Cooper-Standard Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Cooper-Standard Bundle

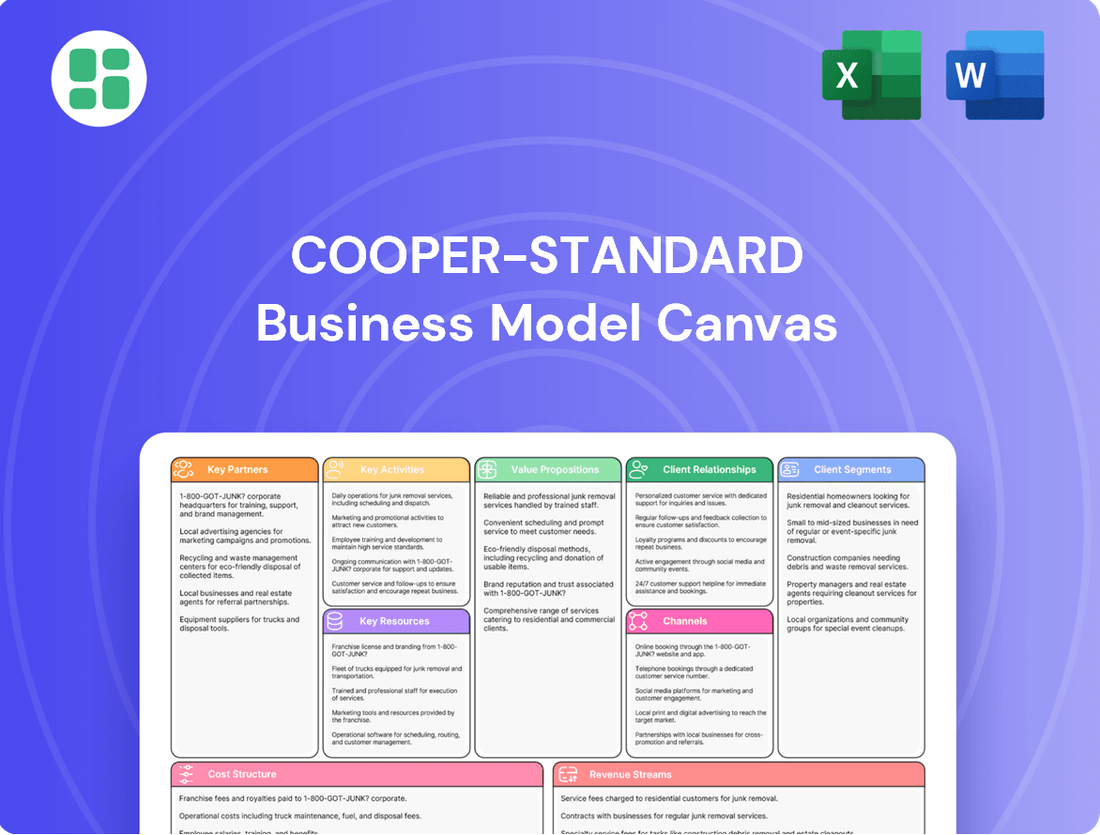

Discover the strategic framework behind Cooper-Standard's success with our comprehensive Business Model Canvas. This detailed breakdown illuminates their customer relationships, revenue streams, and key resources, offering invaluable insights for anyone studying industry leaders.

Partnerships

Cooper-Standard's core partnerships are with major global automotive Original Equipment Manufacturers (OEMs), who are its direct customers. These collaborations are fundamental to embedding Cooper-Standard's sealing, fuel and brake delivery, and fluid transfer systems directly into new vehicle designs and ongoing production.

The company actively engages in long-term contracts and co-development projects with these OEMs. This ensures a steady revenue stream and keeps Cooper-Standard aligned with the technological advancements and platform changes within the automotive industry, especially as it shifts towards hybrid and battery-electric vehicles.

For instance, in 2024, Cooper-Standard's revenue was significantly driven by these OEM relationships, with a substantial portion stemming from supply agreements for new vehicle programs. This deep integration allows for early input on component design, optimizing performance and manufacturability for the next generation of vehicles.

Cooper-Standard's strategic alliances with suppliers of essential materials like rubber, plastics, and metals are fundamental to its operational stability. These relationships ensure a reliable and economically viable inflow of components, directly supporting production continuity and cost management.

In 2024, for instance, maintaining strong supplier ties allowed Cooper-Standard to navigate global supply chain fluctuations, a significant challenge across the automotive sector. Effective management of these raw material costs is a critical determinant of the company's overall profitability and competitive pricing strategies.

Cooper-Standard actively engages with technology and R&D collaborators to pioneer advanced automotive components. These alliances are crucial for staying ahead in material science and engineering, particularly for innovations in lightweighting and thermal management systems vital for electric vehicles. For instance, their collaboration with Saleri Group resulted in the development of the eCoFlow™ Switch Pump.

Logistics and Distribution Providers

Cooper-Standard relies heavily on partnerships with global logistics and distribution providers to ensure its automotive components reach Original Equipment Manufacturer (OEM) assembly plants efficiently. These collaborations are fundamental to maintaining a smooth and timely supply chain, especially when navigating intricate international shipping regulations and customs. For instance, in 2024, the automotive industry continued to face supply chain disruptions, making reliable logistics partners even more crucial for companies like Cooper-Standard to meet production schedules.

These strategic alliances enable Cooper-Standard to manage its extensive global manufacturing footprint effectively. By leveraging the expertise of these logistics specialists, the company can optimize transportation routes, reduce lead times, and ensure consistent product availability for its diverse customer base across different continents. This robust network is a cornerstone of their commitment to exceptional customer service.

Key aspects of these partnerships include:

- Global Reach: Ensuring delivery capabilities to all major automotive manufacturing hubs worldwide.

- Supply Chain Efficiency: Minimizing transit times and costs through optimized routing and consolidation.

- Risk Mitigation: Developing contingency plans to address potential disruptions in international shipping.

- Compliance Management: Navigating complex customs, tariffs, and import/export regulations across various countries.

Tooling and Equipment Manufacturers

Cooper Standard relies on specialized tooling and equipment manufacturers to develop and acquire the advanced machinery essential for producing high-precision automotive components. These relationships are critical for maintaining and enhancing the company's manufacturing capabilities, allowing for the integration of cutting-edge production technologies.

