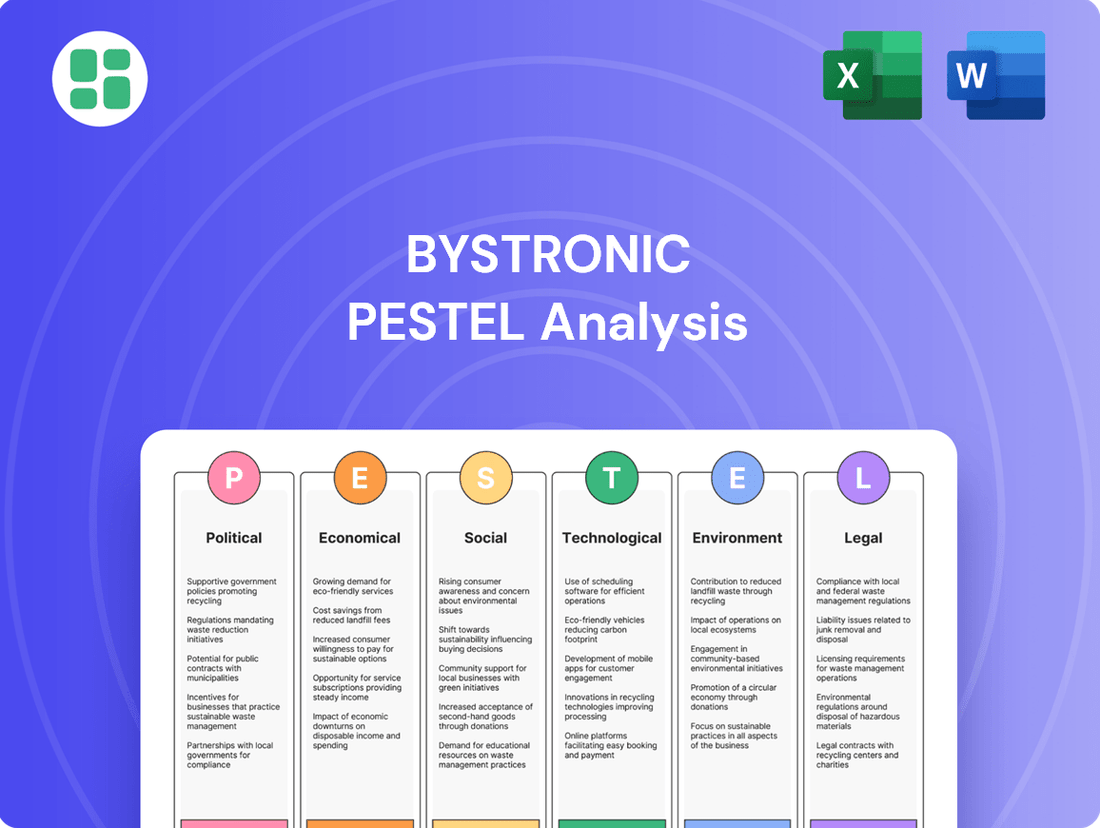

Bystronic PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Bystronic Bundle

Uncover the critical external factors influencing Bystronic's success with our comprehensive PESTLE analysis. Understand how political shifts, economic volatility, and technological advancements are shaping the future of sheet metal processing. Equip yourself with actionable intelligence to refine your strategy and gain a competitive edge. Download the full report now for immediate insights.

Political factors

Bystronic's global operations mean it's keenly exposed to geopolitical shifts and evolving trade agreements. For example, the prospect of U.S. tariff adjustments in 2025 introduces a layer of uncertainty that could affect the company's full-year financial projections. These trade policies directly influence Bystronic's supply chain stability, potentially raising operational costs and impacting the willingness of customers in critical regions to commit to new capital expenditures.

Governments worldwide are increasingly prioritizing domestic manufacturing, with initiatives like India's 'Make in India' and China's 'Made in China 2025' program aiming to boost local production. These policies often translate into direct support for advanced manufacturing technologies, including automation and digitalization, which are core to Bystronic's offerings.

In 2024, many nations are continuing to invest heavily in reshoring and strengthening their industrial bases. For example, the United States' CHIPS and Science Act, while focused on semiconductors, signals a broader trend of government backing for high-tech manufacturing, potentially creating opportunities for suppliers of advanced machinery.

