DMG Mori PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

DMG Mori Bundle

Unlock the strategic advantages of understanding DMG Mori's external environment with our comprehensive PESTLE analysis. Discover how political shifts, economic fluctuations, and technological advancements are shaping the future of advanced manufacturing. Equip yourself with actionable intelligence to make informed decisions and gain a competitive edge. Download the full PESTLE analysis now for a deeper dive into the forces impacting DMG Mori.

Political factors

Government policies play a crucial role in shaping the landscape for DMG Mori. Initiatives like Germany's High-Tech Strategy 2025, which champions Industry 4.0 and digitalization, directly benefit DMG Mori by fostering demand for its advanced manufacturing solutions. Subsidies for upgrading industrial equipment, particularly in sectors like automotive and aerospace, can significantly boost sales opportunities.

Global trade agreements and evolving protectionist policies significantly influence DMG Mori's operational landscape. For instance, the ongoing U.S.-China trade tensions and the imposition of tariffs can directly impact the cost of components and finished goods, affecting DMG Mori's competitive pricing in crucial markets.

Geopolitical instability, exemplified by the conflict in Ukraine, introduces considerable uncertainty into international trade. This can disrupt supply chains, alter demand patterns, and necessitate adjustments in sales strategies for DMG Mori, particularly in affected regions.

Export controls and sanctions imposed by various nations can directly restrict market access for DMG Mori's advanced machinery. This can lead to reduced sales volumes and revenue streams in specific countries, requiring the company to diversify its market presence and explore alternative growth avenues.

Geopolitical stability significantly influences DMG Mori's operating environment, particularly in regions with substantial manufacturing activity. Uncertainty stemming from ongoing conflicts and political unrest in key markets, as observed throughout 2024 and into 2025, directly impacts customer confidence and their willingness to undertake capital expenditures. This can lead to a slowdown in demand for high-value machine tools, a core offering for DMG Mori.

Regulatory Frameworks for Manufacturing

DMG Mori, as a global manufacturer, navigates a complex web of evolving regulations. These include stricter manufacturing standards, updated labor laws, and varying corporate governance requirements across different markets. Compliance with sustainability reporting, such as the Corporate Sustainability Reporting Directive (CSRD) in Europe, significantly impacts operational practices and reporting obligations for companies like DMG Mori, demanding greater transparency and accountability in environmental, social, and governance (ESG) matters.

The increasing emphasis on sustainability is driving new regulations. For instance, by 2024, many European Union member states are implementing stricter emissions standards for industrial machinery, potentially requiring DMG Mori to invest in cleaner technologies. Furthermore, evolving labor laws in key manufacturing hubs, such as Germany and China, necessitate continuous adaptation in workforce management and employee welfare programs to ensure compliance and maintain operational efficiency.

- Evolving Emissions Standards: New regulations by 2024 in the EU mandate reduced emissions for industrial machinery, impacting manufacturing processes and technology investments for DMG Mori.

- Labor Law Adaptations: Ongoing changes in labor laws in major markets like Germany and China require DMG Mori to regularly update its employment practices and worker protections.

- Corporate Governance Scrutiny: Increased global focus on corporate governance means DMG Mori must adhere to diverse and often stringent reporting and ethical conduct standards across its international operations.

- Sustainability Reporting Mandates: Directives like the CSRD in Europe impose significant new reporting obligations related to ESG performance, influencing how DMG Mori tracks and communicates its environmental and social impact.

Political Stability of Customer Industries

Government policies significantly influence the investment appetite of DMG Mori's core customer industries. For instance, the German government's commitment to the automotive industry's transformation, including substantial subsidies for electric vehicle (EV) production and charging infrastructure, directly impacts demand for advanced machine tools. In 2024, Germany allocated billions of euros to support the automotive sector’s transition, creating opportunities for manufacturers of high-precision machinery.

Shifts in defense spending also play a crucial role. Increased geopolitical tensions in 2024 and 2025 have led many nations, including key European markets for DMG Mori, to boost their defense budgets. This heightened investment in aerospace and defense sectors translates into a greater need for sophisticated manufacturing equipment capable of producing complex components for aircraft and military hardware. For example, the European Union's defense initiatives are expected to drive significant capital expenditure in related manufacturing capabilities.

- Automotive Sector Support: Continued government incentives for EV adoption and manufacturing in major markets like Germany and the US are projected to sustain demand for advanced production machinery through 2025.

- Aerospace and Defense Investment: Global defense spending, anticipated to rise by approximately 5-7% in 2024-2025 according to industry analysts, will likely spur demand for high-precision, specialized machine tools.