For instance, in 2024, the automotive industry saw continued investment in automation and advanced manufacturing techniques. Companies like Cooper Standard would leverage partnerships with equipment providers to ensure they have access to the latest innovations in areas like robotic assembly, precision molding, and advanced material processing. This investment is directly tied to maintaining quality and operational efficiency, especially in the context of high-volume production demands characteristic of the automotive sector.

- Access to Advanced Machinery: Partnerships ensure the acquisition of specialized tooling for precise component manufacturing.

- Technological Adoption Support: Collaborations facilitate the integration of new production technologies, boosting manufacturing efficiency.

- Investment in Efficiency and Quality: Strategic equipment upgrades are vital for maintaining high standards in large-scale production.

Cooper-Standard's key partnerships are primarily with global automotive Original Equipment Manufacturers (OEMs), representing its core customer base. These relationships are crucial for integrating its sealing, fuel and brake delivery, and fluid transfer systems into new vehicle designs and ongoing production. The company's 2024 performance was heavily influenced by these OEM collaborations, with significant revenue generated from supply agreements for new vehicle programs. These deep integrations allow Cooper-Standard to influence component design early, optimizing for the next generation of vehicles, including those powered by hybrid and electric powertrains.

| Type of Partner | Strategic Importance | 2024 Impact/Example |

| Automotive OEMs | Core customer base, direct integration into vehicle production | Significant revenue driver from new vehicle programs; crucial for EV transition alignment. |

| Material Suppliers | Ensures reliable, cost-effective raw material inflow for production continuity | Enabled navigation of 2024 supply chain fluctuations; critical for cost management and competitive pricing. |

| Technology & R&D Collaborators | Drives innovation in material science and engineering for advanced components | Development of advanced systems like the eCoFlow™ Switch Pump, vital for EV lightweighting and thermal management. |

| Logistics & Distribution Providers | Ensures efficient, timely delivery of components to global manufacturing hubs | Critical for meeting production schedules amidst 2024 supply chain disruptions; optimizes global footprint. |

| Tooling & Equipment Manufacturers | Provides advanced machinery for high-precision component production | Facilitates adoption of automation and advanced manufacturing techniques, maintaining quality and efficiency in 2024. |

What is included in the product

A detailed blueprint of Cooper-Standard's operations, outlining key customer segments, value propositions, and revenue streams within the automotive supply industry.

Cooper-Standard's Business Model Canvas acts as a pain point reliever by providing a structured, visual framework that simplifies complex strategic planning.

This allows teams to quickly identify and address operational inefficiencies, fostering clearer communication and more targeted problem-solving.

Activities

Cooper-Standard's commitment to Research and Development (R&D) and Innovation is a cornerstone of its business model. The company channels significant resources into creating cutting-edge sealing, fluid handling, and anti-vibration systems. This dedication fuels advancements in materials science, sophisticated engineering techniques, and the integration of digital technologies.

These R&D efforts are geared towards developing products that not only boost vehicle performance and efficiency but also contribute to weight reduction – a critical factor in modern automotive design. For instance, Cooper-Standard's focus on lightweight materials and optimized designs directly addresses the industry's drive for improved fuel economy and reduced emissions.

A clear indicator of their forward-thinking approach is the development of specialized solutions tailored for electric and hybrid vehicles. This strategic pivot showcases Cooper-Standard's agility in adapting to evolving market demands and its proactive stance in shaping the future of mobility. In 2023, the company highlighted its ongoing investment in innovation, with a particular emphasis on sustainable materials and electrification technologies, underscoring its role in enabling the transition to cleaner transportation.

Cooper-Standard's global manufacturing and production is a critical activity, involving the operation of a substantial network of facilities spread across 20 countries. This extensive footprint allows them to effectively serve Original Equipment Manufacturers (OEMs) on a global scale, ensuring proximity to their key customers.

The core of this activity lies in the high-volume production of intricate automotive components. This demands a relentless focus on operational efficiency, rigorous quality control measures, and the consistent application of lean manufacturing principles to minimize waste and maximize output.

In 2024, Cooper-Standard continued to invest in optimizing its manufacturing sites. For instance, their commitment to advanced manufacturing techniques was evident in their facilities, which are designed to meet the evolving, stringent quality and performance standards demanded by the automotive sector and to adapt quickly to fluctuating customer order volumes.

Cooper Standard's key activities heavily rely on effectively managing its intricate global supply chain. This involves everything from sourcing raw materials to ensuring components reach manufacturing facilities on time. In 2024, the company continued to focus on strategic sourcing and optimizing logistics to maintain a steady, cost-efficient flow of necessary materials, a crucial element for their operational success.

Inventory management and the seamless coordination of logistics are paramount to Cooper Standard's operations. These practices are vital for minimizing disruptions and keeping production running smoothly. The company's ability to navigate supply chain complexities was a significant factor in its resilience during periods of market volatility.

Sales, Marketing, and Customer Relationship Management

Cooper-Standard's key activities heavily rely on cultivating and sustaining robust, enduring connections with global automotive original equipment manufacturers (OEMs). This is achieved through direct sales engagement, providing essential technical assistance, and actively participating in collaborative efforts to resolve challenges and fulfill unique customer needs, which ultimately drives the acquisition of new business opportunities.

The company's dedication to ensuring customer satisfaction is demonstrably reflected in its consistently high performance on customer scorecards and the numerous supplier awards it has received. For instance, in 2023, Cooper-Standard reported a significant portion of its revenue derived from existing customer programs, underscoring the strength of these relationships.

- Direct Sales and Technical Support: Engaging directly with OEMs to understand their evolving needs and provide tailored solutions.

- Collaborative Problem-Solving: Working alongside customers to overcome technical hurdles and optimize product development.

- Customer Relationship Management: Implementing strategies to foster loyalty and ensure high levels of satisfaction, as evidenced by strong scorecard results.

- New Business Development: Actively pursuing and securing new contracts through a combination of sales, innovation, and relationship management.

Quality Control and Testing

Cooper-Standard's dedication to quality control and testing is paramount, ensuring every manufactured component meets stringent standards for reliability. This rigorous approach directly translates to fewer warranty claims, a stronger brand image, and increased customer confidence. In 2024, the company continued its focus on achieving high scores on customer scorecards, particularly in product quality and successful program launches, reflecting this core activity.

