Soudronic GmbH SWOT Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Soudronic GmbH Bundle

Soudronic GmbH's SWOT analysis reveals a strong position in specialized welding technology, but also highlights potential challenges in market diversification and technological disruption. Understanding these dynamics is crucial for navigating the competitive landscape effectively.

Want the full story behind Soudronic GmbH's strengths, risks, and growth drivers? Purchase the complete SWOT analysis to gain access to a professionally written, fully editable report designed to support planning, pitches, and research.

Strengths

Soudronic GmbH's core strength lies in its highly specialized expertise in resistance welding, a niche where they have cultivated decades of deep knowledge and practical experience. This focus is particularly evident in their solutions for the can-making industry, where precision and efficiency are paramount.

This specialization translates into the development of highly efficient and precise machines specifically designed for the unique demands of metal container production. Their long-standing commitment to this specialized area has fostered a robust foundation of technical proficiency and continuous innovation, setting them apart from competitors.

Soudronic GmbH's machinery is engineered for peak performance and efficiency, a critical advantage in the competitive can manufacturing sector. Their welding machines and production systems are built to maximize throughput while minimizing operational costs for their clients.

By focusing on reduced energy consumption and faster production cycles, Soudronic helps manufacturers achieve significant cost savings and improve their overall output. For instance, advancements in their welding technology in 2024 have demonstrated potential energy savings of up to 15% compared to previous models, directly impacting a client's bottom line.

Soudronic's strength lies in its ability to offer integrated solutions that manage the entire can body production line. This means customers can rely on a single provider for everything from initial material slitting and welding to final coating, curing, and rigorous testing.

This comprehensive, single-source approach significantly simplifies the procurement process for clients, ensuring all components are designed to work seamlessly together. It also optimizes the overall workflow, leading to greater efficiency and reduced downtime.

By providing these end-to-end solutions, Soudronic fosters stronger customer loyalty and opens up valuable opportunities for upselling additional services and cross-selling complementary products, thereby deepening client relationships and revenue streams.

Commitment to Sustainability

Soudronic's commitment to sustainability is a significant strength, as their welding solutions are integral to creating environmentally friendly can packaging. This directly supports the growing global demand for eco-conscious materials, particularly in the beverage and food industries.

Metal packaging, especially aluminum and steel cans, boasts impressive recyclability rates, often exceeding 70% in developed markets. Soudronic's advanced welding technology facilitates the production of these highly recyclable containers, thereby promoting a circular economy and reducing waste.

This dedication to sustainability serves as a powerful differentiator, attracting customers who prioritize environmental responsibility and enhancing Soudronic's brand reputation. For instance, the European Union's Circular Economy Action Plan, updated in 2020, emphasizes increased recycling and the use of sustainable materials, creating a favorable market for Soudronic's offerings.

- Eco-friendly manufacturing: Soudronic's technology enables the production of cans with a lower environmental footprint.

- Circular economy support: Facilitates the use of highly recyclable aluminum and steel.

- Market appeal: Attracts environmentally conscious clients and strengthens brand image.

Established Market Presence and Reputation

Soudronic GmbH boasts an established market presence, underscored by its impressive global footprint of over 15,000 machines and system components installed worldwide. This extensive reach signifies a deep entrenchment within the can-making industry, built over years of reliable service and product delivery.

The company's long history and substantial installed base translate into a robust reputation for reliability and trust. In the capital-intensive can-making sector, this proven track record is a significant competitive advantage, fostering strong customer relationships and brand recognition.

- Global Reach: Over 15,000 Soudronic machines and system components are operational across the globe.

- Industry Trust: A long-standing presence in the can-making sector has cultivated a reputation for dependability.

- Proven Performance: The sheer volume of installed units attests to the consistent performance and durability of Soudronic's offerings.

- Brand Equity: Decades of operation have cemented Soudronic as a recognized and respected name in its field.

Soudronic's primary strength is its deep specialization in resistance welding for the can-making industry, offering highly efficient and precise machinery. Their integrated solutions cover the entire can body production line, simplifying procurement and optimizing workflows for clients.

The company's commitment to sustainability is a key differentiator, enabling the production of environmentally friendly, highly recyclable metal packaging. This aligns with growing global demand for eco-conscious products and favorable regulatory environments like the EU's Circular Economy Action Plan.

With over 15,000 machines installed globally, Soudronic possesses a significant market presence and a robust reputation for reliability and trust within the capital-intensive can-making sector. This extensive installed base underscores the proven performance and durability of their offerings.

Their welding technology advancements in 2024 have shown potential energy savings of up to 15%, directly benefiting client operational costs and output.

