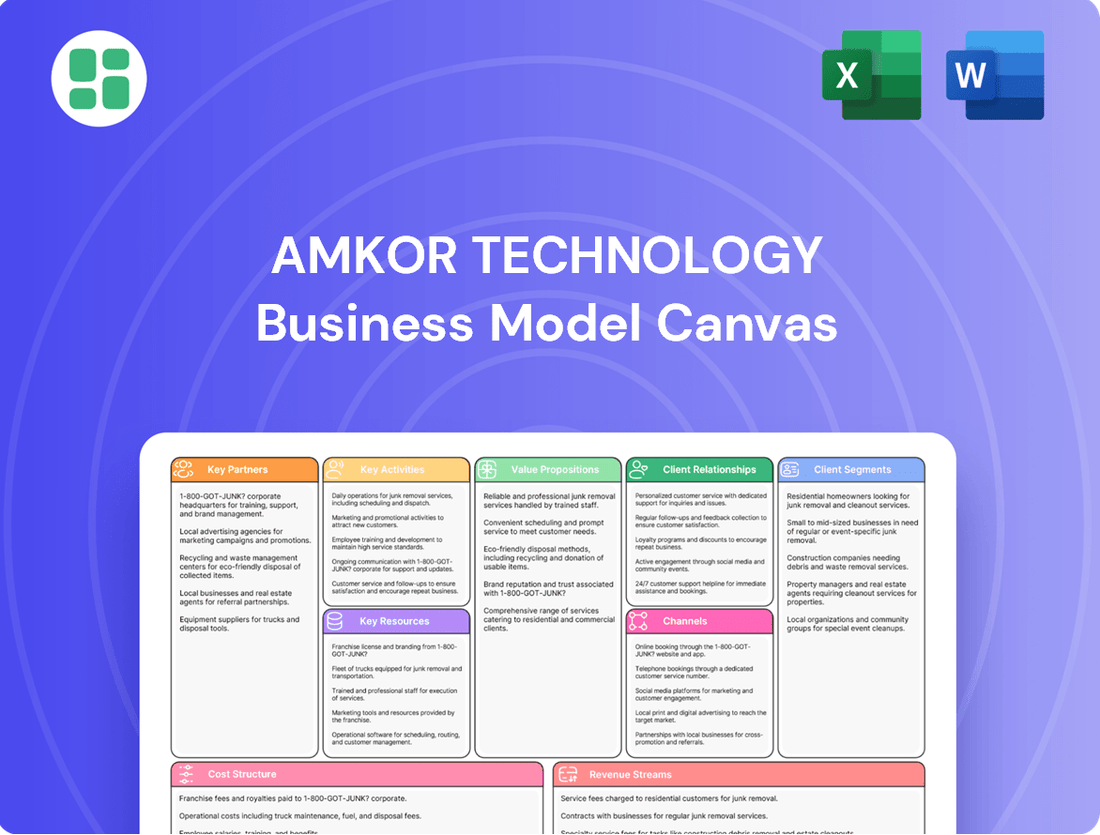

Amkor Technology Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Amkor Technology Bundle

Unlock the strategic blueprint behind Amkor Technology's success with our comprehensive Business Model Canvas. This detailed analysis reveals their key customer segments, value propositions, and revenue streams, offering a clear understanding of their market position. It's an essential tool for anyone seeking to dissect and learn from a leader in the semiconductor packaging industry.

Partnerships

Amkor Technology cultivates enduring partnerships with premier fabless semiconductor firms and Integrated Device Manufacturers (IDMs). These collaborations are fundamental for jointly creating cutting-edge packaging solutions that address the dynamic needs of emerging chip technologies, guaranteeing smooth transitions from wafer production to finished goods.

A notable instance of these strategic alliances is Amkor's work with TSMC in Arizona, focusing on advanced packaging and testing capabilities. This partnership underscores Amkor's commitment to staying at the forefront of semiconductor manufacturing advancements.

Amkor Technology's strategic alliances with Electronic Design Automation (EDA) tool providers are crucial for staying at the forefront of semiconductor packaging innovation. These partnerships ensure that Amkor's advanced packaging solutions, like their advanced substrate technologies, are seamlessly integrated with the design software used by their clients.

By working closely with EDA vendors, Amkor guarantees that their cutting-edge packaging designs are compatible with the latest design tools, significantly accelerating the time-to-market for complex integrated circuits. This synergy directly benefits their customers by streamlining the entire design-to-manufacturing pipeline.

Amkor Technology actively pursues joint development agreements with key customers. These collaborations are designed to co-create highly specialized semiconductor packaging and test solutions. This customer-centric approach ensures Amkor's innovations directly address the unique needs and performance targets of their partners' cutting-edge products.

This strategy is particularly crucial for tackling complex technological hurdles in rapidly expanding market segments. For instance, in 2024, Amkor’s focus on advanced packaging for AI accelerators, a direct result of such partnerships, saw significant demand, reflecting the success of this tailored development model.

Equipment and Material Suppliers

Amkor Technology relies on a robust network of equipment and material suppliers to maintain its competitive edge in semiconductor packaging. These relationships are foundational for securing a consistent flow of essential raw materials and the latest manufacturing technologies, directly impacting production quality and innovation.

- Supplier Diversification: Amkor actively manages a broad supplier base to ensure supply chain resilience and prevent single-source dependencies, a strategy that proved vital in navigating 2023’s supply chain disruptions.

- Quality Assurance: Partnerships with leading equipment manufacturers and material providers guarantee access to high-performance components and advanced processing tools, crucial for Amkor's advanced packaging solutions.

- Risk Mitigation: Proactive supplier relationship management helps Amkor anticipate and address potential supply chain vulnerabilities, ensuring uninterrupted operations and timely delivery to its customers.

Research Institutions and Academia

Amkor Technology actively cultivates relationships with research institutions and academia to drive semiconductor packaging innovation. These partnerships are crucial for staying ahead in a rapidly evolving technological landscape.

Collaborations often focus on joint research projects, exploring next-generation materials and advanced packaging techniques. For instance, Amkor's engagement with universities facilitates access to cutting-edge research and specialized expertise, directly feeding into Amkor's long-term technological development pipeline.