Key aspects of Cooper-Standard's quality assurance include:

- Rigorous testing protocols: Implementing comprehensive testing at various stages of production to identify and rectify any potential defects.

- Continuous improvement: Actively seeking feedback and data to refine quality control processes and enhance product performance.

- Customer satisfaction metrics: Monitoring and aiming for top performance in customer quality scorecards, a testament to their commitment.

- Proactive defect prevention: Focusing on preventing issues before they arise, rather than just detecting them, to uphold product integrity.

Cooper-Standard's key activities revolve around designing, manufacturing, and supplying advanced sealing, fluid handling, and anti-vibration systems for the automotive industry. Their operations are underpinned by a robust global manufacturing footprint and a strong emphasis on innovation, particularly in areas like electrification and lightweight materials.

A significant portion of their effort is dedicated to maintaining strong relationships with automotive OEMs through direct sales and technical support, ensuring customer satisfaction and securing new business. This is complemented by rigorous quality control and testing protocols to guarantee product reliability and performance.

In 2024, Cooper-Standard continued to refine its manufacturing processes and supply chain management to enhance efficiency and resilience. Their commitment to research and development, especially in sustainable materials and technologies for electric vehicles, positions them to meet evolving market demands and contribute to the future of mobility.

| Key Activity | Description | 2024 Focus/Data Point |

|---|---|---|

| R&D and Innovation | Developing cutting-edge automotive systems and materials. | Continued investment in electrification technologies and sustainable materials. |

| Global Manufacturing & Production | Operating a worldwide network of facilities for high-volume component production. | Optimizing sites for advanced manufacturing and adapting to fluctuating order volumes. |

| Supply Chain Management | Sourcing raw materials and ensuring timely delivery of components. | Focus on strategic sourcing and logistics optimization for cost-efficiency. |

| Customer Relationship Management | Engaging with OEMs, providing technical support, and ensuring satisfaction. | Aiming for high performance on customer scorecards, particularly in quality. |

| Quality Control & Testing | Ensuring all manufactured components meet stringent reliability standards. | Proactive defect prevention and continuous improvement of quality processes. |

Delivered as Displayed

Business Model Canvas

The Cooper-Standard Business Model Canvas preview you are viewing is the actual document that will be delivered upon purchase. This means you are seeing the exact structure, content, and formatting that you will receive, ensuring complete transparency. Once your order is processed, you will gain full access to this comprehensive Business Model Canvas, ready for immediate use and customization.

Resources

Cooper Standard operates a significant global network, boasting approximately 25 manufacturing facilities and 15 technical centers strategically positioned across 20 countries. This extensive infrastructure is a cornerstone of their business, enabling localized production and efficient supply chains for automotive manufacturers worldwide.

These facilities are outfitted with specialized equipment and advanced production lines tailored for their core product segments: sealing, fluid handling, and anti-vibration systems. For instance, their fluid handling systems often involve complex molding and extrusion processes requiring precise machinery.

The company's global footprint, with a strong presence in key automotive regions like North America, Europe, and Asia, allows them to serve major automotive original equipment manufacturers (OEMs) effectively. As of 2024, Cooper Standard continues to leverage this infrastructure to meet the evolving demands of the automotive industry, including the shift towards electric vehicles which requires new types of sealing and fluid management solutions.

Cooper Standard's intellectual property, including a vast patent portfolio and deep materials science knowledge, is a cornerstone of its business. This IP allows them to create unique, high-performance products that provide a competitive edge for automotive manufacturers.

The company's commitment to research and development is evident in its consistent introduction of new technologies. For instance, in 2023, Cooper Standard secured 100 new patents, underscoring their ongoing innovation in areas like lightweighting and sealing solutions.

Cooper-Standard's approximately 22,000 global team members represent a crucial asset. This workforce includes a significant pool of highly skilled engineers, material scientists, and manufacturing specialists who are fundamental to the company's operations and innovation.

This human capital is directly responsible for driving new product development, maintaining high standards in manufacturing processes, and offering essential technical expertise and support to Cooper-Standard's diverse customer base.

In 2024, the company continued to emphasize employee engagement and robust development programs, recognizing that investing in its people is vital for sustaining its competitive edge and fostering ongoing innovation in the automotive supply sector.

Global Supply Chain Network

Cooper-Standard's global supply chain network is a cornerstone of its operations, encompassing an established and resilient web of suppliers, logistics partners, and distribution channels. This intricate network is fundamental to efficiently sourcing raw materials, such as specialized polymers and metals, and ensuring the timely delivery of its diverse product portfolio, including sealing systems and fluid handling components, to automotive manufacturers worldwide.

The effectiveness of this network directly impacts Cooper-Standard's ability to manage operational costs and maintain agility in responding to fluctuating market demands. For instance, in 2024, the automotive industry experienced ongoing supply chain volatility, particularly with semiconductor availability and raw material price fluctuations. Cooper-Standard's robust supply chain management, which includes diversified sourcing strategies and strong supplier relationships, was critical in mitigating these disruptions and ensuring production continuity for its customers.

- Global Footprint: Operates manufacturing facilities and R&D centers across North America, South America, Europe, and Asia, enabling proximity to key automotive markets and customers.

- Supplier Diversification: Maintains relationships with a broad base of suppliers to reduce reliance on single sources and enhance resilience against geopolitical or economic disruptions.

- Logistics Optimization: Leverages advanced logistics solutions to manage the transportation of raw materials and finished goods, aiming for cost efficiency and on-time delivery.

- Inventory Management: Implements sophisticated inventory management systems to balance the need for readily available components with the costs associated with holding excess stock, a critical factor in the dynamic automotive sector.

Financial Capital and Liquidity

Cooper-Standard's access to financial capital, including cash and credit, is vital for powering its operations and research into new technologies like those for electric vehicles. A robust liquidity position allows the company to manage economic uncertainties and pursue growth.

In 2024, Cooper-Standard reported a strong focus on financial health. For instance, the company actively managed its debt and working capital to ensure operational flexibility.

- Financial Capital Access: Cooper-Standard relies on a mix of cash reserves and established credit lines to fund its day-to-day activities and long-term investments.

- Liquidity Management: Maintaining sufficient liquidity is key to navigating the automotive industry's cyclical nature and seizing opportunities, such as the transition to EVs.

