Ehlebracht PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Ehlebracht Bundle

Unlock the secrets to Ehlebracht's market position with our comprehensive PESTLE analysis. Understand the political, economic, social, technological, legal, and environmental forces shaping its trajectory. Equip yourself with the strategic foresight needed to navigate this dynamic landscape. Download the full analysis now for actionable intelligence.

Political factors

Governments globally are tightening rules on product traceability, especially for vital sectors like pharma and food. For instance, the EU's Falsified Medicines Directive (FMD) requires unique identifiers on prescription medicines, enhancing safety. This trend directly benefits Ehlebracht AG, as its tracking and coding technologies help companies meet these strict compliance requirements, ensuring product authenticity and enabling swift recalls if issues arise.

Changes in international trade policies and tariffs directly influence Ehlebracht AG's global operations. For instance, the European Union's trade surplus with the United States in goods was approximately $167.9 billion in 2023, highlighting the interconnectedness of these markets and the potential impact of policy shifts. Tariffs on key components or finished products could alter production costs and competitive pricing.

Political stability in Germany, Ehlebracht AG's primary operating region, remains a key consideration. As of early 2024, Germany's coalition government has navigated various economic challenges, maintaining a generally stable political landscape that supports industrial activity. This stability is vital for Ehlebracht's long-term investment planning and supply chain reliability.

Disruptions stemming from political instability, such as trade disputes or sudden policy shifts in key sourcing regions, could impact Ehlebracht's operational costs and market access. For instance, geopolitical tensions in Eastern Europe, a significant sourcing area for certain raw materials, could lead to supply chain volatility, a risk Ehlebracht actively monitors.

Conversely, government initiatives promoting innovation and sustainability, like Germany's ongoing commitment to renewable energy and advanced manufacturing, create favorable conditions for Ehlebracht's strategic growth. The German government's industrial strategy, emphasizing digitalization and green technologies, aligns well with Ehlebracht's forward-looking business model.

Government Incentives for Industry 4.0

Governments worldwide are actively promoting Industry 4.0 adoption through financial incentives. For instance, Germany's "Digital Hubs" initiative, launched in 2017, supports SMEs in digital transformation, with continued funding expected through 2025. These programs, including subsidies and tax credits, directly boost demand for advanced manufacturing solutions like those offered by Ehlebracht AG.

These governmental efforts are crucial for accelerating the modernization of industrial processes, making smart factories more accessible. This trend is evident in the projected growth of the global Industry 4.0 market, which was valued at approximately $80.1 billion in 2023 and is forecast to reach $212.7 billion by 2028, demonstrating a compound annual growth rate of 21.6% during that period. Such support directly benefits companies providing the foundational technologies for this shift.

- Governmental support for Industry 4.0 adoption is a significant driver for companies like Ehlebracht AG.

- Germany's "Digital Hubs" initiative exemplifies direct financial assistance for digitalization.

- The global Industry 4.0 market is experiencing robust growth, projected to exceed $212 billion by 2028.

- These incentives reduce the financial barrier for businesses to invest in smart manufacturing technologies.

Geopolitical Tensions and Supply Chain Resilience

Rising geopolitical tensions are a significant concern for Ehlebracht AG, potentially disrupting its global supply chains and impacting technology transfers. For instance, the ongoing trade disputes and regional conflicts in 2024 have already led to increased shipping costs and delays for many manufacturing firms, a trend that could continue. These factors necessitate a proactive approach to managing operational risks.

The global emphasis on supply chain resilience, spurred by these geopolitical shifts, presents both challenges and opportunities. Many companies, including those in the industrial sector, are re-evaluating their reliance on single-source suppliers. This could influence Ehlebracht AG's strategy towards diversifying its supplier base and potentially investing in more localized manufacturing and assembly capabilities to mitigate future disruptions.

The push for localized production, driven by national security concerns and a desire for greater control over critical components, is a key political trend. For example, governments in 2024 have increasingly offered incentives for domestic manufacturing, particularly in strategic sectors. Ehlebracht AG will need to consider how these policies might affect its competitive landscape and investment decisions regarding regional production facilities.

- Supply Chain Disruptions: Geopolitical instability can lead to sudden interruptions in the flow of goods, impacting production schedules and delivery times.

- Technology Transfer Restrictions: Governments may impose limitations on the export or import of certain technologies, affecting innovation and operational capabilities.

- Increased Operational Risks: Political uncertainty can translate into higher costs for insurance, compliance, and navigating evolving trade regulations.

- Shift to Regionalization: A growing trend towards localized manufacturing and supply chains to enhance resilience against global shocks.

Government regulations concerning data privacy and cybersecurity are becoming increasingly stringent globally. For instance, the EU's General Data Protection Regulation (GDPR) continues to shape data handling practices, with ongoing enforcement actions and potential fines for non-compliance. Ehlebracht AG's solutions, which often involve tracking and managing sensitive industrial data, must adhere to these evolving legal frameworks, ensuring robust data protection measures are in place.

What is included in the product

The Ehlebracht PESTLE Analysis systematically examines the Political, Economic, Social, Technological, Environmental, and Legal factors impacting the company, providing a comprehensive understanding of its external operating landscape.

The Ehlebracht PESTLE Analysis offers a structured framework that simplifies complex external factors, acting as a pain point reliever by providing clear, actionable insights for strategic decision-making.