- Talent Development: Partnerships provide Amkor with access to a pipeline of skilled engineers and researchers, fostering talent acquisition and retention.

- Joint Research: Collaborative projects with academic institutions allow Amkor to explore novel packaging solutions and materials, ensuring a competitive edge.

- Knowledge Exchange: These relationships facilitate the sharing of insights and discoveries, promoting a culture of continuous learning and exploration of future technologies.

- Innovation Ecosystem: By engaging with academia, Amkor contributes to and benefits from a broader innovation ecosystem within the semiconductor industry.

Amkor Technology's key partnerships are essential for its innovation and market reach. These include collaborations with fabless semiconductor companies and Integrated Device Manufacturers (IDMs) for joint development of advanced packaging solutions, as exemplified by their work with TSMC in Arizona on cutting-edge packaging and testing. Furthermore, alliances with Electronic Design Automation (EDA) tool providers ensure seamless integration of Amkor's packaging technologies with client design software, speeding up time-to-market for complex chips. Amkor also engages in joint development agreements with major customers, tailoring solutions for specific product needs, a strategy that proved successful in 2024 with AI accelerators.

These strategic alliances are critical for accessing new markets and technologies. For instance, Amkor's partnerships with leading equipment and material suppliers bolster its supply chain resilience and guarantee access to high-performance components, a crucial factor given the supply chain disruptions experienced in 2023. Additionally, collaborations with research institutions and academia drive innovation by exploring next-generation materials and packaging techniques, ensuring Amkor remains at the forefront of technological advancements and talent acquisition.

| Partner Type | Purpose | Example/Impact |

|---|---|---|

| Fabless Semiconductor Firms & IDMs | Joint development of advanced packaging solutions | Collaborations for cutting-edge chip technologies, like work with TSMC in Arizona. |

| EDA Tool Providers | Ensuring design software compatibility | Streamlining design-to-manufacturing for complex ICs. |

| Key Customers | Co-creation of specialized packaging and test solutions | Addressing unique product needs, driving demand for AI accelerators in 2024. |

| Equipment & Material Suppliers | Securing raw materials and manufacturing technologies | Ensuring supply chain resilience and quality, vital after 2023 disruptions. |

| Research Institutions & Academia | Driving innovation and talent development | Exploring next-gen materials and techniques, fostering a skilled workforce. |

What is included in the product

This Business Model Canvas provides a detailed overview of Amkor Technology's strategy, outlining its key partners, activities, and resources in the semiconductor packaging and testing industry.

It thoroughly covers Amkor's customer relationships, revenue streams, cost structure, and channels to market, offering insights into their operational framework.

Amkor Technology's Business Model Canvas acts as a pain point reliever by offering a clear, visual representation of their complex supply chain and customer relationships, simplifying intricate operations for better understanding and management.

Activities

Amkor's core activities revolve around the intricate processes of semiconductor packaging and assembly. This transforms raw silicon wafers into the sophisticated, finished chips that power our electronics. They offer a wide spectrum of services, including cutting-edge techniques like flip-chip assembly and wafer-level processing.

Furthermore, Amkor excels in developing advanced System-in-Package (SiP) solutions, integrating multiple functionalities into a single package. These capabilities are absolutely essential for enhancing the performance and miniaturization of devices across various sectors, from mobile phones to automotive systems.

In 2024, Amkor Technology reported significant revenue streams driven by these advanced packaging services. The demand for their expertise in SiP solutions, for instance, saw a notable uptick as consumer electronics and high-performance computing markets continued to expand their reliance on integrated functionalities.

Amkor Technology's key activity in semiconductor testing involves providing comprehensive electrical and functional validation for packaged chips. This critical step guarantees the reliability and performance of semiconductors before they become part of larger electronic systems.

The company offers a complete range of test solutions, encompassing wafer probe, final test, and system-level test. This robust offering supports a fully integrated U.S. supply chain, with significant expansion planned through new deployments in their Arizona facility.

Amkor Technology's commitment to Research and Development (R&D) is crucial for staying ahead in the fast-paced semiconductor sector. This includes innovating in areas such as high-density fan-out packaging and advanced thermal management systems. In 2024, Amkor continued to invest heavily in R&D to support the growing demands of AI, high-performance computing, and the automotive industry.

Global Supply Chain Management

Amkor Technology's core operations revolve around managing a highly intricate global supply chain for semiconductor components and essential materials. This encompasses strategic sourcing, efficient logistics, and precise inventory control, all coordinated across their extensive network of manufacturing facilities spanning the globe.

This robust supply chain management is critical for ensuring punctual product delivery to customers and building resilience against potential geopolitical shifts and logistical hurdles. For instance, in 2024, Amkor continued to navigate complex international trade dynamics, aiming to maintain a steady flow of critical materials and finished goods despite ongoing global economic uncertainties.

- Procurement: Securing a consistent supply of raw materials, including lead frames, molding compounds, and packaging substrates, from a diverse global supplier base.

- Logistics: Orchestrating the movement of components and finished products across continents, optimizing transportation routes and modes to minimize transit times and costs.

- Inventory Management: Balancing inventory levels to meet demand without incurring excessive carrying costs, utilizing advanced forecasting and planning tools.

- Risk Mitigation: Proactively identifying and addressing potential disruptions, such as natural disasters, trade disputes, or supplier failures, through diversification and contingency planning.

Quality Assurance and Reliability Engineering

Amkor Technology's Quality Assurance and Reliability Engineering is a cornerstone of its operations, focusing on delivering semiconductor packages that meet the most stringent industry standards. This commitment is demonstrated through extensive quality control measures implemented at every stage of production, from material inspection to final product testing.

The company employs a suite of advanced reliability testing protocols, including highly accelerated stress tests (HAST), temperature cycling, and moisture sensitivity testing, to proactively identify and mitigate potential failure mechanisms. In 2023, Amkor reported a significant reduction in customer-reported defects, a testament to the effectiveness of these rigorous processes.

- Rigorous Quality Control: Implementing comprehensive checks at each manufacturing step to ensure adherence to specifications.