What is included in the product

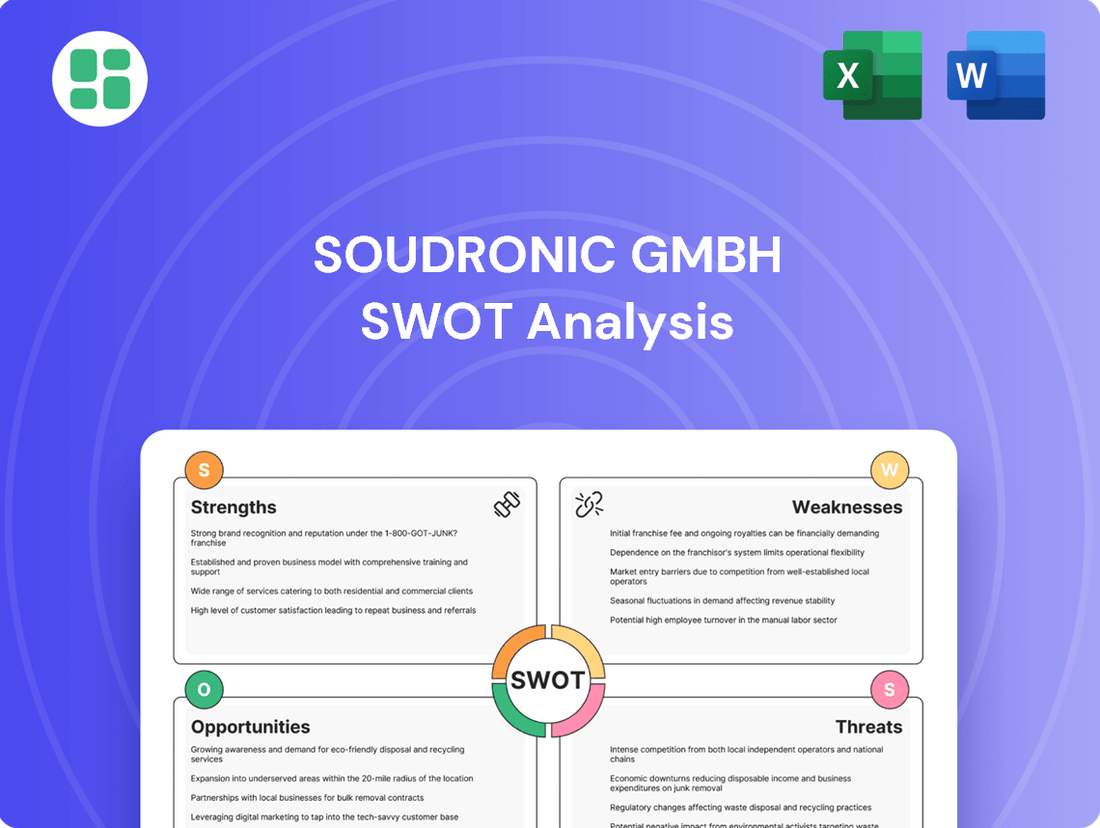

This SWOT analysis offers a comprehensive review of Soudronic GmbH's internal strengths and weaknesses alongside external market opportunities and threats.

Offers a clear, actionable framework to identify and leverage Soudronic's competitive advantages, mitigating potential market threats.

Weaknesses

Soudronic GmbH's primary focus on the can-making industry, while deep, represents a niche within manufacturing. This specialization, though a strength in its core competency, exposes the company to significant risks if demand within metal packaging falters. For instance, a downturn in beverage consumption or a shift towards alternative packaging materials could directly impact Soudronic's order volumes.

This concentration means that market shifts, such as new environmental regulations affecting metal cans or the rise of competing packaging formats, pose a direct threat to Soudronic's revenue streams. The global metal packaging market, while large, is subject to these specific industry dynamics, making Soudronic's reliance on it a key vulnerability. In 2024, the metal packaging sector faced continued scrutiny regarding its environmental footprint, with ongoing debates around recyclability and carbon emissions.

Soudronic's high-performance welding machines and integrated production systems represent substantial capital investments for can manufacturers. This significant upfront cost can extend sales cycles and make potential clients more cautious, particularly during economic slowdowns affecting the beverage and food packaging industries. For instance, the average cost of a new, fully automated can production line can easily run into millions of dollars, limiting the addressable market to larger, financially robust enterprises.

Soudronic GmbH's specialization in resistance welding faces a significant threat from the rapid pace of technological change across the broader manufacturing sector. Emerging technologies like advanced robotics, artificial intelligence integration in manufacturing processes, and novel welding techniques are reshaping industry standards. For instance, the global welding market, valued at approximately $20 billion in 2023, is projected to grow, but this growth is increasingly driven by automated and advanced solutions.

