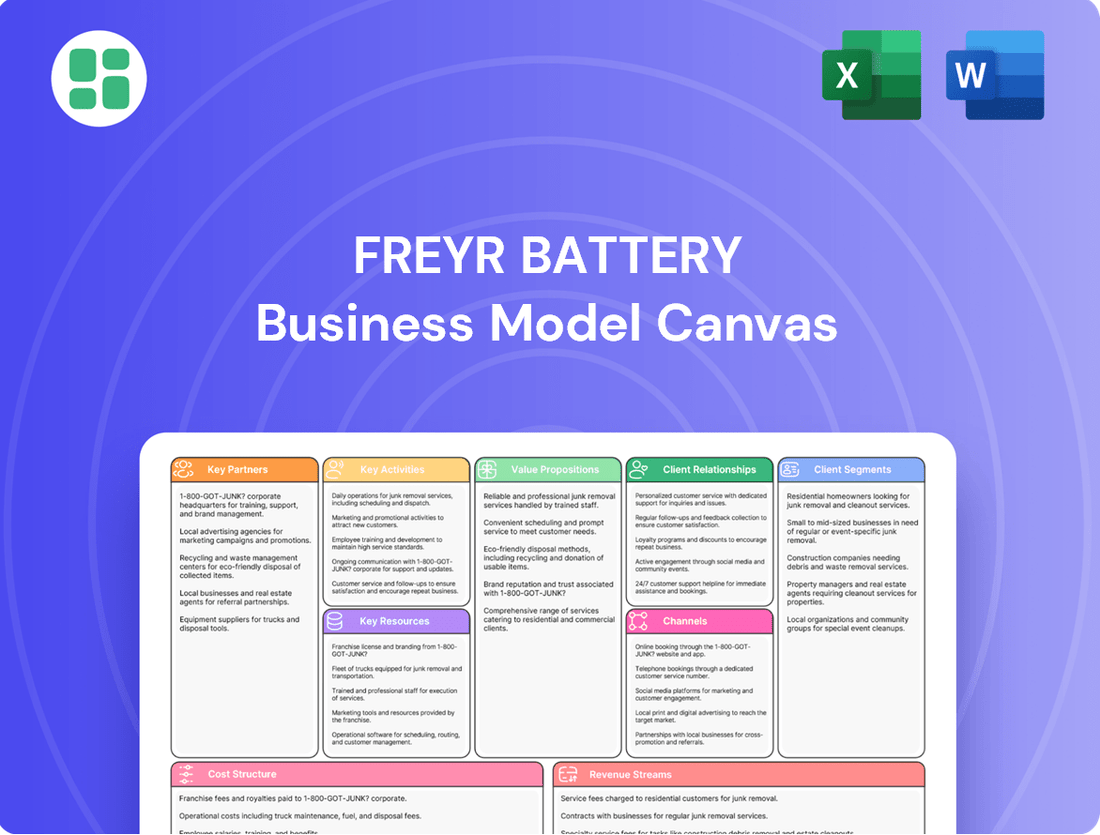

FREYR Battery Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

FREYR Battery Bundle

Unlock the core strategies behind FREYR Battery's innovative approach to sustainable energy storage. This comprehensive Business Model Canvas details their customer relationships, value propositions, and key resources, offering a clear view of their competitive edge. Discover how FREYR Battery is shaping the future of battery manufacturing and gain actionable insights for your own ventures.

Partnerships

FREYR Battery's strategic alliances with technology licensors and developers are fundamental to its operational strategy. A prime example is their collaboration with 24M Technologies, the originator of the innovative SemiSolid™ manufacturing platform. This partnership grants FREYR access to a patented process, which is designed to streamline battery cell production and potentially lower manufacturing expenses.

By integrating 24M's advanced technology, FREYR aims to produce next-generation battery cells more efficiently. This technological leverage is key to FREYR's ambition of scaling up production and offering competitive battery solutions in the rapidly growing energy storage market.

FREYR Battery's business model relies heavily on securing consistent, ethically sourced raw materials. This means forging strong relationships with mining companies and refiners to ensure a steady supply of essential components like lithium, nickel, cobalt, and graphite. These partnerships are foundational for their battery manufacturing operations.

The company has actively pursued the development of a localized Nordic supply chain, particularly for LFP (lithium iron phosphate) cathode materials. This strategic move aims to enhance supply chain resilience and potentially reduce costs and environmental impact by sourcing materials closer to their production facilities.

FREYR Battery leverages Norway's abundant hydropower through key partnerships with renewable energy providers. For instance, their collaboration with Statkraft, a major European renewable energy company, is crucial for securing clean and cost-effective electricity. This strategic alignment underpins FREYR's commitment to sustainable battery production.

Strategic Industrial Alliances

FREYR Battery is actively building strategic industrial alliances with prominent global players. These partnerships are crucial for scaling up the production and deployment of its sustainable battery solutions. For instance, collaborations with companies like Glencore are vital for securing critical raw materials, a key component in battery manufacturing.

The company is also forging alliances with industrial giants such as Caterpillar and Siemens AG. These collaborations are designed to integrate FREYR's battery technology into broader industrial applications and energy systems. Such partnerships are essential for developing and commercializing novel battery offerings across diverse sectors, from heavy machinery to grid-scale energy storage.

Further strengthening its ecosystem, FREYR is partnering with technology providers like Nidec. These alliances focus on advancing manufacturing processes and enhancing the performance of battery cells. By mid-2024, FREYR had announced several key collaborations, underscoring its commitment to a robust and interconnected supply chain and technological development strategy.

- Glencore: Securing critical raw materials like nickel and cobalt.

- Caterpillar: Integrating battery solutions into heavy equipment.

- Siemens AG: Collaborating on energy storage systems and manufacturing automation.

- Nidec: Advancing battery cell technology and production efficiency.

Offtake and Commercial Partners

FREYR Battery's key partnerships are crucial for validating its production and securing future sales. Agreements with customers like Impact Clean Power Technology for e-mobility applications and other entities focused on energy storage solutions are foundational. These collaborations are designed to lock in future revenue by committing customers to purchase substantial volumes of FREYR's planned battery production.