- Advanced Reliability Testing: Utilizing industry-leading tests to validate product durability and performance under various environmental conditions.

- Continuous Improvement: Actively seeking feedback and data to refine processes and enhance product reliability.

- Customer Trust: Maintaining a strong reputation as a dependable partner for global semiconductor leaders, evidenced by long-standing relationships and repeat business.

Amkor Technology's key activities encompass the entire lifecycle of semiconductor packaging and testing, from intricate assembly processes to rigorous quality assurance. They specialize in advanced packaging solutions, including System-in-Package (SiP) technologies, crucial for miniaturization and enhanced performance in electronics. In 2024, Amkor saw increased demand for these SiP solutions, driven by growth in consumer electronics and high-performance computing.

The company's robust supply chain management is vital, involving strategic procurement of materials, efficient global logistics, and precise inventory control to ensure timely delivery and mitigate disruptions. Amkor also places a strong emphasis on Research and Development, investing in innovations like high-density fan-out packaging to meet the evolving needs of AI, HPC, and automotive sectors.

Quality Assurance and Reliability Engineering are paramount, with extensive testing protocols ensuring semiconductors meet stringent industry standards. This commitment is reflected in their continuous process improvement efforts and a strong reputation for dependability among global semiconductor leaders.

Full Document Unlocks After Purchase

Business Model Canvas

The Amkor Technology Business Model Canvas preview you are viewing is the exact document you will receive upon purchase. This is not a sample or mockup, but a direct representation of the complete, ready-to-use file. You will gain full access to this comprehensive Business Model Canvas, allowing you to immediately leverage its insights for strategic planning and operational enhancement.

Resources

Amkor Technology operates a robust global network of advanced manufacturing facilities, crucial for its high-volume semiconductor packaging business. These state-of-the-art sites are strategically positioned in key electronics hubs across Asia, Europe, and the United States.

The company has recently expanded its footprint with new operations in Vietnam, underscoring its commitment to leveraging diverse manufacturing capabilities. Furthermore, Amkor is investing in future growth with planned expansions, notably in Arizona, to meet evolving market demands and technological advancements.

Amkor Technology's specialized semiconductor packaging equipment, including proprietary flip-chip bonders and wafer-level packaging tools, are foundational to its operations. These high-precision machines are essential for producing advanced, high-performance packaging solutions demanded by the industry.

The company's commitment to staying at the forefront of packaging technology necessitates substantial and ongoing capital expenditure for upgrading this critical equipment. For instance, Amkor reported capital expenditures of $428 million in 2023, a significant portion of which is allocated to advanced manufacturing and packaging technologies.

Amkor Technology's highly skilled workforce, comprising over 28,000 employees globally as of 2024, is a cornerstone of its business model. This talent pool includes experienced engineers, technicians, and R&D specialists whose collective expertise spans semiconductor physics, materials science, intricate package design, and rigorous test engineering.

This deep reservoir of knowledge is directly responsible for driving Amkor's innovation pipeline and maintaining operational excellence across its manufacturing and development processes. The company's ability to attract and retain top-tier talent in these specialized fields is a significant competitive advantage, enabling it to deliver advanced packaging solutions.

Intellectual Property (IP) and Patents

Amkor Technology's intellectual property, especially its patents, is a cornerstone of its business model, creating a significant competitive moat. These patents cover a wide array of advanced semiconductor packaging designs, manufacturing processes, and novel materials, safeguarding their innovative edge.

This robust IP portfolio directly translates into a competitive advantage, protecting Amkor's unique solutions in a fast-evolving market. The company's commitment to R&D is evident in its ongoing investment in new patent applications, ensuring a continuous stream of protected innovations.

- Patented Technologies: Focus on advanced packaging solutions like flip-chip, wafer-level packaging, and system-in-package.

- Competitive Advantage: IP protection shields Amkor's proprietary processes and designs from competitors.

- R&D Investment: Continued patent filings underscore a strategic commitment to innovation and market leadership.

- Market Protection: Patents prevent rivals from replicating Amkor's advanced packaging technologies.

Global IT Infrastructure and Data Systems

Amkor Technology relies on a sophisticated global IT infrastructure, encompassing advanced Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems. These are crucial for managing its worldwide operations efficiently. For instance, in 2023, Amkor continued investing in digital transformation initiatives to enhance its operational capabilities. The company’s IT backbone supports seamless communication and provides critical operational visibility across its diverse manufacturing sites.

These integrated systems are the backbone of Amkor's data-driven decision-making. They enable precise production planning, rigorous quality control, and the analysis of vast amounts of operational data. This allows for continuous improvement and optimization of manufacturing processes. The company’s commitment to robust data analytics capabilities ensures that insights are readily available to drive strategic choices and maintain a competitive edge.

- Global IT Infrastructure: Amkor operates a worldwide network of IT systems, including MES and ERP, essential for managing its complex manufacturing operations.

- Data Analytics Capabilities: The company leverages advanced data analytics to support efficient production planning, quality assurance, and informed business decisions.

- Operational Visibility: This integrated infrastructure facilitates real-time communication and provides clear visibility into operations across all geographically dispersed facilities.

- Digital Transformation: Amkor's ongoing investments in its IT systems underscore a commitment to digital transformation, aiming to boost efficiency and responsiveness in the semiconductor packaging industry.

Amkor Technology's key resources include its global manufacturing facilities, specialized packaging equipment, skilled workforce, intellectual property, and advanced IT infrastructure. These elements collectively enable the company to deliver high-quality semiconductor packaging solutions and maintain a competitive edge in the market.

The company’s strategic investments in expanding its manufacturing footprint, particularly with new operations in Vietnam and planned expansions in Arizona, highlight its commitment to meeting future market demands. Amkor's ongoing capital expenditure, such as the $428 million in 2023, is primarily directed towards upgrading its critical, high-precision packaging equipment.

With a global workforce exceeding 28,000 employees in 2024, Amkor leverages deep expertise in semiconductor physics, materials science, and package design. This talent pool is crucial for driving innovation and ensuring operational excellence. Furthermore, Amkor's robust intellectual property portfolio, protected by numerous patents, safeguards its proprietary technologies and provides a significant competitive advantage.

