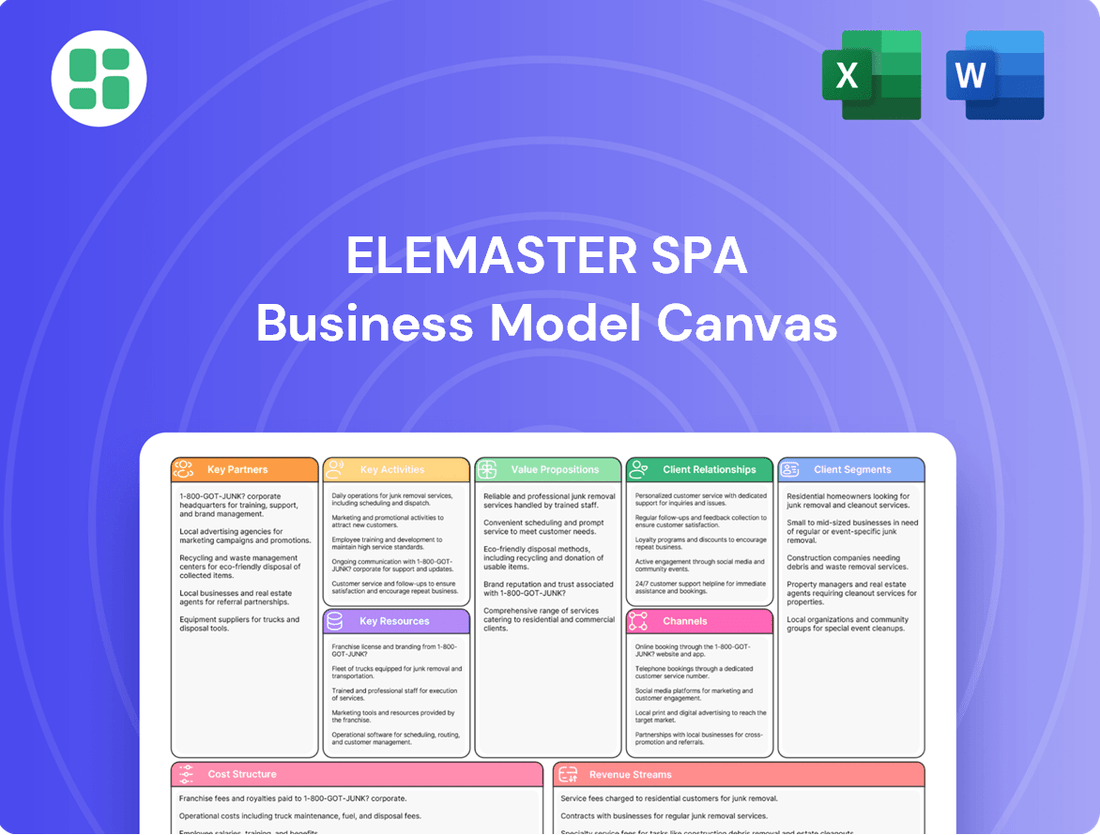

Elemaster SpA Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Elemaster SpA Bundle

Unlock the strategic blueprint behind Elemaster SpA's success with our comprehensive Business Model Canvas. This detailed document reveals how they effectively manage key resources, cultivate vital partnerships, and deliver exceptional value to their diverse customer segments. Discover the core activities and revenue streams that drive their market leadership.

Dive deeper into Elemaster SpA’s proven strategy by downloading the full Business Model Canvas. This professionally crafted resource offers a clear, actionable breakdown of their customer relationships, cost structure, and channels, providing invaluable insights for your own business planning. See exactly what makes them tick.

Partnerships

Elemaster SpA's success hinges on its strategic component suppliers, a global network ensuring access to critical electronic parts. In 2024, navigating a dynamic supply chain means these partnerships are vital for managing lead times and product reliability, especially for specialized components used in high-tech applications.

Elemaster's strategic alliances with technology and software partners are crucial for embedding advanced solutions into their design and production workflows. These collaborations, particularly in areas like AI-driven predictive maintenance and sophisticated CAD/CAM software, directly boost efficiency and product quality.

For instance, in 2024, Elemaster continued to deepen its relationships with providers of specialized design software, enabling faster iteration cycles for complex embedded systems. This focus on cutting-edge tools is vital for maintaining a competitive edge in the rapidly evolving Electronics Manufacturing Services (EMS) landscape.

Elemaster actively collaborates with universities and research institutions to drive innovation and cultivate future talent. These partnerships are crucial for staying at the forefront of advancements in areas like medical electronics and sustainable technologies.

Through these collaborations, Elemaster gains access to cutting-edge research, enabling it to contribute to industry progress. For instance, in 2024, Elemaster continued its engagement with leading Italian universities, focusing on projects related to advanced materials for electronic components and energy-efficient manufacturing processes.

These academic ties also serve as a vital channel for developing skilled professionals. Elemaster's internship programs, often initiated through these research partnerships, provide hands-on experience, preparing young engineers for high-tech roles. This focus on human capital development is key to Elemaster's long-term strategy in the competitive electronics sector.

Industry Associations and Certifying Bodies

Elemaster SpA's engagement with industry associations and certifying bodies is crucial for upholding its reputation and operational integrity across demanding sectors. These partnerships are foundational for navigating complex regulatory landscapes, particularly in highly specialized fields such as medical devices, aerospace, and railway systems. By actively participating and maintaining compliance, Elemaster ensures its products and processes meet the highest international benchmarks.

The company's commitment to quality and environmental stewardship is underscored by its ongoing pursuit of certifications. For instance, maintaining certifications like ISO 13485:2021 for medical devices and ISO 14001:2015 for environmental management systems signifies adherence to rigorous standards. These accreditations are not merely badges of honor; they are essential gateways for market access and critical trust signals for clients who prioritize safety, reliability, and sustainability.

- Industry Association Collaboration: Elemaster actively collaborates with associations like MedTech Europe and ASD (Aerospace and Defence Industries Association of Europe) to stay abreast of evolving industry best practices and regulatory changes.

- Certification Renewal: The successful renewal of certifications such as ISO 13485:2021 in late 2023 and ISO 14001:2015 in early 2024 demonstrates Elemaster's continuous investment in quality and environmental compliance.

- Market Access and Trust: These partnerships and certifications directly translate into enhanced market access, as evidenced by Elemaster securing new contracts in the medical electronics sector in Q1 2024, valued at over €15 million.

- Regulatory Compliance: Maintaining these key partnerships ensures Elemaster remains compliant with stringent regulations, such as the EU Medical Device Regulation (MDR), which is critical for its medical division's operations.