Economic factors

Global economic growth significantly impacts demand for Ehlebracht AG's capital equipment. In 2024, the IMF projected global growth at 3.2%, a slight slowdown from 2023, indicating a cautious business environment that might temper capital expenditure on new production lines.

Industrial production trends are a key indicator for Ehlebracht. For instance, a 0.3% increase in U.S. industrial production in April 2024 suggests some recovery, potentially boosting demand for marking and coding systems as manufacturers expand operations.

Conversely, slowdowns in major manufacturing hubs, such as a projected 1.0% contraction in Eurozone industrial output for 2024, could directly translate to reduced sales for Ehlebracht's capital equipment and consumables.

Inflationary pressures significantly impact Ehlebracht AG by increasing the cost of essential raw materials like specialized inks, labels, and electronic components. For instance, the Producer Price Index for manufactured goods in Germany saw a notable increase in early 2024, directly affecting component sourcing costs.

Furthermore, rising energy prices, evidenced by fluctuations in global oil and gas markets throughout 2024, coupled with elevated transportation expenses, contribute to higher operational expenditures for the company. These combined cost escalations necessitate strategic management to preserve profitability.

Effectively navigating these cost pressures, potentially through optimized procurement strategies and considered price adjustments, is paramount for Ehlebracht AG to maintain its profit margins in the current economic climate.

Ehlebracht AG, engaging in global commerce, faces significant exposure to shifting exchange rates. For instance, if the Euro strengthens considerably against the US Dollar, Ehlebracht's German-made products become pricier for American buyers, potentially dampening export volumes. Conversely, a weaker Euro makes imported components more costly for the company.

These currency movements directly influence Ehlebracht's competitive edge in foreign markets and the cost of its raw materials and finished goods sourced internationally. For example, a 5% appreciation of the Euro against the Yen could increase the cost of Japanese-sourced machinery by that same percentage, impacting Ehlebracht's operational expenses.

The inherent volatility in exchange rates, such as the Euro's fluctuations against the British Pound during 2024, injects considerable uncertainty into Ehlebracht's financial planning. Predicting revenue from sales in the UK or the cost of sourcing from the UK becomes more challenging, making accurate profit forecasting a complex task for the company.

Customer Investment in Capital Equipment

Ehlebracht AG's revenue is heavily influenced by its clients' decisions to purchase new capital equipment. This willingness to invest is often shaped by economic conditions, particularly interest rates and the availability of financing. For instance, a robust lending environment, characterized by lower borrowing costs, directly encourages businesses to upgrade their marking and coding systems, thereby boosting Ehlebracht's sales.

The perceived return on investment (ROI) for new capital equipment is a critical driver for customer spending. When businesses anticipate strong future demand and profitability, they are more likely to commit capital to efficiency-enhancing technologies. This confidence in future returns directly translates into increased orders for companies like Ehlebracht.

In 2024, many sectors are experiencing a cautious optimism regarding capital expenditure. For example, the manufacturing sector, a key market for marking and coding solutions, saw capital expenditures increase by an estimated 5.2% in the US during the first half of 2024 compared to the same period in 2023, according to preliminary industry reports. This trend suggests a growing appetite for equipment upgrades.

- Interest Rates: Falling interest rates in major economies like the Eurozone, with the ECB signaling potential rate cuts in mid-2024, can lower the cost of capital for businesses, making investment in new equipment more attractive.

- Credit Availability: Banks are reporting a slight easing in lending standards for corporate clients in Q2 2024, improving access to credit for capital investments.

- Business Confidence: The Purchasing Managers' Index (PMI) for manufacturing in Germany remained above 45 in early 2024, indicating a contraction but with signs of stabilization, suggesting some level of underlying business confidence for necessary upgrades.

- ROI Projections: Companies are projecting an average ROI of 15-20% within three years for new automation and marking equipment, a figure that supports investment decisions.

Labor Costs and Availability

The increasing expense of skilled labor and the availability of qualified workers directly influence Ehlebracht AG's operating costs and how readily customers can integrate automation. For instance, in the United States, average hourly wages for manufacturing workers saw a notable increase, reaching approximately $25.50 by early 2024, according to Bureau of Labor Statistics data, a trend likely to continue. This upward pressure on wages makes automated marking and coding solutions, such as those offered by Ehlebracht, more economically attractive for manufacturers seeking to control expenses.

Conversely, a scarcity of technical professionals needed for the installation and ongoing maintenance of these advanced systems presents a significant hurdle. As of mid-2024, reports indicated persistent shortages in skilled trades, including automation technicians, with some sectors experiencing unemployment rates below 2%. This talent gap could slow down the widespread adoption of automation, impacting Ehlebracht's market penetration despite the cost-saving incentives.

Key considerations for Ehlebracht AG regarding labor include:

- Impact of Wage Inflation: Rising labor costs for clients can drive demand for automation solutions.

- Skilled Workforce Shortage: Difficulty in finding qualified personnel for installation and support may hinder customer adoption.

- Geographic Labor Market Variations: Differences in labor costs and availability across regions will affect market strategies.

Global economic conditions significantly shape demand for Ehlebracht AG's capital equipment. Projections for 2024 indicated a modest global growth rate, with the IMF estimating 3.2%, suggesting a potentially cautious environment for capital expenditures. Industrial production trends are a direct reflection of manufacturing activity, with a 0.3% rise in U.S. industrial production in April 2024 signaling some expansion, while a projected 1.0% contraction in Eurozone industrial output for the same year points to regional challenges that could impact sales.

