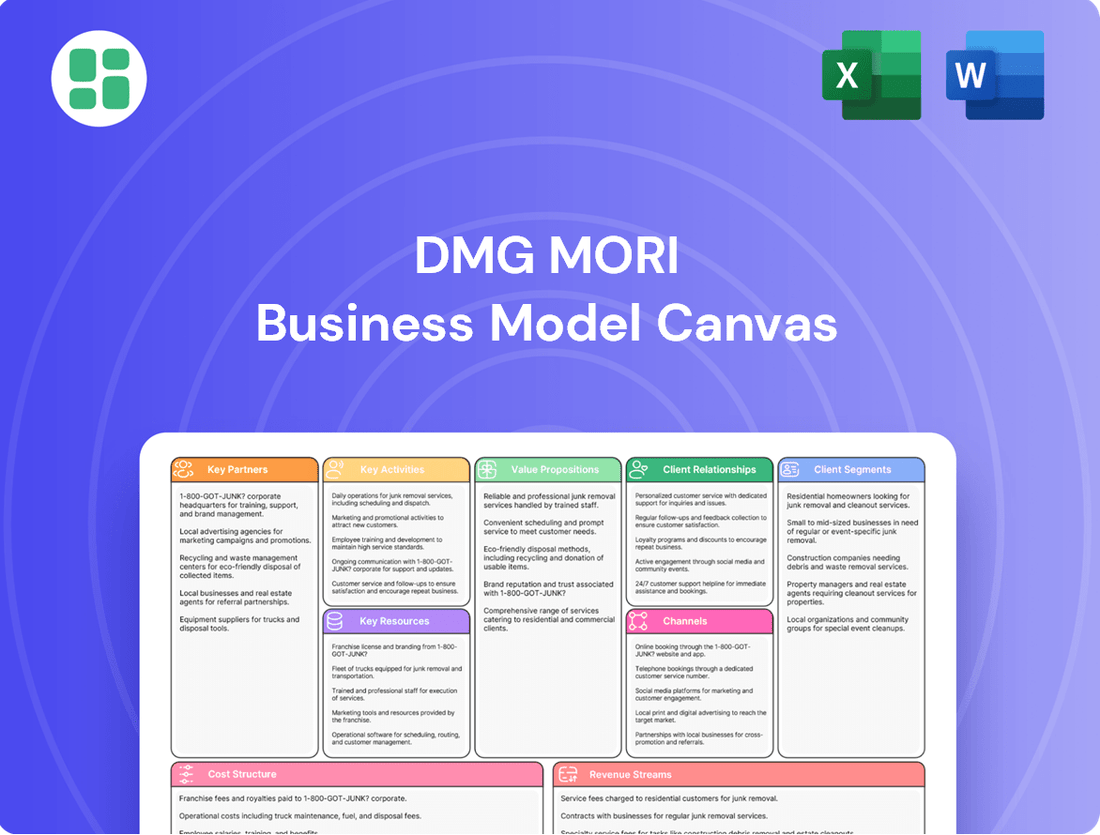

DMG Mori Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

DMG Mori Bundle

Unlock the strategic blueprint of DMG Mori's success with our comprehensive Business Model Canvas. This detailed analysis reveals how they innovate, build customer relationships, and generate revenue in the competitive machine tool industry. Discover the key partnerships and resources that drive their global operations.

Want to understand the engine behind DMG Mori's market dominance? Our full Business Model Canvas provides an in-depth look at their value proposition, customer segments, and revenue streams, offering actionable insights for your own strategic planning. Download the complete, professionally crafted document to gain a competitive edge.

Partnerships

DMG Mori actively cultivates strategic technology alliances with leading providers to embed state-of-the-art components and software into its machine tools. This ensures their offerings remain at the forefront of manufacturing capabilities.

These collaborations concentrate on critical areas such as advanced CNC controls, precision metrology systems, and sophisticated automation solutions. By integrating these technologies, DMG Mori significantly boosts the performance, efficiency, and overall functionality of its machinery.

A cornerstone of this strategy is the DMQP (DMG MORI Qualified Products) program. This initiative guarantees that all peripheral products are perfectly matched and readily available from a single, reliable source, simplifying integration and ensuring optimal system performance for customers.

DMG Mori actively partners with leading universities and research institutes worldwide. For instance, their collaborations contribute to advancements in areas like additive manufacturing and digitalization, ensuring a pipeline of cutting-edge technology. These alliances are crucial for staying ahead in the rapidly evolving manufacturing landscape.

DMG Mori cultivates robust alliances with a worldwide array of specialized suppliers, crucial for sourcing raw materials, essential components, and pre-assembled units. This extensive supplier network is fundamental to bolstering supply chain robustness, guaranteeing the superior quality of incoming materials, and facilitating the streamlined manufacturing of their broad spectrum of machine tools.

Automation Solution Providers

DMG Mori's strategic alliances with automation solution providers are fundamental to its business model. These partnerships are essential for creating sophisticated, integrated automation systems, such as advanced pallet handling and autonomous mobile robot (AMR) solutions. For instance, DMG Mori has collaborated with companies like KUKA and FANUC, leaders in robotics, to seamlessly integrate their technologies into DMG Mori's machine tools.

These collaborations are not merely about technology integration; they enable DMG Mori to deliver complete, turnkey manufacturing cells. These comprehensive solutions are designed to dramatically boost customer productivity and address the growing need to reduce reliance on manual labor. In 2024, the demand for automated manufacturing solutions continued to rise, with the global industrial automation market projected to reach over $290 billion by 2025, highlighting the critical nature of these partnerships.

- Partnerships with automation specialists and robotics companies are key to developing integrated solutions like pallet handling systems and autonomous mobile robots.

- These collaborations allow DMG Mori to offer comprehensive, turnkey manufacturing cells.

- These integrated solutions significantly enhance customer productivity.

- The partnerships help reduce customer labor demands in manufacturing operations.