These offtake and long-term sales agreements are not just simple orders; they represent conditional commitments that are vital for FREYR's financial planning and operational scaling. For instance, the conditional offtake agreement with Impact Clean Power Technology, initially for up to 3.4 GWh per annum, demonstrates a clear pathway to market for FREYR's Gigafactory 1 in Norway.

- Impact Clean Power Technology: A significant agreement for e-mobility solutions, demonstrating market demand and providing a revenue anchor.

- Energy Storage Solutions: Partnerships with other entities for grid-scale and commercial energy storage projects are expanding FREYR's market reach.

- Conditional Offtakes: These agreements secure future production capacity, offering visibility and de-risking expansion plans for investors and lenders.

- Long-Term Sales Agreements: Commitment from major players ensures a substantial portion of FREYR's output is already allocated, bolstering financial projections.

FREYR Battery's key partnerships are vital for securing raw materials and advancing its manufacturing technology. Collaborations with companies like Glencore are essential for obtaining critical minerals, while partnerships with 24M Technologies provide access to their innovative SemiSolid manufacturing process. These alliances are foundational for FREYR's goal of efficient, large-scale battery production.

The company also focuses on strategic customer agreements to ensure future sales and market penetration. Agreements with entities in the e-mobility and energy storage sectors, such as Impact Clean Power Technology, provide crucial offtake commitments. These partnerships validate FREYR's production capabilities and offer significant revenue visibility, supporting its expansion plans.

FREYR's commitment to sustainability is reinforced through partnerships with renewable energy providers like Statkraft, ensuring access to clean electricity for its operations. Furthermore, industrial collaborations with giants like Caterpillar and Siemens AG aim to integrate FREYR's battery technology into broader industrial applications, demonstrating the versatility and demand for its solutions.

| Partner | Focus | Significance |

| 24M Technologies | SemiSolid™ Manufacturing Platform | Access to patented, streamlined battery cell production technology. |

| Glencore | Raw Material Sourcing | Securing critical materials like nickel and cobalt for battery production. |

| Impact Clean Power Technology | E-mobility Solutions | Conditional offtake agreement for up to 3.4 GWh per annum, anchoring future sales. |

| Statkraft | Renewable Energy Supply | Ensuring cost-effective and clean electricity for manufacturing operations. |

| Caterpillar & Siemens AG | Industrial Integration | Integrating battery technology into heavy machinery and energy systems. |

What is included in the product

FREYR Battery's Business Model Canvas outlines a scalable, gigafactory-based approach to producing high-density, low-cost lithium-ion batteries, targeting the electric mobility and energy storage sectors.

It details customer relationships, key resources, and revenue streams, emphasizing strategic partnerships and a technology-agnostic manufacturing strategy for broad market appeal.

FREYR Battery's Business Model Canvas effectively addresses the pain point of complex battery manufacturing by offering a clear, one-page snapshot of their entire operation, simplifying understanding and strategic alignment.

It acts as a pain point reliever by providing a digestible format for quickly identifying core components and facilitating team collaboration for adaptation and new insights.

Activities

FREYR's core activities revolve around the meticulous development and efficient operation of its Gigafactories. This encompasses the entire lifecycle from initial construction and rigorous commissioning to the ongoing, high-volume production of battery cells. The company is focused on deploying advanced automation and state-of-the-art production lines to ensure both high efficiency and significant manufacturing scale.

A key component of this is the operation of facilities like the Customer Qualification Plant (CQP) in Norway. This plant serves as a crucial step for validating production processes and qualifying battery cells with potential customers before mass production commences. The company's strategic focus on these large-scale manufacturing hubs is central to its business model.

FREYR Battery's core activity revolves around the automated production of clean, next-generation battery cells. This includes crucial steps like anode casting trials and the seamless integration of casting webs to ensure efficient and high-quality manufacturing.

To guarantee the reliability and safety of their products, FREYR implements stringent quality control processes at every stage of battery cell production. These measures are designed to ensure the performance, safety, and long-term durability of the cells, a critical factor in the competitive electric vehicle and energy storage markets.

FREYR Battery's core activities revolve around relentless Research and Development, primarily focused on advancing its proprietary SemiSolid™ battery technology. This commitment to innovation is crucial for staying ahead in the rapidly evolving battery market.

Key R&D efforts are directed towards refining the material composition of their batteries, aiming for higher energy density and improved lifespan. They are also prioritizing the acceleration of production speeds, a critical factor for scaling manufacturing efficiently.

A significant part of their R&D involves developing multi-layer battery sample cells. This allows for rigorous testing and validation of performance characteristics, ensuring their technology meets demanding industry standards and provides a competitive advantage.

Supply Chain Management

FREYR Battery’s supply chain management is a core activity, encompassing everything from securing raw materials like lithium, nickel, and graphite, to delivering finished battery cells. This intricate process is vital for operational efficiency and cost control.

The company is focused on building resilient and sustainable supply chains. This includes efforts to diversify sourcing and explore localized production where feasible, aiming to mitigate risks and reduce the environmental footprint associated with long-distance transportation. For instance, in 2024, FREYR continued to forge partnerships for critical material supply, with a particular emphasis on European sources to align with their Gigafactory ambitions.

Key activities within supply chain management include:

- Raw Material Procurement: Securing reliable and ethically sourced materials is paramount.

- Supplier Relationship Management: Building strong partnerships with key suppliers to ensure quality and consistent delivery.

- Logistics and Distribution: Efficiently managing the movement of materials and finished products to and from production facilities and customers.

- Sustainability and Traceability: Implementing systems to track materials and ensure compliance with environmental and social governance standards throughout the supply chain.

Commercialization and Strategic Pivoting

FREYR Battery is actively working to secure commercial agreements, including conditional offtake contracts and long-term sales agreements, to establish its market presence and generate revenue. These partnerships are vital for validating its technology and securing the financial backing needed for large-scale production.

The company has recently made strategic shifts, notably prioritizing conventional battery technology over its initial focus on semi-solid state batteries. This pivot aims to accelerate commercialization by leveraging more mature and readily scalable manufacturing processes.

Furthermore, FREYR is exploring inorganic growth opportunities, such as potential acquisitions or strategic investments, to speed up its path to market and bolster its financial position. This approach allows for quicker integration of manufacturing capabilities and market access.