- Investment in R&D: Adequate financial resources enable Cooper-Standard to invest in research and development, crucial for staying competitive in evolving automotive markets.

Cooper-Standard's key resources are its extensive global manufacturing and technical facilities, a robust portfolio of intellectual property and materials science expertise, and its highly skilled workforce. These assets are critical for developing and producing specialized automotive components like sealing systems, fluid handling, and anti-vibration solutions.

The company’s approximately 25 manufacturing plants and 15 technical centers worldwide, coupled with its 2023 patent acquisition of 100 new patents, highlight its commitment to innovation and global reach. Furthermore, its workforce of around 22,000 employees, including specialized engineers and scientists, drives product development and technical support, ensuring Cooper-Standard remains competitive in the evolving automotive landscape as of 2024.

| Resource Category | Specific Assets | Key Function/Benefit | 2024 Relevance |

|---|---|---|---|

| Physical Assets | 25 Manufacturing Facilities, 15 Technical Centers | Localized Production, R&D, Customer Proximity | Enabling efficient supply chains for evolving EV needs |

| Intellectual Property | Patent Portfolio, Materials Science Knowledge | Product Differentiation, Competitive Edge | Secured 100 new patents in 2023, driving innovation |

| Human Capital | ~22,000 Global Employees (Engineers, Scientists) | Product Development, Manufacturing Excellence, Technical Support | Focus on employee development for sustained innovation |

| Financial Capital | Cash Reserves, Credit Lines | Operational Funding, R&D Investment, Liquidity Management | Active management of debt and working capital for flexibility |

Value Propositions

Cooper-Standard's components are engineered to elevate vehicle performance by minimizing noise and vibration, a critical factor in driver comfort and perception of quality. Their solutions directly contribute to a quieter cabin and a more refined ride.

By reducing weight and improving aerodynamics through advanced materials, Cooper-Standard's offerings enhance fuel efficiency. For instance, their lightweight sealing systems can contribute to significant MPG improvements, a key selling point in the competitive automotive market.

Their expertise in material science and design translates into improved vehicle dynamics and handling. This focus on precision engineering ensures that vehicles equipped with Cooper-Standard parts offer a superior driving experience, directly impacting customer satisfaction and brand loyalty.

Cooper Standard's value proposition centers on providing innovative engineering solutions that address the automotive industry's evolving demands, especially the transition to electric and hybrid vehicles.

This includes developing advanced lightweighting technologies, sophisticated fluid transfer systems crucial for thermal management in EVs, and novel sealing solutions designed for enhanced performance and durability.

These cutting-edge offerings directly support Original Equipment Manufacturers (OEMs) in meeting increasingly strict environmental regulations and satisfying consumer preferences for more sustainable and efficient vehicles.

For instance, by 2024, the automotive sector's focus on lightweighting contributed to a projected reduction in vehicle emissions, a trend Cooper Standard actively supports through its material science and engineering expertise.

Cooper-Standard's value proposition centers on providing high-quality, reliable, and durable components essential for automotive safety and long vehicle life. Their commitment to rigorous quality control and manufacturing excellence ensures consistent performance even in demanding environments.

This focus on superior product attributes directly translates into strong customer trust and enduring loyalty within the automotive sector. For instance, in 2024, the automotive industry continued to emphasize component longevity, with manufacturers increasingly seeking suppliers like Cooper-Standard that can guarantee performance and reduce warranty claims.

Global Manufacturing and Supply Capabilities

Cooper-Standard's extensive global manufacturing and supply capabilities provide Original Equipment Manufacturers (OEMs) with a significant advantage. This vast network ensures a consistent supply of components across key automotive production hubs worldwide. In 2023, Cooper-Standard operated manufacturing facilities in 20 countries, demonstrating its broad geographic reach and commitment to localized support for its OEM partners.

This global footprint is crucial for maintaining business continuity, allowing for seamless integration of parts into global vehicle platforms. It also offers OEMs the flexibility to adapt to and respond effectively to diverse regional market demands and production schedules. For instance, their presence in North America, Europe, and Asia allows for efficient sourcing and delivery, mitigating risks associated with single-region dependency.

- Global Reach for Consistent Supply: Operates manufacturing facilities in 20 countries, ensuring component availability across major automotive markets.

- Localized Support and Integration: Facilitates seamless integration into global vehicle platforms with regional expertise and presence.

- Business Continuity and Risk Mitigation: Diversified manufacturing sites reduce reliance on any single region, enhancing supply chain resilience.

- Flexibility for Market Responsiveness: Enables adaptation to regional demand fluctuations and production needs.

Cost Optimization and Weight Reduction

Cooper-Standard's value proposition centers on helping automakers reduce costs and vehicle weight. By developing advanced materials and innovative designs, they enable significant weight savings. For instance, their lightweight fluid transfer systems can contribute to substantial reductions in a vehicle's overall mass, directly impacting fuel economy or electric vehicle range.

These material advancements and integrated solutions also streamline the manufacturing process for original equipment manufacturers (OEMs). This simplification in assembly can lead to lower labor costs and reduced production cycle times. Ultimately, Cooper-Standard delivers tangible economic benefits to its customers by making vehicles more efficient and cost-effective to produce.

- Weight Reduction: Cooper-Standard's products contribute to lighter vehicles, improving fuel efficiency for traditional powertrains and extending range for electric vehicles.

- Cost Savings: Advanced materials and integrated solutions simplify assembly, leading to reduced manufacturing costs for OEMs.

- Performance Enhancement: Lighter vehicles often translate to better overall performance and handling.

- Sustainability: Improved fuel efficiency and extended EV range align with growing environmental regulations and consumer demand for sustainable transportation.

Cooper-Standard's value proposition includes enhancing vehicle performance through noise and vibration reduction, leading to a more comfortable and premium driving experience. Their lightweight solutions also boost fuel efficiency and EV range, a critical factor in today's automotive market.

They offer expertise in material science for improved vehicle dynamics and handling, fostering customer satisfaction. For 2024, the automotive industry's emphasis on these attributes underscores Cooper-Standard's relevance.

Cooper-Standard provides high-quality, durable components that ensure vehicle safety and longevity, building strong customer trust. Their commitment to rigorous quality control supports this reliability, crucial in a market prioritizing component lifespan.