- Regulatory Landscape: Evolving environmental regulations and trade policies can impact the cost of production and market access for both DMG Mori and its customers, necessitating agile adaptation.

Government policies, particularly those promoting Industry 4.0 and digitalization, directly benefit DMG Mori by driving demand for its advanced manufacturing solutions, with Germany's High-Tech Strategy 2025 being a prime example. Subsidies for upgrading industrial equipment, especially in the automotive and aerospace sectors, are also key sales drivers, with Germany alone allocating billions to support the automotive industry's EV transition in 2024.

Global trade agreements and protectionist policies significantly impact DMG Mori's operations, as seen with U.S.-China trade tensions affecting component costs and competitive pricing. Geopolitical instability, such as the conflict in Ukraine, disrupts supply chains and alters demand patterns, requiring strategic adjustments. Export controls and sanctions further restrict market access, necessitating market diversification.

Evolving regulations, including stricter emissions standards and updated labor laws in markets like Germany and China, demand continuous adaptation from DMG Mori. Sustainability reporting mandates, such as the EU's CSRD, also increase transparency and accountability in ESG matters, influencing operational practices.

Shifts in defense spending, fueled by increased geopolitical tensions in 2024-2025, are boosting defense budgets globally. This heightened investment in aerospace and defense sectors translates into greater demand for sophisticated manufacturing equipment, with European Union defense initiatives expected to drive significant capital expenditure in related manufacturing capabilities.

| Policy Area | Impact on DMG Mori | 2024/2025 Data/Trend |

|---|---|---|

| Industry 4.0 & Digitalization | Increased demand for advanced machinery | Germany's High-Tech Strategy 2025 |

| Trade Policies | Affects component costs & market access | U.S.-China trade tensions |

| Geopolitical Stability | Influences customer confidence & capital expenditure | Ongoing conflicts impacting key markets |

| Sustainability Regulations | Drives investment in cleaner technologies & reporting | EU emissions standards by 2024; CSRD reporting |

| Defense Spending | Boosts demand for specialized equipment | Estimated 5-7% rise in global defense spending (2024-2025) |

