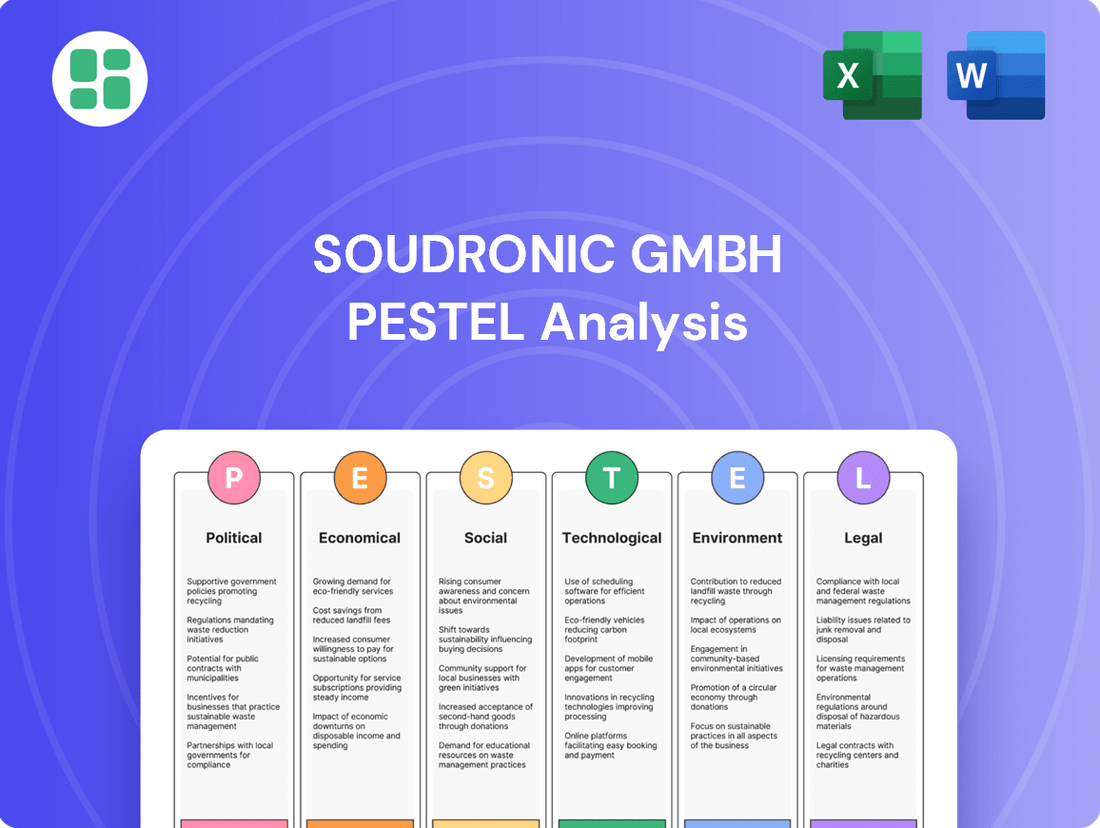

Soudronic GmbH PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Soudronic GmbH Bundle

Soudronic GmbH operates in a dynamic environment shaped by evolving political landscapes, economic fluctuations, and rapid technological advancements. Understanding these external forces is crucial for strategic planning and maintaining a competitive edge.

Our comprehensive PESTEL Analysis delves into these critical factors, offering actionable intelligence to navigate challenges and capitalize on opportunities. Gain the foresight needed to make informed decisions and secure Soudronic GmbH's future success.

Don't be left behind by market shifts. Invest in our expertly crafted PESTEL Analysis for Soudronic GmbH and unlock a deeper understanding of the forces that will shape its trajectory. Download the full version now for immediate, impactful insights.

Political factors

Soudronic GmbH, a key player in the can-making machinery sector, faces significant exposure to global trade policies and tariffs. For instance, the United States imposed tariffs on steel and aluminum imports in 2018, which could indirectly affect the cost of materials used in Soudronic's machinery, impacting their overall production expenses.

Fluctuations in trade agreements, such as potential renegotiations or the emergence of new protectionist measures, can directly influence Soudronic's ability to export its sophisticated machinery. For example, if a major market like the European Union were to implement new tariffs on capital goods, it could raise the landed cost of Soudronic's machines for customers in that region, potentially dampening demand.