Industry Associations and Training Organizations

DMG Mori actively collaborates with key industry associations and vocational training organizations to tackle the critical skills gap in manufacturing. Partnerships with entities like WorldSkills are instrumental in cultivating the next wave of skilled machinists and technicians. This strategic engagement not only secures a vital talent pipeline for DMG Mori but also reinforces its standing as a forward-thinking industry leader.

These collaborations are crucial for ensuring that educational programs align with the evolving demands of advanced manufacturing technologies. For instance, in 2024, DMG Mori continued its support for initiatives aimed at upskilling workers in areas like digital manufacturing and automation. Such partnerships directly contribute to a more robust and capable workforce, benefiting the entire sector.

- Industry Associations: Collaborations with organizations like VDMA (Verband Deutscher Maschinen- und Anlagenbau) in Germany provide insights into market trends and regulatory landscapes.

- Vocational Training: Partnerships with technical schools and apprenticeship programs ensure a steady influx of qualified personnel.

- Skills Development: Jointly developed training modules focus on emerging technologies, enhancing the employability of graduates.

- Talent Pipeline: WorldSkills participation, for example, showcases young talent and provides a recruitment ground for future engineers and technicians.

DMG Mori's key partnerships are vital for innovation and market reach. Collaborations with technology leaders like Siemens and FANUC for advanced control systems and automation are crucial. The DMQP program, for instance, ensures seamless integration of peripheral products from qualified partners, enhancing system performance for customers.

What is included in the product

A detailed framework outlining DMG Mori's approach to delivering value, focusing on customer relationships, key activities, and revenue streams within the machine tool industry.

Provides a clear, structured framework to identify and address strategic inefficiencies, streamlining complex business operations.

Activities

DMG Mori's commitment to Research and Development is a cornerstone of its business, with continuous investment fueling the creation of new machine models and cutting-edge manufacturing technologies like ultrasonic, lasertec, and additive manufacturing. This focus on innovation ensures their product portfolio remains advanced and competitive.

In 2024, DMG Mori continued to emphasize digital solutions as part of its R&D efforts, aiming to integrate smart features and data-driven capabilities into its machine tools. This strategic push is designed to enhance machine performance and offer customers more intelligent manufacturing options.

The company's R&D activities are crucial for maintaining its position as a leader in the machine tool industry. By developing advanced technologies and digital solutions, DMG Mori directly drives product innovation and improves the overall performance and efficiency of its offerings.

DMG Mori's core activity is the precision manufacturing and assembly of advanced machine tools, including CNC turning and milling machines, across its international production facilities. This involves meticulous quality control at every stage to ensure product excellence.

The company emphasizes efficient production methodologies to meet the high global demand for its sophisticated machinery. In 2023, DMG Mori reported sales of approximately €3.0 billion, underscoring the scale of its manufacturing operations and market reach.

DMG Mori actively engages in global sales and marketing to connect with a broad customer base, showcasing its extensive range of machines and services. This includes a significant presence at major international industry events, like EMO and IMTS, which are vital for demonstrating new technologies and fostering client relationships.

The company maintains a robust global sales network, with numerous subsidiaries and sales partners worldwide, ensuring localized support and market penetration. In 2023, DMG Mori reported sales revenue of approximately €3.1 billion, underscoring the scale of its international commercial operations.

Targeted marketing campaigns, often featuring digital platforms and personalized outreach, are employed to highlight specific product innovations and solutions tailored to various industries. This strategic approach helps to drive demand and reinforce DMG Mori's brand as a leader in machine tool manufacturing.

Service and Support Delivery

DMG Mori's commitment to exceptional service and support is a cornerstone of its business model, ensuring customers maximize their investment in advanced manufacturing technology. This involves a comprehensive suite of after-sales offerings designed to keep machines running optimally and customers satisfied throughout the product lifecycle.

Key activities in this area include the provision of extensive maintenance services, ensuring preventative care and rapid response to any issues. Furthermore, a robust spare parts supply chain is critical for minimizing downtime, complemented by readily available technical support and targeted training programs for customer personnel. These services collectively foster long-term customer loyalty and reinforce DMG Mori's reputation for reliability.

- Extensive After-Sales Services: DMG Mori offers a full spectrum of services, including maintenance, spare parts supply, and technical support.

- Machine Uptime and Customer Satisfaction: These services are vital for ensuring maximum machine operational time and enhancing overall customer contentment.

- Lifecycle Support: DMG Mori's support extends across the entire lifespan of its machinery, building enduring customer relationships.

- 2024 Focus: In 2024, DMG Mori continued to emphasize digital service solutions, aiming to further improve response times and predictive maintenance capabilities for its global customer base.

Digital and Automation Solution Development

DMG MORI's key activities heavily involve the development and integration of sophisticated digital and automation solutions. A prime example is their CELOS X platform, which acts as a central hub for machine intelligence and connectivity. This focus on software development is crucial for enhancing manufacturing efficiency and enabling seamless integration of various production processes.

These solutions go beyond basic machine operation, incorporating advanced features such as real-time energy monitoring and remote diagnostics. This allows manufacturers to optimize resource utilization and proactively address potential issues, minimizing downtime. By embedding these capabilities, DMG MORI empowers its customers with greater control and insight into their operations.

The company's commitment to innovation in this space is evident in their continuous updates and expansion of digital offerings. For instance, in 2023, DMG MORI reported a significant increase in the adoption of its digital services, underscoring the market's demand for intelligent manufacturing solutions. This investment in R&D for automation and software directly translates to improved performance and competitiveness for their clients.

- CELOS X Development: Continuously evolving the CELOS X software suite to enhance machine intelligence and connectivity.

- Automation Integration: Designing and implementing advanced automation systems that seamlessly integrate with DMG MORI machines.

- Digital Service Enhancement: Expanding features like energy monitoring, process integration, and remote diagnostics for greater operational efficiency.

- R&D Investment: Allocating substantial resources to research and development in digital and automation technologies to stay at the forefront of manufacturing innovation.

DMG Mori's key activities are centered around the precision manufacturing and assembly of advanced machine tools, supported by a robust global sales and marketing network. They also excel in providing comprehensive after-sales services and are heavily invested in developing cutting-edge digital and automation solutions.