What is included in the product

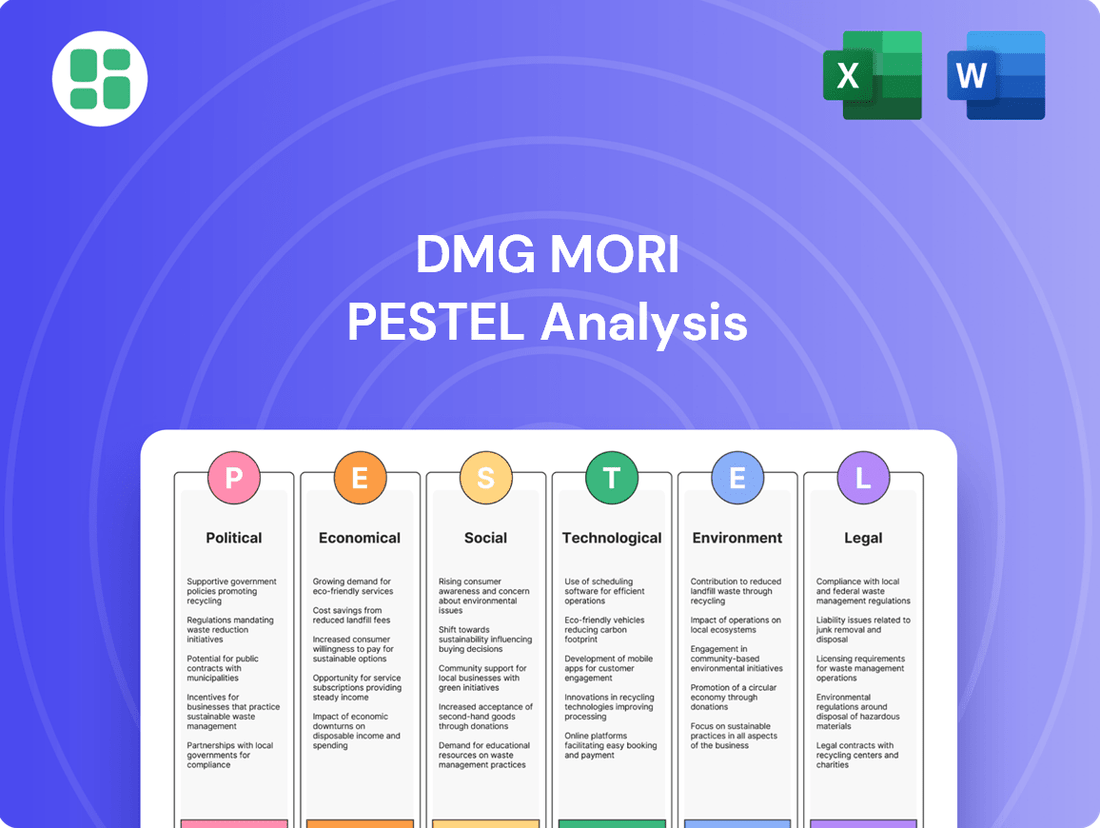

This DMG Mori PESTLE analysis systematically examines the Political, Economic, Social, Technological, Environmental, and Legal forces impacting the company's operational landscape.

It provides a comprehensive understanding of the external macro-environment to inform strategic decision-making and identify potential opportunities and threats.

Provides a concise version that can be dropped into PowerPoints or used in group planning sessions, offering a clear overview of external factors impacting DMG Mori.

Economic factors

The global economic outlook and the pace of industrial production are critical drivers for DMG Mori, as machine tools are essential capital goods. A robust global economy generally translates to higher demand for manufactured goods, directly boosting orders for machine tool manufacturers like DMG Mori.

In 2024, the International Monetary Fund (IMF) projected global economic growth to be around 3.2%, a slight acceleration from previous years, indicating a generally supportive environment for industrial investment. Similarly, industrial production growth, particularly in key manufacturing hubs, directly correlates with DMG Mori's sales performance, with sectors like automotive and aerospace being significant end-users.

DMG Mori's global footprint means currency exchange rate fluctuations significantly impact its financial performance. For instance, a stronger Euro can make its products more expensive for buyers using other currencies, potentially dampening sales in non-Eurozone markets. Conversely, a weaker Yen could increase the cost of imported components for its Japanese manufacturing facilities.

In 2023, DMG Mori reported that approximately 60% of its sales were generated outside of Japan, highlighting the substantial exposure to currency volatility. A notable example is the Yen's performance against the US Dollar; a 10% depreciation of the Yen against the Dollar could, all else being equal, boost DMG Mori's reported profits when translating overseas earnings back into Yen.

Prevailing interest rates significantly impact DMG Mori's sales by influencing customer willingness to invest in new machinery. For instance, if central banks like the Federal Reserve or the European Central Bank maintain or increase benchmark rates in 2024 and into 2025, the cost of borrowing for DMG Mori's clients will rise. This increased cost of capital can make purchasing high-value capital equipment less attractive, potentially leading to deferred investment decisions and a slowdown in order intake for DMG Mori.

Furthermore, the ease of access to credit plays a crucial role. When credit markets tighten, or lending standards become more stringent, businesses may find it harder to secure the financing needed for significant capital expenditures. This reduced access to capital, particularly for small and medium-sized enterprises which are a key customer segment for many machinery manufacturers, can directly translate into lower demand for DMG Mori's advanced manufacturing solutions.

Raw Material and Energy Costs

Fluctuations in raw material and energy costs significantly impact DMG Mori's operational expenses. For instance, the price of steel, a key component in machine tools, experienced volatility throughout 2024. Global energy prices, particularly for natural gas and electricity, also presented challenges.

These cost pressures directly affect DMG Mori's profit margins. If input costs rise faster than the company can adjust its pricing, profitability will likely decrease. This dynamic is particularly relevant given the inflationary environment observed in many industrial sectors during 2024 and early 2025.

- Increased Production Costs: Higher prices for metals like steel and aluminum directly inflate the cost of manufacturing machine tools.

- Energy Price Volatility: Significant swings in electricity and natural gas prices in 2024 and projected into 2025 impact factory operating expenses.

- Margin Squeeze: The inability to fully pass on rising raw material and energy costs to customers can compress DMG Mori's profit margins.

- Strategic Sourcing: DMG Mori's ability to secure long-term supply contracts for key materials and energy at favorable rates is crucial for cost management.

Supply Chain Resilience and Global Disruptions

Global supply chain disruptions, a persistent economic challenge, significantly impact manufacturing giants like DMG Mori. Logistics hurdles and component shortages directly affect production efficiency and delivery timelines. For instance, the ongoing geopolitical tensions and trade policy shifts in 2024 continue to create volatility, impacting the availability and cost of critical raw materials and electronic components essential for machine tool production.