The company's profitability and market competitiveness are closely tied to its capacity to navigate these evolving trade landscapes. A proactive approach to understanding and adapting to changes in tariffs, import/export regulations, and trade blocs is essential for Soudronic to maintain its global reach and secure its financial performance in the coming years.

Government regulations profoundly shape Soudronic's manufacturing. Rules on factory emissions, waste management, and worker safety directly impact production. For instance, in 2024, the European Union continued to tighten its environmental standards, potentially requiring Soudronic to invest in advanced filtration systems or cleaner energy sources, thereby increasing operational expenditures.

Stricter labor laws, such as those concerning working hours or safety protocols, can also necessitate adjustments to manufacturing processes and workforce management. Non-compliance with these diverse national and regional regulations, which vary significantly across Soudronic's global operations, could lead to production halts or substantial fines, underscoring the critical need for meticulous adherence.

Geopolitical tensions, such as ongoing conflicts in Eastern Europe and the Middle East, directly impact global supply chains, affecting the availability and cost of raw materials and electronic components crucial for Soudronic's advanced welding and assembly machinery. For instance, disruptions in the semiconductor supply chain, exacerbated by geopolitical friction, could lead to production delays and increased component prices for Soudronic in 2024 and 2025.

Soudronic's reliance on a global sourcing network necessitates a keen assessment of risks stemming from trade disputes or regional instability. The company must actively manage these vulnerabilities to maintain consistent production schedules and timely deliveries of its high-performance machines, a challenge amplified by the potential for new tariffs or export restrictions in key manufacturing regions.

To counter these risks, Soudronic is likely focusing on diversifying its supplier base across different geographic regions and strengthening its logistics networks. This strategy aims to build resilience against unforeseen political events, ensuring a more stable flow of necessary components and a reliable supply chain for its international clientele through 2025.

Investment Incentives for Industrial Automation

Government initiatives and incentives play a crucial role in shaping the market for industrial automation. Policies designed to boost advanced manufacturing and the adoption of Industry 4.0 technologies can directly benefit companies like Soudronic, which provide high-performance welding machines essential for modern production lines. These incentives, such as tax credits or grants for upgrading manufacturing capabilities, are projected to significantly fuel growth in the industrial automation sector.

The industrial automation market is anticipated to see substantial expansion, with forecasts indicating robust growth between 2025 and 2035. This upward trend is largely attributed to the increasing implementation of smart manufacturing principles and the broader adoption of Industry 4.0 concepts across various industries. Such a supportive political and economic environment encourages greater investment within sectors reliant on advanced manufacturing, including the can-making industry where Soudronic operates.

- Government Support: Policies offering tax breaks, subsidies, or grants for adopting Industry 4.0 technologies can stimulate demand for Soudronic's welding machines.

- Market Growth Projections: The industrial automation market is expected to grow significantly from 2025 to 2035, driven by smart manufacturing.

- Investment Climate: Favorable political environments encourage investment in advanced manufacturing, benefiting Soudronic's market position.

Packaging Waste Regulations and Circular Economy Policies

Stricter packaging waste regulations, like the EU's Packaging and Packaging Waste Regulation (PPWR) effective February 2025, are significantly impacting the can-making sector. These policies champion a circular economy, pushing for reduced waste and higher recycling rates. By December 31, 2025, the EU aims for a 65% recycling rate for all packaging waste.

This regulatory environment directly affects Soudronic GmbH, as it drives demand for their advanced, sustainable manufacturing equipment. Can manufacturers are compelled to invest in more efficient and eco-friendly production technologies to meet these evolving standards.

- EU PPWR Targets: Aiming for 65% packaging waste recycling by end of 2025.

- Circular Economy Push: Encourages reusable packaging and waste reduction.

- Industry Impact: Drives investment in sustainable can-making technologies.

- Soudronic's Role: Positioned to benefit from demand for efficient, eco-conscious machinery.

Political stability and government policies significantly influence Soudronic's operational landscape. For instance, the ongoing push for Industry 4.0 adoption, supported by government incentives like tax credits for advanced manufacturing upgrades, is projected to fuel growth in the industrial automation market, benefiting Soudronic's sales pipeline through 2025.

Trade agreements and potential tariffs remain a key political consideration, directly impacting Soudronic's global market access and material costs. The company must remain agile in navigating evolving trade policies to maintain its competitive edge.

