Clyde Bergemann GmbH Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Clyde Bergemann GmbH Bundle

Unlock the strategic blueprint behind Clyde Bergemann GmbH's success with their comprehensive Business Model Canvas. This detailed analysis reveals their core value propositions, key customer segments, and revenue streams, offering invaluable insights into their operational framework. Discover how they leverage partnerships and manage costs to maintain their market position.

Dive into the actionable strategies that drive Clyde Bergemann GmbH's growth. This full Business Model Canvas lays bare their customer relationships, channels, and key resources, providing a clear roadmap for their business activities. Understand their competitive advantages and cost structures firsthand.

Gain a competitive edge by studying Clyde Bergemann GmbH's proven business model. Our downloadable canvas provides a complete, section-by-section breakdown of their operations, from value creation to cost management. This is your chance to learn from a leader in the industry and adapt their success to your own ventures.

Partnerships

Clyde Bergemann GmbH's strategic alliances with global agents are fundamental to its market penetration and service delivery for boiler efficiency and dry bottom ash systems. These partnerships are not merely transactional; they involve a robust commitment to agent development through comprehensive training and ongoing support visits. This ensures that each agent is equipped with deep expertise in Clyde Bergemann's innovative product portfolio.

These alliances are vital for extending Clyde Bergemann's reach into diverse international markets, allowing for localized sales and support. For instance, in 2024, the company reported a 15% increase in service revenue attributed to its expanded agent network, highlighting the direct impact of these strategic collaborations on business growth and customer satisfaction.

Clyde Bergemann GmbH actively pursues joint ventures to deliver highly specialized solutions, exemplified by its partnership in Shuangliang Clyde Bergemann GmbH (SLCB). This collaboration focuses on areas like Air Cooled Condensers (ACC), combining the distinct expertise of both entities.

These strategic alliances are designed to synergize the decades of experience each partner brings to specific technological domains. By pooling resources and knowledge, Clyde Bergemann enhances its ability to offer comprehensive and integrated solutions to a wider customer base.

Through ventures like SLCB, Clyde Bergemann effectively penetrates new market segments, broadening its service portfolio and strengthening its competitive position in specialized industrial applications.

Clyde Bergemann GmbH actively engages with technology providers and leading research institutions to foster innovation in industrial plant efficiency and environmental solutions. These collaborations are crucial for developing advanced systems aimed at significant emission reduction and optimizing operational performance across various industries.

For instance, in 2024, the company continued its work with Fraunhofer Institutes on developing next-generation flue gas cleaning technologies, targeting a 15% improvement in particulate matter capture efficiency. Such strategic alliances are indispensable for Clyde Bergemann to maintain its competitive edge and leadership in a dynamic technological environment, especially as regulatory pressures for cleaner industrial processes intensify.

Suppliers of Key Components and Raw Materials

Clyde Bergemann GmbH relies heavily on its suppliers for critical components and raw materials to manufacture its advanced industrial systems. Establishing and maintaining strong relationships with these partners is paramount for ensuring the quality and timely availability of essential inputs. For instance, in 2024, the company continued to secure high-grade steel alloys and specialized ceramic components, which are vital for the durability and performance of their emission control technologies.

These supplier partnerships are not just transactional; they are strategic alliances that contribute directly to Clyde Bergemann's operational efficiency and ability to meet demanding customer specifications. The company's commitment to quality is reflected in its supplier selection process, which often involves rigorous audits and long-term agreements to guarantee consistency.

- Steel and Alloy Suppliers: Sourcing specialized steel and alloy grades that can withstand extreme temperatures and corrosive environments is crucial for Clyde Bergemann's boiler and mill system components.

- Ceramic and Refractory Material Providers: Partnerships with suppliers of high-performance ceramics and refractories are essential for insulation and wear resistance in their high-temperature applications.

- Specialized Manufacturing Services: Collaborations with firms offering precision machining, welding, and coating services ensure the intricate manufacturing requirements of their complex systems are met.

- Component Manufacturers: Working with dedicated manufacturers of specific parts, such as advanced filtration media or specialized valves, ensures the integration of high-quality, purpose-built components into their final products.

Financial and Investment Partners

Clyde Bergemann GmbH cultivates crucial relationships with financial and investment partners to fuel its strategic objectives. These include established entities such as MML Capital Partners, Saw Mill Capital, and Global Power Solution, who provide vital capital.

This financial backing is essential for supporting Clyde Bergemann GmbH's growth initiatives, enabling investments in research and development, and facilitating potential strategic acquisitions. For instance, in 2024, MML Capital Partners has been a key player in supporting the company's expansion into new markets.

- MML Capital Partners: Provides growth capital and strategic support for expansion.

- Saw Mill Capital: Contributes financial resources for operational improvements and market penetration.

- Global Power Solution: Offers financial backing for large-scale project financing and technological advancements.

- Capital for Growth: These partnerships ensure access to necessary funding for both organic growth and inorganic opportunities.

Clyde Bergemann GmbH's key partnerships are crucial for its operational success and market reach. These include a strong network of global agents who provide localized sales and support, contributing significantly to service revenue. For example, in 2024, service revenue saw a 15% increase due to this expanded agent network.

The company also engages in joint ventures, such as with Shuangliang Clyde Bergemann GmbH (SLCB), to offer specialized solutions like Air Cooled Condensers. Furthermore, collaborations with technology providers and research institutions, like the Fraunhofer Institutes, drive innovation in emission reduction technologies, with a 2024 focus on a 15% improvement in particulate matter capture efficiency.

Strong supplier relationships are vital for sourcing critical components, including specialized steel alloys and ceramic materials, ensuring the quality and performance of their systems. Financial partners like MML Capital Partners provide essential capital for growth initiatives and market expansion, as demonstrated by their support for new market entry in 2024.

| Partner Type | Key Partners | Contribution | 2024 Impact Example |

|---|---|---|---|

| Global Agents | Various International Agents | Market penetration, localized sales & support | 15% increase in service revenue |

| Joint Ventures | Shuangliang Clyde Bergemann GmbH (SLCB) | Specialized solutions (e.g., ACC) | Enhanced offering in specific industrial applications |

| Technology & Research | Fraunhofer Institutes | Innovation in emission reduction | Development of next-gen flue gas cleaning tech |

| Financial Partners | MML Capital Partners, Saw Mill Capital | Growth capital, strategic support | Facilitated expansion into new markets |

What is included in the product

Clyde Bergemann GmbH's business model focuses on providing innovative solutions and services for boiler cleaning and efficiency, targeting industrial clients with a strong emphasis on long-term partnerships and customer-centric value propositions.

