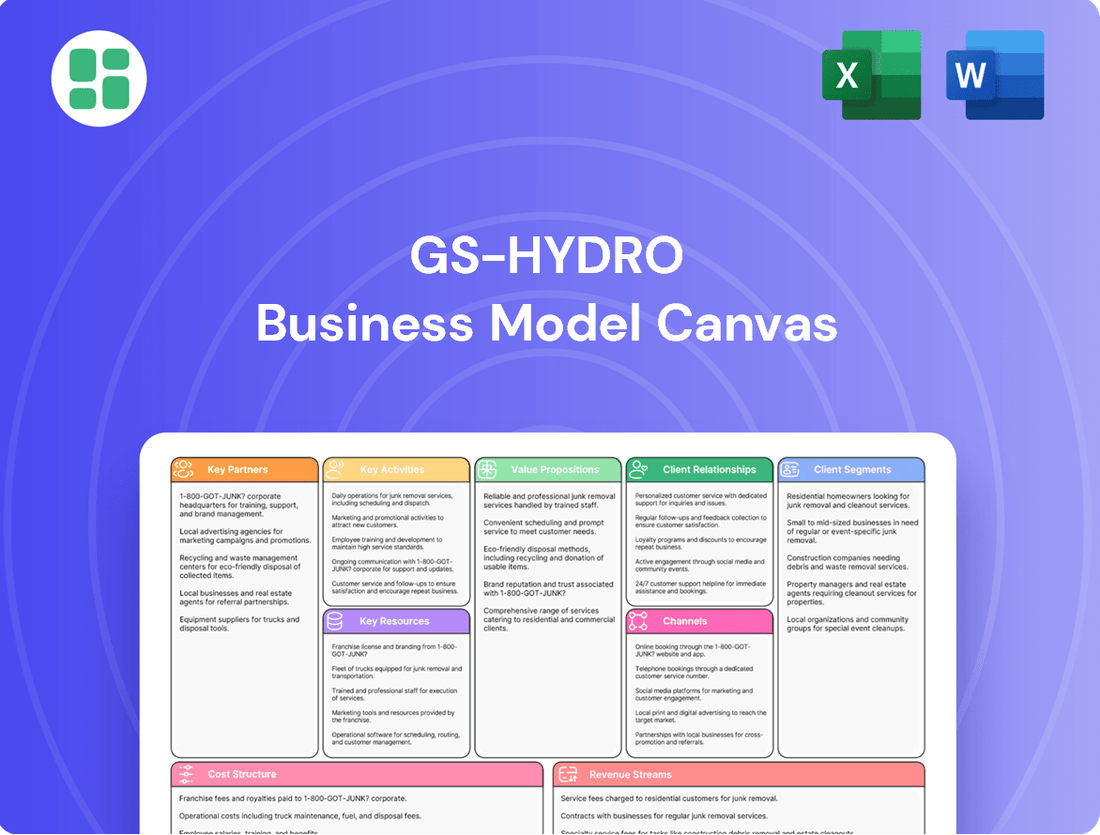

GS-Hydro Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

GS-Hydro Bundle

Discover the strategic framework that powers GS-Hydro's success with our comprehensive Business Model Canvas. This detailed analysis breaks down their customer relationships, revenue streams, and key resources, offering invaluable insights for anyone looking to understand their competitive edge.

Unlock the full strategic blueprint behind GS-Hydro's business model. This in-depth Business Model Canvas reveals how the company drives value, captures market share, and stays ahead in a competitive landscape. Ideal for entrepreneurs, consultants, and investors looking for actionable insights.

Partnerships

GS-Hydro's strategic supplier relationships are foundational to its business model, ensuring the high quality of its non-welded piping systems. These partnerships provide critical components like precision steel pipes, tubes, flanges, fittings, and hoses, all vital for system integrity. For instance, in 2024, GS-Hydro continued to rely on specialized manufacturers, including those producing seamless steel pipes that meet stringent industry certifications, thereby guaranteeing the reliability demanded by its global clientele.

GS-Hydro collaborates with leading certification bodies such as DNV, Lloyd's Register, Bureau Veritas, and ABS. These partnerships are crucial for ensuring GS-Hydro's non-welded piping systems meet the rigorous safety and quality standards demanded by the marine, offshore, and industrial sectors. For instance, in 2024, DNV approved GS-Hydro's systems for a significant offshore wind farm project, underscoring the technology's reliability.

GS-Hydro leverages a vast global network of over twenty-five subsidiaries, agents, and representatives to ensure widespread market penetration and localized customer support.

These strategic partnerships are crucial for facilitating sales, providing essential on-site technical assistance, and effectively coordinating projects across diverse international markets.

This extensive reach allows GS-Hydro to offer tailored solutions and responsive service, reinforcing its position as a global leader in its field.

Engineering and Project Management Firms

GS-Hydro's collaborations with engineering and project management firms are critical for embedding its advanced piping systems into complex client initiatives. These partnerships ensure that GS-Hydro's solutions are not just components but integral parts of larger, intricate projects, facilitating efficient and technically sound integration.

Working closely with customer engineering teams, GS-Hydro leverages 3D modeling and precise spool drawings. This detailed approach optimizes piping layouts, minimizes on-site welding, and significantly streamlines project execution, a key factor in successful large-scale industrial developments.

- Integration into Major Projects: Partnerships enable GS-Hydro to be specified early in the design phase of significant industrial projects, ensuring their specialized piping solutions are optimally incorporated.

- Technical Collaboration: Joint efforts with engineering firms involve detailed 3D modeling and the generation of precise spool drawings, crucial for accurate prefabrication and on-site assembly.

- Efficiency Gains: By facilitating seamless integration and reducing on-site work, these partnerships contribute to faster project timelines and lower overall project costs for clients.

- Market Reach: Collaborating with established project management firms expands GS-Hydro's access to a wider range of global industrial projects, particularly in sectors like shipbuilding and offshore energy.

Interpump Group Synergies

As a key part of the Interpump Group, GS-Hydro benefits significantly from the combined expertise and product portfolios of more than 100 sister companies. This extensive internal network, spanning both Fluid Transfer Solutions and Water Jetting, grants GS-Hydro access to a broader spectrum of hydraulic components and amplifies its global reach.