Inflationary pressures and rising energy costs directly impact Ehlebracht AG's operational expenses. Increases in the German Producer Price Index for manufactured goods in early 2024 highlighted higher raw material costs, while global oil and gas market volatility throughout the year contributed to elevated transportation expenses, necessitating careful cost management.

Ehlebracht AG's financial performance is also sensitive to exchange rate fluctuations. A stronger Euro, for instance, could make its German-made products more expensive for international buyers, potentially reducing export volumes, while a weaker Euro increases the cost of imported components, impacting overall profitability and competitiveness in global markets.

Customer willingness to invest in new capital equipment is a key driver for Ehlebracht AG. Favorable interest rates and accessible credit, such as the European Central Bank's signaling of potential rate cuts in mid-2024, can lower the cost of capital for businesses, encouraging investment. Positive return on investment (ROI) projections, with companies anticipating 15-20% ROI within three years for automation equipment, further support purchasing decisions.

Labor costs and availability also play a crucial role. Rising manufacturing wages in the U.S., averaging around $25.50 per hour by early 2024, make automated solutions more attractive for clients. However, persistent shortages in skilled trades, with some sectors experiencing unemployment rates below 2% for technicians in mid-2024, could hinder the adoption of advanced marking and coding systems.

| Economic Factor | 2024 Data/Projection | Impact on Ehlebracht AG |

|---|---|---|

| Global GDP Growth | IMF projected 3.2% (2024) | Influences overall demand for capital equipment. |

| Industrial Production (US) | +0.3% (April 2024) | Positive signal for manufacturing expansion and equipment needs. |

| Industrial Production (Eurozone) | Projected -1.0% (2024) | Indicates potential slowdown in a key market. |

| Inflation (Germany PPI for manufactured goods) | Notable increase (early 2024) | Raises raw material and component costs. |

| Energy Prices | Volatile global markets (2024) | Increases operational and transportation costs. |

| Interest Rates (Eurozone) | ECB signaling potential cuts (mid-2024) | Potentially lowers borrowing costs, encouraging investment. |

| Manufacturing Wages (US) | ~$25.50/hour (early 2024) | Increases attractiveness of automation solutions for clients. |

| Skilled Labor Shortage (Automation Techs) | Persistent shortages (mid-2024) | May slow adoption of complex systems. |

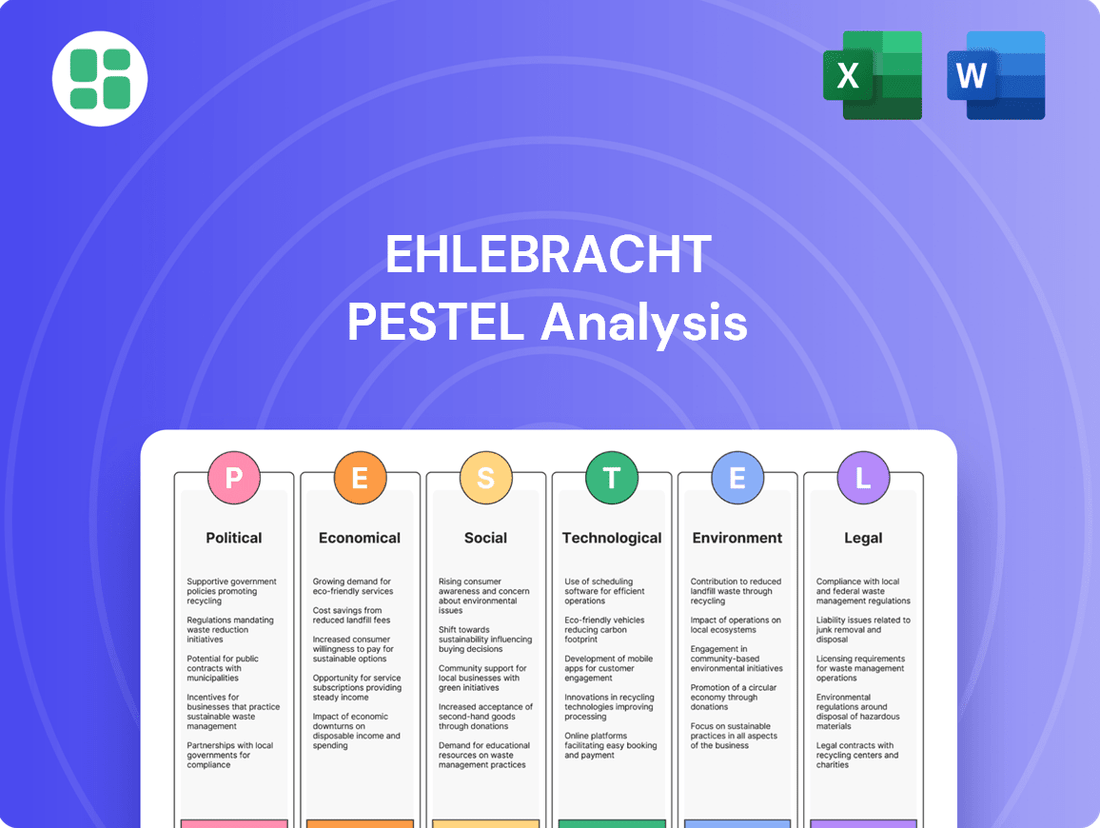

Preview the Actual Deliverable

Ehlebracht PESTLE Analysis

The preview shown here is the exact Ehlebracht PESTLE Analysis document you’ll receive after purchase—fully formatted and ready to use.