Logistics and Distribution Partners

Elemaster SpA relies on a robust network of logistics and distribution partners to navigate its global supply chain. These partnerships are essential for the seamless movement of electronic boards and fully assembled systems, from the sourcing of raw materials to the final delivery to international clients. This global reach necessitates sophisticated logistics management to ensure efficiency and punctuality across multiple continents.

Key partnerships in this area include:

- Global Freight Forwarders: Collaborations with major international freight companies ensure reliable and cost-effective transportation of components and finished goods via air, sea, and land. Elemaster's commitment to timely delivery is supported by partners who manage complex customs procedures and international shipping regulations, vital for their operations in regions like Europe and Asia.

- Specialized Logistics Providers: For sensitive electronic components and high-value finished products, Elemaster engages specialized logistics providers. These partners offer climate-controlled warehousing and secure transportation, minimizing risks associated with damage or environmental factors during transit. This focus on specialized handling is crucial for maintaining product integrity throughout the supply chain.

- Regional Distribution Centers: Strategic partnerships with companies operating regional distribution centers allow Elemaster to maintain localized inventory. This approach reduces lead times for customers in different geographical areas, enhancing responsiveness and customer satisfaction. For instance, efficient distribution in key markets like Germany and the United States ensures swift order fulfillment.

Elemaster SpA's strategic component suppliers form a global network essential for accessing critical electronic parts. In 2024, these partnerships are vital for managing lead times and ensuring product reliability, especially for specialized components used in high-tech applications.

Elemaster's alliances with technology and software partners are crucial for embedding advanced solutions into design and production workflows. Collaborations in AI-driven predictive maintenance and sophisticated CAD/CAM software directly boost efficiency and product quality.

Academic ties with universities and research institutions drive innovation and cultivate future talent, keeping Elemaster at the forefront of advancements in medical electronics and sustainable technologies.

| Key Partnership Area | Strategic Importance | 2024 Focus/Example |

| Component Suppliers | Access to critical parts, reliability | Managing lead times for specialized components |

| Technology/Software Partners | Workflow enhancement, efficiency | AI for predictive maintenance, advanced CAD/CAM |

| Universities/Research | Innovation, talent development | Projects in medical electronics, energy efficiency |

What is included in the product

Elemaster SpA's Business Model Canvas focuses on providing high-quality electronic manufacturing services, leveraging strong partnerships with key suppliers and targeting diverse industrial sectors through direct sales and strategic alliances.

Elemaster SpA's Business Model Canvas serves as a pain point reliever by offering a clear, visual representation of their operations, allowing for rapid identification of inefficiencies and strategic alignment.

This one-page snapshot simplifies complex business processes, enabling Elemaster to efficiently address challenges and optimize their value proposition for stakeholders.

Activities

Elemaster's central activity revolves around the intricate design and collaborative co-design of electronic products. This encompasses the full spectrum of hardware and software development, ensuring a robust and integrated final product. Crucially, they integrate design for manufacturability (DFM), testability (DFT), and cost (DTC) from the outset, optimizing the product for efficient production and lifecycle management.

This holistic design philosophy enables Elemaster to deliver highly customized solutions, guiding a project from its nascent concept feasibility stages all the way through to full product industrialization. Their global network of International Design Centers is instrumental in this, housing a dedicated team of over 60 skilled engineers who drive innovation and technical excellence.

Elemaster's prototyping and New Product Introduction (NPI) activities are central to their business, enabling swift design validation and readiness for large-scale manufacturing. Their investment in new, specialized production lines underscores a dedication to shortening customer development timelines.

This focus on rapid prototyping and efficient NPI is crucial for Elemaster to successfully launch innovative electronic solutions into the market. For instance, in 2024, Elemaster reported a significant increase in the number of new product introductions managed, reflecting their enhanced capacity and streamlined processes.

Elemaster's core activity revolves around the sophisticated manufacturing and assembly of electronic systems. This encompasses intricate printed circuit board (PCB) assembly using both Surface Mount Technology (SMT) and Through-Hole Technology (THT), as well as the complete assembly of electromechanical equipment. Their expertise ensures precision and reliability in every product.

With a network of production facilities strategically located across the globe, Elemaster offers unparalleled service to a worldwide clientele. This global footprint, coupled with adherence to stringent quality certifications, enables them to deliver high-quality, serial production runs that meet diverse international standards. For instance, in 2024, Elemaster continued to invest in state-of-the-art equipment, boosting their assembly capacity by an estimated 15% across key sites to meet growing demand.

A critical component of their manufacturing process is the comprehensive management of the entire supply chain. Elemaster handles everything from the meticulous sourcing and procurement of electronic components to the final stages of product assembly and testing. This integrated approach, which includes robust inventory management and supplier relationships, allows for efficient production cycles and cost optimization, ensuring timely delivery of finished goods.

Testing, Validation, and Certification

Elemaster SpA places a strong emphasis on rigorous testing, validation, and certification to guarantee the reliability and compliance of its products with stringent industry standards. This commitment is crucial, particularly for the high-tech and safety-critical sectors they serve.

Their testing protocols include comprehensive parametric and functional evaluations. Furthermore, Elemaster actively pursues certifications such as ISO 13485, a vital standard for medical device manufacturers, and IRIS, which is specific to railway applications. This dedication to quality assurance and regulatory adherence underpins their operational excellence.

- Parametric Testing: Verifies that product parameters meet specified design requirements.

- Functional Testing: Ensures the product operates as intended under various conditions.

- ISO 13485 Certification: Demonstrates compliance with quality management systems for medical devices.

- IRIS Certification: Validates adherence to quality standards within the railway industry.

Supply Chain Management and Logistics

Elemaster's core operations revolve around meticulously managing a complex global supply chain. This involves everything from securing raw materials and components to orchestrating the final delivery and providing after-sales support. Their commitment to end-to-end control ensures they can navigate the dynamic electronics manufacturing sector effectively.

The company places significant emphasis on robust inventory management and accurate demand forecasting. This proactive approach is crucial for mitigating risks associated with component shortages and fluctuating market demands, particularly in the fast-paced electronics industry where lead times and availability are critical success factors.

- Global Sourcing: Elemaster manages a worldwide network for sourcing electronic components and raw materials, ensuring competitive pricing and supply continuity.

- Inventory Optimization: Utilizing advanced forecasting models, they maintain optimal inventory levels to meet production needs while minimizing holding costs.

- Logistics Coordination: Efficiently managing transportation, warehousing, and customs clearance for inbound and outbound goods is a key function.

