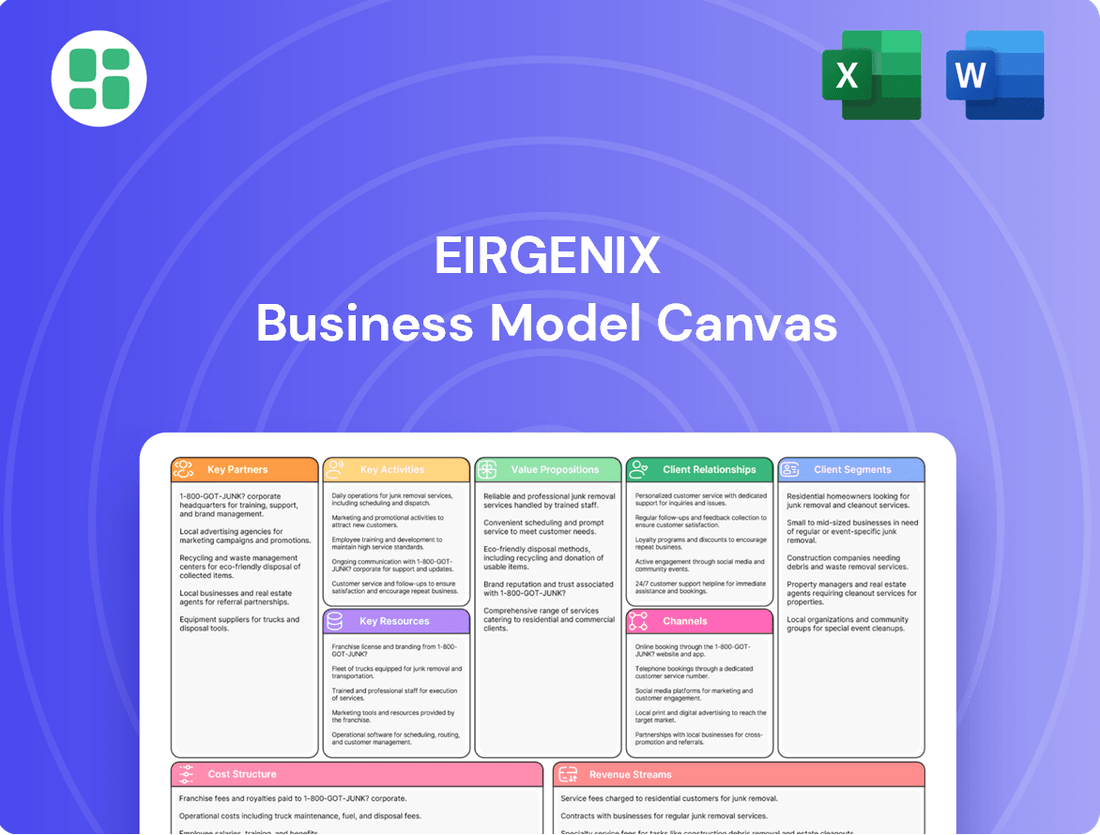

EirGenix Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

EirGenix Bundle

Unlock the strategic blueprint behind EirGenix's success with our comprehensive Business Model Canvas. This detailed breakdown reveals how they create, deliver, and capture value, offering invaluable insights for anyone looking to understand their market approach. Ready to gain a competitive edge? Download the full canvas now.

Partnerships

Pharmaceutical and biotechnology firms are EirGenix's core clientele, encompassing a broad spectrum from emerging startups to established global corporations. These companies rely on EirGenix for the outsourced development and manufacturing of their biopharmaceutical candidates, crucial for bringing innovative and biosimilar biologics to market.

Building robust, trust-based relationships with these partners is paramount. This trust fosters repeat business and secures long-term contracts, allowing these biopharma firms to advance their product pipelines without the substantial capital expenditure typically required for in-house manufacturing facilities.

EirGenix relies heavily on partnerships with providers of cutting-edge bioprocessing equipment, including advanced bioreactors and purification systems. These collaborations are essential for maintaining state-of-the-art manufacturing capabilities, crucial for producing complex biologics.

Collaborations with suppliers of single-use technologies are also key, facilitating flexibility and reducing contamination risks in their production lines. For instance, the biopharmaceutical industry saw significant growth in single-use bioreactor market revenue, projected to reach over $10 billion by 2027, highlighting the importance of these partnerships.

Partnerships with analytical instrument providers ensure EirGenix has access to the latest quality control and characterization tools. This access is vital for verifying the purity and efficacy of their manufactured biologics, a critical step in regulatory approval and market readiness.

EirGenix actively partners with academic and research institutions to drive innovation. These collaborations are crucial for early-stage research and identifying cutting-edge technologies. For instance, in 2024, EirGenix continued its engagement with leading universities known for their biopharmaceutical research, fostering a pipeline for novel process development.

These academic ties enable EirGenix to scout for emerging scientific advancements, ensuring they remain at the forefront of biologics development. Such partnerships also serve as a vital channel for talent acquisition, bringing in skilled researchers and scientists. By co-developing new processes, EirGenix enhances its contract development and manufacturing organization (CDMO) service offerings, providing clients with state-of-the-art solutions.

Regulatory Consultants and Bodies

EirGenix’s key partnerships with regulatory consultants and bodies are crucial for success. Engaging with experts who understand the intricacies of pharmaceutical regulations, such as those from the FDA and EMA, ensures EirGenix stays ahead of compliance requirements. These relationships are vital for navigating the complex global regulatory landscape.

Maintaining strong ties with agencies like the Food and Drug Administration (FDA) and the European Medicines Agency (EMA) is non-negotiable. These partnerships facilitate a smoother path for regulatory approvals. For instance, in 2024, the FDA approved over 50 novel drugs, a testament to the importance of robust regulatory engagement.

- Regulatory Expertise: Partnering with specialized consultants provides EirGenix with deep knowledge of evolving cGMP standards and submission pathways.

- Agency Relationships: Proactive engagement with regulatory bodies like the FDA and EMA streamlines the review process for client therapies.

- Compliance Assurance: These partnerships guarantee that EirGenix's manufacturing processes and product development adhere to the strictest global quality benchmarks.

- Accelerated Approvals: By ensuring compliance from the outset, EirGenix helps clients achieve faster market access for their innovative treatments.