This is a real screenshot of the product you’re buying—delivered exactly as shown, no surprises. You'll gain a comprehensive understanding of the external factors impacting Ehlebracht.

The content and structure shown in the preview is the same Ehlebracht PESTLE Analysis document you’ll download after payment, providing actionable insights.

Sociological factors

Consumers are increasingly demanding to know where their products come from, what's in them, and if they are made ethically. This growing societal trend directly impacts businesses, pushing them to adopt more transparent practices. For instance, a 2024 survey by NielsenIQ found that 73% of global consumers are willing to change their purchasing habits to reduce their environmental impact, highlighting a direct link between transparency and consumer choice.

Ehlebracht AG's expertise in marking and coding solutions is perfectly positioned to address this demand. By enabling detailed product information to be shared, their technology helps companies build trust and foster loyalty. In 2025, the global market for product authentication and traceability is projected to reach over $3.5 billion, underscoring the significant business opportunity in meeting this consumer need.

The global workforce is experiencing significant shifts, with many developed nations seeing an aging population and a concurrent decline in the availability of specialized technical skills. For instance, in the US, the Bureau of Labor Statistics projected that by 2032, the median age of all workers will continue to rise, while demand for skilled technicians in areas like advanced manufacturing is expected to outpace supply. This demographic trend directly impacts industries reliant on precise and efficient processes, like product marking.

Ehlebracht AG's focus on automated and user-friendly marking solutions positions them to address these labor market challenges. Their systems are engineered for seamless integration and minimal operator intervention, offering a viable strategy for companies struggling with labor shortages or the need for highly specialized, yet increasingly scarce, technical expertise. This can lead to increased operational efficiency even with a less experienced or smaller workforce.

Consequently, as companies adopt these advanced marking technologies, there will likely be a growing demand for comprehensive training and ongoing support services. Businesses will need to equip their existing staff with the knowledge to operate and maintain these sophisticated systems, ensuring maximum uptime and benefit realization. This presents an opportunity for service providers and potentially for Ehlebracht AG to expand its service offerings.

Societal values are increasingly prioritizing sustainability, ethical production, and minimizing environmental footprints. This trend directly influences consumer choices and regulatory pressures, compelling manufacturers to integrate eco-friendly practices. For instance, a 2024 report indicated that over 60% of consumers consider sustainability when making purchasing decisions, a significant jump from previous years.

This societal shift mandates that companies like Ehlebracht AG adopt greener production processes, including the use of eco-friendly marking solutions and strategies for waste reduction. The demand for sustainable materials and processes is growing, with the global green technology and sustainability market projected to reach $50.62 billion by 2027, growing at a CAGR of 22.7%.

Ehlebracht AG can strategically leverage this by developing and actively promoting sustainable ink options, investing in energy-efficient marking equipment, and offering solutions designed to minimize material consumption. Such initiatives not only align with evolving consumer preferences but also position the company favorably in a market increasingly defined by environmental responsibility.

Demand for Personalized Products

The growing consumer desire for unique items means businesses need ways to mark and code products that can change easily. This shift towards mass customization is a significant sociological trend. For instance, a 2024 report indicated that 60% of consumers are willing to pay more for personalized products, highlighting a strong market pull for adaptable solutions.

This demand translates into a need for flexible marking and coding systems capable of handling variable data and on-demand printing. Companies must be able to quickly adjust product information, batch codes, or even unique identifiers without significant downtime. Ehlebracht AG's inkjet and laser marking technologies are specifically designed for this agility.

Ehlebracht's solutions support this trend by offering:

- On-demand printing capabilities for variable product data.

- High-speed marking to keep pace with customized production lines.

- Versatile marking technologies suitable for a wide range of materials and product types.

- Integration with manufacturing execution systems (MES) for seamless data flow and personalization.

Impact of Remote Work and Digitalization

The surge in remote work and digital operations within manufacturing, accelerated by events like the COVID-19 pandemic, has underscored the critical need for connected and remotely manageable systems. This trend means that companies like Ehlebracht AG, which provide software for data management, remote monitoring, and integration with existing enterprise resource planning (ERP) systems, are seeing their value proposition significantly enhanced. For instance, a 2024 report by Gartner indicated that 70% of manufacturing companies were investing in digital transformation initiatives to improve operational efficiency and resilience.

This societal shift necessitates a strong focus on digital infrastructure and robust cybersecurity measures. As more operations become digitized and accessible remotely, the risk of cyber threats increases. Companies must invest in secure cloud solutions and advanced threat detection systems to protect sensitive data and ensure operational continuity. The global cybersecurity market, projected to reach over $300 billion by 2025, reflects this growing imperative.

- Increased Demand for Remote Management: The adoption of remote work models in manufacturing has driven a greater need for software solutions enabling remote monitoring and control of production processes.

- Enhanced Value of Digital Solutions: Ehlebracht AG's offerings in data management and system integration are becoming more crucial as businesses prioritize digital connectivity for operational efficiency.