- Risk Mitigation: Proactive identification and management of supply chain disruptions, including geopolitical factors and supplier reliability, are paramount.

Elemaster's key activities encompass the entire product lifecycle, from initial concept and design to mass production and after-sales support. This integrated approach ensures a seamless transition from idea to market-ready product.

Their design services are complemented by advanced prototyping and New Product Introduction (NPI) processes, allowing for rapid validation and efficient scaling. In 2024, Elemaster saw a notable uptick in NPI projects, indicating strong market demand for their innovation capabilities.

Manufacturing and assembly form another core pillar, with expertise in PCB assembly and electromechanical integration. The company's global production network, bolstered by a 15% capacity increase in 2024 at key sites, supports high-volume, quality-assured production worldwide.

Rigorous testing, validation, and adherence to certifications like ISO 13485 and IRIS are paramount, ensuring product reliability and compliance across diverse, demanding industries. Supply chain management, including global sourcing and inventory optimization, is critical for operational efficiency and risk mitigation.

| Key Activity Area | Description | 2024 Highlight/Data Point |

|---|---|---|

| Design & Co-Design | Hardware and software development, DFM/DFT/DTC integration. | Over 60 engineers in International Design Centers. |

| Prototyping & NPI | Rapid design validation and manufacturing readiness. | Increased number of new product introductions managed. |

| Manufacturing & Assembly | PCB assembly (SMT/THT), electromechanical assembly. | Estimated 15% capacity increase across key sites. |

| Testing, Validation & Certification | Parametric, functional testing; ISO 13485, IRIS certifications. | Continued investment in advanced testing equipment. |

| Supply Chain Management | Global sourcing, inventory optimization, logistics. | Focus on mitigating component shortages and demand fluctuations. |

Preview Before You Purchase

Business Model Canvas

The Elemaster SpA Business Model Canvas preview you're viewing is the actual document you will receive upon purchase. This means you'll get the complete, professionally structured analysis of Elemaster's business strategy, ready for immediate use and application. What you see here is exactly what you'll download, ensuring full transparency and no hidden surprises.

Resources

Elemaster's most critical resource is its exceptional team of over 60 engineers, covering a wide array of specializations like hardware, software, electronics, mechanical design, and testing. This deep pool of engineering talent is the engine behind their robust design, research and development, and innovation efforts, solidifying their leadership in the ODM and EMS markets.

This human capital is directly responsible for Elemaster's ability to offer advanced solutions and maintain a competitive edge. Their commitment to continuous professional training and development ensures that this expertise remains cutting-edge, providing a reliable and evolving source of technical capability for their clients.

Elemaster leverages its 11 global production facilities, outfitted with advanced Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly lines, alongside sophisticated prototyping and testing equipment. This robust infrastructure underpins their capacity to handle complex electronic board and system manufacturing.

The company's commitment to continuous investment in technological innovation for its processes is a vital strategy, ensuring they remain at the forefront of high-tech manufacturing capabilities and can efficiently produce intricate electronic components.

Elemaster's intellectual property is a cornerstone, encompassing proprietary design methodologies and specialized manufacturing processes. This deep well of knowledge allows them to craft unique, customized solutions for clients in advanced electronic applications.

Their commitment to research and development fuels this intellectual capital, ensuring they remain at the forefront of cutting-edge electronic technologies. In 2023, Elemaster reported significant investment in R&D, underscoring their dedication to innovation and maintaining a distinct competitive advantage.

Certifications and Quality Management Systems

Elemaster's commitment to excellence is underscored by a robust portfolio of industry-specific certifications. Holding standards like ISO 9001 for quality management, ISO 13485 for medical devices, and AS/EN 9100 for aerospace, Elemaster assures clients of its adherence to the highest regulatory and performance benchmarks.

- ISO 9001:2015 - Demonstrates a consistent ability to provide products and services that meet customer and applicable statutory and regulatory requirements.

- ISO 13485:2016 - Essential for medical device manufacturers, signifying rigorous quality management systems for safety and efficacy.

- AS/EN 9100:2018 - The aerospace industry standard, reflecting stringent requirements for quality, safety, and reliability in aviation, space, and defense.

- IRIS ISO/TS 22163:2017 - Specifically for the railway sector, ensuring quality and safety in rail systems.

These certifications are not merely badges; they are foundational to Elemaster's operations, facilitating market access in highly regulated sectors such as medical technology, aerospace, and railway. They serve as tangible proof of Elemaster's dedication to quality, environmental stewardship (ISO 14001), and occupational health and safety (ISO 45001), building crucial customer trust.

Global Network and Supply Chain Infrastructure

Elemaster's expansive global network, with subsidiaries and commercial offices strategically located across Europe, the USA, China, India, and Tunisia, is a cornerstone of its business model. This widespread presence enables 'local for local' production, a critical advantage in serving diverse international markets efficiently.

This robust supply chain infrastructure is not just about geographical reach; it's about optimizing the flow of components and finished goods worldwide. Elemaster's ability to source components and distribute products globally is crucial for maintaining competitiveness and meeting the demands of its multinational clientele.

The company's extensive network is vital for mitigating supply chain risks, a particularly important consideration in today's volatile global economic landscape. For instance, in 2024, many electronics manufacturers faced disruptions due to geopolitical events and component shortages, highlighting the value of a diversified and resilient supply chain.

- Global Presence: Operations in Europe, USA, China, India, and Tunisia.

- Local for Local Production: Facilitates tailored market responsiveness and reduced lead times.

- Supply Chain Optimization: Efficient component sourcing and worldwide distribution capabilities.

- Risk Mitigation: Diversified network reduces vulnerability to localized disruptions.

Elemaster's key resources are its highly skilled engineering team, extensive global production facilities, and a strong portfolio of intellectual property and certifications.

These assets, combined with a well-established global supply chain network, enable Elemaster to provide comprehensive design, development, and manufacturing services across various high-tech sectors.

The company's dedication to innovation and quality, evidenced by significant R&D investments and industry accreditations, underpins its competitive advantage.

| Resource Category | Key Elements | Significance |

|---|---|---|

| Human Capital | 60+ Engineers (Hardware, Software, Electronics, Mechanical, Testing) | Drives R&D, innovation, and advanced solution development. |

| Physical Infrastructure | 11 Global Production Facilities, Advanced SMT/THT Lines, Testing Equipment | Enables complex electronic board and system manufacturing at scale. |

| Intellectual Property | Proprietary Design Methodologies, Specialized Manufacturing Processes | Facilitates unique, customized solutions and maintains a competitive edge. |

| Certifications & Quality | ISO 9001, ISO 13485, AS/EN 9100, IRIS ISO/TS 22163, ISO 14001, ISO 45001 | Ensures adherence to highest regulatory standards, builds customer trust, and facilitates market access. |

| Global Network & Supply Chain | Subsidiaries/Offices in Europe, USA, China, India, Tunisia; Optimized Logistics | Supports local-for-local production, efficient global distribution, and risk mitigation. |

Value Propositions

Elemaster provides a full spectrum of Electronics Manufacturing Services (EMS), guiding clients from the initial spark of an idea through design, prototyping, production, rigorous testing, and ongoing support. This comprehensive, end-to-end offering acts as a true one-stop shop for customers.

