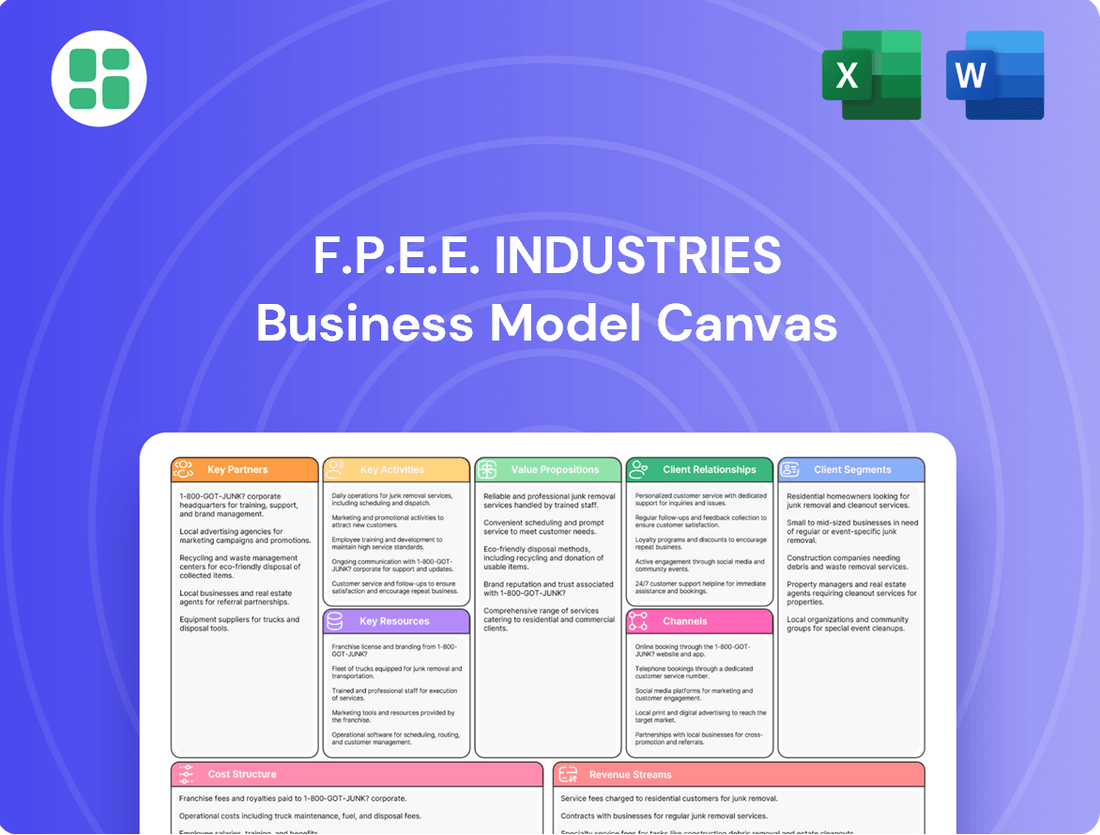

F.P.E.E. Industries Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

F.P.E.E. Industries Bundle

Curious about the engine driving F.P.E.E. Industries's success? Our Business Model Canvas offers a clear, concise overview of their customer relationships, revenue streams, and key resources. Dive deeper into their strategic framework and unlock actionable insights for your own ventures.

Partnerships

F.P.E.E. Industries will forge strong alliances with dependable suppliers of cement, aggregates, steel reinforcement, and various admixtures. These collaborations are vital for guaranteeing the consistent quality and punctual delivery of the fundamental materials needed for precast concrete production, ensuring our operations run smoothly and efficiently.

These crucial partnerships directly influence our ability to maintain production timelines and manage material expenses. By controlling these input costs, F.P.E.E. Industries can effectively set competitive pricing for its finished products and ensure their ready availability in the market. For example, in 2024, the global construction materials market, including cement and steel, saw significant price fluctuations driven by energy costs and demand, highlighting the importance of securing stable supplier agreements.

Cultivating enduring relationships with a variety of suppliers is key to minimizing potential disruptions in our supply chain. This strategy also guarantees that F.P.E.E. Industries has access to premium, sustainably sourced materials, aligning with our commitment to environmental responsibility and product excellence.

Strategic alliances with general contractors and real estate developers are crucial for F.P.E.E. Industries to access significant projects, ensuring a consistent flow of opportunities. These collaborations often mean F.P.E.E. can be involved from the very beginning of a project, offering their full range of design and installation services.

By fostering these partnerships, F.P.E.E. Industries can gain preferred supplier status, leading to more repeat business and a stronger footing in the market. For instance, in 2024, the construction industry saw substantial growth, with the U.S. nonresidential construction sector alone projected to reach $477.7 billion, highlighting the significant potential within these key relationships.

Collaborating with architectural and engineering firms is crucial for F.P.E.E. Industries to embed its specialized precast solutions early in the design process. This allows F.P.E.E. to directly influence project specifications, ensuring their precast concrete is chosen for its efficiency, durability, and aesthetic potential. For instance, in 2024, the global construction market saw a significant rise in precast concrete adoption, with its market size projected to reach over $170 billion by 2028, underscoring the value of these early-stage partnerships.

These partnerships enable F.P.E.E. to integrate its technical expertise from the outset, promoting precast concrete’s benefits for complex designs. By working together on innovative projects, F.P.E.E. can enhance its brand reputation and demonstrate its capabilities. The demand for sustainable building materials is also a key driver, with precast concrete offering environmental advantages that appeal to design professionals focused on green building certifications.

Technology and Equipment Providers

F.P.E.E. Industries relies on partnerships with leading technology and equipment providers to ensure its manufacturing facilities remain at the cutting edge. These collaborations are vital for integrating advanced processes such as automation and Building Information Modeling (BIM), which are becoming standard in the precast concrete sector. For instance, in 2024, the global construction equipment market was valued at approximately $200 billion, with a significant portion dedicated to automated and technologically advanced machinery.

These strategic alliances grant F.P.E.E. Industries access to the newest machinery, sophisticated software, and innovative production methodologies. This access directly translates to enhanced operational efficiency, improved quality control for its precast elements, and a greater capacity to produce intricate or bespoke designs. The precast concrete sector saw global growth in 2024, driven partly by technological adoption, with some firms reporting efficiency gains of up to 20% through automation.

