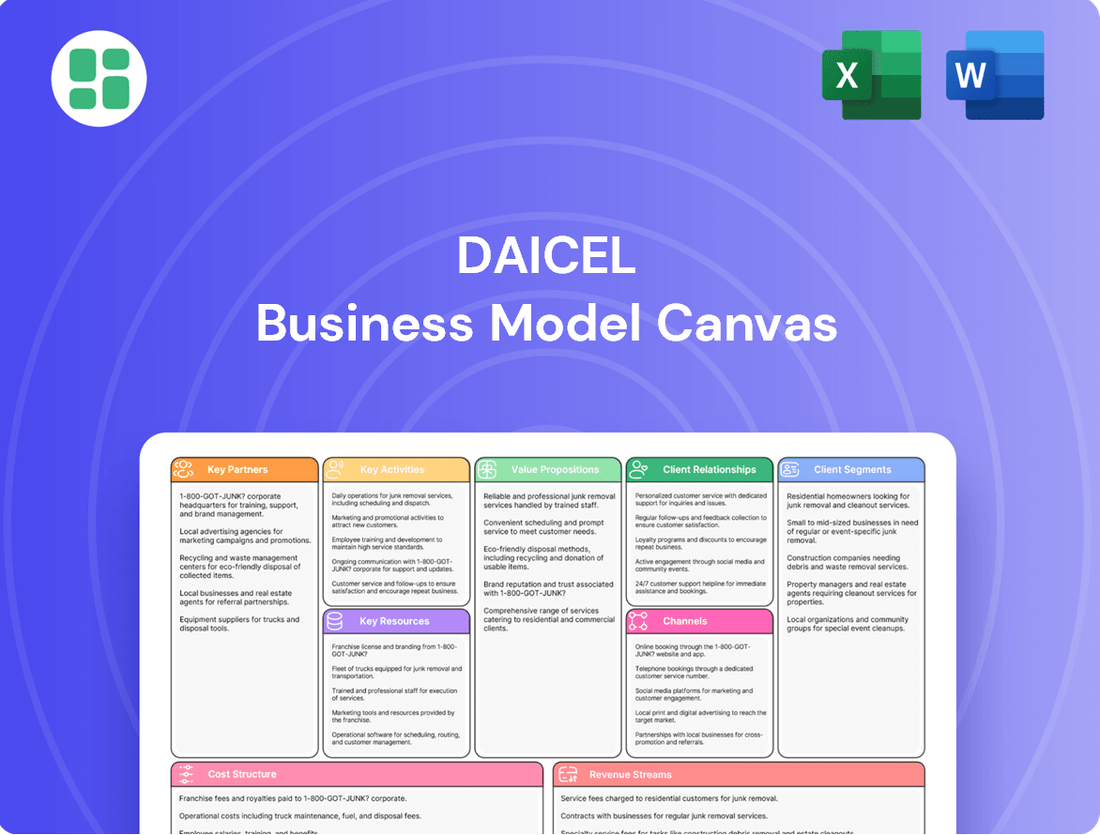

Daicel Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Daicel Bundle

Uncover the intricate workings of Daicel's success with our comprehensive Business Model Canvas. This detailed analysis breaks down their customer relationships, revenue streams, and key resources, offering a clear roadmap to their market dominance. Dive into the strategic blueprint that fuels their innovation and growth.

Partnerships

Daicel actively forms strategic alliances with technology partners and research institutions to drive innovation in advanced materials and chemical solutions.

These partnerships enable co-development of new products and processes, crucial for maintaining a competitive edge in rapidly evolving industries. For instance, Daicel's collaboration with universities on biodegradable plastics research aims to address growing environmental concerns, a market segment projected to reach $10.5 billion by 2027.

Such collaborations often focus on areas like biodegradable plastics and next-generation safety systems, with Daicel investing significantly in R&D to foster these joint ventures.

Daicel strategically forms joint ventures to broaden its market reach and diversify its offerings. A prime example is Novacel Co., Ltd., a collaboration with Inabata & Co., Ltd., aimed at strengthening their resin coloring and compounding operations. These partnerships are crucial for accessing new markets and leveraging specialized knowledge.

Daicel's operational backbone relies heavily on its key partnerships with raw material suppliers, ensuring a steady flow of essential components like cellulose derivatives, organic chemicals, and specialized plastics. These relationships are vital for maintaining production consistency and quality across its diverse product lines.

Complementing its supply chain, Daicel collaborates with robust logistics partners, facilitating the efficient global distribution of its chemical products to a wide array of industrial customers. In 2023, Daicel's Chemicals segment, which includes these core materials, reported net sales of ¥205.5 billion, highlighting the scale of operations supported by these partnerships.

Automotive OEM and Tier-1 Collaborations

Daicel’s strategic alliances with automotive Original Equipment Manufacturers (OEMs) and Tier-1 suppliers are fundamental to its business. These partnerships are crucial for the co-development and seamless integration of Daicel’s advanced safety components, including airbag inflators and seatbelt pretensioners, directly into new vehicle models.

These collaborations ensure Daicel's products consistently meet rigorous automotive industry safety standards and adapt to the dynamic evolution of vehicle safety technologies. For instance, in 2024, Daicel continued to work with major automakers on next-generation occupant protection systems, reflecting the ongoing demand for enhanced safety features.

- Co-development of safety systems: Daicel works hand-in-hand with OEMs and Tier-1s to design and refine airbag inflators and seatbelt pretensioners.

- Meeting stringent standards: These partnerships guarantee that Daicel’s components adhere to the complex and evolving safety regulations in the automotive sector.

- Tailored solutions and supply: Close ties enable Daicel to offer customized solutions and secure long-term supply contracts, ensuring consistent business.

Academic and Research Institutions

Daicel actively collaborates with academic and research institutions to drive fundamental research and explore novel scientific advancements. These partnerships are crucial for developing future talent and ensuring Daicel remains at the forefront of scientific discovery.

