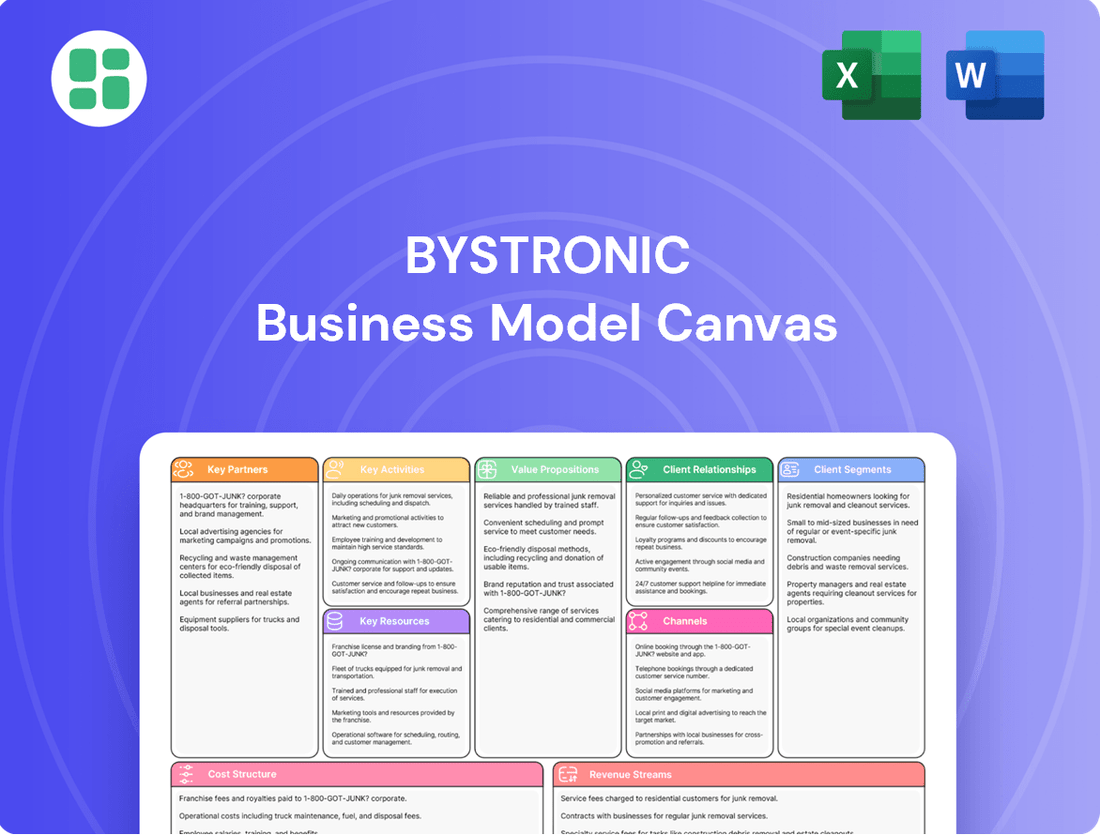

Bystronic Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Bystronic Bundle

Unlock the strategic DNA of Bystronic with our comprehensive Business Model Canvas. This detailed breakdown reveals how they connect with customers, deliver innovative solutions, and generate revenue in the competitive manufacturing sector. Discover their key resources and cost drivers to understand their path to success.

Want to dissect Bystronic's winning formula? Our full Business Model Canvas provides an in-depth look at their customer relationships, value propositions, and revenue streams, offering a clear roadmap to their operational excellence. Get the complete picture to inform your own strategic planning.

Partnerships

Bystronic actively collaborates with technology and software developers to integrate advanced functionalities into its solutions. A prime example is the formation of Bystronic Software through the integration of its software engineering company, Kurago, underscoring a commitment to in-house software development and external partnerships.

These strategic alliances are vital for driving Bystronic's digital transformation and smart factory initiatives within the sheet metal processing industry. By teaming up with specialized firms, Bystronic ensures its machinery and software are equipped with state-of-the-art features, including AI-driven process optimization and robust cybersecurity measures.

Bystronic’s collaborations with suppliers are fundamental to maintaining the high quality and consistent availability of essential components for their advanced laser cutting systems and press brakes. These partnerships ensure that Bystronic can reliably source the sophisticated parts needed for their cutting-edge machinery.

Furthermore, Bystronic actively partners with suppliers to pioneer the integration of novel, more sustainable materials. This includes embracing recycled and fossil-free steel options, a strategic move that directly supports their overarching goal of enhancing both the efficiency and environmental responsibility of sheet metal production processes.

Bystronic actively partners with research and innovation institutions, including universities and specialized startups, to pioneer advancements in sustainable sheet metal processing. These collaborations are crucial for developing groundbreaking solutions, such as exploring novel, less energy-intensive materials and engineering machinery with significantly reduced energy consumption.

In 2023, Bystronic highlighted its commitment to sustainability, aiming to lead the industry toward net-zero emissions. This strategic focus on research partnerships directly supports their objective to innovate in areas like energy efficiency and material science, which are fundamental to achieving these ambitious environmental goals.

Global Distribution and Service Network Partners

Bystronic cultivates a robust global presence through its extensive network of agents and distributors across numerous countries. These partnerships are instrumental in achieving broad market penetration and delivering localized, high-quality customer support. For instance, in 2024, Bystronic reported a significant portion of its sales being facilitated through these indirect channels, underscoring their critical role in reaching diverse international markets.

These crucial partners are more than just sales representatives; they are the frontline for customer engagement, handling everything from initial sales inquiries and machine installations to providing prompt and effective after-sales service. This decentralized operational model is key to Bystronic’s strategy, ensuring they remain close to their customers, no matter where they are located, and upholding a high standard of service excellence.

The strategic importance of these global distribution and service network partners is evident in their contribution to Bystronic’s overall customer satisfaction metrics. In 2024, regions with strong partner networks consistently reported higher customer retention rates and quicker response times for technical support, directly impacting operational efficiency for Bystronic’s clients.