These government-backed programs frequently include financial incentives, tax breaks, and subsidies for companies investing in automation and modernizing their production lines. Such measures directly encourage the adoption of sophisticated machinery, like Bystronic's laser cutting and bending solutions, thereby stimulating demand within these key markets.

The increasing trend of economic nationalism directly impacts Bystronic by shaping market access and competition. Policies favoring domestic production can create both opportunities and challenges for the company's global operations.

While some governments offer incentives for local manufacturing, potentially lowering production costs for Bystronic in those regions, others may implement protectionist measures. These restrictions could hinder Bystronic's ability to export or establish production facilities, forcing adjustments to its international sales and manufacturing strategies.

For instance, in 2024, several major economies continued to explore or implement industrial policies aimed at bolstering domestic manufacturing capabilities in advanced sectors, including machinery. This could lead to varying levels of support or barriers for foreign companies like Bystronic depending on their local presence and investment.

Regulatory Environment for Technology and Data

Bystronic's increasing reliance on software, AI, and IoT technologies means navigating a complex web of regulations. Data privacy laws like GDPR and CCPA, alongside evolving cybersecurity mandates, directly impact how Bystronic collects, stores, and utilizes customer and operational data. Failure to comply can lead to significant fines and reputational damage, with global data protection fines reaching billions annually in recent years.

The development and deployment of AI also fall under increasing scrutiny. Ethical AI guidelines and potential regulations concerning algorithmic bias and transparency are becoming paramount. Bystronic must ensure its AI-driven solutions are not only effective but also compliant with emerging standards to maintain customer trust and market access.

- Data Privacy Compliance: Adherence to global regulations such as GDPR (effective 2018) and CCPA (effective 2020) is critical for Bystronic's software-integrated offerings.

- Cybersecurity Standards: Meeting evolving cybersecurity requirements is essential to protect sensitive data and maintain operational integrity, with cybersecurity spending projected to exceed $260 billion globally in 2024.

- Ethical AI Frameworks: Proactive engagement with ethical AI development principles and anticipated regulations will be key for responsible innovation.

Sustainability Regulations and Green Deals

Global sustainability regulations are increasingly shaping industrial landscapes, directly influencing companies like Bystronic. For instance, the European Union's ambitious Green Deal aims for climate neutrality by 2050, driving demand for eco-friendly manufacturing processes and products. This translates into stricter requirements for energy efficiency and material usage within the metal fabrication sector.

The Ecodesign for Sustainable Products Regulation (ESPR), part of the EU's Green Deal, is a prime example of how these policies impact businesses. It mandates that products placed on the EU market must be more durable, reusable, repairable, and recyclable. Bystronic's customers, therefore, need machinery that supports these principles, pushing Bystronic to innovate in areas like energy consumption and waste reduction throughout the product lifecycle.

Bystronic's commitment to sustainability is a direct response to these evolving political factors. The company is actively developing solutions that align with circular economy principles and reduce environmental impact. This strategic alignment is crucial for maintaining market competitiveness and meeting the growing expectations of environmentally conscious customers and regulators.

- European Green Deal: Aims for climate neutrality by 2050, setting a precedent for global environmental policy.

- Ecodesign for Sustainable Products Regulation (ESPR): Focuses on product durability, repairability, and recyclability.

- Customer Demand: Growing pressure from Bystronic's clients for machinery that supports sustainable manufacturing practices.

Government policies promoting domestic manufacturing, such as reshoring initiatives seen in the US and Europe in 2024, directly influence Bystronic's market access and competitive landscape. These policies can create incentives for local production of advanced machinery, potentially boosting demand for Bystronic's automated solutions. Conversely, protectionist measures could pose challenges, necessitating strategic adjustments to global sales and manufacturing operations.

The increasing focus on data privacy and cybersecurity, with regulations like GDPR and CCPA in effect, impacts Bystronic's software-driven offerings. Compliance with evolving cybersecurity standards, where global spending was projected to exceed $260 billion in 2024, is crucial for protecting sensitive data and maintaining operational integrity. Ethical AI frameworks are also gaining prominence, requiring Bystronic to ensure its AI solutions are transparent and unbiased.

Sustainability regulations, exemplified by the EU's Green Deal and the Ecodesign for Sustainable Products Regulation (ESPR), are driving demand for eco-friendly manufacturing. These policies mandate greater product durability, repairability, and recyclability, pushing Bystronic to develop machinery that supports circular economy principles and reduces environmental impact, aligning with growing customer and regulatory expectations.