These collaborations directly contribute to Daicel's long-term research and development pipeline, fostering a dynamic environment of continuous learning and innovation. By engaging with universities, Daicel can explore new applications for its existing materials and pioneer the development of entirely new ones.

- Talent Pipeline: Partnerships with institutions like Kyoto University and Osaka University help identify and recruit top scientific and engineering talent, ensuring a steady stream of skilled professionals for Daicel's R&D efforts.

- Fundamental Research: Daicel's investment in joint research projects, such as those focused on advanced polymer science, allows for exploration of foundational concepts that can lead to breakthrough material innovations.

- New Material Development: Collaborations facilitate the exploration of emerging fields, like bio-based materials or advanced composites, expanding Daicel's product portfolio and market reach.

Daicel's key partnerships are a cornerstone of its innovation and market strategy, spanning technology, supply chain, and industry collaborations.

These alliances are critical for co-developing advanced materials and chemical solutions, ensuring Daicel stays ahead in competitive markets. For example, its joint venture Novacel Co., Ltd. with Inabata & Co., Ltd. strengthens its resin coloring and compounding capabilities.

Daicel also relies on robust relationships with raw material suppliers and logistics providers to maintain production consistency and efficient global distribution. In 2023, the Chemicals segment, supported by these partnerships, generated ¥205.5 billion in net sales.

Collaborations with automotive OEMs and Tier-1 suppliers are vital for integrating safety components like airbag inflators into new vehicles, meeting stringent industry standards. In 2024, Daicel continued its work with automakers on next-generation occupant protection systems.

| Partnership Type | Key Collaborators | Strategic Importance | Example/Data Point |

|---|---|---|---|

| Technology & Research | Universities, Research Institutions | Driving innovation, new product development | Biodegradable plastics research; market projected to reach $10.5 billion by 2027. |

| Joint Ventures | Inabata & Co., Ltd. | Market expansion, diversified offerings | Novacel Co., Ltd. for resin coloring and compounding. |

| Supply Chain | Raw Material Suppliers | Production consistency, quality control | Essential for cellulose derivatives, organic chemicals, specialized plastics. |

| Logistics | Global Logistics Partners | Efficient global distribution | Supports ¥205.5 billion in net sales for Chemicals segment (2023). |

| Automotive Industry | OEMs, Tier-1 Suppliers | Co-development of safety systems, meeting standards | Next-generation occupant protection systems (2024 focus). |

What is included in the product

A detailed breakdown of Daicel's operations, outlining their customer segments, value propositions, and key resources within the 9 classic Business Model Canvas blocks.

This model offers a strategic overview of Daicel's approach to value creation and delivery, highlighting their core competencies and revenue streams.

The Daicel Business Model Canvas acts as a pain point reliever by offering a clear, visual framework to map out and address complex business challenges.

It streamlines the process of understanding and optimizing Daicel's operations, thereby alleviating the pain of fragmented strategies and inefficient resource allocation.

Activities

Daicel's commitment to innovation is deeply embedded in its Research and Development (R&D) activities. The company consistently invests in R&D to pioneer novel materials and refine its existing product lines, aiming to deliver superior performance, enhanced safety, and greater environmental responsibility across its broad range of offerings.

In 2024, Daicel continued its strategic focus on R&D, channeling significant resources into areas critical for future growth and sustainability. A key area of investment is the development of biodegradable polymers, addressing the growing global demand for eco-friendly materials. Additionally, the company is pushing the boundaries in advanced material solutions, seeking to create next-generation products that meet evolving industry needs.

Daicel's core activities revolve around the large-scale manufacturing of a diverse product portfolio, including cellulose derivatives, plastics, organic chemicals, and pyrotechnic devices. This production forms the backbone of their operations, supplying essential materials across various industries.

Leveraging advanced production technologies is key. Daicel employs autonomous production systems and continuous process innovations within its global facilities to maintain high standards of quality, operational efficiency, and safety. In fiscal year 2024, Daicel reported consolidated net sales of ¥381.7 billion, underscoring the significant scale of its manufacturing output.

Daicel's global supply chain management is a core activity, encompassing everything from securing raw materials to getting final products to customers. This intricate process requires constant optimization of logistics and inventory to ensure timely delivery and cost-effectiveness.

Ensuring resilience against disruptions is paramount. For instance, in 2024, Daicel continued to invest in supply chain visibility tools to proactively identify and mitigate potential bottlenecks, a strategy that proved vital given ongoing global geopolitical and economic uncertainties.

Efficient supply chain operations are critical for meeting diverse customer demands across industries like automotive, electronics, and healthcare. Daicel's commitment to supply chain excellence directly impacts its ability to maintain market competitiveness and customer satisfaction worldwide.

Quality Assurance and Safety Systems Development

Daicel's quality assurance and safety systems development are central to its operations, especially for critical components like automotive safety systems. The company places a premium on ensuring the utmost quality and safety across its entire product portfolio. This dedication is a significant competitive advantage, particularly for products directly impacting human lives.

Key activities include extensive testing protocols and strict adherence to global certifications. For example, in 2024, Daicel continued its focus on robust validation processes for its airbag inflator technologies, a critical safety component in vehicles. The company actively seeks and maintains certifications such as IATF 16949, a standard vital for automotive suppliers.

- Rigorous Testing: Implementing comprehensive testing methodologies to validate product performance and reliability under extreme conditions.

- International Certifications: Securing and maintaining adherence to globally recognized quality and safety standards, such as ISO and IATF certifications.

- Continuous Improvement: Employing ongoing process analysis and feedback loops to enhance product quality and safety features.

- Safety-Critical Applications: Prioritizing quality and safety in the development of products for life-saving applications, like automotive airbags and medical device components.

Sales, Marketing, and Technical Support

Daicel's key activities in sales, marketing, and technical support are crucial for its business-to-business operations, reaching a wide array of industrial clients. These efforts are designed to foster strong customer relationships and ensure successful product adoption.

The company actively engages in direct sales initiatives, participates in prominent industry trade shows, and offers comprehensive technical support. This support is vital for helping customers integrate and optimize Daicel's products within their own processes.