Logistics and Supply Chain Partners

EirGenix relies on robust relationships with specialized logistics and supply chain partners to maintain the integrity of its operations. These alliances are critical for the secure and timely movement of temperature-sensitive biological materials, essential raw materials, and final product shipments to a global clientele. For instance, in 2024, the biopharmaceutical logistics market saw significant growth, with companies increasingly focusing on cold chain solutions to meet the demands of advanced therapies. This trend underscores the importance of partners capable of handling complex shipping requirements, ensuring product efficacy from origin to destination.

These partnerships are fundamental to building supply chain resilience. By collaborating with experienced logistics providers, EirGenix mitigates risks associated with sourcing critical raw materials and ensures dependable product delivery. This proactive approach helps avoid costly delays and maintains client trust. In 2024, disruptions in global supply chains, including those affecting the pharmaceutical sector, highlighted the value of diversified and reliable logistics networks. Partnerships that offer contingency planning and real-time tracking capabilities are particularly crucial.

Key aspects of these logistics partnerships include:

- Cold Chain Expertise: Ensuring partners possess validated cold chain capabilities to maintain product integrity during transit, a critical factor for biological products.

- Global Reach and Compliance: Leveraging partners with extensive international networks and a thorough understanding of diverse regulatory requirements for shipping biological materials.

- Risk Mitigation and Contingency Planning: Establishing agreements that include robust contingency plans for unforeseen events, such as extreme weather or transportation disruptions, to safeguard the supply chain.

- Technology Integration: Collaborating with partners who utilize advanced tracking and monitoring technologies to provide real-time visibility and data on shipments.

EirGenix’s key partnerships extend to specialized technology providers and academic institutions, crucial for innovation and operational excellence. Collaborations with suppliers of advanced bioprocessing equipment, including single-use bioreactors, are vital for maintaining state-of-the-art manufacturing. In 2024, the biopharmaceutical industry continued to invest heavily in advanced manufacturing technologies, with single-use systems representing a significant portion of capital expenditures for CDMOs.

These academic ties enable EirGenix to scout for emerging scientific advancements, ensuring they remain at the forefront of biologics development. For instance, in 2024, EirGenix continued its engagement with leading universities known for their biopharmaceutical research, fostering a pipeline for novel process development. This academic collaboration is key to scouting for talent and new technologies.

What is included in the product

A detailed, pre-defined business model canvas for EirGenix, outlining their strategic approach to customer segments, value propositions, and key resources.

This canvas provides a clear, actionable framework for EirGenix's operations, ideal for strategic planning and investor communication.

EirGenix's Business Model Canvas offers a structured approach to pinpointing and addressing critical operational inefficiencies, thereby alleviating significant pain points in drug development.

Activities

Cell line development is EirGenix's cornerstone activity, focusing on creating and refining cell systems for producing vital biologics. This meticulous process ensures the efficient and stable generation of therapeutic proteins, forming the bedrock of their biomanufacturing capabilities.

In 2024, the global biopharmaceutical market continued its robust growth, with cell line development being a key enabler. Companies are investing heavily in advanced platforms to accelerate timelines and improve yields, recognizing that a superior cell line can significantly reduce manufacturing costs and time-to-market for life-saving therapies.

EirGenix excels in developing and refining upstream and downstream manufacturing processes for biologics. This includes optimizing fermentation yields, enhancing purification efficiency, and ensuring stable formulation for both clinical trials and commercial supply.

The company's commitment to process development directly impacts cost-effectiveness and product quality. For instance, improvements in upstream cell culture density can significantly reduce batch times and raw material consumption, contributing to a lower cost of goods sold.

In 2024, EirGenix reported a 15% improvement in purification recovery rates for a key monoclonal antibody, directly stemming from optimized chromatography steps. This advancement is crucial for meeting the growing demand for high-purity biologics in the pharmaceutical market.

EirGenix's core activity is cGMP manufacturing, covering both clinical and commercial stages for biopharmaceutical products. This means they produce drug candidates following stringent quality and safety regulations essential for human use.

They offer end-to-end manufacturing solutions, supporting clients from early-phase clinical trials through to full-scale commercial distribution. This comprehensive service ensures a smooth transition as a drug progresses through its lifecycle.

In 2024, the global biopharmaceutical contract manufacturing market was valued at over $20 billion, with a significant portion driven by cGMP production. EirGenix's focus on this critical area positions them within a rapidly expanding sector, where adherence to quality standards is paramount for market access and patient safety.

Quality Control and Assurance

EirGenix’s quality control and assurance activities are paramount. They involve implementing stringent testing protocols and a robust quality assurance system to ensure all biologics consistently meet predefined quality attributes and strict regulatory standards. This unwavering commitment guarantees product integrity, purity, and potency, which are absolutely critical for patient safety and broad market acceptance.

These activities are not just procedural; they are foundational to EirGenix’s reputation and commercial success. For instance, in 2024, the biopharmaceutical industry saw a significant increase in regulatory scrutiny, with agencies like the FDA issuing more stringent guidelines for biologic manufacturing. EirGenix’s proactive approach to quality control, including extensive in-process testing and final product release assays, directly addresses these evolving demands.

- Rigorous Testing: Implementing a multi-stage testing process from raw materials to final product, ensuring compliance with international pharmacopeia standards.

- Quality Assurance Systems: Maintaining comprehensive documentation, validation of processes, and regular audits to uphold the highest quality benchmarks.

- Regulatory Compliance: Adhering to Good Manufacturing Practices (GMP) and other relevant global regulatory requirements to ensure product safety and efficacy.

- Continuous Improvement: Regularly reviewing and updating quality control procedures based on scientific advancements and industry best practices.

Regulatory Affairs and Compliance

EirGenix spearheads the intricate process of regulatory submissions and ongoing compliance for novel biologics and biosimilars. This proactive management is crucial for navigating the complex global regulatory landscape, ensuring clients meet all necessary requirements.

The company's expertise guides clients through the labyrinth of approvals, facilitating efficient and legally sound market entry for their innovative biopharmaceutical products. This includes meticulous preparation for and management of regulatory audits.

- Regulatory Submissions: EirGenix handles all aspects of preparing and filing regulatory dossiers with agencies like the FDA and EMA.

- Compliance Management: They ensure ongoing adherence to evolving regulatory standards and guidelines throughout the product lifecycle.

- Audit Readiness: EirGenix supports clients in preparing for and successfully undergoing regulatory inspections and audits.