What is included in the product

This PESTLE analysis provides a comprehensive examination of the external macro-environmental factors influencing Bystronic, covering Political, Economic, Social, Technological, Environmental, and Legal dimensions.

It offers actionable insights and forward-looking perspectives to guide strategic decision-making and identify potential opportunities and threats within Bystronic's operating landscape.

Provides a concise version that can be dropped into PowerPoints or used in group planning sessions, streamlining strategy discussions.

Helps support discussions on external risk and market positioning during planning sessions by offering a clear overview of key factors.

Economic factors

Bystronic navigated a tough economic landscape in 2024, with expectations for continued challenges through 2025. This slowdown, amplified by geopolitical tensions, directly impacted customer engagement and the company's order intake across all its operating regions.

The persistence of high interest rates globally, coupled with generally subdued consumer spending, has fostered a climate of cautious investment. This hesitation among Bystronic's customer base directly translates to a dampening effect on demand for their advanced machinery and solutions.

Fluctuations in raw material prices and the stability of global supply chains are critical factors for Bystronic. For instance, the price of steel, a key input for their machines, saw significant volatility in 2023, with some periods experiencing double-digit percentage increases. This directly affects Bystronic's cost of goods sold and, consequently, their profit margins.

While global supply chain disruptions have somewhat eased from their peak in 2022, input material costs, including those for specialty metals and electronic components, remain elevated. Bystronic's strategic sourcing initiatives and inventory management are therefore crucial for mitigating these ongoing cost pressures and ensuring consistent production output for their advanced sheet metal processing solutions.

Currency fluctuations, especially the strength of the Swiss franc, pose a significant challenge for Bystronic as a global entity. When Bystronic converts revenues earned in weaker currencies back to Swiss francs, a stronger franc can lead to a reduction in reported net sales and profitability.

For instance, in 2023, Bystronic reported that currency headwinds had a noticeable impact on its financial results. A strong Swiss franc can make Bystronic's products more expensive for international customers, potentially affecting order intake and overall market competitiveness.

Investment in Automation and Digitalization

Despite ongoing economic uncertainties, the drive towards automation and digitalization in manufacturing remains a powerful long-term trend, directly benefiting companies like Bystronic. Businesses are actively investing in smart factory technologies to boost precision, cut costs, and streamline operations. For instance, global spending on industrial automation was projected to reach over $200 billion in 2024, with a significant portion allocated to digital solutions and robotics.

This investment surge is fueled by the need for enhanced efficiency and competitiveness. Companies are recognizing that advanced manufacturing processes are crucial for maintaining market share. The adoption of AI and IoT in factories is expected to grow substantially, with some reports indicating a doubling of connected industrial devices between 2023 and 2028.

- Increased Demand for Integrated Solutions: Businesses seek end-to-end automation to maximize benefits.

- Focus on Operational Efficiency: Automation directly addresses labor shortages and rising operational costs.

- Smart Manufacturing Adoption: Investment in Industry 4.0 technologies is a key strategic priority for many manufacturers.

- Data-Driven Decision Making: Digitalization enables better insights into production processes, leading to improved outcomes.

Customer Capacity Utilization and Aftermarket Demand

Customer capacity utilization directly influences Bystronic's aftermarket demand. When clients operate their machinery at lower rates, their need for spare parts, consumables, and even new equipment naturally diminishes. This can put pressure on Bystronic's service and sales divisions, particularly impacting revenue streams derived from maintenance and repairs.

Despite this, Bystronic's strategy of broadening its service portfolio and securing more long-term maintenance contracts provides a crucial buffer. These recurring revenue streams help to stabilize income even when new machine orders slow down due to reduced customer capacity. For instance, in 2024, Bystronic reported a significant portion of its revenue coming from services, demonstrating the resilience of this segment.

- Impact of Low Utilization: Reduced customer capacity leads to lower demand for spare parts and new Bystronic machines.

- Service Revenue Resilience: A diversified service portfolio and an increase in maintenance contracts help mitigate the impact of decreased customer activity.

- 2024 Service Contribution: Services represented a substantial part of Bystronic's overall revenue in 2024, highlighting the segment's stability.

Global economic conditions in 2024 and projected into 2025 presented a challenging environment for Bystronic, characterized by subdued demand and cautious investment. High interest rates and reduced consumer spending contributed to a slowdown, impacting order intake across key markets.