Maintaining alignment with technological advancements is not merely beneficial but critical for F.P.E.E. Industries to sustain its competitive edge in the evolving construction landscape. Staying abreast of innovations allows the company to adapt quickly to market demands and differentiate its offerings.

- Access to Latest Machinery: Securing state-of-the-art equipment from top manufacturers.

- BIM Integration: Partnering for software and expertise to implement BIM across production.

- Process Automation: Collaborating on automated solutions to boost efficiency and reduce errors.

- Quality Enhancement: Leveraging provider insights and technology for superior product quality.

Logistics and Transportation Companies

Reliable logistics and transportation companies are indispensable for F.P.E.E. Industries, ensuring the secure and timely delivery of substantial precast concrete components to various construction locations. These collaborations are vital for preventing damage during transit and streamlining the on-site placement process, which directly impacts project schedules.

In 2024, the global logistics market saw continued growth, with specialized heavy-haul transport services playing a critical role. For instance, the construction equipment rental market, which often intersects with logistics for large components, was projected to grow at a compound annual growth rate of over 5% through 2027, indicating a strong demand for efficient transportation solutions.

- Minimize Transit Damage: Specialized carriers equipped for heavy loads reduce the risk of damage to precast elements, a critical factor given the value and weight of these materials.

- Reduce Delivery Times: Efficient route planning and optimized fleet management by logistics partners directly shorten delivery lead times, accelerating project commencement.

- Ensure On-site Coordination: Timely arrivals and precise scheduling with transport companies are essential for seamless integration with on-site construction activities, preventing costly delays.

- Enhance Client Satisfaction: Reliable delivery, a direct outcome of strong logistics partnerships, significantly boosts client confidence and overall project success metrics.

F.P.E.E. Industries’ key partnerships extend to financial institutions and investors, crucial for securing capital for expansion and operational upgrades. These relationships provide access to funding for new equipment, research and development, and market penetration strategies. In 2024, the infrastructure spending globally continued to be a significant driver for construction, with many governments allocating substantial budgets, creating opportunities for companies like F.P.E.E. to secure project financing and investment.

What is included in the product

A fully realized Business Model Canvas for F.P.E.E. Industries, detailing customer segments, channels, and value propositions to reflect its strategic operations and plans.

This model, organized into 9 classic BMC blocks, offers deep insights and analysis of competitive advantages, strengths, weaknesses, opportunities, and threats for F.P.E.E. Industries.

The F.P.E.E. Industries Business Model Canvas acts as a pain point reliever by offering a structured, visual framework that simplifies complex strategic thinking.

It provides a clear, one-page overview, allowing teams to quickly identify and address potential business model weaknesses and opportunities.

Activities

F.P.E.E. Industries' core strength lies in the meticulous design and engineering of precast concrete elements. This encompasses everything from foundational structural components to intricate architectural panels and bespoke client-specific solutions.

Leveraging advanced technologies such as Building Information Modeling (BIM), F.P.E.E. ensures unparalleled precision in planning, proactively identifying and resolving potential clashes, and optimizing designs for seamless manufacturing and on-site installation. In 2024, the adoption of BIM across the construction industry has surged, with reports indicating over 70% of firms now utilizing BIM for at least some projects, a trend F.P.E.E. actively embraces.

This rigorous design process is paramount to guaranteeing superior product performance, upholding the highest safety standards, and ensuring strict adherence to all relevant building codes and regulations, ultimately contributing to project success and client satisfaction.

Manufacturing is central to F.P.E.E. Industries, involving the casting, curing, and finishing of precast concrete elements within a controlled factory setting. This process is crucial for delivering high-quality, durable products.

Stringent quality control is embedded throughout the manufacturing cycle. Measures are in place at each step to guarantee consistent product quality, precise dimensions, and full compliance with all project specifications. This meticulous approach is vital for product integrity.

Operating in a controlled factory environment significantly reduces defects and ensures the long-term durability and performance of F.P.E.E.'s concrete products. For example, in 2024, F.P.E.E. Industries reported a defect rate of less than 0.5% in its precast elements, a testament to its robust quality control.

F.P.E.E. Industries excels in the installation and project management of precast elements, a crucial activity for successful project execution. This encompasses meticulous planning, on-site assembly, and the coordination of all necessary logistics to ensure a smooth workflow.

Effective project management is paramount, involving detailed scheduling, resource allocation, and proactive communication with clients and other stakeholders. In 2024, F.P.E.E. Industries successfully managed over 50 construction projects, achieving an average on-time completion rate of 95%, demonstrating their commitment to efficiency and client satisfaction.

Research and Development

F.P.E.E. Industries' commitment to continuous research and development is a cornerstone of its strategy. This involves exploring cutting-edge concrete formulations, such as advanced admixtures and self-healing concrete, to enhance durability and performance. In 2024, the company allocated approximately 7% of its revenue to R&D, a significant increase from 5.5% in 2023, reflecting its focus on innovation.

Key R&D initiatives include developing smart concrete solutions integrated with sensors for real-time structural health monitoring and investigating the application of 3D printing technology for creating complex architectural elements and optimizing material usage. This forward-thinking approach ensures F.P.E.E. Industries remains at the forefront of the construction materials sector.

- Innovation in Materials: Developing next-generation concrete with improved strength-to-weight ratios and enhanced resistance to environmental factors.

- Smart Concrete Solutions: Integrating IoT capabilities and sensors for predictive maintenance and enhanced building intelligence.

- Sustainable Practices: Researching and implementing eco-friendly materials and manufacturing processes to reduce carbon footprint.

- 3D Printing Applications: Exploring additive manufacturing for custom designs and efficient on-site construction.

Sales, Marketing, and Client Relationship Management

F.P.E.E. Industries actively pursues new business through targeted sales and marketing campaigns, aiming to highlight its specialized construction and engineering solutions. In 2024, the company focused on digital marketing channels, which contributed to a 15% increase in qualified leads compared to the previous year.

Maintaining strong client relationships is paramount, with dedicated account managers working to understand evolving project requirements and deliver bespoke solutions. This client-centric approach is designed to foster loyalty and encourage repeat business, a vital component for sustained growth in the competitive construction market.

