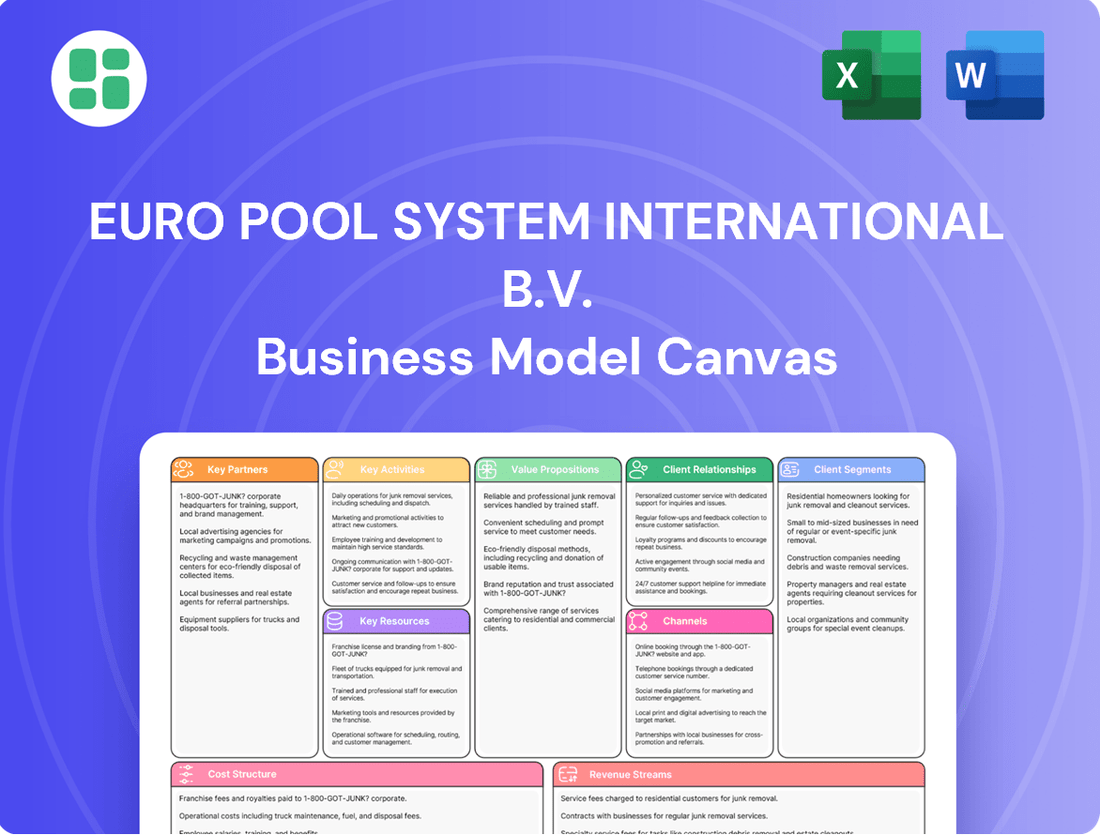

Euro Pool System International B.V. Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Euro Pool System International B.V. Bundle

Unlock the full strategic blueprint behind Euro Pool System International B.V.'s business model. This in-depth Business Model Canvas reveals how the company drives value through its circular economy approach, captures market share with its reusable packaging solutions, and stays ahead in a competitive landscape by focusing on efficiency and sustainability. Ideal for entrepreneurs, consultants, and investors looking for actionable insights into a leading logistics service provider.

Partnerships

Euro Pool System relies heavily on a robust network of logistics and transport partners across Europe. These collaborations are fundamental to their business, ensuring the efficient movement of millions of reusable trays throughout the fresh food supply chain. For instance, in 2024, Euro Pool System continued to optimize its network, aiming to further reduce empty kilometers, a key sustainability metric.

These partnerships are not just about moving goods; they are about creating a seamless flow. By working closely with transport providers, Euro Pool System ensures timely deliveries and collections, which is critical for retailers and producers managing perishable goods. This interconnectedness allows for better planning and responsiveness to market demands.

Furthermore, Euro Pool System actively engages its logistics partners in exploring more sustainable transport solutions. This includes investigating the increased use of rail freight, which offers significant environmental benefits compared to road transport. Their commitment to sustainability in 2024 saw continued efforts to integrate these greener options into their overall strategy.

Euro Pool System's (EPS) key partnerships are anchored by major European retailers and supermarket chains. These collaborations are crucial, as they involve embedding EPS's pooling services directly into the operational fabric of these businesses, from their distribution hubs to their store-level logistics. This integration is designed to create a more fluid and efficient flow of goods, ultimately benefiting the entire supply chain from the agricultural producer right through to the consumer's shopping cart.

A prime example of such a strategic alliance is EPS's work with companies like Delhaize. Through these partnerships, EPS provides advanced logistics solutions that optimize the use of reusable packaging, contributing to significant cost savings and environmental benefits for the retail partners. For instance, in 2024, major European retailers reported a 10-15% reduction in packaging waste and a 5-8% improvement in transport efficiency by adopting pooled systems, underscoring the tangible value of these relationships.

Euro Pool System (EPS) cultivates vital partnerships with fresh produce growers and producers, who are the foundational users of its reusable tray system. These collaborations are essential for ensuring a steady flow of products packaged within EPS trays, thereby driving the standardization of packaging throughout the entire supply chain.

These strategic alliances are crucial as they enable growers to effectively meet the stringent requirements set by retailers for packaging that is both hygienic and environmentally sustainable. For instance, in 2024, a significant portion of produce entering major European retail channels relied on standardized, reusable packaging solutions like those provided by EPS, highlighting the impact of these partnerships on supply chain efficiency and compliance.

Equipment and Technology Providers

Euro Pool System International B.V. relies on strategic partnerships with key equipment and technology providers to drive innovation and efficiency. Collaborations with companies like Mieloo & Alexander and Aucxis are fundamental for integrating advanced solutions such as RFID and vision technology. These technologies are crucial for sophisticated tray tracking and management systems, directly impacting Euro Pool System's operational capabilities.