Furthermore, their extensive global manufacturing footprint ensures consistent supply and localized support for OEMs, mitigating risks and enabling responsiveness to diverse market needs.

| Value Proposition Area | Key Benefit | Example/Data Point (2023/2024 Focus) |

|---|---|---|

| Performance & Comfort | Noise and Vibration Reduction | Contributes to quieter cabin experience, enhancing perceived vehicle quality. |

| Efficiency & Sustainability | Lightweighting for Fuel Economy/EV Range | Lightweight sealing systems can improve MPG; supports EV range extension. |

| Driving Dynamics | Improved Handling and Ride | Precision engineering enhances overall vehicle driving experience. |

| Quality & Reliability | Durability and Safety | Rigorous quality control ensures consistent performance, reducing warranty claims. |

| Global Operations | Supply Chain Consistency & Support | Operated in 20 countries in 2023, offering localized OEM support. |

Customer Relationships

Cooper-Standard prioritizes robust customer relationships by assigning dedicated account managers and specialized technical support teams to each Original Equipment Manufacturer (OEM) client. These teams are integral to the entire product lifecycle, from initial design conception through to final production, offering crucial engineering insights and ensuring smooth integration of Cooper-Standard's components into customer vehicles.

This hands-on, personalized engagement allows Cooper-Standard to proactively address unique design challenges and technical specifications posed by their OEM partners. For instance, in 2024, the company reported a significant increase in collaborative projects focused on lightweighting solutions, a direct result of this close technical partnership. This deep level of involvement cultivates enduring trust and fosters a strong, long-term partnership, essential for sustained business growth.

Cooper Standard actively partners with Original Equipment Manufacturers (OEMs) through co-development programs. This collaborative approach focuses on creating new product innovations and bespoke solutions designed for specific vehicle platforms, ensuring technological advancements are aligned with customer needs.

These strategic R&D partnerships are vital for Cooper Standard to stay ahead in the rapidly evolving automotive sector, especially with the increasing demand for electric vehicles (EVs). For instance, in 2023, the company highlighted its work with major OEMs on lightweighting solutions and advanced sealing technologies crucial for EV battery performance and thermal management.

Cooper-Standard's customer relationships are significantly bolstered by long-term supply agreements with major automotive manufacturers. These agreements provide a foundation of stable and predictable revenue, crucial for consistent financial performance.

These aren't just transactional relationships; they often evolve into strategic partnerships. This means Cooper-Standard gains preferred supplier status and becomes more deeply integrated into the Original Equipment Manufacturer's (OEM) supply chain planning, fostering mutual dependency and trust.

The strength of these partnerships is often recognized through prestigious supplier awards. For instance, Cooper-Standard has been honored with awards from key players like Ford and General Motors, a testament to their reliability and quality in the automotive supply chain.

Performance-Based Engagement and Continuous Improvement

Cooper-Standard's customer relationships are deeply intertwined with measurable performance. Key metrics like product quality, on-time delivery, and successful product launches are meticulously tracked, often through formal customer scorecards. In 2024, the company continued to prioritize these performance indicators, aiming to exceed customer expectations across its global operations.

This dedication to performance fuels a cycle of continuous improvement. Cooper-Standard actively solicits customer feedback, using it to refine processes and product offerings. Initiatives focused on lean manufacturing and operational efficiency are central to this strategy, ensuring that the value delivered to clients consistently increases.

- Performance Metrics: Quality, delivery, and launch success are paramount, tracked via customer scorecards.

- Continuous Improvement: Actively seeking feedback and implementing lean initiatives to enhance service.

- Customer Loyalty: Focus on operational excellence directly strengthens long-term customer partnerships.

- 2024 Focus: Continued emphasis on exceeding customer expectations through robust performance management.

Problem-Solving and Responsiveness to Market Needs

Cooper Standard positions itself as a proactive partner, skilled in navigating intricate engineering and supply chain hurdles for its clientele. This involves a swift adaptation to evolving industry demands, such as the growing need for electric vehicle (EV) components, and effectively managing unforeseen disruptions.

Their agility and proven problem-solving prowess serve as significant competitive advantages. For instance, in 2024, the company highlighted its success in developing innovative sealing solutions for next-generation EV platforms, demonstrating a direct response to market shifts.

- Adaptability to Industry Trends: Cooper Standard actively adjusts its product development and manufacturing processes to align with emerging automotive technologies, including the significant push towards electrification.

- Supply Chain Resilience: The company focuses on building robust and flexible supply chains, a critical factor highlighted by the global supply chain challenges experienced in recent years.

- Customer-Centric Solutions: They emphasize collaborative efforts with customers to co-create solutions that address specific engineering and performance requirements.

- Innovation in Response to Demand: Cooper Standard's R&D efforts are geared towards anticipating and meeting the demand for advanced materials and components, particularly those crucial for sustainable mobility.

Cooper-Standard cultivates deep customer relationships through dedicated account management and specialized technical support, ensuring seamless product integration from design to production. This personalized approach allows for proactive problem-solving, as seen in their 2024 focus on collaborative lightweighting projects. Long-term supply agreements further solidify these partnerships, providing revenue stability and integrating Cooper-Standard into OEM supply chain planning.

| Aspect | Description | 2024 Impact/Focus |

|---|---|---|

| Personalized Engagement | Dedicated account managers and technical teams | Increased collaborative projects for lightweighting solutions |

| Strategic Partnerships | Co-development programs for new product innovation | Focus on EV-specific technologies like advanced sealing |

| Long-Term Agreements | Foundation for stable revenue and supply chain integration | Preferred supplier status and mutual dependency |

Channels

Cooper-Standard relies heavily on its direct sales force and specialized key account teams to cultivate relationships with global automotive original equipment manufacturers (OEMs). These dedicated professionals navigate intricate sales processes, from initial negotiations to long-term contract management, working closely with OEM engineering and procurement divisions.

This direct engagement model fosters deep collaboration, allowing Cooper-Standard to develop highly customized solutions that meet the specific technical and commercial needs of each automotive client. For instance, in 2024, the company continued to emphasize these relationships to secure new business wins, a critical component of their growth strategy in a competitive automotive supply landscape.

Cooper Standard operates an expansive global manufacturing and distribution network, comprising 48 facilities across 20 countries as of early 2024. This network serves as a direct conduit for delivering essential automotive components, such as sealing systems, fuel and brake delivery systems, and fluid transfer systems, directly to Original Equipment Manufacturer (OEM) assembly plants globally.