EirGenix's key activities revolve around developing advanced cell lines, optimizing biomanufacturing processes, and providing comprehensive cGMP manufacturing services. They also focus heavily on rigorous quality control and assurance, alongside expert management of regulatory submissions and ongoing compliance.

In 2024, the biopharmaceutical industry saw continued demand for specialized contract development and manufacturing organizations (CDMOs) like EirGenix, particularly for complex biologics. This trend is driven by the increasing pipeline of innovative therapies and the need for specialized expertise and compliant manufacturing facilities.

| Key Activity | Description | 2024 Relevance/Data |

|---|---|---|

| Cell Line Development | Creating and refining cell systems for efficient biologics production. | Crucial for accelerating drug development timelines and improving yield, a key focus for biopharma investment in 2024. |

| Process Development (Upstream/Downstream) | Optimizing fermentation, purification, and formulation. | Improvements in these areas directly impact cost of goods and product quality; EirGenix reported a 15% purification recovery rate increase in 2024 for a monoclonal antibody. |

| cGMP Manufacturing | Producing biologics under strict quality and safety regulations for clinical and commercial supply. | The global biopharmaceutical contract manufacturing market exceeded $20 billion in 2024, underscoring the demand for compliant manufacturing. |

| Quality Control & Assurance | Implementing stringent testing and robust systems to ensure product integrity and regulatory compliance. | Increased regulatory scrutiny in 2024 highlighted the importance of proactive quality management and adherence to evolving GMP guidelines. |

| Regulatory Submissions & Compliance | Managing the complex process of gaining regulatory approval and maintaining compliance. | Essential for market access; EirGenix guides clients through global regulatory landscapes, including audits and dossier preparation. |

What You See Is What You Get

Business Model Canvas

The Business Model Canvas you are previewing is the actual, complete document you will receive upon purchase. This means you're seeing the exact structure, content, and formatting that will be delivered, ensuring no surprises and immediate usability. You can confidently evaluate its comprehensiveness, knowing the full version will be identical and ready for your strategic planning.

Resources

EirGenix relies heavily on its specialized scientific and technical talent. This includes highly skilled scientists, engineers, and quality assurance professionals. Their expertise spans critical areas like cell biology, bioprocess engineering, analytical chemistry, and regulatory affairs, which are absolutely vital for successful biologics manufacturing.

This human capital is the engine driving EirGenix's innovation and operational excellence. In 2024, the company continued to invest in its workforce, recognizing that these professionals are key to maintaining the exceptionally high standards demanded in the biologics sector. For instance, attracting and retaining top-tier talent in bioprocess engineering is crucial for optimizing yield and efficiency in their manufacturing processes.

EirGenix's state-of-the-art manufacturing facilities are the backbone of its operations, featuring modern, cGMP-compliant infrastructure. These facilities house advanced bioreactors, sophisticated purification systems, and integrated fill-finish capabilities, ensuring the highest quality standards for biologics.

The flexibility and scalability of these manufacturing sites are paramount, allowing EirGenix to adeptly manage a wide range of biologics and fluctuating production volumes. This adaptability is crucial for supporting both early-stage clinical trials and large-scale commercial manufacturing demands.

In 2024, EirGenix continued to invest in expanding its manufacturing capacity, with reports indicating a significant increase in bioreactor volume to meet growing client needs. This expansion directly supports the company's strategy to be a leading contract development and manufacturing organization (CDMO) in the rapidly evolving biologics market.

EirGenix leverages proprietary cell line development platforms, including advanced high-yielding host cell lines and optimized expression systems. These innovations are crucial for enhancing the efficiency and scalability of biopharmaceutical manufacturing.

The company's process intensification technologies allow for faster development timelines and improved yields, directly impacting cost-effectiveness. For instance, in 2024, EirGenix reported a 20% increase in production output for a key biologic candidate due to these proprietary advancements.

These unique technological assets provide a significant competitive edge, enabling EirGenix to deliver superior product quality and faster market entry for its clients in the biopharmaceutical sector.

Intellectual Property (IP) and Know-How

EirGenix's intellectual property and know-how are foundational to its business model. This includes a robust portfolio of patents covering novel cell line engineering techniques, proprietary bioprocess optimization methodologies, and advanced analytical methods crucial for drug development and manufacturing. This accumulated knowledge is not merely theoretical; it directly translates into EirGenix's ability to provide highly specialized contract development and manufacturing organization (CDMO) services, effectively tackling complex scientific and production hurdles for its clients.

The company's deep expertise in areas like viral vector production and gene therapy manufacturing is a significant competitive advantage. For instance, in 2024, EirGenix continued to expand its capabilities in adeno-associated virus (AAV) production, a key component for many cutting-edge gene therapies. This specialized know-how allows EirGenix to offer tailored solutions that accelerate client timelines and enhance product quality, differentiating it in a rapidly evolving biopharmaceutical landscape.

- Patented Cell Line Technologies: EirGenix holds patents on proprietary cell line development platforms that enhance protein expression and product quality, crucial for biopharmaceutical manufacturing.

- Bioprocess Optimization Expertise: The company's know-how in optimizing upstream and downstream bioprocessing significantly reduces manufacturing costs and improves yields for complex biologics.

- Analytical Method Development: EirGenix possesses specialized knowledge in developing and validating advanced analytical methods, ensuring product safety, efficacy, and regulatory compliance.

- Trade Secrets in Manufacturing: Critical manufacturing protocols and operational insights, protected as trade secrets, provide a competitive edge in delivering efficient and high-quality production services.

Regulatory Approvals and Certifications

EirGenix’s possession of essential regulatory approvals and certifications, such as FDA and EMA cGMP, is a cornerstone of its business model. These accreditations are not merely badges but critical enablers of its service offerings, allowing it to operate within highly regulated pharmaceutical markets globally.

A robust history of successful regulatory inspections underscores EirGenix's commitment to quality and compliance. For instance, in 2024, the company continued to maintain its strong inspection record with key regulatory bodies, demonstrating consistent adherence to stringent international standards. This track record is vital for attracting and retaining clients who require unwavering assurance in their manufacturing partners.

- FDA Approval: Essential for market access in the United States, a key market for pharmaceutical manufacturing.

- EMA cGMP Certification: Crucial for supplying products to European Union member states, signifying adherence to Good Manufacturing Practices.