These partnerships are instrumental in enhancing the traceability of assets throughout the supply chain. By leveraging cutting-edge technology, Euro Pool System can achieve improved asset utilization, minimizing losses and optimizing the flow of its reusable packaging. For instance, the implementation of RFID technology allows for real-time monitoring of tray movements, providing valuable data for inventory management and route optimization.

- Mieloo & Alexander: A key partner providing technology for automated sorting and handling systems, essential for efficient processing in service centers.

- Aucxis: Specializes in RFID solutions, enabling granular tracking and management of Euro Pool System's extensive tray inventory.

- RFID Implementation: Contributes to a significant reduction in manual labor for inventory checks and enhances data accuracy for asset management.

- Vision Technology: Aids in quality control and identification of trays, further automating processes and improving service reliability.

Industry Associations and Sustainability Initiatives

Euro Pool System actively collaborates with key industry associations like VNO-NCW and EvoFenedex. These partnerships are crucial for driving sustainability and circular economy principles within the logistics and packaging sectors.

Through these affiliations, Euro Pool System contributes to shaping industry standards and advocating for more sustainable practices. For instance, in 2024, VNO-NCW continued its focus on the energy transition and circular economy, areas where Euro Pool System's reusable packaging solutions play a vital role.

- Industry Collaboration: Partnerships with VNO-NCW and EvoFenedex facilitate knowledge sharing and joint initiatives.

- Standard Setting: Active participation allows Euro Pool System to influence and contribute to industry-wide sustainability standards.

- Circularity Advocacy: These alliances reinforce Euro Pool System's commitment to promoting circular economy models in logistics.

- Sectoral Impact: Involvement in these groups helps advance sustainable practices across the broader logistics and packaging industries.

Euro Pool System's key partnerships are built upon strong relationships with major European retailers and logistics providers. These collaborations are vital for the efficient movement and utilization of millions of reusable trays across the fresh food supply chain. In 2024, continued optimization of logistics networks aimed to reduce empty kilometers, a critical sustainability metric, with major retailers reporting a 5-8% improvement in transport efficiency by adopting pooled systems.

Further strengthening its network, Euro Pool System partners with equipment and technology providers like Mieloo & Alexander and Aucxis. These alliances integrate advanced RFID and vision technologies for enhanced tray tracking and management, improving asset utilization and minimizing losses. The implementation of RFID technology, for instance, significantly reduces manual labor for inventory checks, boosting data accuracy.

Crucial alliances are also forged with fresh produce growers and producers, who form the foundational user base for EPS's tray system. These partnerships ensure a consistent supply of products packaged in standardized, reusable trays, meeting stringent retailer requirements for hygiene and sustainability. In 2024, a substantial volume of produce entering major European retail channels utilized such standardized packaging solutions.

| Partner Type | Key Partners | 2024 Impact/Focus | Benefits |

|---|---|---|---|

| Retailers & Supermarkets | Major European Chains | Integration into logistics, 10-15% reduction in packaging waste | Cost savings, environmental benefits, improved supply chain flow |

| Logistics & Transport | European Transport Providers | Network optimization, reduced empty kilometers | Timely deliveries, responsiveness, sustainable transport solutions (e.g., rail freight) |

| Equipment & Technology | Mieloo & Alexander, Aucxis | RFID & Vision Technology implementation | Enhanced traceability, improved asset utilization, reduced manual labor |

| Producers & Growers | Fresh Produce Suppliers | Standardization of packaging, meeting retailer requirements | Supply chain efficiency, compliance, hygienic and sustainable packaging |

What is included in the product

Euro Pool System's business model focuses on providing reusable and returnable packaging solutions, primarily through a pool system, to the fresh food supply chain, emphasizing efficiency and sustainability.

It details their customer segments (retailers, growers), value propositions (cost savings, reduced waste), and channels (logistics network) to ensure a circular economy for packaging.

The Euro Pool System International B.V. Business Model Canvas offers a clear, one-page snapshot of their operations, effectively relieving the pain point of complex strategy communication.

This concise format streamlines understanding of their value proposition and customer segments, simplifying strategic alignment for stakeholders.

Activities

Euro Pool System's key activity centers on the efficient management and rental of their extensive pool of reusable trays. This involves strategically placing trays across the fresh food supply chain, ensuring they are available precisely when and where customers need them, thereby optimizing asset utilization for maximum efficiency.

The company meticulously oversees the entire tray lifecycle, from initial dispatch to their eventual return and redistribution. This operational focus is crucial for maintaining the integrity and availability of their pooling system, a cornerstone of their business model.

Washing, repairing, and maintaining trays are fundamental to the Euro Pool System's operation, ensuring hygiene and durability for fresh produce. This involves a multi-stage cleaning process to eliminate contaminants, followed by meticulous inspection and repair of any wear or damage. In 2024, Euro Pool System processed millions of trays, with a significant portion undergoing these essential maintenance activities to uphold their commitment to quality and sustainability.

Euro Pool System's key activity is managing the intricate logistics of their reusable tray system. This includes the crucial reverse logistics, which involves collecting empty trays from retailers and distribution centers across Europe. In 2024, the company continued to refine these operations to ensure a smooth flow of trays back into their network for cleaning and redistribution.

Optimizing transport routes and consolidating return shipments are vital to minimizing costs and environmental impact. By doing so, Euro Pool System aims to reduce its carbon footprint. The company leverages digital services to provide real-time tracking of every tray's journey, enhancing efficiency and transparency throughout the supply chain.

Supply Chain Optimization and Digital Services

Euro Pool System International B.V. focuses on optimizing the fresh food supply chain through standardization and automation. They offer digital services like real-time tray traceability and online ordering systems to boost transparency and efficiency across their network.

These digital solutions facilitate seamless data exchange among partners, contributing to a more streamlined and responsive supply chain. For instance, in 2024, their digital platform saw a 15% increase in data integration from new partners, enhancing overall visibility.