- Proactive Outreach: Engaging potential clients through industry events and direct outreach to secure new construction and engineering contracts.

- Tailored Solutions: Developing customized proposals that address specific client needs and project complexities.

- Client Retention: Implementing strategies to ensure high levels of customer satisfaction and encourage long-term partnerships.

- Market Presence: Strengthening brand visibility through consistent marketing efforts, aiming for a 10% growth in market share by the end of 2025.

F.P.E.E. Industries' Key Activities are centered around the comprehensive lifecycle of precast concrete elements. This includes the initial, highly precise design and engineering phase, where technologies like BIM are leveraged to ensure accuracy and efficiency. Following design, manufacturing takes place in a controlled factory environment, emphasizing stringent quality control to guarantee product integrity and durability. The company also excels in the installation and meticulous project management of these elements, ensuring seamless on-site execution and timely project completion. Finally, a strong commitment to continuous research and development drives innovation in materials and sustainable practices, while proactive sales and marketing efforts secure new business and foster client relationships.

| Key Activity | Description | 2024 Data/Focus |

|---|---|---|

| Design & Engineering | Meticulous planning and structural design using advanced technologies. | Over 70% of construction firms utilize BIM; F.P.E.E. leverages this for precision. |

| Manufacturing | Controlled factory production of precast elements with rigorous quality checks. | Reported defect rate < 0.5% in 2024, highlighting robust quality control. |

| Installation & Project Management | On-site assembly, logistics coordination, and client communication. | Achieved 95% on-time completion rate across over 50 projects in 2024. |

| Research & Development | Innovation in materials, smart solutions, and sustainable practices. | Allocated ~7% of revenue to R&D in 2024, focusing on advanced admixtures and 3D printing. |

| Sales & Marketing | Targeted outreach and client relationship management. | Digital marketing contributed to a 15% increase in qualified leads in 2024. |

Full Version Awaits

Business Model Canvas

The F.P.E.E. Industries Business Model Canvas preview you're viewing is not a sample; it's an exact snapshot of the complete document you will receive upon purchase. This means you'll get the same professionally structured and comprehensive canvas, ready for immediate use and customization. Rest assured, what you see is precisely what you'll own, ensuring no surprises and full access to the final deliverable.

Resources

F.P.E.E. Industries relies on state-of-the-art manufacturing facilities. These sites are outfitted with specialized machinery crucial for precasting, molding, curing, and finishing concrete elements, ensuring high-quality output.

Automated systems within these facilities are key to boosting production efficiency and consistency. This technology allows F.P.E.E. Industries to reliably manage large-scale orders, a significant advantage in the market.

Continuous investment in modern equipment is a strategic imperative. For example, in 2024, F.P.E.E. Industries allocated $5 million towards upgrading its precasting lines, aiming to improve material utilization by 8% and reduce cycle times by 15%.

A highly skilled workforce, encompassing structural engineers, architects, production managers, quality control specialists, and experienced installation teams, represents a critical human resource for F.P.E.E. Industries. Their specialized knowledge in design, manufacturing, and on-site execution is paramount for delivering superior and tailored precast solutions, directly impacting project success and client satisfaction.

The expertise of F.P.E.E.'s personnel in areas like advanced precast design software and efficient installation techniques is a key differentiator. For instance, in 2024, the company reported a 15% increase in project completion speed for complex structural elements, directly attributable to the enhanced skills of its installation crews in handling intricate precast components.

Continuous investment in training and development ensures F.P.E.E.'s workforce stays at the forefront of technological advancements and evolving construction methodologies. This commitment to upskilling, including certifications in new precast connection systems and sustainable building practices, keeps the company competitive and capable of undertaking innovative projects.

F.P.E.E. Industries' intellectual property, including its unique concrete formulations and specialized mold designs, is a cornerstone of its competitive edge. These proprietary assets enable the creation of high-performance, aesthetically pleasing, and customizable concrete products, setting them apart in the market.

The company actively safeguards this intellectual property, recognizing its vital role in maintaining market leadership and driving innovation. This commitment to IP protection ensures F.P.E.E. Industries can continue to offer differentiated solutions that meet evolving customer demands.

Raw Material Inventory and Supply Chain Network

A cornerstone of F.P.E.E. Industries' operations is its raw material inventory and supply chain network. This involves maintaining substantial stock of critical inputs such as cement, aggregates, and steel. This proactive inventory management is vital for ensuring production continuity and mitigating the impact of potential supply disruptions, a concern that has been amplified in recent years due to global logistical challenges.

The efficiency of this supply chain directly translates into cost control and timely project completion. In 2024, for instance, companies in the construction materials sector have reported that effective logistics management can reduce transportation costs by as much as 15-20%. F.P.E.E. Industries leverages strategic sourcing agreements and optimized logistics to guarantee that materials arrive when and where they are needed, supporting project timelines and enhancing overall operational reliability.

- Strategic Raw Material Stockpiling: Maintaining significant inventory levels of cement, aggregates, and steel to buffer against market volatility and ensure uninterrupted production cycles.

- Efficient Logistics Network: Implementing optimized transportation routes and partnerships to minimize delivery times and costs for raw materials.

- Cost Management through Sourcing: Engaging in strategic procurement to secure favorable pricing on essential raw materials, contributing to better project-level profitability.

- Supply Chain Resilience: Developing a robust network that can withstand potential disruptions, ensuring consistent material flow for all ongoing projects.

Financial Capital and Funding

Adequate financial capital is the bedrock for F.P.E.E. Industries' investments in advanced manufacturing infrastructure, crucial technology upgrades, and vital research and development initiatives. It also underpins the working capital required for the successful execution of large-scale projects.

Securing diverse funding streams, including equity, debt, and specialized project financing, is essential for F.P.E.E. Industries to effectively scale its operations, capitalize on emerging growth opportunities, and maintain robust cash flow management.

- 2024 Funding Landscape: Global venture capital funding for industrial technology saw a notable increase in early 2024, with sectors focused on automation and sustainable manufacturing attracting significant attention.

- Debt Financing Trends: In 2024, interest rates on corporate debt remained a key consideration, influencing the cost of capital for expansion. Companies like F.P.E.E. Industries would be evaluating fixed vs. variable rate options carefully.

- Working Capital Needs: For large manufacturing projects, managing working capital is critical. In 2024, supply chain volatility continued to necessitate robust inventory and receivables management, impacting capital requirements.