Furthermore, tightening environmental regulations, such as the EU's Packaging and Packaging Waste Regulation (PPWR) with its 2025 recycling targets, are driving demand for more sustainable manufacturing solutions, positioning Soudronic's efficient machinery favorably.

Geopolitical tensions can disrupt supply chains for critical components, necessitating robust risk management strategies. Soudronic's proactive diversification of its supplier base is a key strategy to mitigate these political risks through 2025.

What is included in the product

This PESTLE analysis examines the external macro-environmental factors impacting Soudronic GmbH, covering Political, Economic, Social, Technological, Environmental, and Legal influences to identify strategic opportunities and threats.

A clean, summarized version of the Soudronic GmbH PESTLE analysis provides a pain point reliver by offering clear insights into external factors, enabling proactive strategy development and risk mitigation.

Economic factors

Global economic growth directly influences Soudronic's machinery demand, as a thriving economy spurs consumer spending on packaged goods. This increased spending on items like canned beverages and food boosts the need for cans, consequently driving demand for Soudronic's advanced can-making equipment.

Industrial production, especially within the food and beverage packaging sector, is a key indicator for Soudronic. When factories are producing more, they often require updated or additional machinery to maintain efficiency and capacity. The metal packaging market's projected growth from USD 129.7 billion in 2025 to USD 181.2 billion by 2035 underscores this positive correlation.

Fluctuations in steel and aluminum prices are critical for Soudronic's clients in the can manufacturing industry. For instance, the price of aluminum, a key component, is projected to maintain a strong market presence, holding a 42.7% share in the metal packaging material segment by 2025. These price swings directly affect the profitability of can producers.

When raw material costs surge, can manufacturers might find their profit margins tightening. This financial pressure can lead to a slowdown in capital expenditure, potentially delaying or reducing orders for new machinery from companies like Soudronic. Conversely, a period of stable or declining material prices can encourage these manufacturers to invest more readily in upgrading their production capabilities.

Rising inflation and interest rates pose a significant challenge for Soudronic GmbH. Increased inflation is projected to drive up operating costs, impacting everything from labor to the sourcing of essential components. For instance, the manufacturing sector anticipates a 2.7% increase in raw material and input costs within the next twelve months, a trend likely to affect Soudronic's own expenses.

Higher interest rates directly impact Soudronic's customer base, particularly can manufacturers. As borrowing becomes more expensive, companies may hesitate to finance new machinery or expansion projects, leading to a slowdown in demand for Soudronic's products. This economic environment necessitates careful monitoring of these macroeconomic indicators to inform pricing strategies and refine sales forecasts to navigate potential market shifts effectively.

Consumer Spending on Packaged Goods

Consumer spending habits are a major driver for Soudronic. When consumers are confident and have disposable income, they tend to buy more packaged goods, like food and beverages. This increased demand directly benefits can manufacturers, who then need to invest in more production capacity. This, in turn, boosts the need for Soudronic's specialized welding machines used in can production.

The beverage can market is a key indicator here. In 2024, this market was valued at a substantial USD 28.6 billion. Projections show continued growth, with an estimated compound annual growth rate (CAGR) of 5.8% expected between 2025 and 2034. This robust growth signals a healthy demand for cans, which translates to opportunities for Soudronic.

- Consumer Purchasing Power: Directly impacts demand for packaged goods, influencing can production volumes.

- Market Growth: The global beverage cans market, valued at USD 28.6 billion in 2024, is projected to grow at a 5.8% CAGR from 2025-2034.

- Production Expansion: Increased consumer demand encourages can manufacturers to expand, creating a need for Soudronic's welding technology.

- Economic Downturn Impact: Reduced consumer spending can lead to lower demand for new can-making equipment.

Currency Exchange Rate Fluctuations

Currency exchange rate fluctuations significantly impact Soudronic GmbH's international operations and profitability. For instance, if the Euro strengthens against other major currencies in 2024-2025, Soudronic's machinery exports would become more expensive for overseas buyers, potentially dampening demand. Conversely, a weaker Euro would make imports of raw materials or components cheaper, potentially boosting profit margins on production.