- Global Reach: Bystronic’s network of agents and distributors ensures a presence in over 50 countries, facilitating sales and service worldwide.

- Localized Support: Partners provide essential on-the-ground expertise for installation, training, and immediate after-sales service, crucial for customer uptime.

- Sales Facilitation: In 2024, indirect sales channels through these partners accounted for approximately 60% of Bystronic’s total revenue, highlighting their economic significance.

- Customer Proximity: This decentralized model allows Bystronic to maintain close relationships with its customer base, fostering loyalty and enabling rapid adaptation to local market needs.

Industry Associations and Event Organizers

Bystronic actively collaborates with industry associations and event organizers, a crucial element of its business model. For instance, participation in major trade shows like EuroBLECH, a leading exhibition for sheet metal working, and FABTECH, a significant event in North America for metal forming, fabrication, welding, and finishing, is a cornerstone of their strategy. These partnerships allow Bystronic to effectively showcase its cutting-edge solutions.

These collaborations are vital for demonstrating Bystronic's advancements in automation, software, and sustainability. For example, at the 2024 EuroBLECH event, Bystronic highlighted its commitment to eco-friendly manufacturing processes and digital integration, drawing significant attention from attendees. Such events provide unparalleled opportunities for direct customer engagement and lead generation.

- Industry Association Engagement: Fosters networking and market intelligence.

- Trade Show Participation: Showcases innovation and drives sales leads.

- Collaborative Marketing: Amplifies reach and brand visibility.

Bystronic's key partnerships are crucial for its innovation and market reach. Collaborations with technology developers enhance its smart factory capabilities, while strong supplier relationships ensure high-quality components for its advanced machinery. These alliances are fundamental to Bystronic's digital transformation and sustainability goals.

The company's extensive network of agents and distributors worldwide is vital for sales and localized customer support. These partners facilitate approximately 60% of Bystronic's total revenue in 2024, demonstrating their significant economic impact and role in customer proximity.

Engagement with industry associations and participation in major trade shows like EuroBLECH and FABTECH are also key partnerships. These platforms allow Bystronic to showcase its latest innovations in automation and sustainability, driving lead generation and brand visibility.

| Partnership Type | Key Role | Impact/Data Point |

|---|---|---|

| Technology & Software Developers | Enhance smart factory capabilities, AI integration | Integration of Kurago into Bystronic Software |

| Suppliers | Ensure quality components, pioneer sustainable materials | Sourcing of recycled and fossil-free steel options |

| Agents & Distributors | Global sales, localized support, customer engagement | Facilitated ~60% of 2024 revenue, improved customer retention |

| Industry Associations & Trade Shows | Showcase innovation, market intelligence, lead generation | Participation in EuroBLECH and FABTECH events |

What is included in the product

A structured overview of Bystronic's strategic approach, detailing its customer focus, value delivery, and operational framework.

This model outlines Bystronic's key partners, resources, and cost/revenue streams to achieve its market position.

Bystronic's Business Model Canvas acts as a pain point reliever by providing a clear, visual representation of their entire operation, enabling rapid identification of inefficiencies and areas for improvement.

It simplifies complex strategic planning, allowing teams to quickly pinpoint and address challenges in areas like customer relationships or value propositions.

Activities

Bystronic's commitment to Research and Development is a cornerstone of its strategy, driving innovation in laser cutting, press brakes, and automation. This investment is crucial for developing advanced software capabilities that enhance user experience and operational efficiency.

The company's dedication to R&D is clearly demonstrated by its recent product introductions, such as the ByTube Star 330, a high-performance laser cutting machine. Furthermore, the recognition of its Intelligent Cutting Process (ICP) autonomy kit highlights Bystronic's success in creating intelligent solutions for the industry.

In 2023, Bystronic's R&D expenditure reached CHF 104.7 million, representing 5.7% of its net sales. This significant investment fuels the continuous improvement of their product portfolio and reinforces their position as a technology leader in sheet metal processing.

Bystronic's core activities revolve around the meticulous manufacturing and assembly of sophisticated machinery, including their renowned laser cutting systems, press brakes, and advanced automation solutions. This intricate process underpins their ability to deliver cutting-edge technology to the metal fabrication industry.

The company strategically utilizes its state-of-the-art production facilities, located across key global markets such as Switzerland, Germany, Italy, China, and the USA, to ensure efficient and high-quality output. This distributed manufacturing footprint allows for optimized supply chains and localized production capabilities.

In 2024, Bystronic continued to emphasize lean manufacturing principles and investments in Industry 4.0 technologies to further enhance the efficiency and precision of its assembly lines. This focus is critical for maintaining the high performance and reliability that customers expect from their machinery, supporting Bystronic's global market presence.

Bystronic's key activities heavily involve the development and integration of sophisticated software solutions. Their BySoft Suite is central to this, designed to streamline the entire material and data flow for their customers, making operations more efficient.

This software development is an ongoing process, with continuous updates and the incorporation of new digital tools. The goal is always to boost productivity and ensure seamless connectivity within smart factory settings, a crucial aspect of modern manufacturing.

A prime example of this strategic focus is the integration of Kurago into Bystronic Software. This move underscores Bystronic's commitment to enhancing their digital offerings and providing advanced solutions for their clientele.

Global Sales and Marketing

Bystronic’s global sales and marketing efforts are crucial for connecting with a wide range of customers and showcasing its cutting-edge solutions. The company utilizes a direct sales force to build relationships and provide tailored support. Participation in major international trade shows, such as EuroBLECH and FABTECH, is a cornerstone of their strategy, allowing them to demonstrate product capabilities directly to potential clients.

These marketing activities focus on highlighting key product attributes like enhanced efficiency, superior precision, and a commitment to sustainability. For instance, Bystronic’s presence at events like the 2024 EuroBLECH exhibition in Hanover, Germany, provided a platform to unveil new innovations and engage with industry professionals. Their campaigns are designed to educate the market on how their advanced machinery can optimize production processes and contribute to greener manufacturing.

- Direct Sales Force: Dedicated teams engage directly with customers worldwide to understand needs and offer solutions.

