H.C. Starck PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

H.C. Starck Bundle

Navigate the complex external forces shaping H.C. Starck's future with our comprehensive PESTLE analysis. Understand the political, economic, social, technological, legal, and environmental factors that present both challenges and opportunities for the company. Gain a strategic advantage by leveraging these expert insights to inform your own business planning and investment decisions. Download the full PESTLE analysis now and unlock actionable intelligence.

Political factors

Global trade policies, including tariffs and sanctions, directly affect the cost and availability of essential raw materials such as tungsten and molybdenum, crucial for companies like H.C. Starck Tungsten GmbH. For instance, China's imposition of export controls on critical materials, effective December 2024, is expected to cause significant supply chain disruptions and price hikes. This situation underscores the need for H.C. Starck to develop robust, diversified sourcing strategies and potentially re-evaluate its manufacturing footprint to mitigate these risks.

Governments in key regions like Germany and across the European Union are actively promoting advanced manufacturing and securing critical raw material supply chains. This translates into tangible benefits for companies like H.C. Starck Tungsten. For instance, substantial funding has already been allocated to their battery recycling plant in Germany, underscoring political commitment to strategically important and sustainable sectors.

Geopolitical tensions, particularly in regions like Eastern Europe and parts of Asia, directly impact the stability of raw material supply chains for critical metals used by H.C. Starck. For instance, the ongoing conflict in Ukraine has disrupted established trade routes and increased the cost of transporting materials.

Governments worldwide are prioritizing supply chain resilience. In 2024, the U.S. Department of the Interior announced initiatives to boost domestic critical mineral production, aiming to reduce reliance on imports, which currently account for a significant portion of materials like tungsten and tantalum.

This global push for supply chain security presents both hurdles and advantages for manufacturers. While diversifying sourcing to new regions, such as increased mining exploration in South America and Australia, can mitigate risks, it also introduces new logistical complexities and potential price volatility for companies like H.C. Starck.

International Relations & Market Access

The current geopolitical climate significantly impacts H.C. Starck Tungsten's ability to access international markets. Tensions between major economic blocs can lead to trade restrictions, increasing the cost and complexity of cross-border operations. For instance, ongoing trade disputes, such as those involving tariffs on critical materials, directly affect the competitiveness of tungsten products globally.

Trade agreements play a crucial role in shaping market access. Positive trade relationships, like those facilitated by the European Union's trade policies, can offer H.C. Starck Tungsten preferential access to key markets. Conversely, the absence of favorable agreements can create significant barriers, limiting export opportunities and increasing reliance on domestic or regional demand. In 2024, the global trade landscape continues to be shaped by evolving protectionist policies alongside efforts to strengthen regional trade blocs.

H.C. Starck Tungsten's global manufacturing footprint necessitates stable international relations for efficient supply chain management and market penetration. Disruptions in diplomatic ties can impede the flow of raw materials and finished goods, impacting production schedules and delivery times. The company's success hinges on navigating these complex international dynamics to ensure consistent market access and competitive pricing.

- Trade Tariffs: Increased tariffs on imported tungsten products in key markets can reduce H.C. Starck Tungsten's export volume. For example, a hypothetical 10% tariff could increase the landed cost of products by a similar margin, impacting price competitiveness.

- Supply Chain Stability: Geopolitical instability can disrupt the sourcing of critical raw materials, impacting H.C. Starck Tungsten's production capacity and lead times.

- Market Access Agreements: Favorable trade agreements, such as those within the EU, provide H.C. Starck Tungsten with smoother access to a significant consumer base, reducing regulatory hurdles and import duties.

- Global Economic Outlook: The overall health of the global economy, influenced by international relations, directly affects demand for industrial products like tungsten, impacting H.C. Starck Tungsten's revenue projections for 2024-2025.

Political Stability in Key Operating Regions

Political stability across H.C. Starck Tungsten's key operating regions, including Germany, Canada, China, the US, and Japan, directly impacts its ability to maintain consistent production and secure necessary investments. Unstable political landscapes introduce risks of abrupt policy shifts and regulatory changes, potentially disrupting supply chains and operations.

A predictable political environment fosters confidence for long-term strategic planning and capital allocation. For instance, Germany, a core operational base, consistently ranks high in global political stability indices, offering a secure foundation for H.C. Starck's European operations. Conversely, geopolitical tensions or shifts in trade policies in other regions can introduce volatility.

- Germany's strong rule of law and stable governance provide a reliable operational base.

- China's evolving regulatory landscape requires careful monitoring for potential impacts on sourcing and market access.

- Geopolitical developments in regions supplying raw materials can directly affect supply chain integrity.

- Trade agreements and tariffs between key markets like the US and China can influence market dynamics and operational costs.

Political factors significantly shape H.C. Starck Tungsten's operational landscape, influencing everything from raw material sourcing to market access. Global trade policies, including tariffs and sanctions, directly impact the cost and availability of crucial materials like tungsten and molybdenum. For example, China's December 2024 export controls on critical materials are expected to cause supply chain disruptions and price increases, necessitating diversified sourcing strategies for H.C. Starck.