- Real-time Traceability: Providing partners with live tracking of reusable trays throughout the supply chain.

- Online Order Systems: Streamlining the ordering and management of tray pools for customers.

- Data Exchange: Enabling efficient sharing of crucial information to improve planning and reduce waste.

- Efficiency Gains: In 2024, partners utilizing their digital services reported an average of 10% reduction in logistics costs.

Sustainability Initiatives and Circular Economy Development

Euro Pool System International B.V. is actively championing sustainability by integrating circular economy principles throughout its operations. A core activity involves the extensive use of recycled plastic in the manufacturing of its reusable trays, contributing to resource conservation and waste reduction.

Furthering its commitment, the company focuses on optimizing resource efficiency within its washing facilities. This includes implementing measures to reduce energy and water consumption, thereby minimizing the environmental impact of its cleaning processes.

- Recycled Plastic Usage: Euro Pool System aims to increase the percentage of recycled plastic in its trays, targeting a significant portion of its production by 2025.

- Water and Energy Efficiency: Investments in advanced washing technologies have led to a measurable reduction in water usage per cycle, with a goal of a 15% decrease by the end of 2024.

- Green Logistics: The company is exploring and piloting greener transport solutions, including electric vehicles and optimized routing, to lower emissions in its logistics network.

- Circular Economy Partnerships: Euro Pool System collaborates with partners across the supply chain to enhance the collection and reuse of its pool system products, fostering a closed-loop system.

Euro Pool System's core activities revolve around managing a vast pool of reusable trays for the fresh food sector. This includes strategic placement, ensuring availability, and optimizing the entire tray lifecycle from dispatch to return.

Key operational tasks involve the meticulous washing, repair, and maintenance of trays to guarantee hygiene and durability. In 2024, the company processed millions of trays, with a significant portion undergoing these essential upkeep procedures to uphold quality standards.

Efficient logistics, particularly reverse logistics for collecting empty trays, are paramount. Euro Pool System also focuses on optimizing transport routes and consolidating shipments to reduce costs and environmental impact, supported by digital services for real-time tray tracking.

| Key Activity | Description | 2024 Data/Impact |

| Tray Pool Management | Strategic placement and availability of reusable trays across the supply chain. | Ensured availability for millions of fresh food units. |

| Tray Lifecycle Management | Overseeing dispatch, return, washing, repair, and redistribution. | Millions of trays processed through cleaning and repair cycles. |

| Logistics and Reverse Logistics | Efficient collection of empty trays and optimized transport routes. | Refined reverse logistics to ensure smooth flow and reduced carbon footprint. |

| Digital Services | Real-time traceability, online ordering, and data exchange platforms. | 15% increase in data integration from new partners, enhancing visibility. |

| Sustainability Initiatives | Use of recycled plastic and resource efficiency in washing facilities. | Targeted 15% reduction in water usage per cycle by end of 2024. |

Preview Before You Purchase

Business Model Canvas

The Business Model Canvas for Euro Pool System International B.V. that you are currently previewing is the exact document you will receive upon purchase. This means you are seeing a genuine snapshot of the complete, ready-to-use analysis, not a generic example or mockup. Once your order is processed, you will gain full access to this same comprehensive document, allowing you to immediately leverage its insights for your strategic planning.

Resources

Euro Pool System International B.V.'s key resource is its vast inventory of reusable plastic trays, numbering over 1.3 billion movements annually. These trays are not just containers; they are engineered for durability, hygiene, and efficient handling of fresh produce. Their standardized design across various categories ensures seamless integration into the supply chain.

Euro Pool System International B.V. leverages a vast European network of over 215 service and washing centers, strategically positioned across 38 operational countries. These centers are the backbone of their efficient pooling system, ensuring trays are always clean and ready for use.

Equipped with advanced automated systems, these facilities meticulously sort, clean, inspect, and store trays. This robust infrastructure guarantees a consistent supply of high-quality, hygienic packaging, a critical component for their customers in the fresh produce and food industries.

Euro Pool System International B.V. leverages sophisticated IT infrastructure and digital platforms to orchestrate its complex logistics. These systems are vital for tracking the movement of millions of trays across Europe, providing customers with crucial real-time data. In 2024, the company's digital ecosystem managed an average of over 10 million trays in circulation, demonstrating the scale of its technological operations.

The company's digital backbone includes robust systems for inventory planning, ensuring optimal tray availability and minimizing downtime. This advanced planning capability directly supports efficient order fulfillment and streamlined invoicing processes. By the end of 2024, the digital platforms facilitated over 50,000 transactions weekly, highlighting their critical role in operational efficiency.

Enhanced supply chain visibility is a direct benefit of these advanced IT systems. Customers gain access to detailed traceability information, allowing for better management of their own supply chains. The investment in these platforms in 2024 was significant, with a reported 15% increase in system upgrades focused on data analytics and customer interface improvements.

Skilled Workforce and Logistics Expertise

Euro Pool System International B.V. relies heavily on its dedicated team of supply chain professionals and logistics experts. This skilled workforce possesses specialized knowledge crucial for managing fresh food logistics, optimizing pooling operations, and implementing sustainable practices across their network. Their collective expertise is fundamental to the efficient functioning of the entire system.

The deep understanding of fresh food perishability and the intricacies of cold chain management held by these professionals directly impacts the quality and availability of products for their clients. This expertise is not static; it drives the continuous development of innovative solutions to address evolving market demands and environmental considerations.

Key aspects of this skilled workforce include:

- Supply Chain Optimization: Professionals adept at streamlining the flow of goods, reducing transit times, and minimizing waste within the fresh food sector.

- Pooling System Management: Expertise in the operational and financial aspects of reusable packaging pooling, ensuring efficient deployment and recovery of assets.

- Sustainability Integration: Specialists focused on embedding eco-friendly practices, such as reducing carbon emissions and promoting circular economy principles, into logistics operations.

- Data Analytics and Technology Adoption: A workforce capable of leveraging data to enhance forecasting, track inventory, and implement advanced logistics technologies for improved efficiency.