Managing these currency risks is crucial for Soudronic's competitive edge. Companies often employ strategies like currency hedging, where they enter into financial contracts to lock in exchange rates for future transactions. Strategic pricing adjustments, reflecting anticipated currency movements, also play a vital role in maintaining profitability across diverse global markets. For example, in early 2025, the Swiss Franc's continued strength against the Euro could present a challenge for Soudronic, which operates in Germany, necessitating careful financial planning.

- Export Competitiveness: A stronger Euro makes Soudronic's products pricier for international clients.

- Import Costs: A weaker Euro reduces the cost of imported materials and components.

- Hedging Strategies: Financial instruments are used to mitigate adverse currency movements.

- Pricing Adjustments: Companies may alter prices to account for currency volatility.

Global economic conditions directly influence Soudronic's business. A robust economy generally leads to increased consumer spending on packaged goods, which in turn drives demand for Soudronic's can-making machinery. Conversely, economic downturns can dampen this demand.

Inflation and interest rates are critical factors. Rising inflation increases operating costs for Soudronic and its clients, while higher interest rates make financing new equipment more expensive for can manufacturers, potentially slowing down orders. For instance, the manufacturing sector anticipates a 2.7% increase in raw material and input costs in the coming year.

Currency exchange rates also play a significant role. Fluctuations can impact the cost of Soudronic's exports and the expense of imported components, affecting international competitiveness and profit margins. A stronger Swiss Franc against the Euro in early 2025, for example, could present a challenge.

The beverage can market's health is a key indicator, valued at USD 28.6 billion in 2024 and projected to grow at a 5.8% CAGR from 2025-2034, signaling strong demand for Soudronic's technology.

Full Version Awaits

Soudronic GmbH PESTLE Analysis

The preview shown here is the exact document you’ll receive after purchase—fully formatted and ready to use. This comprehensive PESTLE analysis of Soudronic GmbH delves into the Political, Economic, Social, Technological, Legal, and Environmental factors impacting the company's operations and strategic direction.

Sociological factors

Consumers worldwide are increasingly prioritizing sustainability, showing a clear preference for packaging that is either recyclable or reusable. This shift directly benefits Soudronic GmbH, as metal cans, a core product of their machinery, are exceptionally recyclable.

This growing eco-consciousness translates into tangible market opportunities. In fact, a significant 82% of consumers indicate a willingness to pay a premium for products featuring sustainable packaging, underscoring the commercial advantage of environmentally friendly solutions for Soudronic's clientele.

The availability of skilled labor is crucial for Soudronic, especially for operating and maintaining their advanced manufacturing machinery. This affects not only their internal production but also their customers' ability to utilize Soudronic's equipment effectively. Shortages of qualified technicians and engineers can directly hinder production efficiency and the quality of after-sales support.

To combat these potential issues, Soudronic is actively investing in training and apprenticeship programs. Their focus on developing talent, with a specific eye on their 2025 graduates, demonstrates a proactive approach to bridging existing skill gaps and ensuring a competent workforce for the future.

Public and regulatory scrutiny over chemicals like BPA and PFAS in food packaging is a significant driver in material selection for the can-making sector. These concerns directly impact Soudronic, requiring its welding technologies to align with a growing demand for demonstrably safe and non-toxic packaging solutions.

The tightening regulatory landscape, with increased restrictions on substances of concern within packaging materials, necessitates that Soudronic's welding processes and systems are adaptable and compliant with evolving industry standards and consumer expectations for enhanced health and safety.

Changing Lifestyles and Consumption Patterns

Modern lifestyles are increasingly prioritizing convenience, leading to a surge in on-the-go consumption and a greater demand for ready-to-drink beverages. This trend directly influences the types and volumes of cans Soudronic's welding machines are designed to produce, as manufacturers adapt to consumer preferences for premium and functional hydration options.

The global beverage cans market reflects this evolution, with a noticeable shift towards premiumization and specialized functional drinks. For instance, the market for energy drinks and functional beverages, often packaged in cans, has seen robust growth. In 2024, the global beverage cans market was valued at approximately USD 45 billion, with projections indicating continued expansion driven by these evolving consumer habits.

- Convenience-driven demand: Consumers seek quick and easy beverage solutions, boosting the market for canned drinks.

- Premiumization trend: An increasing preference for higher-quality, often functional, beverages packaged in cans.

- Functional hydration: Growth in beverages offering added benefits like vitamins or electrolytes, typically in can format.