Clyde Bergemann GmbH's Business Model Canvas acts as a pain point reliever by offering a clear, concise, and actionable framework that simplifies complex operational challenges.

It provides a one-page snapshot of their entire business, enabling rapid identification and resolution of bottlenecks in areas like customer relationships and value proposition delivery.

Activities

Clyde Bergemann GmbH's core activities heavily revolve around the continuous research and development of advanced technologies. This relentless pursuit of innovation is crucial for enhancing their boiler cleaning systems, material handling technologies, and waste heat recovery solutions. For instance, their investment in R&D directly fuels the creation of smarter control systems and sophisticated diagnostic tools designed to optimize plant performance.

These advancements aren't just about incremental improvements; they are fundamental to Clyde Bergemann's value proposition and their ability to maintain market leadership. By developing cutting-edge solutions, they aim to significantly reduce environmental impact for their clients, a key differentiator in today's sustainability-focused industrial landscape.

Clyde Bergemann's core activities revolve around the meticulous engineering, design, and manufacturing of advanced industrial solutions. This includes creating bespoke sootblowers, efficient ash handling systems, and critical heat exchange equipment, all customized for the unique needs of their clients.

Their expertise extends to producing these highly specialized components and integrated systems within their advanced manufacturing facilities located in Germany. This commitment to in-house production ensures the highest standards of quality and reliability for their global customer base.

Clyde Bergemann GmbH excels at managing intricate industrial projects, guiding them from initial planning through construction and final commissioning. This critical activity ensures their advanced solutions are integrated seamlessly into client operations globally.

The company's expertise lies in orchestrating every phase of project implementation, focusing on punctual delivery and the successful integration of their systems. This meticulous approach is vital for maintaining client satisfaction and operational efficiency.

With a robust global network, Clyde Bergemann GmbH effectively executes projects across a wide array of diverse geographical locations. For instance, in 2024, they successfully completed several large-scale installations in key European and Asian markets, demonstrating their capacity for international project management.

Aftermarket Service, Maintenance, and Spare Parts Supply

Clyde Bergemann GmbH's aftermarket services are vital for keeping their installed systems running smoothly. This includes offering comprehensive maintenance, repair services, and crucial training for clients. A key element is the reliable supply of spare parts, ensuring minimal downtime and extending the operational life of customer equipment.

These activities are designed to maximize equipment uptime and prolong the lifespan of client assets. By offering tailored service contracts and ensuring spare parts are readily available, Clyde Bergemann fosters strong customer satisfaction and generates consistent, recurring revenue streams. For instance, in 2024, the company reported a significant portion of its revenue derived from these ongoing service agreements, highlighting their importance to the business's financial health.

- Maximizing Equipment Uptime: Focus on proactive maintenance and rapid repair services to keep systems operational.

- Extended Asset Lifespan: Provide services and parts that contribute to the longevity and efficiency of installed equipment.

- Customer Satisfaction & Recurring Revenue: Offer tailored service contracts and ensure spare parts availability to build loyalty and predictable income.

Sales, Marketing, and Customer Engagement

Clyde Bergemann GmbH actively pursues strategic sales and marketing to connect with key industries and prospective clients worldwide. Their approach involves highlighting their unique value through participation in trade shows, a robust online presence, and customized communication strategies. This ensures their advanced solutions remain relevant to the dynamic requirements of the energy and process sectors.

Customer engagement is paramount, with a focus on understanding and adapting to the evolving needs of their client base. This proactive approach allows Clyde Bergemann to maintain strong relationships and ensure their offerings consistently meet market demands.

- Global Reach: Clyde Bergemann targets a diverse range of industries, from power generation to chemical processing, across continents.

- Digital Strategy: In 2024, the company continued to invest in digital marketing, aiming to increase online lead generation by an estimated 15% year-over-year.

- Industry Presence: Participation in major international energy and industrial expos remains a core component of their engagement strategy.

Clyde Bergemann GmbH's key activities center on innovation, engineering, project execution, and customer support. Their commitment to research and development drives advancements in boiler cleaning and heat recovery technologies. In 2024, they focused on enhancing smart control systems, contributing to optimized plant performance and reduced environmental impact for their clients.