The company's advanced IT infrastructure, including MES and ERP systems, supports efficient global operations and data-driven decision-making. These systems are vital for managing complex production processes, ensuring quality control, and maintaining real-time visibility across its worldwide facilities.

| Key Resource | Description | 2024 Data/Context |

|---|---|---|

| Global Manufacturing Facilities | State-of-the-art sites in Asia, Europe, and the US, with new operations in Vietnam and planned expansions in Arizona. | Strategic expansion to meet evolving market demands. |

| Specialized Packaging Equipment | Proprietary flip-chip bonders, wafer-level packaging tools, and other high-precision machinery. | Continuous investment in upgrades; $428 million capital expenditure in 2023 allocated to advanced manufacturing. |

| Skilled Workforce | Over 28,000 employees globally, including engineers, technicians, and R&D specialists. | Deep expertise in semiconductor physics, materials science, and package design driving innovation. |

| Intellectual Property | Extensive patent portfolio covering advanced packaging designs, processes, and materials. | Safeguards proprietary solutions and provides a significant competitive moat. |

| IT Infrastructure | Advanced MES, ERP systems, and global data analytics capabilities. | Enhances operational efficiency, planning, quality control, and provides crucial operational visibility. |

Value Propositions

Amkor Technology's advanced packaging solutions are pivotal for unlocking superior semiconductor performance. By offering cutting-edge technologies such as flip-chip, wafer-level packaging, and sophisticated 2.5D/3D integration, they directly address the escalating needs of demanding sectors like high-performance computing (HPC), artificial intelligence (AI), and the burgeoning 5G market.

These advanced packaging techniques are not merely about miniaturization; they are fundamental enablers of increased functionality and efficiency. For instance, Amkor's 2.5D/3D integration allows for the stacking of multiple semiconductor dies, significantly boosting processing power and reducing latency, which is critical for AI accelerators and advanced networking equipment.

In 2024, the demand for these high-performance solutions is projected to grow robustly. The global advanced packaging market, which Amkor is a significant player in, was valued at approximately $50 billion in 2023 and is expected to see a compound annual growth rate (CAGR) of over 7% through 2028, driven by the relentless pursuit of more powerful and energy-efficient chips across all technology sectors.

Amkor Technology's comprehensive, turnkey outsourced assembly and test (OSAT) services significantly accelerate time-to-market for semiconductor companies. By offering integrated design, assembly, and test solutions, Amkor streamlines the entire manufacturing workflow. This efficiency directly translates to reduced lead times, allowing customers to seize market opportunities faster. In 2023, Amkor reported revenue of $5.7 billion, underscoring their scale and ability to support high-volume production needs critical for rapid market entry.

Amkor Technology presents a compelling value proposition of cost efficiency and capital avoidance for semiconductor manufacturers. By outsourcing packaging and testing, companies sidestep the immense financial burden of building and equipping their own fabrication facilities. This strategy is particularly attractive given the rising costs of advanced manufacturing; for instance, a state-of-the-art semiconductor fab can cost upwards of $20 billion.

Leveraging Amkor's established infrastructure and specialized expertise allows clients to achieve significant operational cost reductions. Amkor's economies of scale mean they can process higher volumes at lower per-unit costs than most individual companies could manage. This frees up valuable capital for semiconductor firms to invest in their core competencies, such as chip design and market development, rather than being tied up in manufacturing overhead.

This outsourced model fosters greater financial flexibility and mitigates risk for Amkor's customers. Instead of committing billions to fixed assets, businesses can maintain a more agile capital structure. This approach proved beneficial in 2024, a year where many tech companies focused on optimizing cash flow and reducing capital expenditure amidst evolving market demands.

Supply Chain Resilience and Geographic Flexibility

Amkor's extensive global manufacturing network provides customers with crucial supply chain resilience. This geographic diversity helps buffer against disruptions, whether they stem from regional events or evolving trade policies. For instance, Amkor's expansion into new facilities, such as those in Vietnam, enhances their ability to offer alternative production sites.

This broad operational footprint translates directly into geographic flexibility for their clients. Customers can strategically shift production or sourcing to mitigate risks tied to geopolitical shifts or economic fluctuations. Amkor's commitment to this flexibility is underscored by their investments in new locations, including facilities in Arizona, further diversifying their manufacturing capabilities.

- Global Manufacturing Footprint: Amkor operates facilities across Asia, Europe, and North America, providing a wide geographic spread for production.

- Risk Mitigation: Diversified operations reduce vulnerability to single-region disruptions, ensuring continuity of supply for customers.

- Strategic Location Expansion: New facilities in Vietnam and Arizona exemplify Amkor's strategy to enhance geographic flexibility and customer options.

Collaborative Innovation and Technical Expertise

Amkor Technology acts as a co-development partner, deeply engaging with clients to jointly tackle intricate packaging hurdles. This close collaboration fosters innovation, allowing Amkor to leverage its extensive technical knowledge from the earliest design stages. By integrating their expertise with customer roadmaps, they accelerate the creation of cutting-edge semiconductor packaging solutions, ensuring offerings are precisely aligned with market demands.

In 2024, Amkor's commitment to collaborative innovation is evident in its sustained investment in research and development, which represented a significant portion of their operational budget. This focus allows them to anticipate and address the evolving needs of the semiconductor industry, particularly in areas like advanced packaging for AI and high-performance computing. Their early design engagement model is crucial for clients seeking to optimize performance and reduce time-to-market for new chip technologies.

- Collaborative Development: Amkor partners with customers to co-create solutions for complex packaging challenges.

- Technical Expertise: Deep engineering knowledge drives innovation and the development of next-generation products.

- Early Design Engagement: Involvement from the initial design phase ensures tailored solutions and faster market entry.

- Customer-Centric Innovation: Amkor's approach guarantees that its packaging technologies align perfectly with customer roadmaps and specific requirements.

Amkor Technology's advanced packaging solutions are crucial for enhancing semiconductor performance, particularly for high-growth sectors like AI and 5G. Their expertise in 2.5D/3D integration and wafer-level packaging directly addresses the increasing demand for more powerful and efficient chips. The global advanced packaging market was valued at approximately $50 billion in 2023 and is projected to grow robustly.