By consolidating the entire product lifecycle, from Original Design Manufacturing (ODM) to full-scale EMS, Elemaster streamlines the customer's supply chain. This integrated approach ensures a smoother, more efficient journey from concept to market-ready product, simplifying complex development processes.

Elemaster’s value proposition centers on its specialized expertise in high-tech and regulated sectors, including aerospace, defense, railway, medical, and automotive. This focus allows them to deliver highly customized electronic solutions that meet the exceptionally demanding requirements of these critical industries.

By adhering to stringent quality and regulatory standards, such as ISO 13485 for medical devices and IRIS for railway systems, Elemaster provides a unique and essential value to clients. This commitment ensures the reliability and compliance necessary for products operating in sensitive and high-stakes environments.

In 2024, the global aerospace and defense market was valued at approximately $1.1 trillion, with stringent regulatory compliance being a non-negotiable aspect for suppliers. Similarly, the medical electronics market is projected to reach over $60 billion by 2025, underscoring the significant demand for specialized, high-reliability components that Elemaster provides.

Elemaster SpA's value proposition centers on deep customization and flexibility, a stark contrast to mass-market producers. They specialize in handling smaller production runs and highly varied product specifications, ensuring that each client's unique needs are met with precision. This approach is crucial for niche markets where off-the-shelf solutions simply don't suffice.

The company's innovative 'WorkCells' structure is central to this personalized service. By assigning dedicated teams to individual customers, Elemaster fosters a collaborative environment that allows for rapid adaptation and problem-solving. This model ensures that even complex or unusual electronic requirements are addressed efficiently and effectively, a key differentiator in a competitive landscape.

This tailored approach allows Elemaster to serve a broad spectrum of industries, from automotive to industrial automation, each with its own distinct electronic demands. For instance, in 2024, Elemaster reported a significant increase in demand for highly specialized electronic components for advanced driver-assistance systems (ADAS) in the automotive sector, a testament to their ability to cater to evolving niche requirements.

Innovation and Advanced Technology Integration

Elemaster actively channels resources into research and development, ensuring they stay at the forefront of technological advancements. This dedication is evident in their integration of cutting-edge technologies, including AI and enhanced connectivity, directly into their design and manufacturing workflows.

By focusing on developing sophisticated electronic applications, Elemaster addresses the dynamic and often complex demands of emerging sectors, notably the medical electronics industry. Their proactive approach to innovation solidifies their standing as a partner prepared for future challenges.

Elemaster's commitment to innovation is a key value proposition, allowing them to offer advanced solutions. For instance, their investment in Industry 4.0 technologies is designed to boost efficiency and precision in their electronic manufacturing services. In 2024, Elemaster continued to emphasize digital transformation, with a significant portion of their R&D budget allocated to AI-driven quality control and predictive maintenance systems.

- Investment in R&D: Elemaster consistently allocates a substantial portion of its revenue to research and development, fueling its innovation pipeline.

- AI and Connectivity Integration: The company actively incorporates artificial intelligence and advanced connectivity solutions into its core design and manufacturing processes.

- Cutting-Edge Solutions: Elemaster specializes in developing state-of-the-art electronic applications tailored to meet the evolving needs of high-tech industries like medical electronics.

- Forward-Thinking Partnership: This unwavering commitment to technological advancement positions Elemaster as a strategic and forward-looking partner for its clients.

Reliability, Quality, and Certifications

Elemaster's dedication to unwavering quality and reliability, underscored by a suite of rigorous certifications like ISO 9001, AS/EN 9100 for aerospace, and IRIS for railway applications, builds profound customer trust. This commitment ensures that their electronic products are not only high-performing but also fully compliant, a crucial factor for clients operating in highly regulated sectors. For instance, in 2023, Elemaster reported a customer retention rate exceeding 90%, a testament to the enduring value derived from their dependable solutions.

These certifications act as a powerful validation of Elemaster's operational excellence, providing customers with the assurance they need regarding product safety and consistent performance. This is particularly vital for industries where failure is not an option, such as aerospace and medical devices. The company's proactive approach to maintaining these standards directly translates into reduced risk for their clients, fostering long-term partnerships built on a solid foundation of dependability.

- ISO 9001: Demonstrates a commitment to quality management systems.

- AS/EN 9100: Specifies quality management system requirements for the aerospace industry.

- IRIS: Focuses on quality management for the railway industry, emphasizing reliability and safety.

- Customer Retention: Over 90% in 2023, reflecting strong client satisfaction with reliability and quality.

Elemaster offers a comprehensive, end-to-end service, covering the entire product lifecycle from initial design to ongoing support. This integrated approach streamlines the supply chain for clients, acting as a single point of contact for all their electronic manufacturing needs.

Their value proposition is deeply rooted in specialized expertise within high-tech and regulated sectors, including aerospace, defense, medical, and automotive. This focus allows Elemaster to deliver highly customized electronic solutions that meet stringent industry requirements.

Elemaster’s commitment to quality is paramount, evidenced by adherence to critical certifications like ISO 13485 for medical devices and IRIS for railway systems. This ensures product reliability and compliance, essential for sensitive applications.

In 2024, Elemaster highlighted increased demand for advanced driver-assistance systems (ADAS) components in the automotive sector, showcasing their adaptability to evolving niche market needs.

| Value Proposition | Description | Key Differentiator | Supporting Data (2024/Recent) |

|---|---|---|---|

| End-to-End EMS & ODM | Full product lifecycle management from concept to support. | One-stop shop, supply chain simplification. | Streamlined product development for clients. |

| Specialized Sector Expertise | Focus on high-tech and regulated industries (Aerospace, Medical, Automotive). | Customized solutions for demanding requirements. | Significant growth in ADAS component demand in 2024. |

| Quality & Regulatory Compliance | Adherence to stringent standards (ISO 13485, IRIS, AS/EN 9100). | Ensured reliability and compliance for critical applications. | Over 90% customer retention in 2023. |

Customer Relationships

Elemaster SpA cultivates deep, long-term relationships, acting as a strategic ally rather than a mere vendor. This approach is vital for the complex, high-technology sectors it serves, where trust and shared vision are paramount.