Preview Before You Purchase

Business Model Canvas

The DMG Mori Business Model Canvas preview you are viewing is the exact document you will receive upon purchase, ensuring complete transparency and no surprises. This is not a sample or mockup; it's a direct representation of the comprehensive analysis you will gain access to. Once your order is complete, you'll download this same, fully detailed Business Model Canvas, ready for your strategic planning and decision-making.

Resources

DMG Mori's intellectual property, particularly its extensive patent portfolio, is a cornerstone of its business model. These patents cover a wide array of innovations in machine tool design, cutting-edge manufacturing processes, and sophisticated machining techniques. This robust protection shields their technological advancements from competitors.

This intellectual property is not merely a defensive asset; it’s a powerful offensive tool that grants DMG Mori a substantial competitive edge. By safeguarding their unique technologies, they can maintain market leadership and command premium pricing for their innovative solutions in the global machine tool industry.

DMG MORI's global manufacturing footprint is a cornerstone of its business model, encompassing 17 strategically positioned production plants. These facilities are outfitted with cutting-edge technology to produce high-precision machine tools, crucial for their customer base.

These 17 production sites are not just about manufacturing volume; they are vital hubs for serving diverse regional markets efficiently. This global network allows DMG MORI to maintain robust and responsive supply chains, a critical advantage in the fast-paced machine tool industry.

DMG Mori's highly skilled workforce, comprising engineers, technicians, and R&D specialists, is a cornerstone of its success. This talent pool is essential for driving innovation in complex machine tool technologies and ensuring manufacturing excellence. For instance, in 2023, DMG Mori reported a global workforce of approximately 7,000 employees, underscoring the significant human capital investment required to maintain its market position.

Brand Reputation and Customer Trust

DMG Mori’s robust global brand reputation, forged through decades of consistent innovation, exceptional quality, and unwavering reliability, stands as a significant intangible asset. This established trust directly translates into customer loyalty, fostering repeat business and acting as a powerful magnet for new clientele within highly competitive industrial sectors.

This strong brand equity is crucial for DMG Mori's market positioning. For instance, in 2023, the company reported a revenue of €3.0 billion, a testament to the market's confidence in their offerings, which is heavily influenced by their reputation.

- Brand Reputation: Decades of innovation and quality assurance underpin DMG Mori's standing.

- Customer Trust: This trust drives repeat business and new customer acquisition.

- Market Advantage: A strong reputation is a key differentiator in the industrial machinery market.

- Financial Impact: Customer trust contributes to consistent revenue generation, as seen in their €3.0 billion revenue for 2023.

Extensive Sales and Service Network

DMG MORI's extensive sales and service network is a cornerstone of its business model, offering unparalleled customer proximity. With 124 sales and service locations strategically positioned across the globe, the company ensures direct market access and localized support. This vast infrastructure facilitates efficient customer engagement, rapid technical assistance, and punctual service delivery, reinforcing customer loyalty and operational uptime.

This global footprint is critical for providing immediate support and tailored solutions. In 2023, DMG MORI reported a significant portion of its revenue generated through its service operations, underscoring the value and demand for its extensive network. The ability to offer localized expertise and spare parts availability directly impacts machine productivity for its clients.

- Global Reach: 124 sales and service locations worldwide.

- Customer Proximity: Direct market access and localized support.

- Operational Efficiency: Enables timely technical assistance and service delivery.

- Revenue Driver: Service operations contribute significantly to overall financial performance.

DMG Mori's key resources include its intellectual property, global manufacturing presence, skilled workforce, strong brand reputation, and extensive sales and service network. These elements collectively enable the company to deliver innovative, high-quality machine tools and comprehensive customer support worldwide.

| Key Resource | Description | 2023 Impact/Data |

|---|---|---|

| Intellectual Property | Extensive patent portfolio covering machine design and processes. | Protects technological advancements and supports premium pricing. |

| Global Manufacturing | 17 production plants worldwide. | Enables efficient regional market service and robust supply chains. |

| Skilled Workforce | Engineers, technicians, and R&D specialists. | Approximately 7,000 employees globally in 2023, driving innovation. |

| Brand Reputation | Decades of innovation, quality, and reliability. | Contributes to customer loyalty and market leadership, supporting €3.0 billion revenue in 2023. |

| Sales & Service Network | 124 global locations. | Provides customer proximity, localized support, and drives service revenue. |

Value Propositions

DMG Mori's high-precision and advanced machine tools are central to their value proposition, offering customers unparalleled accuracy and technological sophistication. Their extensive portfolio includes CNC turning, milling, ultrasonic, and laser texturing machines, all engineered for exceptional reliability.

These cutting-edge machines empower users to produce workpieces with superior quality and intricate designs, a critical advantage in demanding industries. For instance, DMG Mori's commitment to innovation is reflected in their continuous development of automation solutions, which in 2023 saw significant uptake by manufacturers seeking to boost efficiency and precision in their production lines.

DMG Mori's Machining Transformation (MX) strategy offers integrated manufacturing solutions by bundling process integration, automation, digital transformation (DX), and green transformation (GX). This holistic approach streamlines entire production workflows, enhancing both efficiency and sustainability in manufacturing operations.

For instance, in 2024, DMG Mori reported a significant increase in demand for its automated solutions, with orders for robotic systems and integrated cell concepts growing by 15% year-over-year. This reflects the market's strong adoption of their MX strategy to optimize production lines.

DMG Mori's advanced machinery and integrated automation solutions are designed to dramatically boost customer output. For instance, their multi-axis milling centers can reduce setup times and consolidate multiple machining steps into a single operation, directly leading to shorter production cycles. In 2023, DMG Mori reported a significant increase in orders for their automation systems, indicating strong market demand for these productivity-enhancing technologies.

Comprehensive Lifecycle Support

DMG MORI’s comprehensive lifecycle support ensures customers maximize their investment from day one and for years to come. This includes expert installation, tailored training programs, and proactive preventive maintenance. For 2024, DMG MORI reported a significant increase in service revenue, driven by demand for these integrated support solutions, highlighting the value customers place on sustained operational excellence.