By offering comprehensive outsourced assembly and test (OSAT) services, Amkor significantly reduces time-to-market for semiconductor companies. This streamlined approach, coupled with their $5.7 billion in revenue in 2023, highlights their capacity to support high-volume production and rapid market entry for clients.

Amkor provides cost efficiencies and capital avoidance by allowing manufacturers to bypass the immense costs of building their own fabrication facilities, which can exceed $20 billion. This financial flexibility enables clients to invest in core competencies like chip design, a strategy that proved particularly advantageous in 2024.

Their extensive global manufacturing footprint, including new facilities in Vietnam and Arizona, offers crucial supply chain resilience and geographic flexibility. This diversification mitigates risks associated with regional disruptions or geopolitical shifts, ensuring continuity of supply for customers.

As a co-development partner, Amkor engages deeply with clients to solve complex packaging challenges, leveraging their technical knowledge from early design stages. This collaborative approach, supported by significant R&D investment in 2024, ensures their packaging technologies align perfectly with customer roadmaps and market demands.

Customer Relationships

Amkor Technology cultivates robust strategic partnerships with its major clients, frequently engaging in joint development for cutting-edge packaging solutions. This collaborative strategy ensures Amkor's offerings are precisely tailored to meet customers' evolving product development plans.

In 2024, Amkor continued to emphasize these deep customer relationships, which are crucial for driving innovation in the semiconductor packaging industry. For example, their work with leading fabless semiconductor companies often involves co-development projects that anticipate future market needs, solidifying Amkor's position as a key enabler of technological advancement.

Amkor Technology offers dedicated account managers and expert technical support teams. This ensures personalized service and rapid resolution for intricate engineering challenges faced by their clients in semiconductor manufacturing.

This direct communication channel is vital for managing complex projects and fostering high customer satisfaction. In 2023, Amkor reported that over 90% of their customer inquiries were resolved within 24 hours, underscoring their commitment to responsive support.

Amkor Technology's long-term contracts and supply agreements with leading semiconductor manufacturers are a cornerstone of its customer relationships. These partnerships, often extending for several years, offer significant stability and predictability. For instance, in 2024, Amkor continued to secure multi-year agreements with major players in the automotive and consumer electronics sectors, bolstering its revenue forecasts.

These agreements typically include commitments for specific production volumes and align with customers' evolving technology roadmaps. This mutual alignment ensures consistent business for Amkor while providing customers with a reliable supply chain partner. Such arrangements are crucial for managing Amkor's capacity planning and stabilizing input costs, especially amidst fluctuating market demands.

Customer Training and Knowledge Sharing

Amkor Technology actively engages in customer training and knowledge sharing to ensure clients can maximize the benefits of its cutting-edge packaging solutions. These programs are designed to build a deeper comprehension of Amkor's advanced technologies, accelerating the integration of new products and solidifying collaborative relationships.

By positioning itself as an industry authority, Amkor's commitment to education empowers customers to navigate complex technological landscapes. This proactive approach fosters a stronger partnership, ensuring clients are well-equipped to leverage Amkor's innovations for their own success.

- Enhanced Adoption: Training programs facilitate quicker integration of Amkor's advanced packaging solutions, reducing time-to-market for customers.

- Expertise Showcase: Knowledge sharing initiatives highlight Amkor's deep industry expertise, reinforcing its role as a trusted technology partner.

- Partnership Deepening: By investing in customer understanding, Amkor strengthens its relationships, moving beyond a transactional supplier role.

Global Customer Service and Support Network

Amkor Technology operates a robust global customer service and support network, featuring numerous sales and support offices strategically positioned worldwide. This extensive infrastructure allows Amkor to cater effectively to its diverse international clientele, overcoming geographical barriers and time zone differences. For instance, as of early 2024, Amkor maintained a significant presence with facilities across Asia, North America, and Europe, ensuring localized expertise and rapid response times.

This commitment to localized support is paramount for addressing customer needs promptly and delivering a seamless service experience, irrespective of a customer's location. It reinforces Amkor's dedication to global accessibility and building strong, responsive relationships with its partners in the semiconductor industry.

Key aspects of Amkor's global customer service include:

- Worldwide Presence: Amkor's network spans over 20 countries, facilitating direct engagement with customers in their respective regions.

- 24/7 Support Capabilities: The global distribution of support teams enables Amkor to offer assistance across different time zones, ensuring continuous service availability.

- Technical Expertise: Localized teams possess in-depth knowledge of regional market demands and specific customer requirements, enhancing problem-solving efficiency.

- Relationship Management: Dedicated account managers and technical support staff work closely with clients to foster long-term partnerships and ensure satisfaction.

Amkor Technology prioritizes deep, collaborative relationships with its clients, often engaging in joint development projects to create tailored packaging solutions. This approach ensures Amkor's offerings align with customers' evolving product roadmaps, a strategy that proved vital in 2024 for driving innovation in semiconductor packaging.

The company reinforces these bonds through dedicated account managers and expert technical support, ensuring prompt resolution of complex engineering challenges. In 2023, Amkor reported resolving over 90% of customer inquiries within 24 hours, highlighting their commitment to responsive service.

Long-term contracts and supply agreements, often spanning multiple years, provide stability and predictability, with Amkor securing several such deals in 2024 across automotive and consumer electronics sectors.

Amkor also invests in customer education through training and knowledge sharing, aiming to accelerate the adoption of its advanced packaging solutions and solidify its role as a trusted technology partner.

Channels

Amkor Technology heavily relies on its direct sales force and specialized key account teams to cultivate relationships with its most significant semiconductor clients. This direct approach ensures clear communication and a thorough grasp of customer requirements, facilitating the negotiation of intricate, long-term agreements.

These dedicated teams are instrumental in nurturing strategic partnerships and securing substantial, high-volume orders, which are vital for Amkor's revenue streams. For instance, in 2023, Amkor reported net sales of $5.7 billion, with a significant portion driven by these key customer relationships managed through direct sales channels.

Amkor Technology's global manufacturing facilities are the core channels through which its semiconductor packaging and test services reach customers worldwide. These sites are where production happens, quality is assured, and products are shipped, creating a direct touchpoint for clients.

