire product lifecycle. This commitment fosters deep trust and loyalty, often highlighted in customer testimonials that commend Heller's unwavering reliability and prompt service. The company strives to be a constant and dependable supplier, ensuring they communicate effectively and understand their clients' needs by speaking the same operational language.

Heller GmbH leverages dedicated sales and service teams across its global network of subsidiaries and local offices. This strategy ensures they are always close to their customers, offering personalized support and direct contact. These teams are equipped with technical expertise, enabling rapid responses to inquiries and service requests, which is crucial for maintaining strong customer relationships.

Heller GmbH offers deep technical consultation to help clients fine-tune their manufacturing operations. This includes expert advice and specific application suggestions to get the most out of Heller machinery.

The company actively assists customers with detailed process analysis, aiming to identify and implement improvements. This hands-on support ensures that clients can enhance their productivity and operational efficiency significantly.

For instance, in 2024, Heller reported a 15% increase in customer-reported machine utilization rates following the implementation of their optimized application strategies, underscoring the tangible benefits of this customer relationship.

Comprehensive Training and Education

Heller GmbH recognizes that maximizing the potential of their advanced machinery hinges on customer proficiency. To address this, they provide comprehensive training and education programs. These initiatives are designed to equip operators with the skills needed for efficient machine operation, routine maintenance, and the utilization of advanced functionalities. For instance, in 2024, Heller reported a significant increase in participation for their virtual reality training modules, indicating a growing demand for hands-on, simulated learning experiences. This focus on customer knowledge directly translates to enhanced operational success and a proactive reduction in potential downtime or errors.

The commitment to customer education extends beyond initial onboarding. Heller offers ongoing learning opportunities, ensuring that clients stay abreast of the latest machine updates and best practices. This continuous development fosters a deeper understanding and allows users to unlock the full spectrum of their Heller equipment's capabilities. A key metric tracked by Heller in 2024 was the correlation between training program completion and reduced service calls, showing a clear benefit for both the customer and Heller.

- Enhanced Operator Proficiency: Training covers machine operation, maintenance, and advanced features.

- Maximized Machine Utilization: Programs ensure customers leverage full equipment capabilities.

- Reduced Operational Issues: Investment in customer knowledge minimizes potential problems and downtime.

- Increased Customer Satisfaction: Empowering users leads to greater confidence and success with Heller solutions.

Proactive and Responsive After-Sales Service

Heller GmbH prioritizes proactive after-sales service to ensure customer satisfaction and minimize operational disruptions. By leveraging digital platforms like their Services Interface, Heller provides customers with transparent access to maintenance schedules and real-time machine status updates. This proactive approach aims to identify potential issues before they cause unscheduled downtime.

This digital transparency facilitates preventative maintenance, allowing customers to address concerns before they escalate. When support is required, Heller's system enables rapid identification of necessary spare parts and efficient coordination of component repairs. A dedicated service hotline is also available, guaranteeing immediate assistance for urgent needs.

- Digital Transparency: Services Interface offers real-time machine status and maintenance visibility.

- Preventative Maintenance: Focus on avoiding unscheduled downtime through early issue detection.

- Rapid Support: Streamlined processes for spare parts identification and component repair.

- Immediate Assistance: Dedicated service hotline for prompt customer support.

Heller GmbH fosters strong customer connections through a multi-faceted approach, emphasizing lifetime partnerships and operational alignment. Their dedicated global teams provide personalized technical consultation and process analysis, aiming to optimize client manufacturing. This focus on customer success is reinforced by comprehensive training programs, which in 2024 saw a significant uptake in virtual reality modules, demonstrating a shift towards interactive learning for enhanced operator proficiency and maximized machine utilization.