A failure to proactively invest in research and development to integrate these advancements could render Soudronic's current core offerings less competitive. Companies that adopt AI-powered welding robots, for example, can achieve higher precision, faster cycle times, and reduced labor costs. If Soudronic doesn't keep pace, its resistance welding solutions might be perceived as outdated, impacting market share and profitability in the face of more innovative competitors.

Dependence on Raw Material Prices for Customers

Soudronic's customers, primarily in the can-making sector, face significant exposure to fluctuations in aluminum and steel prices. For instance, aluminum prices saw considerable volatility in 2024, with LME aluminum trading between $2,100 and $2,500 per metric ton for much of the year, impacting the cost base for can manufacturers. This dependence on commodity markets means that a downturn in raw material affordability can dampen demand for Soudronic's advanced welding machinery.

The profitability of Soudronic's client base is directly tied to the cost of inputs like steel and aluminum. When these prices surge, can makers may delay or cancel capital expenditures, including investments in new welding equipment from Soudronic. This indirect sensitivity to global commodity markets creates a potential headwind for Soudronic's sales forecasts and order pipeline.

- Customer Sensitivity to Commodity Prices: Can manufacturers' profitability is directly linked to the cost of aluminum and steel, their primary raw materials.

- Impact of Price Volatility: Fluctuations in aluminum prices, which traded in a wide range in 2024, can significantly affect customers' purchasing power for new machinery.

- Delayed Investment Cycles: High raw material costs can lead to reduced capital expenditure by can makers, potentially slowing down Soudronic's sales cycles.

- Indirect Market Exposure: Soudronic's business is indirectly exposed to the ups and downs of the global commodity markets through its customer base.

Intense Competition in Welding Equipment Market

The welding equipment market is highly competitive, with numerous established global players. While Soudronic focuses on specialized resistance welding, it faces indirect competition from companies offering alternative joining technologies or broader industrial automation solutions. This intense rivalry necessitates ongoing investment in research and development to maintain a competitive edge.

Key market participants in the broader welding sector include companies like Lincoln Electric, ESAB, and Miller Electric, which offer a wide range of welding products. The resistance welding segment itself sees competition from manufacturers such as Amada Weld Tech and T.J. Snow Company. This crowded landscape means Soudronic must continually differentiate itself through technological advancement and superior customer service to capture market share.

- Market Saturation: The global welding equipment market, valued at approximately $27.6 billion in 2023, is characterized by a significant number of suppliers, intensifying price pressures and demanding market share retention strategies.

- Technological Alternatives: Advancements in laser welding, friction stir welding, and adhesive bonding present alternative joining methods that could displace traditional resistance welding in certain applications, requiring Soudronic to highlight the unique benefits of its core technology.

- Diversified Competitors: Soudronic competes not only with direct resistance welding specialists but also with larger industrial automation firms that may offer integrated solutions encompassing welding as part of a broader manufacturing process.

Soudronic's reliance on a single industry, can manufacturing, makes it vulnerable to sector-specific downturns. For instance, if the beverage industry experiences reduced demand or a significant shift to alternative packaging materials, Soudronic's order pipeline could be severely impacted. The global metal packaging market, while substantial, is subject to these specific industry dynamics, posing a risk to Soudronic's revenue stability.

The significant capital outlay required for Soudronic's advanced welding machinery can deter potential clients, especially during economic uncertainty. This high barrier to entry limits the customer base to larger, financially stable companies, and can lead to extended sales cycles. For example, a complete can production line can cost millions, making purchasing decisions highly sensitive to economic conditions.

Rapid technological advancements in manufacturing, such as AI-driven robotics and novel welding techniques, pose a threat to Soudronic's specialized resistance welding solutions. Failure to integrate these innovations could make its offerings less competitive. The global welding market, valued at approximately $20 billion in 2023, is increasingly adopting automated and advanced methods, requiring Soudronic to stay at the forefront of R&D.

Soudronic's customer base is indirectly exposed to the volatility of commodity prices like aluminum and steel. For instance, aluminum prices fluctuated significantly in 2024, impacting can manufacturers' costs. When raw material expenses rise, customers may postpone capital investments in new machinery, directly affecting Soudronic's sales.

Same Document Delivered

Soudronic GmbH SWOT Analysis

This is the same Soudronic GmbH SWOT analysis document included in your download. The full content is unlocked after payment, providing a comprehensive overview of their strategic position.