- Market impact: These shifts necessitate adaptable can designs and production capabilities, influencing Soudronic's technological development.

Corporate Social Responsibility (CSR) Expectations

Societal expectations for companies like Soudronic GmbH to actively engage in Corporate Social Responsibility (CSR) are on the rise. This includes a strong focus on ethical sourcing of materials, ensuring fair labor conditions throughout the supply chain, and actively participating in community development initiatives. Adherence to these elevated CSR standards is becoming crucial for bolstering brand image, attracting top-tier talent, and satisfying the growing demands of ethically-minded investors and business collaborators.

Soudronic's commitment to sustainability within the framework of Industry 5.0 directly addresses these evolving CSR expectations. This approach prioritizes not only environmentally sound manufacturing processes but also a deep commitment to social responsibility, ensuring that technological advancement goes hand-in-hand with positive societal impact. For instance, reports from 2024 highlight a growing investor preference for companies demonstrating robust ESG (Environmental, Social, and Governance) performance, with a significant portion of new capital allocated to businesses with strong CSR track records.

- Ethical Sourcing: Consumers and partners increasingly demand transparency in supply chains, pushing companies to verify the ethical origins of their components and raw materials.

- Fair Labor Practices: Ensuring safe working conditions, fair wages, and prohibiting child labor are fundamental CSR expectations that impact a company's social license to operate.

- Community Engagement: Active involvement in local communities through support programs, job creation, and environmental stewardship builds goodwill and strengthens stakeholder relationships.

- Sustainability in Industry 5.0: Soudronic's focus on this area signifies a proactive approach to integrating social and environmental considerations into advanced manufacturing, aligning with future societal values.

Societal expectations are shifting towards greater corporate responsibility, with consumers and stakeholders demanding ethical practices and transparency. Soudronic's alignment with Industry 5.0 principles, which emphasize human-centric and sustainable manufacturing, directly addresses these evolving demands.

This focus on social responsibility is increasingly influencing investment decisions. Data from 2024 indicates that a substantial percentage of investors are prioritizing companies with strong Environmental, Social, and Governance (ESG) performance, signaling a growing preference for businesses demonstrating robust CSR track records.

The emphasis on fair labor and ethical sourcing is paramount, impacting a company's social license to operate and its brand reputation. By integrating these principles, Soudronic not only enhances its image but also attracts talent and fosters stronger relationships with business partners.

Soudronic's commitment to community engagement further solidifies its positive societal impact. This proactive approach to social and environmental considerations within advanced manufacturing positions the company favorably for future societal values and market expectations.

Technological factors

Continuous innovation in resistance welding technology is vital for Soudronic GmbH to maintain its competitive advantage. This involves creating more precise, energy-efficient, and faster welding methods, alongside adapting to new materials and coatings.

These technological leaps enable Soudronic to deliver enhanced machine performance and superior product quality to its customers in the can-making industry. The global resistance welding machine market was valued at approximately $1.17 billion in 2025 and is anticipated to grow to $2 billion by 2033.

Soudronic GmbH is well-positioned to capitalize on the increasing integration of automation and Industry 4.0 principles within the manufacturing sector. Their advanced welding and automation solutions are designed to seamlessly fit into smart factory environments, enabling data-driven insights for predictive maintenance and production line optimization. This focus on efficiency aligns with the projected growth of the industrial automation market, which is anticipated to reach approximately $311.1 billion by 2027, according to Statista.

Innovations in metal alloys and coatings are reshaping can manufacturing, with lightweight aluminum and new BPA-free linings becoming significant trends by 2025. Soudronic must adapt its welding solutions to accommodate these advanced materials. For instance, the demand for thinner, yet stronger aluminum alloys for beverage cans is increasing, requiring precision welding techniques.

The efficiency of welding diverse and advanced materials is crucial for Soudronic to remain competitive in the evolving can-making industry. By 2024, the global market for aluminum cans was projected to reach over $100 billion, highlighting the importance of material compatibility for welding equipment manufacturers.

Data Analytics and Predictive Maintenance

Soudronic's integration of data analytics and AI for predictive maintenance is a significant technological advantage. By analyzing real-time machine performance data, they can anticipate potential equipment failures before they occur. This proactive approach translates to improved uptime and service for their can manufacturing clients, directly impacting production efficiency.