Government initiatives promoting advanced manufacturing and securing critical raw material supply chains offer tangible benefits. Germany's substantial funding for H.C. Starck's battery recycling plant highlights political commitment to strategic sectors. Conversely, geopolitical tensions, such as the conflict in Ukraine, disrupt trade routes and increase transportation costs for essential materials.

Governments worldwide are prioritizing supply chain resilience. In 2024, the U.S. Department of the Interior launched initiatives to boost domestic critical mineral production, aiming to reduce import reliance for materials like tungsten. This global push for security presents both challenges and opportunities, with diversification into regions like South America and Australia mitigating risks but introducing new logistical complexities.

The current geopolitical climate impacts H.C. Starck Tungsten's international market access. Trade restrictions stemming from tensions between economic blocs increase the cost and complexity of cross-border operations. Ongoing trade disputes, including tariffs on critical materials, directly affect the global competitiveness of tungsten products.

| Political Factor | Impact on H.C. Starck Tungsten | Example/Data Point (2024-2025) |

| Trade Policies & Tariffs | Affects cost of raw materials and export competitiveness. | China's December 2024 export controls on critical materials expected to increase prices. Hypothetical 10% tariff could increase landed product cost. |

| Geopolitical Stability | Disrupts supply chains and increases transportation costs. | Conflict in Ukraine has disrupted trade routes and increased material transport costs. |

| Government Support for Critical Materials | Provides funding and promotes strategic sectors. | Germany allocated substantial funding to H.C. Starck's battery recycling plant. U.S. initiatives aim to boost domestic critical mineral production. |

| Trade Agreements | Shapes market access and reduces regulatory hurdles. | EU trade policies offer preferential access to key markets; evolving protectionist policies alongside regional trade bloc strengthening in 2024. |

What is included in the product

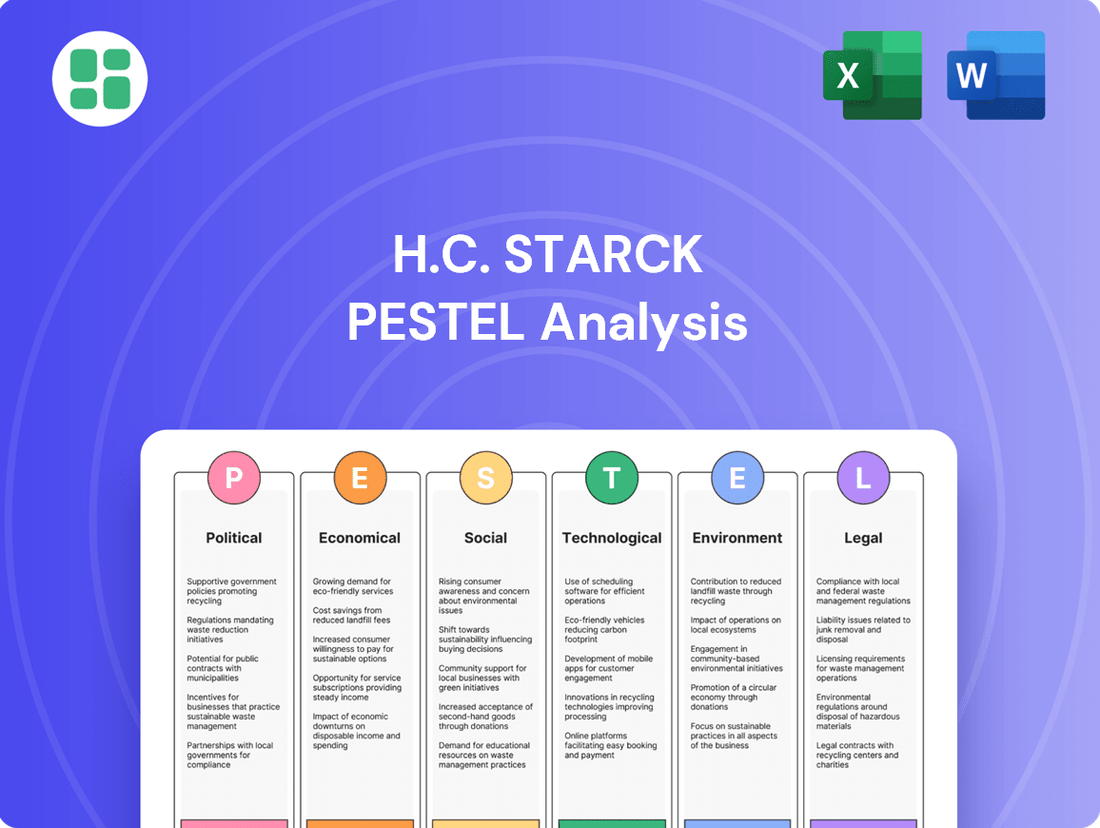

This PESTLE analysis provides a comprehensive examination of the external macro-environmental factors influencing H.C. Starck's operations and strategic positioning.

It delves into Political, Economic, Social, Technological, Environmental, and Legal forces, offering actionable insights for strategic decision-making.