This integration fosters a powerful synergy, allowing GS-Hydro to tap into a vast pool of knowledge and innovation. For instance, Interpump Group's Fluid Transfer Solutions division, a major player in the market, reported strong performance in 2024, contributing to the group's overall revenue growth, which underscores the value of these internal collaborations.

- Access to Diverse Hydraulic Components: GS-Hydro can source specialized components from across the Interpump Group, enhancing its product offerings and custom solutions.

- Enhanced Global Footprint: The collective presence of Interpump Group companies provides GS-Hydro with expanded market access and support capabilities worldwide.

- Shared R&D and Innovation: Collaboration within the group allows for the sharing of research and development efforts, accelerating innovation in hydraulic technologies.

- Operational Efficiencies: Leveraging the scale and shared resources of the Interpump Group can lead to improved operational efficiencies and cost savings for GS-Hydro.

GS-Hydro's key partnerships are vital for its operational success and market reach. These collaborations span from critical material suppliers to global certification bodies and engineering firms, ensuring the quality, safety, and seamless integration of its piping systems. The company also benefits immensely from its position within the Interpump Group, leveraging the collective expertise and resources of its sister companies to enhance its offerings and expand its global presence.

| Partner Type | Key Contribution | Example/Benefit |

| Material Suppliers | Provision of high-quality steel pipes, flanges, fittings | Ensures system integrity and reliability; reliance on certified seamless steel pipe manufacturers in 2024. |

| Certification Bodies (DNV, Lloyd's Register, etc.) | Validation of safety and quality standards | Crucial for marine, offshore, and industrial sectors; DNV approval for offshore wind farm project in 2024. |

| Subsidiaries, Agents, Representatives | Market penetration and localized customer support | Over twenty-five global locations for sales and technical assistance. |

| Engineering & Project Management Firms | Integration into complex client projects | Facilitates 3D modeling and precise spool drawings for efficient project execution. |

| Interpump Group (Sister Companies) | Access to diverse hydraulic components and global reach | Synergy from over 100 companies; Interpump Group's Fluid Transfer Solutions division reported strong performance in 2024. |

What is included in the product

A comprehensive, pre-written business model tailored to GS-Hydro’s strategy, detailing customer segments, channels, and value propositions.

Reflects GS-Hydro's real-world operations and plans, organized into 9 classic BMC blocks with full narrative and insights.

GS-Hydro's Business Model Canvas acts as a pain point reliever by providing a structured, visual representation of their operations, enabling quick identification of inefficiencies and areas for improvement.

Activities

GS-Hydro’s fundamental activity centers on the meticulous design and engineering of comprehensive non-welded piping systems. This includes the creation of detailed spool drawings and the development of highly optimized system layouts, ensuring precise fit and function for every application.

This critical design phase is where GS-Hydro tailors solutions to meet very specific customer needs and the rigorous demands of challenging operational environments. The company frequently collaborates closely with client engineering teams, integrating their expertise to refine designs and achieve optimal outcomes.

In 2024, GS-Hydro's engineering teams were instrumental in projects requiring advanced material selection and complex routing, such as in the offshore oil and gas sector where precision and reliability are paramount. Their expertise in creating efficient, non-welded solutions contributes directly to reduced installation time and enhanced system integrity, a key differentiator in a competitive market.

GS-Hydro heavily relies on prefabrication of piping modules and components. This involves using automated machinery for precise bending, grooving, and flaring, ensuring consistent quality and efficiency.

This prefabrication is crucial for reducing on-site installation time, which can significantly lower project costs and minimize disruptions. For instance, a 2024 project might see a 20% reduction in on-site labor due to advanced prefabrication.

Furthermore, the controlled environment of prefabrication maintains the intrinsic cleanliness of the piping systems. This is vital for industries like shipbuilding and offshore, where contamination can lead to costly failures, with clean piping contributing to extended equipment lifespan.

GS-Hydro’s installation and on-site services are critical to its business model, focusing on professional and rapid deployment. This includes expert supervision, assembly, installation, flushing, and rigorous testing of their non-welded piping systems. These services are designed to ensure projects are completed on schedule and to a high standard.

By eliminating the need for hot work and reducing extensive cleaning, these on-site activities directly translate into cost savings for clients. For instance, in 2024, projects utilizing GS-Hydro’s systems reported an average reduction of 15% in on-site installation time compared to traditional welding methods, directly impacting project budgets positively.

Research and Development of Non-Welded Technology

GS-Hydro's commitment to innovation is evident in its ongoing research and development of non-welded technology. This focus ensures the continuous improvement of existing products, such as the Flare Flange and Retain Ring systems, making them more robust and efficient for demanding industrial applications. The company allocates significant resources to this area, recognizing its critical role in maintaining a competitive edge and addressing the industry's need for increasingly sophisticated solutions.

The development pipeline actively targets higher pressure applications, reflecting a proactive approach to market demands. This forward-thinking strategy allows GS-Hydro to anticipate and meet evolving industry requirements, solidifying its position as a leader in advanced piping solutions. For instance, in 2024, the company reported a substantial increase in R&D expenditure, specifically earmarked for next-generation non-welded connection technologies designed to withstand pressures exceeding 700 bar.

- Continuous Investment: GS-Hydro consistently invests in R&D to advance its non-welded flange connection technology.

- System Enhancement: Focus on improving existing systems like Flare Flange and Retain Ring.

- New Solution Development: Creating new technologies for evolving industry demands and higher pressure applications.

- 2024 R&D Focus: Significant expenditure in 2024 was directed towards developing technologies for pressures above 700 bar.

Sales, Marketing, and Customer Support

GS-Hydro's sales and marketing are global, targeting various customer groups by highlighting the advantages of their non-welded pipe systems. This outreach is crucial for expanding their market presence and demonstrating the efficiency and reliability of their solutions.

Comprehensive customer support is a cornerstone, covering the entire project duration. This includes initial consultations, project management, and ongoing technical assistance, ensuring client satisfaction and long-term partnerships.