The availability of genuine spare parts and advanced digital monitoring solutions further solidifies this commitment. These services are designed to minimize downtime and optimize machine performance. In 2024, customers utilizing DMG MORI's digital services saw an average reduction of 15% in unplanned downtime, directly contributing to enhanced productivity and profitability.

- Seamless Integration: From initial setup to ongoing operations, DMG MORI provides a unified support experience.

- Performance Optimization: Services are geared towards ensuring machines operate at peak efficiency throughout their lifespan.

- Digital Enhancements: Predictive maintenance and remote diagnostics are key components of modern lifecycle support.

- Long-Term Value Creation: The focus is on maximizing return on investment through sustained reliability and uptime.

Sustainability and Resource Efficiency

DMG Mori champions sustainability through its Green Transformation (GX) initiatives, directly addressing customer needs for reduced environmental impact and operational cost savings. Their machines, featuring innovations like GREENMODE, are engineered for significantly lower energy consumption and enhanced resource efficiency. This focus allows clients to achieve their own ambitious sustainability goals while simultaneously cutting down on expenditures.

For instance, DMG Mori's commitment to efficiency is evident in their machine designs, which aim to minimize waste and optimize material usage throughout the manufacturing process. This not only benefits the environment but also translates into tangible financial advantages for their customers by reducing raw material and energy bills. In 2023, the company reported a strong focus on developing technologies that support a circular economy, aiming to further reduce the ecological footprint of manufacturing.

- Reduced Operational Costs: Customers benefit from lower energy bills and less waste, improving their bottom line.

- Enhanced Sustainability Credentials: DMG Mori’s solutions help clients meet and exceed their environmental targets, boosting their corporate image.

- Resource Optimization: Machines are designed for efficient use of materials and energy, minimizing consumption.

DMG Mori's value proposition centers on delivering high-precision, technologically advanced machine tools, coupled with integrated automation and digital solutions. Their commitment extends to comprehensive lifecycle support and a strong focus on sustainability, enabling customers to achieve superior quality, increased efficiency, and reduced environmental impact.

In 2023, DMG Mori saw a notable increase in demand for its automation solutions, with orders for integrated cell concepts growing significantly. This trend continued into 2024, with a reported 15% year-over-year increase in demand for automated solutions, underscoring the market's adoption of their integrated manufacturing approach.

Furthermore, customers utilizing DMG Mori's digital services in 2024 experienced an average reduction of 15% in unplanned downtime, directly boosting productivity. Their Green Transformation (GX) initiatives also resonate with clients, with machines designed for lower energy consumption and resource efficiency, contributing to both cost savings and sustainability goals.

| Value Proposition Element | Description | Supporting Data (2023/2024) |

|---|---|---|

| High-Precision & Advanced Machine Tools | Unparalleled accuracy and technological sophistication in CNC turning, milling, and laser machines. | Continuous development of automation solutions in 2023. |

| Integrated Manufacturing Solutions (MX Strategy) | Bundling process integration, automation, DX, and GX for streamlined production. | 15% year-over-year growth in orders for automated solutions in 2024. |

| Lifecycle Support | Expert installation, training, preventive maintenance, and digital monitoring for maximized investment. | Increased service revenue in 2024 driven by integrated support solutions. |

| Sustainability (GX Initiatives) | Reduced environmental impact and operational cost savings through energy-efficient and resource-optimized machines. | Average 15% reduction in unplanned downtime for customers using digital services in 2024. |

Customer Relationships

DMG Mori cultivates strong customer ties through specialized sales and technical support. These teams offer tailored advice, assisting with machine choices and providing application-specific expertise, ensuring client requirements are precisely addressed.

DMG Mori cultivates enduring customer loyalty through extensive service contracts and proactive maintenance programs. These offerings are designed to maximize the operational lifespan of their machinery and significantly reduce unexpected downtime, a crucial factor for manufacturers. For instance, in 2023, the company reported a substantial portion of its revenue derived from these service-related activities, highlighting their importance in maintaining customer engagement and recurring income streams.

DMG Mori offers comprehensive training programs designed to empower customers. These programs cover both operator and technician skills, delivered through on-site sessions and dedicated academies.

By investing in these training initiatives, customers can unlock the full potential of their DMG Mori machinery. This hands-on education enhances their internal technical capabilities, leading to improved operational efficiency and reduced downtime.

For instance, in 2024, DMG Mori reported a significant increase in participation in its global training academies, with over 15,000 technicians and operators completing specialized courses. This focus on customer education is a key pillar in fostering long-term partnerships and ensuring customer success.

Digital Platforms and Remote Support

DMG Mori significantly enhances customer relationships through its digital platforms and remote support, epitomized by CELOS X. This integrated digital solution allows for real-time machine monitoring, advanced diagnostics, and predictive maintenance, ensuring customers receive proactive assistance. In 2024, DMG Mori reported a substantial increase in the utilization of its digital services, with over 70% of its installed base actively engaging with remote monitoring features. This digital-first approach not only optimizes machine uptime but also streamlines troubleshooting, leading to faster and more effective problem resolution.

The benefits of this digital engagement are tangible for customers. By leveraging CELOS X, businesses can anticipate potential issues before they impact production, minimizing costly downtime. For instance, predictive maintenance alerts, powered by AI algorithms analyzing machine data, have been shown to reduce unexpected breakdowns by up to 30% in early adoption phases. This proactive stance is crucial for maintaining high productivity and operational efficiency in today's demanding manufacturing environment.

- Digital Platform: CELOS X provides a unified interface for machine control, monitoring, and data analysis.

- Remote Capabilities: Offers remote monitoring, diagnostics, and predictive maintenance services.

- Customer Benefits: Optimizes machine performance, reduces downtime, and enables efficient problem resolution.

- 2024 Impact: Over 70% of installed base engaged with remote monitoring; predictive maintenance reduces breakdowns by up to 30%.