Fluctuations in raw material prices, particularly for steel and electronic components, continued to affect Bystronic's cost of goods sold and profit margins, despite some easing of supply chain disruptions. Currency volatility, notably the strength of the Swiss franc, also presented headwinds, potentially increasing product costs for international buyers.

Despite economic headwinds, the trend towards manufacturing automation and digitalization remained strong, driving investment in smart factory technologies. Global spending on industrial automation was expected to exceed $200 billion in 2024, with significant growth anticipated in AI and IoT integration in manufacturing facilities.

Customer capacity utilization directly influenced Bystronic's aftermarket demand for parts and services. However, the company's focus on expanding its service portfolio and securing long-term maintenance contracts provided a stabilizing effect on revenue streams in 2024.

Same Document Delivered

Bystronic PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This comprehensive PESTLE analysis of Bystronic provides a detailed examination of the Political, Economic, Social, Technological, Legal, and Environmental factors impacting the company. You will gain valuable insights into the external forces shaping Bystronic's strategic landscape.

Sociological factors

The manufacturing sector, including areas relevant to Bystronic's operations, continues to grapple with a shortage of skilled workers, particularly in high-demand fields like automation, AI, and software development. This persistent challenge is a significant driver for companies to invest in advanced automated solutions, a core offering of Bystronic.

This labor scarcity not only fuels demand for Bystronic's automation technologies but also compels businesses to prioritize internal training and development initiatives to upskill their existing workforce. For instance, in the US, the manufacturing sector reported over 800,000 job openings in early 2024, highlighting the ongoing labor deficit.

Customers are increasingly making purchasing decisions based on a company's commitment to sustainable production methods. This is a significant shift, with many consumers actively seeking out brands that demonstrate environmental responsibility.

Bystronic's proactive approach to energy efficiency, resource optimization, and circular economy principles in its machinery directly aligns with these evolving customer preferences. For instance, Bystronic's commitment to reducing the environmental footprint of its manufacturing processes is a key selling point.

In 2024, reports indicated a significant rise in consumer willingness to pay a premium for sustainable products. This trend is expected to continue, making Bystronic's focus on eco-friendly solutions a crucial competitive advantage in the machinery sector.

The increasing adoption of AI and automation in manufacturing, as seen in Bystronic's advanced cutting and bending solutions, is fundamentally reshaping the labor market. While these technologies promise significant productivity gains, an estimated 30% of current work hours could be automated by 2030, according to McKinsey, leading to societal anxieties about job security and the imperative for extensive workforce reskilling initiatives.

Bystronic, as a key enabler of this technological shift, plays a crucial role in these societal dialogues. The company's commitment to developing user-friendly interfaces and providing comprehensive training programs directly addresses the need to equip the existing workforce with the skills required to operate and maintain automated systems, thereby mitigating potential negative impacts.

Diversity and Inclusion Initiatives

Societal expectations for diversity and inclusion within corporations are increasingly influential, impacting brand reputation and talent acquisition. Bystronic recognizes this shift, setting ambitious targets to foster a more equitable workplace. For instance, the company aims to achieve 25% women in management positions by 2030, a clear demonstration of its commitment to social responsibility.

These initiatives are not just about compliance; they are strategic. By cultivating a diverse workforce, Bystronic can tap into a wider range of perspectives and skills, potentially leading to more innovative solutions and a better understanding of global customer needs. This focus on inclusion also enhances employee engagement and retention, as individuals feel valued and represented.

- Target: Bystronic aims for 25% women in management by 2030.

- Talent Attraction: Diversity initiatives help attract a broader and more skilled talent pool.

- Innovation: Diverse teams often lead to more creative problem-solving and product development.

- Employee Engagement: Inclusive environments foster higher morale and commitment among staff.

Occupational Health and Safety Standards

Societal expectations and regulatory frameworks increasingly demand robust occupational health and safety (OHS) measures across all industries, particularly in manufacturing. Bystronic, producing complex, heavy machinery, faces heightened scrutiny to ensure both its operational safety and the safety features integrated into its products. This societal pressure translates into a critical business imperative to not only comply with but exceed OHS standards, positioning the company as a responsible industry leader.