DMG Mori's strategic response to these disruptions is crucial for maintaining its competitive edge. The company's investments in diversifying its supplier base and exploring localized production or assembly options directly mitigate the risks associated with single-source dependencies. Successfully navigating these challenges translates into more predictable production schedules and improved customer satisfaction, ultimately safeguarding revenue streams.

- Logistics Bottlenecks: Shipping costs saw significant increases in late 2023 and early 2024, with some routes experiencing delays of up to 30% compared to pre-pandemic levels, impacting DMG Mori's ability to deliver finished products promptly.

- Component Availability: Shortages of semiconductors and specialized electronic parts, critical for advanced machine tool control systems, persisted into 2024, forcing manufacturers to manage lead times and potentially alter production plans.

- Sourcing Strategies: DMG Mori's proactive approach to establishing regional supply hubs and strengthening relationships with multiple suppliers aims to buffer against unforeseen disruptions, ensuring greater operational continuity.

- Impact on Delivery Times: Extended lead times for key components in 2024 have, in some cases, pushed delivery schedules for complex machinery by several weeks, directly affecting customer project timelines and DMG Mori's order fulfillment rates.

The global economic climate and industrial production rates are paramount for DMG Mori, as machine tools are fundamental capital goods. Strong economic growth worldwide typically leads to increased demand for manufactured products, directly benefiting machine tool makers like DMG Mori.

In 2024, the IMF projected global economic growth at approximately 3.2%, indicating a generally favorable environment for industrial investments. Key manufacturing sectors such as automotive and aerospace are significant end-users, meaning growth in industrial production, particularly in these areas, directly impacts DMG Mori's sales.

Currency exchange rate fluctuations significantly affect DMG Mori's financial results due to its international operations. A stronger Euro, for example, can make its products more expensive for customers in other currency zones, potentially reducing sales. Conversely, a weaker Yen could increase the cost of imported parts for its Japanese facilities.

In 2023, DMG Mori reported that about 60% of its sales originated outside Japan, underscoring its substantial exposure to currency volatility. For instance, a 10% depreciation of the Yen against the US Dollar could positively impact DMG Mori's reported profits when converting overseas earnings back into Yen, assuming other factors remain constant.

| Economic Factor | Impact on DMG Mori | 2024/2025 Data/Outlook |

|---|---|---|

| Global Economic Growth | Drives demand for capital goods like machine tools. | Projected 3.2% global growth in 2024 (IMF). |

| Industrial Production | Directly correlates with sales performance in key sectors. | Growth in automotive and aerospace sectors is crucial. |

| Currency Exchange Rates | Affects international sales competitiveness and reported profits. | Approx. 60% of 2023 sales were outside Japan; Yen depreciation can boost profits. |

| Interest Rates & Credit Access | Influences customer investment decisions and financing availability. | Higher rates increase borrowing costs for clients, potentially delaying investments. |

| Raw Material & Energy Costs | Impacts operational expenses and profit margins. | Volatility in steel and energy prices in 2024 presented cost pressures. |

| Supply Chain Disruptions | Affects production efficiency and delivery timelines. | Logistics bottlenecks and component shortages persisted into 2024. |

What You See Is What You Get

DMG Mori PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This PESTLE analysis of DMG Mori provides a comprehensive overview of the political, economic, social, technological, legal, and environmental factors impacting the company. You can trust that the detailed insights and structured format you see will be yours to leverage immediately.

Sociological factors

Securing and keeping skilled workers is a major hurdle for manufacturers, especially those needing expertise with advanced CNC machinery and new tech. In 2024, the manufacturing sector continued to grapple with a significant skills gap, with reports indicating millions of unfilled positions requiring specialized technical abilities.

DMG Mori is actively tackling this by investing heavily in training and upskilling programs for its employees and customers. They also focus on creating automation solutions that are easier to operate, aiming to reduce the reliance on highly specialized labor and ease the pressure from ongoing workforce shortages.

Developed economies are experiencing a significant aging workforce, with the average age of manufacturing workers steadily increasing. For instance, in the United States, the average age of production occupations was around 45 years old in 2023, a trend expected to continue. This demographic shift directly impacts the availability of skilled machinists and experienced engineers, creating a potential talent gap.

The scarcity of experienced manual labor due to an aging workforce heightens the demand for automation and digital manufacturing solutions. Companies like DMG Mori, which offers advanced machine tools and integrated digital services, are well-positioned to address this need by reducing reliance on traditional, labor-intensive processes.