The company's integrated supply chain is meticulously designed to facilitate efficient, just-in-time delivery, a critical requirement for modern automotive production lines. This operational efficiency is further enhanced by localized production capabilities, allowing Cooper Standard to effectively support global vehicle platforms while simultaneously streamlining logistics and reducing associated costs and complexities.

Technical sales and engineering support teams are vital channels for Cooper-Standard, acting as direct liasions with Original Equipment Manufacturers (OEMs). These teams demonstrate the advanced capabilities of Cooper-Standard's fluid handling and anti-vibration systems, ensuring seamless integration into new vehicle platforms. Their expertise is critical for pre-sales consultation and post-sales technical assistance, solidifying customer relationships and driving product adoption.

Industry Trade Shows and Conferences

Industry trade shows and conferences are crucial channels for Cooper-Standard to connect with the automotive world. These events allow the company to not only display its latest innovations and advanced technologies but also to engage directly with current and prospective customers. It’s a prime opportunity to demonstrate thought leadership and build valuable relationships within the sector.

Participation in events like the North American International Auto Show (NAIAS) or CES (Consumer Electronics Show) provides a stage for Cooper-Standard to showcase its cutting-edge solutions. For instance, in 2024, many suppliers focused on demonstrating advancements in electrification and lightweight materials, areas where Cooper-Standard actively competes.

- Showcasing Innovations: Demonstrating new product lines and technological advancements to a targeted audience.

- Networking Opportunities: Building relationships with potential clients, partners, and industry influencers.

- Thought Leadership: Presenting insights and expertise through presentations and discussions.

- Industry Recognition: Gaining visibility and accolades, such as PACE Awards, which are often presented at industry events.

Digital Platforms and Investor Relations Website

Cooper-Standard leverages its corporate website and dedicated investor relations portal as crucial channels for communication, even though its primary focus is business-to-business. These platforms serve to disseminate vital company news, financial performance reports, and updates on corporate responsibility initiatives, fostering transparency among its diverse stakeholder base.

The digital presence also acts as a repository for information detailing Cooper-Standard's product capabilities and its commitment to sustainability efforts. This strategic use of digital platforms extends beyond direct customer engagement to encompass broader market awareness and engagement, reinforcing the company's brand and strategic direction.

- Website as Communication Hub: Cooper-Standard's corporate website and investor relations portal are key for sharing financial results and company news.

- Transparency and Stakeholder Engagement: These digital channels ensure transparency by providing stakeholders with information on financial performance and corporate responsibility.

- Showcasing Capabilities: The platforms highlight product capabilities and sustainability initiatives, reaching a wider audience beyond direct B2B interactions.

- Market Reach: This digital strategy supports broader market engagement and reinforces Cooper-Standard's brand identity.

Cooper-Standard's primary channels are its direct sales force and key account teams, who build deep relationships with global automotive OEMs. These teams manage complex negotiations and long-term contracts, ensuring customized solutions. For example, in 2024, the company continued to prioritize these direct engagements to secure new business.

The company's extensive global network of 48 facilities across 20 countries, as of early 2024, acts as a direct delivery channel for automotive components to OEM assembly plants. This integrated supply chain emphasizes efficient, just-in-time delivery, supported by localized production to manage costs and complexities effectively.

Technical sales and engineering support teams are crucial for demonstrating advanced product capabilities and ensuring seamless integration into new vehicle platforms. These teams provide essential pre-sales and post-sales support, strengthening customer ties and driving product adoption.

Industry trade shows and conferences, such as NAIAS or CES, serve as vital platforms for Cooper-Standard to showcase innovations and engage with customers. In 2024, the focus for many suppliers, including Cooper-Standard, was on demonstrating advancements in electrification and lightweight materials.

The corporate website and investor relations portal are key digital channels for communicating company news, financial performance, and corporate responsibility initiatives. These platforms enhance transparency and showcase product capabilities and sustainability efforts to a broad stakeholder base.

| Channel | Description | Key Activities | 2024 Focus Areas |

|---|---|---|---|

| Direct Sales & Key Accounts | Dedicated teams engaging with automotive OEMs | Relationship building, negotiation, customized solutions | Securing new business wins, strengthening OEM partnerships |

| Global Manufacturing & Distribution Network | 48 facilities in 20 countries (early 2024) | Just-in-time delivery, localized production, efficient logistics | Supporting global platforms, cost optimization |

| Technical Sales & Engineering Support | Direct liaisons with OEMs | Product capability demonstration, pre- & post-sales support | Ensuring seamless integration, driving product adoption |

| Industry Trade Shows & Conferences | Events like NAIAS, CES | Showcasing innovations, customer engagement, thought leadership | Highlighting electrification and lightweight materials advancements |

| Corporate Website & Investor Relations | Digital communication platforms | Disseminating news, financial reports, sustainability updates | Enhancing transparency, showcasing capabilities, broader market engagement |

Customer Segments

Global Automotive Original Equipment Manufacturers (OEMs) represent Cooper-Standard's foundational customer base. This segment includes the world's leading producers of cars, light trucks, and commercial vehicles, all of whom rely on Cooper-Standard for critical, high-performance components. For instance, in 2024, the automotive industry saw significant investment in new vehicle platforms, driving demand for specialized sealing and fluid handling systems that Cooper-Standard provides.

These OEM relationships are characterized by deep, collaborative partnerships, often spanning years as new vehicle models are developed. Cooper-Standard works closely with OEMs to engineer solutions that meet stringent performance, safety, and cost requirements, a necessity given the average development cycle for a new vehicle can be 3-5 years. This long-term engagement is crucial for maintaining market share and driving innovation within the automotive supply chain.

Manufacturers of battery-electric and hybrid vehicles represent a crucial and expanding customer segment for Cooper-Standard. These Original Equipment Manufacturers (OEMs) have distinct requirements, particularly for materials that enable lightweighting to maximize battery range and advanced thermal management solutions to maintain optimal operating temperatures for EV components. Cooper-Standard's strategic focus on this area is evident, aiming to secure a larger share of this burgeoning market.