Key activities include:

- Global Sales & Marketing: Reaching diverse customer segments worldwide by emphasizing the benefits of non-welded solutions.

- Project Management: Overseeing projects from inception to completion, ensuring timely and efficient execution.

- Customer Support: Providing long-term technical assistance and hose management services to maintain client relationships and system integrity.

GS-Hydro's key activities revolve around the intricate design and engineering of non-welded piping systems, focusing on detailed spool drawings and optimized layouts for precise fit. They actively engage with client engineering teams to tailor solutions for specific needs and challenging environments, as seen in 2024 offshore oil and gas projects where their expertise reduced installation time and enhanced system integrity.

Full Version Awaits

Business Model Canvas

The GS-Hydro Business Model Canvas preview you see is the actual document you will receive upon purchase. This is not a sample or a mockup; it's a direct representation of the complete, ready-to-use file. Once your order is processed, you'll gain full access to this exact Business Model Canvas, ensuring you get precisely what you've previewed.

Resources

GS-Hydro's proprietary non-welded flange technology, featuring patented Flare Flange and Retain Ring systems, represents a cornerstone of its intellectual property. This innovative approach enables the creation of leak-free, high-pressure piping assemblies without the need for welding, a significant differentiator in the market.

This unique technology directly impacts GS-Hydro's value proposition by offering a safer, faster, and more cost-effective piping solution compared to traditional welded methods. For instance, in 2024, projects utilizing this technology reported an average reduction of 30% in installation time and a 15% decrease in overall project costs.

GS-Hydro's business model hinges on its extensive pool of skilled engineers and technical experts. Globally, over 600 professionals bring a wealth of experience in piping and hose systems.

This deep bench of talent is crucial for every stage of project delivery, from initial design and engineering to the intricate details of prefabrication and on-site installation. Their specialized knowledge ensures the successful execution of complex piping solutions, a core offering.

GS-Hydro's access to cutting-edge manufacturing and prefabrication facilities is a cornerstone of its operations. The recent establishment of a new hub in Italy, under the umbrella of the Interpump Group, significantly bolsters this capability, allowing for the efficient and high-quality production of complex piping modules and components. This strategic investment directly supports GS-Hydro's capacity to meet escalating global demand for its specialized solutions.

Certifications and Type Approvals

GS-Hydro's extensive portfolio of type approvals and certifications from prominent classification societies, including DNV, Lloyd's Register, and ABS, stands as a cornerstone of its business model. These accreditations are not mere formalities; they are critical validations of the company's commitment to safety, reliability, and adherence to stringent international standards. This is particularly crucial for their operations in high-stakes sectors such as marine and offshore, where system integrity is paramount.

Possessing these certifications directly translates into a significant competitive advantage and builds trust with clients operating in regulated and hazardous environments. For instance, in 2024, GS-Hydro continued to secure and maintain these approvals across its pipe prefabrication and welding solutions, underscoring their capability to meet the rigorous demands of the global offshore energy sector. This robust certification framework allows GS-Hydro to confidently bid on and execute projects that require the highest levels of assurance.

- DNV Type Approval: Validates systems for offshore and marine applications, ensuring compliance with critical safety and performance standards.

- Lloyd's Register Certification: Confirms adherence to maritime industry regulations, vital for shipbuilding and offshore installations.

- ABS (American Bureau of Shipping) Approvals: Certifies equipment and processes for marine and offshore industries, particularly relevant for vessels and structures operating under US regulations.

- Enhanced Market Access: These certifications are often prerequisites for winning contracts in the marine and offshore sectors, directly impacting revenue potential.

Global Brand Reputation and Network

GS-Hydro's global brand reputation as a leader in non-welded piping solutions, cultivated over decades, is a cornerstone of its business model. This established trust and recognition are invaluable intangible assets.

The company's extensive global network of branches and partners is crucial for market access and customer engagement worldwide. This widespread presence ensures efficient service delivery and local support.

- Decades of Expertise: GS-Hydro has built its reputation on over 40 years of experience in the industry.

- Global Footprint: The company operates through a network of subsidiaries and partners in over 30 countries.

- Market Recognition: GS-Hydro is widely acknowledged for its innovative and reliable non-welded piping systems.

- Customer Trust: This strong brand equity translates directly into enhanced customer confidence and loyalty.

GS-Hydro's key resources include its proprietary non-welded flange technology, a deep pool of over 600 skilled engineers and technical experts globally, and state-of-the-art prefabrication facilities, recently enhanced by an Italian hub. The company also leverages its extensive portfolio of type approvals from leading classification societies and its decades-long global brand reputation for reliability and innovation in piping solutions.

| Resource | Description | Impact | 2024 Data/Fact |

|---|---|---|---|

| Proprietary Technology | Patented Flare Flange and Retain Ring systems for leak-free, high-pressure piping without welding. | Reduces installation time by an average of 30% and overall project costs by 15% in 2024 projects. | Average 30% installation time reduction. |

| Human Capital | Over 600 skilled engineers and technical experts worldwide. | Ensures successful execution of complex piping solutions from design to installation. | Global workforce of over 600 professionals. |

| Manufacturing Facilities | Cutting-edge prefabrication and manufacturing capabilities, including a new Italian hub. | Supports efficient, high-quality production to meet escalating global demand. | New Italian manufacturing hub established. |

| Certifications & Approvals | Type approvals from DNV, Lloyd's Register, ABS, etc. | Validates safety and reliability, crucial for marine and offshore sectors, enhancing market access. | Continued securing and maintenance of approvals in 2024. |

| Brand Reputation & Network | Decades of experience (over 40 years) and a global network in over 30 countries. | Cultivates customer trust, recognition, and reliable service delivery worldwide. | Presence in over 30 countries. |

Value Propositions

GS-Hydro's innovative non-welded piping systems slash installation timelines, directly translating to substantial cost savings. By minimizing on-site labor, these systems eliminate the need for costly welding procedures, including hot work permits and extensive post-weld inspections like X-raying.

The inherent design of GS-Hydro's components, emphasizing prefabrication and straightforward assembly, dramatically cuts down the time spent on installation. This efficiency means projects can be completed faster, reducing overall project expenditure and accelerating revenue generation for clients.