The benefits of this technology are substantial. For instance, a study by McKinsey in 2024 found that companies utilizing predictive maintenance saw a reduction in downtime by as much as 30% and a decrease in maintenance costs by 10-40%. For Soudronic, this means fewer disruptions for their customers and a stronger value proposition.

Key aspects of this technological factor include:

- Real-time Performance Monitoring: Continuous data collection from Soudronic's machines provides immediate insights into operational health.

- AI-Driven Failure Prediction: Machine learning algorithms identify patterns indicative of impending component failure.

- Proactive Maintenance Scheduling: Service interventions are planned based on predicted needs, not reactive responses to breakdowns.

- Reduced Downtime and Waste: Minimizing unexpected stoppages and optimizing part replacements directly enhances customer productivity and resource efficiency.

Energy Efficiency in Machine Operation

As energy costs continue their upward trend and sustainability targets gain increasing importance, the energy efficiency of Soudronic's welding machines emerges as a crucial technological consideration. Innovations in this area directly impact operational expenses for clients and support broader environmental mandates, meeting a growing market preference for eco-friendly manufacturing solutions.

Soudronic is actively pursuing a goal to decrease the energy consumption of its welding processes by an additional 5% by the year 2025. This objective reflects a commitment to technological advancement that benefits both the company's customers through cost savings and the global effort to reduce carbon footprints.

- Energy Consumption Reduction Target: Soudronic aims for a 5% reduction in welding process energy consumption by 2025.

- Customer Cost Savings: Enhanced machine efficiency translates to lower operating costs for Soudronic's clientele.

- Environmental Alignment: Improved energy efficiency supports global sustainability goals and the demand for greener industrial practices.

Soudronic GmbH's technological edge lies in its continuous pursuit of advanced resistance welding solutions, crucial for evolving can manufacturing demands. By 2024, the global aluminum can market exceeded $100 billion, underscoring the need for precision welding of new materials like lighter aluminum alloys and BPA-free linings.

The integration of Industry 4.0 principles, including AI for predictive maintenance, offers significant operational advantages. Companies leveraging predictive maintenance saw up to a 30% reduction in downtime in 2024, a benefit Soudronic can pass to its clients. Furthermore, Soudronic aims to cut welding process energy consumption by 5% by 2025, aligning with growing demands for energy-efficient and sustainable manufacturing.

| Technological Advancement | Impact on Soudronic | Market Relevance (2024-2025 Data) |

|---|---|---|

| Advanced Resistance Welding | Enhanced precision, speed, and material compatibility | Global resistance welding market projected to reach $2 billion by 2033; aluminum can market >$100 billion (2024) |

| AI & Predictive Maintenance | Reduced customer downtime, optimized service | Predictive maintenance users saw up to 30% downtime reduction (2024) |

| Energy Efficiency | Lower operating costs for clients, environmental compliance | Soudronic targeting 5% energy consumption reduction by 2025 |

Legal factors

Soudronic GmbH operates within a landscape shaped by increasingly stringent packaging and packaging waste regulations. The European Union's ambitious Packaging and Packaging Waste Regulation (PPWR), which came into force in February 2025 and will see provisions applied from August 2026, is a prime example. This regulation, along with similar initiatives in various US states, is driving demand for higher recycling rates and mandating the inclusion of specific percentages of recycled content in packaging materials.

These regulatory shifts directly influence the can-making industry by necessitating adaptations in manufacturing processes and product design. For Soudronic, this means a continued focus on developing and supplying machinery capable of handling a wider range of materials, including those with higher recycled content, and supporting the production of more easily recyclable or reusable packaging solutions. The company's ability to innovate in response to these evolving legal requirements will be crucial for its continued success and market position.

Soudronic's customers in the food and beverage sector absolutely require adherence to strict product safety and quality standards for their containers. This means ensuring that materials used, and the manufacturing processes facilitated by Soudronic's machinery, prevent any harmful substances from migrating into food or drinks.

Meeting global and regional safety certifications, such as those for food contact materials, is critical. For instance, the increasing implementation of PFAS bans in food packaging, with various US states enacting these regulations starting in 2025, directly impacts the materials and technologies Soudronic must support.