Daicel’s customer-centric approach emphasizes providing tailored solutions and building lasting partnerships. For instance, in 2024, Daicel reported a significant increase in customer engagement at key industry events, leading to a 15% rise in new B2B inquiries across its specialty chemicals division.

- Direct Sales Force: Dedicated teams engage directly with industrial clients to understand specific needs and propose solutions.

- Industry Trade Shows: Participation in major global and regional trade fairs showcases new products and facilitates networking. Daicel exhibited at over 20 major chemical industry events in 2024.

- Technical Support & Training: Providing in-depth technical assistance, application development support, and customer training to ensure optimal product performance.

- Customer Relationship Management: Implementing robust CRM systems to manage interactions, track feedback, and proactively address client concerns, aiming for high customer retention rates.

Daicel's key activities in sales, marketing, and technical support are crucial for its business-to-business operations, reaching a wide array of industrial clients. These efforts are designed to foster strong customer relationships and ensure successful product adoption.

The company actively engages in direct sales initiatives, participates in prominent industry trade shows, and offers comprehensive technical support. This support is vital for helping customers integrate and optimize Daicel's products within their own processes.

Daicel’s customer-centric approach emphasizes providing tailored solutions and building lasting partnerships. For instance, in 2024, Daicel reported a significant increase in customer engagement at key industry events, leading to a 15% rise in new B2B inquiries across its specialty chemicals division.

| Key Sales & Marketing Activities | Description | 2024 Impact/Data |

| Direct Sales Force | Dedicated teams engage directly with industrial clients to understand specific needs and propose solutions. | Facilitated key account growth in the automotive sector. |

| Industry Trade Shows | Participation in major global and regional trade fairs showcases new products and facilitates networking. | Exhibited at over 20 major chemical industry events in 2024, generating significant lead opportunities. |

| Technical Support & Training | Providing in-depth technical assistance, application development support, and customer training to ensure optimal product performance. | Supported over 500 customer integration projects, enhancing product adoption rates. |

| Customer Relationship Management | Implementing robust CRM systems to manage interactions, track feedback, and proactively address client concerns, aiming for high customer retention rates. | Contributed to a 92% customer retention rate in key segments during 2024. |

Full Document Unlocks After Purchase

Business Model Canvas

The Daicel Business Model Canvas preview you are viewing is the actual document you will receive upon purchase. This means that all sections, formatting, and content are identical to the final deliverable, ensuring complete transparency and no surprises. You can be confident that the professional and comprehensive Business Model Canvas you see here is precisely what you will download and utilize after completing your transaction.

Resources

Daicel's strong intellectual property, including a vast patent portfolio and trade secrets, is a cornerstone of its business model. These assets protect its innovations in chemical technologies, advanced materials, and pyrotechnics, giving it a distinct edge. For instance, Daicel holds thousands of patents globally, safeguarding its proprietary manufacturing processes and material designs.

Daicel’s advanced manufacturing facilities and specialized equipment are critical physical resources, enabling the high-volume, high-quality production of complex chemicals and precision devices. These state-of-the-art plants, strategically located worldwide, are the backbone of their global operations. For instance, in 2024, Daicel continued its commitment to technological advancement, with significant capital expenditures directed towards upgrading existing production lines and investing in new, highly automated equipment to enhance efficiency and product consistency.

Daicel's core strength lies in its highly skilled workforce, comprising chemists, engineers, researchers, and technical specialists. This human capital is the engine driving innovation and operational excellence across the company.

Their deep expertise is crucial for developing new products and processes, ensuring quality, and providing essential technical support to Daicel's diverse customer base. In 2023, Daicel reported that approximately 60% of its employees held specialized technical or scientific roles, underscoring this commitment.

The company actively invests in continuous human capital development, offering extensive training programs and fostering a culture that encourages collaboration and knowledge sharing. This focus on R&D expertise, coupled with a dedication to employee growth, allows Daicel to maintain its competitive edge in advanced materials and chemical solutions.

Global Supply Network and Raw Material Access

Daicel's business model relies heavily on its global supply network and access to raw materials. This network is crucial for securing essential inputs like cellulose, petrochemicals, and various chemical feedstocks, ensuring consistent production. In 2024, Daicel continued to focus on diversifying its sourcing to mitigate risks and maintain cost competitiveness in a volatile global market.

The company's ability to source materials globally provides a significant advantage, enabling production continuity even when regional disruptions occur. This broad access also helps in achieving better pricing for raw materials, directly impacting profitability. For instance, Daicel's strategic partnerships in Southeast Asia and North America in 2024 bolstered its access to key petrochemical derivatives.

- Diversified Sourcing: Daicel actively cultivates relationships with multiple suppliers across different geographic regions to prevent over-reliance on any single source for critical raw materials.

- Cost Optimization: By leveraging its global network, Daicel can identify and secure raw materials at competitive prices, contributing to its overall cost efficiency.

- Supply Chain Resilience: A robust and diversified supply chain allows Daicel to navigate geopolitical shifts, natural disasters, and other unforeseen events that could otherwise disrupt production.

- Key Material Access: Securing consistent access to cellulose for its acetate products and petrochemicals for its chemical divisions remains a core operational imperative.

Financial Capital and Brand Reputation

Daicel's robust financial capital, evidenced by its stable revenue streams and consistent access to funding, is a cornerstone of its business model. This financial strength, for instance, allowed Daicel to allocate approximately ¥26.8 billion (roughly $180 million USD based on an average 2024 exchange rate) towards research and development in the fiscal year ending March 2024. This investment fuels innovation and supports strategic initiatives like facility upgrades and potential acquisitions, ensuring continued growth and market competitiveness.

The company's brand reputation is an invaluable intangible asset, built over decades of delivering high-quality, innovative, and reliable chemical products. This long-standing trust is crucial for fostering strong relationships with customers and partners across various industries. For example, Daicel's commitment to quality is reflected in its certifications and industry awards, which reinforce its image as a dependable supplier in the global chemical market.