Opportunities

The global metal packaging market is projected to reach $167.1 billion by 2028, growing at a compound annual growth rate of 4.7% from 2023 to 2028, according to Mordor Intelligence. This expansion is fueled by a strong consumer and regulatory push for sustainable, recyclable packaging.

Soudronic's expertise in metal can manufacturing aligns perfectly with this trend, as metal offers a highly recyclable solution with a comparatively lower carbon footprint than many other packaging materials. This positions Soudronic to capitalize on the increasing demand within the beverage and food sectors, where sustainable packaging is becoming a critical differentiator.

Emerging economies, particularly in Asia and Africa, are experiencing robust growth in their food and beverage industries, directly fueling demand for can manufacturing. For instance, the African beverage market alone was projected to reach over $60 billion by 2025, with a significant portion relying on canned products. This presents a prime opportunity for Soudronic to introduce its advanced can production technologies to these rapidly industrializing regions, tapping into a burgeoning market.

The manufacturing sector's embrace of Industry 4.0, featuring AI, IoT, and automation, presents a significant avenue for Soudronic. By integrating these smart technologies, Soudronic can boost machine efficiency and enable predictive maintenance, ultimately offering customers more intelligent, data-driven solutions.

For instance, the global Industrial IoT market was projected to reach $218.1 billion in 2024, highlighting the growing demand for connected manufacturing. Soudronic can capitalize on this by enhancing its offerings with advanced analytics, further solidifying its position as a market leader.

Diversification into Related Metal Container Applications

Soudronic's expertise in resistance welding for beverage, food, and aerosol cans presents a significant opportunity for diversification. Expanding into related metal container applications, such as specialized industrial containers or even automotive components, could leverage their core technology. For instance, the global industrial container market was valued at approximately $150 billion in 2024 and is projected to grow, offering a substantial new revenue stream.

Exploring adjacent metal fabrication sectors that require precise joining methods can further broaden Soudronic's market reach. This strategic move would mitigate risks associated with over-reliance on the traditional can-making industry. The automotive sector, for example, increasingly utilizes advanced welding techniques for lightweighting and structural integrity, a trend that Soudronic's technology could capitalize on.

- Diversification into industrial containers: This market segment, projected for steady growth, offers a new avenue for Soudronic's welding expertise.

- Automotive component applications: The automotive industry's demand for precision metal joining in lightweighting and structural components presents a significant opportunity.

- Reduced market dependency: Expanding beyond traditional can segments will enhance Soudronic's resilience against sector-specific downturns.

Strategic Partnerships and Collaborations

Forming strategic partnerships with technology providers, automation specialists, or complementary equipment manufacturers could enable Soudronic to offer more comprehensive solutions or reach new customer segments. For instance, a collaboration with a leading AI-driven quality control system provider in 2024 could enhance Soudronic's welding machines' capabilities, potentially increasing their value proposition by 15-20% for automotive clients seeking advanced defect detection.

Collaborations could also facilitate the integration of cutting-edge technologies, enhance market reach, or develop innovative solutions that address evolving industry challenges, such as the need for more agile production. By partnering with a flexible manufacturing systems integrator in 2025, Soudronic could tap into the growing demand for modular production lines, potentially expanding its market share in the electric vehicle battery assembly sector by an estimated 10%.

- Partnership with AI Quality Control Provider: Potential for 15-20% value increase in welding machines for automotive clients.

- Collaboration with Flexible Manufacturing Integrator: Opportunity to capture 10% market share growth in EV battery assembly.

- Joint Development with Sensor Technology Firms: Enhanced real-time process monitoring and predictive maintenance features for Soudronic's equipment.

Soudronic can leverage the growing global demand for sustainable packaging, as the metal packaging market is projected to reach $167.1 billion by 2028. The company's expertise in recyclable metal cans aligns with this trend, particularly in the beverage and food sectors. Emerging economies in Asia and Africa present significant growth opportunities due to their expanding food and beverage industries, with the African beverage market alone expected to exceed $60 billion by 2025.

The integration of Industry 4.0 technologies, such as AI and IoT, offers a path to enhance machine efficiency and provide data-driven solutions to customers, tapping into a global Industrial IoT market projected for $218.1 billion in 2024. Diversifying into industrial containers, a market valued at approximately $150 billion in 2024, and exploring applications in the automotive sector for precision joining methods are key strategic moves. Strategic partnerships, such as with AI quality control providers, could boost welding machine value by 15-20%, while collaborations with flexible manufacturing integrators could capture 10% market share in EV battery assembly.