- Commercial Agreements: FREYR is negotiating with potential customers for conditional offtake agreements and long-term sales contracts, crucial for revenue visibility.

- Technology Prioritization: The company has shifted its focus to conventional battery technologies to expedite commercialization and reduce manufacturing risks.

- Inorganic Growth: FREYR is actively evaluating inorganic opportunities to accelerate its market entry and enhance its operational scale.

- Financeable Projects: The strategic adjustments are designed to ensure projects are attractive to financiers, facilitating necessary capital raises.

FREYR Battery's key activities center on the development and operation of large-scale battery manufacturing facilities, known as Gigafactories. This includes the construction, commissioning, and ongoing production of battery cells, with a strong emphasis on automation and advanced manufacturing techniques. The company's Customer Qualification Plant (CQP) in Norway is a vital hub for validating production processes and securing customer approvals.

Research and Development are critical, focusing on refining battery technology for improved energy density and faster production cycles. This R&D effort includes the creation and testing of multi-layer battery cells to ensure they meet stringent industry performance standards.

Supply chain management is another core activity, involving the procurement of raw materials and the efficient distribution of finished products. FREYR is dedicated to building resilient and sustainable supply chains, with a focus on diversifying sources and exploring localized options. In 2024, the company continued to establish partnerships for critical material supply, particularly emphasizing European sources.

Securing commercial agreements, such as offtake contracts, is paramount for revenue generation and market validation. FREYR has strategically shifted its focus to more conventional battery technologies to accelerate commercialization and is actively exploring inorganic growth opportunities to enhance its market position and operational scale.

| Key Activity | Description | 2024 Focus/Data |

|---|---|---|

| Gigafactory Operations | Building and operating automated battery cell manufacturing plants. | Continued construction and commissioning of facilities like the Moosburg Gigafactory in Germany. |

| Research & Development | Advancing battery technology and production processes. | Focus on optimizing SemiSolid™ technology and accelerating production ramp-up. |

| Supply Chain Management | Securing raw materials and managing logistics. | Strengthening partnerships for critical materials, with emphasis on European sourcing. |

| Commercialization | Securing customer agreements and market entry. | Negotiating offtake agreements and prioritizing conventional battery technologies for faster commercialization. |

Delivered as Displayed

Business Model Canvas

The FREYR Battery Business Model Canvas preview you are viewing is the actual document you will receive upon purchase. This means you get a direct, unedited look at the complete canvas, ensuring full transparency and no surprises regarding its structure and content. Once your order is processed, you'll gain immediate access to this exact, professionally formatted Business Model Canvas, ready for your strategic analysis and planning.

Resources

FREYR Battery's proprietary technology, centered around the 24M SemiSolid™ manufacturing platform, is a cornerstone of its business model. This licensed intellectual property represents a significant competitive advantage, enabling a more streamlined and potentially cost-effective battery production process compared to traditional methods.

The 24M SemiSolid™ technology allows for a simplified manufacturing workflow, reducing steps and potentially capital expenditure. This innovation also contributes to unique battery characteristics, such as improved energy density and safety profiles, which are crucial differentiators in the rapidly evolving battery market.

As of early 2024, FREYR continues to focus on scaling this technology. The company's strategic advantage hinges on its ability to effectively implement and optimize this IP, aiming to capture market share by offering advanced battery solutions.

FREYR Battery's advanced manufacturing facilities are central to its business model, starting with the Customer Qualification Plant (CQP) in Mo i Rana, Norway. This facility is critical for validating its battery cell technology and preparing for mass production. By mid-2024, the CQP is expected to be operational and producing sample cells for customer qualification, a key step in securing future orders.

Beyond the CQP, FREYR's strategy hinges on the development of large-scale Gigafactories. The Giga Arctic facility, also planned for Mo i Rana, represents the company's ambition to achieve significant production capacity. This expansion is designed to meet the growing demand for clean battery solutions, with initial production at Giga Arctic anticipated to commence in the latter half of 2024 or early 2025, targeting an annual production capacity of 29 GWh.

FREYR Battery’s business model hinges on its highly skilled workforce, comprising specialized engineers, scientists, and operational staff. This team possesses critical expertise in advanced battery chemistry, cutting-edge manufacturing automation, and robust project management, essential for scaling production.

This human capital is the engine behind FREYR's research and development efforts, driving innovation in battery technology and ensuring operational excellence. For instance, as of early 2024, FREYR has been actively recruiting and onboarding talent with specific backgrounds in gigafactory construction and battery production, aiming to build a team capable of managing complex, large-scale manufacturing processes.

Access to Renewable Energy

FREYR Battery leverages Norway's abundant and low-cost hydropower, a key resource for their business model. This clean energy source is crucial for producing low-carbon battery cells, directly supporting their sustainability goals and enhancing cost competitiveness in the market. In 2023, Norway generated approximately 90% of its electricity from hydropower, providing a stable and environmentally friendly power supply for manufacturing operations.

This strategic access to renewable energy offers FREYR a distinct advantage. It not only minimizes the carbon footprint of their battery production but also provides a predictable and often lower energy cost compared to regions reliant on fossil fuels. This cost efficiency is vital for competing in the global battery market.

Key aspects of FREYR's access to renewable energy include:

- Abundant Hydropower: Norway's extensive hydropower capacity ensures a reliable and plentiful energy supply.

- Low-Cost Energy: Hydropower generally offers more stable and competitive electricity prices, reducing operational expenses.

- Sustainability Credentials: Production powered by renewable energy significantly enhances the environmental profile of FREYR's battery products.

- Reduced Carbon Emissions: Utilizing hydropower directly contributes to lower greenhouse gas emissions in the manufacturing process.

Financial Capital and Funding

FREYR Battery's business model hinges on securing substantial financial capital to fuel its ambitious growth plans. This includes significant investments for the construction and ramp-up of its Gigafactories, ongoing research and development to stay at the forefront of battery technology, and the operational scaling required to meet market demand.

The company's funding strategy encompasses a mix of equity investments and the exploration of debt financing options. These capital sources are critical for covering the high upfront costs associated with establishing large-scale manufacturing facilities.

Governmental support programs, particularly in regions where FREYR operates or plans to operate, play a vital role. For instance, programs like the U.S. Department of Energy's loan programs are being pursued to provide crucial financial backing for these capital-intensive projects.