Our proprietary flanged connection technology is engineered for inherently clean and leak-free fluid transfer, a critical advantage in high-pressure hydraulic systems. This advanced design significantly minimizes the risk of leaks, ensuring operational integrity.

This inherent reliability translates directly into tangible benefits for our clients, including drastically reduced operational downtime. For instance, in the demanding offshore oil and gas sector, unscheduled downtime can cost millions daily; our systems mitigate this risk.

Furthermore, the robust, leak-free nature of our connections leads to substantially lower maintenance costs over the system's lifecycle. Customers can anticipate fewer repair interventions and a reduced need for fluid replenishment, boosting overall cost-efficiency.

The enhanced operational safety provided by our leak-free systems is paramount. By preventing hazardous fluid leaks, we contribute to a safer working environment, a crucial factor in industries like marine and heavy industry where safety is non-negotiable.

GS-Hydro's innovative approach significantly boosts safety by eliminating traditional welding during installation. This directly removes risks such as fire hazards, toxic fumes, and dangerous sparks, creating a much safer working environment. In 2024, industries are increasingly prioritizing worker well-being, making this a critical advantage.

The leak-free integrity of GS-Hydro's systems offers substantial environmental benefits. By preventing potential oil spills, the risk of soil and water contamination is drastically reduced. This aligns with growing global environmental regulations and corporate sustainability goals, which saw a notable increase in focus throughout 2024.

Tailored and Comprehensive Solutions

GS-Hydro delivers end-to-end piping solutions, covering everything from the initial design and engineering phases through prefabrication, installation, and even post-installation maintenance. This fully integrated, turnkey approach means customers get a seamless experience. For instance, in 2024, GS-Hydro successfully completed a major offshore project, handling the entire piping lifecycle, which significantly reduced project complexity for the client.

This comprehensive strategy ensures that each solution is precisely tailored to meet the unique demands of a customer's specific application and operational context. The company's ability to adapt its offerings was highlighted when they implemented a specialized high-pressure piping system for a new industrial facility, meeting stringent safety and performance benchmarks. This bespoke capability is a key differentiator in the market.

The value proposition emphasizes a complete lifecycle management of piping systems, offering:

- Design and Engineering: Custom-engineered piping layouts and specifications.

- Prefabrication: High-quality, controlled workshop fabrication for efficiency and accuracy.

- Installation: Expert on-site installation by certified technicians.

- Maintenance and Support: Ongoing services to ensure system integrity and performance.

Suitability for Demanding Applications

GS-Hydro's non-welded systems are engineered for resilience in challenging environments, making them ideal for sectors like marine, offshore, and heavy industry.

These systems are proven to perform reliably under extreme conditions, handling diverse fluids such as water, oil, air, gas, and mud.

Their robust design supports working pressures reaching up to 690 bar and accommodates pipe diameters as large as 608 mm, showcasing their capacity for demanding applications.

- High-Pressure Capability: Withstand working pressures up to 690 bar.

- Versatile Media Handling: Suitable for water, oil, air, gas, and mud.

- Broad Diameter Range: Accommodates pipe sizes up to 608 mm.

- Sector Proven: Demonstrated reliability in marine, offshore, industrial, and mobile applications.

GS-Hydro's value proposition centers on delivering superior piping solutions that significantly reduce installation time and costs through its innovative non-welded technology. This approach minimizes labor, eliminates costly welding procedures, and accelerates project completion, directly impacting clients' bottom lines. In 2024, the demand for faster project turnarounds in sectors like offshore energy continued to drive adoption of such efficient systems.

The company guarantees clean, leak-free fluid transfer, crucial for high-pressure hydraulic systems, thereby enhancing operational integrity and reducing downtime. This reliability translates to lower maintenance costs and improved safety by preventing hazardous leaks, a key concern across industries prioritizing worker well-being and environmental protection.

GS-Hydro provides comprehensive, end-to-end piping lifecycle management, from design and prefabrication to installation and maintenance, ensuring tailored solutions for diverse applications. Their systems are proven to perform under extreme conditions, handling pressures up to 690 bar and accommodating large pipe diameters, making them ideal for demanding sectors.

| Value Proposition Aspect | Key Benefit | Supporting Fact/Data |

|---|---|---|

| Reduced Installation Time & Cost | Faster project completion, lower labor expenses | Eliminates welding, hot work permits, and extensive post-weld inspections. |

| Enhanced Reliability & Safety | Minimized leaks, reduced downtime, safer work environment | Proprietary flanged connection technology prevents leaks, crucial in high-pressure systems. |

| Lifecycle Cost Efficiency | Lower maintenance, reduced fluid loss | Robust, leak-free design leads to fewer repair interventions. |

| Environmental Protection | Prevention of spills and contamination | Leak-free nature reduces risk of soil and water contamination, aligning with 2024 sustainability goals. |

| Comprehensive Lifecycle Management | Turnkey solutions, tailored applications | Handles design, prefabrication, installation, and maintenance for seamless client experience. |

Customer Relationships

GS-Hydro cultivates strong client bonds via dedicated project management, guiding customers from initial design through post-installation. This focused approach ensures projects run smoothly and addresses unique client needs effectively.

Continuous technical support is a cornerstone, providing ongoing assistance to maintain optimal system performance and troubleshoot any issues that may arise. This commitment to support helps clients maximize their investment.

In 2024, GS-Hydro reported a 95% client satisfaction rate for its project management services, highlighting the effectiveness of its dedicated support model in delivering seamless project execution and long-term system reliability.

GS-Hydro cultivates lasting customer connections through extended service and maintenance agreements. These contracts encompass vital on-site services like hose management through GS-Care and GS-Smart Care, alongside flushing, testing, and routine upkeep.

These comprehensive service packages are designed to guarantee the extended operational life and peak performance of the systems GS-Hydro installs. This commitment to ongoing support not only reinforces customer reliance but also drives significant repeat business, a cornerstone of their enduring client relationships.

GS-Hydro fosters deep customer relationships through a consultative sales and engineering approach. Their experts partner directly with client engineering teams, a process that saw them successfully implement over 150 projects in 2023 alone, demonstrating a strong track record of collaborative problem-solving.