A clear, actionable H.C. Starck PESTLE analysis that highlights key external factors, enabling proactive strategy adjustments and mitigating potential market disruptions.

Economic factors

The health of the global economy is a direct indicator of demand for specialized metals like those H.C. Starck produces. Industries such as aerospace, automotive, and electronics, which rely heavily on these high-performance materials, are sensitive to economic cycles. A strong global economic performance, especially in key manufacturing hubs, typically translates into increased industrial activity and, consequently, higher demand for H.C. Starck's offerings.

Projections for 2024-2025 indicate a continued expansion of global GDP, with the International Monetary Fund forecasting 3.2% growth for both years. This economic buoyancy is particularly important for sectors H.C. Starck serves. For instance, the aerospace sector is expected to see significant order backlogs fulfilled, driving demand for refractory metals, while the automotive industry's shift towards electric vehicles will increase the need for specialized materials in components.

The Asia Pacific region, a major consumer and producer of tungsten, is a critical market for H.C. Starck. Economic growth in this region, estimated to be around 4.5% in 2024, directly supports the demand for tungsten and its derivatives. This robust regional economic activity fuels manufacturing and infrastructure development, creating a strong market for the high-performance metals H.C. Starck specializes in.

The prices of essential refractory metals like tungsten and molybdenum are inherently volatile, driven by shifts in supply and demand, alongside geopolitical influences. For instance, China's imposition of export restrictions is projected to cause a significant increase in tungsten prices throughout 2025, potentially impacting global markets.

These price fluctuations directly affect H.C. Starck Tungsten's operational expenses and profitability. The company's ability to manage these raw material cost swings will be crucial for maintaining its competitive edge and financial performance in the coming year.

Currency exchange rate fluctuations pose a significant challenge for H.C. Starck Tungsten, a global manufacturer with operations spanning multiple continents. These shifts directly impact the company's revenues, costs, and overall profitability.

For instance, a strengthening Euro, as seen in recent periods where the EUR/USD rate has hovered around 1.08-1.10 in early 2024, can make H.C. Starck's exports more expensive for international buyers. Conversely, it can lead to cheaper imports of raw materials or components, potentially lowering production costs.

These dynamics directly influence H.C. Starck's competitive positioning in global markets and affect the cost of sourcing essential materials like tungsten ore, the price of which is often denominated in US dollars.

Inflationary Pressures & Operating Costs

Inflationary pressures continue to impact operating costs for businesses like H.C. Starck. These pressures are evident in rising expenses for essential inputs such as energy, raw materials, and skilled labor. For instance, global energy prices saw significant volatility throughout 2024, directly affecting manufacturing overheads.

While some forecasts suggest a moderation in inflation for 2025, companies must still navigate the residual effects of these cost increases. Maintaining profitability hinges on the ability to effectively manage these elevated operating expenses. This requires a strategic approach to cost control and operational efficiency.

- Energy Costs: Global energy benchmarks, like Brent crude, fluctuated significantly in 2024, impacting industrial energy bills.

- Labor Expenses: Wage growth in key manufacturing regions remained elevated in 2024 due to tight labor markets, increasing payroll costs.

- Logistics & Supply Chain: Shipping costs, while potentially stabilizing, are still influenced by earlier supply chain disruptions and fuel price volatility.

- Raw Material Prices: The cost of essential metals and chemicals, critical for H.C. Starck's operations, experienced upward trends in various segments during 2024.

Investment in Key End-User Industries

Investment in sectors like aerospace and defense is a significant driver for H.C. Starck Tungsten. For instance, the global aerospace market was valued at approximately $860 billion in 2023 and is projected to grow, with a substantial portion of this growth expected to come from defense spending and new aircraft development.

The automotive sector, particularly electric vehicles (EVs), presents a growing demand. Global EV sales reached over 13 million units in 2023, a significant increase from previous years, boosting the need for advanced materials used in battery technology and lightweighting, where tungsten alloys can play a role.

The electronics industry also contributes to demand. The semiconductor market, a key component of electronics, is expected to see a compound annual growth rate (CAGR) of around 6-8% through 2025, indicating a steady need for high-performance materials in manufacturing processes.

- Aerospace & Defense: Global market valued at ~$860 billion in 2023, with growth fueled by defense budgets and new aircraft programs.

- Automotive (EVs): Over 13 million EVs sold globally in 2023, increasing demand for specialized materials in batteries and components.

- Electronics: Semiconductor market projected to grow at a CAGR of 6-8% through 2025, supporting demand for materials in manufacturing.

Global economic growth, projected at 3.2% for 2024 and 2025 by the IMF, underpins demand for H.C. Starck's specialized metals. Key sectors like aerospace and automotive are poised for expansion, with the Asia Pacific region's estimated 4.5% growth in 2024 particularly vital for tungsten demand.

Price volatility for refractory metals like tungsten is a significant factor, with China's export restrictions anticipated to drive prices higher in 2025. Currency fluctuations, such as the Euro's strength against the dollar (around 1.08-1.10 in early 2024), also impact H.C. Starck's international pricing and sourcing costs.