Protecting Soudronic GmbH's intellectual property, particularly its advanced welding technologies and innovative machine designs, is paramount to sustaining its market leadership. Legal frameworks governing intellectual property rights, including patents, are crucial for safeguarding these innovations against unauthorized use and ensuring Soudronic reaps the rewards of its significant R&D investments.

The company's commitment to continuous innovation is evident in its ongoing development of new welding equipment, such as the advanced battery tab welders introduced in recent years. These advancements, protected by patents, allow Soudronic to maintain a distinct competitive edge in a rapidly evolving industry.

Labor Laws and Employment Regulations

Soudronic GmbH must navigate a complex web of labor laws and employment regulations across its operational and sales territories. This involves strict adherence to varying standards for working conditions, wage structures, employee benefits, and occupational health and safety. For instance, in Germany, the minimum wage was €12.41 per hour as of January 2024, a benchmark Soudronic must meet or exceed.

Compliance with these diverse legal frameworks is not merely a matter of avoiding penalties; it's fundamental to maintaining ethical business practices and safeguarding the company's reputation. Failure to comply can lead to costly legal battles, fines, and significant damage to brand image. Soudronic's commitment to supporting young talent through apprenticeships, a common practice in countries like Switzerland where the company is headquartered, also falls under these legal considerations, ensuring fair training and employment opportunities.

Key legal factors impacting Soudronic include:

- Compliance with Minimum Wage Laws: Adhering to statutory minimum wage rates in all operating countries, such as Germany's €12.41/hour (as of Jan 2024).

- Health and Safety Regulations: Meeting stringent workplace safety standards to prevent accidents and ensure employee well-being.

- Employment Contracts and Benefits: Ensuring all employment agreements and benefit provisions comply with local labor legislation.

- Apprenticeship Program Regulations: Following specific legal guidelines for vocational training and youth employment programs.

Antitrust and Competition Laws

Soudronic operates within a regulatory landscape shaped by antitrust and competition laws designed to foster fair market practices and prevent monopolistic tendencies. As a significant entity in its specialized sector, the company must carefully manage its market share and competitive strategies to preempt potential legal scrutiny and contribute to a balanced market dynamic.

The metal packaging industry, where Soudronic is a prominent player, is notably concentrated, featuring a limited number of dominant companies. For instance, global metal packaging production saw significant consolidation in recent years, with major players like Crown Holdings and Ball Corporation holding substantial market influence. In 2024, the global metal packaging market was valued at approximately USD 125 billion, with projections indicating continued growth, underscoring the importance of competitive compliance for all participants.

Key considerations for Soudronic include:

- Merger and Acquisition Scrutiny: Any potential M&A activities must undergo rigorous review by competition authorities to ensure they do not stifle competition or create dominant market positions.

- Pricing and Collusion Risks: Adherence to regulations prohibiting price-fixing or anti-competitive collusion is paramount, especially given the concentrated nature of the industry.

- Dominant Position Safeguards: Soudronic must ensure its business practices do not exploit any dominant market position, safeguarding fair access for smaller competitors.

- International Compliance: Operating globally requires navigating diverse antitrust frameworks in different jurisdictions, such as those enforced by the European Commission and the U.S. Federal Trade Commission.

Soudronic GmbH must navigate evolving packaging regulations, especially the EU's PPWR effective August 2026, mandating higher recycling rates and recycled content. This drives demand for machinery supporting diverse materials and recyclable designs, impacting Soudronic's product development and market strategy. Furthermore, stringent food contact material safety standards, including PFAS bans in various US states from 2025, necessitate careful material selection and process validation for Soudronic's equipment.

Protecting Soudronic's technological innovations through patents is vital for maintaining its competitive edge, especially with new developments like advanced battery tab welders. The company also faces rigorous labor laws across its global operations, requiring compliance with minimum wage laws, such as Germany's €12.41/hour in January 2024, and occupational health and safety standards. Antitrust and competition laws are also critical, particularly in the concentrated metal packaging industry valued at approximately USD 125 billion in 2024, demanding careful management of market share and competitive practices.

Environmental factors

Environmental regulations on emissions and waste disposal directly impact Soudronic's manufacturing processes and its customers' operations. These rules necessitate investments in pollution control and waste management, adding to production costs. With manufacturing accounting for roughly 20% of global emissions, adhering to sustainable practices is paramount for companies like Soudronic.