- Cybersecurity as a Priority: The digitalization trend necessitates significant investment in cybersecurity infrastructure to safeguard sensitive manufacturing data and prevent operational disruptions.

- Digital Transformation Investment: A significant majority of manufacturing firms, around 70% according to 2024 industry analysis, are actively investing in digital transformation to adapt to new work paradigms and enhance resilience.

Societal values are increasingly prioritizing sustainability, ethical production, and minimizing environmental footprints. This trend directly influences consumer choices and regulatory pressures, compelling manufacturers to integrate eco-friendly practices. For instance, a 2024 report indicated that over 60% of consumers consider sustainability when making purchasing decisions, a significant jump from previous years.

This societal shift mandates that companies like Ehlebracht AG adopt greener production processes, including the use of eco-friendly marking solutions and strategies for waste reduction. The demand for sustainable materials and processes is growing, with the global green technology and sustainability market projected to reach $50.62 billion by 2027, growing at a CAGR of 22.7%.

Ehlebracht AG can strategically leverage this by developing and actively promoting sustainable ink options, investing in energy-efficient marking equipment, and offering solutions designed to minimize material consumption. Such initiatives not only align with evolving consumer preferences but also position the company favorably in a market increasingly defined by environmental responsibility.

Technological factors

Continuous innovation in inkjet and laser marking technologies is a key technological driver. These advancements are delivering faster speeds, higher resolution, and greater material versatility, enhancing product identification capabilities. For instance, advancements in industrial inkjet printing are projected to see the global market reach approximately $15 billion by 2028, indicating significant investment and development in this area.

These technological leaps allow Ehlebracht AG to offer more sophisticated and durable solutions, directly addressing increasingly complex industry demands for precise and long-lasting product marking. Staying abreast of these rapid developments, such as the integration of AI in laser marking for real-time quality control, is vital for maintaining Ehlebracht's competitive edge and delivering superior identification technologies.

The ongoing integration of Industry 4.0 principles, including the Internet of Things (IoT) and Artificial Intelligence (AI), is fundamentally reshaping manufacturing. Ehlebracht AG's ability to connect its systems with these advanced production networks is crucial for real-time data exchange, enabling predictive maintenance and workflow optimization, thereby boosting operational efficiency.

By 2024, the global IoT market in manufacturing was projected to reach over $200 billion, highlighting the significant investment in connected systems. This trend necessitates that Ehlebracht AG's offerings are compatible with these evolving industrial ecosystems to leverage real-time data for enhanced performance and competitive advantage.

The persistent challenge of product counterfeiting is a major catalyst for innovation in anti-counterfeiting technologies. This includes the advancement of covert marking, unique serialization, and the integration of blockchain for enhanced traceability. These developments are crucial for industries worldwide, with the global anti-counterfeiting market projected to reach approximately $370 billion by 2026, indicating significant investment and demand.

Ehlebracht AG, with its established proficiency in product identification systems, is well-positioned to leverage these emerging technologies. By developing and integrating sophisticated anti-counterfeiting features into its offerings, Ehlebracht can provide its clients with superior product security and robust brand protection. This strategic alignment ensures that Ehlebracht remains at the forefront of safeguarding its clients' valuable intellectual property and market integrity.

Software Innovations for Data Management

Innovations in software for data management, analytics, and cloud connectivity are fundamentally changing how marking and coding data is leveraged. Ehlebracht AG’s software solutions, designed to handle extensive serialization and traceability data, are vital for meeting regulatory requirements, enhancing supply chain transparency, and gaining operational intelligence. For instance, the global market for data management software was projected to reach over $120 billion in 2024, underscoring the significant investment in these capabilities.

Continuous software development is paramount for Ehlebracht AG to deliver value that extends beyond its hardware offerings. This includes developing advanced analytics tools that can process the massive datasets generated by serialization, offering predictive insights into production efficiency and supply chain disruptions. The company’s commitment to software innovation ensures its solutions remain competitive and address evolving market demands for real-time data utilization.

- Enhanced Data Utilization: Software innovations are enabling more sophisticated analysis of serialization and traceability data, moving beyond simple record-keeping to actionable insights.

- Cloud Connectivity: Advancements in cloud platforms allow for seamless integration and real-time data sharing across complex supply chains, improving visibility and collaboration.

- Value-Added Services: Ehlebracht AG's focus on software development allows it to offer services like predictive maintenance and optimized inventory management, increasing the overall value proposition.

- Market Growth: The increasing digitization of supply chains, driven by regulations like the EU's Falsified Medicines Directive, fuels demand for robust data management software, with the serialization software market alone expected to grow significantly in the coming years.

Emergence of New Materials and Packaging

The constant evolution of materials and packaging presents a dynamic landscape for marking and coding solutions. Innovations in sustainable materials, such as biodegradable plastics and plant-based films, alongside advancements in flexible packaging and high-performance composites, require adaptable technologies. For Ehlebracht AG, this means a continuous need to update its marking and coding equipment and consumables, like specialized inks, to ensure clear, durable, and compliant markings on these diverse and often challenging surfaces. For instance, the global sustainable packaging market was valued at approximately USD 278.5 billion in 2023 and is projected to reach USD 440.4 billion by 2030, indicating a significant shift towards new material types that Ehlebracht must support.