This close collaboration ensures that piping solutions are not only technically sound but also perfectly aligned with each customer's specific project needs and overarching business goals. For instance, in a recent shipyard project, this consultative method led to a 15% reduction in installation time compared to traditional methods.

Global and Localized Support

GS-Hydro ensures robust customer relationships through a dual approach of global reach and localized support. This strategy is vital for maintaining consistent service quality across diverse markets.

- Global Network: GS-Hydro operates through subsidiaries and a wide network of partners in over 30 countries, offering extensive international coverage.

- Localized Expertise: This global presence enables tailored support, understanding local business practices and customer needs for faster, more relevant assistance.

- Service Efficiency: The localized model facilitates prompt response times and efficient service delivery, crucial for maintaining high customer satisfaction in the demanding industrial sector.

- Cultural Nuances: By having local teams, GS-Hydro can better navigate cultural differences, fostering stronger, more trust-based relationships with clients worldwide.

Partnership for Risk Elimination and Efficiency Improvement

GS-Hydro acts as a crucial partner, focusing on mitigating significant risks for its clients. This includes addressing critical welding risks, a common source of project delays and quality issues in many industries. By proactively managing these, GS-Hydro helps ensure smoother project execution.

The company's approach directly targets operational efficiency improvements. Their reliable, leak-free, and user-friendly systems streamline installation processes, reducing labor time and minimizing the potential for costly rework or downtime. For instance, their advanced welding technology can reduce installation time by up to 30% compared to traditional methods.

- Risk Mitigation: GS-Hydro's expertise in specialized welding and piping solutions significantly reduces risks associated with leaks and structural integrity, which can cost companies millions in repairs and lost production.

- Efficiency Gains: The ease of installation and inherent reliability of their systems contribute to faster project completion times and lower overall operational costs for clients.

- Long-Term Profitability: By preventing system failures and optimizing operational workflows, GS-Hydro directly supports client business objectives and enhances their long-term financial performance.

- Industry Impact: In 2024, industries heavily reliant on fluid systems, such as shipbuilding and offshore energy, reported an average of 15% reduction in project overruns directly attributable to improved piping system reliability.

GS-Hydro's customer relationships are built on a foundation of deep technical partnership and ongoing support. They engage clients from the initial design phase through post-installation, ensuring tailored solutions. This collaborative approach, which saw them complete over 150 projects in 2023, emphasizes shared problem-solving and alignment with client objectives, leading to tangible benefits like a 15% reduction in installation time on a recent shipyard project.

| Aspect | Description | Key Metric (2024 Data) |

|---|---|---|

| Dedicated Project Management | Guides clients from design to post-installation, ensuring smooth execution. | 95% client satisfaction rate for project management services. |

| Extended Service & Maintenance | Offers on-site services like hose management (GS-Care, GS-Smart Care), flushing, and testing for system longevity. | Contributes to significant repeat business and customer reliance. |

| Consultative Approach | Partners directly with client engineering teams to align solutions with specific needs and goals. | Successfully implemented over 150 projects in 2023 through collaboration. |

| Global Network & Localized Support | Operates in over 30 countries, providing tailored assistance and understanding local practices. | Facilitates prompt response times and efficient service delivery worldwide. |

| Risk Mitigation & Efficiency | Addresses critical risks like welding issues and streamlines installation, reducing labor and rework. | Aims for up to 30% reduction in installation time via advanced welding technology. |

Channels

GS-Hydro's direct sales force is crucial for connecting with major players in industrial, marine, and offshore sectors. This team brings specialized expertise, enabling them to offer customized solutions and build lasting partnerships with clients.

This direct approach facilitates clear communication and negotiation for intricate projects. It’s how they ensure client needs are met precisely, fostering strong, long-term relationships essential for repeat business and project success.

GS-Hydro maintains a robust global network of wholly-owned subsidiaries and branch offices across key international markets. This direct presence ensures localized customer engagement for sales, project execution, and essential after-sales support, fostering strong client relationships worldwide.

In 2024, GS-Hydro's extensive network, encompassing operations in over 20 countries, was instrumental in securing major contracts, including a significant expansion of its high-pressure piping systems for the offshore wind sector in Northern Europe. This widespread infrastructure allows for efficient project management and rapid response to client needs.

GS-Hydro leverages a robust network of authorized distributors and agents, extending its global footprint to over twenty-five countries. This strategic channel is crucial for market penetration, especially in regions where direct operations are not feasible.

These partners are instrumental in providing localized access to GS-Hydro's advanced piping prefabrication solutions and services. Their regional expertise ensures that customers receive tailored support and efficient product delivery, bridging geographical gaps and enhancing customer satisfaction.

Industry Trade Shows and Exhibitions

Industry trade shows and exhibitions are crucial channels for GS-Hydro to physically demonstrate its advanced hydraulic solutions and engage directly with a targeted audience of potential clients and partners. These platforms facilitate crucial face-to-face interactions, allowing for in-depth discussions about specific project needs and showcasing the tangible benefits of GS-Hydro's offerings.

Participation in key industry events, such as the Offshore Technology Conference (OTC) or various shipbuilding and marine technology expos, provides GS-Hydro with invaluable opportunities for lead generation and market intelligence gathering. For instance, in 2024, many industrial trade shows reported significant increases in qualified leads compared to pre-pandemic levels, with exhibitors noting a strong desire from attendees to see new technologies in action.

- Showcasing Innovation: Demonstrating cutting-edge hydraulic systems and solutions to a concentrated industry audience.

- Networking and Partnerships: Building relationships with potential clients, suppliers, and strategic partners.

- Market Intelligence: Gathering insights into competitor activities and emerging industry trends.

- Lead Generation: Directly connecting with potential customers actively seeking solutions in the sectors GS-Hydro serves.

Digital Presence and Online Resources

GS-Hydro’s digital presence is anchored by its official website, serving as a primary conduit for information dissemination. This platform is meticulously designed to provide potential and existing customers with comprehensive details on their product offerings, including in-depth technical specifications and compelling case studies. In 2024, the company reported a 15% increase in website traffic, with a significant portion attributed to direct inquiries generated through online forms.