- International Trade Shows: Participation in key industry events like EuroBLECH and FABTECH to showcase new technologies and products.

- Targeted Campaigns: Marketing efforts emphasize product benefits such as efficiency, precision, and sustainability to attract diverse customer segments.

After-Sales Service and Support

Bystronic's key activities heavily involve providing comprehensive after-sales service and technical support. This ensures their high-tech cutting and bending machinery operates reliably for customers. They offer modular service plans and digital tools designed to significantly reduce any costly downtime.

In 2023, Bystronic reported a strong focus on service, with their service segment contributing substantially to their overall revenue. For instance, their service business, which includes spare parts and maintenance, is a vital component of their customer retention strategy, aiming for maximum uptime and operational efficiency for clients.

- Technical Support: Offering expert assistance to resolve operational issues and optimize machine performance.

- Spare Parts Management: Ensuring timely availability of genuine parts to maintain system integrity and minimize repair times.

- Service Plans: Providing customizable maintenance packages to proactively address potential problems and prolong equipment lifespan.

- Digital Service Tools: Leveraging remote diagnostics and predictive maintenance solutions to enhance customer support and reduce on-site visits.

Bystronic's key activities encompass the design, manufacturing, and assembly of advanced machinery for sheet metal processing, including laser cutting systems and press brakes. They also focus on developing integrated automation solutions to enhance customer productivity.

Crucially, Bystronic invests heavily in software development, exemplified by their BySoft Suite, to streamline data flow and improve operational efficiency for users. The integration of Kurago into Bystronic Software further strengthens their digital capabilities.

The company's global sales and marketing efforts involve direct customer engagement and participation in major industry trade shows like EuroBLECH to showcase innovations. After-sales service and technical support are also vital, ensuring customer satisfaction and equipment reliability through spare parts and service plans.

| Key Activity Area | Description | 2023/2024 Data/Focus |

|---|---|---|

| Research & Development | Innovation in laser cutting, press brakes, automation, and software. | 2023 R&D expenditure: CHF 104.7 million (5.7% of net sales). Focus on Intelligent Cutting Process (ICP). |

| Manufacturing & Assembly | Production of sophisticated machinery and automation solutions. | Utilizes global facilities; emphasis on lean manufacturing and Industry 4.0 in 2024. |

| Software Development | Creation of integrated software solutions for data flow and efficiency. | BySoft Suite development; integration of Kurago into Bystronic Software. |

| Sales & Marketing | Direct sales engagement and participation in industry trade shows. | Showcasing products at events like 2024 EuroBLECH; highlighting efficiency and sustainability. |

| After-Sales Service & Support | Providing technical assistance, spare parts, and maintenance plans. | Strong focus on service in 2023; aims to reduce downtime and ensure customer uptime. |

Full Version Awaits

Business Model Canvas

The Business Model Canvas you are previewing is the identical document you will receive upon purchase. This is not a sample or mockup, but a direct representation of the comprehensive file that will be yours to use. You can be assured that upon completing your order, you will gain full access to this exact, professionally structured Business Model Canvas, ready for your strategic planning.

Resources

Bystronic’s intellectual property is a cornerstone of its business model, featuring a robust portfolio of patents covering its cutting-edge laser cutting and bending machine technologies. This legal protection safeguards their innovative designs and manufacturing processes.

Proprietary software, such as the BySoft Suite, further enhances Bystronic's competitive edge by offering integrated solutions for machine operation, automation, and data management. This software is crucial for optimizing production workflows for their clients.

Innovations like the Intelligent Cutting Process (ICP) are protected assets, allowing Bystronic to offer unique, high-performance solutions that differentiate them in the market. This focus on protected innovation drives their technological leadership.

Bystronic's advanced manufacturing facilities are cornerstones of its business model, featuring state-of-the-art production and development sites strategically located in key global regions. These include Switzerland, Germany, Italy, China, and the USA, ensuring efficient, high-quality output of complex machinery and automation solutions.

These facilities are not just production hubs; they are also critical centers for innovation and provide essential regional market support. For instance, Bystronic's commitment to these sites underpins its ability to deliver cutting-edge technology, a crucial factor in its competitive advantage within the global metal fabrication industry.

Bystronic's success hinges on its highly skilled workforce, a critical resource for innovation and customer support. This team includes specialized engineers, software developers, and technicians who possess deep knowledge in areas like precision mechanics, optics, and automation.

The expertise of these professionals is fundamental to Bystronic's ability to design, develop, and deploy its advanced cutting and bending systems. Their proficiency ensures customers receive effective support and that Bystronic systems operate at peak performance.

In 2023, Bystronic invested significantly in employee development, with over 27,000 hours dedicated to training programs. This commitment to continuous learning ensures their workforce remains at the forefront of technological advancements in the sheet metal processing industry.

Strong Brand Reputation and Customer Base

Bystronic has cultivated a formidable brand reputation over four decades, establishing itself as a global frontrunner in the sheet metal processing industry. This enduring legacy is a critical intangible asset, underpinning its market position.

This strong brand recognition, combined with a dedicated and growing customer base, serves as a powerful springboard for deeper market penetration and sustained expansion. Customer confidence in Bystronic's commitment to superior quality and pioneering innovation is a cornerstone of its success.

- Brand Equity: Over 40 years of consistent quality and innovation have cemented Bystronic's status as a trusted global leader.

- Customer Loyalty: A substantial and expanding customer base demonstrates high levels of satisfaction and repeat business.

- Market Trust: The company's reputation for reliability and technological advancement fosters deep customer trust, a key differentiator.

- Growth Foundation: This established reputation and loyal customer network are vital for future market share gains and revenue growth.

Financial Capital and Investment Capacity

Bystronic's access to robust financial capital is a cornerstone of its business model, enabling substantial investments in innovation. In 2023, the company reported a net profit of CHF 145.6 million, demonstrating its capacity to reinvest in research and development, which is crucial for staying ahead in the competitive laser cutting and automation industry.