Adapting to these material shifts is crucial for maintaining marking integrity and brand consistency. New materials may have different surface energies, porosity, or chemical compositions, impacting ink adhesion and print durability. Ehlebracht AG's commitment to research and development is therefore paramount to stay ahead of these trends. This includes developing inks that can adhere effectively to non-porous surfaces, withstand various environmental conditions, and meet regulatory requirements for food contact or medical applications, all while supporting the sustainability goals driving these material innovations.

Key considerations for Ehlebracht AG regarding new materials and packaging include:

- Material Compatibility: Ensuring inks and marking technologies adhere properly to new sustainable materials like bioplastics and recycled content.

- Durability Requirements: Developing marking solutions that can withstand the specific stresses associated with flexible packaging, such as stretching, folding, and temperature fluctuations.

- Regulatory Compliance: Staying abreast of and adapting to evolving regulations concerning marking on new packaging types, particularly in food and beverage or pharmaceutical sectors.

- R&D Investment: Allocating resources to research new ink formulations and printhead technologies that can effectively mark a wider array of advanced composite materials.

Technological advancements are continuously refining product identification. Innovations in inkjet and laser marking offer faster speeds, higher resolution, and greater material versatility, enhancing capabilities. The global industrial inkjet printing market is expected to reach approximately $15 billion by 2028, showcasing significant investment in this sector.

The integration of Industry 4.0, including IoT and AI, is transforming manufacturing. Ehlebracht AG's ability to connect with these networks is vital for real-time data exchange, predictive maintenance, and workflow optimization. The manufacturing IoT market was projected to exceed $200 billion in 2024, underscoring the importance of connected systems.

Anti-counterfeiting technologies are advancing rapidly, incorporating covert marking, serialization, and blockchain for traceability. The global anti-counterfeiting market is anticipated to reach around $370 billion by 2026, highlighting a strong demand for enhanced product security solutions.

Software innovations in data management and cloud connectivity are crucial for leveraging marking and coding data. Ehlebracht AG's solutions for serialization and traceability are essential for regulatory compliance and supply chain transparency. The data management software market was projected to surpass $120 billion in 2024, indicating substantial investment in these areas.

The evolving landscape of materials and packaging, especially sustainable options, requires adaptable marking technologies. Innovations in bioplastics and flexible packaging necessitate updated equipment and consumables. The global sustainable packaging market was valued at approximately USD 278.5 billion in 2023, with a projected growth to USD 440.4 billion by 2030, indicating a significant shift that demands technological adaptation.

Legal factors

Ehlebracht AG's reliance on data for product traceability means strict adherence to data privacy laws like GDPR and CCPA is essential. These regulations, which govern how personal data is collected, processed, and stored, carry substantial penalties for non-compliance. For instance, GDPR fines can reach up to 4% of global annual turnover or €20 million, whichever is greater, as seen in various enforcement actions throughout 2023 and early 2024.

The secure handling, storage, and transmission of this sensitive product and potential consumer data are therefore paramount. Implementing robust cybersecurity measures within their software solutions is not just a technical requirement but a legal imperative. A data breach could expose Ehlebracht AG to significant financial liabilities and severe reputational damage, impacting trust with clients and partners.

Ehlebracht AG operates under stringent product liability laws, ensuring its hardware and consumables meet rigorous safety standards. This means their printing equipment must be demonstrably safe for operational use, minimizing risks for end-users.

Compliance extends to the chemical safety of their inks and labels, adhering to regulations like REACH in Europe, which governs the registration, evaluation, authorization, and restriction of chemicals. For instance, in 2024, regulatory bodies continue to emphasize transparency in chemical composition for industrial consumables.

Furthermore, the durability and accuracy of marking are critical legal factors. Reliable product identification and clear labeling are essential for effective recall procedures, a crucial element in consumer product safety and liability management. In 2024, the EU's General Product Safety Regulation (GPSR) reinforces these requirements, placing greater responsibility on manufacturers for product traceability.

Protecting Ehlebracht AG's intellectual property, such as patents for its unique marking technologies, software algorithms, and ink formulations, is paramount to preserving its competitive edge. This legal framework safeguards their innovations from unauthorized use.

Conversely, Ehlebracht must diligently ensure its products do not infringe upon the existing patents or intellectual property rights of competitors. Legal scrutiny in this domain is essential to avoid costly disputes and maintain market access.

In 2024, the global intellectual property market saw significant activity, with patent filings continuing to rise, underscoring the increasing importance of IP protection for companies like Ehlebracht. For instance, the World Intellectual Property Organization (WIPO) reported a substantial increase in international patent applications, reflecting a growing emphasis on innovation across industries.

Industry-Specific Compliance Standards

Ehlebracht AG operates in sectors with stringent legal frameworks. For instance, the pharmaceutical industry, a key market for Ehlebracht, is governed by regulations like the U.S. Drug Supply Chain Security Act (DSCSA) and the EU Falsified Medicines Directive (EU FMD), both emphasizing product marking and traceability. Failure to comply can lead to significant penalties and market access issues.

These industry-specific compliance standards are not static; they are continually updated to enhance consumer safety and product integrity. Ehlebracht AG's ability to adapt its solutions to meet these evolving mandates, such as new serialization requirements or data exchange protocols, is critical for its continued success. For example, the DSCSA's full implementation phase, requiring interoperable data exchange, is a significant undertaking for supply chain partners.

- Pharmaceuticals: Compliance with DSCSA and EU FMD for serialization and traceability.