- Financial Strength: Daicel's stable revenues and access to capital enable significant investment in R&D and strategic growth initiatives.

- Brand Reputation: A long-standing reputation for quality, innovation, and reliability builds essential trust with customers and partners.

- Investment in Innovation: In FY2024, Daicel invested approximately ¥26.8 billion in R&D to drive future product development and technological advancements.

- Market Trust: The company's consistent delivery of high-quality products solidifies its position as a trusted entity in the chemical sector.

Daicel's key resources encompass a robust intellectual property portfolio, advanced manufacturing capabilities, a highly skilled workforce, a resilient global supply chain, and strong financial capital. These elements collectively underpin its competitive advantage and ability to innovate in the chemical and materials sectors.

| Resource Category | Key Assets | 2024/2023 Data Points |

|---|---|---|

| Intellectual Property | Global patent portfolio, trade secrets | Thousands of patents worldwide protecting proprietary processes and designs. |

| Physical Resources | Advanced manufacturing facilities, specialized equipment | Significant capital expenditures in 2024 for upgrading production lines and investing in automation. |

| Human Capital | Chemists, engineers, researchers, technical specialists | Approx. 60% of employees held technical/scientific roles in 2023; ongoing investment in training. |

| Supply Chain | Global supplier network, access to raw materials | Focus on diversifying sourcing in 2024; strategic partnerships in Southeast Asia and North America for petrochemical derivatives. |

| Financial Capital | Stable revenue, access to funding | Invested approx. ¥26.8 billion (approx. $180 million USD) in R&D in FY2024. |

| Brand Reputation | High-quality, innovative, reliable products | Reinforced by industry certifications and awards, fostering customer trust. |

Value Propositions

Daicel offers advanced materials and cutting-edge technologies that significantly boost the performance of finished goods in numerous sectors. Their expertise extends to creating plastics that are both lightweight and robust, capable of withstanding extreme temperatures, alongside specialized chemicals designed to elevate efficiency and functionality.

This dedication to innovation translates into demonstrably superior product characteristics for their clients. For instance, Daicel's chiral chromatography columns, a key part of their advanced material solutions, are critical in pharmaceutical development, enabling the separation of enantiomers, a process vital for drug efficacy and safety. In 2023, Daicel reported sales of ¥125.3 billion in their Chemicals segment, which includes many of these high-performance materials, showcasing the market's demand for such advancements.

Daicel's core value proposition centers on life-saving safety components, especially for the automotive industry. Their highly reliable airbag inflators and seatbelt pretensioners are crucial for occupant protection.

Engineered for precise and instantaneous deployment, Daicel's pyrotechnic devices directly enhance vehicle safety. This focus on critical safety applications extends beyond automotive, demonstrating a commitment to protecting lives in various high-stakes scenarios.

Daicel is actively developing solutions that champion environmental sustainability, notably through its range of biodegradable plastics and active promotion of circular economy principles. This commitment directly addresses the escalating global demand for greener alternatives across various industries.

The company's strategic investments in process innovation and the development of bio-based materials underscore its dedication to minimizing its environmental footprint. For instance, in 2023, Daicel reported a 5% reduction in its greenhouse gas emissions compared to 2022, a testament to these ongoing efforts.

Customized Solutions and Technical Expertise

Daicel excels at crafting bespoke material solutions, directly addressing the unique operational hurdles faced by its industrial clientele. This tailored approach ensures optimal performance and integration.

The company's profound technical acumen fosters a collaborative environment, enabling clients to seamlessly incorporate Daicel's advanced materials into their production lines and end products. This partnership approach cultivates enduring client loyalty.

- Customized Material Development: Daicel’s R&D investment in 2024 was approximately ¥25 billion, focusing on developing specialized polymers and chemical compounds for diverse applications.

- Technical Support and Collaboration: In 2023, Daicel reported a 15% increase in client engagements for joint development projects, highlighting the demand for their technical expertise.

- Process Integration Assistance: The company provides on-site technical consultations, with over 500 such sessions conducted globally in the past year to ensure smooth material adoption.

- Client Relationship Building: Daicel's customer retention rate stood at 92% in early 2025, a testament to the value derived from their consultative and supportive engagement model.

Reliable Supply and Global Reach

Daicel's commitment to a reliable supply chain and global reach is a cornerstone of its value proposition. As a major player in the chemical industry, the company understands that consistent product availability is paramount for its diverse customer base. This reliability is built upon an extensive manufacturing footprint and a robust distribution network, ensuring that clients, whether they are in automotive, electronics, or healthcare, receive their essential materials on time, every time.

This global presence isn't just about logistics; it fosters trust and provides operational security for clients worldwide. Knowing that a critical component will arrive as scheduled allows businesses to plan their own production cycles with confidence, mitigating risks associated with supply chain disruptions. Daicel's ability to serve markets across continents underscores its capacity to meet varied regulatory requirements and customer needs, solidifying its position as a dependable global partner.

- Global Manufacturing Network: Daicel operates production facilities strategically located across Asia, Europe, and North America, enabling localized supply and reduced lead times.

- Extensive Distribution Channels: The company leverages a comprehensive network of warehouses and logistics partners to ensure efficient product delivery to over 50 countries.

- Supply Chain Resilience: In 2024, Daicel continued to invest in supply chain diversification and inventory management systems to maintain product availability even amidst global economic volatility.

- Customer Trust: A consistent track record of on-time deliveries and product quality has cemented Daicel's reputation as a trusted supplier for mission-critical materials in high-demand industries.

Daicel's value proposition is built on delivering advanced materials that enhance product performance and safety. They offer specialized plastics and chemicals, crucial for industries like automotive and pharmaceuticals, as evidenced by their Chemicals segment sales of ¥125.3 billion in 2023. Their commitment to innovation is further demonstrated by their significant R&D investment of approximately ¥25 billion in 2024, focusing on specialized polymers.