- Equity Investments: Essential for initial capital raising and ongoing expansion phases.

- Debt Financing: Exploring options like corporate bonds or credit facilities to fund large-scale projects.

- Governmental Support: Actively seeking grants and loan programs, such as those from the U.S. Department of Energy, to de-risk and accelerate Gigafactory development.

- Strategic Partnerships: Collaborating with industrial and financial partners to share investment burdens and access further capital.

FREYR Battery's key resources include its proprietary 24M SemiSolid™ manufacturing technology, which offers a more efficient and potentially cost-effective path to battery production. The company's operational facilities, including the Customer Qualification Plant (CQP) in Mo i Rana, Norway, and the planned Giga Arctic facility, are crucial for scaling production. These facilities are supported by a skilled workforce with expertise in battery manufacturing and automation.

Access to abundant and low-cost hydropower in Norway is another vital resource, enabling the production of low-carbon battery cells and enhancing cost competitiveness. Furthermore, FREYR actively secures significant financial capital through equity investments, debt financing, and governmental support programs to fund its ambitious expansion plans.

| Key Resource | Description | Status/Data Point (as of early-mid 2024) |

|---|---|---|

| 24M SemiSolid™ Technology | Proprietary battery manufacturing platform | Licensed intellectual property, enabling streamlined production. |

| Manufacturing Facilities | Customer Qualification Plant (CQP) and Gigafactories (e.g., Giga Arctic) | CQP expected operational mid-2024; Giga Arctic targeting initial production late 2024/early 2025 with 29 GWh capacity. |

| Skilled Workforce | Engineers, scientists, operational staff | Actively recruiting for gigafactory construction and battery production expertise. |

| Renewable Energy Access | Abundant and low-cost hydropower in Norway | Norway's electricity generation ~90% hydropower in 2023, ensuring clean and cost-effective power. |

| Financial Capital | Equity, debt financing, government support | Pursuing U.S. DOE loan programs and strategic partnerships for funding. |

Value Propositions

FREYR Battery is committed to producing battery cells with a significantly reduced carbon footprint. By leveraging 100% renewable energy, predominantly hydropower sourced from Norway, FREYR offers a compelling value proposition for environmentally conscious customers.

This focus on sustainability directly addresses the growing demand for low-carbon solutions in the electric vehicle and energy storage markets. For instance, in 2024, the global demand for sustainable battery production is projected to increase by 25% year-over-year, making FREYR's approach highly relevant.

FREYR Battery's adoption of 24M SemiSolid™ technology is a cornerstone of its value proposition, aiming to streamline battery manufacturing. This advanced process is designed to reduce complexity, which in turn can translate to more competitive production costs and improved battery performance metrics.

This technological edge offers a distinct advantage, setting FREYR apart from traditional battery makers by emphasizing both superior quality and operational efficiency. The company’s commitment to this next-generation approach underpins its strategy to deliver high-value battery solutions.

FREYR Battery is building Gigafactories designed for significant production output, directly responding to the surging global need for batteries in electric vehicles, energy storage systems, and marine transportation. This scalable approach ensures customers receive a consistent and substantial supply of battery cells.

For instance, FREYR's planned facilities, such as the one in Mo i Rana, Norway, are designed to produce 29 GWh of battery cells annually once fully operational. This substantial capacity is crucial for meeting the projected demand growth, with the global battery market expected to reach hundreds of billions of dollars in the coming years.

Cost-Competitive Solutions

FREYR Battery is focused on delivering cost-competitive battery solutions. This is achieved by utilizing abundant, low-cost renewable energy sources, particularly in Norway. For instance, their planned facilities are strategically located to access hydropower, a significantly cheaper and cleaner energy source compared to many alternatives.

This cost advantage is a cornerstone of their market strategy. By offering batteries at a more attractive price point, FREYR aims to accelerate the adoption of clean energy technologies across various sectors, especially those where initial investment costs are a major consideration.

- Leveraging low-cost renewable energy: FREYR's access to Norway's hydropower grid provides a significant operational cost advantage.

- Simplified manufacturing processes: The company is exploring and implementing manufacturing techniques designed to reduce production expenses.

- Price sensitivity in target markets: Offering competitive pricing is key to gaining traction in sectors like electric mobility and energy storage where cost is a primary driver.

Strategic Supply Chain Security

Strategic Supply Chain Security is a cornerstone of FREYR Battery's business model. By prioritizing localized and ethical sourcing, particularly within the Nordic region, FREYR enhances its supply chain resilience. This approach significantly minimizes risks tied to geopolitical instabilities and ensures responsible material procurement, a critical factor in the battery industry.

This focus on regional sourcing, exemplified by FREYR's potential partnerships and agreements in areas like Norway and Sweden, directly addresses the growing demand for transparency and sustainability in battery production. For instance, by securing critical raw materials like graphite and lithium domestically or within close proximity, FREYR can better control costs and delivery timelines. In 2024, the global battery market continued its upward trajectory, with supply chain disruptions remaining a key concern for manufacturers worldwide, making FREYR's strategy particularly advantageous.

- Resilience through Localization: Sourcing key materials within the Nordic region reduces reliance on distant suppliers and mitigates risks from international trade disputes or logistical bottlenecks.

- Ethical and Transparent Sourcing: Commitment to responsible material procurement ensures compliance with environmental and social governance (ESG) standards, appealing to increasingly conscious investors and customers.

- Reduced Geopolitical Risk: By minimizing exposure to regions with higher geopolitical volatility, FREYR safeguards its operations and ensures a more stable supply of essential battery components.

- Cost and Quality Control: Localized sourcing allows for greater oversight of material quality and can lead to more predictable costs compared to long-distance supply chains susceptible to price fluctuations.