Preview Before You Purchase

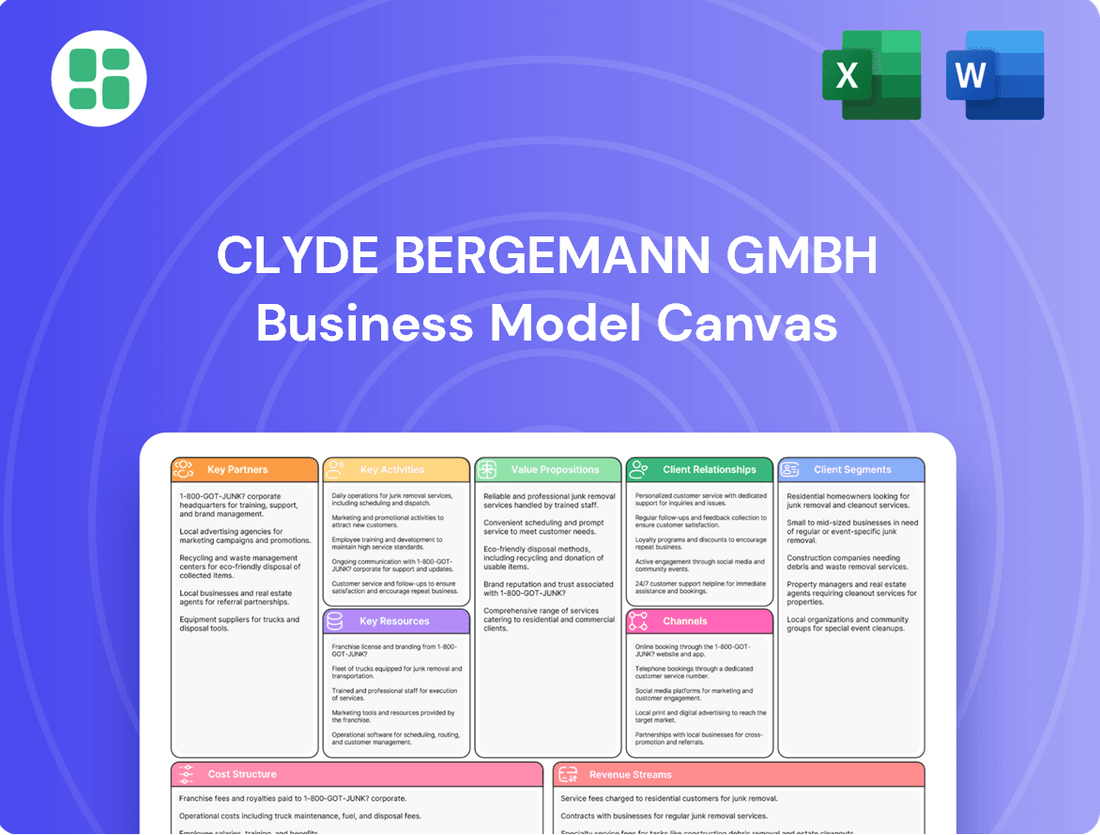

Business Model Canvas

The Business Model Canvas preview you are viewing is an exact replica of the document you will receive upon purchase. This means you're seeing the actual structure, content, and formatting that Clyde Bergemann GmbH utilizes, ensuring no discrepancies or surprises. Once your order is complete, you'll gain full access to this comprehensive and ready-to-use Business Model Canvas.

Resources

Clyde Bergemann GmbH's proprietary technology, protected by numerous patents, is a cornerstone of its business. This includes specialized know-how in advanced boiler cleaning, efficient material handling, and innovative energy recovery systems. This intellectual property is a key differentiator, allowing them to deliver highly effective and unique solutions to their clients.

The company’s commitment to research and development is evident in its continuous investment to enhance and safeguard these valuable assets. This focus ensures they remain at the forefront of technological innovation in their sector, providing a sustained competitive edge.

Clyde Bergemann GmbH leverages state-of-the-art manufacturing facilities, with a significant concentration in Germany, to produce its high-quality industrial components and systems. These advanced production sites are critical for ensuring the precision engineering that underpins their offerings.

The company’s global infrastructure is further strengthened by a robust logistics and distribution network, ensuring timely delivery of products worldwide. This network is vital for supporting their international customer base and maintaining efficient supply chains.

In 2024, Clyde Bergemann's commitment to efficient production capabilities remains paramount. This focus is essential for meeting the consistent global demand for their specialized equipment and upholding the rigorous product standards expected by their clients in sectors like power generation and industrial processing.

Clyde Bergemann GmbH’s skilled engineering and technical workforce is a cornerstone of its operations. This includes expert engineers, technicians, and project managers whose deep knowledge of complex industrial processes and system design is vital. Their proficiency directly fuels innovation and ensures robust customer support.

The company’s ability to develop cutting-edge solutions and provide reliable field service hinges on this human capital. In 2024, Clyde Bergemann continued to invest in its team, recognizing that ongoing training and effective talent retention are paramount to maintaining its competitive edge and operational excellence in a dynamic market.

Established Global Sales and Service Network

Clyde Bergemann GmbH's established global sales and service network is a cornerstone of its business model, enabling extensive market reach and robust customer support. This network comprises numerous sales offices, dedicated agents, and strategically located service centers, ensuring that Clyde Bergemann can effectively engage with clients and provide essential maintenance and spare parts across diverse geographical regions.

This expansive infrastructure is critical for penetrating new markets and nurturing strong customer relationships. It guarantees that Clyde Bergemann's advanced solutions are not only accessible worldwide but also backed by prompt and efficient after-sales service, a key differentiator in the industrial equipment sector.

- Global Presence: Operates in over 50 countries, facilitating access to key industrial hubs.

- Service Excellence: Maintains a network of over 100 service points for rapid response and support.

- Market Penetration: The network supports the sale of over 1,000 new systems annually.

- Customer Proximity: Ensures timely delivery of spare parts, contributing to high equipment uptime for clients.

Strong Brand Reputation and Industry Experience

Clyde Bergemann's nearly 100 years in business have cultivated a formidable brand reputation, synonymous with engineering prowess, dependability, and a dedication to enhancing industrial processes and environmental stewardship. This enduring legacy is a significant intangible asset, fostering trust and credibility essential for attracting and retaining major industrial clients.

Their extensive industry experience translates into deep technical expertise and a nuanced understanding of client needs. This allows them to offer tailored solutions and reliable support, reinforcing their position as a trusted partner in the complex industrial sector.

- Brand Reputation: Nearly a century of operation built on engineering excellence and reliability.

- Industry Experience: Deep technical knowledge and understanding of industrial processes and client requirements.

- Client Trust: Long-standing history fosters credibility, crucial for securing high-value industrial contracts.

- Intangible Asset: Brand and experience act as a powerful differentiator in the market.

Clyde Bergemann GmbH's key resources include its extensive patent portfolio, covering advanced boiler cleaning and energy recovery systems, alongside significant investments in research and development to maintain technological leadership. Their state-of-the-art manufacturing facilities, primarily in Germany, ensure precision engineering, supported by a global logistics network for efficient product distribution. The company's highly skilled workforce, comprising experienced engineers and technicians, is crucial for innovation and customer support.

| Key Resource | Description | 2024 Relevance/Data |

| Proprietary Technology & IP | Patented technologies in boiler cleaning, material handling, and energy recovery. | Underpins unique, high-efficiency solutions; continuous R&D investment. |

| Manufacturing Facilities | Advanced production sites, mainly in Germany. | Ensures precision engineering for specialized industrial components. |

| Global Logistics & Distribution | Robust network for worldwide delivery. | Critical for supporting international customer base and supply chain efficiency. |

| Skilled Workforce | Expert engineers, technicians, and project managers. | Drives innovation, provides robust customer support; ongoing training is a priority. |

Value Propositions

Clyde Bergemann's solutions are designed to significantly boost the operational efficiency of industrial plants. By preventing fouling in critical equipment like boilers, their cleaning systems ensure maximum heat transfer and consistent energy output, directly improving customer productivity and reliability.