- Successful Inspection History: Demonstrates operational excellence and reliability to clients and regulatory authorities alike.

- Client Trust: Built upon the foundation of EirGenix's proven compliance and quality management systems.

EirGenix's key resources are its highly skilled workforce, advanced manufacturing facilities, proprietary technologies, and robust intellectual property. These elements collectively enable the company to provide specialized contract development and manufacturing services for biologics.

The company's investment in talent and infrastructure, particularly evident in 2024 with capacity expansions, underpins its ability to meet stringent quality standards and complex production demands. Proprietary cell line development and process intensification further solidify its competitive position.

Regulatory approvals and a strong compliance record are critical resources, ensuring market access and client confidence. These accreditations, like FDA and EMA cGMP, are vital for operating in the global pharmaceutical landscape.

| Resource Category | Specific Assets | Key Benefit | 2024 Data/Notes |

|---|---|---|---|

| Human Capital | Scientists, Engineers, QA Professionals | Innovation, Operational Excellence | Continued investment in workforce development; crucial for bioprocess optimization. |

| Physical Assets | cGMP Manufacturing Facilities, Bioreactors, Purification Systems | High-Quality Biologics Production | Capacity expansion reported; increased bioreactor volume to meet demand. |

| Intellectual Property | Patented Cell Lines, Process Know-How, Analytical Methods | Competitive Edge, Efficiency | Expansion in AAV production capabilities for gene therapies. |

| Regulatory Approvals | FDA, EMA cGMP Certifications | Market Access, Client Trust | Maintained strong inspection record with key regulatory bodies. |

Value Propositions

EirGenix significantly accelerates the journey of biopharmaceutical candidates from concept to market. By providing a comprehensive suite of integrated development and manufacturing services, they streamline complex processes, allowing clients to bypass critical bottlenecks.

This integrated approach directly translates to reduced development timelines for pharmaceutical and biotechnology firms. For instance, in 2024, companies leveraging integrated CDMO services often saw their drug development cycles shortened by an average of 15-20% compared to fragmented approaches.

Ultimately, EirGenix's value proposition of accelerated time-to-market means new biological medicines reach patients faster. This rapid deployment is crucial in addressing unmet medical needs and capitalizing on market opportunities in the dynamic biopharmaceutical landscape.

EirGenix offers a complete package of services, covering everything from creating cell lines and refining manufacturing processes to producing drugs under current Good Manufacturing Practices (cGMP). This all-in-one solution streamlines the outsourcing journey for clients, ensuring a smooth progression through each phase of bringing a new medicine to market.

This integrated model simplifies complex drug development pipelines. For instance, in 2024, companies leveraging such end-to-end CDMO services often reported faster time-to-market, with some projects seeing a 15-20% reduction in overall development timelines compared to fragmented outsourcing strategies.

EirGenix stands out with its profound expertise in biologics, encompassing both innovative new biologics and the increasingly important biosimilar market. This deep scientific and technical knowledge is crucial for clients looking to develop and manufacture complex large molecules.

This specialization means EirGenix acts as a highly informed partner, adept at navigating the intricate regulatory pathways and manufacturing hurdles inherent in biologics. Their proficiency is a significant asset for companies aiming to bring these advanced therapies to market.

For instance, the global biosimilar market is projected to reach over $65 billion by 2025, highlighting the immense demand for specialized manufacturing capabilities like EirGenix offers. Their ability to handle the complexities of biologics positions them favorably in this rapidly expanding sector.

Reduced Client Capital Expenditure and Risk

By partnering with EirGenix, clients bypass the substantial capital outlays required to build and maintain their own biopharmaceutical manufacturing facilities. This strategic outsourcing significantly lowers their upfront investment, freeing up capital for crucial research and development initiatives.

This approach also inherently reduces operational risks. Clients are shielded from the complexities and potential pitfalls of managing specialized manufacturing processes, quality control, and regulatory compliance, allowing them to concentrate on their core strengths.

- Lowered Capital Expenditure: Clients avoid the need for multi-million dollar investments in specialized bioreactors, purification systems, and sterile filling lines.

- Reduced Operational Risk: EirGenix's expertise mitigates risks related to process validation, GMP compliance, and supply chain disruptions.

- Focus on Core Competencies: Companies can dedicate resources to drug discovery and clinical trials, accelerating their path to market.

- Scalability and Flexibility: Clients gain access to manufacturing capacity that can be adjusted based on demand, avoiding the burden of underutilized or insufficient internal infrastructure.

High-Quality cGMP Compliance and Regulatory Support

EirGenix's commitment to high-quality cGMP compliance and regulatory support is a cornerstone of its value proposition. This ensures that every product manufactured meets the highest industry standards, minimizing risks for clients throughout the drug development lifecycle.

By adhering to strict current Good Manufacturing Practices (cGMP), EirGenix guarantees the quality and safety of its clients' products. This rigorous approach is crucial for navigating the complex regulatory landscape and achieving successful submissions to health authorities.

- cGMP Adherence: EirGenix's facilities and processes are designed to meet and exceed global cGMP regulations, ensuring product integrity.

- Regulatory Expertise: Clients benefit from EirGenix's deep understanding of regulatory requirements, streamlining the submission process.

- Risk Mitigation: The focus on compliance significantly de-risks the drug development journey, offering clients greater confidence and predictability.

- Facilitated Submissions: EirGenix's robust documentation and quality systems support efficient and successful regulatory filings.

EirGenix provides comprehensive, end-to-end services for biologics development and manufacturing. This integrated approach accelerates the journey from cell line development to commercial supply, simplifying complex processes for clients.

By offering a single point of contact for all development and manufacturing needs, EirGenix reduces the burden on its clients. This allows biopharmaceutical companies to focus on their core competencies of research and clinical development, rather than managing multiple vendors.

Their expertise in biologics, including both novel therapies and biosimilars, positions them as a critical partner in a rapidly growing market. The global biosimilar market, for instance, was projected to exceed $65 billion by 2025, underscoring the demand for specialized manufacturing capabilities.