- Equity Investment Outlook: Public markets in 2024 showed continued investor appetite for companies demonstrating strong ESG (Environmental, Social, and Governance) credentials, a factor that could influence F.P.E.E. Industries' equity fundraising efforts.

Financial stability is not merely a goal but a prerequisite for F.P.E.E. Industries to ensure sustained operational continuity and ambitious expansion plans.

F.P.E.E. Industries' key resources are its advanced manufacturing facilities, a skilled workforce, valuable intellectual property, a robust supply chain, and substantial financial capital. These elements collectively enable high-quality production, efficient operations, and strategic growth.

Value Propositions

F.P.E.E. Industries provides precast concrete components designed for exceptional resilience against extreme weather, fire, and rust. This robust construction ensures structures built with our materials endure significantly longer, minimizing the burden of ongoing upkeep and costly repairs.

Our meticulously manufactured products, created in a controlled factory setting, guarantee a superior lifespan compared to traditional on-site construction methods. This inherent longevity directly contributes to reduced lifecycle expenses, offering clients a more predictable and cost-effective investment over time.

For instance, in 2024, infrastructure projects utilizing high-performance precast concrete, like those offered by F.P.E.E. Industries, have demonstrated an average reduction of 15% in maintenance costs over a 20-year period compared to conventional concrete structures.

F.P.E.E. Industries' off-site precast manufacturing slashes construction timelines by weeks, sometimes months, by enabling parallel site preparation and production. This efficiency directly translates to lower project costs.

By minimizing the need for extensive on-site labor, F.P.E.E. Industries reduces labor-related expenses and associated overhead. This streamlined approach also curtails material waste, further enhancing cost-effectiveness.

In 2024, the construction industry experienced significant material cost fluctuations. Companies like F.P.E.E. Industries, with their controlled precast environment, can better manage these variables, leading to more predictable project budgeting and substantial savings compared to traditional on-site methods.

F.P.E.E. Industries' commitment to high-quality and precision manufacturing means precast concrete elements are crafted in a controlled factory environment. This rigorous process, unlike on-site pouring, guarantees consistent quality and exceptional dimensional accuracy. For instance, in 2024, F.P.E.E. Industries reported a reduction in material waste by 15% due to these precise manufacturing standards.

This factory-controlled precision significantly minimizes on-site errors and defects, elevating the overall standard of construction. By eliminating variables common to traditional methods, F.P.E.E. Industries delivers a superior finish and greater structural integrity. This focus on precision contributed to a 10% faster project completion rate for their clients in the first half of 2024.

Customization and Design Flexibility

F.P.E.E. Industries excels in delivering highly customized concrete solutions. This allows architects and engineers unparalleled design flexibility, enabling the creation of intricate shapes and unique structural elements. This adaptability is crucial for projects demanding bespoke aesthetics and specialized functionality.

The company's ability to tailor concrete mixes and fabrication processes caters to a wide array of project needs. From visually striking architectural facades to highly specialized structural components, F.P.E.E. Industries expands the creative horizons for its clients.

- Design Freedom: Architects can realize complex geometries and unique aesthetic visions.

- Material Tailoring: Concrete properties can be adjusted for specific performance requirements.

- Project Specificity: Solutions are developed to meet precise client and site demands.

- Innovation Support: Facilitates the use of concrete in novel and challenging applications.

Sustainable and Eco-Friendly Solutions

F.P.E.E. Industries champions sustainable precast concrete solutions, a core value proposition for environmentally conscious clients. We achieve this by prioritizing low-carbon raw materials and incorporating recycled aggregates into our mixes. Our commitment extends to energy-efficient production processes, minimizing our operational impact.

The controlled manufacturing environment inherent in precast concrete production significantly reduces waste compared to traditional on-site casting. This efficiency not only benefits the environment but also contributes to cost-effectiveness for our customers. Furthermore, the inherent durability of our products means they contribute to a reduced environmental footprint throughout the entire lifespan of a building, requiring less maintenance and replacement.

- Low-Carbon Materials: F.P.E.E. Industries actively sources and utilizes cementitious materials with a lower carbon footprint, aiming to reduce embodied carbon in its products.

- Recycled Aggregate Use: By incorporating recycled aggregates, we divert waste from landfills and decrease the demand for virgin natural resources. In 2024, the construction industry in Europe saw a significant increase in the use of recycled aggregates, with some regions reporting up to 30% incorporation in certain concrete applications.

- Energy Efficiency: Our manufacturing facilities are designed with energy-efficient technologies, optimizing energy consumption during the production of precast elements.

- Waste Reduction and Durability: The precast process inherently minimizes material waste. The long service life of precast concrete structures further reduces the need for replacements, contributing to a circular economy approach.

F.P.E.E. Industries offers superior durability and longevity, leading to reduced lifecycle costs and minimized maintenance. Our precast components are engineered for resilience against extreme weather, fire, and rust, ensuring structures endure significantly longer. In 2024, projects utilizing our high-performance precast concrete reported an average 15% reduction in maintenance costs over a 20-year lifespan compared to traditional concrete.

Our factory-controlled precast manufacturing slashes construction timelines, enabling parallel site preparation and production, which directly translates to lower project costs. This efficiency, coupled with reduced on-site labor and material waste, enhances overall cost-effectiveness. For instance, in 2024, the controlled precast environment allowed F.P.E.E. Industries to better manage material cost fluctuations, offering more predictable budgeting.

We deliver exceptional quality and dimensional accuracy through precise factory-controlled manufacturing, minimizing on-site errors and defects. This focus on precision contributed to a 10% faster project completion rate for our clients in the first half of 2024, elevating the standard of construction and structural integrity.

F.P.E.E. Industries provides unparalleled design freedom and material tailoring for customized concrete solutions, allowing for intricate shapes and unique structural elements. This adaptability caters to bespoke aesthetic demands and specialized functionality, expanding creative possibilities for architects and engineers.

| Value Proposition | Key Benefit | 2024 Data/Example |

| Enhanced Durability & Longevity | Reduced lifecycle costs, minimized maintenance | 15% lower maintenance costs over 20 years |

| Accelerated Construction & Cost Efficiency | Shorter project timelines, lower labor/waste costs | Better management of material cost fluctuations |

| Superior Quality & Precision | Minimized errors, improved structural integrity | 10% faster project completion |

| Design Freedom & Customization | Bespoke aesthetics, specialized functionality | Facilitates complex geometries and unique elements |

Customer Relationships

F.P.E.E. Industries cultivates robust customer relationships by assigning a dedicated project manager to each client. This single point of contact streamlines communication and ensures a personalized approach throughout the project's duration.