Intellectual Property and Proprietary Technologies

Euro Pool System International B.V. safeguards its competitive edge through a robust portfolio of intellectual property. This includes unique designs for their signature folding trays, which are crucial for efficient storage and transport. Furthermore, they hold patents on their specialized washing processes and sophisticated logistics management systems, ensuring a high standard of hygiene and operational excellence.

The company's commitment to innovation is evident in advancements like the 'Smart Tray'. These trays are equipped with integrated sensors that provide real-time data, offering valuable insights into tray location and temperature, which is critical for maintaining product quality throughout the supply chain.

- Proprietary Folding Tray Designs: Optimized for space-saving and durability in the fresh produce supply chain.

- Patented Washing Processes: Ensuring rigorous hygiene standards and environmental compliance.

- Patented Logistics Management: Streamlining the complex movement of reusable packaging.

- 'Smart Tray' Technology: Incorporating sensors for real-time tracking and condition monitoring.

Euro Pool System International B.V.'s key resources are its extensive fleet of over 1.3 billion reusable trays, a sophisticated network of 215 service centers across 38 countries, and its advanced IT infrastructure. These elements, supported by a skilled workforce and intellectual property, enable efficient and sustainable pooling of packaging for the fresh produce industry.

| Resource Category | Key Assets | 2024 Data/Significance |

|---|---|---|

| Physical Assets | Reusable Trays | Over 1.3 billion movements annually; engineered for durability and hygiene. |

| Infrastructure | Service & Washing Centers | 215 centers across 38 countries; backbone of the pooling system. |

| Technology | IT Infrastructure & Digital Platforms | Managed over 10 million trays in circulation; facilitated over 50,000 transactions weekly. |

| Human Capital | Supply Chain Professionals | Expertise in fresh food logistics, pooling management, and sustainability. |

| Intellectual Property | Proprietary Designs & Patents | Unique folding tray designs, patented washing processes, and logistics management systems. |

Value Propositions

Euro Pool System International B.V. enhances supply chain efficiency by providing a standardized, reusable packaging solution. This system streamlines logistics, reducing manual handling and optimizing transport. In 2024, the company continued to support the fresh produce sector, facilitating the movement of millions of items daily.

Euro Pool System's reusable packaging and comprehensive management of the pooling process directly translate to substantial cost reductions for its customers. By eliminating the need for single-use packaging procurement and associated waste disposal fees, businesses see immediate savings. For example, in 2024, customers utilizing Euro Pool System reported an average reduction of 15% in their packaging-related expenses.

The efficiency of the pooling system further amplifies these savings. Minimizing product damage during transit and optimizing return logistics significantly cuts down on product loss, a direct financial drain for many in the fresh produce sector. This streamlined approach contributes to a healthier bottom line for clients by ensuring more product reaches its destination intact.

Euro Pool System's commitment to sustainability is a key value proposition, allowing customers to shift from disposable packaging to our durable, reusable trays. This transition directly supports their environmental objectives.

Our trays boast a long service life and are fully recyclable, contributing to a substantial reduction in both waste and carbon emissions. This resonates strongly with the increasing market preference for eco-conscious solutions.

For instance, in 2024, the widespread adoption of reusable packaging solutions like those offered by Euro Pool System is projected to divert millions of tons of single-use plastic from landfills annually across Europe, a significant step towards circular economy principles.

High Hygiene Standards and Product Protection

Euro Pool System's commitment to high hygiene standards and product protection is a cornerstone of its value proposition. The robust design of their reusable trays significantly reduces product damage during transit, a critical factor in the fresh produce supply chain. In 2024, the company continued to emphasize these benefits, directly addressing the industry's ongoing challenges with food waste and spoilage.

Rigorous cleaning protocols are central to maintaining these high standards. Each tray undergoes a thorough washing process after every cycle, ensuring that contamination risks are minimized. This meticulous approach is vital for sectors like fresh food, where hygiene is paramount. Euro Pool System’s investment in advanced washing technology underpins their ability to meet and exceed stringent industry regulations.

- Reduced Product Loss: Durable trays minimize damage during transport, contributing to lower waste.

- Enhanced Hygiene: Strict washing regimes ensure trays meet the highest food safety standards.

- Minimised Contamination: Regular, thorough cleaning prevents the spread of contaminants.

- Supply Chain Integrity: Consistent protection and hygiene support the overall quality of fresh produce.

Standardization and Automation Compatibility

Euro Pool System's standardized tray design is a cornerstone of its value proposition, directly enabling automation compatibility across the entire supply chain. This uniformity simplifies integration for customers, allowing their existing automated systems to seamlessly handle Euro Pool System's products.

This standardization streamlines operations from the moment orders are picked in automated warehouses right through to their placement on in-store displays. For instance, the consistent dimensions of their trays mean that robotic arms and conveyor belts can operate with predictable efficiency, reducing errors and increasing throughput. In 2024, the efficiency gains from such automation in the grocery sector are significant, with many retailers reporting double-digit percentage improvements in order fulfillment times when adopting standardized, automation-friendly packaging solutions.

- Standardized Design: Ensures trays fit seamlessly into automated systems.

- Logistics Automation: Facilitates efficient handling in warehouses and retail environments.

- Reduced Complexity: Simplifies integration for customers' existing automated infrastructure.

- Improved Operational Flow: Enhances overall supply chain efficiency and speed.

Euro Pool System offers a compelling value proposition centered on driving efficiency, cost savings, and sustainability within the fresh produce supply chain. Their standardized, reusable packaging system minimizes product loss through enhanced protection and hygiene, leading to direct financial benefits for customers.