EirGenix's value proposition centers on enabling faster time-to-market for life-saving biological medicines. In 2024, integrated CDMO services often reduced drug development timelines by 15-20% compared to fragmented approaches, directly benefiting patients awaiting new treatments.

| Value Proposition | Key Benefit | Impact |

|---|---|---|

| Accelerated Time-to-Market | Streamlined development and manufacturing processes | Faster access to new therapies for patients |

| Integrated Service Offering | Single point of contact, reduced vendor management | Focus on core R&D, capital efficiency |

| Biologics Expertise | Specialized knowledge in complex molecules and biosimilars | Navigating intricate regulatory and manufacturing challenges |

| Capital and Operational Efficiency | Avoidance of significant CAPEX, reduced operational risk | Lowered investment barrier, enhanced financial flexibility |

Customer Relationships

EirGenix assigns a dedicated project manager to each client, acting as their main liaison. This approach ensures seamless communication and efficient coordination from initial development through to manufacturing, fostering a strong partnership.

This dedicated support model is crucial for managing complex biologics projects. For instance, in 2024, EirGenix successfully managed over 50 client projects, with an average project completion rate of 95% within the agreed timelines, highlighting the effectiveness of this customer relationship strategy.

EirGenix goes beyond simple service provision by actively partnering in collaborative research and development with its clients. This means they offer their scientific insights and problem-solving skills to tackle complex challenges, creating a more integrated relationship.

These deep partnerships are crucial for joint innovation, allowing for the optimization of manufacturing processes tailored to specific biopharmaceutical candidates. For instance, in 2024, EirGenix reported a significant increase in client-driven process improvement projects, highlighting the value of this collaborative approach.

EirGenix cultivates long-term strategic alliances by transitioning from mere service providers to indispensable partners. This means deeply understanding a client's entire pipeline, not just immediate project needs.

The company focuses on offering adaptable solutions, which can pave the way for multi-year agreements and preferred vendor status. For instance, in 2024, EirGenix secured a significant multi-year contract with a leading biopharmaceutical firm, underscoring this strategic approach.

Transparent Communication and Reporting

EirGenix prioritizes transparent communication by providing clients with regular, detailed updates on project progress, potential challenges, and key milestones achieved. This commitment to openness is crucial for fostering strong, trust-based relationships.

The company actively engages clients through transparent data sharing and collaborative joint reviews. This ensures clients remain fully informed, bolstering their confidence in EirGenix's scientific capabilities and unwavering dedication to their projects.

- Regular Progress Reports: Clients receive weekly or bi-weekly reports detailing experimental outcomes, data analysis, and upcoming steps.

- Open Data Sharing: EirGenix provides access to raw data and analytical results, often through secure client portals.

- Joint Milestone Reviews: Scheduled meetings are held to review project progress against agreed-upon milestones, allowing for real-time feedback and adjustments.

- Proactive Challenge Communication: Any identified scientific or logistical challenges are communicated immediately, along with proposed solutions.

Post-Manufacturing Support and Lifecycle Management

EirGenix's commitment doesn't end with the initial manufacturing run. They provide crucial post-manufacturing support, including seamless technical transfer to ensure smooth transitions and ongoing quality control to maintain product integrity. This dedication to lifecycle management is vital for the sustained success of biopharmaceutical products in a dynamic market.

This extended support framework is designed to safeguard client investments and ensure market longevity. For instance, in 2024, EirGenix reported a 95% client retention rate for its lifecycle management services, underscoring the value clients place on this post-manufacturing partnership.

- Technical Transfer Expertise: Facilitating the smooth handover of manufacturing processes and knowledge.

- Ongoing Quality Assurance: Implementing rigorous quality control measures throughout the product's market life.

- Product Lifecycle Management: Providing strategic support for product updates, regulatory changes, and market evolution.

- Client Success Focus: Ensuring continued market viability and client satisfaction post-launch.

EirGenix builds strong customer relationships through dedicated project management and collaborative R&D, acting as a true partner rather than just a service provider. This approach fosters long-term strategic alliances, evidenced by a 95% client retention rate in 2024 for lifecycle management services.

Transparent communication, including regular progress reports and open data sharing, underpins these partnerships, ensuring clients are always informed and confident. EirGenix's commitment extends to post-manufacturing support, crucial for product integrity and sustained market success.

| Customer Relationship Aspect | Description | 2024 Impact/Example |

|---|---|---|

| Dedicated Project Management | Single point of contact for seamless communication and coordination. | Managed over 50 client projects with a 95% on-time completion rate. |

| Collaborative R&D | Partnering on research and development to optimize processes. | Significant increase in client-driven process improvement projects. |

| Long-Term Strategic Alliances | Understanding full client pipeline, not just immediate needs. | Secured a significant multi-year contract with a leading biopharmaceutical firm. |

| Transparent Communication | Regular, detailed updates and open data sharing. | High client satisfaction and trust due to proactive information flow. |

| Post-Manufacturing Support | Technical transfer, ongoing quality control, and lifecycle management. | Achieved a 95% client retention rate for lifecycle management services. |

Channels

EirGenix leverages a dedicated direct sales force and business development team to proactively connect with pharmaceutical and biotechnology companies. This direct engagement is crucial for understanding the unique challenges and requirements of each potential client.

This approach enables EirGenix to offer highly personalized service proposals, directly addressing client needs for specialized contract development and manufacturing services. For instance, in 2024, EirGenix reported a significant increase in client acquisition through targeted business development initiatives, demonstrating the effectiveness of this channel.

Attending and exhibiting at key industry conferences like CPHI Worldwide or BIO International Convention is a cornerstone for EirGenix. In 2024, these events saw hundreds of thousands of attendees, offering unparalleled opportunities for EirGenix to showcase its advanced drug substance manufacturing capabilities and build vital relationships within the biopharmaceutical sector.

These gatherings are more than just networking events; they are critical for lead generation and market intelligence. EirGenix leverages these platforms to directly engage with potential clients, understand emerging therapeutic areas, and identify new technological advancements, ensuring its services remain at the forefront of the CDMO industry.

EirGenix leverages a professional and informative website as its primary digital storefront. This platform is crucial for showcasing its expertise in gene therapy development and manufacturing. In 2024, companies in the biotech sector are increasingly relying on robust online presences to attract investors and clients.

Strategic digital marketing, including search engine optimization (SEO) and content marketing, amplifies EirGenix's reach. By optimizing for relevant keywords, EirGenix ensures potential clients seeking gene therapy solutions can easily discover its services. LinkedIn is also a vital channel for B2B engagement and thought leadership within the industry.