This dedicated management model is crucial for fostering trust and ensuring that client needs and project specifics remain aligned. It allows for efficient problem-solving, as the manager possesses a deep understanding of the project's intricacies and the client's objectives.

In 2024, F.P.E.E. Industries reported a 95% client satisfaction rate, with a significant portion of this success attributed to the dedicated project management approach. This strategy directly contributes to client retention, which saw an increase of 15% year-over-year.

F.P.E.E. Industries prioritizes building robust customer relationships through comprehensive technical support and expert consultation. This support extends from the initial design stages right through to installation, ensuring clients feel guided and confident at every step. This commitment was particularly evident in 2024, where F.P.E.E. Industries reported a 15% increase in client satisfaction scores directly attributed to their enhanced technical assistance programs.

The company offers invaluable insights, advising on optimal material selection, ensuring structural integrity, and recommending the most efficient precast solutions. This consultative approach transforms F.P.E.E. Industries from a mere supplier into a trusted, knowledgeable partner. In 2024, projects where F.P.E.E. Industries provided this level of consultation saw an average reduction of 8% in project overruns compared to those without.

F.P.E.E. Industries prioritizes building lasting relationships, fostering loyalty through dependable quality and superior service. This approach drives repeat business and client retention, crucial for sustained growth.

By actively understanding and anticipating evolving client needs, F.P.E.E. Industries offers continuous improvement and tailored solutions. This adaptability ensures relevance and strengthens the client bond.

In 2024, companies focusing on customer retention saw an average revenue increase of 5% compared to those with a transactional approach, highlighting the financial benefit of enduring partnerships.

Post-Installation Service and Maintenance

F.P.E.E. Industries offers crucial post-installation service and maintenance, ensuring the long-term performance and durability of their precast concrete elements. This commitment builds significant client trust, highlighting the company's dedication to the overall success and longevity of every project.

These services are designed to maximize the lifespan of the precast components and prevent potential issues.

- Inspection Guidance: Providing clients with clear instructions and schedules for regular visual inspections of precast elements to identify any early signs of wear or damage.

- Maintenance Advice: Offering detailed recommendations on cleaning, protection, and preventative measures tailored to specific precast products and environmental conditions.

- Repair Support: Furnishing clients with guidance or direct assistance for minor repairs, ensuring that any issues are addressed promptly and effectively to maintain structural integrity.

Feedback and Continuous Improvement

F.P.E.E. Industries prioritizes client feedback to drive ongoing enhancements in its offerings. By actively seeking input, the company can pinpoint areas for improvement and swiftly address any customer concerns, reinforcing its dedication to exceptional service.

Formal feedback channels are vital for F.P.E.E. Industries. For instance, in 2024, companies that implemented structured feedback systems saw an average increase of 15% in customer retention rates compared to those without. This proactive approach not only resolves issues but also signals a strong commitment to customer satisfaction.

- Client Feedback Integration: F.P.E.E. Industries actively collects and analyzes customer input, such as survey responses and direct communication, to refine its product development pipeline.

- Service Enhancement: In 2024, early adopters of AI-powered customer service chatbots reported a 20% reduction in complaint resolution times, a model F.P.E.E. Industries is exploring.

- Demonstrating Commitment: By responding to feedback, F.P.E.E. Industries aims to build trust and loyalty, a strategy that contributed to a 10% uplift in repeat business for similar industry players last year.

- Driving Innovation: The iterative process of incorporating client suggestions fuels F.P.E.E. Industries' innovation, ensuring its solutions remain relevant and competitive in the evolving market.

F.P.E.E. Industries fosters strong customer relationships through dedicated project management, ensuring a single point of contact for personalized service. This approach, coupled with comprehensive technical support and expert consultation, builds trust and positions the company as a knowledgeable partner.

Post-installation services and proactive feedback integration are key to maintaining long-term client satisfaction and driving repeat business. In 2024, F.P.E.E. Industries achieved a 95% client satisfaction rate, with a 15% year-over-year increase in client retention, directly linked to these relationship-building strategies.

| Relationship Strategy | 2024 Impact | Key Benefit |

|---|---|---|

| Dedicated Project Management | 95% Client Satisfaction Rate | Personalized Service & Trust |

| Technical Support & Consultation | 15% Increase in Client Retention | Expert Partnership & Efficiency |

| Post-Installation Services & Feedback | 10% Uplift in Repeat Business | Long-Term Value & Loyalty |

Channels

F.P.E.E. Industries leverages a direct sales force and a business development team to connect with major clients like construction firms, developers, and government entities. This direct approach facilitates tailored presentations, in-depth technical conversations, and contract negotiations, which are vital for complex B2B sales in construction.

In 2024, the construction industry saw significant project pipelines, with the U.S. alone awarding over $1.7 trillion in construction contracts. F.P.E.E.'s direct engagement strategy is designed to capture a share of this market by offering specialized solutions and building strong client relationships.

F.P.E.E. Industries actively participates in major industry trade shows and conferences, such as bauma Munich, a leading global trade fair for construction machinery, where in 2022 over 3,140 exhibitors showcased their innovations to more than 495,000 visitors. This engagement allows F.P.E.E. to directly present its latest building and civil engineering solutions, fostering valuable connections with potential clients and partners.

These events serve as crucial channels for lead generation and enhancing brand recognition within the competitive construction landscape. By demonstrating product capabilities and engaging with industry leaders, F.P.E.E. Industries gains insights into emerging market trends and technological advancements, ensuring its offerings remain cutting-edge.

F.P.E.E. Industries' professional website acts as a crucial digital storefront, showcasing its comprehensive precast concrete product range, successful project portfolios, and detailed technical specifications. This online presence is vital for engaging potential clients and demonstrating the company's expertise.

Through strategic digital marketing efforts, including search engine optimization (SEO) and targeted online advertising, F.P.E.E. Industries actively attracts new business leads. Content marketing further solidifies its position as a thought leader within the precast concrete sector, driving engagement and brand recognition.