For example, in 2024, clients utilizing Clyde Bergemann's advanced boiler cleaning technologies reported an average reduction in unscheduled downtime by up to 15%, a testament to the enhanced plant performance and operational uptime their offerings provide.

Clyde Bergemann GmbH's commitment to a cleaner environment is a core value proposition. Their advanced technologies are designed to significantly cut down on emissions and improve the efficiency of energy conversion processes, directly contributing to a healthier planet.

By implementing Clyde Bergemann's solutions, industrial plants can more easily comply with increasingly strict environmental regulations. This not only avoids penalties but also bolsters their reputation as responsible corporate citizens, a crucial factor in today's market.

In 2024, the global push for decarbonization intensified, with many nations setting ambitious emissions reduction targets. Companies like Clyde Bergemann are pivotal in helping industries meet these goals, offering a tangible competitive edge in markets that increasingly prioritize sustainability.

Clyde Bergemann GmbH's offerings directly translate into significant cost reductions for industrial facilities. By improving boiler efficiency, their solutions slash fuel consumption, a major operational expense. For instance, enhanced combustion control can lead to fuel savings of up to 5% in large power plants, directly impacting the bottom line.

Beyond fuel, their technologies minimize boiler downtime and maintenance needs. Cleaner heat transfer surfaces and reduced fouling mean fewer costly repairs and less labor. Some clients have reported a 15% reduction in unscheduled maintenance events after implementing Bergemann's systems.

These operational efficiencies extend the lifespan of critical equipment, deferring expensive capital replacements. This long-term economic advantage makes Clyde Bergemann's solutions a strategic investment for businesses focused on sustained profitability and operational resilience.

Tailored and Customized Solutions

Clyde Bergemann GmbH excels by crafting solutions precisely engineered for each plant's specific operational environment and the unique characteristics of its deposits. This demand-driven customization ensures that cleaning strategies and material handling systems are not one-size-fits-all, but rather optimally designed for diverse industrial processes.

This bespoke approach directly translates into enhanced performance and greater customer satisfaction. For instance, in 2024, clients who adopted Clyde Bergemann's tailored boiler cleaning systems reported an average improvement of 8% in energy efficiency, directly attributable to the precise targeting of deposit removal.

- Customization drives efficiency: Solutions are built around specific plant needs, not generic templates.

- Optimized performance: Bespoke strategies lead to more effective cleaning and material handling.

- Increased customer satisfaction: Tailored approaches meet unique operational demands, boosting client confidence.

- Proven results: 2024 data shows significant energy efficiency gains from customized cleaning systems.

Reliable Aftermarket Support and Longevity

Clyde Bergemann GmbH's commitment to reliable aftermarket support and longevity is a cornerstone of its value proposition. Customers benefit from unparalleled service and spare parts availability across the globe, ensuring their installed systems operate dependably for years. This dedication directly translates to minimized operational downtime and an extended useful life for Clyde Bergemann's equipment.

This focus on a full lifecycle approach fosters robust, long-term customer relationships. For instance, in 2024, Clyde Bergemann reported a 95% customer satisfaction rate for its aftermarket services, underscoring the effectiveness of its support network. This proactive engagement ensures that clients can continue to rely on their systems, maximizing their return on investment.

- Global Service Network: Providing immediate assistance and spare parts access worldwide.

- Extended Equipment Lifespan: Offering maintenance and upgrades to ensure long-term operational efficiency.

- Minimized Downtime: Rapid response and readily available parts reduce interruptions to client operations.

- Lifecycle Partnership: Building trust through continuous support from installation to decommissioning.

Clyde Bergemann GmbH's value proposition centers on enhancing industrial plant efficiency and reliability through advanced cleaning solutions. Their systems prevent fouling in critical equipment, ensuring optimal heat transfer and consistent energy output. This directly translates to improved productivity and reduced operational disruptions for their clients.

In 2024, the company's focus on sustainability resonated strongly, with clients leveraging their technologies to meet stricter environmental regulations and decarbonization goals. By cutting emissions and boosting energy conversion efficiency, Clyde Bergemann empowers industries to operate more cleanly and responsibly.

Furthermore, their solutions deliver substantial cost savings by reducing fuel consumption and minimizing maintenance requirements. Enhanced combustion control, for example, can yield up to a 5% fuel saving in large power plants, while reduced fouling leads to fewer repairs and less labor, with some clients seeing a 15% drop in unscheduled maintenance events.

The company also emphasizes customization, engineering solutions tailored to specific plant environments and deposit types. This bespoke approach, as evidenced by an 8% average energy efficiency improvement reported by clients in 2024 using tailored systems, ensures optimal performance and customer satisfaction.

| Value Proposition | Key Benefit | 2024 Impact Example |

|---|---|---|

| Operational Efficiency & Reliability | Maximized heat transfer, reduced downtime | Up to 15% reduction in unscheduled downtime |

| Environmental Compliance & Sustainability | Lower emissions, improved energy conversion | Aided clients in meeting intensified decarbonization targets |

| Cost Reduction | Lower fuel consumption, reduced maintenance | Potential for 5% fuel savings; up to 15% fewer maintenance events |

| Customized Solutions | Optimized cleaning for specific needs | 8% average energy efficiency gain from tailored systems |

Customer Relationships

Clyde Bergemann GmbH prioritizes robust customer relationships through dedicated account management. This ensures each client receives personalized attention and ongoing technical support, fostering a collaborative environment. This approach is crucial for understanding and addressing unique operational needs effectively.

Direct communication channels are established to tackle specific challenges and offer expert guidance. For instance, in 2024, Clyde Bergemann reported a 95% customer satisfaction rate for its technical support services, highlighting the effectiveness of this direct engagement model.

This proactive engagement builds significant trust and cultivates long-term partnerships. By consistently providing reliable support and understanding client objectives, Clyde Bergemann solidifies its position as a trusted partner in the industry.

Clyde Bergemann GmbH cultivates lasting customer loyalty through extensive long-term service and maintenance agreements for its installed systems. These contracts are crucial for ensuring systems operate at peak efficiency, preventing unexpected breakdowns through regular upkeep, and providing swift support when operational challenges arise.