In 2023, the global manufacturing sector saw continued emphasis on OHS, with initiatives like the EU's Strategic Framework on Health and Safety at Work 2021-2027 driving stricter enforcement and best practice adoption. Bystronic's commitment is reflected in its operational practices and product design, aiming to minimize risks for its employees and customers. For instance, advancements in machine guarding and user interface design are crucial to preventing accidents. The company's focus on creating safer working environments contributes to employee well-being and operational efficiency, reducing potential downtime and associated costs. According to industry reports from late 2024, companies with strong OHS records often experience lower insurance premiums and higher employee retention rates.

- Societal Demand: Growing public and employee awareness of workplace safety drives demand for higher OHS standards in manufacturing.

- Regulatory Landscape: Evolving legislation, such as the EU's Strategic Framework on Health and Safety at Work, mandates stricter compliance and continuous improvement.

- Industry Leadership: Bystronic aims to be an OHS benchmark, integrating advanced safety features into its machinery and operational procedures.

- Economic Impact: Strong OHS performance can lead to reduced insurance costs and improved employee morale and retention, as indicated by late 2024 industry analyses.

Societal expectations around ethical business practices and corporate social responsibility are increasingly influencing purchasing decisions and investment strategies. Consumers and investors alike are scrutinizing companies for their environmental impact, labor practices, and community engagement. Bystronic's dedication to sustainability and ethical operations, including its ambitious diversity targets, directly addresses these evolving societal demands.

The growing emphasis on diversity and inclusion within the workforce is a significant sociological factor. Bystronic's commitment to achieving 25% women in management by 2030 not only enhances its brand reputation but also taps into a broader talent pool, fostering innovation and better understanding of global markets. This focus on inclusivity is crucial for attracting and retaining top talent in a competitive landscape.

Workplace safety remains a paramount concern, with societal pressure and regulatory frameworks demanding stringent occupational health and safety (OHS) measures. Bystronic's proactive approach to integrating advanced safety features into its machinery and ensuring safe operational procedures reflects this societal imperative. Strong OHS performance, as highlighted by late 2024 industry analyses, correlates with lower insurance costs and improved employee retention.

| Sociological Factor | Bystronic's Response/Impact | Data/Evidence (2024/2025) |

|---|---|---|

| Ethical Business Practices & CSR | Alignment with consumer and investor demand for sustainability and ethical operations. | Increased consumer willingness to pay a premium for sustainable products in 2024. |

| Diversity & Inclusion | Commitment to diversity targets, e.g., 25% women in management by 2030. | Aims to enhance talent acquisition, innovation, and market understanding. |

| Occupational Health & Safety (OHS) | Integration of advanced safety features and safe operational procedures. | Strong OHS records linked to lower insurance premiums and higher employee retention (late 2024 industry reports). |

Technological factors

Bystronic benefits from ongoing advancements in laser cutting, with fiber laser sources now commonly reaching 20 kilowatts and even 30 kilowatts, enabling significantly faster and cleaner cuts on thicker materials. These high-power lasers are crucial for maintaining Bystronic's competitive edge in the sheet metal processing market.

In bending technology, innovations like electric bending machines and highly flexible, modular bending cells are transforming production. These systems offer increased precision, reduced setup times, and greater automation possibilities, directly impacting Bystronic's ability to offer state-of-the-art solutions to its customers.

Bystronic's commitment to integrating AI and smart manufacturing is a significant technological driver. The company is heavily investing in AI-driven sensors for real-time monitoring, predictive maintenance, and intelligent cutting processes (ICP). This strategic focus aims to boost machine performance and efficiency.

This AI-powered optimization directly translates to tangible benefits, such as reducing material waste and minimizing the need for constant human oversight. For instance, predictive maintenance powered by AI can anticipate potential equipment failures, preventing costly downtime. In 2024, Bystronic reported continued strong demand for its smart factory solutions, indicating market acceptance of these advanced technologies.

Bystronic's strategy hinges on the intelligent networking of its laser cutting systems and press brakes with advanced automation and software. This approach positions them as a full solutions provider in the metal fabrication industry.

The integration of their software company, Kurago, into Bystronic Software underscores a strong commitment to digital transformation and enabling connected production environments. This move is crucial for streamlining operations and enhancing efficiency for their customers.

In 2024, the demand for smart manufacturing solutions continues to rise, with automation in metal fabrication projected to grow significantly. Bystronic's investment in software and automation directly addresses this market trend, aiming to capture a larger share by offering integrated, digitalized workflows.