In 2024, Amkor continued to invest in expanding this direct channel, notably with new facilities in Vietnam and Arizona. This expansion not only increases Amkor's overall capacity but also strengthens its ability to serve diverse geographic markets and customer needs directly from its operational hubs.

Amkor Technology leverages customer portals and online collaboration platforms as key channels for engaging with its clients. These digital spaces are instrumental in managing orders, providing real-time updates on production status, and securely sharing vital technical documentation. This digital infrastructure fosters a more efficient and transparent relationship, allowing for streamlined communication and data exchange.

These platforms significantly enhance operational workflows by enabling collaborative design efforts and facilitating prompt responses to customer inquiries. For instance, in 2024, Amkor reported a notable increase in customer satisfaction scores directly attributed to the improved accessibility and responsiveness offered by its online portals. This digital engagement ensures that customers have constant visibility into their projects, from initial design to final delivery.

Industry Conferences and Trade Shows

Amkor Technology leverages industry conferences and trade shows as a crucial channel to highlight its advanced semiconductor packaging and test solutions. These events are instrumental in connecting with a broad spectrum of industry stakeholders, from potential clients to technology partners. For instance, Amkor's presence at SEMICON West, a premier event in the semiconductor industry, allows them to directly engage with decision-makers and showcase their latest advancements in areas like advanced packaging technologies.

These gatherings are not just about visibility; they are vital for lead generation and understanding market trends. In 2024, Amkor continued to actively participate in key global events, reinforcing its position as a leader in the outsourced semiconductor assembly and test (OSAT) sector. Their participation helps solidify relationships and identify new business opportunities within the rapidly evolving semiconductor landscape.

- Showcasing Innovations: Amkor uses these platforms to demonstrate cutting-edge packaging technologies, such as advanced substrate designs and thermal management solutions.

- Customer Engagement: Direct interaction at shows facilitates discussions with potential clients about their specific needs and Amkor's tailored solutions.

- Market Visibility: Consistent participation enhances Amkor's brand recognition and strengthens its reputation as a reliable industry partner.

- Lead Generation: These events are a primary source for identifying and nurturing new business leads, contributing directly to revenue growth.

Investor Relations and Corporate Communications

Investor Relations and Corporate Communications serve as crucial conduits, primarily targeting financial stakeholders like shareholders and analysts. However, these channels, including annual reports and earnings calls, also indirectly showcase Amkor Technology's operational strengths and strategic vision to a wider audience, such as potential clients and collaborators.

These communications are vital for projecting Amkor's stability, commitment to innovation, and competitive standing within the semiconductor packaging and test industry. For instance, Amkor's 2024 financial reports would detail significant R&D investments and new product introductions, indirectly signaling advanced manufacturing capabilities to prospective customers.

- Highlighting Financial Stability: Amkor's consistent revenue growth, such as the reported $2.04 billion in Q1 2024, reassures investors and signals operational reliability to potential business partners.

- Showcasing Technological Advancements: Investor presentations often feature details on new packaging technologies, like advanced substrate technologies, demonstrating Amkor's innovation pipeline to a broad audience.

- Communicating Strategic Direction: Discussions around market expansion and capital allocation in investor calls provide insights into Amkor's future growth strategies, influencing perceptions across the industry.

Amkor Technology's channels are multifaceted, blending direct sales with digital engagement and strategic industry presence. Their direct sales force and key account teams are paramount for nurturing relationships with major semiconductor clients, securing large-volume orders, and negotiating complex agreements. This direct approach is supported by robust customer portals and online collaboration platforms, which streamline order management, provide production updates, and facilitate secure data exchange, enhancing efficiency and transparency. Furthermore, Amkor actively participates in industry conferences and trade shows to showcase innovations, engage with stakeholders, and generate leads, reinforcing its market position.

| Channel Type | Description | Key Activities | 2024 Focus/Data Point |

|---|---|---|---|

| Direct Sales & Key Accounts | Dedicated teams for major clients | Relationship building, contract negotiation, high-volume order securing | Continued investment in global facilities to directly serve diverse markets. |

| Customer Portals & Online Platforms | Digital spaces for client interaction | Order management, real-time status updates, technical documentation sharing | Increased customer satisfaction attributed to improved accessibility and responsiveness. |

| Industry Conferences & Trade Shows | Events for showcasing solutions and networking | Demonstrating new technologies, lead generation, market trend analysis | Active participation in global events to reinforce leadership in OSAT. |

Customer Segments

Fabless semiconductor companies, those that design chips but outsource production, represent a key customer segment for Amkor Technology. These innovators, focused on R&D and market engagement, rely on Amkor for critical packaging and testing, enabling them to bring advanced silicon to market efficiently. In 2024, the fabless semiconductor market continued its robust growth, with revenue projected to reach over $250 billion, highlighting the increasing demand for specialized services like those Amkor provides.

Amkor's value proposition resonates strongly with these design-centric firms, offering them access to sophisticated packaging technologies that support their high-performance, cutting-edge chip architectures. As the complexity of integrated circuits escalates, the need for advanced packaging solutions, such as wafer-level packaging and 2.5D/3D integration, becomes paramount. The global advanced packaging market, a significant portion of which serves fabless clients, was estimated to be worth approximately $30 billion in 2024 and is expected to see continued expansion.

Integrated Device Manufacturers (IDMs) are companies that handle the entire process of creating their own integrated circuits, from design to manufacturing and sales. Amkor Technology plays a crucial role by supplementing these in-house capabilities. We offer specialized packaging and testing services, particularly for products that are manufactured in high volumes or involve complex technologies.

Amkor serves as a strategic manufacturing partner for IDMs, providing them with much-needed flexibility and scalability in their production processes. This partnership allows IDMs to focus on their core design and marketing strengths while relying on Amkor for advanced manufacturing solutions. In 2024, the semiconductor industry saw significant growth, with global semiconductor revenue projected to reach over $600 billion, underscoring the demand for specialized manufacturing support like Amkor provides.

Amkor Technology serves a critical customer segment within the automotive and industrial sectors, encompassing manufacturers of automotive electronics, industrial control systems, and power management devices.