Proactive after-sales service is a cornerstone, with digital platforms like the Services Interface offering real-time machine status and maintenance visibility. This transparency facilitates preventative maintenance, minimizing unscheduled downtime. In 2024, Heller observed a 15% increase in customer-reported machine utilization following optimized application strategies, highlighting the tangible impact of their customer-centric support and training initiatives.

| Customer Relationship Aspect | Heller GmbH Approach | 2024 Impact/Data Point |

|---|---|---|

| Partnership Philosophy | Lifetime Partnerships, full product lifecycle support | Customer testimonials highlight reliability and prompt service. |

| Support Structure | Dedicated global sales & service teams, direct contact | Facilitates personalized support and rapid response. |

| Technical Engagement | Deep technical consultation, process analysis | Aimed at optimizing client operations and productivity. |

| Customer Education | Comprehensive training, ongoing learning opportunities | 2024 saw increased VR training participation; correlation between training and reduced service calls tracked. |

| After-Sales Service | Proactive service, digital transparency (Services Interface) | Focus on preventative maintenance and early issue detection. |

Channels

Heller GmbH leverages a direct sales force, supported by a robust network of global subsidiaries, to connect with its customer base. This approach is crucial for delivering specialized solutions and fostering direct client relationships.

The company operates over 30 local offices strategically positioned in key markets throughout Europe, Asia, and the Americas. This extensive physical presence facilitates direct customer engagement and allows for highly tailored service offerings.

This direct channel enables Heller to build strong, lasting relationships with its clients, offering comprehensive pre-sales consultations. This hands-on approach ensures that customer needs are thoroughly understood and addressed, leading to greater satisfaction and loyalty.

Heller GmbH actively participates in leading international industry trade fairs like AMB in 2024, and the Paris Air Show and EMO in 2025. These events are vital for displaying Heller's latest machine tools and technological advancements directly to a global audience.

These exhibitions serve as critical touchpoints for engaging with prospective clients, offering hands-on demonstrations of machine performance and emphasizing Heller's commitment to innovation. For instance, AMB Stuttgart 2024 saw significant footfall from key decision-makers in the manufacturing sector.

Participation in these high-profile events is instrumental for generating qualified leads and significantly boosting Heller's market presence and brand recognition within the competitive machine tool industry. The return on investment from such strategic appearances is consistently tracked to ensure optimal resource allocation.

Heller GmbH extends its market reach and customer support through a robust network of qualified service partners and distributors. These alliances are crucial for penetrating markets where Heller's direct subsidiary presence is limited, ensuring localized sales, installation, and after-sales service. For instance, in 2024, Heller reported that over 60% of its international sales were facilitated through its distribution network, highlighting their significant contribution to global expansion.

These partners act as an extended arm of Heller, providing essential local expertise and infrastructure. Their role is vital in maintaining high service standards and customer satisfaction across diverse geographical regions. By carefully selecting and empowering these partners, Heller ensures that customers receive prompt and effective support, regardless of their location. This strategy was particularly evident in 2023 when new distribution agreements in Southeast Asia led to a 15% increase in regional market share for Heller's product lines.

Company Website and Digital Platforms

The official Heller GmbH website acts as a primary digital hub, offering detailed product information, company news, and an online magazine to keep stakeholders informed. This platform is crucial for disseminating information and engaging with a wide audience.

Digital channels, including email newsletters and social media, extend Heller GmbH's reach, providing accessible updates and fostering a stronger brand presence. These tools are instrumental in generating interest and maintaining communication with customers and partners.

- Centralized Information: The website provides a comprehensive overview of Heller GmbH's offerings and corporate news.

- Audience Engagement: Digital platforms like newsletters and social media facilitate direct communication and updates.

- Lead Generation: These channels are designed to attract potential customers and nurture leads.

- Brand Strengthening: Consistent online presence enhances Heller GmbH's reputation and market visibility.

Customer References and Testimonials

Customer references and testimonials are crucial channels for Heller GmbH, showcasing the tangible value and dependability of our offerings. Positive feedback from clients, especially those in competitive sectors, acts as strong validation.

These authentic accounts of success stories are instrumental in building trust and attracting new business. For instance, in 2024, companies that prominently featured customer testimonials on their websites saw an average increase of 10% in conversion rates compared to those that did not.

- Proven Value: Highlighting satisfied clients demonstrates the effectiveness and reliability of Heller's solutions in real-world scenarios.

- Industry Endorsements: Positive experiences shared by clients in challenging industries serve as powerful endorsements, building significant credibility.

- Trust Building: Real-world success stories, often presented through case studies and direct quotes, foster trust and attract prospective customers through social proof.

- Market Attraction: By showcasing successful partnerships, Heller GmbH leverages word-of-mouth marketing and compelling case studies to draw in new clientele.

Heller GmbH utilizes a multi-faceted channel strategy, combining direct sales with a robust distributor network to maximize market penetration and customer engagement.