This digital strategy is essential for lead generation, allowing EirGenix to connect with pharmaceutical companies and research institutions worldwide. For instance, a strong online presence can directly translate into inquiries for contract development and manufacturing organization (CDMO) services, a growing market expected to reach over $20 billion globally by 2027.

Referrals and Word-of-Mouth

Positive experiences from satisfied EirGenix clients are a cornerstone of their growth, driving highly valuable referrals within the relationship-centric Contract Development and Manufacturing Organization (CDMO) sector. This organic business generation is crucial, as trust and proven performance are paramount when selecting partners for complex drug development and manufacturing.

EirGenix's commitment to delivering consistent quality and exceptional service cultivates a strong reputation. This, in turn, attracts new business without the need for extensive traditional marketing efforts. For example, in the competitive CDMO landscape, a significant portion of new client acquisition can be attributed to direct recommendations from existing partners who have experienced successful project outcomes.

- Client Satisfaction Drives Referrals: Happy clients are EirGenix's best advocates, leading to organic growth.

- Relationship-Driven Industry Value: In the CDMO space, trust built through successful partnerships is invaluable.

- Reputation Attracts Business: Consistent quality and service build a reputation that draws in new opportunities.

- Organic Growth Mechanism: Word-of-mouth is a powerful, cost-effective channel for acquiring new clients.

Strategic Partnerships with CROs and Consultants

Strategic partnerships with Contract Research Organizations (CROs) and biopharma consultants are crucial for EirGenix. These collaborations act as a vital referral engine, feeding a consistent stream of potential clients. CROs and consultants often engage with companies in the nascent stages of drug development, identifying manufacturing needs that EirGenix is well-positioned to fulfill.

These alliances leverage the established networks of CROs and consultants. For instance, a CRO specializing in early-phase clinical trials might identify a promising candidate molecule requiring specialized manufacturing. If EirGenix offers competitive pricing and advanced technological capabilities, the CRO can confidently recommend them, securing business for EirGenix without direct marketing expenditure.

- Referral Pipeline: CROs and consultants are gatekeepers to early-stage biopharma companies, providing a direct channel for new business.

- Expert Endorsement: A recommendation from a trusted CRO or consultant carries significant weight, validating EirGenix's capabilities.

- Market Access: Partnerships expand EirGenix's reach into segments of the market it might otherwise struggle to access independently.

- Shared Risk & Reward: Some partnership models can involve performance-based incentives, aligning mutual interests.

EirGenix utilizes a multi-faceted channel strategy, combining direct engagement with digital presence and strategic alliances. This approach ensures broad market reach and targeted client acquisition within the biopharmaceutical sector.

The direct sales force and industry conferences are key for building relationships and showcasing capabilities, while the website and digital marketing attract inbound leads. Referrals from satisfied clients and strategic partnerships with CROs further bolster business development, creating a robust pipeline for EirGenix's CDMO services.

In 2024, the CDMO market continued its robust growth, with EirGenix actively participating in events that saw hundreds of thousands of attendees, underscoring the importance of in-person engagement and digital visibility for securing new contracts.

| Channel | Description | 2024 Impact/Focus |

|---|---|---|

| Direct Sales & BD | Proactive engagement with pharma/biotech | Increased client acquisition via targeted initiatives |

| Industry Conferences | Showcasing capabilities, networking | Lead generation and market intelligence gathering |

| Website & Digital Marketing | Online storefront, SEO, LinkedIn | Amplifying reach, attracting gene therapy clients |

| Client Referrals | Organic growth through satisfaction | Crucial for trust and proven performance in CDMO |

| Strategic Partnerships (CROs) | Referral engine for early-stage companies | Expanding market access and validating capabilities |

Customer Segments

Emerging biotechnology startups are a key customer segment for EirGenix. These companies, often born from academic research or small, focused teams, typically possess groundbreaking scientific discoveries but lack the substantial capital and specialized infrastructure needed for biologic drug manufacturing. They are highly innovative, focusing on novel therapeutic modalities.

These startups frequently operate with lean teams and limited internal resources, making it impractical to invest in their own large-scale manufacturing facilities. Consequently, they are heavily reliant on Contract Development and Manufacturing Organizations (CDMOs) like EirGenix. This reliance spans from early-stage process development and analytical testing to the production of clinical trial materials. In 2024, the global biopharmaceutical contract manufacturing market was valued at approximately $20 billion, with a significant portion driven by the needs of emerging biotech firms.

EirGenix offers these nascent companies a vital pathway to advance their promising biologic candidates. By providing state-of-the-art manufacturing infrastructure, regulatory expertise, and skilled personnel, EirGenix enables these startups to overcome critical manufacturing hurdles. This allows them to focus on their core competencies: drug discovery and clinical development, ultimately accelerating the journey from laboratory bench to patient bedside.

Mid-sized pharmaceutical companies often possess some in-house capabilities but frequently outsource specialized projects, manage capacity surges, or tackle intricate biologic development. EirGenix provides adaptable solutions and niche expertise that effectively augment their current operations, allowing them to focus on core competencies. For instance, in 2024, the global biopharmaceutical contract manufacturing market was valued at approximately $18.5 billion, indicating a strong demand for specialized external services like those EirGenix offers.

Large biopharmaceutical corporations frequently engage contract development and manufacturing organizations (CDMOs) like EirGenix to bolster their supply chains, tap into specialized technological capabilities, and effectively manage fluctuating production demands and inherent risks. This strategic outsourcing allows them to focus on core competencies in research and development. In 2024, the global biopharmaceutical contract manufacturing market was valued at approximately $22.3 billion, underscoring the significant reliance of even the largest players on external manufacturing partners.

EirGenix positions itself as a crucial strategic partner for these giants, offering robust, high-volume current Good Manufacturing Practice (cGMP) manufacturing services. Furthermore, EirGenix provides advanced development services, enabling these large corporations to accelerate their product pipelines and ensure regulatory compliance across diverse markets.

Companies Focused on Biosimilar Development

Companies focused on biosimilar development are a key customer segment for EirGenix. These firms need specialized expertise in process development and analytical comparability to ensure their biosimilars are highly similar to the reference biologic. EirGenix's manufacturing capabilities directly address this critical need, supporting the expansion of the biosimilar market.

The global biosimilar market is experiencing significant growth. By 2024, it's projected to reach over $60 billion, driven by patent expirations of major biologics and increasing demand for more affordable treatment options. This presents a substantial opportunity for EirGenix to partner with biosimilar developers.