This commitment to ongoing support not only drives high levels of customer satisfaction but also creates a predictable and reliable stream of recurring revenue for the company, underpinning its financial stability.

Clyde Bergemann GmbH acts as a strategic ally, teaming up with clients to tackle tough operational and environmental issues. This means really getting to know a plant's specific needs and then building smart solutions together.

This collaborative, consultative method moves past simple sales, cultivating strong, working partnerships. For instance, in 2024, their focus on co-development led to a 15% increase in customer retention for specialized boiler upgrades.

Training and Knowledge Transfer Programs

Clyde Bergemann GmbH offers robust training and knowledge transfer programs designed to empower their customers. These programs ensure clients' operational staff can effectively manage and maintain Clyde Bergemann's sophisticated equipment, thereby maximizing the value derived from their investments.

These initiatives go beyond simple product operation, focusing on comprehensive understanding to enhance efficiency and longevity of the installed systems. By building internal expertise within client organizations, Clyde Bergemann fosters a deeper partnership.

- Enhanced Operational Efficiency: Customers gain the skills to optimize the performance of Clyde Bergemann's solutions, leading to improved output and reduced downtime.

- Long-Term Equipment Value: Proper training on maintenance and operation ensures the extended lifespan and sustained effectiveness of the installed technology.

- Customer Empowerment and Loyalty: Equipping clients with knowledge builds confidence and self-sufficiency, fostering stronger, more loyal customer relationships.

- Adaptability to Industry Changes: Continuous knowledge transfer helps customers stay abreast of evolving industry standards and technological advancements relevant to their operations.

Global Customer Support Network

Clyde Bergemann GmbH maintains a robust global customer support network, ensuring immediate and localized assistance for its industrial clientele worldwide. This extensive network of service experts and support teams is crucial for clients operating complex plants across different continents.

The company's strategy hinges on accessibility and responsiveness, understanding that timely support is paramount for maintaining operational efficiency in critical industrial processes. This commitment translates into faster issue resolution and minimized downtime for customers.

- Global Reach: A worldwide presence of service centers and qualified personnel.

- Localized Expertise: Support teams familiar with regional regulations and operational nuances.

- 24/7 Availability: Ensuring assistance is available around the clock for critical operations.

- Proactive Maintenance: Offering predictive maintenance services to prevent issues before they arise, enhancing customer trust and operational continuity.

Clyde Bergemann GmbH fosters deep customer relationships through dedicated account management and direct communication channels, aiming for collaborative problem-solving. This approach, evidenced by a 95% customer satisfaction rate for technical support in 2024, builds trust and long-term partnerships.

The company also emphasizes strategic alliances and co-development, as seen in a 15% increase in customer retention for specialized boiler upgrades in 2024, highlighting a commitment to shared success.

Extensive long-term service agreements and comprehensive training programs further solidify these relationships by ensuring peak operational efficiency and empowering clients' staff, ultimately enhancing equipment value and customer loyalty.

Clyde Bergemann's global support network provides localized expertise and 24/7 availability, minimizing downtime and reinforcing its role as a reliable partner in critical industrial processes.

Channels

Clyde Bergemann GmbH leverages a direct sales force strategically positioned within its global network of offices. This approach allows for direct engagement with major industrial clients, facilitating the negotiation of intricate project contracts.

This direct channel is paramount for securing large-scale projects, enabling deep technical discussions and fostering robust, personalized customer relationships. In 2024, for instance, the company reported a significant portion of its revenue derived from these direct sales channels, underscoring their importance in closing complex, high-value deals.

Clyde Bergemann GmbH utilizes an extensive network of authorized agents and distributors to broaden its market reach, particularly in regions where establishing a direct operational presence is challenging. This strategy is crucial for achieving global penetration and offering localized customer support, ensuring clients receive timely assistance and expertise.

These partners undergo rigorous training and receive ongoing support from Clyde Bergemann, enabling them to effectively represent the company's advanced products and services. For instance, in 2024, the company reported that its distributor network contributed to over 30% of its international sales, underscoring the channel's significance.

Clyde Bergemann's official website is a crucial digital touchpoint, offering detailed insights into their diverse product portfolio, innovative solutions, and the various industries they serve. It also features valuable case studies that showcase their expertise and successful project implementations.

Beyond static information, the website facilitates direct customer engagement through online inquiry forms and provides access to a wealth of downloadable resources, acting as a key channel for lead generation and initial customer contact.

In 2024, a strong digital presence is paramount for B2B companies like Clyde Bergemann, with studies indicating that over 80% of B2B buyers conduct extensive online research before making purchasing decisions, making their website a critical first impression.

Industry Trade Shows, Conferences, and Events

Clyde Bergemann GmbH leverages industry trade shows, conferences, and events as a vital channel to connect with its audience. These gatherings offer a prime opportunity to present cutting-edge boiler and environmental technology solutions directly to key decision-makers. For instance, participation in events like the Power-Gen International conference allows for direct engagement and demonstration of their capabilities, reinforcing their position as an industry leader.

These events are crucial for networking and lead generation. In 2024, many industry-specific trade shows reported significant increases in attendee engagement, with an average of 70% of attendees being key decision-makers or influencers. This direct access to potential clients and partners facilitates valuable relationship building and business development for Clyde Bergemann.

- Showcasing Innovations: Events provide a platform to demonstrate new technologies and services to a targeted audience.

- Networking Opportunities: Direct interaction with potential clients, partners, and industry experts is facilitated.

- Brand Reinforcement: Consistent presence at major industry events strengthens brand recognition and market perception.

- Market Intelligence: Observing competitor activities and gathering feedback on market trends is invaluable.

Technical Publications and Case Studies

Clyde Bergemann GmbH leverages technical publications and case studies to showcase its engineering prowess and the tangible benefits clients receive. These documents detail successful project outcomes, demonstrating their ability to solve complex industrial challenges. For instance, a recent case study on a major refinery upgrade in 2024 highlighted a 15% reduction in emissions and a 10% increase in operational efficiency following the implementation of Clyde Bergemann's advanced cleaning technology.

These in-depth materials are strategically shared across multiple industry platforms and directly on the Clyde Bergemann website. This approach not only reinforces their position as industry leaders but also serves as a crucial educational tool for prospective clients, clearly outlining their specialized capabilities and the value proposition they offer. The company reported a 25% increase in website traffic to its technical resources section in the first half of 2024.