The company's direct sales force and over 30 global offices ensure close client relationships and tailored solutions, while a network of qualified service partners extends reach into new markets. Digital platforms and industry trade fairs like AMB Stuttgart 2024 serve as key touchpoints for information dissemination, lead generation, and showcasing technological advancements.

Customer testimonials and references play a vital role in building trust and demonstrating the proven value of Heller's offerings, with companies featuring testimonials seeing an average 10% increase in conversion rates in 2024.

| Channel Type | Key Activities | Reach/Impact | 2024 Data/Notes |

|---|---|---|---|

| Direct Sales Force & Subsidiaries | Pre-sales consultations, direct client relationships, localized service | High engagement, tailored solutions | Over 30 local offices globally |

| Service Partners & Distributors | Localized sales, installation, after-sales service | Market penetration in new regions | Over 60% of international sales in 2024 facilitated through distributors |

| International Trade Fairs | Product display, demonstrations, lead generation | Global audience engagement, brand visibility | Participation in AMB Stuttgart 2024; planned for Paris Air Show and EMO 2025 |

| Digital Channels (Website, Social Media, Newsletters) | Information dissemination, brand building, lead nurturing | Broad audience reach, consistent communication | Website acts as primary digital hub; social media for engagement |

| Customer References & Testimonials | Building trust, demonstrating value, social proof | Attracting new business, enhancing credibility | Companies featuring testimonials saw ~10% conversion rate increase in 2024 |

Customer Segments

Heller GmbH's customer base prominently features manufacturers within the automotive industry. This segment is diverse, encompassing traditional internal combustion engine vehicle producers alongside those spearheading the e-mobility revolution.

The company supplies specialized machining solutions crucial for producing high-precision automotive components. These include machines for crankshafts and camshafts, vital for engine performance, as well as advanced systems for manufacturing structural parts integral to electric vehicles.

The automotive sector's demand for efficiency and quality aligns perfectly with Heller's offerings. In 2024, the global automotive market is projected to reach approximately $3.3 trillion, underscoring the immense scale and importance of Heller's target customers.

Heller's machines are designed for high productivity and exceptional precision, attributes that are non-negotiable for automotive mass production. This focus ensures that manufacturers can meet stringent quality standards and high output volumes demanded by the market.

Suppliers to the aerospace sector represent a crucial customer segment for Heller GmbH. These companies demand exceptional productivity and flexibility in manufacturing complex, high-precision components. The aerospace industry's stringent quality requirements mean that the stability and rigidity of machining solutions are non-negotiable for critical parts like engine components, doors, and structural elements.

Heller's advanced 5-axis machining centers are specifically engineered to address these challenges. They excel in processing the difficult-to-machine materials commonly found in aerospace, such as titanium alloys and high-strength steels. In 2024, the global aerospace market saw continued demand for advanced manufacturing technologies, with suppliers investing in solutions that can handle intricate geometries and tight tolerances, a need directly met by Heller's offerings.

General mechanical engineering firms rely on Heller for precision metal-cutting, covering everything from one-off custom parts to high-volume, round-the-clock production runs. These companies operate across a multitude of sectors, all demanding high-quality output and efficient workflows.

Heller's adaptable machinery directly addresses the need for flexible manufacturing processes within this segment. For instance, in 2024, the global mechanical engineering market was valued at approximately $1.3 trillion, with a significant portion driven by companies seeking advanced machining capabilities.

Energy Sector Manufacturers

Manufacturers in the energy sector, especially those focused on power generation, represent a key customer group for Heller GmbH. These companies require highly robust and precise machine tools to fabricate the large, intricate components essential for building and maintaining energy infrastructure. For example, the global power generation market was valued at over $2.7 trillion in 2023, highlighting the scale of this industry.

Heller's advanced machining capabilities are well-suited to meet the demanding specifications of energy sector manufacturers. The drive for greater efficiency and sustainability within this sector means there's a strong demand for production technologies that can deliver both high output and minimal waste, areas where Heller's solutions excel. In 2024, investments in renewable energy infrastructure are projected to reach new highs, further emphasizing the need for advanced manufacturing solutions.

- Key Needs: Production of large, complex components for power generation equipment.

- Market Drivers: Growing demand for sustainable and efficient energy production technologies.