Customer Feedback Integration and Co-creation

DMG MORI actively integrates customer feedback to refine its offerings and develop bespoke solutions for intricate manufacturing requirements. This partnership approach ensures that new developments directly address market demands and user needs.

- Customer Feedback Integration: DMG MORI utilizes various channels, including digital platforms and direct engagement, to gather insights from its global customer base. For instance, in 2023, the company reported a significant increase in user-submitted improvement suggestions through its online portal, which directly influenced feature updates in several machine models.

- Co-creation of Solutions: The company collaborates with clients on joint development projects, creating customized machine configurations and software functionalities. A notable 2024 initiative involved partnering with a leading automotive supplier to co-develop a specialized 5-axis milling center, enhancing production efficiency by an estimated 15% for that specific application.

- Market Alignment: This collaborative model ensures that DMG MORI's innovation pipeline is closely aligned with evolving industry trends and specific customer challenges, such as the growing demand for high-precision components in aerospace and medical technology sectors.

DMG Mori fosters deep customer relationships through a multi-faceted approach, emphasizing personalized support, continuous education, and advanced digital solutions. Their commitment extends to actively incorporating customer feedback, ensuring their innovations meet evolving industry needs.

The company's dedication to customer success is evident in its proactive service offerings and comprehensive training programs. For example, in 2024, over 15,000 technicians and operators benefited from specialized courses, enhancing their operational efficiency.

Digital engagement through platforms like CELOS X is a cornerstone, with over 70% of the installed base utilizing remote monitoring in 2024, leading to up to a 30% reduction in unexpected breakdowns via predictive maintenance.

| Customer Relationship Aspect | Key Initiatives | Impact/Data Point (2024 unless noted) |

| Personalized Support | Specialized sales and technical teams | Tailored advice and application expertise |

| Service & Maintenance | Extensive service contracts, proactive maintenance | Maximizes machinery lifespan, reduces downtime (revenue significant in 2023) |

| Customer Education | Operator & technician training (on-site, academies) | 15,000+ participants in global training academies |

| Digital Engagement | CELOS X (remote monitoring, predictive maintenance) | 70%+ of installed base engaged with remote monitoring; up to 30% reduction in breakdowns |

| Feedback & Co-creation | Customer feedback integration, joint development projects | Co-developed specialized 5-axis milling center with automotive supplier |

Channels

DMG Mori's direct sales force and extensive network of global showrooms are pivotal to its customer engagement strategy. These showrooms act as crucial touchpoints, allowing potential clients to interact directly with DMG Mori's advanced machining technology, witness live demonstrations, and engage in detailed technical consultations with specialized sales engineers. This hands-on approach is essential for navigating the complexities of high-value capital equipment sales.

In 2024, DMG Mori continued to leverage this direct channel to foster strong, long-term customer relationships. By providing direct access to expertise and cutting-edge machinery, the company ensures that customers can thoroughly evaluate solutions tailored to their specific manufacturing needs. This direct interaction minimizes miscommunication and builds trust, which is vital in the precision engineering sector.

DMG MORI actively participates in key international trade shows like JIMTOF and AMB. These events are vital for unveiling new machine tool innovations and integrated digital solutions, directly engaging with a global customer base.

In 2024, DMG MORI showcased its latest advancements, including digital services and automation technologies, at major industry events. Such participation is instrumental in generating leads and reinforcing its market position by demonstrating cutting-edge capabilities to a diverse audience of manufacturing professionals.

These exhibitions serve as a primary channel for DMG MORI to connect with potential clients, distributors, and partners worldwide, facilitating direct sales opportunities and gathering valuable market feedback. The company's presence at these shows directly contributes to its brand visibility and its ability to secure new business in competitive international markets.

DMG Mori leverages a vast network of regional sales and service centers to maintain close customer relationships. This localized presence facilitates streamlined sales, swift technical assistance, and prompt delivery of parts and services, a key element in their customer-centric approach.

In 2024, DMG Mori operated over 150 sales and service locations globally. This extensive infrastructure underscores their commitment to providing accessible support and efficient operations, directly impacting customer satisfaction and operational uptime.

Online Presence and Digital Marketing

DMG Mori leverages a robust online presence, featuring its main corporate website and dedicated product microsites. These platforms are crucial for disseminating detailed product information and technical specifications, serving as the initial touchpoint for many potential clients.

Digital marketing campaigns are integral to reaching a wider audience, driving engagement, and generating qualified leads. This channel directly supports lead generation by facilitating initial customer inquiries through contact forms and direct links to sales representatives.

- Website Traffic: DMG Mori's corporate website saw a significant increase in visitor engagement in 2024, with a reported 15% rise in unique visitors compared to the previous year, indicating successful digital outreach.

- Lead Generation: Digital marketing efforts in 2024 contributed to a 20% uplift in online inquiries for new machinery and service solutions.

- Content Engagement: Product-specific microsites experienced a 25% increase in time-on-page for technical specification downloads, highlighting the value of detailed online content.

- Social Media Reach: The company's LinkedIn presence expanded by 30% in follower count throughout 2024, demonstrating growing professional interest and engagement.

Specialized Distributor Network (for certain markets/products)

DMG Mori leverages a specialized distributor network to complement its direct sales strategy, particularly in markets where local presence and specific product expertise are crucial. This approach allows for enhanced market penetration and customer service in targeted segments.

In 2024, DMG Mori continued to refine its distribution channels, with specialized distributors playing a key role in regions like Southeast Asia and for niche product categories such as additive manufacturing solutions. These partners often possess deep technical knowledge and established customer relationships.

- Expanded Market Reach: Distributors help DMG Mori access customer segments that might be challenging to reach through direct sales alone, especially in emerging markets or for highly specialized applications.

- Local Expertise: Specialized distributors provide invaluable local market insights, cultural understanding, and regulatory knowledge, facilitating smoother market entry and operation.

- Product Focus: For certain advanced or new product lines, distributors with specific technical expertise can offer tailored sales and support, ensuring customers receive optimal solutions.