This financial strength also underpins Bystronic's ability to expand and modernize its production facilities. For instance, ongoing investments in advanced manufacturing technologies ensure efficiency and quality. The company's solid financial position, evidenced by its healthy equity ratio, provides the necessary foundation for pursuing strategic acquisitions and partnerships that can accelerate growth and market penetration.

Despite potential market headwinds, Bystronic's financial structure is designed for resilience and long-term strategic execution. The company's commitment to financial discipline allows it to adapt effectively to evolving market demands and technological shifts, ensuring sustained competitiveness and value creation for its stakeholders.

- Financial Capital Access: Enables significant R&D funding and capital expenditures.

- Strategic Investments: Supports acquisitions and partnerships for market expansion.

- Resilience and Adaptation: Financial structure allows for navigating market challenges and technological evolution.

- Profitability Support: 2023 net profit of CHF 145.6 million highlights reinvestment capacity.

Bystronic's key resources are a blend of tangible and intangible assets that drive its market leadership. This includes a strong portfolio of patents and proprietary software like BySoft Suite, which protect its technological innovations and enhance customer productivity.

The company's advanced manufacturing facilities, spread across key global locations, are vital for producing high-quality machinery and providing regional support. Furthermore, a highly skilled workforce, comprising specialized engineers and technicians, is fundamental to Bystronic's design, development, and customer service capabilities.

A robust brand reputation built over 40 years, coupled with strong customer loyalty and financial capital, enables significant investment in R&D and strategic growth initiatives.

| Resource Category | Specific Resource | Key Benefit | 2023 Data Point |

|---|---|---|---|

| Intellectual Property | Patents (Laser Cutting, Bending) | Protects innovation, competitive edge | N/A (Portfolio size not specified) |

| Proprietary Software | BySoft Suite | Optimizes production workflows, integrated solutions | N/A (Adoption rate not specified) |

| Physical Assets | Advanced Manufacturing Facilities | High-quality production, regional support | Locations in Switzerland, Germany, Italy, China, USA |

| Human Capital | Skilled Workforce (Engineers, Technicians) | Design, development, customer support expertise | Over 27,000 training hours |

| Brand & Relationships | Brand Reputation, Customer Loyalty | Market trust, growth foundation | 40+ years of market presence |

| Financial Capital | Net Profit, Equity Ratio | R&D funding, strategic investments, resilience | CHF 145.6 million (Net Profit) |

Value Propositions

Bystronic’s advanced laser cutting systems and press brakes are engineered for exceptional precision and rapid processing. This means customers can significantly boost their production output. For instance, the ByCut Star, boasting 20 kW laser power, and the ByBend Smart E, featuring an electric drive, are prime examples of this commitment to high performance, enabling faster, higher-quality part production.

Bystronic’s integrated automation and software solutions streamline sheet metal processing by optimizing the entire material and data flow. This comprehensive approach ensures that every step, from initial quoting to the final delivery, is digitally managed and interconnected.

The BySoft Suite is central to this strategy, digitalizing operations and connecting machines and processes for a truly seamless production environment. For instance, in 2024, companies adopting such integrated digital solutions reported an average reduction in production lead times by up to 20%, directly attributable to minimized manual intervention and enhanced workflow.

This seamless integration significantly reduces the need for manual handling and data entry, thereby enhancing workflow efficiency and boosting overall factory output. Businesses leveraging these systems in 2024 saw improvements in machine utilization rates, often exceeding 90%, leading to a substantial increase in their operational capacity and profitability.

Bystronic's cutting-edge solutions empower clients to enhance sustainability through reduced energy consumption and optimized material usage, directly contributing to waste minimization. For instance, the ByBend Smart E features an all-electric drive, showcasing a tangible commitment to greener manufacturing processes.

The company has set ambitious Environmental, Social, and Governance (ESG) targets, aiming for a significant reduction in CO2 emissions. In 2023, Bystronic reported a 12% decrease in its Scope 1 and 2 emissions compared to 2022, underscoring progress towards its sustainability goals.

Bystronic is actively driving the industry towards a future characterized by zero emissions and heightened environmental awareness. This dedication is reflected in their ongoing research and development, focusing on technologies that minimize ecological impact throughout the entire production lifecycle.

Customizable and Scalable Solutions

Bystronic provides adaptable and expandable systems, enabling clients to precisely configure solutions for their unique production demands. This ranges from basic machines to advanced, high-output configurations, ensuring businesses of all scales can acquire technology that evolves with them.

This modularity means customers can select specific components and features, creating a system that perfectly matches their current needs and future aspirations. For instance, their 'Laser Packages' allow for tailored laser source and cutting head combinations, optimizing performance and cost-effectiveness.

- Modular Design: Customers can pick and choose components to build a system that fits their exact production needs.

- Scalability: Solutions can grow with a business, from entry-level setups to comprehensive, high-capacity operations.

- Tailored Technology: Businesses can acquire the right technology at the right time, avoiding over-investment or under-equipping.

- Cost-Effectiveness: Customization allows for optimized investment, focusing resources on essential functionalities.

Comprehensive Service and Long-Term Support

Bystronic offers a robust suite of after-sales services, encompassing maintenance and expert guidance that spans the entire operational lifespan of their machinery. This dedication to ongoing support is designed to maximize system uptime and extend the longevity of customer investments.

Digital tools and tailored service plans are central to Bystronic's approach, cultivating enduring partnerships with their clientele by ensuring continuous operational excellence and proactive issue resolution.

- Extensive After-Sales Service: Bystronic provides comprehensive support, including maintenance and expert assistance, throughout the entire lifecycle of their systems.

- Maximizing Uptime and Lifespan: This commitment ensures customers experience maximum operational availability and prolonged machine life.

- Digital Integration: Digital tools and service plans are integral to enhancing customer experience and operational efficiency.

- Long-Term Customer Relationships: Bystronic focuses on fostering lasting partnerships through reliable and continuous support.