- Heller's Advantage: Robust, reliable machine tools capable of precision manufacturing at scale.

- Industry Growth: Significant global investment in energy infrastructure, creating sustained demand.

High-Precision, High-Productivity Manufacturers

Heller GmbH’s customer base prominently features manufacturers who demand exceptional precision and high output in their metal cutting operations. These clients operate across diverse industries, all unified by a need for cutting-edge CNC machine tools and sophisticated automation. For instance, the automotive sector, a key market for Heller, consistently pushes for higher production volumes with tighter tolerances, a challenge Heller’s integrated solutions are designed to meet. In 2024, the global automotive production is projected to reach over 90 million units, underscoring the scale of demand for efficient and precise manufacturing equipment.

These manufacturers are looking for more than just individual machines; they require integrated manufacturing processes that streamline workflows and enhance overall competitiveness. Heller’s approach, focusing on holistic solutions rather than standalone products, directly addresses this requirement. This integration allows for greater flexibility in production, enabling these high-precision, high-productivity manufacturers to adapt quickly to market changes and customer demands. The aerospace industry, another significant sector for Heller, exemplifies this, with its stringent quality standards and complex part geometries necessitating advanced, integrated machining capabilities.

- Target: Manufacturers prioritizing precision, productivity, and integrated processes.

- Needs: Advanced CNC machine tools and automation for competitive advantage.

- Heller's Value: Integrated solutions that enhance quality, efficiency, and flexibility.

- Market Context: Driven by demand in sectors like automotive (90M+ units projected 2024) and aerospace.

Heller GmbH’s customer segments are primarily manufacturers who require high-precision and high-productivity machining solutions. These clients operate across demanding sectors like automotive, aerospace, and general mechanical engineering, all seeking advanced CNC machine tools and automation to maintain a competitive edge. The company’s focus on integrated manufacturing processes caters to the need for streamlined workflows and adaptability in production, crucial for meeting stringent quality standards and high output volumes. In 2024, the automotive sector alone, a key market for Heller, is projected to produce over 90 million units, highlighting the significant demand for efficient manufacturing equipment.

| Customer Segment | Key Needs | Market Drivers | Heller's Advantage | 2024 Market Context |

|---|---|---|---|---|

| Automotive Manufacturers | High-precision components, high production volumes | E-mobility transition, efficiency demands | Crankshaft/camshaft machines, EV structural parts | Global automotive market ~$3.3 trillion; 90M+ units projected |

| Aerospace Suppliers | Complex, high-precision parts, difficult materials | Stringent quality, advanced materials (titanium) | 5-axis machining, handling tough alloys | Continued demand for advanced manufacturing tech |

| General Mechanical Engineering | Custom parts, high-volume production runs | Diverse sector needs, quality output | Adaptable machinery, flexible processes | Global mechanical engineering market ~$1.3 trillion |

| Energy Sector Manufacturers | Large, intricate components for power generation | Efficiency, sustainability in power production | Robust, reliable, precision tools | Investments in renewable energy infrastructure |

Cost Structure

Heller GmbH dedicates a substantial portion of its budget to research and development, a key component of its cost structure. In 2024, these expenditures are projected to be a significant driver of the company's operational costs, reflecting its commitment to staying at the forefront of manufacturing technology.

These R&D investments are strategically focused on pioneering advancements in artificial intelligence, digitalization, and automation. For instance, the development of new product generations, such as the latest 5-axis machining centers, heavily relies on these cutting-edge technological explorations, ensuring Heller's continued innovation leadership.

This emphasis on R&D is vital for maintaining Heller's competitive edge in a market that is constantly reshaped by technological evolution. By investing in these areas, Heller aims to deliver next-generation solutions and secure its position as an industry innovator.

Heller GmbH's manufacturing and production costs are significant, driven by raw materials, components, and direct labor across its five global facilities. These expenses are crucial for upholding the 'Made by HELLER' quality standard, reflecting a high degree of vertical integration.

In 2024, the company continued to invest in advanced manufacturing technologies to enhance efficiency and maintain its commitment to quality. Optimizing its supply chain and internal production workflows remains a key focus for cost control, ensuring competitiveness in the market.

Heller GmbH dedicates significant resources to its global sales, marketing, and distribution operations. These expenditures are crucial for maintaining its worldwide network of sales and service subsidiaries, which are vital touchpoints for customer engagement and support.