Inflationary pressures in 2024, seen in rising energy, labor, and raw material costs, continue to affect operational expenses, necessitating strategic cost management for profitability in 2025.

| Economic Factor | 2024 Projection/Data | 2025 Projection | Impact on H.C. Starck |

|---|---|---|---|

| Global GDP Growth | 3.2% (IMF) | 3.2% (IMF) | Drives demand for specialized metals in key industries. |

| Asia Pacific GDP Growth | ~4.5% | N/A | Crucial for tungsten demand and market activity. |

| Tungsten Price Trend | Volatile, potential increases due to export restrictions | Expected increase | Affects raw material costs and profitability. |

| EUR/USD Exchange Rate | ~1.08-1.10 (early 2024) | N/A | Impacts export competitiveness and import costs. |

| Inflationary Pressures | Elevated energy, labor, raw material costs | Moderation expected, residual effects persist | Increases operating expenses, requires cost control. |

Full Version Awaits

H.C. Starck PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This comprehensive H.C. Starck PESTLE analysis delves into the Political, Economic, Social, Technological, Legal, and Environmental factors impacting the company. You'll gain valuable insights into market dynamics and strategic considerations.

Sociological factors

The advanced manufacturing sector, including metal powder production, faces persistent challenges in securing skilled labor and attracting top talent, especially within Europe. The demand for individuals possessing advanced digital and technical proficiencies is escalating, yet a noticeable skills gap persists as educational frameworks struggle to keep pace.

Addressing this requires significant investment in robust training and upskilling programs to bridge the divide between current educational outputs and industry needs. For instance, Germany's VDMA reported in early 2024 that 60% of its member companies in mechanical engineering faced a shortage of skilled workers, a trend directly impacting specialized sectors like metal powder production.

The aging workforce in developed economies, particularly in Europe, presents a significant hurdle for manufacturing sectors like those H.C. Starck operates within. This demographic trend, with a growing proportion of older workers, can exacerbate existing labor shortages and lead to a critical loss of accumulated expertise and institutional knowledge.

This demographic shift directly impacts production continuity and the capacity for innovation. For instance, in Germany, the proportion of workers aged 55 and over in manufacturing was projected to increase significantly in the coming years, highlighting the urgency for companies to address knowledge transfer and talent pipeline issues.

Customers and investors increasingly demand that companies like H.C. Starck demonstrate robust Corporate Social Responsibility (CSR). This expectation translates into a need for ethical sourcing of raw materials, fair labor practices, and positive contributions to the communities where they operate. For instance, a 2024 survey indicated that 70% of consumers consider a company's CSR efforts when making purchasing decisions.

Adherence to high CSR standards is no longer just a feel-good initiative; it directly impacts reputation and stakeholder trust. Companies with strong CSR profiles often experience greater customer loyalty and attract more socially conscious investors. In 2025, the global sustainable investment market is projected to reach $50 trillion, highlighting the financial significance of these expectations.

Consumer & Industry Preference for Sustainable Products

There's a clear shift in what people and businesses want, with a strong leaning towards products made sustainably and with less impact on the environment. This means companies like H.C. Starck Tungsten are seeing more demand for tungsten materials produced using greener methods and a greater focus on recycling. For instance, the global market for sustainable materials is projected to reach over $10 trillion by 2027, highlighting the economic significance of this trend.

This growing preference directly influences how H.C. Starck Tungsten operates, pushing for innovation in their production processes to meet these eco-conscious demands. They are actively exploring and implementing recycling programs, recognizing that circular economy principles are becoming increasingly important for maintaining market relevance and competitiveness. Companies that prioritize sustainability are often viewed more favorably by investors and consumers alike.

- Growing Demand: Consumers and industries increasingly favor products with a reduced environmental impact.

- Eco-friendly Processes: H.C. Starck Tungsten faces pressure to adopt and showcase sustainable manufacturing techniques for its tungsten products.

- Recycling Emphasis: Initiatives focused on recycling and material recovery are becoming critical for demonstrating environmental responsibility.

- Market Advantage: Companies demonstrating strong sustainability practices, like those in the recycled metals sector which saw significant growth in 2024, gain a competitive edge.

Health and Safety Standards in Manufacturing

The metal manufacturing sector, including companies like H.C. Starck, faces significant scrutiny regarding health and safety due to inherent risks from heavy machinery, hazardous materials, and high-temperature processes. In 2024, workplace safety regulations continue to tighten globally, with a strong emphasis on preventing occupational illnesses and injuries. Failure to comply can result in substantial fines and reputational damage.

Adherence to these stringent health and safety standards is not merely a legal obligation; it's a cornerstone of responsible corporate citizenship and vital for employee morale and retention. For instance, the Occupational Safety and Health Administration (OSHA) in the United States reported that in 2023, the manufacturing sector accounted for a significant portion of workplace injuries, underscoring the ongoing need for vigilance.

Companies are therefore compelled to make substantial investments in:

- Advanced safety equipment and personal protective gear.

- Regular, comprehensive training programs for all personnel.

- Implementing robust risk assessment and mitigation strategies.

- Maintaining up-to-date safety management systems.