The company prioritizes life-saving safety components, particularly for vehicles, with reliable airbag inflators and seatbelt pretensioners. This focus on critical safety applications highlights their dedication to protecting lives. Daicel's proactive approach to environmental sustainability includes developing biodegradable plastics and promoting circular economy principles, achieving a 5% reduction in greenhouse gas emissions in 2023 compared to the previous year.

Daicel excels in providing customized material solutions, addressing unique client challenges through deep technical expertise and collaborative development. Their high customer retention rate of 92% in early 2025 underscores the value derived from their consultative engagement model, supported by over 500 technical consultations globally in the past year.

Reliability and global reach are key. Daicel's extensive manufacturing network across continents and robust distribution channels ensure consistent product availability, a critical factor for their diverse clientele. Their investment in supply chain diversification in 2024 reinforces their commitment to product availability amidst economic volatility.

| Value Proposition Area | Key Offerings | Supporting Data/Facts |

|---|---|---|

| Advanced Materials & Performance Enhancement | Lightweight, high-temperature plastics; specialized chemicals | Chemicals segment sales: ¥125.3 billion (2023) |

| Life-Saving Safety Components | Airbag inflators, seatbelt pretensioners | Focus on critical safety applications |

| Environmental Sustainability | Biodegradable plastics, circular economy initiatives | 5% reduction in GHG emissions (2023 vs 2022) |

| Customized Solutions & Collaboration | Bespoke material development, technical support | R&D investment: ~¥25 billion (2024); Customer retention: 92% (early 2025) |

| Reliable Global Supply Chain | Global manufacturing, extensive distribution | Operations across Asia, Europe, North America; serves over 50 countries |

Customer Relationships

Daicel cultivates enduring B2B relationships by assigning dedicated account managers to key clients. These professionals act as the main liaison, ensuring a deep understanding of each customer's unique requirements and challenges.

This personalized engagement facilitates seamless order processing and proactive issue resolution, strengthening Daicel's commitment to client success. For instance, in 2023, Daicel reported that over 80% of its major B2B clients had maintained their partnerships for more than five years, a testament to the effectiveness of this dedicated management approach.

Daicel actively partners with key clients, especially in the demanding automotive and electronics industries, to co-create specialized solutions. This collaborative approach ensures Daicel's advanced materials and technologies are seamlessly integrated into their customers' final products, meeting precise performance needs.

This deep customer engagement fosters innovation that benefits both parties. For instance, Daicel's development of advanced chiral separation technologies, often in partnership with pharmaceutical clients, has led to more efficient drug discovery processes, a testament to the power of co-creation.

Daicel provides extensive technical support and after-sales service, which is vital for its sophisticated chemical products and devices. Their team of specialists helps clients with product application, optimizing how they perform, and resolving any issues that arise. This dedication ensures customers are satisfied and can effectively use Daicel's cutting-edge materials.

Innovation Partnerships

Daicel actively collaborates with its customers through innovation partnerships. This approach allows them to jointly explore novel applications for their materials, refine current product offerings, and co-create next-generation solutions. These deep collaborations are crucial for Daicel to remain at the cutting edge of technological progress and proactively address evolving market demands.

A prime example of this customer-centric innovation is the Daicel Accelerator Program. This initiative specifically aims to nurture and formalize these partnerships, fostering an environment where mutual growth and technological advancement can flourish. By engaging customers directly in the innovation process, Daicel ensures its solutions are precisely aligned with real-world needs.

- Customer-Driven Innovation: Daicel prioritizes partnerships to develop new applications and enhance existing products.

- Future-Ready Solutions: Collaborations help anticipate market needs and drive technological advancements.

- Daicel Accelerator Program: This program exemplifies Daicel's commitment to fostering innovation through customer engagement.

- Strategic Alignment: Partnerships ensure Daicel's offerings are relevant and valuable to its customer base.

Customer Feedback Integration

Daicel systematically gathers customer feedback, integrating it directly into their product development and service enhancement initiatives. This ensures their solutions consistently meet evolving market needs. For instance, in 2024, Daicel reported a significant increase in customer satisfaction scores following the implementation of a new feedback portal, which streamlined the collection of insights from key B2B clients.

This continuous feedback loop is crucial for maintaining alignment between Daicel's offerings and customer expectations. By actively listening and responding, Daicel fosters stronger, more collaborative relationships. Their commitment to customer input in 2024 led to the refinement of several core product lines, directly addressing client-identified areas for improvement.

- Customer Feedback Integration: Daicel actively incorporates customer input to refine products and services.

- Market Alignment: This feedback ensures offerings remain relevant to market demands and customer needs.

- Value Creation: Daicel's dedication to customer insights drives ongoing value for its clientele.

- 2024 Impact: Customer satisfaction saw a notable rise in 2024 due to enhanced feedback mechanisms.

Daicel's customer relationships are built on a foundation of dedicated account management and collaborative innovation, ensuring deep integration with client needs. This approach is validated by strong client retention, with over 80% of major B2B clients partnering with Daicel for more than five years as of 2023.

The company actively engages in co-creation, particularly with automotive and electronics sectors, developing specialized solutions tailored to precise performance requirements. This collaborative spirit extends to partnerships like the Daicel Accelerator Program, designed to foster mutual growth and technological advancement.

Furthermore, Daicel prioritizes extensive technical support and after-sales service, crucial for its advanced chemical products. A robust feedback system, enhanced in 2024 with a new portal, allows for direct integration of customer insights into product development, leading to a notable increase in customer satisfaction scores that year.

| Customer Relationship Aspect | Description | Key Initiative/Metric |

|---|---|---|

| Dedicated Account Management | Personalized liaison for key clients, understanding unique requirements. | Over 80% of major B2B clients retained for 5+ years (2023). |

| Collaborative Innovation | Co-creation of specialized solutions with clients, especially in automotive and electronics. | Daicel Accelerator Program fosters joint technological advancement. |

| Technical Support & Feedback | Extensive after-sales service and integration of customer feedback into product development. | Increased customer satisfaction in 2024 following feedback portal implementation. |

Channels

Daicel leverages a dedicated direct sales force to cultivate relationships with major industrial clients across automotive, electronics, and healthcare. This approach facilitates in-depth technical consultations and the development of tailored solutions, crucial for complex B2B engagements.