Customers are increasingly demanding highly automated and digitally integrated manufacturing solutions, pushing companies like DMG Mori to adapt their product development. This shift means machines need to be seamless components of smart factories, enabling data-driven decision-making. For instance, DMG Mori's focus on digital solutions like their CELOS platform directly addresses this by offering integrated machine control and data management.

Corporate Social Responsibility (CSR) Expectations

Societal expectations for ethical conduct, including human rights and community involvement, significantly shape DMG Mori's reputation and how stakeholders perceive the company. Adhering to codes of conduct and transparently reporting on social impacts are crucial for maintaining trust. For instance, in 2023, DMG Mori reported on its sustainability efforts, highlighting initiatives aimed at employee well-being and local community support, which are increasingly scrutinized by investors and consumers alike.

These expectations translate into a demand for responsible supply chains and fair labor practices. Companies like DMG Mori are pressured to demonstrate commitment beyond mere compliance, actively contributing to social progress. This includes ensuring safe working conditions throughout their operations and partnerships, a factor that influences brand loyalty and attracts talent.

Key areas influenced by CSR expectations include:

- Ethical Sourcing: Ensuring raw materials and components are obtained without exploitation.

- Community Investment: Engaging in local projects and supporting social development.

- Employee Welfare: Prioritizing fair wages, safe working environments, and professional development.

- Transparent Reporting: Clearly communicating social performance and impact metrics to the public.

Workplace Safety and Health Standards

Societal expectations and regulatory bodies are increasingly prioritizing workplace safety and health, directly impacting how DMG Mori designs and operates its machinery. This emphasis drives the need for more ergonomic machine tools and the promotion of secure manufacturing environments, reflecting a commitment to both employee well-being and legal adherence.

For instance, in 2023, workplace safety initiatives in Germany, a key market for DMG Mori, saw a continued focus on reducing occupational accidents, with statistics from the German Social Accident Insurance (DGUV) consistently highlighting the importance of preventative measures in industrial settings. This trend is expected to persist and intensify through 2024 and into 2025, pushing manufacturers towards even higher safety standards in equipment design and operational protocols.

- Increased regulatory scrutiny on machine safety features and operator ergonomics.

- Societal demand for manufacturers to demonstrate a strong commitment to employee health and well-being.

- Potential for higher insurance premiums and legal liabilities for companies failing to meet evolving safety standards.

Societal trends like an aging workforce and the demand for automation significantly shape DMG Mori's operational landscape. The increasing average age of skilled manufacturing labor, with many developed nations seeing averages around 45 years old in 2023, creates a critical need for solutions that reduce reliance on traditional expertise. This demographic shift fuels the market for advanced machinery and digital integration, areas where DMG Mori is actively investing.

Customer expectations are evolving towards highly automated, digitally integrated manufacturing solutions, pushing companies like DMG Mori to develop seamless components for smart factories. Their CELOS platform, for example, exemplifies this by offering integrated machine control and data management, directly addressing the demand for data-driven decision-making in modern production environments.

Societal emphasis on ethical conduct, including human rights and community engagement, directly impacts DMG Mori's reputation and stakeholder trust. In 2023, the company's sustainability reporting, which included initiatives for employee well-being and local community support, reflects the growing scrutiny from investors and consumers on corporate social responsibility. This translates into a demand for responsible supply chains and fair labor practices, influencing brand loyalty and talent acquisition.

Workplace safety and health are paramount, with regulatory bodies and societal expectations driving stricter standards in machinery design and operation. In 2023, Germany, a key market for DMG Mori, continued to focus on reducing occupational accidents, with preventative measures in industrial settings being a consistent highlight. This trend is projected to intensify through 2024 and 2025, compelling manufacturers to adopt higher safety standards for both equipment and operational protocols.

Technological factors

Continuous innovation in Computer Numerical Control (CNC) technology, coupled with advancements in artificial intelligence (AI) and the Internet of Things (IoT), is a cornerstone of DMG Mori's competitive edge. These technologies are the driving force behind smart factories, enabling predictive maintenance and highly optimized production workflows. For instance, DMG Mori's own advancements in digital solutions, like their CELOS control system, integrate these elements to offer enhanced efficiency and data-driven insights for manufacturers. In 2023, the global smart manufacturing market was valued at over $275 billion, with significant growth projected due to these technological integrations.

Digital Transformation (DX) and Industry 4.0 are fundamentally reshaping manufacturing, and DMG Mori is actively integrating these trends into its core strategy. By embedding digital solutions like its CELOS X platform and advanced data analytics into its machine tools and services, the company is enabling customers to achieve seamless connectivity and real-time process optimization. This focus on digital integration is crucial for enhancing operational efficiency and providing customers with greater insights into their production processes.