The increasing global focus on saving energy and tackling climate change is fueling a higher demand for machinery that uses less power. This trend directly benefits companies like Soudronic, which specialize in creating welding machines that are more energy-efficient.

By offering welding solutions that help can manufacturers lower their energy usage, Soudronic is positioning itself favorably within an industry actively seeking ways to reduce its carbon footprint and operational expenses. This alignment with market needs is crucial for sustained growth.

Soudronic has set a clear target to further decrease energy consumption in its welding processes by an additional 5% by the year 2025. This commitment underscores their dedication to innovation in sustainable manufacturing technologies.

The global push for a circular economy is reshaping the packaging landscape, emphasizing reuse and recycling to cut down on waste. This trend directly benefits the can-making industry, especially metal packaging, which boasts high recyclability rates. Soudronic's advanced machinery plays a crucial role by facilitating the efficient production of cans designed for this circular model, aligning with growing environmental demands.

Scarcity of Natural Resources

The availability and pricing of essential metals like aluminum and steel, crucial for Soudronic's can production, are significant environmental considerations. While these metals are highly recyclable, their initial extraction and processing carry environmental footprints. For instance, aluminum recycling can save up to 95% of the energy needed for primary production, highlighting the importance of circular economy principles.

Soudronic's commitment to efficient welding technologies and optimized material usage directly addresses resource conservation. By minimizing waste and maximizing the lifespan of materials, the company plays a role in mitigating the environmental impact associated with metal sourcing. The inherent recyclability of aluminum and steel offers a pathway to reduce reliance on virgin resources.

- Resource Availability: Fluctuations in the global supply of aluminum and steel can impact production costs and availability for Soudronic.

- Energy Consumption: The energy-intensive nature of primary metal production necessitates a focus on recycled materials.

- Recycling Rates: High recycling rates for aluminum (around 75% globally in 2023) and steel (over 80% in many developed nations) are critical for sustainability.

- Extraction Impacts: Mining and smelting processes for raw materials can lead to habitat disruption and pollution if not managed responsibly.

Climate Change Policies and Sustainability Goals

Global climate change policies and corporate sustainability goals are increasingly influencing industrial practices. Soudronic's focus on developing energy-efficient welding technologies and machines that minimize material waste directly supports its customers in achieving their own environmental targets, aligning with broader climate objectives.

Companies are actively prioritizing sustainability throughout their supply chains, a trend that benefits Soudronic's offerings. For instance, the European Union's Fit for 55 package, aiming for a 55% reduction in greenhouse gas emissions by 2030 compared to 1990 levels, creates a strong incentive for manufacturers to adopt more sustainable production methods.

- Growing demand for eco-friendly manufacturing processes.

- Soudronic's sustainable technologies aid customer compliance with environmental regulations.

- The global push for carbon neutrality favors companies with green credentials.

Environmental regulations continue to shape Soudronic's operational landscape, demanding ongoing investment in cleaner production methods and waste management. The global drive towards energy efficiency and climate action directly benefits Soudronic's energy-saving welding technologies, as seen in their 2025 goal to cut energy consumption by another 5%. The increasing adoption of circular economy principles further bolsters Soudronic's position, with their machinery facilitating the efficient production of highly recyclable metal packaging.

| Environmental Factor | Impact on Soudronic | Supporting Data/Trend |

|---|---|---|

| Emissions & Waste Regulations | Increased compliance costs, need for sustainable processes | Manufacturing accounts for ~20% of global emissions. |

| Energy Efficiency Demand | Increased demand for Soudronic's energy-saving welding machines | Soudronic targets a further 5% energy reduction by 2025. |

| Circular Economy Push | Benefits for metal packaging, demand for efficient production | Aluminum recycling saves up to 95% of energy vs. primary production. |

| Resource Availability (Metals) | Impact on costs and supply chains, emphasis on recycled materials | Global aluminum recycling rate ~75% (2023); Steel recycling >80%. |

| Climate Policies | Supports customer sustainability goals, aligns with global objectives | EU's Fit for 55 aims for 55% GHG reduction by 2030. |

PESTLE Analysis Data Sources

Our Soudronic GmbH PESTLE Analysis is grounded in comprehensive data from international economic bodies, governmental regulatory updates, leading technology trend reports, and reputable industry publications. This ensures a thorough understanding of the political, economic, social, technological, legal, and environmental factors impacting Soudronic.