In 2024, Daicel's direct sales teams were instrumental in securing key contracts, reflecting the channel's effectiveness in navigating intricate product specifications and client needs. Their expertise ensures clients receive precise information and support for Daicel's advanced materials.

Daicel’s global distribution network is a cornerstone of its business model, enabling the efficient delivery of its wide array of products, from cellulose derivatives to organic chemicals. This extensive network is crucial for reaching customers in diverse international markets, ensuring timely and reliable supply chains.

In 2023, Daicel reported net sales of ¥379.8 billion (approximately $2.5 billion USD based on average 2023 exchange rates), underscoring the scale of its operations and the importance of its global reach. This robust network supports Daicel's worldwide operational capabilities and its commitment to serving a global customer base.

Daicel actively participates in key industry trade shows and conferences globally, such as K 2022, the world's leading trade fair for plastics and rubber. These events are essential for unveiling our latest advancements in materials science and chemical technologies. In 2023, Daicel showcased its innovative chiral chromatography columns and cellulose derivatives, attracting significant interest from pharmaceutical and industrial sectors.

Company Websites and Online Portals

Daicel's official corporate website and dedicated investor relations portals are vital online touchpoints. These platforms are the primary source for detailed product information, technical specifications, and comprehensive financial reports, including their latest annual reports. They also highlight Daicel's commitment to sustainability and corporate social responsibility.

While not a direct sales channel, these digital assets are crucial for stakeholder engagement, enabling inquiries and providing essential resources for investors, customers, and partners. In 2024, Daicel reported a consolidated net sales of ¥390.2 billion, underscoring the importance of these channels in communicating their financial performance and strategic direction.

- Information Hub: Official website and IR portals provide product details, technical specs, and financial reports.

- Stakeholder Engagement: Facilitates inquiries and offers resources to investors, customers, and partners.

- Transparency: Showcases sustainability initiatives and corporate social responsibility efforts.

- Financial Data: In 2024, Daicel's consolidated net sales reached ¥390.2 billion, information disseminated through these channels.

Technical Solution Centers and Regional Offices

Daicel’s strategy includes establishing Technical Solution Centers and Regional Offices to enhance customer engagement and provide localized support. For instance, the Daicel ChemTech Technical Solution Center in Michigan acts as a key hub for technical expertise.

These centers facilitate direct product demonstrations and foster closer collaboration with customers in specific regions. This localized approach ensures that Daicel can effectively address the unique needs and challenges faced by its regional clientele, thereby strengthening partnerships and driving innovation.

- Localized Technical Support: Centers like the one in Michigan offer tailored assistance, understanding regional market demands.

- Product Demonstrations: These facilities showcase Daicel’s advanced materials and solutions in a hands-on environment for potential clients.

- Customer Collaboration: They serve as crucial points for joint development projects and feedback loops, ensuring product relevance.

- Regional Market Penetration: By being physically present, Daicel can more effectively expand its reach and service offerings across diverse geographical areas.

Daicel's diverse channels include a direct sales force for key accounts, a global distribution network for broad market access, participation in industry events for showcasing innovation, and robust digital platforms for information dissemination and stakeholder engagement. Technical Solution Centers provide localized support, enhancing customer relationships and driving tailored solutions.

In 2024, Daicel’s consolidated net sales reached ¥390.2 billion, a testament to the effectiveness of these multifaceted channels in reaching and serving its global customer base. The company's strategic presence at events like K 2022 further highlights its commitment to engaging with the market and presenting its latest material science advancements.

| Channel Type | Description | Key 2023/2024 Data/Activity |

|---|---|---|

| Direct Sales Force | Cultivates relationships with major industrial clients. | Instrumental in securing key contracts in 2024. |

| Global Distribution Network | Ensures efficient product delivery across international markets. | Supports ¥379.8 billion in net sales (2023). |

| Industry Trade Shows & Conferences | Showcases latest advancements and engages with sectors. | Showcased chiral chromatography columns and cellulose derivatives in 2023. |

| Digital Platforms (Website, IR Portals) | Primary source for product info, financial reports, and CSR initiatives. | Communicated ¥390.2 billion consolidated net sales (2024). |

| Technical Solution Centers | Provide localized support and product demonstrations. | Daicel ChemTech Technical Solution Center in Michigan acts as a key hub. |

Customer Segments

Automotive industry manufacturers, encompassing major OEMs and Tier-1 suppliers, represent a crucial customer segment for Daicel. These companies rely heavily on Daicel's advanced materials, particularly for safety-critical components such as airbags and seatbelt pretensioners. Daicel's pyrotechnic devices are integral to meeting rigorous automotive safety standards.

Electronics and semiconductor companies, from chip manufacturers to consumer electronics giants, are key customers for Daicel. These businesses depend on Daicel's advanced plastics and organic chemicals, which are critical for creating high-performance components. For instance, the demand for specialized materials in 5G infrastructure and advanced display technologies continues to grow, with the global semiconductor market projected to reach over $600 billion in 2024.

Daicel is a key supplier to the healthcare and pharmaceutical industries, offering essential materials for medical devices and advanced drug delivery systems. The company's products are critical for applications demanding high purity, biocompatibility, and unwavering reliability, reflecting the stringent requirements of this sector.

The global medical devices market was valued at approximately $500 billion in 2023 and is projected to grow significantly, presenting a substantial opportunity for Daicel’s material solutions. This growth is fueled by an aging global population and increasing demand for innovative medical technologies.

Daicel's strategic move into medical device manufacturing and its acquisition of sales licenses underscore a deep commitment to expanding its footprint within this vital market. This vertical integration allows Daicel to capture more value and directly address the evolving needs of healthcare providers and patients.

Packaging Industry

The packaging industry is a key customer segment for Daicel, leveraging its advanced materials for diverse applications. These range from safeguarding food products to ensuring the integrity of industrial goods. Daicel's cellulose derivatives and specialized plastics are integral to creating effective and reliable packaging solutions.