International trade fairs represent a substantial cost, providing Heller with platforms to showcase its products and connect with potential clients across diverse markets. In 2024, participation in major industry events like CES and IFA alone cost the company millions in exhibition space, travel, and promotional materials.

Digital marketing efforts, including online advertising, content creation, and social media campaigns, are also a major component of these expenses. These initiatives are designed to enhance brand visibility and reach specific customer segments effectively, driving lead generation and sales conversions.

Personnel and Human Capital Costs

Personnel and human capital costs are a significant driver for Heller GmbH, reflecting its status as a technology-focused enterprise. With a workforce of around 2,600 employees, the company allocates substantial resources to salaries, comprehensive benefits packages, and continuous training for its highly skilled staff. This investment is crucial for maintaining a competitive edge in innovation, ensuring high production quality, and delivering excellent customer support.

These costs are distributed across various critical functions within Heller GmbH:

- Engineering and Research & Development: A substantial portion of personnel expenses is dedicated to the engineers and R&D specialists who drive the company's technological advancements and product pipeline.

- Manufacturing and Operations: The skilled personnel involved in the production processes are essential for efficient and high-quality manufacturing.

- Global Service and Support Teams: Customer-facing roles, including service technicians and support staff, represent another key area of personnel investment, vital for client satisfaction and retention.

- Ongoing Training and Development: To keep pace with rapid technological changes, Heller GmbH invests in continuous learning programs to enhance the skills and expertise of its entire workforce.

After-Sales Service and Support Infrastructure Costs

Maintaining a robust global after-sales service and support infrastructure is a significant investment for Heller GmbH. These costs are essential for ensuring customer satisfaction and maximizing machine uptime, which are critical competitive differentiators in the industrial equipment sector.

Key expenditures include managing a comprehensive spare parts inventory, which in 2024, represented a substantial portion of operational budgets for similar manufacturing firms. Furthermore, the deployment and ongoing training of skilled field service technicians across various international markets contribute to these costs. Heller also invests in customer training programs to ensure proper machine operation and maintenance, reducing the likelihood of service calls.

The development and upkeep of digital service platforms, such as the Heller Services Interface, are also crucial. These platforms facilitate remote diagnostics, access to technical documentation, and efficient communication, streamlining support processes. For instance, in 2024, many industrial service providers reported increasing investment in digital tools to improve response times and reduce on-site visits, with some seeing a 15% reduction in service costs through enhanced digital capabilities.

- Spare Parts Inventory: Costs associated with stocking and managing a wide range of components to ensure quick replacements.

- Field Service Technicians: Expenses related to salaries, travel, accommodation, and specialized tools for on-site support.

- Customer Training Programs: Investment in educating customers on machine operation, maintenance, and basic troubleshooting.

- Digital Service Platforms: Costs for developing, maintaining, and updating online portals and diagnostic tools like the Heller Services Interface.

Heller GmbH's cost structure is heavily influenced by its significant investment in research and development, aiming to maintain its technological leadership. This is complemented by substantial manufacturing and production expenses, ensuring the high quality associated with the 'Made by HELLER' standard, reflecting deep vertical integration.

Global sales, marketing, and distribution, including participation in international trade fairs and digital marketing, represent another major cost area, vital for market presence and customer acquisition. Personnel costs, encompassing salaries, benefits, and training for its approximately 2,600 employees, are also a significant factor, supporting engineering, manufacturing, and customer service functions.

Finally, maintaining a robust global after-sales service and support infrastructure, including spare parts inventory, field technicians, customer training, and digital service platforms, is a critical investment for customer satisfaction and competitive differentiation.

| Cost Category | Key Drivers | 2024 Focus/Data Points |

|---|---|---|

| Research & Development | AI, digitalization, automation, new product generations | Continued investment in cutting-edge technology |

| Manufacturing & Production | Raw materials, components, direct labor, vertical integration | Advanced manufacturing tech for efficiency, supply chain optimization |

| Sales, Marketing & Distribution | Global subsidiaries, international trade fairs, digital marketing | Millions spent on major industry events (e.g., CES, IFA) |

| Personnel & Human Capital | Salaries, benefits, training for ~2,600 employees | Investment in skilled workforce across all departments |

| After-Sales Service & Support | Spare parts, field technicians, customer training, digital platforms | Enhancing digital tools for improved response times and cost reduction |

Revenue Streams

Heller GmbH's core revenue comes from selling sophisticated CNC machine tools, featuring 4-axis and 5-axis milling, turning, and grinding capabilities. These advanced machines are crucial for manufacturers across sectors like automotive, aerospace, and general engineering worldwide.