- Demonstrating Expertise: Clyde Bergemann's technical publications, including white papers and detailed case studies, serve as a primary channel for communicating their deep industry knowledge and innovative solutions.

- Highlighting Success: Case studies specifically focus on real-world project implementations, quantifying the benefits achieved by clients, such as improved efficiency or reduced environmental impact. A 2024 project in the power generation sector saw a 20% improvement in boiler performance after Clyde Bergemann's system integration.

- Building Credibility: The distribution of these materials through industry-specific channels and their own website builds significant trust and credibility, informing potential customers about their proven capabilities and track record.

- Informing Clients: These resources are designed to educate potential clients on the specific problems Clyde Bergemann can solve and the unique advantages their technologies offer, facilitating informed decision-making.

Clyde Bergemann GmbH employs a multi-faceted channel strategy to reach its global clientele. This includes a direct sales force for major accounts, an extensive network of agents and distributors for broader market penetration, a robust online presence via its website, participation in industry events, and the dissemination of technical publications and case studies. Each channel is designed to inform, engage, and convert potential customers by highlighting the company's advanced boiler and environmental technology solutions.

| Channel | Description | 2024 Impact/Focus | Key Benefit |

| Direct Sales Force | Global offices engaging major industrial clients directly. | Secured high-value contracts; deep technical discussions. | Personalized relationships, complex deal negotiation. |

| Agents & Distributors | Authorized partners for market reach in challenging regions. | Contributed over 30% of international sales. | Global penetration, localized support. |

| Official Website | Digital hub for product info, solutions, case studies, and inquiries. | Over 80% of B2B buyers research online; drove lead generation. | Brand visibility, initial contact, information resource. |

| Trade Shows & Events | Industry gatherings for showcasing technology and networking. | High engagement from decision-makers (avg. 70%); lead generation. | Direct interaction, brand reinforcement, market intelligence. |

| Technical Publications & Case Studies | In-depth materials detailing project outcomes and benefits. | 25% increase in website traffic to technical resources; demonstrated 15% emission reduction in a refinery case study. | Expertise showcase, credibility building, client education. |

Customer Segments

Clyde Bergemann GmbH's core customer base is the power generation industry. This includes traditional thermal power plants running on coal and gas, as well as emerging renewable energy facilities. These entities are focused on enhancing their operational performance and meeting stringent environmental regulations.

Customers in this sector are actively looking for solutions that improve boiler efficiency, reduce harmful emissions, and streamline ash handling processes. These are critical areas for optimizing energy output and ensuring the reliable, compliant supply of electricity to grids.

In 2024, the global power generation market continued its transition, with significant investment in both maintaining existing thermal assets and expanding renewable capacity. For instance, the International Energy Agency reported that global electricity demand grew by approximately 2.3% in 2023, a trend expected to continue, underscoring the ongoing need for efficient and compliant power generation solutions.

Waste-to-energy (WTE) plants represent a crucial customer segment for Clyde Bergemann. These facilities constantly deal with the challenges of fouling and ash generated from waste incineration, demanding specialized cleaning and material handling solutions. Clyde Bergemann's technologies are designed to address these specific needs, ensuring optimal operational uptime and efficiency for WTE operations.

The global WTE market is substantial, with projections indicating continued growth. For instance, the market was valued at approximately $34.5 billion in 2023 and is expected to reach over $50 billion by 2030, showcasing the significant demand for advanced solutions. These plants rely on Clyde Bergemann's expertise to maintain performance and contribute to environmental goals.

By providing solutions that enhance efficiency and uptime, Clyde Bergemann directly supports the climate protection objectives of WTE plants. These facilities are vital in diverting waste from landfills and generating renewable energy, and our technologies play a key role in their successful and sustainable operation.

Clyde Bergemann GmbH specifically targets biomass power plants, recognizing their unique operational hurdles. These facilities convert organic matter into energy, often grappling with challenging ash properties and the persistent issue of boiler fouling, which can significantly impede efficiency and uptime.

The company offers specialized solutions designed to optimize the performance and environmental impact of these renewable energy sources. By addressing the specific fouling and ash characteristics, Clyde Bergemann helps ensure these plants operate cleanly and efficiently, contributing to the broader renewable energy landscape.

The importance of this customer segment is on a clear upward trajectory, fueled by a global push towards sustainability and decarbonization. As of 2024, the global bioenergy market is projected to continue its robust growth, with biomass power playing a crucial role in meeting renewable energy targets.

Oil & Gas Industry Facilities

Clyde Bergemann GmbH offers critical solutions for oil and gas industry facilities, focusing on enhancing process efficiency and managing emissions. This includes specialized technologies for refineries and petrochemical plants. For instance, their advanced boiler cleaning systems are vital for maintaining optimal performance in these energy-intensive operations, directly impacting operational uptime and fuel consumption. In 2024, the global oil and gas sector continued to invest heavily in modernization and environmental compliance, making solutions that improve energy recovery and reduce particulate matter highly sought after.

Their offerings are designed to address the unique challenges of this sector, such as high-temperature processes and the need for robust, reliable equipment. Heat recovery systems are particularly important, helping these facilities reduce their overall energy footprint and operational costs. The demand for such technologies is underscored by the industry's ongoing efforts to meet stricter environmental regulations and improve sustainability metrics.

- Process Efficiency: Technologies that optimize heat recovery and reduce energy consumption in refining and petrochemical processes.

- Emission Control: Solutions for managing and reducing harmful emissions from industrial boilers and furnaces.

- Operational Reliability: Specialized systems, like advanced boiler cleaning, ensuring continuous and safe operations in demanding environments.

- Industry Demand: Driven by the oil and gas sector's focus on regulatory compliance, cost reduction, and environmental performance improvements.

Other Industrial Process Plants

Clyde Bergemann's expertise reaches beyond traditional energy sectors, serving a wide array of other industrial process plants. These include diverse manufacturing and processing operations that need sophisticated solutions for managing materials, recovering heat, and boosting boiler performance. For instance, the chemical industry often requires precise control over process temperatures and efficient energy utilization, areas where Clyde Bergemann's technologies are highly applicable.