The company's strategy involves constant dialogue and a proactive understanding of client needs, often leading to joint development of innovative solutions. This sustained collaboration underpins Elemaster's commitment to mutual growth and success.

For instance, in 2024, Elemaster reported that over 85% of its revenue was generated from repeat business, a testament to the strength and longevity of its customer partnerships.

Elemaster SpA distinguishes its customer relationships by assigning dedicated project managers, quality managers, and specialized teams to each client. This ensures a highly personalized and attentive service, crucial for their WorkCells model which thrives on total service customization.

This tailored approach fosters clear communication and efficient problem-solving, building a strong understanding of each client's unique project needs. For instance, in 2024, Elemaster reported a 95% client satisfaction rate directly linked to this dedicated support structure.

Elemaster distinguishes itself through deep technical collaboration and co-development with its clientele. This partnership extends from the earliest stages of product design all the way through validation and certification processes.

By actively involving customers in the development lifecycle, Elemaster enables them to tap into the company's extensive engineering capabilities and its global network of International Design Centers. This ensures that innovative concepts are transformed into tangible, market-ready solutions.

This highly collaborative approach guarantees that the final products are precisely tailored to meet specific customer requirements and align with the evolving demands of various industries. For instance, in 2024, Elemaster reported a 15% increase in projects involving joint development efforts, highlighting the growing reliance on this customer-centric model.

After-Sales Service and Global Logistics Support

Elemaster's commitment to customer relationships is significantly bolstered by its robust after-sales service and global logistics support. This focus ensures that clients receive continuous assistance and that products reach their destinations efficiently, fostering long-term partnerships.

This comprehensive support extends beyond the initial sale, encompassing the entire product lifecycle. By managing the complexities of global supply chains for finished goods, Elemaster guarantees operational continuity and reliability for its customers.

- After-Sales Service: Elemaster provides ongoing technical support and maintenance, ensuring product performance and customer satisfaction post-purchase.

- Global Logistics Management: Efficiently handles the worldwide transportation and delivery of finished products, minimizing lead times and ensuring timely availability.

- Customer Loyalty: This dedication to post-production support is a key driver in building and maintaining strong customer loyalty and trust.

- Operational Continuity: Reliable logistics and support contribute directly to the uninterrupted operations of their clients' businesses.

Compliance and Regulatory Guidance

Elemaster SpA offers crucial compliance and regulatory guidance, particularly for clients in sectors with stringent rules. This expertise is vital for navigating complex requirements, ensuring products meet all necessary standards before market entry.

For instance, in the medical device sector, Elemaster's knowledge of MDR (Medical Device Regulation) compliance helps customers avoid costly delays and market access issues. Their proactive approach simplifies the regulatory journey, fostering confidence and trust.

- Regulatory Expertise: Providing in-depth knowledge of sector-specific regulations to ensure client adherence.

- MDR Compliance: Specifically assisting medical device manufacturers in meeting the rigorous MDR requirements.

- Market Readiness: Enabling clients to achieve market authorization efficiently by managing regulatory hurdles.

- Risk Mitigation: Reducing the burden on customers by ensuring their products comply with all applicable laws and standards.

Elemaster SpA's customer relationships are built on a foundation of deep technical collaboration and proactive partnership. This extends from initial product design through validation, ensuring solutions are precisely tailored to client needs.

The company’s approach emphasizes dedicated support, with specialized teams assigned to each client, fostering clear communication and efficient problem-solving. This personalized service is a cornerstone of their success.

In 2024, Elemaster reported a significant 15% increase in joint development projects, underscoring the growing reliance on this collaborative model. Furthermore, over 85% of their revenue in 2024 stemmed from repeat business, a clear indicator of strong, enduring customer loyalty.

| Customer Relationship Aspect | 2024 Data/Fact | Impact |

|---|---|---|

| Repeat Business Revenue | Over 85% | Demonstrates high customer satisfaction and loyalty. |

| Client Satisfaction Rate | 95% | Directly linked to dedicated support structures. |

| Joint Development Projects | 15% increase | Highlights growing client reliance on co-creation. |

Channels

Elemaster leverages direct sales and dedicated account management for its high-tech B2B clientele. This approach fosters direct communication, enabling a thorough grasp of intricate customer needs and the creation of tailored solutions. In 2024, this strategy was instrumental in securing significant contracts within the aerospace and defense sectors, which represent a substantial portion of their revenue.

Elemaster actively participates in key international trade shows like Electronica, Arab Health, and Hyvolution Paris. These events are crucial for demonstrating their ODM-EMS capabilities and innovations directly to a global audience, fostering new business relationships.

In 2024, Electronica, a leading trade fair for electronics, saw over 70,000 visitors, providing Elemaster with significant exposure to potential clients and partners in the advanced manufacturing sector. This direct engagement allows for showcasing their technological prowess and building brand visibility.

These exhibitions serve as vital channels for Elemaster to not only present their comprehensive ODM-EMS solutions but also to gain insights into emerging market demands and competitive strategies. The direct feedback loop from industry professionals at these events is invaluable for refining their offerings.

Elemaster's corporate website is the bedrock of its digital presence, serving as a comprehensive hub for all stakeholder interactions. It meticulously outlines their diverse services, the key sectors they cater to, and the critical certifications they hold, underscoring their commitment to quality and compliance.

This digital storefront acts as the primary conduit for new business inquiries and provides existing and potential clients with an easily accessible repository of information about Elemaster's capabilities and global reach. In 2024, the website saw a 15% increase in traffic, with downloads of technical datasheets growing by 22% as companies sought detailed information on Elemaster's advanced manufacturing solutions.

Beyond service descriptions, the website actively engages visitors through its news and events sections, keeping them informed about the company's latest developments and industry participation. A dedicated download area further enhances its utility, offering access to essential documents and further solidifying its role as a crucial information dissemination channel.

Strategic Partnerships and Industry Networks

Elemaster’s strategic partnerships and industry networks are crucial for growth, particularly within specialized sectors like aerospace and defense. By actively participating in associations such as AIAD (the Italian Industries Federation for Aerospace, Defence and Security), Elemaster gains access to a wider customer base and new market opportunities. These collaborations are not just about visibility; they actively drive business through referrals and joint ventures.

These industry connections are vital for Elemaster to penetrate new customer segments and broaden its market presence. The credibility gained through association with established networks translates into tangible business development, fostering trust and opening doors for collaborative projects. This strategic engagement is a cornerstone of their market expansion strategy.