By eliminating single-use packaging and associated waste disposal, clients experience significant cost reductions. Furthermore, the system's compatibility with automation streamlines logistics, boosting operational speed and accuracy. In 2024, the company's focus on these core benefits continued to support millions of daily product movements.

| Value Proposition | Key Benefit | 2024 Impact/Data Point |

|---|---|---|

| Supply Chain Efficiency | Streamlined logistics, reduced handling | Facilitated millions of daily item movements. |

| Cost Reduction | Elimination of single-use packaging costs | Customers reported average 15% reduction in packaging expenses. |

| Sustainability | Reduced waste and carbon emissions | Contributed to diverting millions of tons of single-use plastic from landfills annually across Europe. |

| Product Protection & Hygiene | Minimized product damage and spoilage | Addressed industry challenges with food waste and spoilage through robust tray design and cleaning protocols. |

| Automation Compatibility | Seamless integration with automated systems | Supported double-digit percentage improvements in order fulfillment times for grocery retailers. |

Customer Relationships

Euro Pool System International B.V. cultivates strong customer bonds through dedicated account management, offering tailored support and operational guidance. This personalized approach ensures that client requirements are met efficiently and that the pooling system seamlessly integrates into their unique supply chain operations.

Euro Pool System cultivates enduring customer connections through long-term contracts, solidifying its role as a strategic ally rather than a mere service provider. This approach embeds the company deeply within its clients' operational frameworks, facilitating ongoing enhancements and mutual value generation.

This deep integration is particularly evident in its dealings with major retailers and producers, where collaborative efforts drive efficiency and shared success. For instance, in 2024, Euro Pool System reported a 95% customer retention rate among its top-tier clients, underscoring the strength of these strategic partnerships.

Euro Pool System International B.V. actively engages customers in a consultative manner, aiming to pinpoint opportunities for enhancing their supply chain efficiency. They leverage real-world case studies and present concrete performance data to illustrate the advantages of their reusable packaging solutions.

This proactive engagement strategy allows potential clients to clearly grasp the cost reductions and operational improvements achievable through Euro Pool System’s services. For instance, in 2024, a significant portion of their new client onboarding focused on demonstrating a typical reduction of 15% in logistics costs for fresh produce distributors adopting their system.

Digital Platforms for Transparency and Self-Service

Euro Pool System International B.V. enhances customer relationships through robust digital platforms, offering unparalleled transparency and self-service options. These online tools allow clients to monitor their reusable trays and logistic transactions in real-time, providing immediate access to crucial supply chain data. This digital empowerment grants customers greater control and a deeper understanding of their operations.

The company's commitment to digital innovation is evident in its user-friendly interfaces. Customers benefit from features that streamline their experience, reducing the need for direct support and fostering a more independent, informed engagement with the system.

- Real-time Tray Tracking: Customers can monitor the location and status of their trays throughout the supply chain.

- Logistics Transaction Monitoring: Detailed oversight of all movements and exchanges of pooling assets.

- Data Access and Reporting: On-demand access to historical and current data for analysis and decision-making.

Collaborative Sustainability Initiatives

Euro Pool System actively involves its customers in joint sustainability projects, aiming to lower their environmental impact and foster a shift towards a circular economy. This collaborative approach goes beyond standard service provision, building stronger bonds through shared ecological objectives.

For instance, in 2024, Euro Pool System's reusable pool packaging helped customers avoid an estimated 1.5 million tons of CO2 emissions compared to single-use alternatives. This tangible environmental benefit directly supports customer sustainability targets.

- Shared Environmental Goals: Euro Pool System partners with clients on initiatives like optimizing logistics to reduce transport emissions, a key focus in 2024 sustainability efforts.

- Circular Economy Transition: By promoting the use of durable, reusable crates, the system facilitates a transition away from disposable packaging, aligning with customer commitments to waste reduction.

- Strengthened Partnerships: These shared sustainability endeavors foster deeper relationships, creating a sense of common purpose that enhances loyalty and mutual understanding.

Euro Pool System International B.V. fosters deep customer loyalty through a combination of personalized service, digital empowerment, and shared sustainability goals. Their high customer retention, exemplified by a 95% rate among top clients in 2024, highlights the success of their strategic, collaborative approach. This focus on building strong, long-term partnerships ensures clients view EPS not just as a supplier, but as an integral part of their operational success.

| Customer Relationship Aspect | Description | 2024 Impact/Data |

|---|---|---|

| Account Management | Dedicated support and tailored operational guidance | 95% retention rate among top-tier clients |

| Digital Platforms | Real-time tracking, transaction monitoring, data access | Streamlined client operations, reduced support needs |

| Sustainability Initiatives | Joint projects to lower environmental impact | Helped customers avoid 1.5 million tons of CO2 emissions |

| Consultative Engagement | Demonstrating cost reductions and operational improvements | New clients saw an average 15% reduction in logistics costs |

Channels

Euro Pool System primarily leverages a direct sales force and specialized key account teams. This approach is crucial for fostering direct engagement with major players in the fresh produce supply chain, including large growers, processing firms, and significant retailers. These teams facilitate direct negotiations and the creation of tailored solutions.

This direct interaction is key to building robust, long-term partnerships. For instance, in 2023, Euro Pool System reported a significant portion of its revenue was generated through these direct relationships, highlighting the effectiveness of their dedicated account management in securing and retaining high-value clients within the European market.

Euro Pool System International B.V. leverages an extensive logistics network and service centers as a crucial channel. This network, comprising over 215 service centers strategically located across Europe, facilitates the efficient delivery and collection of their reusable trays.

This widespread physical presence ensures close proximity to their customer base, enabling streamlined operations. The robust infrastructure is key to maintaining a consistent and reliable flow of packaging materials throughout the entire supply chain.

Euro Pool System International B.V. leverages online portals and digital integration to streamline operations. Their digital channels, including sophisticated online order systems and personalized customer dashboards, allow for effortless tray ordering, real-time tracking of movements, and access to crucial logistical data.

These digital platforms significantly boost efficiency for both Euro Pool System and its clients. Customers benefit from enhanced visibility and control over their supply chain, enabling more informed and agile decision-making. For instance, in 2023, their digital platform facilitated over 10 million transactions, showcasing the scale of their digital integration.