Societal expectations are increasingly shaping business operations, with a growing emphasis on ethical conduct and community engagement. Companies like H.C. Starck are expected to contribute positively to the social fabric where they operate, which includes fair labor practices and support for local development. A 2024 report by the World Economic Forum highlighted that 65% of global consumers believe companies have a responsibility to address societal issues.

The demand for transparency in supply chains and product origins is also rising, pushing companies to provide clear information about their materials and manufacturing processes. This transparency builds trust and loyalty among consumers and investors, who are more informed than ever. For instance, a survey in early 2025 found that 75% of investors consider ESG (Environmental, Social, and Governance) factors as crucial for long-term investment decisions.

The workforce demographic is shifting, with an aging population in many developed countries, including Germany, leading to potential skill shortages and a loss of experienced personnel. This trend necessitates proactive strategies for knowledge transfer and talent acquisition to maintain operational efficiency and innovation. In 2024, Germany's Federal Employment Agency noted a growing gap between the skills available and those required by advanced manufacturing sectors.

| Sociological Factor | Impact on H.C. Starck | Supporting Data/Trend (2024-2025) |

|---|---|---|

| Ethical Consumerism & CSR | Increased demand for ethically sourced materials and responsible business practices. | 65% of global consumers believe companies should address societal issues (WEF, 2024). |

| Transparency Expectations | Need for clear communication on supply chains and manufacturing. | 75% of investors consider ESG factors crucial (Investor Survey, early 2025). |

| Aging Workforce & Skills Gap | Potential labor shortages and loss of institutional knowledge. | Growing skills gap in advanced manufacturing in Germany (Federal Employment Agency, 2024). |

Technological factors

Additive manufacturing, especially using metal powders, is a key technological force for H.C. Starck Tungsten. The global 3D printing market, projected to reach $62.5 billion by 2030, highlights the rapid growth in this area.

Innovations in 3D printing are making it possible to produce intricate, high-performance metal components for critical sectors like aerospace, medical devices, and the automotive industry. For example, GE Aviation's LEAP engine fuel nozzle, produced via additive manufacturing, demonstrates the precision achievable.

This technological advancement directly boosts the demand for specialized metal powders, such as tungsten, which H.C. Starck Tungsten supplies. It also creates opportunities to enter new, high-value market segments by offering advanced materials for these cutting-edge applications.

Continuous advancements in material science, particularly in alloy development, are vital for H.C. Starck Tungsten's competitive edge. Research into novel alloys offering superior strength, corrosion resistance, and high-temperature performance directly expands the application potential for their refractory metals.

The company's commitment to this innovation pipeline ensures it can consistently meet the evolving demands of industries like aerospace and electronics. For instance, the global advanced materials market was projected to reach over $100 billion by 2024, highlighting the significant opportunities for companies like H.C. Starck Tungsten that invest in cutting-edge material solutions.

The ongoing integration of automation and Industry 4.0 principles, encompassing AI, robotics, and the Internet of Things (IoT), is fundamentally reshaping manufacturing landscapes. These advancements are crucial for boosting operational efficiency, refining precision, and enabling sophisticated data analysis within production cycles. For instance, a 2024 report indicated that companies investing in automation saw an average productivity increase of 15%.

H.C. Starck Tungsten's strategic emphasis on adopting these cutting-edge processes directly mirrors and capitalizes on these pervasive industry shifts. This alignment is key to maintaining a competitive edge and optimizing their complex material processing operations, particularly in areas like tungsten powder production where precision is paramount.

R&D Investment & Product Development Cycles

H.C. Starck Tungsten's commitment to R&D is crucial for maintaining its edge in advanced materials. For instance, in 2024, the company continued to invest significantly in developing next-generation tungsten powders and compounds, aiming to enhance performance in demanding applications like aerospace and electronics.

The accelerated pace of technological advancement means that product development cycles are shrinking. This necessitates agile R&D processes, enabling H.C. Starck Tungsten to quickly move from concept to market-ready products, a strategy that proved vital in responding to emerging demand for specialized materials in the renewable energy sector during 2024.

To further strengthen its innovation capabilities, H.C. Starck Tungsten actively pursues collaborations. These partnerships, including those with universities and research institutions announced in late 2024, are designed to leverage external expertise and accelerate the development of novel material solutions.

- R&D Investment: Continued significant capital allocation towards research and development throughout 2024 to pioneer new tungsten applications.

- Product Development Cycles: Focus on streamlining R&D pipelines to achieve faster time-to-market for innovative tungsten-based materials.

- Strategic Partnerships: Engagement in collaborative projects with academic and industry leaders to enhance material science advancements.

- Market Responsiveness: Agile development strategies to meet evolving demands in high-tech sectors like semiconductors and advanced manufacturing.

Digitalization of Supply Chain Management

The ongoing digitalization of supply chain management is a significant technological factor impacting H.C. Starck Tungsten. Leveraging technologies such as big data analytics and the Internet of Things (IoT) is crucial for enhancing transparency, boosting efficiency, and building resilience within their operations. This digital transformation allows for more precise tracking of raw materials throughout the supply chain, leading to optimized logistics and a stronger ability to anticipate and mitigate potential disruptions. For a company dealing with complex global networks, this advanced visibility is indispensable.