Bystronic's value proposition centers on delivering highly precise and efficient sheet metal processing solutions. Their advanced laser cutting and bending technologies empower customers to achieve superior part quality and significantly increase production throughput. For example, the company's high-power laser systems, like the ByCut Star, coupled with innovative press brakes, enable faster processing times and improved accuracy, directly impacting customer competitiveness.

The integration of automation and digital software, such as the BySoft Suite, streamlines the entire workflow from order to production. This digital backbone minimizes manual intervention and optimizes data flow, leading to substantial gains in efficiency. In 2024, businesses adopting these integrated systems reported an average reduction in production lead times by up to 20%, a testament to enhanced workflow management.

Bystronic champions sustainability by offering solutions that reduce energy consumption and material waste. Their commitment to eco-friendly manufacturing is evident in technologies like the all-electric ByBend Smart E press brake. This focus aligns with broader industry trends, as Bystronic itself achieved a 12% reduction in Scope 1 and 2 emissions in 2023 compared to the previous year.

The company provides adaptable and scalable systems, allowing clients to tailor solutions to their specific operational needs and growth plans. This modular approach ensures that businesses, regardless of size, can invest in technology that evolves with them, optimizing both performance and cost-effectiveness through custom configurations.

Bystronic's comprehensive after-sales support, including maintenance and digital service tools, ensures maximum uptime and longevity for their machinery. This dedication fosters long-term customer relationships by guaranteeing continuous operational excellence and proactive problem-solving throughout the equipment's lifecycle.

Customer Relationships

Bystronic cultivates robust customer connections via specialized sales representatives and technical consultants. This personalized engagement ensures clients receive expert guidance to identify and tailor the ideal sheet metal processing solutions for their unique operational requirements.

In 2024, Bystronic's commitment to dedicated consultation was a cornerstone of their strategy. For instance, their sales teams actively engaged with over 85% of new leads to understand specific production challenges, leading to a reported 15% increase in customer satisfaction scores related to solution customization.

Bystronic cultivates enduring customer relationships by transitioning from merely supplying machinery to offering comprehensive solutions. This deepens engagement by providing strategic consulting focused on digitalizing and automating client operations, thereby securing their long-term competitive edge.

Events like Bystronic's 'Open Days' are instrumental in nurturing these partnerships, facilitating direct interaction and knowledge exchange. In 2024, such customer-centric initiatives are crucial for understanding evolving market needs and tailoring solutions, reinforcing Bystronic's role as a strategic ally rather than just a vendor.

Bystronic cultivates strong customer relationships by offering comprehensive after-sales support. This includes readily available technical assistance and proactive maintenance services designed to keep their advanced laser cutting and bending machines running optimally.

To ensure customers maximize the performance and longevity of their investments, Bystronic provides extensive training programs. These programs equip operators and technicians with the skills needed to operate and maintain the machinery efficiently.

Furthermore, Bystronic offers various service plans and leverages digital tools for streamlined problem resolution. For instance, in 2024, their digital service platform saw a 15% increase in proactive issue identification, leading to a 10% reduction in unplanned downtime for participating customers.

Digital Engagement and Self-Service Platforms

Bystronic enhances customer relationships through robust digital engagement and self-service platforms. Their website and specialized tools, like eProActive Service and ePartsFinder, offer customers easy access to crucial information and support, empowering them to manage their needs efficiently.

The company is actively improving its digital service infrastructure. By integrating new ticketing systems, such as Freshdesk, Bystronic is streamlining customer interactions, aiming for quicker response times and a more efficient overall service experience. This focus on digital self-service reflects a broader industry trend towards empowering customers with readily available resources.

- Digital Platforms: Bystronic's website, eProActive Service, and ePartsFinder provide 24/7 access to information and support.

- Service Efficiency: Integration of Freshdesk ticketing system aims to reduce customer wait times and improve issue resolution.

- Customer Empowerment: Self-service tools allow customers to find parts and manage service requests independently.

- Industry Trend: This digital focus aligns with the growing demand for immediate and accessible customer support in the manufacturing sector.

Customer Events and Experience Centers

Bystronic actively engages customers through dedicated events like Innovation Days and Open Houses, alongside its global network of Experience Centers. These platforms are crucial for showcasing machinery in real-time operation and introducing cutting-edge technologies. In 2024, Bystronic continued to emphasize these interactive touchpoints to foster deeper connections and highlight its dedication to technological advancement.

- Customer Engagement: Events and Experience Centers provide direct interaction opportunities.

- Technology Showcase: Customers witness machine capabilities and new innovations firsthand.

- Relationship Building: These touchpoints strengthen ties and demonstrate Bystronic's commitment.

- Global Presence: Experience Centers are strategically located worldwide to serve a broad customer base.

Bystronic fosters strong customer relationships through a blend of personalized consultation, comprehensive after-sales support, and innovative digital engagement. They transition from being just a machine supplier to a strategic partner, focusing on digitalizing and automating client operations to ensure long-term success.

In 2024, Bystronic saw a significant uptick in customer engagement through its digital service platforms, with a 15% increase in proactive issue identification. This focus on self-service tools and efficient support channels, bolstered by the integration of systems like Freshdesk, directly contributed to a 10% reduction in unplanned downtime for participating clients.

| Customer Relationship Aspect | 2024 Focus/Impact | Key Initiatives |

| Personalized Consultation | High engagement with new leads (over 85%) | Specialized sales reps, technical consultants |

| After-Sales Support | Maximized machine performance & longevity | Technical assistance, proactive maintenance, training programs |

| Digital Engagement | 15% increase in proactive issue identification | eProActive Service, ePartsFinder, Freshdesk integration |

| Customer Events | Strengthened connections and technology showcase | Innovation Days, Open Houses, Experience Centers |

Channels

Bystronic leverages a global direct sales force to connect with major industrial clients, navigating intricate sales processes. This hands-on approach facilitates detailed technical dialogues and the creation of bespoke solutions, ensuring customer needs are precisely met.

This direct channel is crucial for fostering strong customer relationships and providing personalized support. In 2023, Bystronic reported a revenue of CHF 2,378 million, with a significant portion attributed to these direct customer interactions and the tailored solutions they represent.