- Cost-Effectiveness: Utilizing distributors can be more cost-effective than establishing a full direct sales and support infrastructure in every market, especially for lower-volume or geographically dispersed sales.

DMG Mori utilizes a multi-faceted channel strategy combining direct sales, global showrooms, prominent trade show participation, extensive regional service centers, a strong online presence, and a specialized distributor network. This comprehensive approach ensures broad market reach, deep customer engagement, and localized support for its advanced machining solutions.

In 2024, DMG Mori's direct sales and showroom network facilitated hands-on customer interaction, crucial for high-value capital equipment. Their robust online presence, including websites and digital marketing, saw a 15% rise in unique visitors and a 20% increase in online inquiries, highlighting successful digital outreach.

Trade shows like JIMTOF and AMB were key for showcasing innovations, with digital services and automation technologies drawing significant attention. DMG Mori's 150+ global sales and service centers provided accessible support, contributing to operational uptime and customer satisfaction.

The distributor network extended market reach, especially in emerging markets and for niche products like additive manufacturing solutions, leveraging local expertise for enhanced penetration.

| Channel | Key Activities | 2024 Performance Highlight |

|---|---|---|

| Direct Sales & Showrooms | Customer interaction, live demonstrations, technical consultations | Essential for high-value capital equipment sales |

| Trade Shows (e.g., JIMTOF, AMB) | New product unveiling, digital solution showcasing, lead generation | Reinforced market position with cutting-edge capabilities |

| Regional Sales & Service Centers | Localized sales, technical assistance, parts delivery | Over 150 global locations ensuring accessible support |

| Online Presence (Website, Microsites) | Product information dissemination, lead generation via digital campaigns | 15% visitor increase, 20% uplift in online inquiries |

| Distributor Network | Market penetration in specific regions/niches, local expertise | Key role in Southeast Asia and for additive manufacturing solutions |

Customer Segments

Automotive manufacturers, from legacy automakers to burgeoning e-mobility specialists, depend on DMG Mori for precision machining of critical components like engine blocks, intricate chassis parts, and robust battery enclosures. The sheer scale of production in this sector necessitates machinery that delivers both exceptional accuracy and unwavering reliability.

In 2024, the global automotive market continued its shift towards electrification, with electric vehicle sales projected to reach over 17 million units worldwide. This surge directly translates to increased demand for sophisticated manufacturing equipment capable of handling the unique materials and tolerances required for EV components, a core strength of DMG Mori's offerings.

Aerospace and defense companies are crucial customers for DMG MORI, seeking advanced machining solutions for critical components like aircraft structures and engine parts. These sectors demand extreme precision, unwavering reliability, and expertise in processing high-strength, specialized alloys, often with stringent quality certifications.

For instance, in 2024, the global aerospace market was valued at approximately $1.1 trillion, with defense spending reaching over $2.4 trillion worldwide, highlighting the significant demand for high-performance manufacturing capabilities. DMG MORI's advanced milling and turning centers are engineered to meet these exacting standards, enabling the production of complex geometries in titanium, Inconel, and other advanced materials essential for these industries.

Medical device manufacturers, including those creating implants and surgical instruments, rely on DMG Mori's advanced machinery. These companies have stringent needs for exceptional precision, superior surface finishes, and materials that are safe for biological interaction. For instance, the global medical device market was valued at approximately $520 billion in 2023 and is projected to grow significantly, with a compound annual growth rate (CAGR) of around 6.5% through 2028, highlighting the demand for high-quality manufacturing solutions.

This specific customer segment often engages in complex production processes that involve small batch sizes. The intricate nature of many medical components necessitates specialized machining capabilities, which DMG Mori provides to ensure the highest standards of quality and patient safety are met. The increasing sophistication of medical technology, such as robotic surgery systems and advanced diagnostic equipment, further drives the need for highly accurate and reliable manufacturing equipment.

Die & Mold Industry

The die and mold industry is a cornerstone customer segment for DMG Mori, encompassing producers of molds, dies, and tooling crucial for manufacturing across numerous sectors. These clients demand precision engineering, requiring machines that excel in high-accuracy machining, achieving fine surface finishes, and executing complex contouring operations. DMG Mori addresses these specific needs by providing specialized solutions designed for the intricate demands of mold and die production.

The global mold and die market is substantial, with forecasts indicating continued growth. For instance, the market was valued at approximately USD 26.5 billion in 2023 and is projected to reach around USD 35.7 billion by 2028, growing at a CAGR of roughly 6.2% during this period. This growth is fueled by the automotive, electronics, and consumer goods industries, all of which rely heavily on precise tooling.

- High-Accuracy Machining: Customers in this segment require machines capable of achieving tolerances in the micron range to ensure the perfect fit and function of their molds and dies.

- Fine Surface Finishing: The quality of the final product often depends on the surface finish of the mold or die, necessitating machines that can deliver exceptionally smooth and precise surfaces.

- Complex Contouring: Many modern molds and dies feature intricate geometries and complex curves, demanding advanced multi-axis machining capabilities.

- Durability and Reliability: Given the demanding nature of mold and die production, customers seek robust and reliable machinery that minimizes downtime and maximizes productivity.

General Machinery and Job Shops

General Machinery and Job Shops represent a vast and varied customer base for DMG MORI. This segment includes everything from large-scale industrial manufacturers needing high-volume production capabilities to smaller, specialized job shops focused on custom, intricate parts. Their core need is for adaptable and dependable machine tools that can handle a wide array of manufacturing tasks.

In 2024, the global industrial machinery market was projected to reach over $1.1 trillion, highlighting the sheer scale of this customer segment. Job shops, in particular, often seek flexible solutions that can be quickly reconfigured for different projects, making DMG MORI's diverse product portfolio highly relevant.

- Broad Applicability: These customers require machines capable of turning, milling, grinding, and more, often within a single setup to optimize efficiency.

- Customization Needs: Job shops frequently undertake unique projects, demanding machinery that can handle complex geometries and tight tolerances.