Additive manufacturing, or 3D printing, is increasingly vital, and DMG Mori is at the forefront with its hybrid machines. These integrate additive and subtractive capabilities, allowing for the creation of intricate parts and accelerating rapid prototyping. For instance, DMG Mori's LASERTEC 400 3D machine can deposit metal powder and then precisely mill the part, a significant advancement in manufacturing flexibility.

Automation and Robotics in Production

DMG Mori is actively responding to the surge in automation and robotics within manufacturing by providing comprehensive, integrated solutions. This includes their offerings of autonomous mobile robots (AMRs) and advanced pallet handling systems, designed to streamline production lines.

The drive behind this trend is clear: manufacturers are seeking to boost productivity and lessen their reliance on manual labor. For instance, the global industrial robotics market was valued at approximately $50 billion in 2023 and is projected to grow significantly, with some forecasts suggesting it could reach over $100 billion by 2030, highlighting the immense opportunity for companies like DMG Mori that cater to this demand.

- Increased Productivity: Automation allows for faster cycle times and consistent output, directly addressing the need for higher production volumes.

- Reduced Labor Costs: Robotics can perform repetitive or hazardous tasks, decreasing the need for human intervention and associated labor expenses.

- Enhanced Quality and Precision: Automated systems offer superior accuracy and repeatability compared to manual operations, leading to improved product quality.

- Flexibility in Production: Modern robotic systems, like AMRs, can be reprogrammed and redeployed, offering manufacturers greater agility in adapting to changing product demands.

Cybersecurity and Data Protection for Connected Machines

As machine tools become increasingly interconnected and data-centric, robust cybersecurity and data protection are paramount for DMG Mori. Protecting customer data and intellectual property is essential in today's highly digitalized manufacturing landscape, necessitating secure software and systems.

The increasing reliance on connected machinery means that vulnerabilities in cybersecurity can have significant financial and operational repercussions. For instance, a report from IBM in 2024 indicated that the average cost of a data breach in the manufacturing sector reached $4.53 million, highlighting the financial stakes involved.

- Increased Threat Landscape: The proliferation of IoT devices in manufacturing environments expands the potential attack surface for cyber threats.

- Data Integrity and IP Protection: Ensuring the security of sensitive design data, production parameters, and customer information is critical for maintaining competitive advantage and trust.

- Regulatory Compliance: Evolving data protection regulations, such as GDPR and similar frameworks globally, require stringent measures to safeguard personal and corporate data.

- Operational Continuity: Cyberattacks can disrupt production lines, leading to significant downtime and revenue loss, making resilience a key factor.

Technological advancements are reshaping manufacturing, with DMG Mori leveraging AI, IoT, and advanced automation. The global smart manufacturing market exceeded $275 billion in 2023, underscoring the demand for these integrated solutions. DMG Mori's CELOS X platform and hybrid additive/subtractive manufacturing capabilities, like their LASERTEC 400 3D, exemplify their commitment to Industry 4.0 and enhanced production efficiency. This technological integration is critical for staying competitive in a rapidly evolving industrial landscape.

| Technology Area | DMG Mori's Focus | Market Relevance (2023/2024 Data) |

|---|---|---|

| AI & IoT | Smart factories, predictive maintenance, data analytics (CELOS) | Smart manufacturing market > $275 billion (2023) |

| Automation & Robotics | AMRs, pallet handling systems | Industrial robotics market ~$50 billion (2023), projected to double by 2030 |

| Additive Manufacturing | Hybrid machines (additive/subtractive) | Enables complex part creation and rapid prototyping |

| Cybersecurity | Data protection for connected machinery | Average data breach cost in manufacturing ~$4.53 million (2024) |

Legal factors

DMG Mori operates within a robust legal framework governing product liability and safety for industrial machinery. Compliance with directives like the EU Machinery Directive 2006/42/EC is paramount, ensuring machine tools meet rigorous safety standards to prevent accidents and potential lawsuits. Failure to adhere can result in significant fines and reputational damage.

In 2023, the global industrial machinery market saw continued emphasis on enhanced safety features, driven by evolving regulations and a focus on reducing workplace injuries. DMG Mori's commitment to these standards is crucial for maintaining market access and customer confidence, especially as international trade agreements often incorporate harmonized safety requirements for imported goods.