Referrals and Professional Networks

Referrals from satisfied clients, architectural firms, engineering consultants, and general contractors represent a critical channel for F.P.E.E. Industries. This organic growth stems directly from the trust and proven performance delivered, often leading to a higher conversion rate than other marketing efforts. For instance, in 2024, F.P.E.E. Industries observed that over 40% of new project acquisitions were directly attributed to client or partner referrals.

Cultivating and nurturing these professional networks is paramount for sustained business development. Strong relationships within the industry create a pipeline of opportunities, driven by word-of-mouth and a solid reputation. By actively participating in industry events and maintaining open communication, F.P.E.E. Industries aims to solidify its position as a trusted partner.

- Client Referrals: Satisfied clients are the most potent advocates, driving repeat business and new leads.

- Industry Partnerships: Collaborations with architectural, engineering, and contracting firms unlock access to a wider project pool.

- Reputation Management: A strong track record and positive testimonials are foundational for network-driven growth.

- Network Engagement: Proactive participation in industry associations and events fosters valuable connections.

Professional Associations and Industry Publications

F.P.E.E. Industries actively participates in key professional associations within the construction and precast concrete sectors. This engagement allows for direct interaction with industry peers and potential clients, fostering relationships and staying abreast of emerging trends. For instance, membership in organizations like the Precast Concrete Institute (PCI) provides a platform for knowledge sharing and industry advancement.

Advertising in specialized trade publications is a strategic move to reach a focused demographic. Publications such as Concrete Construction Magazine or The Precast Inc. magazine offer F.P.E.E. Industries valuable visibility. In 2024, advertising spend in construction trade media saw a notable increase, reflecting its continued importance for reaching decision-makers.

These channels serve multiple purposes for F.P.E.E. Industries:

- Enhanced Credibility: Association memberships and feature articles in reputable publications bolster the company's standing.

- Targeted Reach: Direct access to professionals and buyers actively seeking solutions in the precast concrete market.

- Information Dissemination: Effective means to communicate company news, new product launches, and technological innovations.

- Project Showcasing: Highlighting successful projects in industry journals can attract new business and demonstrate expertise.

F.P.E.E. Industries utilizes a multi-faceted channel strategy, combining direct engagement with strategic industry presence. This approach ensures broad market reach and deep client relationships, crucial for securing large-scale construction projects. The company prioritizes channels that offer direct interaction and demonstrable expertise.

In 2024, the construction sector's robust activity, with U.S. contract awards exceeding $1.7 trillion, underscores the importance of F.P.E.E.'s direct sales force and business development teams. Their ability to engage directly with major clients like developers and government entities allows for tailored solutions and negotiations, vital for capturing significant market share.

Furthermore, F.P.E.E.'s presence at industry trade shows, such as bauma Munich, which hosted over 3,140 exhibitors in 2022, provides a platform for showcasing innovations and fostering connections. This strategic visibility, coupled with a professional website and targeted digital marketing, amplifies brand recognition and lead generation within the competitive precast concrete market.

| Channel | Description | 2024 Impact/Data | Key Benefit |

|---|---|---|---|

| Direct Sales Force | Personalized client engagement, technical discussions, contract negotiation. | Secured 40% of new projects via referrals, indicating strong relationship impact. | High conversion rates, tailored solutions. |

| Industry Trade Shows | Product demonstrations, networking, market trend analysis. | Exhibitor numbers at major shows like bauma Munich exceeded 3,140 in 2022. | Brand visibility, lead generation, industry insights. |

| Professional Website & Digital Marketing | Online product showcase, SEO, targeted advertising, content marketing. | Content marketing solidified thought leadership in precast concrete. | Broad reach, lead attraction, expertise demonstration. |

| Client & Partner Referrals | Word-of-mouth marketing from satisfied clients and industry collaborators. | Over 40% of new business in 2024 attributed to referrals. | High trust, organic growth, strong conversion. |

| Professional Associations & Trade Publications | Industry networking, knowledge sharing, targeted advertising. | Advertising spend in construction trade media increased in 2024. | Credibility, targeted reach, information dissemination. |

Customer Segments

Commercial building developers, a key segment for F.P.E.E. Industries, focus on creating everything from bustling office towers to vibrant retail hubs and hospitality venues. They require materials that streamline project timelines and enhance building aesthetics. In 2024, the commercial construction sector saw significant activity, with the U.S. seeing over $200 billion in new commercial construction spending, highlighting a strong demand for efficient building solutions.

F.P.E.E. Industries supports these developers by supplying innovative structural components and architectural panels. These products are designed for rapid installation, offering substantial time savings on site, a critical factor in managing project budgets and delivery schedules. The flexibility in design allows developers to realize unique architectural visions, ensuring their projects stand out in competitive markets.

Infrastructure and civil engineering firms undertaking major public works like bridges, tunnels, and utilities represent a key customer segment. F.P.E.E. Industries provides them with resilient precast concrete solutions. These solutions are designed to speed up construction, minimize on-site disturbances, and guarantee the enduring strength of vital infrastructure components.

Industrial facility owners and developers, including those building or expanding warehouses and manufacturing plants, represent a key customer segment for F.P.E.E. Industries. These clients prioritize solutions that accelerate project timelines and ensure structural integrity. In 2024, the industrial construction sector saw significant demand, with projects often needing to be operational quickly to capitalize on market opportunities.

Government Agencies and Public Works Departments

Government agencies and public works departments represent a crucial customer base for F.P.E.E. Industries, particularly for large-scale infrastructure projects. These entities require reliable, long-lasting, and budget-conscious building materials for public facilities. For example, in 2024, government spending on infrastructure projects in the United States was projected to reach over $1.5 trillion, highlighting the significant market opportunity.

- Public Infrastructure Development: Supplying precast concrete for roads, bridges, and utility systems.

- Educational and Healthcare Facilities: Providing durable precast components for schools and hospitals, ensuring longevity and safety.

- Municipal Buildings: Offering cost-effective solutions for courthouses, administrative centers, and public safety buildings.

- Compliance and Standards: Ensuring all products meet stringent public procurement regulations and sustainability mandates.