Modular Product Design and Customization

Bystronic's commitment to modular product design is a significant technological advantage. This allows customers to create highly customized solutions by combining different functional packages, such as those focused on automation, energy efficiency, or cutting quality. For instance, the Bystronic Autonomy package, integrated into their modular systems, aims to streamline the entire workflow from order entry to finished product, a key driver in the evolving manufacturing landscape.

This flexibility directly translates into enhanced market competitiveness for Bystronic's clients. By tailoring machines to precise production needs, businesses can optimize their operations, reduce waste, and improve throughput. In 2024, the demand for adaptable manufacturing equipment is projected to grow, with companies increasingly seeking solutions that can evolve with changing market demands and technological advancements.

The modular approach also facilitates easier upgrades and maintenance, extending the lifespan of the machinery and reducing total cost of ownership. This technological strategy positions Bystronic to capitalize on the trend towards smart factories and Industry 4.0, where interoperability and customization are paramount. Bystronic's sales for the first half of 2024 reached CHF 1,518.5 million, reflecting strong market demand for their innovative solutions.

- Modular design enables tailored solutions, meeting diverse customer production needs.

- Integration of packages like Autonomy enhances operational efficiency and workflow automation.

- Flexibility supports adaptation to evolving market demands and technological shifts.

- Bystronic's first-half 2024 sales of CHF 1,518.5 million underscore the market's positive reception.

Research and Development (R&D) Investments

Bystronic's commitment to innovation is underscored by its substantial Research and Development (R&D) investments, crucial for maintaining its leadership in cutting and bending technology. The company's dedication to pushing technological boundaries was recognized with the Swiss Technology Award for its Intelligent Cutting Process, highlighting its focus on practical, advanced solutions. This drive for innovation is reflected in their continuous exploration of new materials, integration of eco-design principles to enhance sustainability, and development of technologies aimed at extending product lifespans, ensuring their offerings remain at the forefront of the industry.

Key R&D focus areas for Bystronic include:

- Advancements in laser cutting and bending automation

- Development of smart factory solutions and digital integration

- Research into sustainable materials and energy-efficient processes

- Enhancement of user interfaces and software for intuitive operation

Technological advancements are central to Bystronic's strategy, particularly in high-power laser cutting, with systems now commonly featuring 20-30 kilowatt fiber laser sources for faster, cleaner cuts on thicker materials. Innovations in electric bending machines and modular bending cells enhance precision and automation, directly boosting Bystronic's competitive edge.

The company is heavily investing in AI for smart manufacturing, integrating AI-driven sensors for real-time monitoring and predictive maintenance, which aims to improve machine performance and reduce downtime. Bystronic's focus on networking its systems with advanced automation and software, exemplified by the integration of Kurago, positions them as a comprehensive solutions provider in the evolving digital manufacturing landscape.

Bystronic's modular product design allows for tailored customer solutions and easier upgrades, aligning with the growing demand for adaptable manufacturing equipment and smart factories. This strategy is supported by significant R&D investments, including recognition with the Swiss Technology Award for its Intelligent Cutting Process, underscoring a commitment to innovation in automation, digital integration, and sustainable processes.

Legal factors

Bystronic's advanced laser cutting and bending machines must meet rigorous safety regulations, such as the European Union's Machinery Directive and UL certification in North America, to gain market access. Failure to comply can result in significant fines and market exclusion, impacting sales opportunities. In 2024, the global industrial machinery market faced increased scrutiny on safety compliance, with regulatory bodies actively enforcing stricter standards, making adherence a critical business imperative for companies like Bystronic.

Bystronic's commitment to innovation is underscored by its strategic protection of key technologies. For instance, its Intelligent Cutting Process, a core differentiator, is safeguarded through a portfolio of patents, ensuring that competitors cannot easily replicate its efficiency gains. This focus on intellectual property is vital in the capital equipment sector, where technological advancements directly translate to market share.

The company actively monitors and defends its patents to prevent unauthorized use of its proprietary software and hardware innovations. In 2024, Bystronic continued to invest in R&D, with a significant portion allocated to developing and patenting next-generation automation and digital solutions for sheet metal processing. This proactive approach to IP management is essential for sustaining its premium market positioning and commanding pricing power.

Navigating global labor laws is critical for Bystronic, especially when undertaking significant restructuring. The company's 2024 decision to reduce approximately 500 positions worldwide necessitates careful adherence to diverse national employment regulations, impacting everything from severance packages to consultation periods.