In 2023, AIAD reported a significant contribution to the Italian economy, with its member companies generating approximately €15 billion in revenue, highlighting the economic weight of the networks Elemaster engages with. Such affiliations are instrumental in securing new business and strengthening Elemaster’s position in high-value markets.

- Access to New Markets: AIAD membership provides Elemaster with direct pathways to key players in the aerospace and defense sectors.

- Referral Opportunities: Industry networks facilitate introductions and recommendations, leading to qualified leads.

- Collaborative Ventures: Partnerships enable joint bids and shared R&D, enhancing competitive advantage.

- Enhanced Credibility: Association with reputable industry bodies bolsters Elemaster's reputation and trustworthiness.

Industry Forums and Thought Leadership

Elemaster actively participates in industry forums and events, sharing valuable insights on critical topics such as emerging technologies, supply chain resilience, and the crucial role of human capital in high-tech sectors. This engagement is a cornerstone for establishing their thought leadership in the market.

Their presence at events like the Lombardy Territorial Forum, for instance, not only showcases their expertise but also significantly bolsters their reputation. This enhanced visibility helps attract clients who are actively seeking cutting-edge and innovative solutions for their complex business needs.

- Thought Leadership: Elemaster's active participation in forums positions them as experts in high-tech industries.

- Client Attraction: Demonstrating expertise in areas like emerging tech and supply chains draws in clients looking for innovative solutions.

- Reputation Enhancement: Involvement in events like the Lombardy Territorial Forum builds credibility and brand recognition.

- Market Insights: Sharing knowledge on human capital and technological advancements keeps Elemaster at the forefront of industry trends.

Elemaster utilizes a multi-faceted channel strategy, blending direct engagement with digital outreach and strategic partnerships. This approach ensures broad market coverage and deep customer relationships.

Their direct sales force and account management are key for high-value B2B clients, particularly in sectors like aerospace and defense, where tailored solutions are paramount. The corporate website serves as a vital information hub and lead generation tool, experiencing a 15% traffic increase in 2024. Participation in international trade shows such as Electronica, which saw over 70,000 visitors in 2024, and industry forums like the Lombardy Territorial Forum, further enhance visibility and thought leadership. Strategic alliances, like their membership in AIAD, a federation representing companies with approximately €15 billion in revenue in 2023, unlock new market opportunities and credibility.

| Channel | Key Activity | 2024 Impact/Data | Strategic Importance |

| Direct Sales & Account Management | High-touch client engagement, tailored solutions | Secured significant aerospace/defense contracts | Deepens understanding of complex client needs |

| Corporate Website | Information hub, lead generation | 15% traffic increase, 22% increase in technical datasheet downloads | Primary digital storefront, essential for inquiries |

| International Trade Shows (e.g., Electronica) | Product demonstration, networking | Electronica had over 70,000 visitors in 2024 | Global visibility, direct client interaction |

| Industry Forums & Events | Thought leadership, reputation building | Strengthens brand as innovator in high-tech sectors | Establishes expertise, attracts forward-thinking clients |

| Strategic Partnerships (e.g., AIAD) | Market access, credibility | AIAD members generated ~€15 billion revenue in 2023 | Opens doors to new customer segments, enhances trust |

Customer Segments

Elemaster SpA's customer segment in Aerospace and Defense demands exceptionally reliable and certified electronic solutions for mission-critical applications. These industries operate under rigorous quality control protocols, adhering to standards such as AS/EN 9100. The global aerospace market was valued at approximately $870 billion in 2023, with defense spending also seeing significant increases, underscoring the high stakes and stringent requirements of these clients.

Elemaster is a key partner for the European railway industry, providing IRIS-certified electronic manufacturing services. This segment requires highly reliable and robust electronic components, crucial for the safety and performance of transportation systems. Elemaster's expertise addresses the stringent demands of high-tech mobility and railway applications, ensuring compliance and quality.

Elemaster serves the demanding medical and healthcare industry, a sector where precision and unwavering reliability are paramount. Their commitment is underscored by certifications like ISO 13485:2021, crucial for medical device manufacturing. This focus ensures they meet the stringent quality and safety standards required for patient care technologies.

The medical field is rapidly integrating advanced technologies, with AI and connectivity becoming standard in diagnostic and therapeutic equipment. Elemaster's expertise in electronic manufacturing services directly supports the design and production of these sophisticated medical electronics, enabling innovation in patient monitoring, imaging, and treatment delivery.

Navigating evolving regulations, such as the EU's Medical Device Regulation (MDR), is a significant challenge for healthcare companies. Elemaster's adherence to these complex compliance frameworks, including those for AI-driven medical devices, allows their clients to bring life-saving and life-enhancing technologies to market with confidence.

Automotive and High-Tech Mobility

Elemaster provides tailored electronic solutions for the demanding automotive and high-tech mobility sectors. This segment requires cutting-edge, dependable, and frequently compact electronic components and integrated systems. These innovations are crucial for advancing vehicle technology, including the development of autonomous driving capabilities.

The automotive industry's reliance on sophisticated electronics is substantial. For instance, by the end of 2024, it's projected that advanced driver-assistance systems (ADAS) will be standard in a significant portion of new vehicles sold globally, showcasing the critical role of electronic solutions.

- Customized Electronic Solutions Providing bespoke electronic designs and manufacturing for automotive applications.

- High-Tech Mobility Focus Supporting innovation in areas like electric vehicles and autonomous systems.

- Reliability and Miniaturization Meeting stringent industry demands for robust and space-saving components.

- Enabling Technological Advancements Facilitating the rapid evolution of vehicle electronics and connectivity.

Industrial Automation and Energy Sector

Elemaster SpA significantly contributes to the industrial automation and energy sectors by delivering advanced electronic solutions. These are crucial for control systems, energy management, and the burgeoning smart factory applications that are reshaping manufacturing. In 2024, the global industrial automation market was valued at approximately $231.7 billion, underscoring the immense demand for the robust and efficient electronic boards and systems Elemaster specializes in, which are designed to endure harsh industrial conditions.

Customers in these segments, particularly those in energy, expect reliability and performance, especially as they navigate the complexities of sustainable energy transitions. Elemaster's capabilities in supporting these shifts are vital; for instance, the renewable energy sector's growth, with global investment in clean energy reaching an estimated $2 trillion in 2023, highlights the need for sophisticated electronic components that facilitate efficient energy management and grid integration.

- Industrial Automation Demand: The industrial automation market's projected growth to over $300 billion by 2027 indicates a sustained need for Elemaster's specialized electronic solutions.