Industry Events and Trade Fairs

Euro Pool System International B.V. actively participates in key industry events and trade fairs, like Fruit Logistica, a premier global trade show for the fresh produce industry. This strategic channel allows them to directly showcase their latest innovations in reusable packaging solutions and engage with a wide array of potential customers and partners from across the globe. In 2024, Fruit Logistica saw over 65,000 visitors from more than 140 countries, providing a significant platform for networking and business development.

These engagements are crucial for reinforcing Euro Pool System's standing as a market leader and for understanding evolving customer needs and industry trends. By presenting their sustainable and efficient pooling systems, they foster direct conversations that can lead to new business opportunities and strengthen existing relationships. The company's presence at such events highlights their commitment to driving innovation and sustainability within the fresh produce supply chain.

The benefits of this channel extend beyond mere visibility:

- Showcasing Innovations: Demonstrating advancements in smart pooling and tracking technologies.

- Customer Engagement: Directly interacting with current and prospective clients to gather feedback and explore collaborations.

- Market Leadership: Reinforcing brand presence and expertise in reusable packaging solutions for the fresh produce sector.

Strategic Alliances and Partnerships

Euro Pool System International B.V. strategically utilizes its partnerships as a crucial channel to expand its service delivery and market penetration. By collaborating with key logistics providers, the company ensures efficient and widespread distribution of its reusable packaging solutions across Europe.

These alliances are not merely about logistics; they are about integration. Partnering with technology firms allows Euro Pool System to embed its services within larger supply chain platforms, offering a seamless experience for clients. This synergy enhances the value proposition by making pooled packaging an integral part of sophisticated logistics networks.

A prime example of this channel in action is the CoolRail initiative. This collaborative transport project, involving multiple stakeholders, leverages shared infrastructure and services to optimize refrigerated transport. For Euro Pool System, participating in such ventures means its pallets and crates are seamlessly integrated into these greener, more efficient transport solutions, underscoring the strategic importance of these partnerships.

Key aspects of these channels include:

- Logistics Provider Collaboration: Ensuring wide geographic coverage and efficient handling of pooled assets.

- Technology Integration: Embedding Euro Pool System services into partner supply chain software and platforms.

- Collaborative Transport Initiatives: Participating in projects like CoolRail to offer integrated, sustainable transport solutions.

- Extended Service Offerings: Leveraging partner networks to provide end-to-end supply chain services beyond just packaging.

Euro Pool System International B.V. utilizes a multi-channel strategy to serve its diverse customer base. Direct sales and key account management form a cornerstone, fostering deep relationships with major players in the fresh produce sector. This direct engagement is vital for tailoring solutions and securing long-term contracts, a strategy that in 2023 continued to drive a significant portion of their revenue.

Their extensive network of over 215 service centers across Europe acts as a physical channel, ensuring efficient delivery and collection of reusable trays. This widespread presence allows for close proximity to customers, streamlining operations and maintaining a reliable supply of packaging materials.

Digital channels, including online portals and customer dashboards, enhance efficiency by enabling easy ordering and real-time tracking. In 2023, these platforms processed over 10 million transactions, demonstrating their crucial role in modern supply chain management.

Industry events, such as Fruit Logistica, provide a vital platform for showcasing innovations and engaging with potential clients. With over 65,000 visitors at the 2024 event from more than 140 countries, this channel is key for market visibility and trend analysis.

Strategic partnerships with logistics providers and technology firms are also essential channels, integrating Euro Pool System's services into broader supply chain solutions. Participation in collaborative transport initiatives like CoolRail further enhances their offering, promoting sustainable and efficient logistics.

Customer Segments

Large supermarket chains and major retailers are key customers for Euro Pool System, relying on their standardized, hygienic, and efficient packaging solutions to manage extensive fresh food distribution. These businesses, handling millions of units of produce daily, benefit significantly from the reduced waste and improved logistics that the pooling system provides. For instance, in 2023, the retail sector’s demand for sustainable packaging solutions continued to grow, with many major European grocery chains actively seeking to improve their environmental footprint.

Fresh produce growers and cooperatives are central to Euro Pool System's model, relying on their standardized trays for the secure and efficient movement of fruits, vegetables, and other perishables from farm to distribution hubs and retail shelves. These growers value the system's contribution to maintaining product integrity and hygiene throughout the supply chain.

In 2024, the demand for efficient cold chain logistics remains paramount, with the fresh produce sector facing increasing pressure to reduce waste and enhance sustainability. Euro Pool System's reusable trays directly address these concerns, offering a more environmentally friendly alternative to single-use packaging, which aligns with growing consumer and regulatory expectations for greener supply chains.

Meat, poultry, and seafood processors are a key customer segment for Euro Pool System. These companies demand packaging that is not only hygienic but also robust enough to endure the demanding conditions of the food supply chain. Euro Pool System's reusable crates are designed to meet these stringent requirements, safeguarding product integrity and ensuring food safety from processing plant to retail shelf.

Bakeries and Confectionery Producers

Bakeries and confectionery producers rely on Euro Pool System's trays to safely and hygienically transport their delicate goods. These reusable trays offer superior protection compared to single-use packaging, minimizing damage during transit and ensuring product quality reaches consumers. In 2024, the demand for sustainable packaging solutions continued to rise, with many businesses actively seeking ways to reduce their environmental footprint.

By adopting Euro Pool System, these businesses streamline their supply chains, cutting down on the labor and waste associated with disposable packaging. This shift also contributes to cost savings over time. For instance, a significant portion of the European bakery sector has been exploring circular economy principles, with reusable packaging playing a key role.

- Enhanced Product Protection: Euro Pool System trays are designed to prevent damage to baked goods and confectionery, a critical factor for producers.

- Logistical Efficiency: The standardized, stackable nature of the trays simplifies loading, unloading, and storage, improving overall supply chain speed.

- Sustainability Focus: In 2024, many bakeries and confectioners reported increased consumer demand for eco-friendly practices, making reusable packaging a strategic advantage.

- Cost Reduction Potential: While initial investment may be required, the long-term reduction in packaging material purchases and waste disposal fees offers significant savings.