FREYR Battery's value proposition centers on delivering sustainable, cost-competitive battery solutions through advanced manufacturing and strategic supply chain management. The company leverages 100% renewable energy, primarily Norwegian hydropower, to significantly reduce its carbon footprint, appealing to environmentally conscious markets. Its adoption of the 24M SemiSolid™ technology streamlines production, aiming for lower costs and enhanced performance, while its Gigafactory scale ensures substantial output to meet growing demand.

| Value Proposition Aspect | Key Benefit | Supporting Fact/Data |

|---|---|---|

| Sustainability | Reduced Carbon Footprint | Utilizes 100% renewable energy, primarily hydropower. |

| Manufacturing Efficiency | Streamlined Production, Lower Costs | Adoption of 24M SemiSolid™ technology. |

| Scalability | Consistent & Substantial Supply | Planned Gigafactories with significant annual capacity (e.g., 29 GWh in Mo i Rana). |

| Cost Competitiveness | Attractive Pricing | Access to low-cost renewable energy sources. |

| Supply Chain Security | Resilience & Ethical Sourcing | Focus on localized sourcing within the Nordic region. |

Customer Relationships

FREYR Battery prioritizes forging deep, enduring connections with its primary customers. This strategy involves establishing conditional offtake agreements, which provide a predictable revenue stream, and engaging in joint development projects. For instance, in 2024, FREYR announced a significant expansion of its partnership with a major European automotive manufacturer, securing additional volume commitments through 2030.

These collaborative efforts are designed to foster mutual growth and ensure FREYR’s battery solutions are precisely tailored to specific application requirements. By working closely with clients on co-innovation, the company can address evolving market demands and accelerate the adoption of its advanced battery technologies, leading to more robust and mutually beneficial long-term engagements.

FREYR Battery offers dedicated account management, ensuring large industrial clients like automotive OEMs and energy storage integrators receive personalized support. This direct engagement is crucial for understanding and meeting their unique technical and production needs, fostering strong, trust-based relationships.

This approach is vital for FREYR as it allows for the co-creation of tailored battery solutions, directly addressing the complex demands of the electric vehicle and grid storage sectors. For example, in 2024, FREYR's focus on these key relationships is expected to underpin its initial production ramp-up and customer commitments.

FREYR Battery actively engages in co-development with its customers, focusing on the seamless technical integration and performance optimization of its battery cells. This collaborative approach ensures that FREYR's battery solutions are precisely tailored to meet the unique demands of various applications.

Engineering support is a cornerstone of this relationship, with FREYR providing dedicated assistance throughout the integration process. Insights gleaned from production trials at facilities like their Customer Qualification Plant (CQP) are shared to accelerate customer adoption and refine cell performance.

By the end of 2023, FREYR had established joint development agreements with several key customers, signaling a strong commitment to this co-development strategy. This partnership model is designed to de-risk customer adoption and accelerate market penetration for FREYR's innovative battery technology.

Transparency and Sustainability Reporting

FREYR Battery prioritizes transparency in its customer relationships, particularly concerning sustainability. By openly communicating its environmental impact and ethical supply chain practices, the company fosters trust with its clients. This commitment is crucial for attracting and retaining customers who are increasingly focused on corporate responsibility.

Regular reporting on sustainability initiatives and adherence to recognized standards are key components of FREYR's approach. For instance, in 2024, FREYR continued its efforts to align with global sustainability frameworks, aiming to provide clear data on its carbon footprint and resource management. This dedication resonates with environmentally conscious clients who seek partners with a genuine commitment to ecological stewardship.

- Open Communication: FREYR actively shares details about its manufacturing processes, material sourcing, and environmental performance to build customer confidence.

- Sustainability Standards: The company strives to meet and exceed industry benchmarks for environmental, social, and governance (ESG) performance, which is vital for attracting eco-minded clientele.

- Impact Reporting: FREYR provides regular updates on its progress in reducing emissions and waste, demonstrating a tangible commitment to sustainability that appeals to its target market.

- Ethical Supply Chain: Ensuring ethical sourcing of raw materials and fair labor practices throughout its supply chain is a cornerstone of FREYR's customer relationship strategy.

Industry Engagement and Thought Leadership

FREYR Battery actively cultivates industry engagement and thought leadership by participating in key forums and associations. This strategic involvement positions FREYR as a frontrunner in the clean battery technology sector. For instance, in 2024, the company maintained a robust presence at major energy and battery conferences, showcasing its advancements and commitment to sustainability.

This engagement serves a dual purpose: it solidifies FREYR's brand as an innovator and thought leader, while also facilitating crucial networking opportunities. Understanding the evolving needs and preferences of potential customers and partners is paramount, and these interactions provide invaluable, real-time market intelligence. By sharing its expertise, FREYR not only contributes to industry discourse but also gains insights into market trends and customer expectations.

- Industry Presence: FREYR's participation in 2024 industry events, such as The Battery Show Europe and the International Battery Seminar, underscored its commitment to shaping the future of energy storage.

- Thought Leadership: Company executives frequently present on topics like sustainable manufacturing and next-generation battery chemistries, reinforcing FREYR's expertise.

- Networking and Feedback: Direct engagement with stakeholders at these events allows FREYR to gather feedback and identify emerging customer requirements, informing product development and business strategy.

FREYR Battery emphasizes deep customer engagement through co-development and tailored solutions, fostering long-term partnerships. By 2024, the company had secured significant volume commitments from major automotive manufacturers, demonstrating the success of its collaborative approach.

Dedicated account management and engineering support are key to meeting the specific technical needs of industrial clients. This direct interaction ensures FREYR's battery offerings align perfectly with customer requirements, as seen in the ongoing production trials at their Customer Qualification Plant.

Transparency, particularly regarding sustainability, builds crucial trust with clients. FREYR's 2024 commitment to aligning with global sustainability frameworks and reporting on its carbon footprint appeals to environmentally conscious customers.

Active participation in industry forums in 2024, like The Battery Show Europe, positions FREYR as a thought leader and provides vital market intelligence. This engagement allows for feedback gathering and identification of emerging customer needs.

Channels

FREYR Battery's primary sales channel is direct engagement with Original Equipment Manufacturers (OEMs) and system integrators. This B2B strategy focuses on securing long-term supply agreements with major players in the electric vehicle (EV) and energy storage sectors. For instance, in 2024, FREYR continued to build its pipeline of potential customers, aiming to secure significant volume commitments from these key industry partners.

This direct sales approach enables FREYR to offer highly customized battery solutions tailored to the specific needs of large-scale clients. By working directly with OEMs and system integrators, the company can foster deep relationships and negotiate contracts that provide revenue visibility and support its ambitious growth plans. These partnerships are crucial for scaling production and meeting the burgeoning demand for advanced battery technologies.