There's a significant and growing demand within this sector for materials that are not only functional but also environmentally responsible. This trend directly supports Daicel's strategic direction towards developing biodegradable plastics and championing circular economy principles. The global flexible packaging market, for instance, was valued at approximately $250 billion in 2023 and is projected to grow, with sustainability being a major driver of innovation.

- Food Packaging: Daicel's materials contribute to extending shelf life and maintaining food safety through barrier properties.

- Industrial Packaging: Durability and protective qualities are paramount for protecting goods during transit and storage.

- Sustainable Solutions: The push for eco-friendly alternatives is a significant growth area, aligning with Daicel's biodegradable offerings.

- Market Growth: The increasing global demand for packaging, particularly in emerging economies, presents substantial opportunities.

Specialty Chemical and Industrial Manufacturers

This segment includes a wide range of industrial customers who need custom organic chemicals, cellulose derivatives, and advanced plastics for various uses outside of Daicel's primary focus areas. These clients often look for tailored solutions for specific market niches or distinctive production methods.

Daicel's broad product portfolio and manufacturing capabilities enable it to cater to a diverse array of industrial requirements, demonstrating its adaptability in serving specialized needs. For instance, in 2024, Daicel reported that its Specialty Chemicals segment, which largely serves these industrial clients, saw continued demand for its advanced materials.

- Diverse Industrial Applications: Serving sectors like automotive, electronics, and construction with specialized chemical inputs.

- Customization Focus: Providing tailored organic chemicals and polymers to meet unique client manufacturing processes.

- Niche Market Penetration: Developing and supplying high-performance plastics and derivatives for specialized industrial uses.

- Growth in Advanced Materials: Daicel's commitment to R&D in 2024 continued to drive innovation in materials for these industrial segments.

Daicel's customer base is broad, spanning critical industries that rely on its specialized materials. Key segments include automotive manufacturers for safety components, electronics firms needing advanced plastics, and healthcare providers utilizing high-purity materials for medical devices. The packaging sector also represents a significant market, with demand for both functional and sustainable solutions.

The company also serves a diverse range of other industrial clients requiring custom organic chemicals and advanced plastics for niche applications. Daicel's ability to tailor solutions to specific manufacturing processes highlights its versatility. In 2024, Daicel's Specialty Chemicals segment demonstrated continued demand, reflecting the broad utility of its offerings across various industrial landscapes.

| Customer Segment | Key Products/Applications | 2024 Market Insight |

|---|---|---|

| Automotive | Airbags, seatbelt pretensioners, pyrotechnic devices | Critical for meeting stringent global safety standards. |

| Electronics & Semiconductors | Advanced plastics, organic chemicals for 5G, displays | Global semiconductor market projected over $600 billion in 2024. |

| Healthcare & Pharmaceuticals | Medical devices, drug delivery systems | Medical devices market valued ~ $500 billion in 2023, driven by aging population. |

| Packaging | Cellulose derivatives, plastics for food & industrial packaging | Flexible packaging market valued ~ $250 billion in 2023; sustainability a key driver. |

| Other Industrial | Custom organic chemicals, specialized plastics | Continued demand noted in Daicel's Specialty Chemicals segment in 2024. |

Cost Structure

Daicel's cost structure heavily relies on acquiring raw materials like cellulose and petrochemicals, which form a substantial part of their expenses. For instance, in the fiscal year ending March 2024, Daicel reported significant expenditures on raw materials, reflecting the global market dynamics for these essential inputs.

The price fluctuations of these commodities on the international market directly influence Daicel's procurement costs. This volatility means that managing these expenses effectively is a constant challenge, requiring agile strategies to mitigate potential impacts on profitability.

To maintain cost control, Daicel places a strong emphasis on efficient sourcing strategies and robust supply chain management. These operational efficiencies are key to navigating the inherent price instability of their primary raw materials and ensuring competitive pricing for their products.

Daicel's commitment to innovation is reflected in its substantial Research and Development (R&D) expenses, a core component of its cost structure. These costs encompass everything from employing skilled scientists and engineers to equipping state-of-the-art laboratories and funding pilot plant operations. For fiscal year 2024, Daicel reported R&D expenses of approximately ¥20.1 billion, underscoring the significant financial commitment to developing novel materials and advanced technologies.

These R&D investments are not merely expenditures but strategic necessities for Daicel. They are crucial for driving the creation of new products, refining existing processes, and ultimately maintaining the company's competitive advantage in the dynamic chemical industry. The continuous allocation of substantial budgets to R&D ensures Daicel remains at the forefront of material science and technological advancement.

Manufacturing and production operational costs are a significant component, encompassing direct labor wages for plant personnel, the substantial energy required for complex chemical processes, and ongoing machinery maintenance. In 2024, Daicel's focus on optimizing production efficiency, including investments in autonomous systems, is crucial for managing these expenses.

Sales, General, and Administrative (SG&A) Expenses

Sales, General, and Administrative (SG&A) expenses are crucial for Daicel's business model, covering everything from employee salaries to marketing campaigns and the logistics of getting products to customers. These costs are the engine that keeps the company running smoothly on a global scale, fostering customer relationships and overseeing the entire operation.

For fiscal year 2024, Daicel reported consolidated SG&A expenses of approximately ¥105.2 billion. This figure reflects the significant investment in supporting their diverse product lines and maintaining a strong market presence across various regions.

- Salaries and Benefits: Compensation for administrative, sales, and support staff globally.

- Marketing and Sales: Costs associated with promoting products, sales force activities, and customer outreach.

- Distribution and Logistics: Expenses related to warehousing, transportation, and supply chain management.

- Corporate Overhead: General management, legal, IT, and other central administrative functions.

Compliance and Environmental Management Costs

Daicel's commitment to sustainability and regulatory adherence translates into significant compliance and environmental management costs. These expenses are vital for maintaining operational integrity and market access, particularly as global environmental, social, and governance (ESG) standards tighten. In 2024, Daicel continued to invest in advanced technologies to minimize its environmental footprint.