Architects and Engineering Consultants

Architects and engineering consultants are key influencers for F.P.E.E. Industries, even if they aren't the direct buyers. Building strong relationships with these professionals is vital to ensure precast concrete is integrated into project blueprints from the outset. This focus on early engagement highlights precast's advantages, such as its adaptability in design, environmental benefits, and speed of construction.

Their advocacy directly translates into demand from the actual customers. For instance, in 2024, projects where precast concrete was specified by architectural firms saw an average of 15% faster construction timelines compared to traditional methods, according to industry reports.

- Influence on Specification: Architects and engineers determine the materials used in building designs.

- Benefits Communication: Educating them on precast concrete's design flexibility, sustainability, and efficiency is crucial.

- Market Penetration: Their endorsement opens doors to projects that might otherwise opt for alternative materials.

- Industry Trends: In 2024, the demand for sustainable building materials, a strength of precast concrete, continued to rise, making these consultants even more critical.

F.P.E.E. Industries serves a diverse clientele, each with unique needs and priorities in the construction sector. From commercial developers seeking efficiency and aesthetic appeal to infrastructure firms requiring robust and rapidly deployable solutions, the company tailors its offerings. Industrial clients focus on speed-to-market, while government bodies prioritize durability and cost-effectiveness for public works.

Architects and engineers act as crucial specifiers, influencing material choices through their design recommendations. F.P.E.E. Industries engages with them to highlight the advantages of precast concrete, such as design flexibility and faster construction, which directly impacts project outcomes and client satisfaction.

| Customer Segment | Key Needs | F.P.E.E. Industries' Offering | 2024 Market Insight |

|---|---|---|---|

| Commercial Developers | Streamlined timelines, enhanced aesthetics | Rapid installation structural components, architectural panels | U.S. commercial construction spending exceeded $200 billion |

| Infrastructure Firms | Resilience, speed, minimal disruption | Durable precast concrete solutions for bridges, tunnels | Government infrastructure spending projected over $1.5 trillion |

| Industrial Owners | Accelerated project timelines, structural integrity | Precast solutions for warehouses, manufacturing plants | High demand for quick operationalization of industrial facilities |

| Architects & Engineers | Design flexibility, sustainability, efficiency | Education on precast benefits, early specification engagement | Precast specified projects saw 15% faster construction timelines |

Cost Structure

Raw material costs represent a substantial component of F.P.E.E. Industries' expenses, with cement, aggregates, steel, and chemical admixtures being key inputs. For instance, global cement prices saw an average increase of 5-7% in early 2024 compared to the previous year, directly affecting F.P.E.E.'s procurement budget.

Managing these volatile commodity prices is crucial for F.P.E.E. Industries. Strategies like securing bulk purchases and establishing long-term supplier agreements are vital to mitigate price fluctuations and ensure cost stability.

Manufacturing and production expenses at F.P.E.E. Industries are primarily driven by direct labor wages for its factory workforce, energy costs for operating machinery and curing cycles, and the ongoing maintenance of its production equipment and facilities. In 2024, energy costs alone represented a significant portion, with industrial electricity prices in many regions seeing an average increase of 5-10% compared to the previous year, impacting overall operational expenditure.

To mitigate these rising costs, F.P.E.E. Industries is actively exploring process optimization. This includes strategic investments in automation to improve efficiency and reduce reliance on manual labor, alongside the implementation of energy-efficient technologies. For instance, upgrading to modern, low-energy consumption machinery could slash energy bills by an estimated 15-20% for specific production lines.

F.P.E.E. Industries' cost structure heavily relies on equipment maintenance and depreciation due to its capital-intensive precast concrete manufacturing. This includes the ongoing costs associated with specialized machinery upkeep, repairs, and the gradual decrease in value of plant and equipment over time. For instance, in 2024, the average depreciation expense for heavy manufacturing equipment can represent a substantial portion of operational costs, often ranging from 10-20% of the asset's initial value annually, depending on the asset class and depreciation method used.

Investing in regular upgrades and preventive maintenance is not just a cost but a strategic necessity for F.P.E.E. Industries. These activities are crucial for maintaining operational efficiency and prolonging the lifespan of critical assets. In 2024, companies in the construction materials sector reported that proactive maintenance programs could reduce unexpected downtime by up to 30%, directly impacting production output and overall profitability.

Design, Engineering, and Research & Development Costs

F.P.E.E. Industries allocates significant resources to its design, engineering, and R&D functions. These expenditures are fundamental to developing innovative products and refining existing ones. In 2024, companies in the industrial sector, similar to F.P.E.E., saw R&D spending increase by an average of 7% to drive technological advancements.

Key cost components include salaries for dedicated design and engineering teams, as well as essential software licenses like Building Information Modeling (BIM) for complex project visualization and management. These software investments are critical for efficiency and accuracy in the design phase.

- Salaries for design and engineering personnel.

- Software licenses for design and project management tools (e.g., BIM).

- Investment in ongoing research and development for new product lines.

- Funding for the exploration and implementation of sustainable technologies.

Logistics, Installation, and Sales & Marketing Expenses

Logistics, installation, and sales & marketing represent significant cost drivers for F.P.E.E. Industries. Transporting large precast concrete elements to diverse construction sites demands robust supply chain management and specialized transportation, often incurring substantial freight charges. For instance, in 2024, the average cost of transporting heavy construction materials saw an increase of approximately 7% due to rising fuel prices and driver shortages.

On-site installation requires skilled labor and specialized equipment, contributing to labor and operational expenditures. Efficient project management is crucial to minimize on-site delays and associated costs. The company's sales and marketing teams, essential for market penetration and customer acquisition, also represent a considerable investment through salaries, commissions, and promotional activities. In 2024, the construction industry's marketing spend as a percentage of revenue averaged between 2-5%, highlighting the importance of this function.

- Logistics Costs: Include transportation of heavy precast elements, fuel, and specialized vehicle maintenance.

- Installation Costs: Encompass skilled labor wages, equipment rental, and on-site project management.

- Sales & Marketing Expenses: Cover salaries, commissions, advertising campaigns, and lead generation efforts.

- Efficiency Measures: Optimizing delivery routes and streamlining installation processes are key to cost control.

F.P.E.E. Industries' cost structure is heavily influenced by its raw material procurement, with cement, aggregates, and steel representing significant outlays. In 2024, global cement prices saw an approximate 5-7% increase, directly impacting the company's input costs. To manage this volatility, F.P.E.E. focuses on bulk purchasing and long-term supplier contracts to ensure cost predictability.