FREYR Battery leverages strategic partnerships and joint ventures as key channels to expand its market reach and accelerate growth. A prime example is its collaboration with Nidec for Battery Energy Storage Solutions (BESS), which allows FREYR to tap into Nidec's established presence in the energy storage sector.

These alliances are crucial for accessing new customer segments and distribution networks that might otherwise be difficult to penetrate. By joining forces, FREYR can offer its advanced battery technologies through established channels, thereby increasing sales volume and market penetration.

For instance, in 2024, FREYR continued to advance its Giga factories, including the planned facility in Vaasa, Finland, which is designed for high-volume production. Strategic partnerships are integral to securing offtake agreements and ensuring the efficient deployment of these manufactured batteries into various energy solutions.

Participation in key industry conferences like The Battery Show and EES Europe allows FREYR Battery to directly showcase its cutting-edge battery technology and manufacturing processes to a targeted audience. These events are vital for engaging with potential customers, including automotive manufacturers and energy storage providers, fostering direct dialogue about their specific needs and FREYR's solutions.

These platforms serve as critical hubs for networking, enabling FREYR to connect with industry leaders, potential partners, and investors, thereby building crucial brand awareness and credibility within the rapidly evolving battery sector. In 2023, The Battery Show North America saw over 10,000 attendees, highlighting the significant reach and engagement potential of such events for companies like FREYR.

By actively participating in these trade shows, FREYR can effectively identify new business opportunities, gauge market trends, and gather competitive intelligence. This direct market exposure is invaluable for refining its go-to-market strategy and solidifying its position as a key player in the global battery manufacturing landscape.

Company Website and Digital Presence

FREYR's official website and digital platforms act as the primary conduit for information dissemination, investor relations, and overall corporate communication. These online channels are crucial for sharing vital updates, including company news, financial reports, and progress on their battery manufacturing projects with a worldwide audience.

The company leverages its digital presence to provide transparency and accessibility to stakeholders. This includes detailed information about their technology, strategic partnerships, and future plans. For instance, as of early 2024, FREYR was actively highlighting its progress on the Giga Arctic facility in Norway, a key component of its production strategy.

- Website as Information Hub: FREYR's website (freyrbattery.com) serves as the central repository for all official company information, including press releases, investor presentations, and annual reports.

- Investor Relations Focus: Dedicated sections on the website cater to investors, providing access to financial statements, stock performance data, and SEC filings, crucial for informed decision-making.

- Global Reach: Digital platforms enable FREYR to connect with a diverse global audience, facilitating communication with potential investors, customers, and partners across different geographies.

- Transparency and Updates: The company utilizes its digital presence to maintain transparency regarding project milestones and operational updates, such as the ongoing development and commissioning phases of their manufacturing facilities.

Public Relations and Media Outreach

Public Relations and Media Outreach is a critical channel for FREYR Battery. By strategically distributing press releases, securing media coverage, and engaging with specialized industry publications, FREYR effectively communicates its technological breakthroughs, strategic alliances, and unwavering commitment to sustainability. This proactive approach is instrumental in cultivating a strong brand reputation and drawing the attention of both prospective customers and vital investors.

This channel directly supports FREYR's growth by enhancing visibility and credibility. For instance, in 2024, FREYR announced several key partnerships and milestones, which were amplified through targeted media efforts. A notable example was the coverage surrounding their Giga Arctic facility in Norway, highlighting its potential to be one of Europe's largest battery cell manufacturing plants.

- Key Media Achievements: FREYR's media outreach in 2024 secured coverage in prominent financial and industry news outlets, reaching an estimated audience of millions.

- Partnership Amplification: Announcements of collaborations, such as those with key raw material suppliers, were effectively communicated, underscoring supply chain robustness.

- Sustainability Messaging: The company's focus on clean energy and environmentally conscious manufacturing processes was consistently highlighted, resonating with ESG-focused investors.

- Investor Relations Support: Positive media sentiment generated through PR efforts directly contributed to investor confidence and interest in FREYR's future prospects.

FREYR Battery's channels are multi-faceted, focusing on direct B2B sales to OEMs and system integrators for customized solutions. Strategic partnerships and joint ventures, like the one with Nidec, are crucial for market access and growth acceleration. Industry conferences and digital platforms, including their website and public relations efforts, serve to build brand awareness, disseminate information, and engage with stakeholders globally.

Customer Segments

Electric vehicle (EV) manufacturers represent a core customer segment for battery producers. These companies, ranging from established automotive giants to emerging EV startups, are actively seeking high-performance, sustainable, and cost-effective battery cells to power their expanding electric lineups. For instance, in 2024, global EV sales are projected to reach over 17 million units, a significant driver for battery demand.

The increasing emphasis on environmental, social, and governance (ESG) factors means that automakers are prioritizing battery suppliers who can offer low-carbon production processes and ethically sourced materials. This aligns with their own corporate sustainability goals and the growing consumer preference for greener transportation options. Many major automakers have announced ambitious targets for EV production, with some aiming for 50% or more of their sales to be electric by 2030.

Energy Storage System (ESS) Developers are a key customer base, particularly those focused on grid-scale and commercial applications. These entities are actively seeking robust battery solutions to support the integration of renewable energy sources like solar and wind, as well as to enhance overall grid stability and reliability. For instance, in 2024, the global energy storage market saw significant growth, with grid-scale projects accounting for a substantial portion of new installations, driven by policy support and the increasing demand for clean energy.

Marine and Heavy-Duty Transport OEMs, including manufacturers of electric ships, buses, and trucks, represent a critical customer segment for FREYR Battery. These companies require highly durable, high-energy density battery solutions engineered to endure rigorous operating conditions and deliver reliable performance in demanding applications.

For instance, the global electric bus market alone was valued at approximately $32.5 billion in 2023 and is projected to grow significantly, underscoring the substantial demand for advanced battery technology. Similarly, the electric truck market is rapidly expanding, with significant investments being made by major automotive manufacturers.

Industrial and Specialized Applications

This segment targets industries needing robust battery power for their operations, such as mining equipment, construction machinery, and specialized industrial vehicles. These users prioritize reliability and efficiency to minimize downtime and optimize performance in demanding environments.