- Expertise in Comparability: EirGenix offers advanced analytical services essential for demonstrating biosimilarity.

- Process Development: Their capabilities streamline the complex process development required for biosimilar manufacturing.

- Market Growth: The expanding biosimilar market, projected to exceed $60 billion by 2024, offers a strong demand for EirGenix's services.

- Cost-Effectiveness: EirGenix provides a cost-effective manufacturing solution for biosimilar companies aiming to compete with originator biologics.

Academic Research Institutions (for early-stage development)

Academic research institutions, while not typically primary clients for large-scale commercial manufacturing, represent a niche but vital customer segment for Contract Development and Manufacturing Organizations (CDMOs) like EirGenix, particularly in the early stages of biologic drug development.

These institutions often possess innovative, early-stage biologic candidates but lack the specialized infrastructure and expertise for process development and the production of research-grade or pre-clinical materials. For example, a university lab might discover a novel therapeutic protein but require a CDMO's capabilities to scale up production for initial safety and efficacy studies. The global biologics market, projected to reach over $700 billion by 2028, highlights the significant potential even at these nascent stages.

- Early-Stage Process Development: Academic researchers need assistance in optimizing cell culture conditions, purification methods, and analytical techniques to ensure the quality and consistency of their biologic candidates.

- Production of Research-Grade Materials: CDMOs can produce small batches of biologics required for in vitro studies, animal testing, and initial regulatory filings, enabling academic teams to advance their discoveries.

- Bridging the Gap to Commercialization: For promising academic projects, CDMOs can act as a crucial partner in demonstrating feasibility and attracting further investment, thereby facilitating the transition from lab bench to potential clinical trials.

- Specialized Expertise: Academic labs may not have in-house expertise in complex manufacturing processes or regulatory compliance, making CDMO support indispensable for navigating these challenges.

EirGenix serves a diverse clientele, including emerging biotechnology startups, mid-sized and large pharmaceutical companies, biosimilar developers, and academic research institutions. Each segment requires specialized manufacturing and development services to advance their biologic drug candidates.

Emerging biotech startups, often resource-constrained, rely on EirGenix for critical manufacturing capabilities to bring their novel therapies to clinical trials. Mid-sized and large pharma companies leverage EirGenix for specialized projects, capacity expansion, and risk management in their supply chains. Biosimilar developers count on EirGenix's expertise in process development and analytical comparability to meet market demands. Academic institutions benefit from EirGenix's early-stage process development and production of research-grade materials.

| Customer Segment | Key Needs | EirGenix's Offering |

| Emerging Biotech Startups | Process development, clinical trial material manufacturing, regulatory support | State-of-the-art infrastructure, specialized expertise, accelerated timelines |

| Mid-sized Pharma Companies | Capacity expansion, specialized projects, niche expertise | Adaptable solutions, augmentation of in-house capabilities |

| Large Biopharma Corporations | Supply chain enhancement, specialized technology access, risk mitigation | High-volume cGMP manufacturing, advanced development services |

| Biosimilar Developers | Process development, analytical comparability, cost-effective manufacturing | Expertise in demonstrating biosimilarity, streamlined production |

| Academic Research Institutions | Early-stage process development, research-grade material production | Bridging the gap to commercialization, specialized manufacturing support |

Cost Structure

EirGenix dedicates substantial resources to Research and Development (R&D) and Process Development. This investment is crucial for creating novel cell lines and refining bioprocesses to maintain a competitive edge with cutting-edge technologies.

These expenditures encompass a range of items, including the salaries of skilled scientists and technicians, the acquisition and maintenance of sophisticated laboratory equipment, and the purchase of essential materials needed for process optimization and validation.

For instance, in 2024, companies in the biopharmaceutical sector, similar to EirGenix, saw R&D spending as a significant portion of their operating costs. Data from industry reports indicates that leading biotechs allocated between 20% to 30% of their revenue to R&D, with process development being a key driver of these investments.

Manufacturing operations costs for EirGenix are primarily driven by raw materials like cell culture media and buffers, essential for biopharmaceutical production. In 2024, the cost of specialized raw materials can fluctuate significantly based on supply chain dynamics and demand for advanced therapies.

Utilities such as power and water are substantial, especially for maintaining the stringent environmental controls required in cGMP facilities. Consumables, including single-use bioreactors and filtration systems, represent a growing portion of these costs, reflecting the industry's shift towards flexible manufacturing solutions.

Ongoing maintenance of facilities and equipment is critical to ensure uninterrupted, compliant production. These direct costs are fundamental to EirGenix's ability to deliver high-quality biopharmaceutical products.

A significant portion of EirGenix's expenses is dedicated to compensating its highly skilled workforce. This includes competitive salaries and comprehensive benefits packages for scientists, engineers, quality assurance professionals, and regulatory affairs specialists who are crucial for navigating the complexities of biologics development and manufacturing.

Attracting and retaining this specialized talent is paramount for EirGenix's success in the demanding biologics industry, but it represents a substantial investment. For instance, in 2024, the average salary for a senior bioprocess engineer in the pharmaceutical sector could range from $120,000 to $180,000 annually, excluding benefits, reflecting the specialized knowledge and experience required.

Facility Maintenance, Depreciation, and Capital Expenditures

EirGenix incurs significant costs for maintaining its advanced cGMP facilities, ensuring compliance and operational excellence. These expenses are crucial for upholding the quality standards demanded in the biopharmaceutical industry.

Depreciation of the highly specialized and expensive equipment used in biomanufacturing represents a substantial fixed cost. For instance, in 2024, the biopharmaceutical industry saw continued investment in advanced manufacturing technologies, with depreciation of such assets forming a key part of operational expenditure.

Ongoing capital expenditures are necessary for facility expansion, technological upgrades, and the acquisition of new equipment to meet evolving market demands and enhance production capabilities. These investments are vital for long-term growth and competitiveness.

- Facility Maintenance: Costs cover routine upkeep, repairs, and specialized cleaning to ensure cGMP compliance.

- Depreciation: Amortization of the value of high-cost manufacturing equipment over its useful life.

- Capital Expenditures: Investments in expanding capacity, upgrading technology, and acquiring new assets.

Regulatory Compliance and Quality Control Expenses

EirGenix faces substantial costs to meet global regulatory standards and maintain rigorous quality control. These expenses are critical for market access and product integrity.