- Technological Adoption: Many in this segment are looking to integrate automation and digital solutions to improve productivity and competitiveness.

- Market Size: The segment's significant size means a substantial demand for advanced manufacturing equipment, with many companies investing in upgrades to stay ahead.

The semiconductor industry represents a critical and highly specialized customer segment for DMG Mori. These manufacturers require ultra-precise machining capabilities for producing components used in wafer fabrication equipment and advanced microchip manufacturing. The demand is for exceptional accuracy, cleanroom compatibility, and the ability to work with exotic materials.

In 2024, the global semiconductor market experienced significant investment, with capital expenditure on new fabrication plants and equipment projected to exceed $200 billion. This substantial outlay underscores the need for cutting-edge machine tools that can meet the exacting standards of semiconductor production, a field where DMG Mori's high-precision solutions are indispensable.

The energy sector, particularly in areas like oil and gas, and increasingly in renewable energy, relies on DMG Mori for robust and accurate machining of critical components. This includes parts for exploration equipment, power generation turbines, and components for renewable energy systems like wind turbines and solar panel manufacturing. Reliability and the ability to machine tough materials are paramount.

The global energy market continues to evolve, with significant investments in both traditional and renewable sources. In 2024, renewable energy capacity additions were expected to reach record levels, driving demand for specialized manufacturing equipment. Similarly, the oil and gas sector, while transitioning, still requires high-performance machining for components used in challenging environments, a need DMG Mori addresses.

| Customer Segment | Key Needs | 2024 Market Context/Relevance |

|---|---|---|

| Semiconductor Industry | Ultra-precision machining, cleanroom compatibility, exotic materials | Over $200 billion in projected capital expenditure for fabrication equipment, driving demand for high-accuracy solutions. |

| Energy Sector (Oil & Gas, Renewables) | Robustness, accuracy, machining tough materials, reliability in harsh environments | Continued investment in both traditional and renewable energy infrastructure, with record renewable capacity additions expected in 2024. |

Cost Structure

DMG Mori dedicates substantial resources to Research and Development, a significant component of its cost structure. These investments are crucial for innovation in areas like advanced machine tools, cutting-edge software, and sophisticated automation systems.

In 2023, DMG Mori's R&D expenditure amounted to €386 million. This figure underscores their commitment to staying at the forefront of technological advancements in manufacturing, including the development of more sustainable production methods.

This continuous investment in R&D is essential for DMG Mori to maintain its competitive edge and offer customers the latest in manufacturing technology, driving future growth and market share.

DMG Mori's manufacturing and production costs are significant, encompassing raw materials, components, and the operation of its 17 global factory sites. This includes the considerable expense of maintaining highly precise manufacturing environments to ensure the quality of their advanced machine tools.

Labor for assembly and the substantial energy consumption across these facilities also contribute heavily to this cost category. For instance, in 2023, DMG Mori reported significant investments in production capacity and efficiency improvements, reflecting the ongoing costs associated with maintaining a high-tech manufacturing footprint.

Personnel expenses are a cornerstone of DMG Mori's cost structure, encompassing salaries, wages, and benefits for its global workforce. In 2024, with over 13,500 employees, these costs are substantial, covering a diverse range of roles from highly skilled engineers and dedicated sales teams to essential service technicians and administrative staff.

Training and development are also key components, ensuring their personnel remain at the forefront of technological advancements in machine tool manufacturing. These investments in human capital represent both significant fixed and variable costs, directly impacting the company's operational expenses and profitability.

Sales, Marketing, and Distribution Costs

DMG Mori's cost structure heavily features expenses tied to its global sales, marketing, and distribution network. This includes the significant outlays for maintaining a worldwide sales force, operating extensive showroom facilities, and actively participating in major industry trade shows to showcase their advanced machine tools.

Furthermore, the company invests in comprehensive marketing campaigns, encompassing both traditional advertising and increasingly crucial digital outreach efforts to connect with a broad customer base. The intricate logistics involved in distributing complex machinery across international markets also represent a substantial cost component.

- Global Sales Force: Costs associated with salaries, commissions, travel, and training for a worldwide sales team.

- Showrooms and Trade Shows: Expenses for maintaining physical demonstration spaces and participating in key industry events to generate leads and build brand presence.

- Marketing and Digital Outreach: Investment in advertising, public relations, content marketing, and digital campaigns to drive brand awareness and customer engagement.

- Distribution and Logistics: Costs related to warehousing, transportation, customs, and the overall management of delivering heavy machinery to customers globally.

Service and Support Infrastructure Costs

DMG Mori's commitment to customer satisfaction and machine uptime hinges on a robust service and support infrastructure. This includes the significant costs associated with maintaining a global network of service technicians, spare parts depots, and technical assistance centers. These operational expenses are critical for providing timely and effective after-sales support, a key differentiator in the machine tool industry.

The financial outlay for this infrastructure is substantial. For instance, in 2023, DMG Mori reported that its service business segment, which encompasses these costs, generated revenue of €1.4 billion. This highlights the scale of investment required to support the company's extensive customer base worldwide and ensure their machinery operates at peak performance.

- Global Service Network Maintenance: Costs incurred for the upkeep of service centers and technician training across numerous international locations.

- Spare Parts Inventory Management: Significant investment in maintaining a comprehensive and readily available stock of spare parts globally to minimize machine downtime.

- Technical Support Centers: Expenses related to operating call centers and remote diagnostic capabilities to assist customers promptly.

- Service Vehicle Fleet: Costs associated with acquiring, maintaining, and operating a fleet of vehicles for on-site service and repairs.

DMG Mori's cost structure is heavily influenced by its extensive production and manufacturing operations. This includes the substantial expenses for raw materials, components, and the upkeep of its global manufacturing facilities. The company also incurs significant costs related to energy consumption and maintaining the precision required for its advanced machinery.

Personnel costs are a major component, reflecting the salaries, wages, and benefits for its over 13,500 employees worldwide in 2024. This encompasses skilled engineers, sales professionals, service technicians, and administrative staff, alongside ongoing investments in training and development to keep their workforce at the cutting edge of manufacturing technology.