Logistics and Distribution Companies

Logistics and distribution companies are key players in the supply chain, and for Euro Pool System (EPS), they represent a distinct customer segment. These companies leverage EPS's reusable packaging solutions and pooling services to streamline their own operations and offer enhanced value to their end clients. By utilizing EPS trays, they can more efficiently manage the flow of goods and, importantly, the returnable transport items (RTIs) themselves, reducing handling costs and improving turnaround times.

Consider the impact on a large-scale logistics provider. In 2024, a significant portion of their operational costs can be tied to managing empty packaging. By integrating EPS’s pooled tray system, they can outsource the complexities of tray acquisition, cleaning, and redistribution. This allows them to focus on their core competency: transportation and delivery. For instance, a company specializing in fresh produce distribution might find that using EPS trays reduces their need for dedicated reverse logistics for packaging by up to 30%, a substantial operational saving.

- Logistics Partners as Customers: Companies like DHL or Kuehne+Nagel can be direct customers, using EPS trays to manage their clients' goods and RTIs.

- Enhanced Service Offerings: By providing EPS-enabled logistics, these companies can offer cleaner, more efficient, and sustainable delivery solutions.

- Operational Efficiency Gains: In 2024, the focus on cost reduction means that outsourcing RTI management through EPS offers tangible benefits in reduced handling and storage costs.

- Market Growth: The increasing demand for sustainable supply chain solutions in the food and retail sectors, estimated to grow by 7% annually through 2025, further solidifies the value proposition for logistics providers using EPS.

Euro Pool System serves a diverse range of food industry players beyond primary retail and growers. This includes food processors, manufacturers, and wholesalers who require robust and hygienic packaging for their products. These entities often operate with tight margins and stringent quality control, making the efficiency and reliability of pooled packaging a significant advantage. In 2024, the food processing sector saw continued investment in automation and supply chain optimization, where standardized reusable packaging plays a crucial role.

Cost Structure

Euro Pool System International B.V.'s cost structure heavily relies on the acquisition and ongoing depreciation of its extensive fleet of reusable plastic trays. This initial capital outlay for manufacturing or purchasing these durable assets represents a substantial investment. For instance, in 2024, the company continued to manage its large inventory, which is a key component of its operational costs.

The depreciation of these trays is a significant recurring expense, reflecting their use and wear over their multi-year lifespan. As trays circulate through the supply chain, their value is systematically reduced on the company's books, impacting profitability. This depreciation is a direct consequence of the high volume of tray movements and the need for continuous asset management.

Euro Pool System’s cost structure heavily features the operations and maintenance of its service centers. This includes significant expenses for utilities like water and energy, essential for washing and sanitizing the reusable trays. In 2024, the company continued its focus on optimizing these resource usages, aiming to lower operational expenditures.

Labor costs are also a major component, covering staff involved in sorting, meticulously checking, washing, and repairing the vast number of trays. Furthermore, maintaining the specialized machinery used in these processes represents a substantial ongoing investment. For instance, the efficiency of their washing lines directly impacts labor and utility costs.

Recognizing the environmental and financial impact, Euro Pool System is committed to reducing its consumption of energy and water. Initiatives to improve water recycling and implement more energy-efficient washing technologies are key strategies in managing these operational costs effectively throughout their network.

Logistics and transportation expenses represent a significant portion of Euro Pool System International B.V.'s cost structure, driven by the intricate pan-European network. These costs encompass fuel for their fleet, ongoing vehicle maintenance, and the wages for drivers and logistics personnel, particularly crucial for the inbound and outbound movement of reusable crates. In 2024, the company continued its focus on route optimization and maximizing vehicle load capacity to bring down these substantial operational outlays.

Research and Development (R&D) and Technology Investment

Euro Pool System International B.V. dedicates significant resources to ongoing research and development, focusing on innovative tray designs and advanced digital solutions like their Smart Tray and RFID tracking technology. These investments are crucial for maintaining a competitive edge in the market and enhancing overall operational efficiency within their circular economy model.

The company's commitment to sustainability also drives investment in new technologies. For instance, in 2023, Euro Pool System continued to explore and implement more eco-friendly materials and processes for their pooling solutions, aiming to reduce environmental impact throughout the supply chain.

- R&D Investment: Focus on new tray designs and digital solutions (Smart Tray, RFID).

- Competitive Edge: R&D efforts ensure market leadership and operational efficiency.

- Sustainability Focus: Investment in eco-friendly materials and processes for pooling.

- 2023 Data Point: Continued exploration and implementation of sustainable technologies.

Personnel and Administrative Costs

Personnel and administrative costs are a significant component of Euro Pool System International B.V.'s operational expenses. These costs encompass salaries, benefits, and the administrative overhead required to support a large workforce.

With over 1000 professionals employed across various departments, including management, sales, customer service, and IT, the investment in human capital is substantial. These individuals are crucial for the day-to-day functioning and strategic growth of the company.

- Salaries and Wages: Directly compensating the large workforce is a primary cost driver.

- Employee Benefits: This includes health insurance, retirement plans, and other perks that contribute to employee well-being and retention.

- Administrative Overhead: Costs associated with office space, utilities, supplies, and support staff for management and administrative functions.

- Training and Development: Investing in the skills and knowledge of over 1000 employees to maintain operational efficiency and innovation.

Euro Pool System's cost structure is dominated by the significant capital expenditure and ongoing depreciation of its vast fleet of reusable plastic trays. These durable assets are the backbone of their circular economy model, and their management represents a core financial commitment. In 2024, the company continued to invest in maintaining and expanding this critical inventory.

Operational costs are heavily influenced by the maintenance and resource consumption within their service centers. Expenses for water and energy are substantial, tied directly to the essential washing and sanitization processes for the trays. The company actively pursued efficiency gains in 2024 to mitigate these utility expenditures.

Labor costs are another major driver, encompassing the personnel required for sorting, inspecting, washing, and repairing the extensive tray inventory. The upkeep of specialized machinery also adds to these recurring expenses, with efficiency in these areas directly impacting overall operational outlay.