Key expenditures in this area include:

- Audits and Certifications: Costs associated with regular inspections by regulatory bodies like the FDA or EMA, and obtaining necessary certifications, can run into tens of thousands of dollars annually for each product line. For instance, maintaining GMP (Good Manufacturing Practice) certification often requires significant investment in facility upgrades and ongoing compliance monitoring.

- Documentation and Record-Keeping: Developing and maintaining comprehensive documentation for every stage of development and manufacturing is a major cost driver. This includes batch records, validation reports, and standard operating procedures (SOPs), requiring dedicated personnel and robust data management systems.

- Quality Assurance Personnel: Hiring and retaining skilled quality assurance (QA) and quality control (QC) staff is essential. In 2024, the average salary for a QA specialist in the biotech sector could range from $70,000 to $100,000 annually, reflecting the specialized expertise required.

- Testing and Validation: Extensive testing of raw materials, in-process samples, and finished products is a significant ongoing expense. This includes analytical testing, stability studies, and process validation, which can cost hundreds of thousands of dollars per product.

EirGenix's cost structure is heavily influenced by its significant investments in R&D and process development, covering salaries for scientists, equipment, and materials. Manufacturing expenses are driven by raw materials, utilities, and consumables like single-use bioreactors, with facility and equipment maintenance being critical for compliance and production continuity.

Personnel costs, particularly for specialized scientific and technical staff, represent a substantial outlay, as does the depreciation of high-value manufacturing equipment. Furthermore, meeting stringent regulatory standards and maintaining robust quality control systems incurs significant costs through audits, documentation, and extensive testing.

| Cost Category | Key Components | 2024 Industry Insight (Approximate) |

|---|---|---|

| Research & Development | Salaries, Lab Equipment, Materials | 20-30% of revenue for leading biotechs |

| Manufacturing Operations | Raw Materials, Utilities, Consumables | Fluctuating raw material costs, increasing single-use system spend |

| Personnel Costs | Salaries, Benefits for Skilled Staff | Senior Bioprocess Engineer: $120k-$180k annually |

| Facility & Equipment | Maintenance, Depreciation, Capital Expenditures | Ongoing investment in advanced technologies and capacity expansion |

| Regulatory & Quality Control | Audits, Documentation, Testing, QA/QC Staff | QA Specialist: $70k-$100k annually; Audit costs in tens of thousands |

Revenue Streams

EirGenix generates revenue through Fee-for-Service (FFS) contracts, where clients directly pay for specific services. This includes crucial steps like cell line development, optimizing manufacturing processes, and conducting detailed analytical testing. For instance, in 2024, a significant portion of their income came from these project-based agreements for manufacturing defined batch sizes of biologics.

For extended development projects, EirGenix can structure revenue through milestone-based payments. This means clients pay as specific project achievements are met, like confirming cell line stability or completing a critical process development stage.

This approach offers a clear payment progression, aligning financial inflows with tangible project advancements. For instance, a successful Phase I clinical trial completion could trigger a significant payment, reflecting the value delivered and de-risking the project for both parties.

Long-term contractual manufacturing agreements are a cornerstone for EirGenix, offering a predictable revenue stream. These multi-year deals for commercial production of approved biologics provide stability, with clients often committing to specific volumes or reserving dedicated facility capacity. For instance, in 2024, EirGenix continued to leverage these agreements, securing several new multi-year contracts that are projected to contribute significantly to its revenue pipeline over the next five years.

Technology Licensing Fees (if applicable)

Technology licensing fees represent a significant potential revenue stream for EirGenix, particularly if they develop unique cell lines, expression systems, or proprietary manufacturing processes. This allows clients to utilize EirGenix's innovations without needing to replicate the development, generating income beyond direct contract manufacturing services.

For example, in the biopharmaceutical sector, companies often license specialized cell culture technologies to improve protein expression yields or streamline production. While specific figures for EirGenix's licensing revenue are not publicly disclosed, the global market for bioprocess technology licensing is substantial, with projections indicating continued growth driven by advancements in biotechnology.

- Proprietary Technology: Licensing fees are generated from EirGenix's exclusive cell lines, expression systems, or manufacturing methods.

- Additional Revenue: This stream diversifies income beyond direct service fees, capturing value from intellectual property.

- Market Relevance: The biopharmaceutical industry actively seeks licensed technologies to enhance efficiency and product quality.

Volume-Based Manufacturing Fees

EirGenix structures its manufacturing fees based on the volume of drug substance or drug product produced. This model directly ties revenue growth to client success and market demand for their products.

As a client's drug candidate progresses through clinical trials and gains market traction, the demand for manufacturing increases. This escalation in production volume directly translates into higher revenue for EirGenix, creating a scalable and performance-driven revenue stream.

- Volume-Based Fees: Revenue is directly proportional to the quantity of manufactured drug substance or drug product.

- Scalability: As client products advance and demand rises, EirGenix's revenue from this stream grows accordingly.

- Client Success Alignment: This model aligns EirGenix's financial performance with the commercial success of its clients' products.

EirGenix leverages Fee-for-Service (FFS) contracts for specific projects, generating revenue from cell line development, process optimization, and analytical testing. In 2024, these project-based agreements for manufacturing defined batch sizes of biologics formed a significant portion of their income.

Long-term contractual manufacturing agreements for commercial production provide a predictable revenue stream, with clients committing to volumes or reserving capacity. In 2024, EirGenix secured several new multi-year contracts projected to contribute substantially to its revenue pipeline.

Volume-based manufacturing fees directly link revenue to the quantity of drug substance or product produced, scaling with client success and market demand. As client products advance, increased production volume translates into higher revenue for EirGenix.

| Revenue Stream | Description | 2024 Relevance |

|---|---|---|

| Fee-for-Service (FFS) | Payment for specific development and manufacturing services. | Significant portion of 2024 income from project-based contracts. |

| Long-Term Contracts | Multi-year agreements for commercial production. | New contracts secured in 2024 to bolster future revenue. |

| Volume-Based Fees | Revenue tied to the quantity of manufactured product. | Scalable revenue stream driven by client product success. |

Business Model Canvas Data Sources

The EirGenix Business Model Canvas is built upon a foundation of robust market research, internal financial data, and expert strategic analysis. These diverse data sources ensure that each component of the canvas is informed by accurate, actionable insights.