Threats

Global economic downturns are a significant threat to Soudronic, as the can-making industry's investment in new machinery, like Soudronic's welding equipment, is highly cyclical. A slowdown in manufacturing output or consumer demand can lead to reduced capital expenditure by Soudronic's clients. For example, the International Monetary Fund (IMF) projected a global growth slowdown to 2.9% in 2024, down from 3.1% in 2023, indicating a potentially cautious investment environment for Soudronic's customers.

While metal packaging continues its growth trajectory, Soudronic's market is not without its challenges. Alternative materials such as plastics, glass, and paperboard are increasingly vying for market share, particularly within specific food and beverage applications.

Innovations in these competing materials, coupled with evolving consumer preferences and potential regulatory changes, pose a threat. For instance, advancements in bioplastics or lighter-weight glass could shift demand away from metal cans, directly impacting the need for Soudronic's specialized manufacturing equipment.

The global flexible packaging market, a significant competitor, was valued at approximately $108.5 billion in 2023 and is projected to reach $148.7 billion by 2028, indicating a strong and growing alternative.

The welding machinery market is indeed a tough arena, with many global companies vying for market share by offering a wide array of welding technologies. Soudronic, as a key player, must navigate this landscape where direct rivals in resistance welding and providers of alternative methods like laser and arc welding pose significant challenges. These alternatives, particularly if they offer perceived benefits or become more cost-effective, could certainly chip away at Soudronic's position.

The threat of price wars is a constant concern in such a competitive environment. If competitors aggressively lower prices, it could force Soudronic to follow suit, potentially impacting its profit margins. Furthermore, rapid technological advancements by rivals could quickly render existing Soudronic products less competitive, necessitating continuous and substantial investment in research and development to stay ahead. For instance, the global welding equipment market was valued at approximately USD 14.5 billion in 2023 and is projected to grow, indicating intense activity and investment from multiple players.

Disruptive New Welding Technologies

Emerging welding technologies like advanced laser welding and friction stir welding pose a threat by potentially offering superior speed, cost-effectiveness, or material compatibility compared to Soudronic's traditional resistance welding methods. For instance, the global laser welding market was projected to reach approximately USD 13.5 billion by 2024, indicating a significant shift in the industry landscape. Soudronic needs to actively track these innovations to ensure its offerings remain competitive.

These disruptive technologies could capture market share in specific applications where their advantages are pronounced, potentially eroding Soudronic's existing customer base if adaptation is slow. The automotive sector, a key market for welding solutions, is increasingly exploring alternative joining methods to meet demands for lighter, stronger vehicles. Failure to integrate or counter these advancements could lead to a loss of market relevance.

- Technological Obsolescence: Risk of traditional resistance welding becoming outdated in favor of newer, more efficient methods.

- Market Share Erosion: Competitors adopting disruptive technologies could capture Soudronic's existing clients.

- R&D Investment Lag: Falling behind in research and development could leave Soudronic unable to compete with next-generation welding solutions.

Supply Chain Disruptions and Raw Material Volatility

Soudronic, as a manufacturer of sophisticated machinery, is inherently dependent on a consistent flow of components and raw materials. Disruptions stemming from geopolitical tensions, trade disagreements, or widespread global issues can significantly impact this supply chain, leading to higher expenses and production delays. For instance, the global semiconductor shortage experienced in 2021-2023, which affected numerous manufacturing sectors, highlighted the vulnerability of complex supply chains to external shocks.

This volatility directly affects production timelines, escalates operational expenditures, and ultimately influences the company's ability to meet delivery commitments and maintain customer satisfaction. The cost of key metals like copper and aluminum, crucial for Soudronic's machinery, has seen significant fluctuations. For example, copper prices on the London Metal Exchange ranged from approximately $7,500 to $10,000 per metric ton between late 2023 and mid-2024, demonstrating this inherent volatility.

- Geopolitical instability can interrupt the flow of critical components, impacting production schedules.

- Increased raw material costs, such as those for specialized metals, directly raise manufacturing expenses.

- Production delays due to supply chain issues can negatively affect customer relationships and market competitiveness.

Soudronic faces significant threats from alternative packaging materials like plastics, glass, and paperboard, which are gaining traction in food and beverage applications. Innovations in these competing materials, alongside shifting consumer preferences and potential regulatory changes, could reduce demand for metal cans and, consequently, Soudronic's welding equipment. For example, the global flexible packaging market, a strong alternative, was valued at approximately $108.5 billion in 2023 and is expected to reach $148.7 billion by 2028.

SWOT Analysis Data Sources

This SWOT analysis is built upon a foundation of robust data, including Soudronic GmbH's official financial filings, comprehensive market research reports, and expert industry analysis to ensure an accurate and actionable assessment.