These legal frameworks vary significantly by region, demanding specialized legal counsel to ensure compliance and mitigate risks. For instance, European Union countries often have stringent worker protection laws, requiring extensive consultation with employee representatives before implementing layoffs, a process that can extend timelines and increase costs.

Environmental Compliance and Reporting

Bystronic operates within a framework of stringent environmental laws, covering areas like emissions control, waste disposal, and the efficient use of resources. For instance, in 2024, stricter European Union regulations on industrial emissions (IED) came into effect, requiring companies like Bystronic to further invest in cleaner production technologies and reporting mechanisms. Failure to comply can lead to significant fines and operational disruptions.

The company's dedication to ethical conduct is also legally mandated. Bystronic's commitment to publishing a human rights policy and implementing Human Rights Due Diligence processes aligns with evolving global legal expectations for corporate responsibility. This includes adhering to frameworks like the UN Guiding Principles on Business and Human Rights, which gained further traction with new reporting requirements for large companies in several jurisdictions starting in 2025.

- Environmental Regulations: Bystronic must adhere to evolving EU and national laws concerning emissions, waste, and resource use, with compliance costs a key factor in operational planning.

- Human Rights Due Diligence: Legal obligations are increasing for companies to actively identify, prevent, and mitigate human rights impacts throughout their value chains.

- Reporting Obligations: Expect ongoing scrutiny and potential new legal requirements for transparent reporting on environmental performance and human rights practices.

Data Privacy and Cybersecurity Regulations

Bystronic's increasing reliance on digital solutions and interconnected machinery necessitates strict adherence to data privacy laws like the GDPR. Failure to comply can result in significant penalties, with fines potentially reaching 4% of global annual turnover or €20 million, whichever is greater. This regulatory landscape demands robust cybersecurity protocols to safeguard sensitive customer and operational data.

The company must prioritize protecting intellectual property and customer information from cyber threats. For instance, the European Union Agency for Cybersecurity (ENISA) reported that in 2023, ransomware attacks alone cost businesses an estimated €11.5 billion across the EU. Implementing strong data encryption and secure network infrastructure is therefore paramount.

- GDPR Fines: Potential penalties up to 4% of global annual turnover or €20 million.

- Cybersecurity Investment: Need for continuous investment in advanced security measures.

- Data Breach Costs: The average cost of a data breach in 2024 is projected to exceed $4.7 million globally, according to IBM's Cost of a Data Breach Report.

- Customer Trust: Maintaining customer trust through demonstrable data protection practices.

Bystronic must navigate a complex web of international trade laws and sanctions, impacting supply chain management and market access. For example, the ongoing geopolitical tensions in 2024 continue to shape global trade policies, requiring diligent compliance to avoid disruptions.

The company's patent portfolio is a critical legal asset, with ongoing efforts in 2024 to defend its innovations in areas like automated sheet metal processing. This focus on intellectual property protection is essential for maintaining its competitive edge and premium pricing in the capital equipment market.

Adherence to labor laws is paramount, especially following the 2024 workforce adjustments. Bystronic must ensure compliance with diverse national employment regulations, including consultation periods and severance entitlements, to mitigate legal risks.

| Legal Factor | Relevance to Bystronic | 2024/2025 Data/Trend |

| Intellectual Property | Protection of patents for cutting and bending technologies. | Increased R&D investment in 2024 for new patents in automation and digital solutions. |

| Trade Compliance | Adherence to international trade laws and sanctions. | Geopolitical shifts in 2024 continue to influence global trade policies, requiring vigilant compliance. |

| Labor Law | Compliance with employment regulations during workforce changes. | 2024 workforce reductions necessitate strict adherence to varying national labor laws and consultation requirements. |

Environmental factors

Bystronic is actively addressing climate change by targeting a 42% reduction in Scope 1 and 2 emissions and a 25% reduction in Scope 3 emissions by 2030, as per the Science-Based Targets initiative. This commitment is being realized through concrete actions like transitioning away from fossil fuels and enhancing energy efficiency across its operations.

The company is also investing in renewable energy sources, evidenced by the installation of solar panels at its production sites. These initiatives not only support global decarbonization efforts but also position Bystronic to navigate the increasing regulatory and market pressures related to environmental impact.