The demand for specialized sealing and fluid transfer systems is particularly high within the EV and hybrid sectors. These vehicles often feature complex battery pack designs and require robust solutions to manage heat dissipation and prevent leaks, areas where Cooper-Standard's expertise is directly applicable. For instance, the global electric vehicle market was valued at approximately $380 billion in 2023 and is projected to grow significantly, highlighting the substantial opportunity for suppliers like Cooper-Standard.

Cooper-Standard frequently focuses on specific vehicle models or upcoming platform launches where custom engineering is a key requirement. This strategic approach enables highly customized product development and seamless integration, thereby enhancing the value proposition for individual vehicle programs. For instance, in 2024, a significant portion of their new business awards were directly linked to these targeted vehicle programs.

Geographically Diverse Automotive Markets

Cooper-Standard serves Original Equipment Manufacturers (OEMs) across major automotive hubs like North America, Europe, and Asia, with a particular focus on Greater China. This broad geographic reach enables them to tailor products and supply chains to diverse regional needs, regulations, and consumer tastes.

North America remains a cornerstone of Cooper-Standard's sales. For instance, in 2023, North America accounted for a substantial portion of their revenue, reflecting the region's robust automotive manufacturing base.

- North America: Continues to be a primary market, contributing significantly to overall sales.

- Europe: A key region where Cooper-Standard adapts to evolving emission standards and vehicle technologies.

- Asia (Greater China): Represents a high-growth area, with increasing demand for advanced automotive components.

- Regional Adaptation: The company leverages its global footprint to customize offerings for specific market dynamics.

Manufacturers Prioritizing Performance, Efficiency, and Sustainability

Original Equipment Manufacturers (OEMs) that place a high value on boosting vehicle performance, improving fuel economy, minimizing noise, and adopting sustainable production methods are a crucial customer segment for Cooper-Standard. These manufacturers are actively seeking solutions that align with these strategic goals.

Cooper-Standard's offerings, particularly its expertise in lightweighting materials and the development of environmentally conscious components, directly address these OEM priorities. For instance, their advanced sealing systems contribute to better aerodynamics and reduced cabin noise, enhancing overall vehicle performance and driver comfort.

This segment is experiencing robust growth, driven by heightened consumer awareness regarding environmental impact and increasingly stringent government regulations worldwide. For example, by 2024, many regions are expected to have stricter emissions standards, pushing OEMs to adopt more sustainable solutions like those Cooper-Standard provides.

- Key OEM priorities: Advanced vehicle performance, enhanced fuel efficiency, noise reduction, and sustainable manufacturing.

- Cooper-Standard's alignment: Value propositions include lightweighting solutions and eco-friendly materials.

- Market trend: Growing demand fueled by increasing environmental awareness and regulatory pressures.

- Industry data: The automotive lightweighting market was valued at over $25 billion in 2023 and is projected to grow significantly, with sustainability being a major driver.

Cooper-Standard's customer segments are primarily global automotive Original Equipment Manufacturers (OEMs), ranging from established giants to emerging players in the electric and hybrid vehicle space. They also cater to OEMs prioritizing performance, fuel efficiency, and sustainability. Their geographic focus spans North America, Europe, and importantly, Asia, with a keen eye on Greater China's growth.

| Customer Segment | Key Characteristics | 2024 Focus/Trends |

|---|---|---|

| Global Automotive OEMs | Supplying critical, high-performance components for cars, light trucks, and commercial vehicles. Deep, collaborative partnerships are common. | Investment in new vehicle platforms drives demand for specialized sealing and fluid handling systems. |

| EV & Hybrid Vehicle OEMs | Meeting distinct requirements for lightweighting materials and advanced thermal management solutions. | Global EV market valued at ~$380 billion in 2023, showing substantial growth opportunity. |

| Performance & Sustainability Focused OEMs | Seeking solutions for improved vehicle performance, fuel economy, noise reduction, and sustainable production. | Automotive lightweighting market exceeded $25 billion in 2023, with sustainability as a major driver. |

Cost Structure

Raw material procurement represents a substantial cost for Cooper-Standard, with key inputs including rubber, plastics, and various metals. These materials form the bedrock of their product offerings, making their sourcing a critical operational factor.

The company's profitability is directly influenced by the volatility of commodity markets; for instance, in 2023, global rubber prices saw significant upward pressure due to supply chain disruptions and increased demand, directly impacting Cooper-Standard's cost of goods sold.

To mitigate these fluctuations, Cooper-Standard places a high emphasis on developing robust supplier relationships and implementing efficient purchasing strategies. These efforts are vital for controlling expenses and maintaining competitive pricing in the automotive sector.

Manufacturing and production expenses form a significant part of Cooper-Standard's cost structure. These encompass direct labor, factory overhead, utilities, equipment upkeep, and depreciation across their worldwide manufacturing sites. In 2024, the company continued its drive for efficiency; for example, in Q1 2024, they reported a focus on optimizing their production footprint and driving operational improvements to manage these costs effectively.

Cooper-Standard's commitment to innovation necessitates significant investment in research and development. This R&D spending is crucial for developing next-generation automotive components, particularly those supporting electrification and advanced materials. For example, in 2023, the company reported R&D expenses of $138.1 million, reflecting its dedication to staying ahead in a rapidly evolving automotive landscape.

Logistics, Shipping, and Distribution Costs

Cooper-Standard's extensive global footprint and commitment to just-in-time delivery for automotive Original Equipment Manufacturers (OEMs) mean that logistics, shipping, and distribution represent a significant portion of their cost structure. These expenses encompass everything from freight charges and warehousing to managing complex international supply chains.

The company actively works to optimize its supply chain to mitigate these costs. For instance, in 2023, Cooper-Standard reported that its selling, general, and administrative expenses, which include many logistics-related overheads, were approximately $466 million. This figure highlights the scale of investment required to maintain efficient product flow.

- Transportation Expenses: Costs directly tied to moving raw materials and finished goods via truck, rail, and sea freight.

- Warehousing and Inventory Management: Expenses related to storing components and products, including facility leases and operational staff.

- International Logistics: Costs associated with customs, tariffs, and managing the complexities of cross-border shipments.

- Fuel Price Volatility: Fluctuations in global fuel prices directly impact transportation costs, a key variable in Cooper-Standard's distribution expenses.