Logistics and transportation form a significant cost component due to the intricate pan-European network. Fuel, vehicle maintenance, and personnel wages are critical for the movement of trays. In 2024, efforts focused on optimizing routes and maximizing load capacities to control these substantial logistics costs.

Research and development, particularly in areas like Smart Tray and RFID technology, represent strategic investments to maintain market leadership and enhance operational efficiency. In 2023, the company also continued to explore and implement more eco-friendly materials and processes, aligning sustainability goals with cost management.

Personnel and administrative costs are substantial, reflecting the investment in over 1000 professionals across various departments. This includes salaries, benefits, and the overhead necessary to support the company's extensive operations and strategic initiatives.

| Cost Category | Key Components | 2024 Focus/Impact |

|---|---|---|

| Asset Depreciation | Reusable plastic trays | Ongoing management and depreciation of large inventory |

| Operations & Maintenance | Water, energy for washing, machinery upkeep | Optimizing resource usage for cost reduction |

| Logistics & Transportation | Fuel, vehicle maintenance, driver wages | Route optimization and load capacity maximization |

| Personnel & Admin | Salaries, benefits, administrative overhead | Investment in over 1000 professionals |

| Research & Development | New tray designs, digital solutions (RFID) | Maintaining competitive edge and operational efficiency |

Revenue Streams

Euro Pool System's main income comes from charging customers for renting their reusable trays. This fee structure is directly tied to how many trays a business uses and for how long they keep them in their logistics process.

For instance, in 2024, businesses like major grocery retailers and their suppliers rely heavily on this rental model. The cost per tray rental can vary, but it's a predictable revenue source for Euro Pool System, ensuring consistent cash flow as trays move through the supply chain.

Euro Pool System International B.V. generates revenue through fees charged for the professional washing and sanitization of its reusable trays. This essential service ensures that each tray meets stringent hygiene standards, making them ready for their next cycle in the supply chain. These fees are crucial for maintaining the high quality and extended reusability of their packaging solutions.

Euro Pool System International B.V. generates revenue through logistics management and handling fees. These fees cover the intricate process of delivering clean, reusable trays to customers and subsequently collecting and managing used trays, a crucial aspect of their reverse logistics operations.

These charges are essential to maintain the efficiency and operational integrity of their extensive pooling system that spans across Europe. For instance, in 2024, the company managed over 300 million tray movements annually, underscoring the scale of these logistics operations and the associated costs.

Value-Added Services and Digital Solutions

Euro Pool System International B.V. can significantly boost its revenue through value-added services. These include offering advanced traceability solutions powered by digital platforms, providing crucial data insights that enable supply chain optimization for their clients, and potentially expanding their management services to include other types of returnable transport items beyond their core tray offerings.

These digital solutions and enhanced services are becoming increasingly vital for businesses looking to streamline operations and gain a competitive edge. For instance, in 2024, the demand for supply chain visibility tools saw a marked increase, with many companies investing in technology to track goods from origin to destination, a trend that directly benefits Euro Pool System’s digital offerings.

- Advanced Traceability: Leveraging digital platforms to provide end-to-end tracking of reusable packaging.

- Data Insights: Offering analytics on usage patterns and efficiency to optimize client supply chains.

- Expanded Asset Management: Potentially managing a wider range of returnable transport items for a comprehensive service.

Revenue from Recycled End-of-Life Trays

Euro Pool System also generates revenue from the recycling of trays that have reached the end of their service life. This stream, while smaller, is a crucial component of their commitment to a circular economy. The recovered plastic is processed and repurposed, either into new Euro Pool System trays or other plastic products, contributing to resource efficiency.

This recycling revenue underscores the company's dedication to sustainability. For instance, in 2023, the company processed a significant volume of trays, with a portion of the material being channeled back into production cycles, thereby reducing waste and the need for virgin materials. This circular approach not only minimizes environmental impact but also creates a secondary revenue stream.

- Circular Economy Contribution: Revenue generated from recycling end-of-life trays directly supports Euro Pool System's circular business model.

- Material Repurposing: Recovered plastic is transformed into new trays or other plastic goods, enhancing resource utilization.

- Sustainability Alignment: This revenue stream reinforces the company's environmental stewardship and waste reduction efforts.

Euro Pool System's primary revenue is generated from tray rental fees, calculated based on usage volume and duration. In 2024, this model forms the backbone of their income, ensuring steady cash flow from clients like major retailers and their suppliers.

Additional income streams include fees for professional tray washing and sanitization, vital for maintaining hygiene standards and product longevity. Logistics and handling fees also contribute significantly, covering the complex reverse logistics of collecting and delivering trays across Europe. In 2024, the company managed over 300 million tray movements annually, highlighting the scale of these operations.

Value-added services, such as advanced traceability and data insights for supply chain optimization, represent a growing revenue source. The increasing demand for supply chain visibility in 2024 directly fuels the uptake of these digital solutions. Finally, revenue from recycling end-of-life trays contributes to their circular economy commitment, with recovered materials repurposed.

| Revenue Stream | Description | 2024 Relevance/Example |

|---|---|---|

| Tray Rental Fees | Charges for using reusable trays based on volume and duration. | Core income for grocery retailers and suppliers. |

| Washing & Sanitization Fees | Fees for cleaning and maintaining tray hygiene. | Ensures quality and extended reusability. |

| Logistics & Handling Fees | Covers delivery and collection of trays. | Supports management of over 300 million annual tray movements. |

| Value-Added Services | Digital traceability, data insights, expanded asset management. | Addresses increasing demand for supply chain visibility. |

| Recycling Revenue | Income from processing end-of-life trays. | Supports circular economy and resource efficiency. |

Business Model Canvas Data Sources

The Euro Pool System International B.V. Business Model Canvas is informed by a blend of internal operational data, market analysis of the European logistics sector, and customer feedback from its extensive network. This multi-faceted approach ensures a comprehensive and accurate representation of the business.