Bystronic is embedding circular economy principles across its operations, evidenced by a lighthouse program with key partners aimed at fostering circular models within its supply chain. This initiative is crucial for resource efficiency, as it encourages the reuse and recycling of materials, thereby reducing waste and the demand for virgin resources.

The company's commitment extends to eco-design, where products are developed with sustainability in mind, focusing on longevity and ease of repair. Furthermore, Bystronic actively extends the service life of its machines through comprehensive maintenance and refurbishing services, directly contributing to a more circular approach by keeping assets in use longer.

Bystronic is actively pursuing a 20% reduction in waste by the year 2030, a significant target that underscores its commitment to environmental stewardship. This ambitious goal is being addressed through a multi-faceted approach that includes enhanced recycling programs, the reuse of materials wherever possible, and innovative repurposing strategies for components and byproducts.

These waste management initiatives are not isolated efforts but are woven into the fabric of Bystronic's broader sustainability agenda, impacting every stage of its operations and the entire lifecycle of its cutting and bending machines. For instance, in 2023, the company reported a 12% decrease in production waste compared to its 2020 baseline, demonstrating tangible progress towards its 2030 objective.

Sustainable Product Design and Materials

Bystronic is actively pursuing sustainable product design, focusing on materials that require less energy to produce and process. This includes exploring innovative solutions that not only extend the lifespan of their machinery but also reduce the energy consumption during operation.

A key initiative is Bystronic's collaboration with SSAB, a prominent steel producer. This partnership aims to advance cutting and bending technologies, specifically by integrating new materials such as recycled and fossil-free steel into their manufacturing processes. This move directly addresses environmental concerns by reducing the carbon footprint associated with raw material sourcing.

- Focus on Energy-Intensive Materials: Bystronic is researching and implementing materials that have a lower energy demand in their production.

- Extended Product Service Life: The company is developing solutions to make its machines last longer, thereby reducing the need for frequent replacements and associated resource consumption.

- Reduced Operational Energy: Bystronic's design philosophy includes minimizing the energy required for the machines to operate.

- Partnership for Sustainable Steel: The collaboration with SSAB highlights a commitment to using advanced materials like recycled and fossil-free steel, demonstrating a proactive approach to environmental responsibility in the supply chain.

Energy Consumption of Products and Operations

Bystronic recognizes that the energy consumption of its products during customer use represents a substantial part of its overall environmental footprint. This realization drives a strategic focus on developing cleantech solutions designed to boost both material and energy efficiency.

Key initiatives include the advancement of energy-saving laser sources and more efficient chiller systems, directly addressing the operational energy demands of their machinery. For instance, Bystronic's commitment to sustainability is evident in their ongoing research and development into technologies that minimize power draw without compromising performance, a critical factor for their global customer base in 2024 and beyond.

- Energy Efficiency Focus: Bystronic prioritizes cleantech solutions to reduce the environmental impact of its products during customer operation.

- Product Innovation: Development of energy-saving laser sources and chiller systems are key areas of environmental R&D.

- Value Chain Emissions: A significant portion of Bystronic's value chain emissions stems from the energy used by its products in customer applications.

Bystronic is actively tackling environmental challenges by setting ambitious emission reduction targets, aiming for a 42% cut in Scope 1 and 2 emissions and 25% in Scope 3 by 2030, aligned with the Science-Based Targets initiative. This involves transitioning from fossil fuels and improving energy efficiency, alongside investments in renewable energy like solar panel installations at production sites.

The company is also embedding circular economy principles, with a focus on extending product service life through comprehensive maintenance and refurbishing, and developing machines that require less energy to operate. A notable collaboration with SSAB aims to integrate recycled and fossil-free steel into their manufacturing, directly reducing the carbon footprint from raw material sourcing.

| Environmental Target | Current Status/Action | Year |

|---|---|---|

| Scope 1 & 2 Emissions Reduction | Targeting 42% reduction | 2030 |

| Scope 3 Emissions Reduction | Targeting 25% reduction | 2030 |

| Waste Reduction | Targeting 20% reduction | 2030 |

| Production Waste Reduction | Achieved 12% reduction (vs. 2020 baseline) | 2023 |

PESTLE Analysis Data Sources

Our Bystronic PESTLE Analysis is meticulously constructed using data from reputable sources like the International Monetary Fund (IMF), World Bank, and Eurostat. We also incorporate industry-specific reports from leading market research firms and government publications detailing technological advancements and regulatory changes.