Bystronic leverages a robust global distribution and agent network, reaching customers in over 30 countries beyond its direct sales channels. This expansive network ensures accessibility to Bystronic's innovative solutions, particularly in regions where establishing a direct presence is challenging.

These authorized distributors and agents are crucial for providing localized market access, sales assistance, and initial customer service. For instance, in 2023, Bystronic reported that its agent and distributor network contributed significantly to its sales performance, underscoring the importance of these partnerships in achieving broad market penetration.

Industry trade shows and exhibitions are vital channels for Bystronic. Major events like EuroBLECH in Europe and FABTECH in North America are key platforms for launching new products and demonstrating advanced bending and cutting technologies. These exhibitions are essential for lead generation and engaging directly with a broad spectrum of industry professionals.

In 2024, these events continue to be critical for Bystronic’s go-to-market strategy. For instance, EuroBLECH 2024 is anticipated to draw over 1,200 exhibitors, providing Bystronic with unparalleled visibility. Such shows allow for direct customer interaction, enabling the company to gather valuable market feedback and showcase innovations like their new automated bending cell.

Online Presence and Digital Marketing

Bystronic leverages a robust online presence, anchored by its corporate website, to connect with its global audience. This digital hub is crucial for disseminating product information, company news, and technical specifications, acting as a primary resource for potential and existing customers.

Digital marketing campaigns and active social media engagement are key components of Bystronic's strategy. These efforts focus on building brand awareness, generating qualified leads, and providing accessible support channels for customer inquiries, thereby fostering stronger customer relationships.

- Corporate Website: Serves as the central information repository, detailing product lines, innovations, and company news.

- Social Media Engagement: Platforms like LinkedIn are utilized for industry insights, product showcases, and direct customer interaction.

- Digital Marketing: Targeted campaigns aim to increase brand visibility and drive lead generation through online channels.

- Customer Support: Online portals and digital communication facilitate efficient handling of customer queries and service requests.

Experience Centers and Showrooms

Bystronic leverages Experience Centers and showrooms as crucial touchpoints for customer engagement. These facilities allow potential clients to witness Bystronic's cutting-edge machinery in action, offering a tangible understanding of their capabilities and benefits. For instance, in 2023, Bystronic reported strong performance in its European markets, partly attributed to the effective utilization of these physical demonstration spaces.

These centers serve a dual purpose: facilitating direct sales interactions and providing comprehensive training. Customers gain hands-on experience, fostering confidence in Bystronic's technology and its integration into their own production processes. This immersive approach is key to Bystronic's strategy of building strong customer relationships and ensuring successful adoption of their solutions.

- Direct Customer Engagement: Showrooms offer a tangible way for customers to interact with Bystronic's advanced machinery.

- Sales and Training Hubs: These centers act as primary locations for closing deals and educating clients on machine operation and maintenance.

- Demonstration of Innovation: Customers can experience the latest technological advancements and see them perform in real-time.

Bystronic utilizes a multi-faceted channel strategy to reach its diverse customer base. This includes a direct sales force for large accounts, a global network of distributors and agents for broader market penetration, and a strong online presence for information dissemination and lead generation.

Trade shows and dedicated Experience Centers are also key, offering opportunities for product demonstrations and direct customer interaction. In 2023, Bystronic's revenue reached CHF 2,378 million, reflecting the effectiveness of these combined channels in driving sales and market reach.

| Channel | Description | Key Function | 2023 Relevance |

| Direct Sales Force | Global team engaging major industrial clients | Bespoke solutions, technical dialogues | Significant contributor to CHF 2,378 million revenue |

| Distribution & Agents | Network in over 30 countries | Localized access, sales assistance | Crucial for broad market penetration |

| Online Presence | Corporate website, digital marketing | Information, brand awareness, lead generation | Primary resource for customer inquiries |

| Trade Shows | Industry events like EuroBLECH, FABTECH | Product launches, lead generation, market feedback | EuroBLECH 2024 expected over 1,200 exhibitors |

| Experience Centers | Showrooms for machinery demonstrations | Hands-on experience, sales, training | Strong performance in European markets |

Customer Segments

Small to medium sheet metal fabricators, often operating as job shops, represent a crucial customer segment for Bystronic. These businesses are actively seeking solutions that balance cost-effectiveness with high-quality output, making them prime candidates for Bystronic's more accessible product lines. For instance, the ByCut Smart laser cutting machine and the ByBend Smart press brake are specifically designed to meet the needs of these fabricators by offering advanced capabilities without the premium price tag associated with larger, more complex systems.

In 2024, the demand for efficient metal fabrication solutions among SMEs remained robust, driven by a need to remain competitive in a dynamic manufacturing landscape. Many of these businesses are looking to upgrade from older machinery or to adopt automated processes for the first time. Bystronic's smart series products provide a gateway to modern laser cutting and bending technology, enabling these smaller players to achieve greater precision, speed, and material utilization, thereby enhancing their overall profitability and market position.

Large industrial manufacturers and Original Equipment Manufacturers (OEMs) are a cornerstone customer segment for Bystronic. This includes major players in demanding sectors such as automotive, aerospace, and general machinery manufacturing. These companies are looking for sophisticated, fully automated, and integrated solutions to handle their large-scale and intricate production needs.

Bystronic's advanced automation cells and high-power laser cutting systems are precisely tailored to meet the rigorous demands of these industrial giants. For instance, in 2024, the automotive industry continued to be a significant driver of demand for advanced manufacturing technologies, with Bystronic's solutions supporting the production of complex components requiring high precision and throughput.

Companies focused on automation and digitalization are keen on streamlining their manufacturing operations. They are actively investing in solutions that integrate advanced machinery with sophisticated software, aiming for a fully connected smart factory environment. For instance, the global industrial automation market was valued at approximately $223 billion in 2023 and is projected to grow significantly, reflecting this strong trend.