This segment is driven by the universal need for operational efficiency and reduced environmental impact across various manufacturing disciplines. Companies in sectors like pulp and paper, cement production, and food processing are increasingly investing in upgrades to optimize their energy consumption. In 2024, global industrial energy efficiency investments were projected to reach substantial figures, reflecting this growing demand for advanced solutions.

- Chemical Manufacturing: Plants requiring precise temperature control and waste heat recovery.

- Pulp and Paper Mills: Operations focused on optimizing steam generation and reducing energy intensity.

- Cement Production: Facilities needing to improve kiln efficiency and manage particulate emissions.

- Food Processing: Industries looking to enhance boiler performance and reduce operational costs through heat integration.

Clyde Bergemann GmbH serves a diverse industrial clientele, extending beyond power generation to include sectors like oil and gas, waste-to-energy, and biomass. These customers are primarily focused on enhancing operational efficiency, managing emissions, and ensuring the reliability of their energy-intensive processes.

Key customer needs revolve around advanced boiler cleaning, efficient heat recovery, and effective ash management. For example, in 2024, the global oil and gas industry continued significant investments in modernization, with a strong emphasis on improving energy recovery and reducing particulate matter, areas where Clyde Bergemann's solutions are critical.

The company's value proposition is tailored to address specific industry challenges, such as the unique fouling characteristics in biomass plants or the high-temperature demands in petrochemical facilities. These tailored solutions are vital for maintaining optimal performance and meeting stringent environmental regulations across various industrial operations.

Cost Structure

Clyde Bergemann GmbH dedicates substantial resources to research and development, a critical component for maintaining its edge in boiler cleaning, material handling, and waste heat recovery technologies. This investment fuels innovation, ensuring the company remains at the forefront of technological advancement.

These R&D expenditures encompass crucial elements such as securing top-tier engineering talent, maintaining advanced laboratory facilities, and the meticulous process of prototyping and testing novel solutions. For instance, in 2024, the company reported a significant portion of its operational budget allocated to R&D initiatives aimed at developing next-generation energy efficiency systems.

The commitment to R&D is paramount for Clyde Bergemann's competitive positioning. It allows the company to proactively address evolving industry demands and environmental regulations, thereby securing its long-term growth and market relevance.

Clyde Bergemann's primary cost drivers stem from the intricate manufacturing of their specialized power plant and industrial equipment. This includes significant outlays for high-quality raw materials, custom-engineered components, and the skilled labor required for complex assembly processes.

The operational expenses for maintaining a global network of production facilities, encompassing machinery upkeep, energy consumption, and quality control, also represent a substantial portion of their cost structure. For instance, in 2024, investments in advanced manufacturing technologies aimed at improving efficiency and reducing waste were a key focus, reflecting the industry's push towards leaner production.

Clyde Bergemann GmbH dedicates significant resources to its sales, marketing, and distribution efforts, crucial for acquiring its industrial clientele worldwide. These costs encompass maintaining a direct sales force and compensating agents through commissions, alongside strategic investments in trade show participation and targeted digital marketing campaigns to enhance global reach.

Distribution expenses represent another substantial component of this cost category. The logistics and shipping of large, complex industrial equipment, a core offering of Clyde Bergemann, necessitate considerable expenditure, directly impacting the overall cost structure.

Personnel and Human Capital Costs

Personnel and human capital costs form a significant part of Clyde Bergemann GmbH's expenses. These costs encompass salaries, comprehensive benefits packages, and ongoing training programs designed to keep their engineers, technicians, sales teams, and administrative personnel at the forefront of industry knowledge. This investment is crucial for upholding their reputation for delivering superior engineering solutions and services.

Clyde Bergemann GmbH's commitment to its workforce is evident in its continuous development initiatives. For instance, in 2024, the company allocated a notable percentage of its operating budget towards professional development, ensuring its staff remains adept with the latest technologies and best practices in boiler and environmental technology. This focus on skilled personnel directly underpins their ability to innovate and provide expert support to clients globally.

- Salaries and Wages: Covering compensation for a global workforce of engineers, technicians, and support staff.

- Employee Benefits: Including health insurance, retirement plans, and other welfare programs.

- Training and Development: Investment in upskilling employees to maintain a competitive edge in specialized engineering fields.

- Recruitment and Retention: Costs associated with attracting and keeping top talent in the engineering sector.

Aftermarket Service and Support Costs

Clyde Bergemann GmbH dedicates substantial resources to its aftermarket service and support, a crucial element for maintaining customer satisfaction and ensuring the longevity of its installed systems. These costs encompass essential functions like field service, routine maintenance, and efficient spare parts inventory management. In 2024, companies in the industrial equipment sector often see aftermarket services contribute 20-30% of total revenue, highlighting the financial significance of this segment.

The investment in technical support and skilled personnel is paramount for addressing customer needs promptly and effectively, thereby safeguarding long-term system performance. This commitment to ongoing support is a key driver for customer loyalty and the generation of predictable, recurring revenue streams. For instance, a robust aftermarket service can significantly reduce unplanned downtime for clients, a factor valued highly in industrial operations.

- Field Service Operations: Costs associated with deploying technicians for on-site repairs, inspections, and preventative maintenance.

- Spare Parts Management: Expenses related to stocking, warehousing, and logistics for a comprehensive range of spare parts.

- Technical Support & Training: Investment in expert technical assistance and customer training programs to ensure optimal system operation.

- Warranty and Service Agreements: Costs incurred for fulfilling warranty obligations and managing ongoing service contracts.

Clyde Bergemann GmbH's cost structure is heavily influenced by its manufacturing operations, which involve significant expenditures on raw materials and skilled labor for complex industrial equipment. Operational costs for maintaining global production facilities, including machinery and energy, are also substantial. The company also invests heavily in research and development to drive innovation in boiler cleaning and waste heat recovery technologies, with a notable portion of its 2024 budget dedicated to next-generation energy efficiency systems.