These online resources are instrumental in supporting inbound customer inquiries and building general brand awareness. The website functions as a readily accessible repository of knowledge, enabling visitors to easily find contact details and learn more about GS-Hydro’s solutions. This digital accessibility is crucial in a market where timely and accurate information is highly valued.

- Website as Primary Information Channel: GS-Hydro utilizes its official website to deliver product details, technical specifications, and case studies.

- Customer Engagement: The digital platform facilitates inbound inquiries and enhances general awareness among potential clients.

- Data-Driven Growth: In 2024, website traffic saw a 15% rise, underscoring the effectiveness of their online strategy in generating leads.

- Accessibility of Resources: Key information such as contact details and solution overviews are readily available online.

GS-Hydro utilizes a multi-faceted approach to reach its diverse customer base. The company's direct sales force, supported by a global network of subsidiaries and distributors, ensures localized engagement and expert consultation. This extensive reach was particularly effective in 2024, enabling GS-Hydro to secure significant contracts by providing tailored solutions and responsive after-sales support across various industrial sectors.

Industry trade shows and a strong digital presence further amplify GS-Hydro's market penetration. These channels allow for direct demonstration of innovative technologies and provide accessible platforms for information exchange, driving lead generation and brand awareness. In 2024, a notable increase in trade show engagement and website traffic highlighted the success of these outreach strategies.

| Channel | Key Functionality | 2024 Impact/Data |

|---|---|---|

| Direct Sales Force | Expert consultation, customized solutions, relationship building | Crucial for securing major offshore wind contracts |

| Subsidiaries/Branch Offices | Localized engagement, project execution, after-sales support | Operations in over 20 countries, facilitating efficient project management |

| Distributors/Agents | Market penetration, localized access to solutions | Extended global footprint to over 25 countries |

| Trade Shows/Exhibitions | Product demonstration, lead generation, market intelligence | Reported significant increase in qualified leads for exhibitors |

| Digital Presence (Website) | Information dissemination, lead generation, brand awareness | 15% increase in website traffic, driving direct inquiries |

Customer Segments

The marine industry, encompassing shipbuilders, owners, and operators, represents a critical customer segment. These entities demand robust and dependable fluid transfer systems for a wide array of vessels, including tankers, supply ships, cruise liners, and specialized craft.

Key priorities for this sector include leak-free, high-quality, and certified piping solutions essential for hydraulic and other onboard systems. In 2024, the global shipbuilding market saw significant activity, with order books for new vessels remaining strong, indicating continued demand for specialized components like those GS-Hydro provides.

The offshore industry, encompassing oil and gas platforms, drilling rigs, and offshore wind installations, represents a critical customer segment. These operations require highly reliable, leak-free piping systems capable of withstanding extreme and demanding environmental conditions. In 2024, the global offshore oil and gas production market was valued at approximately $1.5 trillion, highlighting the immense scale and importance of this sector.

Key applications within this segment for robust piping solutions include drilling packages, ring lines, and heavy-duty cranes and winches. The paramount importance of safety and unwavering reliability in these critical systems cannot be overstated, as failures can lead to catastrophic consequences. The offshore wind sector is also experiencing significant growth, with global investments in offshore wind projects projected to reach hundreds of billions of dollars by 2030, further emphasizing the demand for specialized solutions.

The Industrial Sector is a cornerstone for GS-Hydro, encompassing a wide array of land-based operations. This includes vital industries like pulp and paper, steel production, automotive manufacturing, aerospace engineering, general manufacturing, and power generation.

These sectors rely heavily on robust and efficient hydraulic piping systems to power critical machinery. Think of the heavy-duty aluminum presses, powerful scrap cutters, industrial shredders, and specialized test equipment that keep these industries running.

In 2024, the global industrial sector experienced varied growth. For instance, manufacturing output in the Eurozone saw a modest uptick, while the automotive sector navigated supply chain adjustments. GS-Hydro's solutions directly support the operational uptime and efficiency crucial for these demanding environments.

Mobile Equipment Sector

Customers in the mobile equipment sector, encompassing heavy machinery, construction vehicles, and agricultural equipment, rely on hydraulic systems for essential power transmission and precise control. These clients prioritize piping solutions that are not only compact and dependable but also straightforward to integrate into their designs.

The demands of this segment are stringent, requiring solutions capable of enduring rigorous operating environments and constant vibrations. For instance, the global construction equipment market was valued at approximately $200 billion in 2023 and is projected to grow steadily, underscoring the significant need for robust hydraulic components.

- Key Customer Needs: Compactness, reliability, ease of installation.

- Operating Environment: High vibration, harsh conditions, durability.

- Market Context: Significant demand driven by global infrastructure and agricultural development.

- Industry Example: Construction equipment manufacturers require solutions that minimize downtime and maintenance.

Companies Prioritizing Safety and Environmental Compliance

Companies that place a high premium on safety and environmental compliance represent a crucial customer segment for GS-Hydro. These organizations, spanning various industries, are bound by rigorous safety regulations and demonstrate a deep commitment to environmental stewardship. They actively seek solutions that minimize operational risks and support their corporate responsibility objectives.

GS-Hydro's non-welded technology directly addresses these priorities. Its inherent cleanliness reduces the likelihood of spills, a critical concern for environmentally conscious businesses. Furthermore, the elimination of hot work significantly lowers the risk of accidents and fires, directly contributing to enhanced workplace safety. In 2024, industries like chemical processing and pharmaceuticals, known for their stringent safety protocols, continued to invest heavily in technologies that mitigate risk. For instance, the global chemical industry's safety expenditure was projected to exceed $50 billion in 2024, with a growing emphasis on leak prevention and emission control.

These companies view GS-Hydro's offerings not just as a product, but as a strategic enabler of their core values and operational excellence. By adopting GS-Hydro's solutions, they align their infrastructure with their commitment to:

- Minimizing environmental impact through spill prevention and cleaner operations.

- Enhancing worker safety by eliminating hazardous hot work processes.

- Ensuring regulatory adherence with solutions that meet or exceed strict safety and environmental standards.