Protecting DMG Mori's extensive intellectual property, particularly its innovative machine designs and proprietary software, is a critical legal imperative. Navigating the intricate landscape of international patent laws is essential for safeguarding these assets. DMG Mori actively defends its patents against infringement to maintain its technological leadership and competitive advantage in the global machine tool market.

Evolving data privacy regulations, like the GDPR in Europe, significantly impact how DMG Mori handles data from its connected machines and customer interactions. Compliance with these laws is essential to avoid substantial financial penalties, which can reach up to 4% of global annual revenue or €20 million, whichever is higher. For instance, a data breach could lead to significant fines and damage to customer trust in DMG Mori's digital offerings.

Antitrust and Competition Laws

Antitrust and competition laws significantly shape DMG Mori's strategic maneuvers, particularly concerning mergers, acquisitions, and efforts to expand market share. These regulations, enforced by bodies like the European Commission and the U.S. Federal Trade Commission, aim to prevent monopolistic practices and ensure a level playing field for all market participants. Failure to comply can result in substantial fines and divestiture orders, impacting profitability and market access.

Key considerations for DMG Mori include:

- Merger Control: Regulatory reviews of potential acquisitions, such as the acquisition of a smaller competitor or a technology provider, assess whether the deal would unduly lessen competition. For instance, in 2023, the German Federal Cartel Office reviewed several industry consolidation deals, highlighting the scrutiny applied to market-leading companies.

- Abuse of Dominance: DMG Mori must avoid practices that could be construed as exploiting a dominant market position, such as predatory pricing or exclusive dealing arrangements that stifle smaller rivals.

- Cartel Prohibitions: Agreements with competitors to fix prices, divide markets, or rig bids are strictly prohibited and carry severe penalties.

- State Aid Regulations: In regions like the EU, government subsidies or support for DMG Mori must adhere to state aid rules to prevent unfair competitive advantages.

International Trade and Export Control Laws

International trade and export control laws present significant legal hurdles for DMG Mori. These regulations, including sanctions and licensing requirements, can directly limit sales to specific nations. For instance, navigating export controls for advanced machinery is crucial for global market access.

DMG Mori's business is demonstrably impacted by these legal frameworks. Past challenges, such as those concerning export licenses and their implications for the Russian market, highlight the critical need for strict compliance. The company must remain vigilant regarding evolving international trade restrictions.

- Export Control Compliance: DMG Mori must adhere to stringent export control regulations, which govern the transfer of technology and goods across borders, particularly for dual-use items.

- Sanctions Impact: International sanctions imposed on various countries can directly restrict DMG Mori's ability to conduct business, potentially leading to lost sales opportunities and the need for market diversification.

- Licensing Requirements: Obtaining necessary export licenses for complex machinery and advanced technologies is a complex legal process that can influence delivery timelines and market entry strategies.

DMG Mori faces evolving legal landscapes in product safety, intellectual property protection, and data privacy. Compliance with directives like the EU Machinery Directive 2006/42/EC is critical, as is safeguarding patents against infringement. Data privacy regulations, such as GDPR, impose strict handling requirements, with potential fines up to 4% of global annual revenue for non-compliance.

Antitrust laws and international trade regulations, including export controls and sanctions, significantly influence DMG Mori's market access and strategic operations. For example, navigating export restrictions for advanced machinery is a constant challenge, impacting global sales and requiring diligent adherence to prevent penalties and maintain market presence.

Environmental factors

The manufacturing sector faces mounting pressure from governments worldwide to enhance energy efficiency and slash greenhouse gas emissions. This regulatory shift is directly impacting machine tool manufacturers like DMG Mori, pushing them to innovate towards more sustainable production methods.

DMG Mori's strategic emphasis on Green Transformation (GX) is a clear acknowledgment of these environmental mandates. Their development of machines incorporating features like GREENMODE, designed to significantly reduce energy consumption during operation, directly addresses both regulatory compliance and growing customer demand for eco-friendly solutions. For instance, their eco-friendly machine concepts aim to cut energy usage by up to 30% compared to previous models, a crucial factor in meeting stricter emissions targets.

The increasing global focus on sustainable sourcing directly impacts DMG Mori's operations, particularly concerning raw material acquisition for its advanced machine tools. As industries worldwide push for greener supply chains, DMG Mori's commitment to optimizing resource use and enhancing transparency around Scope 3 emissions with its suppliers becomes crucial. This proactive approach not only mitigates environmental risks but also aligns with growing customer demand for eco-conscious manufacturing solutions.