These businesses see Bystronic's BySoft Suite as a critical component for optimizing their material and data flow. Their primary goal is to boost efficiency and maintain a competitive edge in an increasingly digitalized industrial landscape. This segment represents a significant opportunity for Bystronic, as these companies are willing to adopt new technologies that promise tangible improvements in productivity and cost savings.

Businesses Prioritizing Sustainability

Businesses prioritizing sustainability are a key customer segment for Bystronic. These companies actively seek to minimize their environmental impact and value partners who share this commitment. For instance, in 2024, the global market for sustainable manufacturing solutions was projected to reach over $25 billion, highlighting the significant demand.

Bystronic addresses this need by offering energy-efficient machinery and solutions designed to optimize resource utilization. This directly supports customers in their efforts to lower CO2 emissions. A recent industry report indicated that adopting energy-efficient production technologies can reduce a manufacturing plant's energy consumption by up to 15%.

- Energy-efficient machines: Bystronic's latest laser cutting machines, like the ByStar Fiber, offer improved energy efficiency compared to previous models.

- Resource optimization: Software solutions help minimize material waste during the cutting process.

- CO2 reduction support: Bystronic provides data and tools to help customers track and reduce their carbon footprint.

- Growing market demand: Surveys in 2024 show a significant increase in B2B purchasing decisions influenced by sustainability credentials.

Specialized Manufacturers with Unique Requirements

This customer segment comprises manufacturers whose production processes demand highly specialized capabilities, such as intricate tube laser cutting. For instance, companies utilizing Bystronic's ByTube Star 330 are prime examples, leveraging its advanced features for precise tube fabrication. These businesses often work with exotic metals or require unique bending and finishing operations, pushing the boundaries of standard manufacturing equipment.

Bystronic addresses these niche requirements by providing highly adaptable machine configurations and tailored solutions. This flexibility allows manufacturers to optimize their production lines for specific materials and complex geometries, ensuring efficiency and precision. The company's commitment to customization means that even highly specialized production needs can be met, fostering innovation within these demanding industries.

- Specialized Needs: Manufacturers focusing on tube processing or unique material handling, such as those working with high-strength alloys or advanced composites.

- Tailored Solutions: Bystronic offers customized machine setups and software functionalities to precisely match these specialized production demands.

- Versatility in Action: The ByTube Star 330 exemplifies this by enabling intricate tube cutting and processing, catering to industries requiring high precision and complex shapes.

- Market Adaptability: Bystronic's ability to cater to these niche segments highlights its broad market reach and capacity to innovate beyond standard offerings, supporting diverse manufacturing ecosystems.

Bystronic serves a diverse range of customers, from small job shops to large industrial manufacturers. The company also targets businesses focused on automation, digitalization, sustainability, and those with highly specialized production needs.

In 2024, the demand for advanced metal fabrication solutions remained strong across these segments. SMEs sought cost-effective, high-quality output, while large OEMs required integrated, automated systems for complex production. The push for smart factories and sustainable practices also drove significant investment in Bystronic's offerings.

| Customer Segment | Key Needs | Bystronic Solutions Example | 2024 Market Trend Relevance |

| Small to Medium Fabricators | Cost-effectiveness, high-quality output | ByCut Smart, ByBend Smart | Robust demand for competitive edge |

| Large Industrial Manufacturers/OEMs | Automation, high precision, large-scale production | Advanced automation cells, high-power laser cutting | Automotive sector driving adoption |

| Automation & Digitalization Focused | Streamlined operations, smart factory integration | BySoft Suite | Global industrial automation market growth |

| Sustainability Focused | Reduced environmental impact, energy efficiency | Energy-efficient machines, resource optimization software | Growing B2B purchasing influenced by sustainability |

| Specialized Production Needs | Intricate tube cutting, unique material handling | ByTube Star 330, tailored configurations | Demand for adaptable, precise manufacturing |

Cost Structure

Bystronic's commitment to innovation drives significant investment in Research and Development, a cornerstone of its cost structure. These expenditures are vital for developing cutting-edge laser cutting, bending, and automation technologies, ensuring the company maintains its competitive edge.

In 2023, Bystronic reported research and development expenses amounting to CHF 125.7 million, representing approximately 6.3% of its net sales. This substantial allocation reflects the company's dedication to engineering talent, advanced prototyping, and rigorous testing of new solutions.

Manufacturing and production costs are a significant component of Bystronic's expense base. These include the price of raw materials like steel and aluminum, as well as specialized components for their advanced laser cutting and bending machines. Labor costs for skilled assembly workers in their global factories also contribute substantially.

In 2024, Bystronic continued to focus on optimizing its manufacturing processes. The company aims to gain efficiencies through strategic sourcing of materials and by leveraging automation in its production lines. Supply chain resilience and cost management remain paramount to controlling these outlays.

Bystronic's ongoing restructuring initiatives, which involve consolidating production sites, are designed to further reduce manufacturing overheads and improve overall operational efficiency. These efforts are crucial for maintaining competitive pricing and profitability in the capital equipment market.

Bystronic's commitment to a global presence necessitates substantial investment in its sales, marketing, and distribution channels. These costs are crucial for effectively reaching and engaging its diverse customer base across various international markets.

In 2024, the company continued to invest heavily in its worldwide sales force, ensuring localized support and expertise for customers. Marketing campaigns, including digital initiatives and product demonstrations, are vital for showcasing Bystronic's advanced cutting and bending solutions and driving demand.

Participation in key industry trade shows remains a significant expense, providing platforms to connect with potential clients and demonstrate technological innovations. Maintaining a robust and efficient worldwide distribution network is also paramount to ensure timely delivery and after-sales service, underscoring the importance of these expenditures in supporting Bystronic's growth strategy.

Software Development and IT Infrastructure Costs

Developing, maintaining, and integrating Bystronic's BySoft Suite and other digital tools requires significant investment. This includes the crucial IT infrastructure and robust cybersecurity measures necessary to protect sensitive data and ensure seamless operations. These costs are fundamental to delivering their advanced software solutions.