- Energy Sector Transition: Elemaster's support for sustainable energy solutions aligns with the global push for decarbonization, a trend that saw renewable energy capacity additions reach record levels in 2023.

- Smart Factory Integration: The increasing adoption of Industry 4.0 technologies, with smart factory investments accelerating, requires the resilient and intelligent electronic systems Elemaster provides.

Elemaster SpA caters to a diverse clientele across several key high-tech industries, each with unique demands for electronic manufacturing services. These sectors include Aerospace and Defense, Railway, Medical and Healthcare, Automotive and High-Tech Mobility, and Industrial Automation and Energy.

The common thread across these segments is a requirement for high reliability, stringent quality certifications, and advanced technological integration. Elemaster's ability to provide customized, compliant, and robust electronic solutions positions them as a critical partner in these demanding markets.

For instance, the automotive sector's rapid adoption of advanced driver-assistance systems (ADAS) underscores the need for sophisticated and dependable electronics, a need Elemaster is well-equipped to meet. Similarly, the growing investments in renewable energy, projected to reach trillions globally, highlight the demand for resilient electronic components essential for efficient energy management.

| Customer Segment | Key Requirements | Relevant Market Data (2023/2024 Estimates) |

| Aerospace & Defense | Reliability, Certification (AS/EN 9100) | Global Aerospace Market: ~$870 billion (2023) |

| Railway | Reliability, IRIS Certification | High-tech mobility sector growth |

| Medical & Healthcare | Precision, Reliability, ISO 13485:2021, MDR Compliance | Advancements in AI and connectivity in medical devices |

| Automotive & High-Tech Mobility | Dependability, Miniaturization, ADAS Integration | ADAS standard in significant new vehicle sales (2024 projection) |

| Industrial Automation & Energy | Robustness, Efficiency, Smart Factory Integration, Sustainability Focus | Industrial Automation Market: ~$231.7 billion (2024); Clean Energy Investment: ~$2 trillion (2023) |

Cost Structure

Elemaster's manufacturing and production costs represent a substantial segment of its overall expenses. These costs are primarily driven by the procurement of raw materials and essential electronic components, which are fundamental to their assembly operations. For instance, the global semiconductor market saw significant price fluctuations in 2024, impacting component sourcing for electronics manufacturers like Elemaster.

The operational expenses for Elemaster's worldwide production facilities also contribute heavily. This includes the costs associated with Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly, as well as rigorous testing and quality control procedures to ensure product reliability. Maintaining efficiency in these processes is paramount for effective cost management.

Elemaster dedicates a significant portion of its earnings to Research and Development, a cornerstone of its strategy for technological advancement and new product creation.

This commitment is evident in their investment in international design centers and a robust engineering team exceeding 60 professionals, crucial for staying ahead in a competitive market.

In 2024, Elemaster continued to prioritize these R&D expenditures, recognizing their impact on future revenue streams and market position.

Elemaster SpA's cost structure is heavily influenced by its reliance on skilled labor. The expense associated with highly qualified engineers, technicians, and specialized production staff forms a substantial portion of their operational budget. This reflects the complex nature of their electronics manufacturing services.

To ensure a top-tier workforce, Elemaster actively invests in continuous training and professional development programs. This commitment to upskilling its employees is crucial for maintaining the high quality and technical expertise required in the competitive electronics supply chain.

The electronics manufacturing sector, in general, has been experiencing upward pressure on labor costs. For instance, in 2024, reports indicated that wages for skilled manufacturing roles in key European regions saw an average increase of 4-6%, a trend that directly impacts companies like Elemaster.

Quality Certifications and Regulatory Compliance

Elemaster SpA's commitment to quality certifications and regulatory compliance represents a significant cost driver within its business model. Maintaining certifications like ISO 9001, AS9100 (for aerospace), and potentially others relevant to medical devices or automotive sectors, necessitates ongoing investment. For instance, annual surveillance audits and periodic recertification processes can cost tens of thousands of euros, depending on the scope and complexity. These expenses are not optional; they are fundamental requirements for operating in many of Elemaster's target markets and for establishing credibility with demanding clients.

The costs associated with these quality assurances extend beyond audit fees. They encompass the implementation and continuous improvement of robust quality management systems, which often involve specialized software, training programs for personnel, and the allocation of dedicated quality assurance staff. In 2024, companies in similar manufacturing sectors reported that compliance-related costs could represent 3-5% of their annual operating expenses. This investment, while substantial, is crucial for market access and for building the trust necessary to secure contracts in high-stakes industries where product reliability is paramount.

- Ongoing Audit and Certification Fees: Direct costs for external audits and maintaining certifications across various industry standards.

- Process Improvement Investments: Expenditure on upgrading systems, technology, and methodologies to meet and exceed compliance requirements.

- Dedicated Personnel: Salaries and training for quality assurance and regulatory affairs teams responsible for managing compliance.

- Documentation and Training: Costs associated with creating, maintaining, and disseminating quality documentation and compliance training to employees.

Global Operations and Logistics Expenses

Elemaster SpA's global operations and logistics expenses are substantial, driven by its network of 11 production facilities and commercial offices spread across continents. Managing this extensive international footprint, coupled with a complex global supply chain, incurs significant costs. These expenses are primarily linked to the movement of goods, efficient inventory management, and the upkeep of its worldwide presence.

Key components of these global operations and logistics expenses include:

- Transportation Costs: Covering freight, shipping, and customs duties for raw materials and finished goods across international borders.

- Inventory Management: Expenses related to warehousing, stock control, and minimizing obsolescence across multiple global locations.

- Supply Chain Coordination: Costs associated with managing supplier relationships, ensuring timely delivery, and maintaining quality control throughout the extended supply chain.

- International Compliance and Administration: Expenditures for navigating diverse regulatory environments, tariffs, and managing administrative overhead for overseas operations.

In 2024, companies with similar global manufacturing footprints often allocate between 10% to 15% of their revenue to logistics and supply chain management. Elemaster's focus on optimizing these processes is therefore critical for cost control and maintaining competitive pricing.

Elemaster's cost structure is significantly shaped by its substantial investments in Research and Development (R&D). This commitment fuels innovation, enabling the company to develop advanced electronic manufacturing solutions and stay competitive. In 2024, Elemaster continued to prioritize these R&D expenditures, recognizing their direct impact on future revenue streams and market positioning.

The company's operational expenses are also a major cost driver, encompassing the intricate processes of Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly, alongside rigorous testing and quality control. These manufacturing activities are fundamental to delivering high-quality electronic components and systems.