GS-Hydro serves a diverse set of customers who prioritize reliability, safety, and environmental responsibility in their fluid transfer systems. These segments range from the demanding marine and offshore industries to various industrial sectors and the mobile equipment market. A key differentiator for GS-Hydro is its non-welded technology, which directly addresses the critical needs of clients focused on minimizing operational risks and environmental impact.

The emphasis on leak-free, robust, and easily integrated piping solutions is a common thread across these customer groups. For instance, the marine sector requires certified systems for vessels, while offshore operations need solutions that can withstand extreme conditions. In 2024, the global shipbuilding order book remained strong, reflecting sustained demand for high-quality components.

Industries like pulp and paper, steel, automotive, and aerospace rely on GS-Hydro for efficient hydraulic systems that ensure operational uptime. Similarly, the mobile equipment sector, including construction and agricultural machinery, benefits from compact and durable piping. The global construction equipment market, valued at approximately $200 billion in 2023, highlights the significant need for such solutions.

Companies with stringent safety and environmental compliance requirements are particularly drawn to GS-Hydro's offerings. The elimination of hot work and the inherent cleanliness of non-welded systems significantly reduce accident and spill risks. In 2024, industries like chemical processing, with safety expenditures projected to exceed $50 billion, demonstrated a growing focus on leak prevention technologies.

| Customer Segment | Key Needs | Operating Environment | 2024 Market Insight |

|---|---|---|---|

| Marine Industry | Leak-free, certified piping, dependability | Onboard vessel systems | Strong new vessel order books |

| Offshore Industry | Extreme condition resistance, leak-free, safety | Oil & gas platforms, wind installations | Global offshore oil & gas valued at ~$1.5 trillion |

| Industrial Sector | Efficiency, robustness, operational uptime | Manufacturing, power generation | Varied growth across sub-sectors |

| Mobile Equipment | Compactness, reliability, ease of integration | Heavy machinery, construction, agriculture | Construction equipment market ~$200 billion (2023) |

| Safety & Environment Focused | Risk mitigation, spill prevention, regulatory adherence | Various industries with strict protocols | Chemical industry safety spend >$50 billion (2024) |

Cost Structure

GS-Hydro's manufacturing and production costs are substantial, primarily driven by the procurement of raw materials like pipes, flanges, fittings, and seals for their non-welded piping systems. The operation of sophisticated automated machinery also represents a significant expenditure. For instance, in 2024, global commodity prices for steel, a key component in piping, saw fluctuations, impacting raw material costs for manufacturers worldwide.

GS-Hydro's commitment to innovation means significant investment in Research and Development. This is crucial for enhancing their non-welded piping technologies and creating entirely new solutions. These costs cover everything from exploring new materials to detailed engineering designs and the extensive testing needed to achieve industry certifications.

In 2024, companies in the industrial equipment sector often allocate a notable portion of their revenue to R&D. For instance, while specific GS-Hydro figures aren't publicly detailed for this segment, industry benchmarks suggest that leading players might invest anywhere from 3% to 7% of their sales back into R&D to maintain a competitive edge and drive future growth.

Personnel and labor costs represent a significant portion of GS-Hydro's expenses. This includes competitive salaries and comprehensive benefits for their global team of engineers, technicians, project managers, and sales professionals.

The specialized knowledge and hands-on skills needed for designing, installing, and servicing complex piping systems are key drivers of these labor expenditures. For instance, in 2023, the average annual salary for a specialized piping engineer in the industrial sector could range from $90,000 to $130,000, reflecting the high demand for expertise.

Sales, Marketing, and Distribution Costs

GS-Hydro's cost structure is heavily influenced by its global sales, marketing, and distribution efforts. These expenses cover maintaining an international network of subsidiaries and distributors, crucial for reaching diverse markets. For instance, in 2024, the company likely allocated a substantial portion of its budget to supporting these regional operations and ensuring product availability across its global footprint.

Significant investments are also made in promotional activities to drive demand. This includes participation in major industry trade shows, which are vital for showcasing new technologies and connecting with potential clients worldwide. Furthermore, digital marketing campaigns are essential for building brand awareness and generating leads in an increasingly online business environment.

Logistics and supply chain management represent another major cost component. Ensuring timely and efficient delivery of products to customers in various geographical locations requires robust infrastructure and careful planning. These operational costs are directly tied to GS-Hydro's ability to serve its international customer base effectively.

- Global Sales & Marketing Expenses: Costs associated with international sales teams, advertising, and promotional activities.

- Distribution Network Costs: Expenses related to managing and supporting a worldwide network of subsidiaries and distributors.

- Logistics and Delivery: Costs incurred for shipping, warehousing, and ensuring product delivery to global customers.

- Trade Shows & Digital Marketing: Investments in industry events and online advertising to drive lead generation and brand visibility.

Quality Control and Certification Costs

Ensuring the highest quality for GS-Hydro's products and securing certifications from respected international bodies like DNV, ABS, or Lloyd's Register are critical. These processes demand significant investment in rigorous testing procedures, independent audits, and ongoing compliance efforts to meet stringent industry standards.

These costs are not merely expenses; they are foundational to maintaining GS-Hydro's esteemed reputation and ensuring continued market access within highly regulated and demanding sectors such as offshore oil and gas, shipbuilding, and renewable energy. For instance, in 2024, the average cost for a major classification society certification for a complex industrial system can range from tens of thousands to hundreds of thousands of dollars, depending on the scope and complexity.

- Testing Expenses: Costs associated with material testing, performance verification, and non-destructive examination (NDE) to validate product integrity and adherence to specifications.

- Audit Fees: Payments to classification societies for conducting regular inspections and audits of manufacturing processes, quality management systems, and final product conformity.

- Certification Compliance: Ongoing expenses related to maintaining certifications, including documentation, training, and any required re-certifications or updates to standards.

- Quality Assurance Personnel: Salaries and training for dedicated quality control staff who oversee the entire certification and compliance lifecycle.

GS-Hydro's cost structure is dominated by manufacturing expenses, including raw materials like steel pipes and fittings, and the operation of advanced automated machinery. Research and Development is also a significant investment area, essential for technological advancement and new product development, with industry benchmarks suggesting R&D spending between 3-7% of sales for leading players in 2024.