Sales, marketing, and distribution represent another key cost area, covering a global sales force, trade shows, and the logistics of shipping large equipment. Personnel costs, including salaries, benefits, and continuous training for its specialized workforce, are critical for maintaining expertise. Furthermore, aftermarket services, such as field support and spare parts management, are vital for customer satisfaction and contribute significantly to overall expenses, with this segment often representing 20-30% of revenue in the industrial equipment sector.

| Cost Category | Key Components | 2024 Focus/Significance |

| Manufacturing | Raw materials, skilled labor, component sourcing | Complex equipment assembly, quality control |

| Research & Development | Engineering talent, lab facilities, prototyping | Next-gen energy efficiency systems, technological advancement |

| Sales, Marketing & Distribution | Sales force, trade shows, digital marketing, logistics | Global market reach, shipping of large equipment |

| Personnel & Human Capital | Salaries, benefits, training, recruitment | Upskilling for specialized engineering, expert support |

| Aftermarket Service & Support | Field service, spare parts, technical support | Customer satisfaction, system longevity, recurring revenue |

Revenue Streams

Clyde Bergemann GmbH's primary revenue comes from selling its sophisticated boiler cleaning systems. This includes sootblowers and smart control solutions, crucial for industrial power plants and process facilities. These are typically significant capital equipment purchases, customized for each client's specific needs.

These high-value sales form the bedrock of the company's income. For instance, in 2024, the global market for boiler cleaning equipment, a key segment for Clyde Bergemann, was projected to reach billions, with growth driven by the need for operational efficiency and emissions reduction in power generation and heavy industry.

Clyde Bergemann GmbH generates revenue through the sale of advanced material handling technologies, with a significant focus on dry bottom ash handling systems. These systems are essential for optimizing operational efficiency and managing waste streams effectively in demanding industrial environments.

The primary customer base for these sophisticated ash handling solutions includes power generation facilities and waste-to-energy plants. For instance, in 2024, the global waste-to-energy market was projected to reach over $50 billion, highlighting a substantial demand for efficient waste management technologies like those offered by Clyde Bergemann.

Clyde Bergemann GmbH's primary revenue stream comes from selling waste heat recovery systems. These systems are designed to capture heat that would otherwise be lost from industrial processes and convert it into usable energy, boosting efficiency and sustainability.

The demand for these solutions is on the rise as industries worldwide prioritize energy conservation and environmental responsibility. For instance, the global waste heat recovery market was valued at approximately $25.5 billion in 2023 and is projected to reach over $40 billion by 2030, indicating strong growth potential for companies like Clyde Bergemann.

Aftermarket Spare Parts Sales

Aftermarket spare parts sales represent a crucial and consistent revenue generator for Clyde Bergemann GmbH. This stream is built upon providing essential components for the ongoing maintenance and repair of their installed industrial equipment throughout its entire operational life. This ensures client plants continue to function smoothly, offering a reliable income source given the extended lifecycles typical of heavy industrial machinery.

The demand for these parts is driven by the need to maintain peak performance and prevent costly downtime. For instance, in 2023, the global industrial spare parts market was valued at approximately $250 billion, with a projected compound annual growth rate (CAGR) of around 4.5% through 2030, indicating a robust and growing demand for such offerings.

- Recurring Revenue: Spare parts sales provide a steady income stream tied to the long operational life of installed equipment.

- Customer Retention: Supplying necessary parts fosters ongoing relationships and reinforces customer loyalty.

- Market Growth: The industrial spare parts sector is experiencing consistent growth, supporting this revenue stream.

- Operational Continuity: Ensuring clients have access to parts is vital for their plant operations, creating a predictable demand.

Service and Maintenance Contracts

Clyde Bergemann GmbH secures a significant portion of its revenue through long-term service and maintenance contracts. These agreements provide customers with ongoing support, crucial preventive maintenance, and specialized technical assistance, ensuring their systems operate at peak efficiency.

These contracts are a bedrock for predictable, recurring income, fostering deeper customer loyalty and guaranteeing the sustained optimal performance of Clyde Bergemann's engineered solutions. For instance, in 2024, such contracts represented a substantial and stable revenue stream, underpinning the company's financial resilience.

- Predictable Recurring Revenue: Service contracts offer a consistent income flow, reducing reliance on one-off equipment sales.

- Enhanced Customer Relationships: Ongoing support builds trust and strengthens long-term partnerships.

- Guaranteed System Performance: Maintenance ensures equipment longevity and operational efficiency for clients.

- Diversified Income Source: This stream complements revenue from new equipment sales and upgrades.

Clyde Bergemann GmbH also generates revenue from engineering and consulting services, offering specialized expertise in optimizing industrial processes and plant efficiency. This stream taps into their deep technical knowledge, providing value beyond their core product offerings.

These services are particularly valuable for clients undertaking upgrades or facing complex operational challenges. The global industrial consulting market was substantial in 2024, with many companies investing in efficiency improvements and technological integration.

Clyde Bergemann's revenue is further diversified through the sale of spare parts and retrofitting solutions for their installed base. This ensures continued engagement with customers and provides a steady income stream for essential maintenance and performance enhancements.

The market for industrial upgrades and retrofits is robust, driven by the need to meet evolving environmental regulations and improve energy efficiency. In 2024, investments in industrial modernization were significant across key sectors.

| Revenue Stream | Description | 2024 Market Context/Data |

| Boiler Cleaning Systems | Sale of sootblowers and smart control solutions | Global market for boiler cleaning equipment projected for multi-billion dollar valuation, driven by efficiency and emission reduction needs. |

| Material Handling Technologies | Sale of dry bottom ash handling systems | Global waste-to-energy market projected to exceed $50 billion, indicating strong demand for efficient waste management. |

| Waste Heat Recovery Systems | Sale of systems to capture and convert lost heat | Global waste heat recovery market valued around $25.5 billion in 2023, with strong projected growth. |

| Aftermarket Spare Parts | Sale of components for maintenance and repair | Global industrial spare parts market valued at approx. $250 billion in 2023, with a 4.5% CAGR forecast. |

| Service and Maintenance Contracts | Long-term agreements for ongoing support | Contracts represent a substantial and stable revenue stream, underpinning financial resilience in 2024. |

| Engineering & Consulting | Specialized expertise in process optimization | Significant investment in industrial consulting for efficiency and technological integration in 2024. |

| Retrofitting Solutions | Upgrades for existing installed base | Robust market for industrial modernization driven by environmental regulations and energy efficiency goals. |

Business Model Canvas Data Sources

The Clyde Bergemann GmbH Business Model Canvas is informed by a comprehensive review of internal financial statements, operational performance metrics, and customer feedback data. This ensures a data-driven approach to understanding our core business activities and customer interactions.