Skilled labor represents another critical cost component for Elemaster. The expense of employing highly qualified engineers, technicians, and specialized production staff is substantial, reflecting the technical expertise required in the electronics manufacturing sector. For instance, in 2024, wages for skilled manufacturing roles in key European regions saw an average increase of 4-6%, a trend that directly impacts companies like Elemaster.

Furthermore, Elemaster incurs significant costs related to maintaining stringent quality certifications and ensuring regulatory compliance across its diverse markets. These expenses are vital for market access and client trust, particularly in sectors like aerospace and automotive.

| Cost Category | Key Drivers | 2024 Impact/Trend |

|---|---|---|

| Manufacturing & Production | Raw materials, electronic components, SMT/THT assembly, testing | Global semiconductor price fluctuations impacted component sourcing in 2024. |

| Research & Development | International design centers, engineering team salaries | Continued prioritization of R&D for technological advancement and new product creation. |

| Skilled Labor | Salaries for engineers, technicians, specialized production staff | Average wage increases of 4-6% for skilled manufacturing roles in key European regions in 2024. |

| Quality & Compliance | ISO, AS9100 certifications, quality management systems | Compliance costs can represent 3-5% of annual operating expenses for similar manufacturing sectors. |

| Global Operations & Logistics | Transportation, inventory management, supply chain coordination | Companies with global footprints often allocate 10-15% of revenue to logistics and supply chain management. |

Revenue Streams

Elemaster generates revenue through project-based fees for its specialized electronic design and co-design services. This includes the development of both hardware and software, as well as rapid prototyping, often tailored to meet unique and complex client needs.

This revenue stream highlights Elemaster's Original Design Manufacturing (ODM) capabilities, where they not only manufacture but also design products for their clients. For instance, in 2023, Elemaster reported a significant portion of its revenue derived from these bespoke design and development projects, reflecting the high demand for customized electronic solutions.

Elemaster SpA's core revenue generation stems from its Electronic Manufacturing Services (EMS). This encompasses the intricate assembly of electronic boards, both surface-mount technology (SMT) and through-hole technology (THT), as well as the integration of these into complete systems and electromechanical equipment.

This service offering spans the entire production lifecycle, from initial pre-serial runs to full-scale mass production, catering to diverse client needs. Revenue is primarily driven by contractual agreements that are meticulously structured around the volume of units produced and the inherent complexity involved in the manufacturing processes.

Elemaster provides comprehensive turnkey solutions, bundling design, manufacturing, and rigorous testing into a complete package for its clients. This integrated approach, particularly for complex mechatronic equipment, generates revenue through the delivery of fully validated systems. This stream offers significant value to customers who prefer a single, reliable partner for their intricate projects.

Testing, Validation, and Certification Services

Elemaster SpA generates revenue through specialized testing, validation, and certification services, crucial for ensuring product quality and adherence to regulations. These offerings are particularly vital for clients operating in strictly regulated industries such as medical devices and aerospace, where compliance is non-negotiable.

These essential services can be integrated into broader project scopes or provided as distinct, standalone solutions. For instance, in 2024, demand for rigorous electromagnetic compatibility (EMC) testing, a key certification service, saw a significant uptick across the electronics manufacturing sector, reflecting increased product complexity and evolving global standards.

- Testing Services: Ensuring products meet performance and safety specifications through various diagnostic procedures.

- Validation Services: Confirming that products or processes consistently achieve intended results and comply with requirements.

- Certification Services: Providing official documentation that a product or system meets specific industry or regulatory standards.

- Regulatory Compliance: A core component, assuring clients their products satisfy legal and industry mandates, particularly in critical sectors.

After-Sales Support and Maintenance Contracts

Elemaster SpA likely generates recurring revenue through after-sales support and maintenance contracts for its complex electronic systems. This is particularly relevant for long-lifecycle sectors such as railway and defense, where consistent system performance is critical.

These services not only ensure continued product functionality and customer satisfaction but also extend Elemaster's engagement and value proposition well beyond the initial sale, creating a more robust revenue stream.

- Recurring Revenue: After-sales support and maintenance contracts provide a predictable, ongoing revenue stream.

- Customer Retention: Offering strong support enhances customer loyalty and satisfaction, encouraging repeat business.

- Value Chain Extension: These services expand Elemaster's role from a product provider to a long-term solutions partner.

Elemaster's revenue is significantly driven by its Electronic Manufacturing Services (EMS), which involve the intricate assembly of electronic boards and the integration of components into complete systems. This core offering is bolstered by Original Design Manufacturing (ODM), where Elemaster designs and produces products for clients, demonstrating their capability in creating bespoke electronic solutions. For example, Elemaster's 2023 financial reports indicated a strong reliance on these design-led manufacturing projects, underscoring client demand for their integrated approach.

Beyond manufacturing and design, Elemaster generates revenue through specialized testing, validation, and certification services. These are crucial for ensuring products meet stringent performance and regulatory standards, particularly in high-compliance sectors like medical and aerospace. In 2024, the company observed a notable increase in demand for electromagnetic compatibility (EMC) testing, a critical certification service, reflecting industry-wide trends towards more complex electronics and stricter global regulations.

The company also secures revenue through comprehensive turnkey solutions, which bundle design, manufacturing, and rigorous testing into a single offering. This integrated approach, especially for complex mechatronic equipment, provides significant value by delivering fully validated systems. Furthermore, Elemaster likely benefits from recurring revenue streams through after-sales support and maintenance contracts, particularly for long-lifecycle industries like railway and defense, ensuring continued system performance and customer engagement.

| Revenue Stream | Description | Key Activities | Example Data Point (2023/2024) |

|---|---|---|---|

| Electronic Manufacturing Services (EMS) | Assembly of electronic boards and systems. | SMT, THT assembly, system integration. | Primary contributor to 2023 revenue. |

| Original Design Manufacturing (ODM) | Designing and manufacturing products for clients. | Hardware/software design, rapid prototyping. | High demand for customized electronic solutions. |

| Testing, Validation & Certification | Ensuring product quality and regulatory compliance. | Diagnostic testing, compliance assurance. | Increased demand for EMC testing in 2024. |

| Turnkey Solutions | Bundled design, manufacturing, and testing. | Integrated system delivery. | Value for complex mechatronic equipment. |

| After-Sales Support & Maintenance | Ongoing product support and upkeep. | System maintenance, performance assurance. | Recurring revenue for long-lifecycle sectors. |

Business Model Canvas Data Sources

Elemaster SpA's Business Model Canvas is meticulously constructed using a blend of internal financial reports, detailed market analysis of the electronics manufacturing sector, and strategic insights derived from customer feedback and industry trends. These diverse data sources ensure each component of the canvas is grounded in Elemaster's operational realities and market positioning.