Specifically for H.C. Starck Tungsten, the integration of these digital tools offers tangible benefits. For instance, the ability to analyze vast datasets can identify bottlenecks in real-time, enabling proactive adjustments to shipping routes or inventory levels. IoT sensors can provide continuous updates on the condition and location of materials, reducing the risk of loss or damage. This heightened level of control is vital in managing the inherent volatility of international trade and resource availability.

- Enhanced Visibility: Digital tools provide end-to-end tracking of tungsten raw materials, from mining to processing.

- Optimized Logistics: Big data analytics helps in planning the most efficient transportation routes and inventory management, potentially reducing shipping costs by up to 15% in optimized scenarios as reported by industry studies in 2024.

- Risk Mitigation: Real-time data from IoT devices allows for quicker responses to potential supply chain disruptions, such as geopolitical events or transportation delays, improving overall resilience.

- Improved Forecasting: Advanced analytics can predict demand fluctuations more accurately, enabling better production planning and resource allocation.

Technological advancements in additive manufacturing, particularly for metal powders, are a significant driver for H.C. Starck Tungsten. The global 3D printing market is expanding rapidly, projected to reach $62.5 billion by 2030, creating demand for specialized materials like tungsten. Innovations enable the production of complex, high-performance components for critical industries, directly increasing the need for H.C. Starck Tungsten's advanced materials.

Continuous progress in material science, especially alloy development, is crucial for H.C. Starck Tungsten's competitive edge. Research into novel alloys with enhanced strength and thermal properties broadens the application scope for their refractory metals. The global advanced materials market, anticipated to exceed $100 billion by 2024, underscores the opportunities for companies investing in cutting-edge material solutions.

The integration of Industry 4.0 principles, including AI and robotics, is transforming manufacturing by boosting efficiency and precision. Companies adopting automation saw an average productivity increase of 15% in 2024. H.C. Starck Tungsten's adoption of these processes aligns with industry shifts, optimizing their operations, particularly in high-precision tungsten powder production.

Digitalization of supply chain management, utilizing big data and IoT, enhances transparency and efficiency for H.C. Starck Tungsten. This digital transformation allows for precise tracking of raw materials, optimizing logistics and mitigating disruptions. For instance, optimized logistics scenarios reported by industry studies in 2024 showed potential shipping cost reductions of up to 15%.

| Technological Factor | Description | Impact on H.C. Starck Tungsten | 2024/2025 Data Point |

| Additive Manufacturing | 3D printing with metal powders | Increases demand for specialized tungsten powders | Global 3D printing market projected to reach $62.5 billion by 2030 |

| Material Science Advancements | Development of new alloys | Expands application potential for refractory metals | Global advanced materials market projected to exceed $100 billion by 2024 |

| Industry 4.0 | Automation, AI, IoT in manufacturing | Enhances operational efficiency and precision | Automation investment leads to ~15% productivity increase (2024 report) |

| Digital Supply Chain | Big data analytics, IoT for logistics | Improves visibility, efficiency, and resilience | Optimized logistics can reduce shipping costs by up to 15% (2024 studies) |

Legal factors

Environmental regulations are becoming stricter globally, affecting metal producers like H.C. Starck. For instance, the European Union's Green Deal aims for climate neutrality by 2050, which will necessitate significant changes in industrial processes.

Meeting these mandates, which cover areas like carbon emissions and waste management, demands substantial capital. Companies are investing in advanced technologies for cleaner production and improved waste treatment.

These compliance efforts translate into higher operational expenses. For example, the cost of complying with stricter emissions standards can add a notable percentage to a manufacturer's overall production costs, impacting profitability.

H.C. Starck Tungsten's global operations mean it navigates a complex web of international trade laws and customs duties. Fluctuations in these regulations, including tariffs and import/export restrictions, directly impact the cost of sourcing raw materials like tungsten ore and influence the pricing and market access for its finished products. For instance, the imposition of new tariffs on critical materials can significantly alter production costs, making it challenging to maintain competitive pricing in diverse international markets.

The company must remain agile in adapting to evolving trade policies worldwide. For example, changes in trade agreements or the introduction of new customs procedures can create unexpected hurdles or opportunities. Staying abreast of these legal frameworks is crucial for ensuring smooth supply chains and maintaining profitability across its various operational regions, especially as global trade dynamics continue to shift.

H.C. Starck's high-performance metal powders and components are integral to sensitive sectors such as medical technology and aerospace. These industries demand strict adherence to product liability and safety regulations, meaning any lapse in quality or safety can result in significant legal penalties.

Failure to meet these stringent standards, particularly those concerning material purity and performance in critical applications, could trigger costly product recalls. For instance, in 2024, the medical device industry saw an estimated $1.5 billion in recall costs globally, highlighting the financial impact of safety failures.

Beyond financial penalties and recalls, non-compliance poses a substantial risk to H.C. Starck's reputation. Such issues can erode customer trust, particularly in markets where reliability is paramount, potentially leading to a loss of competitive advantage and future business opportunities.