These clients depend on Amkor for highly reliable and robust semiconductor packaging solutions designed to endure demanding operational conditions and adhere to rigorous quality specifications.

The strategic importance of this segment is underscored by Amkor's revenue growth from these automotive and industrial clients, reflecting a strong market demand for their specialized packaging capabilities.

Communications Sector Clients

Amkor's Communications Sector clients include major manufacturers of smartphones, 5G infrastructure, and the rapidly expanding Internet of Things (IoT) device market. These companies require highly sophisticated packaging that is not only compact but also incredibly energy-efficient to meet the demands of modern connected devices.

Amkor's advanced System-in-Package (SiP) and wafer-level packaging technologies are essential for enabling the miniaturization and enhanced performance needed in these communication applications. For instance, SiP solutions allow for the integration of multiple semiconductor components into a single package, reducing size and power consumption, which is crucial for everything from wearable tech to complex base stations.

- Smartphone Manufacturers: Demand for advanced packaging to support higher processing power and multiple functionalities in smaller form factors.

- 5G Infrastructure Providers: Require robust and high-performance packaging for base stations and network equipment, enabling faster data speeds and lower latency.

- IoT Device Creators: Need cost-effective, miniature, and power-efficient packaging solutions to support the massive proliferation of connected devices across various industries.

This sector represents a substantial portion of Amkor's revenue. Analysts project strong sequential growth for Amkor in 2024, largely driven by the continued demand for these advanced packaging solutions within the communications industry, particularly as 5G adoption accelerates and the IoT ecosystem expands further.

Computing and Consumer Electronics Clients

Amkor's Computing and Consumer Electronics segment serves a broad range of technology manufacturers. This includes companies involved in personal computers, powerful servers, expansive data centers, and specialized AI accelerators. They also cater to the diverse needs of the consumer electronics market, encompassing everything from smartphones to advanced wearables.

For these clients, Amkor provides critical high-performance semiconductor packaging. This is essential for components like CPUs, GPUs, and memory chips, where advanced solutions such as flip-chip technology and sophisticated 2.5D/3D integration are paramount. These advanced packaging techniques are key to unlocking greater processing power and efficiency in modern devices.

- Fastest Growing Market: This sector represents Amkor's most dynamic growth area.

- Record 2024 Revenue: The segment achieved unprecedented revenue figures in 2024.

- Projected 2025 Growth: Amkor anticipates continued record-breaking performance in 2025.

- Key Product Demand: High demand exists for advanced packaging for CPUs, GPUs, and memory.

Amkor Technology's customer base is diverse, spanning key sectors within the semiconductor ecosystem. These include fabless semiconductor companies, which design chips but outsource manufacturing, and Integrated Device Manufacturers (IDMs) that handle the entire chip production process. The company also serves the automotive and industrial sectors, providing solutions for demanding operational environments, and the communications sector, supporting advancements in 5G and IoT. Furthermore, Amkor is a vital partner for the computing and consumer electronics markets, enabling high-performance components for everything from servers to smartphones.

| Customer Segment | Key Needs | 2024 Relevance/Data |

|---|---|---|

| Fabless Semiconductor | Advanced packaging, testing | Global fabless market projected >$250B in 2024 |

| Integrated Device Manufacturers (IDMs) | Specialized packaging, high-volume manufacturing | Global semiconductor revenue projected >$600B in 2024 |

| Automotive & Industrial | Reliability, robust packaging | Strong market demand for specialized capabilities |

| Communications | Miniaturization, energy efficiency (SiP, WLP) | Strong sequential growth driven by 5G and IoT expansion |

| Computing & Consumer Electronics | High-performance packaging (flip-chip, 2.5D/3D) | Amkor's fastest growing area, record 2024 revenue |

Cost Structure

The Cost of Goods Sold (COGS) is the most significant expense for Amkor Technology. This category encompasses direct materials like substrates and molding compounds, the direct labor involved in production, and manufacturing overhead. For instance, in 2023, Amkor reported COGS of $4.65 billion, highlighting the substantial investment in these core production elements.

Direct material costs are particularly impactful, often constituting a considerable percentage of Amkor's total revenue. Any shifts in the prices of these essential raw materials, or changes in labor expenses, can directly affect the company's bottom line and overall profitability.

Capital Expenditures are a significant part of Amkor's business model, reflecting substantial ongoing investments. These include acquiring new manufacturing equipment, expanding existing facilities, and upgrading technology to stay competitive.

These outlays are essential for Amkor to maintain its technological edge in advanced packaging solutions and to boost its production capacity. For instance, Amkor projected around $850 million in capital expenditures for the year 2025, highlighting the scale of these investments.

Amkor Technology dedicates significant resources to Research and Development (R&D) to pioneer new semiconductor packaging solutions and enhance current offerings. In 2023, Amkor reported R&D expenses of $248.7 million, underscoring its commitment to innovation. This substantial investment fuels the development of advanced packaging technologies essential for the rapidly evolving electronics industry.

These R&D costs encompass a broad range of expenditures, including competitive salaries for highly skilled engineers and scientists, the operational costs of state-of-the-art laboratories, and the crucial process of securing and maintaining intellectual property through patents. For instance, Amkor's focus on advanced packaging like 2.5D and 3D integration requires specialized equipment and materials, contributing to these expenses.

Viewing R&D as a strategic investment, Amkor Technology aims to drive future revenue streams and solidify its competitive edge in the global semiconductor packaging market. This ongoing commitment ensures Amkor remains at the forefront of technological advancements, enabling them to offer cutting-edge solutions to their diverse customer base.

Selling, General, and Administrative (SG&A) Expenses

Selling, General, and Administrative (SG&A) expenses are a significant component of Amkor Technology's cost structure, encompassing all costs not directly related to production. These include compensation for employees in sales, marketing, finance, and executive functions, alongside office rent, utilities, legal services, and accounting fees. Efficient management of SG&A is crucial for maintaining healthy profit margins and ensuring the company's financial well-being.