Stricter regulations on industrial waste management and the recycling of machine components are becoming increasingly common globally. For instance, the European Union's Waste Framework Directive continues to evolve, pushing for higher recycling rates and responsible disposal of complex industrial byproducts. DMG Mori's commitment to a 360° sustainability approach, which includes the refurbishment and recycling of its machines, directly addresses these evolving environmental mandates.

These regulations often mandate extended producer responsibility, meaning manufacturers like DMG Mori are accountable for the entire lifecycle of their products, including their end-of-life. In 2023, the global waste management market was valued at over $1.7 trillion and is projected to grow significantly, driven by these regulatory pressures. DMG Mori's proactive stance on machine overhaul and recycling demonstrates foresight in navigating this complex landscape and potentially creating new revenue streams from circular economy practices.

Climate Change Impacts and Adaptation

Climate change presents significant challenges and opportunities for DMG Mori. Extreme weather events, such as the floods impacting Germany in 2021, can disrupt global supply chains, affecting production and delivery schedules. This necessitates enhanced operational resilience and robust strategic planning to mitigate such risks.

DMG Mori is actively addressing these challenges. Their commitment to Science Based Targets (SBTi) underscores a strategic focus on decarbonization, aligning their operations with global climate goals. Furthermore, their adherence to Task Force on Climate-related Financial Disclosures (TCFD) reporting demonstrates a proactive approach to transparency and risk management related to climate change.

- Supply Chain Disruptions: DMG Mori's reliance on a global supply chain makes it vulnerable to climate-induced disruptions, impacting raw material availability and logistics.

- Decarbonization Pressure: Increasing regulatory and market pressure to reduce carbon emissions influences DMG Mori's product development and manufacturing processes, driving innovation in energy-efficient machinery.

- Adaptation Strategies: The company is likely investing in measures to adapt its operations and product portfolio to a changing climate, potentially including developing more sustainable manufacturing technologies and offering solutions that help customers reduce their own environmental footprint.

Customer Demand for Eco-Friendly Solutions

Customer awareness regarding sustainability is significantly influencing manufacturing choices, pushing companies like DMG Mori to innovate in eco-friendly technologies. This growing demand directly fuels investment in machines that support the production of components for burgeoning sectors such as renewable energy and electric mobility. For instance, the global electric vehicle market was projected to reach over $1.5 trillion by 2030, creating substantial opportunities for manufacturers of specialized components.

DMG Mori's strategic focus on green technologies directly addresses this market shift. Their machine tool solutions are increasingly geared towards enabling efficient and precise manufacturing of parts crucial for sustainability initiatives. This includes machinery designed for producing lightweight components for electric vehicles or specialized parts for wind turbines and solar panels, aligning with global decarbonization efforts.

- Growing EV Market: The electric vehicle market's rapid expansion, with projections indicating substantial growth through 2030, underscores the demand for advanced manufacturing capabilities.

- Renewable Energy Components: Increased investment in renewable energy infrastructure necessitates specialized machinery for producing components like turbine blades and solar panel parts.

- Resource Efficiency: Customers are increasingly seeking manufacturing processes that minimize energy consumption and waste, driving demand for more efficient machine tools.

- Circular Economy Alignment: DMG Mori's solutions can support the production of components designed for longevity and recyclability, aligning with circular economy principles.

Environmental factors are increasingly shaping the machine tool industry, pushing companies like DMG Mori towards sustainability. Regulatory pressures on energy efficiency and emissions are driving innovation in eco-friendly machine designs, with DMG Mori's GREENMODE technology aiming for up to 30% energy reduction.

Global demand for sustainable sourcing impacts DMG Mori's supply chain, necessitating transparency in Scope 3 emissions and resource optimization. Evolving waste management regulations, like the EU's Waste Framework Directive, require manufacturers to take responsibility for product lifecycles, encouraging practices like machine refurbishment and recycling.

Climate change poses risks through potential supply chain disruptions from extreme weather, such as the 2021 German floods, highlighting the need for operational resilience. DMG Mori's commitment to SBTi and TCFD reporting demonstrates a proactive approach to managing climate-related risks and aligning with global decarbonization goals.

Customer demand for sustainable manufacturing is a significant driver, particularly with the growth of sectors like electric mobility. The EV market, projected to exceed $1.5 trillion by 2030, creates opportunities for DMG Mori's specialized machinery that supports the production of lightweight EV components and renewable energy parts.

PESTLE Analysis Data Sources

Our DMG Mori PESTLE analysis is meticulously constructed using data from official government publications, international economic organizations, and leading industry research firms. This ensures that every aspect, from political stability to technological advancements, is informed by credible and current information.