Intellectual Property Protection

Protecting intellectual property (IP) is paramount for H.C. Starck Tungsten, especially concerning patents for novel materials and advanced processing techniques. This safeguards their market edge and encourages continued investment in research and development.

Strong legal frameworks for IP protection are crucial. For instance, in 2024, the global intellectual property market saw significant activity, with patent filings continuing to rise across advanced materials sectors, underscoring the importance of robust legal recourse for innovators like H.C. Starck Tungsten.

- Patents: Securing patents for unique tungsten alloys and production methods is a core strategy.

- Trade Secrets: Maintaining proprietary knowledge regarding specialized manufacturing processes is vital.

- Enforcement: Actively defending IP rights against infringement ensures market exclusivity.

- R&D Investment: The company's commitment to innovation, evidenced by its R&D spending, relies on IP protection for a return on investment.

Labor Laws & Employment Regulations

H.C. Starck Tungsten navigates a complex web of labor laws across its global operations in Germany, Canada, China, and beyond. Adherence to these varying regulations, which dictate everything from minimum wages and working hours to collective bargaining rights and employee safety standards, is paramount. Failure to comply can lead to significant legal penalties, operational disruptions, and damage to the company's reputation. For instance, Germany's Works Constitution Act (Betriebsverfassungsgesetz) grants substantial co-determination rights to employee works councils, impacting management decisions on various workplace matters.

The company must ensure its employment practices align with local legal requirements, which can differ significantly. This includes managing diverse workforces with varying contractual terms, benefits, and termination procedures. Staying updated on legislative changes, such as potential minimum wage hikes or new regulations on remote work, is critical for maintaining compliance and fostering a harmonious employee-employer relationship. In 2024, many countries are reviewing and updating their labor laws to reflect evolving economic conditions and workforce expectations.

- Germany: Strong employee protections, co-determination rights for works councils, and sector-specific collective bargaining agreements.

- Canada: Provincial variations in employment standards, including minimum wage, overtime, and termination notice periods.

- China: Strict labor contract laws, emphasis on employee rights, and government oversight of labor practices.

- Global Compliance: The need to integrate diverse legal frameworks into a cohesive HR strategy to mitigate risks and ensure fair treatment of all employees.

H.C. Starck Tungsten operates within a landscape shaped by evolving trade policies and customs regulations. For example, the US International Trade Administration reported that global trade in metals and minerals is subject to fluctuating tariffs and import/export controls, directly impacting sourcing costs and market access for H.C. Starck's products. Navigating these diverse international legal frameworks is crucial for maintaining competitive pricing and ensuring smooth supply chains across its global operations.

The company's high-performance materials are used in critical sectors like aerospace and medical technology, necessitating strict adherence to product liability and safety standards. In 2024, the medical device industry alone faced an estimated $1.5 billion in recall costs globally due to safety failures, underscoring the severe financial and reputational risks of non-compliance for companies like H.C. Starck.

Intellectual property protection is a cornerstone of H.C. Starck Tungsten's strategy, safeguarding its innovations in advanced tungsten alloys and processing techniques. The global intellectual property market saw continued growth in patent filings in 2024, particularly in advanced materials, highlighting the critical need for robust legal recourse to protect R&D investments and maintain market exclusivity.

Labor laws vary significantly across H.C. Starck Tungsten's operational sites in Germany, Canada, and China. For instance, Germany's Works Constitution Act grants substantial co-determination rights to employee works councils, impacting management decisions. Staying current with these diverse regulations, including potential minimum wage adjustments and new remote work laws, is vital for compliance and employee relations, especially as many countries updated labor laws in 2024.

Environmental factors

The global demand for critical raw materials like tungsten and molybdenum is intensifying, making resource scarcity a significant environmental concern. This scarcity directly impacts industries reliant on these materials, pushing for more sustainable sourcing practices. H.C. Starck Tungsten, now part of Mitsubishi Materials, has strategically invested in recycling capabilities, a move that addresses this environmental imperative by reducing reliance on primary extraction.

Metal production, including the processes H.C. Starck engages in, is inherently energy-intensive. This makes managing energy consumption and reducing its associated carbon footprint a critical environmental consideration. For instance, the global metals industry's energy use accounts for a substantial portion of industrial energy consumption, often exceeding 30% in many developed economies, directly impacting its carbon emissions.

Growing regulatory pressures and evolving industry standards are compelling companies like H.C. Starck to actively adopt more energy-efficient technologies. There's a clear push towards integrating renewable energy sources into manufacturing operations. Many leading industrial players have set ambitious targets, aiming for 20-40% reduction in energy intensity by 2030, reflecting this significant shift.

In response, many companies are focusing on integrating low-emission processes to actively cut their carbon footprints. This involves optimizing production methods, investing in advanced equipment, and exploring innovative material science solutions. For example, the European Union's Green Deal aims to significantly reduce industrial emissions, pushing for a more sustainable approach across sectors, including advanced materials.