Amkor Technology actively works to control its operating expenses while strategically allocating resources to support growth initiatives. This balancing act is key to their profitability. For instance, in the first quarter of 2024, Amkor reported SG&A expenses of $157.1 million. This figure demonstrates the scale of investment in the non-manufacturing aspects of the business. The company's focus remains on optimizing these overhead costs without hindering its ability to drive future revenue.

- Salaries and Benefits: Compensation for administrative, sales, and marketing teams.

- Office Expenses: Rent, utilities, and supplies for non-manufacturing facilities.

- Professional Services: Legal, accounting, and consulting fees.

- Marketing and Sales Costs: Advertising, promotional activities, and travel expenses.

Depreciation and Amortization

Given Amkor Technology's capital-intensive semiconductor manufacturing operations, depreciation of plant and equipment, and amortization of intangible assets are substantial non-cash expenses. These costs directly reflect the physical wear and tear and technological obsolescence inherent in their significant machinery and facility investments.

- Depreciation: Represents the systematic allocation of the cost of tangible assets like manufacturing equipment and buildings over their useful lives.

- Amortization: Accounts for the gradual expensing of intangible assets, such as software licenses or patents, over their estimated periods of benefit.

- Financial Impact: For Amkor, these expenses significantly reduce reported net income, though they do not involve an outflow of cash in the current period.

- 2024 Data Snapshot: In the first quarter of 2024, Amkor Technology reported depreciation and amortization expenses of approximately $129.2 million, highlighting its substantial asset base and the ongoing cost of maintaining its manufacturing capabilities.

Amkor Technology's cost structure is dominated by its manufacturing operations, with Cost of Goods Sold (COGS) being the largest expense. Significant investments in capital expenditures and research and development are also key cost drivers, reflecting the company's commitment to innovation and capacity expansion. Selling, General, and Administrative (SG&A) expenses, along with depreciation and amortization, further shape the company's financial outlay.

| Expense Category | Q1 2024 (Millions USD) | 2023 (Millions USD) |

|---|---|---|

| Cost of Goods Sold (COGS) | $1,175.6 | $4,650.0 |

| Selling, General, and Administrative (SG&A) | $157.1 | Not specified separately for full year |

| Research and Development (R&D) | Not specified separately for Q1 2024 | $248.7 |

| Depreciation & Amortization | $129.2 | Not specified separately for full year |

Revenue Streams

Advanced Products Packaging and Test Services represent Amkor's most significant and rapidly expanding revenue source. This segment includes sophisticated offerings such as flip-chip packaging, wafer-level packaging (WLP), and System-in-Package (SiP) technologies.

These high-value services are crucial for demanding applications in areas like advanced computing, artificial intelligence (AI), and high-end mobile devices. In 2024, advanced products were a dominant force, contributing roughly 80% to Amkor's total net sales, underscoring their critical role in the company's financial performance.

Revenue from mainstream products encompasses traditional wirebond packaging and testing services for a wide array of integrated circuits. This segment, while representing a smaller share of overall revenue compared to advanced offerings, provides a foundational stability and caters to a diverse spectrum of consumer and industrial needs.

In 2024, this crucial segment accounted for approximately 18% of Amkor Technology's net sales, underscoring its consistent contribution to the company's financial performance.

Amkor Technology generates revenue by offering comprehensive, turnkey solutions that bundle package design, assembly, and testing services. This integrated approach allows customers to outsource multiple critical back-end semiconductor processes to a single, reliable partner, simplifying their supply chain management.

This end-to-end service model is highly valued by clients looking for operational efficiency and a streamlined manufacturing process. For instance, in 2024, Amkor's focus on these integrated solutions continued to be a significant driver of its revenue, reflecting the industry’s demand for simplified and efficient semiconductor manufacturing pathways.

Volume-Based Manufacturing Fees

Amkor Technology generates a substantial portion of its income through fees charged for each semiconductor device it packages and tests. This revenue stream is directly linked to the production volumes of its clients, meaning that as customer demand for semiconductors rises, so does Amkor's revenue.

The company's performance in this area is heavily influenced by the health of various end markets. For instance, increased demand in crucial sectors such as computing and communications directly boosts Amkor's revenue from these volume-based manufacturing fees.

- Revenue Driver: Fees charged per unit of packaged and tested semiconductor devices.

- Volume Sensitivity: Revenue directly correlates with customer production volumes across diverse end markets.

- Market Impact: Higher demand in computing and communications segments directly increases revenue.

Technology Licensing and Royalties

Amkor Technology’s significant investment in research and development, evidenced by its robust intellectual property portfolio, positions it to potentially generate revenue through technology licensing and royalties. This avenue allows Amkor to monetize its innovations beyond its core manufacturing services.

While Amkor's primary focus is on providing advanced semiconductor packaging and test services, its extensive patent filings suggest opportunities for licensing its proprietary technologies to other industry players. This can include access to specialized packaging designs or manufacturing processes.

- Intellectual Property Monetization: Amkor holds numerous patents related to advanced packaging solutions, which can be licensed.

- Royalty Agreements: Companies utilizing Amkor's patented technologies in their own products or processes may pay royalties.

- Strategic Partnerships: Licensing can foster collaborations, enabling broader adoption of Amkor's innovations.

Amkor Technology’s revenue streams are primarily driven by its advanced and mainstream product packaging and test services. The company also benefits from integrated, turnkey solutions and potential revenue from technology licensing.

| Revenue Stream | Description | 2024 Contribution (Approx.) |

|---|---|---|

| Advanced Products Packaging and Test Services | High-value packaging like flip-chip, WLP, and SiP for demanding applications. | 80% of Net Sales |

| Mainstream Products Packaging and Test Services | Traditional wirebond packaging and testing for a broad range of ICs. | 18% of Net Sales |

| Integrated Turnkey Solutions | Bundled services including design, assembly, and testing. | Significant driver, reflecting industry demand for efficiency. |

| Technology Licensing and Royalties | Monetizing intellectual property through licensing of proprietary technologies. | Potential future revenue stream based on IP portfolio. |

Business Model Canvas Data Sources

Amkor Technology's Business Model Canvas is informed by a blend of internal financial statements, operational performance metrics, and extensive market research. This data ensures each component reflects current industry realities and strategic objectives.