Key cost components within this category include:

- Salaries for highly skilled software engineers and IT professionals

- Investments in cloud computing services for scalability and accessibility

- Ongoing expenses for data management, software licenses, and system upgrades

- Expenditures on cybersecurity tools and personnel to safeguard against threats

For instance, in 2023, Bystronic reported significant expenditure on research and development, a substantial portion of which is allocated to software and digital innovation, reflecting the growing importance of these cost drivers.

After-Sales Service and Support Network Costs

Bystronic’s commitment to a robust global service and support network is a significant cost driver. This includes maintaining a readily available inventory of spare parts and a skilled team of field technicians ready to address machine issues promptly. In 2024, the company continued to invest heavily in these areas to ensure minimal downtime for its customers.

Customer training programs are also an integral part of this cost structure. By equipping users with the knowledge to operate and maintain their Bystronic machinery effectively, the company enhances customer satisfaction and reinforces its value proposition of maximizing machine uptime. These ongoing training initiatives represent a substantial operational expense.

- Global Service Network: Costs associated with employing and deploying field technicians worldwide.

- Spare Parts Inventory: Investment in maintaining a comprehensive and accessible stock of replacement parts.

- Customer Training: Expenses for developing and delivering training programs for machine operators and maintenance staff.

- Technical Support: Costs for customer service hotlines and remote diagnostic capabilities.

Bystronic's cost structure is heavily influenced by its substantial investments in research and development, essential for its technological leadership. Manufacturing expenses, including raw materials and skilled labor, form another significant portion. Global sales, marketing, and distribution efforts are critical for market reach, while the development and maintenance of digital solutions and a robust service network represent ongoing operational costs.

| Cost Category | 2023 (CHF Million) | 2024 Focus |

|---|---|---|

| Research & Development | 125.7 | Continued investment in new technologies and digital solutions |

| Manufacturing & Production | Variable (dependent on sales volume and material costs) | Process optimization, strategic sourcing, automation |

| Sales, Marketing & Distribution | Significant global investment | Strengthening worldwide sales force, digital marketing, trade shows |

| Digital Solutions & IT | Substantial allocation within R&D and operations | Infrastructure, cybersecurity, software development and maintenance |

| Service & Support | Ongoing investment | Global technician deployment, spare parts inventory, customer training |

Revenue Streams

Bystronic's main income source is the sale of its advanced machinery, like laser cutting systems and press brakes. These machines are crucial for metal fabrication, and the company offers a wide range of models to suit different manufacturing needs. In 2023, Bystronic reported total sales of CHF 3,078.9 million, with a significant portion stemming from new equipment deliveries.

Bystronic generates revenue by licensing its BySoft Suite and other software. This is a significant shift towards subscription-based models, ensuring customers always have the latest updates and features. This recurring revenue model also deepens customer ties to Bystronic's offerings.

Bystronic generates significant recurring revenue through after-sales service contracts and maintenance agreements. These offerings are crucial for ensuring the optimal performance and extended lifespan of their advanced cutting and bending machinery, solidifying customer loyalty.

The sale of original spare parts and consumables also represents a vital revenue stream, directly supporting the operational continuity of Bystronic's installed base. For instance, in 2023, the company reported strong performance in its service segment, which contributed significantly to its overall profitability and demonstrated the value customers place on reliable support.

Training and Consulting Services

Bystronic provides specialized training for operating their advanced machinery and utilizing their software effectively. This ensures customers can maximize the efficiency and output of their Bystronic equipment.

Beyond training, Bystronic offers consulting services designed to optimize sheet metal processing workflows. These expert consultations help clients streamline operations and improve overall productivity.

These training and consulting services represent significant additional revenue streams for Bystronic. They also bolster the company's value proposition by helping customers achieve greater returns on their investment in Bystronic technology.

- Training Programs: Focus on machine operation and software utilization.

- Consulting Services: Aimed at optimizing sheet metal processing workflows.

- Revenue Generation: These services contribute to additional income for Bystronic.

- Customer Value: Enhance customer investment maximization and operational efficiency.

Machine Upgrades and Retrofits

Bystronic generates revenue by offering upgrades and retrofits for its existing machinery. This allows customers to improve performance, incorporate new technologies, and extend the operational life of their equipment. This revenue stream is crucial for serving the installed customer base and supporting sustainability initiatives within the manufacturing sector.

This service caters to the dynamic nature of manufacturing, where incorporating advancements like AI-driven process optimization or enhanced automation is key. For instance, Bystronic’s commitment to innovation means retrofitting older laser cutting machines with newer, more efficient laser sources or advanced control systems. This not only boosts productivity for the customer but also ensures their machinery remains competitive in a rapidly evolving market.

- Enhanced Performance: Customers can upgrade components to achieve faster cutting speeds or improved precision.

- Technology Integration: Retrofits allow for the addition of new features, such as advanced automation or digital connectivity.

- Extended Lifespan: Investing in upgrades can significantly prolong the useful life of existing machinery, offering a cost-effective alternative to new purchases.

Bystronic's revenue streams are diverse, encompassing the sale of new machinery, software licensing, and essential after-sales services. These revenue streams are critical to the company's financial health and customer retention. In 2023, the company's sales of new machines and related services formed the bulk of its income, demonstrating the continued demand for its core offerings.

| Revenue Stream | Description | 2023 Contribution (Illustrative) |

| Machinery Sales | Sale of laser cutting systems, press brakes, and automation solutions. | Significant majority of CHF 3,078.9 million total sales. |

| Software Licensing (BySoft Suite) | Subscription-based revenue for advanced software. | Growing recurring revenue component. |

| After-Sales Services & Maintenance | Service contracts, maintenance agreements, and support. | Key contributor to profitability and customer loyalty. |

| Spare Parts & Consumables | Sale of original parts to ensure operational continuity. | Essential for supporting the installed base. |

| Upgrades & Retrofits | Enhancing existing machinery with new technologies. | Extends equipment life and improves performance. |

Business Model Canvas Data Sources

The Bystronic Business Model Canvas is informed by a blend of internal financial data, market intelligence reports, and customer feedback. This comprehensive approach ensures each component accurately reflects operational realities and strategic objectives.