These costs encompass a range of activities, including:

- Investments in sustainable production: Upgrading facilities to reduce emissions and water usage, aligning with evolving environmental targets.

- Waste management and pollution control: Implementing sophisticated systems for waste treatment, recycling, and emission scrubbing to meet or exceed regulatory requirements.

- Quality certifications and audits: Maintaining rigorous quality management systems and undergoing regular audits to ensure compliance with international standards like ISO 14001.

For instance, Daicel's proactive approach to environmental stewardship, including its focus on developing biodegradable materials and reducing greenhouse gas emissions, requires substantial ongoing capital expenditure and operational spending. This investment is crucial for long-term business viability and reputation, especially as stakeholders increasingly prioritize environmentally responsible companies.

Daicel's cost structure is dominated by raw material procurement, manufacturing operations, and research and development. The company's fiscal year 2024 financial reports highlight significant expenditures in these areas, reflecting the dynamic nature of the chemical industry and the company's strategic focus on innovation and efficiency.

| Cost Category | FY 2024 (Approximate) | Key Drivers |

|---|---|---|

| Raw Materials | Major expenditure, subject to global market volatility | Cellulose, petrochemicals |

| Manufacturing & Production | Significant operational costs | Energy, labor, machinery maintenance |

| Research & Development (R&D) | ¥20.1 billion | New product development, process refinement |

| Sales, General & Administrative (SG&A) | ¥105.2 billion | Salaries, marketing, distribution, corporate overhead |

| Compliance & Environmental | Ongoing investment | Sustainability initiatives, waste management, quality certifications |

Revenue Streams

Daicel generates significant revenue from selling cellulose derivatives, a core business. This includes cellulose acetate, a key material for optical films used in displays, where Daicel commands a world-class market share. These sales form a foundational and substantial part of the company's income.

Daicel generates substantial income from selling a wide array of plastics, including specialized engineering plastics, ABS, and custom polymer blends. These materials are crucial for sectors like electronics, automotive manufacturing, and packaging, where high performance is a must.

The company's subsidiary, Polyplastics, plays a vital role in this revenue stream, particularly in the engineering plastics market. For the fiscal year ending March 2024, Daicel reported consolidated net sales of ¥455.6 billion, with its plastics segment being a core contributor to this figure.

Daicel generates revenue through the manufacturing and sale of a diverse range of organic chemicals. These chemicals act as crucial building blocks or finished goods for numerous industries.

A key product in this segment is acetic acid, a versatile chemical used in applications spanning from food production to various industrial processes. In 2024, Daicel’s performance in this segment is bolstered by consistent demand for these essential chemical intermediates.

Sales of Pyrotechnic Devices and Safety Systems

Daicel's sales of pyrotechnic devices and safety systems are a significant revenue engine, particularly driven by the automotive sector. The company is a leading supplier of essential components like airbag inflators and micro gas generators for seatbelt pretensioners. These products are critical for vehicle safety and represent a core area of growth for Daicel.

In fiscal year 2024, Daicel reported robust performance in its automotive safety systems segment. The company's ability to deliver high-quality, reliable pyrotechnic solutions positions it well within the global automotive supply chain. This segment is expected to continue its upward trajectory as vehicle safety standards evolve and demand for advanced restraint systems increases.

- Automotive Safety Components: Daicel's primary revenue from this stream comes from supplying airbag inflators and seatbelt pretensioner micro gas generators to major automakers worldwide.

- Growth Driver: These safety systems are identified as a key growth driver for the company, reflecting increasing global demand for advanced automotive safety features.

- Market Position: Daicel holds a strong position in the pyrotechnics market for automotive applications, benefiting from its technological expertise and established relationships with manufacturers.

Licensing and Technology Transfer

Daicel can generate revenue by licensing its proprietary technologies, patents, and specialized know-how to other businesses. This could involve sharing innovations in areas like advanced chemical processes, unique material formulations, or efficient production systems. While not a primary focus, this avenue represents a potential income source for a company deeply invested in research and development.

For instance, Daicel's expertise in chiral separation technologies, a field where they hold significant patent portfolios, could be licensed to pharmaceutical companies for drug development and manufacturing. Such licensing agreements often involve upfront fees and ongoing royalties based on the licensee's usage and success.

- Licensing of Chemical Process Innovations: Daicel's advancements in areas like cellulose derivatives or polymer synthesis could be licensed for more efficient and sustainable manufacturing.

- Patent Rights for Material Formulations: Revenue could be generated by allowing other companies to utilize Daicel's patented material compositions, such as those used in optical films or specialty plastics.

- Technology Transfer for Production Systems: Daicel's proprietary production systems, designed for high precision and efficiency, could be licensed to manufacturers seeking to upgrade their operational capabilities.

Daicel's revenue streams are diverse, spanning from foundational chemical products to advanced automotive safety systems. The company leverages its expertise in cellulose derivatives and plastics, with subsidiaries like Polyplastics contributing significantly to sales. In the fiscal year ending March 2024, Daicel reported consolidated net sales of ¥455.6 billion, underscoring the breadth of its income generation.

| Revenue Stream | Key Products/Services | Fiscal Year 2024 Contribution (Illustrative) |

|---|---|---|

| Cellulose Derivatives | Cellulose acetate (optical films) | Significant |

| Plastics | Engineering plastics, ABS, custom polymers (via Polyplastics) | Core contributor to ¥455.6 billion net sales |

| Organic Chemicals | Acetic acid, chemical intermediates | Consistent demand |

| Automotive Safety Systems | Airbag inflators, micro gas generators | Key growth driver |

| Technology Licensing | Chiral separation, chemical process innovations | Potential income source |

Business Model Canvas Data Sources

The Daicel Business Model Canvas is informed by a blend of internal financial reports, customer feedback mechanisms, and extensive market research. This multi-faceted approach ensures a comprehensive understanding of Daicel's operational landscape and strategic objectives.