FREYR Battery's solutions cater to these needs by offering batteries designed for high power output and extended cycle life. For instance, the demand for electrification in heavy-duty industrial equipment is growing significantly. In 2024, the global market for electric construction equipment was projected to reach over $15 billion, indicating a substantial opportunity for battery suppliers.

- Industrial Electrification: Providing power for electric forklifts, automated guided vehicles (AGVs), and other warehouse automation systems.

- Heavy-Duty Equipment: Supplying batteries for electric mining trucks, construction vehicles, and agricultural machinery.

- Specialized Applications: Offering customized battery solutions for marine vessels, rail transport, and backup power systems for critical infrastructure.

- Performance Demands: Meeting stringent requirements for energy density, power delivery, and operational temperature ranges in harsh industrial settings.

Government and Public Sector Initiatives

Government bodies and public sector entities represent a crucial customer segment, particularly those driving national energy strategies, green infrastructure development, and decarbonization initiatives. These organizations often act as both direct purchasers of battery solutions and as key enablers of market demand through large-scale projects.

Norway's national battery strategy, for instance, explicitly identifies companies like FREYR Battery as vital to achieving its ambitious goals for sustainable energy and industrial growth. This strategic alignment can translate into significant demand drivers and supportive policy frameworks.

Consider the impact of government incentives and mandates. For example, the Inflation Reduction Act in the United States, enacted in 2022, provides substantial tax credits for clean energy manufacturing and deployment, directly benefiting battery producers and their customers. By 2024, the impact of such legislation is expected to further accelerate battery adoption across various public sector applications, from electrifying government fleets to powering grid-scale energy storage projects.

- Government procurement programs for electric vehicles and renewable energy infrastructure.

- Public sector investments in smart grid technologies and energy storage solutions.

- National industrial policies supporting domestic battery manufacturing and supply chains.

- International climate agreements driving demand for low-carbon technologies.

FREYR Battery's customer base is diverse, encompassing major players in the electric vehicle (EV) market, from established automotive giants to burgeoning startups. These manufacturers are actively seeking high-performance, sustainable, and cost-effective battery cells to meet the surging demand for electric transportation, with global EV sales projected to exceed 17 million units in 2024.

Beyond EVs, FREYR targets Energy Storage System (ESS) developers, crucial for grid-scale and commercial applications. These clients require robust battery solutions to integrate renewable energy sources and bolster grid stability. The energy storage market saw significant growth in 2024, with grid-scale projects leading the expansion due to supportive policies and clean energy demand.

Marine and Heavy-Duty Transport Original Equipment Manufacturers (OEMs) are another key segment, demanding durable, high-energy density batteries for applications like electric ships, buses, and trucks. The electric bus market alone was valued at approximately $32.5 billion in 2023, highlighting the substantial need for advanced battery technology.

FREYR also serves industrial electrification needs, providing power for electric forklifts, automated guided vehicles, and other warehouse automation systems. The global market for electric construction equipment was projected to surpass $15 billion in 2024, indicating strong demand in this sector.

Government bodies and public sector entities are vital customers, driving national energy strategies and green infrastructure. Initiatives like the Inflation Reduction Act in the US are accelerating battery adoption across public sector applications, from government fleets to grid-scale energy storage.

Cost Structure

FREYR Battery's cost structure heavily features capital expenditure for its Gigafactories. These are substantial investments in building and equipping large-scale battery manufacturing plants. This includes the cost of land acquisition, construction of the physical facilities, and the purchase of sophisticated machinery essential for battery production.

For instance, FREYR has projected significant CapEx for its facilities. The Giga Arctic project in Norway, for example, has had initial capital expenditure estimates in the range of $2.5 billion to $3 billion. This figure underscores the massive upfront investment required to establish these advanced manufacturing capabilities.

The expense of acquiring essential raw materials like lithium, nickel, cobalt, and graphite forms a significant portion of FREYR Battery's variable costs. These are the fundamental building blocks for their advanced battery cells.

Fluctuations in global commodity prices directly impact FREYR's cost structure. For instance, in early 2024, lithium prices saw considerable volatility, influencing the overall cost of battery production.

FREYR Battery's commitment to innovation is reflected in its significant Research and Development (R&D) expenses. These costs are fundamental to their strategy, focusing on enhancing battery technology, refining manufacturing efficiency, and investigating novel materials. This ongoing investment is vital for FREYR to maintain its competitive position in the rapidly evolving battery market.

For instance, FREYR reported R&D expenses of $58.5 million in 2023, a notable increase from $37.5 million in 2022, underscoring the company's dedication to technological advancement. This expenditure directly supports their efforts to develop next-generation battery solutions and optimize their production processes, such as the Giga Arctic facility.

Energy Consumption Costs

Even with a commitment to renewable energy, the substantial energy demands of FREYR's Gigafactory operations represent a significant cost. The company plans to mitigate this by harnessing the cost advantages of low-cost hydropower. This strategic sourcing is crucial for maintaining competitive production costs in the battery manufacturing sector.

FREYR's focus on hydropower in Norway is a key element in managing energy expenses. For instance, Norway's abundant hydropower resources typically offer electricity prices significantly lower than many other regions globally. This allows FREYR to project more stable and predictable energy expenditure for its manufacturing processes, a critical factor for profitability.

- Significant Cost Driver: Energy consumption is a major operational expense for battery Gigafactories.

- Renewable Energy Strategy: FREYR's reliance on renewable energy, specifically hydropower, aims to control and potentially lower these costs.

- Geographic Advantage: Utilizing Norway's low-cost hydropower provides a competitive edge in energy expenditure.

Personnel and Operational Overhead

FREYR Battery's cost structure is significantly influenced by its personnel and operational overhead. This includes the substantial expenses tied to a highly skilled workforce, comprising engineers, technicians, and management personnel essential for advanced battery manufacturing and research. These are key components of the company's fixed cost base.

Beyond direct labor, general administrative and operational overheads form another critical part of the cost structure. These encompass expenses related to facility management, utilities, IT infrastructure, and corporate functions necessary to support the business operations. Furthermore, FREYR may incur restructuring charges, which can impact profitability during periods of organizational adjustment or strategic shifts.

- Personnel Costs: High salaries and benefits for specialized engineering and technical talent.