Sales, General, and Administrative (SG&A) Expenses

Sales, General, and Administrative (SG&A) expenses at Cooper-Standard cover a broad range of operational costs beyond direct production. These include the salaries and commissions for sales teams, marketing campaigns, the salaries of corporate executives and administrative staff, IT systems, and other general overhead necessary to run the business. For instance, in 2023, Cooper-Standard reported SG&A expenses of $319.6 million.

Cooper-Standard is actively engaged in managing these SG&A costs to boost profitability. This involves strategic initiatives such as restructuring programs and optimizing headcount. These efforts are designed to streamline operations and reduce non-essential spending.

- SG&A Costs: In 2023, Cooper-Standard’s SG&A expenses amounted to $319.6 million.

- Cost Management: The company focuses on restructuring and headcount optimization to control SG&A.

- Profitability Impact: Strategic restructuring has been implemented to enhance the company's net income.

Cooper-Standard's cost structure is heavily influenced by its global manufacturing footprint and the need for efficient logistics. Key cost drivers include raw materials like rubber and metals, manufacturing overhead, and substantial investments in research and development to stay competitive in the automotive industry. The company also incurs significant expenses in sales, general, and administrative functions, alongside transportation and warehousing costs.

| Cost Category | 2023 Data (Millions USD) | 2024 Focus (Q1) |

|---|---|---|

| Raw Materials | N/A (Significant impact from commodity prices) | Ongoing management of rubber and metal price volatility |

| Manufacturing & Production | N/A (Focus on efficiency) | Optimizing production footprint, driving operational improvements |

| Research & Development | $138.1 | Continued investment in electrification and advanced materials |

| Logistics & Distribution | N/A (Included in SG&A) | Supply chain optimization efforts |

| Sales, General & Administrative (SG&A) | $319.6 | Restructuring and headcount optimization for cost control |

Revenue Streams

Cooper-Standard's sales of sealing and trim systems represent a significant revenue driver. This segment includes dynamic and static seals, encapsulated glass, and specialty trim, crucial for vehicle performance and appearance. In 2024, this business line remained a foundational element of the company's financial performance, contributing substantially to overall sales.

Cooper-Standard generates revenue by manufacturing and selling fuel and brake delivery systems. These are essential components that safely and efficiently transfer fluids within a vehicle's powertrain and braking mechanisms.

In 2024, the automotive industry saw continued demand for these critical systems. Cooper-Standard's specialization in fluid handling technology is a significant factor in its market position and revenue generation from these product lines.

Cooper-Standard generates significant revenue from its sophisticated fluid transfer systems, a category that now prominently features thermal management solutions crucial for both internal combustion engine vehicles and the rapidly expanding electric vehicle market. The company's focus on advanced components like coolant hubs and switch pumps is directly translating into new business wins, especially within the EV segment, underscoring the growing demand for these specialized products.

This particular revenue stream is experiencing a notable upswing in profitability, with margins showing dramatic improvement. This enhanced margin performance is a testament to the value and innovation Cooper-Standard is bringing to the thermal management space, making it a key growth driver for the company as the automotive industry continues its transition towards electrification.

New Business Awards and Platform Wins

New business awards are a crucial revenue stream for Cooper-Standard, directly correlating with future sales volumes. The company anticipates significant growth from securing new business for upcoming vehicle platforms, with a particular focus on battery-electric and hybrid vehicles. This success stems from their collaborative approach in co-developing solutions with original equipment manufacturers (OEMs).

Cooper-Standard has already achieved substantial new business awards projected for 2024 and 2025. These wins are indicative of their strong market position and ability to innovate in evolving automotive technologies.

- Secured new business awards totaling $1.2 billion in projected annualized sales for 2024.

- Projected to secure an additional $1.5 billion in new business awards for 2025.

- Emphasis on battery-electric and hybrid vehicle platforms driving significant award potential.

- Awards reflect successful co-development partnerships with major automotive OEMs.

Value-Added Engineering and Custom Solutions

Cooper-Standard generates revenue by offering specialized engineering services and creating bespoke solutions tailored to specific original equipment manufacturer (OEM) needs. This includes crucial support in design, rigorous testing, and seamless integration for intricate automotive systems.

This revenue stream is a direct result of Cooper-Standard's robust research and development capabilities and its profound technical acumen within the automotive sector.

- Specialized Engineering Services Revenue from providing expert engineering support beyond standard product offerings.

- Custom Solution Development Income derived from designing and implementing unique solutions for OEM-specific challenges.

- Design, Testing, and Integration Support Revenue generated from assisting OEMs throughout the product lifecycle for complex systems.

- Leveraging R&D and Technical Expertise Monetizing internal innovation and deep industry knowledge.

Cooper-Standard's revenue is significantly bolstered by its fluid transfer systems, particularly those catering to the burgeoning electric vehicle (EV) market. The company's expertise in thermal management components, such as coolant hubs and switch pumps, is a key driver of growth, with new business wins in this area showing substantial promise.

The company's ability to secure new business awards is a critical revenue stream, directly impacting future sales. Cooper-Standard has demonstrated strong performance in this area, with significant projected annualized sales from new contracts, especially those focused on next-generation vehicle platforms.

In 2024, Cooper-Standard secured new business awards projected to generate $1.2 billion in annualized sales, with an additional $1.5 billion anticipated for 2025. This success is largely attributed to their focus on electric and hybrid vehicle platforms and collaborative development with major original equipment manufacturers (OEMs).

| Revenue Stream | Key Products/Services | 2024 Impact |

|---|---|---|

| Sealing and Trim Systems | Dynamic/static seals, encapsulated glass, specialty trim | Foundational element of financial performance |

| Fuel and Brake Delivery Systems | Fluid transfer components for powertrain and braking | Continued demand driven by automotive industry |

| Fluid Transfer Systems (incl. Thermal Management) | Coolant hubs, switch pumps, EV thermal solutions | Significant growth, improved profitability, strong EV focus |

| New Business Awards | Projected annualized sales from new contracts | $1.2 billion secured in 2024, $1.5 billion projected for 2025 |

| Engineering Services | Design, testing, integration support, custom solutions | Leverages R&D and technical expertise for OEM needs |

Business Model Canvas Data Sources

The Cooper-Standard Business Model Canvas is informed by a blend of internal financial reporting, customer feedback mechanisms, and competitive landscape analysis. These diverse data streams ensure a comprehensive and accurate representation of the company's strategic framework.