Effective waste management and participation in circular economy initiatives are becoming crucial for businesses. H.C. Starck Tungsten demonstrates this commitment through its active involvement in recycling, notably its pioneering work in black mass recycling for lithium-ion batteries. This strategic focus not only tackles environmental concerns but also significantly bolsters supply chain resilience.

Climate Change Policies & Emissions Targets

Global and regional climate change policies, including ambitious emissions targets, are increasingly shaping the operational landscape for industrial manufacturers like H.C. Starck. For instance, the European Union's Fit for 55 package aims to cut greenhouse gas emissions by at least 55% by 2030 compared to 1990 levels, directly influencing energy-intensive industries.

These stringent regulations compel companies to invest significantly in green technologies and cleaner production processes to reduce their carbon footprint. Failure to adapt can lead to penalties and a loss of market access, especially in regions with strict environmental mandates. H.C. Starck’s commitment to sustainability, therefore, becomes a critical factor for long-term viability and competitiveness.

- EU Emissions Trading System (ETS): Companies face costs for their carbon emissions, incentivizing reductions. In 2023, carbon prices averaged around €95 per tonne of CO2.

- National Climate Targets: Countries are setting their own net-zero goals, requiring sector-specific strategies for industrial decarbonization.

- Green Technology Investment: The global market for green technologies is projected to reach trillions of dollars by 2030, presenting both challenges and opportunities for manufacturers.

- Supply Chain Scrutiny: Companies are increasingly being held accountable for the emissions throughout their entire value chain, requiring robust environmental management systems.

Supply Chain Environmental Due Diligence

Companies are increasingly expected to perform thorough environmental checks on their entire supply chains. This means looking closely at the environmental impact of getting raw materials and how suppliers process them, aiming to reduce any negative effects. For H.C. Starck Tungsten, making sure its suppliers meet environmental standards is key to building a strong sustainability reputation.

This due diligence involves evaluating suppliers' practices, from mining to initial processing, to identify and manage environmental risks. For instance, the European Union's proposed Corporate Sustainability Due Diligence Directive (CSDDD), expected to be fully enacted by 2025, mandates such assessments, impacting companies like H.C. Starck Tungsten and their global suppliers. Failure to comply can lead to significant penalties and reputational damage.

- Growing Regulatory Pressure: The EU's CSDDD, anticipated to be fully operational in 2025, will require companies to identify, prevent, and mitigate adverse environmental impacts within their value chains.

- Supplier Audits and Certifications: H.C. Starck Tungsten likely engages in supplier audits and encourages certifications like ISO 14001 to ensure environmental compliance.

- Resource Scarcity and Impact: The extraction of critical raw materials, such as tungsten, often carries significant environmental footprints, including water usage and land disruption, necessitating careful supplier selection and monitoring.

- Reputational Risk Management: Negative environmental incidents within the supply chain can severely damage a company's brand and market standing, making proactive due diligence a crucial risk mitigation strategy.

The increasing demand for critical raw materials like tungsten and molybdenum poses a significant environmental challenge due to resource scarcity. This pressure drives a need for sustainable sourcing and highlights the importance of recycling, as demonstrated by H.C. Starck Tungsten's investments in this area. The energy-intensive nature of metal production also necessitates a focus on reducing carbon footprints, with the global metals industry consuming over 30% of industrial energy in many developed economies.

Regulatory frameworks, such as the EU's Fit for 55 package aiming for a 55% greenhouse gas reduction by 2030, are pushing companies like H.C. Starck to adopt cleaner technologies and renewable energy sources. This includes optimizing processes and investing in green technologies, with the global green technology market projected to reach trillions by 2030. Furthermore, heightened scrutiny of supply chains, exemplified by the proposed EU Corporate Sustainability Due Diligence Directive (CSDDD) expected by 2025, requires rigorous environmental checks on suppliers to mitigate risks and maintain reputational integrity.

| Environmental Factor | Impact on H.C. Starck | Relevant Data/Initiatives (2024-2025 Focus) |

|---|---|---|

| Resource Scarcity | Increased cost and availability challenges for raw materials like tungsten and molybdenum. Drives investment in recycling. | Global demand for critical minerals projected to grow significantly. H.C. Starck's focus on black mass recycling for batteries. |

| Energy Consumption & Carbon Footprint | Operational costs and regulatory compliance linked to energy use and emissions. | Metals industry accounts for over 30% of industrial energy use globally. EU ETS carbon prices averaged ~€95/tonne CO2 in 2023. |

| Regulatory Compliance | Need to adhere to evolving environmental laws, emissions targets, and due diligence requirements. | EU's Fit for 55 package (55% GHG reduction by 2030). Proposed CSDDD by 2025 mandates supply chain environmental due diligence. |

| Waste Management & Circular Economy | Opportunity to reduce waste, create value from by-products, and enhance sustainability reputation. | Growing emphasis on circular economy principles in manufacturing. H.C. Starck's recycling initiatives contribute to this. |

PESTLE Analysis Data Sources

Our H.C. Starck PESTLE analysis is meticulously constructed using data from reputable financial news outlets, industry-specific market research reports, and official government publications. This ensures a comprehensive understanding of the political, economic, social, technological, legal, and environmental forces impacting the company.