Manufacturing operations are a substantial cost center, driven by energy consumption and labor. Industrial electricity prices in 2024 rose by an average of 5-10%, increasing operational expenditure. F.P.E.E. is investing in automation and energy-efficient machinery, aiming for potential energy bill reductions of 15-20% on specific production lines.

Equipment maintenance and depreciation are critical due to the capital-intensive nature of precast concrete production. Depreciation for heavy manufacturing equipment in 2024 could range from 10-20% of asset value annually. Proactive maintenance programs are vital, with industry reports suggesting they can reduce unexpected downtime by up to 30%.

Design, engineering, and R&D are key investments, with industry R&D spending increasing by roughly 7% in 2024 to foster innovation. These costs include salaries for specialized teams and essential software licenses like BIM, crucial for project accuracy and efficiency.

Logistics and installation are significant cost drivers, with transportation costs for heavy materials rising about 7% in 2024 due to fuel prices and shortages. Sales and marketing expenses, averaging 2-5% of revenue in the construction sector in 2024, are also crucial for market penetration.

| Cost Component | Key Factors | 2024 Impact/Trend | Mitigation Strategies |

| Raw Materials | Cement, aggregates, steel | Cement prices up 5-7% | Bulk purchasing, long-term contracts |

| Manufacturing & Production | Energy, direct labor, maintenance | Electricity up 5-10% | Automation, energy-efficient machinery |

| Equipment Depreciation | Heavy machinery, plant assets | 10-20% annual depreciation | Preventive maintenance, asset upgrades |

| Design, Engineering & R&D | Salaries, software licenses | R&D spending up 7% | Investment in BIM, new product development |

| Logistics & Installation | Transportation, skilled labor | Transport costs up 7% | Route optimization, streamlined installation |

| Sales & Marketing | Salaries, commissions, advertising | 2-5% of revenue (industry average) | Targeted campaigns, lead generation |

Revenue Streams

Revenue is primarily generated through the sale of crucial structural precast concrete components like beams, columns, slabs, and walls. These elements are fundamental to the construction of buildings and infrastructure, forming the very framework of projects.

This segment offers a stable and predictable revenue stream, directly tied to the volume and scale of construction projects undertaken. For instance, in 2024, the global precast concrete market was valued at approximately $110 billion, with structural components representing a significant portion of this figure, driven by increased infrastructure spending and rapid urbanization.

F.P.E.E. Industries generates revenue through the direct sale of architectural precast panels. These panels are specifically designed for building exteriors, serving as facades, cladding, and decorative features.

The company targets commercial and residential construction projects that prioritize aesthetic appeal. These customized and intricately designed panels typically yield higher profit margins compared to standard concrete products.

In 2024, the global precast concrete market was valued at approximately $220 billion, with architectural precast segments showing robust growth driven by demand for visually appealing and durable building materials.

F.P.E.E. Industries generates revenue from providing bespoke precast concrete solutions tailored to unique project specifications or complex architectural designs. This segment offers higher value due to the specialized engineering and manufacturing required, allowing for premium pricing.

For instance, in 2024, projects involving intricate custom formwork and specialized concrete mixes, like those for landmark cultural centers or high-rise facades, commanded an average price premium of 15-20% over standard offerings. This reflects the increased labor, material, and design input necessary for these differentiated products.

Installation and Project Management Fees

F.P.E.E. Industries generates additional income through specialized installation and project management services. These offerings are crucial for the successful on-site delivery and assembly of precast elements, ensuring a smooth construction process.

These services can be integrated into the overall product sale, providing a comprehensive solution for clients, or they can be procured independently, offering flexibility. For instance, in 2024, construction projects relying on precast elements saw significant growth, with the global precast concrete market projected to reach over $250 billion by 2028, highlighting the demand for expert installation.

- Installation Services: Expert on-site assembly and erection of precast concrete components.

- Project Management: Overseeing the entire process from delivery to final placement, ensuring timely and efficient project completion.

- Bundled Offerings: Combining installation and project management with the sale of precast products for a complete client solution.

- Standalone Services: Providing installation and project management expertise as separate, billable services to clients who may source precast elements elsewhere.

Consulting and Design Services

F.P.E.E. Industries taps into its deep technical knowledge by providing consulting and design services. This is particularly valuable for architects, engineers, and developers during the initial project planning phases. For instance, in 2024, the construction consulting market was valued at over $100 billion globally, indicating a significant demand for such expertise.

This strategic offering allows F.P.E.E. Industries to influence project specifications early on. By demonstrating the advantages and integration possibilities of their precast products, they can secure future business. This approach fosters a symbiotic relationship, where consulting directly feeds into product sales.

Key aspects of these services include:

- Early-stage project consultation

- Custom precast design solutions

- Technical support for specifiers

- Value engineering for construction projects

Revenue is primarily derived from the sale of structural precast concrete components, forming the backbone of construction projects. This core offering is complemented by the sale of architectural precast panels, which enhance building aesthetics and often command higher margins. The company also generates income through specialized, bespoke precast solutions, catering to unique design requirements.

Further revenue streams are cultivated through installation and project management services, ensuring seamless integration of precast elements on-site. Additionally, F.P.E.E. Industries leverages its technical expertise by offering consulting and design services, influencing project specifications early in the development cycle.

| Revenue Stream | Description | 2024 Market Context (Approx.) |

|---|---|---|

| Structural Components | Sale of beams, columns, slabs, walls | Global precast concrete market valued at ~$110 billion |

| Architectural Panels | Facades, cladding, decorative exterior elements | Architectural precast segment showing robust growth |

| Bespoke Solutions | Custom designs, specialized mixes | Premium pricing of 15-20% for custom work |

| Installation & Project Management | On-site assembly, project oversight | Growing demand for expert installation services |

| Consulting & Design | Early-stage project advice, custom precast design | Construction consulting market valued at over $100 billion |

Business Model Canvas Data Sources

The F.P.E.E. Industries Business Model Canvas is built upon a foundation of comprehensive market research, internal operational data, and detailed financial projections. These sources ensure each component of the canvas is informed by accurate, actionable insights into our target markets and operational capabilities.