- Food & Beverage: Adherence to food safety regulations and country-specific labeling laws.

- Medical Devices: Meeting stringent quality management systems (e.g., ISO 13485) and unique device identification (UDI) mandates.

- Evolving Regulations: Proactive monitoring and adaptation to new or revised legal requirements across all served industries.

Environmental Regulations on Consumables and Waste

Legal frameworks governing industrial consumables, especially inks and solvents, are tightening globally. Ehlebracht AG must navigate evolving regulations concerning Volatile Organic Compound (VOC) emissions, hazardous waste management, and chemical substance restrictions. For instance, the European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation continues to influence chemical sourcing and product formulation, with ongoing reviews of various substances impacting industrial applications. Non-compliance can lead to significant fines and operational disruptions, making proactive adaptation crucial for sustainable business practices.

These environmental laws directly shape Ehlebracht AG's product development pipeline and necessitate rigorous oversight of its supply chain. Stricter limits on VOC emissions, as seen in various regional air quality standards updated through 2024 and projected for 2025, require innovation in low-VOC or VOC-free ink and solvent technologies. Furthermore, the disposal of industrial waste, particularly hazardous materials, is subject to increasingly stringent national and international guidelines, impacting logistics and waste treatment costs. For example, by the end of 2023, many countries had implemented updated hazardous waste tracking and disposal protocols, with further refinements expected in 2024-2025.

- Stricter VOC Emission Limits: Many regions are updating air quality standards, pushing for reduced VOC content in industrial inks and solvents.

- Hazardous Waste Regulations: Enhanced tracking, treatment, and disposal requirements for industrial waste, including chemical byproducts, are in effect.

- Chemical Substance Restrictions: Ongoing reviews and potential bans on specific chemicals under frameworks like REACH impact product formulation and material sourcing.

- Extended Producer Responsibility (EPR): Emerging EPR schemes may place greater onus on manufacturers like Ehlebracht AG for the end-of-life management of their products and packaging.

Ehlebracht AG must navigate a complex web of international and national laws impacting its operations, particularly concerning data privacy and product safety. Regulations like GDPR and CCPA impose strict rules on handling personal data, with potential fines reaching up to 4% of global annual turnover, a significant deterrent for non-compliance as observed in enforcement actions throughout 2023 and early 2024. Product liability laws mandate that Ehlebracht's hardware and consumables meet rigorous safety standards, ensuring user protection. Furthermore, chemical safety regulations, such as Europe's REACH, require transparency in ink and label composition, with continued emphasis on this in 2024.

Intellectual property law is crucial for protecting Ehlebracht's proprietary technologies and algorithms, safeguarding its competitive advantage. The World Intellectual Property Organization (WIPO) reported a substantial increase in international patent applications in 2024, highlighting the growing importance of IP protection. Conversely, Ehlebracht must ensure its products do not infringe on competitors' patents to avoid costly legal battles and maintain market access.

Industry-specific legal requirements, such as the U.S. Drug Supply Chain Security Act (DSCSA) and the EU Falsified Medicines Directive (EU FMD), are critical for Ehlebracht's pharmaceutical clients, with the DSCSA's interoperable data exchange phase presenting a significant compliance challenge. Adapting to evolving mandates, like new serialization requirements, is key to continued success in these regulated sectors.

Environmental laws are increasingly impacting industrial consumables, with tighter regulations on Volatile Organic Compound (VOC) emissions and hazardous waste management. For instance, updated air quality standards through 2024 and projected for 2025 necessitate innovation in low-VOC ink technologies. Stricter hazardous waste disposal protocols, implemented by many countries by the end of 2023, are also affecting logistics and costs, with further refinements expected in 2024-2025.

| Legal Area | Key Regulations/Impacts | 2024/2025 Relevance |

|---|---|---|

| Data Privacy | GDPR, CCPA | Fines up to 4% global turnover; ongoing enforcement actions |

| Product Safety & Liability | General Product Safety Regulation (GPSR) | Reinforced manufacturer responsibility for traceability and safety |

| Chemical Safety | REACH | Continued emphasis on chemical transparency in industrial consumables |

| Intellectual Property | WIPO filings | Increased international patent applications, rising importance of IP protection |

| Industry-Specific Compliance | DSCSA, EU FMD | Critical for pharma clients; DSCSA interoperability phase is a major undertaking |

| Environmental Regulations | VOC limits, Hazardous Waste Management | Stricter emission standards require low-VOC innovation; updated waste protocols in effect |

Environmental factors

Growing environmental awareness and stricter regulations are significantly boosting the market for eco-friendly inks and consumables. Consumers and businesses alike are actively seeking out products with a reduced environmental footprint. This trend is particularly evident in packaging and printing industries, where sustainability is becoming a key purchasing driver.

Ehlebracht AG needs to prioritize research and development to create and supply low-VOC inks, biodegradable labels, and solvent-free cleaning agents. For instance, the global market for sustainable packaging, which includes eco-friendly inks and labels, was projected to reach over $350 billion by 2024, highlighting a substantial opportunity. By investing in these areas, Ehlebracht can meet evolving customer demands and bolster its corporate image as an environmentally responsible company.

Ehlebracht AG faces increasingly stringent regulations concerning industrial waste management and the recycling of electronic equipment, directly influencing its operational costs and product lifecycle strategies. The company must prioritize the recyclability of its hardware and consumables, alongside implementing robust responsible disposal practices.