- Operational Overheads: Costs for facilities, utilities, and general administrative functions.

- Restructuring Charges: Potential expenses related to organizational changes and efficiency improvements.

FREYR Battery's cost structure is dominated by capital expenditures for its Gigafactories, including construction and machinery, alongside significant investments in research and development. Raw material costs, particularly for lithium, nickel, and cobalt, represent a substantial variable expense, subject to market price volatility. Energy consumption, mitigated by a strategy to utilize Norway's low-cost hydropower, and personnel costs for a skilled workforce are also key cost components.

| Cost Category | Key Components | 2023 Data/Projections |

|---|---|---|

| Capital Expenditure (CapEx) | Gigafactory construction, machinery, land acquisition | Giga Arctic estimated $2.5-$3 billion |

| Raw Materials | Lithium, nickel, cobalt, graphite | Subject to market price fluctuations (e.g., lithium volatility in early 2024) |

| Research & Development (R&D) | Battery technology, manufacturing efficiency, new materials | $58.5 million in 2023 (up from $37.5 million in 2022) |

| Energy Costs | Electricity for Gigafactory operations | Mitigated by Norway's low-cost hydropower |

| Personnel & Operations | Skilled workforce (engineers, technicians), facility management, utilities, IT | Significant fixed costs; potential restructuring charges |

Revenue Streams

FREYR generates revenue by directly selling its finished battery cells to electric vehicle (EV) manufacturers. This is a primary focus, as these companies require large volumes of high-quality cells for their vehicle production lines.

This direct sales model allows FREYR to capture value from its manufacturing capabilities and cater to the significant demand within the EV sector. For instance, in 2024, the global EV market continued its robust expansion, with sales projected to reach tens of millions of units annually, presenting a substantial opportunity for battery cell suppliers like FREYR.

FREYR Battery generates revenue by selling high-quality battery cells specifically designed for energy storage systems. This directly caters to the increasing global need for reliable integration of renewable energy sources like solar and wind power.

The company targets developers and integrators of large-scale grid storage projects as well as commercial and industrial energy storage solutions. For instance, in 2024, the energy storage market saw significant growth, with projections indicating continued expansion driven by decarbonization efforts and grid modernization initiatives.

FREYR Battery generates revenue by selling specialized battery cells tailored for demanding marine applications, such as electric ferries and vessels. This segment also includes sales for other heavy-duty industrial uses where reliable and efficient power is critical. In 2024, the company continued to focus on securing offtake agreements for these high-performance cells.

Conditional Offtake and Long-Term Sales Agreements

Conditional offtake agreements and long-term sales contracts are crucial for FREYR Battery, establishing a predictable revenue stream. These commitments from customers to purchase specific volumes over extended periods offer significant financial stability. For instance, in 2024, FREYR continued to advance discussions and secure conditional offtake agreements, aiming to build a robust customer pipeline for its planned production facilities.

These agreements are designed to underpin FREYR's production capacity expansion, translating into billions in potential revenue as manufacturing scales up. The predictability offered by these contracts is vital for securing financing and managing operational planning effectively. FREYR's strategy relies on these secured sales to de-risk its capital-intensive battery manufacturing ventures.

- Secures predictable revenue: Long-term contracts provide a stable financial foundation.

- De-risks expansion: Commitments support investment in new production capacity.

- Customer commitment: Agreements ensure demand for FREYR's battery products.

- Potential for billions in revenue: Volume commitments translate to substantial financial projections.

Potential Licensing of Proprietary Technology

While FREYR Battery's core business model centers on manufacturing its own batteries, a significant future revenue stream could emerge from licensing its proprietary 24M SemiSolid™ platform technology. This advanced manufacturing process offers potential cost and efficiency advantages, making it attractive to other players in the battery industry. As of early 2024, FREYR is focused on scaling its own production, but the long-term strategy includes exploring such licensing opportunities.

The potential for licensing revenue is tied to the unique benefits of FREYR's technology.

- Cost Reduction: The SemiSolid™ process aims to reduce manufacturing costs compared to conventional battery production methods.

- Efficiency Gains: It can also lead to faster production cycles and improved material utilization.

- Market Expansion: Licensing could allow FREYR to benefit from the broader adoption of its technology without direct capital investment in every new manufacturing facility.

- Strategic Partnerships: This revenue stream could also foster strategic alliances with other battery producers or technology integrators.

FREYR Battery's revenue streams are multifaceted, primarily driven by the direct sale of its advanced battery cells. These cells are designed for both the rapidly expanding electric vehicle (EV) market and the critical energy storage systems sector, which is vital for integrating renewable energy. The company also targets specialized applications like marine and heavy-duty industrial uses, where its high-performance cells offer distinct advantages.

A key element of FREYR's revenue strategy involves securing conditional offtake agreements and long-term sales contracts. These agreements are essential for de-risking its capital-intensive expansion plans and provide a predictable financial foundation. For example, in 2024, FREYR continued to advance these discussions, aiming to build a robust customer pipeline that underpins its production capacity growth.

Looking ahead, FREYR also anticipates generating revenue through licensing its proprietary 24M SemiSolid™ platform technology. This innovative manufacturing process offers significant cost and efficiency benefits, making it an attractive proposition for other industry players. By exploring licensing, FREYR can broaden its market reach and benefit from the wider adoption of its technology.

| Revenue Stream | Target Market | Key Differentiator | 2024 Relevance |

|---|---|---|---|

| Direct Battery Cell Sales | EV Manufacturers | High-quality, high-volume production | Continued robust EV market growth |

| Direct Battery Cell Sales | Energy Storage Systems | Reliability for renewable integration | Expansion driven by decarbonization |

| Direct Battery Cell Sales | Marine & Industrial Applications | High-performance, specialized cells | Securing offtake agreements |

| Licensing of 24M SemiSolid™ Platform | Other Battery Manufacturers | Cost reduction & efficiency gains | Strategic long-term opportunity |

Business Model Canvas Data Sources

The FREYR Battery Business Model Canvas is built upon extensive market research, including battery industry trends and competitive analysis, alongside FREYR's internal strategic planning documents and financial projections. These sources ensure each canvas block is filled with accurate, up-to-date information relevant to FREYR's operations and market position.