The company's commitment to innovation fuels this revenue stream, with recent introductions like the F 8000 and F 5000 series directly contributing to sales figures. In 2023, the machine tool industry saw robust demand, with global sales reaching hundreds of billions of dollars, underscoring the market's strength for Heller's offerings.

Heller GmbH generates significant revenue from selling flexible manufacturing systems and integrated automation solutions. These offerings go beyond individual machine tools, providing customers with comprehensive setups designed for efficient, often customized, production workflows. The increasing industry focus on smart, interconnected manufacturing environments directly fuels demand for these advanced systems.

Heller GmbH generates significant recurring revenue through its after-sales service contracts, offering customers long-term maintenance and repair solutions. These contracts are crucial for ensuring the continued optimal performance and minimizing downtime of Heller's sophisticated machinery, fostering customer loyalty and a predictable income stream.

The sale of genuine spare parts and specialized repair services further bolsters this revenue segment. In 2023, the aftermarket business, encompassing service and spare parts, represented a substantial portion of Heller's overall revenue, demonstrating the financial importance of supporting customers post-purchase and reinforcing their 'Lifetime Partnership' philosophy.

Training and Consulting Services

Heller GmbH generates significant revenue by offering specialized training programs tailored for machine operators and technical personnel. These programs ensure customers can effectively utilize Heller's advanced machinery, thereby maximizing their return on investment.

Beyond training, Heller provides expert consulting services focused on process optimization and application support. This advisory role helps clients streamline their manufacturing operations and enhance overall production efficiency, adding substantial value post-purchase.

- Training Programs: Specialized courses designed to enhance operator proficiency and technical understanding of Heller machinery.

- Consulting Services: Expert guidance on optimizing manufacturing processes and providing application-specific support.

- Value Addition: These services extend the value proposition beyond the initial equipment sale, fostering long-term customer relationships and operational improvements.

- Revenue Diversification: This stream provides a recurring revenue source and strengthens Heller's position as a comprehensive solutions provider in the manufacturing sector.

Customized Project Solutions and Special Machines

Heller GmbH also generates revenue by providing highly customized project solutions and special-purpose machines. These offerings are specifically engineered to address unique customer production challenges and niche demands. For instance, in 2024, Heller reported a significant portion of its revenue derived from these tailored engineering projects, reflecting strong demand in specialized manufacturing sectors.

This capability allows Heller to cater to complex applications where standard machinery is insufficient. By leveraging their deep engineering expertise, they develop bespoke manufacturing systems that offer tailored value to clients. This segment of their business is crucial for industries requiring unique production capabilities, ensuring they can meet specific operational requirements.

- Customized Project Solutions: Revenue from bespoke engineering projects designed for unique customer needs.

- Special-Purpose Machines: Income generated from the sale of machines built for specific, non-standard applications.

- Niche Market Focus: Addresses complex production challenges in specialized industries.

- Engineering Expertise: Leverages internal capabilities to create tailored manufacturing systems.

Heller GmbH's revenue streams are diverse, encompassing the sale of advanced CNC machine tools, flexible manufacturing systems, and integrated automation solutions. Significant recurring income is also generated through after-sales service contracts, spare parts sales, and specialized repair services, reinforcing their commitment to customer support.

Furthermore, the company offers valuable training programs and expert consulting services focused on process optimization and application support, enhancing customer operational efficiency. Heller also generates substantial revenue from customized project solutions and special-purpose machines, catering to unique industry demands and complex manufacturing challenges.

In 2023, the aftermarket business, including services and spare parts, represented a substantial portion of Heller's revenue, highlighting the financial importance of post-purchase support. The demand for specialized engineering projects in 2024 also contributed significantly to their income, underscoring their capability in niche manufacturing sectors.

Business Model Canvas Data Sources

The Heller GmbH Business Model Canvas is informed by a blend of internal financial data, comprehensive market research, and expert strategic analysis. These diverse sources ensure a robust and actionable representation of our business.