Compliance with directives like the Waste Electrical and Electronic Equipment (WEEE) is crucial, with global e-waste expected to reach 74.3 million metric tons by 2030, a significant increase from 53.6 million metric tons in 2019. Ehlebracht may need to invest in take-back programs, mirroring industry trends where companies are increasingly held accountable for the end-of-life management of their products.

The energy efficiency of industrial marking systems is a growing concern for manufacturers focused on lowering their environmental impact. Ehlebracht AG has an opportunity to stand out by developing and marketing energy-saving laser markers and inkjet printers.

This focus on reduced energy usage not only benefits the planet but also translates directly into operational cost reductions for Ehlebracht's clientele. For instance, by 2025, the industrial printing market is projected to see a significant increase in demand for sustainable solutions, with energy efficiency being a primary driver.

Supply Chain Sustainability Requirements

Customers and regulators are increasingly demanding greater transparency and sustainability throughout the supply chain. For instance, a 2024 report by McKinsey found that 66% of consumers are willing to pay more for sustainable products, highlighting a significant market driver for supply chain improvements. Ehlebracht AG may face pressure to demonstrate that its own operations and those of its suppliers adhere to environmental best practices.

This includes responsible sourcing of raw materials and minimizing the environmental impact of logistics. According to the European Environment Agency, transportation accounts for approximately 25% of greenhouse gas emissions in the EU, making logistics a key area for sustainability focus. Ehlebracht AG will likely need to implement strategies to reduce its carbon footprint in this sector.

- Growing Consumer Demand: 66% of consumers willing to pay more for sustainable products (McKinsey, 2024).

- Regulatory Scrutiny: Increased focus on environmental compliance across the entire value chain.

- Logistics Impact: Transportation responsible for roughly 25% of EU greenhouse gas emissions (EEA).

- Supplier Accountability: Pressure to ensure upstream partners meet environmental standards.

Corporate Social Responsibility (CSR) Initiatives

Many companies are increasingly prioritizing Corporate Social Responsibility (CSR) initiatives, often embedding ambitious environmental targets within these programs. For instance, a 2024 report indicated that over 60% of large corporations globally have publicly stated net-zero emission goals, a trend likely to accelerate into 2025. Ehlebracht AG can capitalize on this by highlighting how its product designs and operational efficiencies actively contribute to customers' own sustainability objectives, potentially reducing their carbon footprint.

This alignment with customer CSR goals can significantly bolster Ehlebracht AG's brand image. Companies that demonstrate a clear commitment to environmental stewardship are often viewed more favorably by consumers and business partners alike. In fact, a recent survey found that 75% of consumers are more likely to purchase from brands with strong CSR track records, a sentiment that extends to B2B relationships as well.

Leveraging its environmental commitments can translate into tangible market advantages for Ehlebracht AG. By showcasing how its offerings support sustainable supply chains and reduce environmental impact, the company can differentiate itself in a competitive landscape. This strategic positioning can attract new business and strengthen existing partnerships, particularly as regulatory pressures and stakeholder expectations around environmental performance continue to rise through 2024 and into 2025.

- Customer Demand for Sustainability: A 2024 study revealed that 70% of businesses consider supplier sustainability performance a key factor in their procurement decisions.

- Brand Reputation Enhancement: Companies with robust CSR programs saw an average 15% increase in positive brand sentiment in 2023, a trend expected to continue.

- Operational Efficiency Gains: Implementing eco-friendly practices, such as energy reduction, can lead to cost savings; many companies reported a 5-10% reduction in operational costs through such initiatives in 2024.

- Market Differentiation: In sectors like manufacturing, companies with certified green products are experiencing higher demand, with some reporting a 10% sales uplift attributed to their sustainability credentials.

Environmental factors are increasingly shaping market dynamics, with a significant portion of consumers, around 66% according to a 2024 McKinsey report, willing to pay a premium for sustainable products. This growing demand necessitates that companies like Ehlebracht AG focus on eco-friendly solutions, such as low-VOC inks and biodegradable materials, to meet market expectations and enhance their brand image. Furthermore, the environmental impact of logistics, which accounts for roughly 25% of greenhouse gas emissions in the EU according to the European Environment Agency, highlights the need for sustainable supply chain practices and reduced carbon footprints.

| Environmental Factor | Impact on Ehlebracht AG | Data/Statistic |

|---|---|---|

| Consumer Demand for Sustainability | Increased sales for eco-friendly products; Brand image enhancement | 66% of consumers willing to pay more for sustainable products (McKinsey, 2024) |

| Regulatory Compliance (e.g., WEEE) | Higher operational costs; Need for end-of-life product management | Global e-waste projected to reach 74.3 million metric tons by 2030 |

| Energy Efficiency in Products | Competitive advantage; Operational cost savings for clients | Industrial printing market sees growing demand for energy-efficient solutions (projected for 2025) |

| Supply Chain Transparency | Pressure to ensure supplier environmental practices; Logistics optimization | Transportation accounts for ~25% of greenhouse gas emissions in the EU (EEA) |

PESTLE Analysis Data Sources

Our PESTLE analysis is built on a robust foundation of data from reputable sources including government publications, international organizations, and leading market research firms. We synthesize information on political stability, economic indicators, technological advancements, environmental regulations, and societal trends to provide a comprehensive overview.