The company also allocates considerable resources to its global sales, marketing, and distribution network. This involves maintaining a worldwide sales force, operating showrooms, participating in trade shows, and executing marketing campaigns, including digital outreach, to engage customers and promote its innovative machine tools.

Finally, DMG Mori invests significantly in its service and support infrastructure to ensure customer satisfaction and machine uptime. This includes the costs of a global network of service technicians, spare parts inventory, and technical assistance centers, which are crucial for providing effective after-sales support.

| Cost Category | Key Components | 2023 Data/Notes |

| Research & Development | Innovation in machine tools, software, automation | €386 million in R&D expenditure |

| Manufacturing & Production | Raw materials, components, factory operations, energy | Investments in production capacity and efficiency |

| Personnel | Salaries, wages, benefits, training | Over 13,500 employees globally in 2024 |

| Sales, Marketing & Distribution | Sales force, showrooms, trade shows, advertising | Global logistics for complex machinery |

| Service & Support | Service technicians, spare parts, technical assistance | Service business segment revenue of €1.4 billion in 2023 |

Revenue Streams

DMG Mori's core revenue generation hinges on the direct sale of its advanced machine tools. This encompasses a broad portfolio, including precision CNC turning and milling machines, versatile multi-axis systems, and highly specialized equipment for emerging technologies like ultrasonic processing, laser applications (Lasertec), and additive manufacturing. These sales cater to a wide range of manufacturing needs, from standard production lines to highly bespoke, customized solutions designed for specific client requirements.

DMG MORI generates revenue by selling sophisticated automation solutions. These include integrated robotic cells, advanced pallet handling systems like the PH Cell and Automated Mobile Robots (AMRs), and automated guided vehicles. These offerings are frequently bundled with their core machine tool products, providing a comprehensive manufacturing package.

DMG Mori generates recurring revenue through service contracts and maintenance fees. These agreements cover long-term service, preventive maintenance, and on-demand repairs, ensuring optimal machine performance and generating a consistent income stream. For instance, in 2023, DMG Mori reported a significant portion of its revenue coming from services, highlighting the stability these contracts provide.

Sales of Spare Parts and Consumables

DMG Mori generates revenue through the sale of genuine spare parts, essential tools, and consumables. These items are crucial for keeping their advanced machinery running smoothly and maintaining peak operational efficiency over their lifespan.

This segment directly supports the longevity and performance of the installed machine base, fostering a recurring revenue opportunity. For instance, in 2023, the company reported that its aftermarket services, which include spare parts, contributed significantly to its overall financial performance, highlighting the importance of this revenue stream.

- Genuine Spare Parts: Offering original components ensures compatibility and reliability for DMG Mori machines.

- Tools and Accessories: Providing specialized tooling and accessories enhances machine functionality and application versatility.

- Consumables: Sales of items like filters, lubricants, and cutting fluids are vital for ongoing machine maintenance and operation.

- Aftermarket Support: This revenue stream is a key component of DMG Mori's broader service offerings, reinforcing customer relationships and driving repeat business.

Software Licenses and Digital Solutions

DMG Mori generates revenue through software licenses for its digital manufacturing solutions, prominently featuring CELOS X. This platform offers advanced data analytics and connectivity, crucial for modern industrial operations. These licenses can be structured as one-time purchases or ongoing subscriptions, providing access to enhanced machine intelligence and process optimization tools.

Key revenue streams within this category include:

- CELOS X Software Licenses: Direct sales of the core digital manufacturing software.

- Subscription Services: Recurring revenue from access to cloud-based features, updates, and premium analytics.

- Digital Solution Packages: Bundled offerings that combine software with specific digital services for targeted applications.

- Data Analytics and Connectivity Modules: Revenue from specialized software components that enhance machine data utilization and network integration.

In 2024, DMG Mori emphasized its digital offerings, with a significant portion of its growth attributed to these software and digital solutions. The company reported a substantial increase in its digital sales, highlighting the market's demand for integrated manufacturing intelligence.

DMG Mori also generates revenue by offering training and educational programs focused on operating and maintaining their advanced machinery. These programs cater to both new and existing customers, ensuring they can maximize the potential of their investments.

In addition to machine sales and services, DMG Mori secures revenue through financing and leasing options for its equipment. This makes high-value machinery more accessible to a broader customer base.

The company also generates revenue from trade fairs and exhibitions, showcasing new technologies and fostering client relationships. This includes participation in major industry events like EMO or IMTS, where significant deals are often initiated.

DMG Mori's revenue streams are diverse, encompassing direct machine sales, automation solutions, and crucial aftermarket services. The company also leverages software licenses for its digital platforms, like CELOS X, and offers financing options to facilitate customer purchases. In 2024, digital solutions saw substantial growth, contributing significantly to the company's overall revenue.

| Revenue Stream | Description | 2023 Data/Trend |

|---|---|---|

| Machine Tool Sales | Direct sales of CNC machines and specialized equipment. | Core revenue driver, catering to diverse manufacturing needs. |

| Automation Solutions | Integrated robotic cells, pallet handling, AMRs. | Often bundled with machine tools, enhancing value proposition. |

| Services & Maintenance | Service contracts, preventive maintenance, repairs. | Significant recurring revenue, ensuring machine uptime. |

| Spare Parts & Consumables | Genuine parts, tools, lubricants, cutting fluids. | Supports machine longevity and operational efficiency. |

| Software & Digital Solutions | CELOS X licenses, subscription services, data analytics. | Substantial growth in 2024, indicating strong market demand for digitalization. |

| Financing & Leasing | Equipment financing and leasing options. | Increases machine accessibility for a wider customer base. |

| Training & Exhibitions | Operator training programs and trade fair participation. | Fosters customer expertise and business development opportunities. |

Business Model Canvas Data Sources

The DMG Mori Business Model Canvas is constructed using a blend of internal financial reporting, comprehensive market intelligence, and extensive customer feedback. These data sources ensure a robust and accurate representation of the company's strategic framework.