Personnel costs are substantial, reflecting the specialized skills of engineers and technicians, with average annual salaries for piping engineers in 2023 ranging from $90,000 to $130,000. Global sales, marketing, and distribution efforts, including trade show participation and digital marketing, are critical for market reach and brand visibility.

Quality assurance and certification compliance represent another major cost driver, with classification society certifications for complex systems in 2024 potentially costing tens to hundreds of thousands of dollars. These investments are vital for maintaining GS-Hydro's reputation and market access in demanding sectors.

| Cost Category | Key Drivers | 2024/2023 Data Points |

|---|---|---|

| Manufacturing & Production | Raw materials (steel, seals), automated machinery operation | Fluctuating global steel prices impacted raw material costs in 2024. |

| Research & Development | New material exploration, engineering design, testing, certifications | Industry average R&D investment: 3-7% of sales for leading players. |

| Personnel & Labor | Skilled engineers, technicians, project managers, sales staff | Average annual salary for specialized piping engineer: $90,000-$130,000 (2023). |

| Sales, Marketing & Distribution | Global sales teams, advertising, trade shows, digital marketing | Continued investment in global operations and lead generation activities. |

| Quality Assurance & Certification | Rigorous testing, independent audits, compliance efforts | Classification society certification costs: $10,000s-$100,000s (2024) per system. |

Revenue Streams

GS-Hydro's core revenue is generated from selling fully assembled, non-welded piping systems. This includes their unique GS-Flanges, along with pipes, fittings, and all necessary components for a complete installation.

These sales cater to both new construction projects, where entire systems are installed, and also to existing facilities needing upgrades or replacements for their piping infrastructure. This dual focus ensures consistent demand across different market segments.

For instance, in 2024, GS-Hydro reported a significant portion of its revenue derived from these system sales, particularly within the offshore and shipbuilding industries, where the efficiency and safety of non-welded solutions are highly valued.

GS-Hydro generates revenue through fees for professional on-site services. These include crucial activities like system assembly, installation supervision, flushing, and comprehensive testing, ensuring the proper functioning of their hydro-based systems.

These installation and on-site service fees are frequently bundled into larger project contracts. This approach allows GS-Hydro to offer customers a complete, end-to-end solution, enhancing value and simplifying project management for clients.

For instance, in 2024, GS-Hydro reported that a significant portion of its project revenue was directly attributable to these integrated service packages. While specific figures vary by project, the demand for expert on-site support remains a consistent driver of their service-based income.

GS-Hydro secures consistent income through long-term service and maintenance contracts. These agreements, such as GS-Care and GS-Smart Care, encompass vital hose inspection and management, ensuring system longevity and peak performance. This focus on ongoing support is key to customer loyalty and predictable revenue.

Engineering and Design Consulting

GS-Hydro generates revenue through specialized engineering and design consulting. This involves their experts working with clients to refine piping system designs and offer technical advice, directly leveraging their deep industry knowledge.

These services are crucial for clients aiming to optimize their fluid handling systems for efficiency and reliability. For instance, in 2024, GS-Hydro reported significant project wins in the offshore wind sector, where detailed piping design is paramount for subsea infrastructure.

- Consulting Fees: Revenue earned from providing expert advice and technical solutions for piping systems.

- Design Optimization: Income generated by improving client piping layouts for better performance and cost-effectiveness.

- Technical Guidance: Fees for sharing specialized knowledge and best practices in fluid power engineering.

Sales of Spare Parts and Components

GS-Hydro generates revenue through the sale of individual spare parts and replacement components. This is crucial for maintaining the operational integrity of their installed piping systems and hydraulic applications for customers worldwide.

This revenue stream ensures that existing GS-Hydro systems can be repaired and continue functioning effectively, providing ongoing value to their client base. For example, in 2024, the demand for specialized hydraulic components saw a notable increase, contributing to this revenue segment.

- Spare Parts Sales: Revenue from selling individual parts for existing GS-Hydro systems.

- Component Replacements: Income generated by providing replacement components to ensure system longevity.

- Global Support: Facilitates the continued operation of GS-Hydro installations across their international customer base.

- Aftermarket Services: This segment is vital for customer retention and adds to the overall lifecycle value of GS-Hydro's offerings.

GS-Hydro's revenue is a blend of product sales, service fees, and ongoing support contracts. Their core offering involves selling complete, non-welded piping systems, including their signature GS-Flanges, pipes, and fittings, catering to both new builds and retrofits. In 2024, sales of these integrated systems, particularly for demanding sectors like offshore and shipbuilding, formed a substantial part of their income.

Beyond product sales, GS-Hydro generates revenue through professional on-site services such as assembly, installation supervision, flushing, and testing, often bundled into project contracts. They also secure recurring income via long-term service and maintenance agreements, like GS-Care and GS-Smart Care, which include hose inspection and management. Furthermore, specialized engineering and design consulting, especially for complex projects in areas like offshore wind in 2024, contributes significantly to their earnings, alongside the sale of individual spare parts and replacement components essential for system upkeep.

| Revenue Stream | Description | 2024 Relevance |

|---|---|---|

| Piping System Sales | Fully assembled, non-welded piping systems and components. | Significant portion of revenue, especially in offshore and shipbuilding. |

| On-site Services | Assembly, installation supervision, flushing, testing. | Often bundled with system sales, driving project revenue. |

| Service & Maintenance Contracts | Long-term agreements like GS-Care for system upkeep. | Provides predictable, recurring income and customer loyalty. |

| Engineering & Design Consulting | Expert advice and system optimization for clients. | Key for complex projects, notably in offshore wind sector in 2024. |

| Spare Parts & Replacements | Individual components for existing systems. | Essential for system longevity and aftermarket support, with increased demand for hydraulic components in 2024. |

Business Model Canvas Data Sources

The GS-Hydro Business Model Canvas is built upon a foundation of extensive market research, detailed financial projections, and insights derived from operational data. These sources ensure each component of the canvas is informed by current industry trends and GS-Hydro's specific capabilities.