Columbus McKinnon Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Columbus McKinnon Bundle

Uncover the strategic framework that powers Columbus McKinnon's success with our comprehensive Business Model Canvas. This detailed analysis breaks down their customer relationships, revenue streams, and key resources, offering a clear roadmap for understanding their competitive advantage. Download the full canvas to gain actionable insights for your own business strategy.

Partnerships

Columbus McKinnon strategically leverages acquisitions to enhance its market presence, diversify its product portfolio, and integrate advanced technologies. This approach has been a cornerstone of its growth strategy, allowing it to enter new segments and strengthen existing ones.

Notable recent acquisitions include Dorner, a leader in conveyor technology, and montratec, a provider of automated guided vehicle systems, both contributing to expanded capabilities. The pending acquisition of Kito Crosby Limited, a significant move, is expected to substantially increase Columbus McKinnon's global scale and unlock considerable operating synergies, further solidifying its position in the lifting and material handling industry.

Columbus McKinnon actively pursues technology collaborations to enhance its product offerings. A prime example is their partnership with Milwaukee Tool to develop a battery-powered chain hoist, integrating cutting-edge power technology into their lifting solutions.

These strategic alliances are vital for Columbus McKinnon to embed advanced technologies, driving innovation across their intelligent motion solutions. This focus on collaboration helps them maintain a competitive edge in a rapidly evolving market.

Columbus McKinnon leverages a vast global distribution network, a cornerstone of its business model, to effectively market and sell its extensive range of lifting and material handling products. This network is crucial for penetrating diverse industrial and commercial sectors across the globe.

These key partnerships are vital for reaching end-users in various markets, ensuring that Columbus McKinnon's products are accessible and supported locally. For instance, in 2023, the company continued to strengthen its relationships with distributors to enhance market penetration and customer service.

A well-established distribution infrastructure guarantees the efficient delivery of goods and provides essential local technical support, which is paramount for customer satisfaction and retention in the industrial equipment sector.

Key Suppliers and Manufacturers

Columbus McKinnon relies on a robust network of key suppliers to ensure a consistent flow of essential raw materials and components. These partnerships are fundamental to maintaining production efficiency and product quality across its diverse range of lifting and material handling solutions.

The company actively collaborates with manufacturing partners, particularly as it optimizes its global production footprint. A prime example is the strategic ramp-up of its Monterrey, Mexico facility, which aims to enhance manufacturing capabilities and supply chain agility.

- Key Supplier Relationships: Essential for securing critical raw materials like steel and specialized components, ensuring uninterrupted manufacturing.

- Manufacturing Partnerships: Strategic alliances that support production scaling and operational efficiency.

- Facility Consolidation: Working with partners to streamline production, exemplified by the expansion of the Monterrey, Mexico plant.

- Supply Chain Resilience: Building strong supplier and manufacturing relationships to mitigate risks and ensure reliable product delivery.

Industry Associations and Standards Bodies

Columbus McKinnon actively engages with industry associations and adheres to recognized standards, which is crucial for building market credibility and exerting influence. These collaborations are instrumental in shaping industry best practices and ensuring that CM's lifting and material handling solutions consistently meet stringent performance and safety benchmarks.

This commitment to industry standards directly supports Columbus McKinnon's strategic focus on commercial and industrial sectors, where superior design, robust engineering, and unwavering reliability are paramount. For instance, participation in organizations like the Association for Materials Handling Manufacturers (AMH) allows for direct input into standards development that impact product specifications and market access.

- Industry Standards Adherence: Ensures products meet rigorous safety and performance requirements, vital for commercial and industrial clients.

- Market Credibility: Active participation in associations like the Association for Materials Handling Manufacturers (AMH) enhances brand reputation and trust.

- Influence on Best Practices: Partnerships help shape industry standards, aligning CM's offerings with evolving market needs and regulatory landscapes.

- Product Development Alignment: Participation informs product design and engineering, ensuring solutions are optimized for demanding applications.

Columbus McKinnon's key partnerships are a mix of strategic acquisitions, technology collaborations, and robust distribution networks. Acquisitions like Dorner and montratec, along with the pending Kito Crosby deal, significantly expand their market reach and technological capabilities. Collaborations, such as the one with Milwaukee Tool for battery-powered hoists, drive innovation in intelligent motion solutions. These alliances are crucial for integrating advanced technologies and maintaining a competitive edge.

The company's extensive global distribution network is fundamental to reaching end-users and providing local support, ensuring product accessibility and customer satisfaction. Furthermore, strong supplier relationships are vital for securing raw materials and components, underpinning production efficiency and quality. Strategic manufacturing partnerships, like the ramp-up of the Monterrey, Mexico facility, enhance production capabilities and supply chain agility.

Columbus McKinnon also actively engages with industry associations, such as the Association for Materials Handling Manufacturers (AMH), to uphold market credibility and influence industry best practices. This commitment ensures their lifting and material handling solutions meet stringent safety and performance benchmarks, crucial for their commercial and industrial clientele.

| Partnership Type | Example | Impact | 2024 Data/Trend |

|---|---|---|---|

| Acquisitions | Dorner, montratec, Kito Crosby (pending) | Market expansion, technology integration, global scale | Kito Crosby acquisition expected to close in 2024, significantly boosting revenue and synergies. |

| Technology Collaboration | Milwaukee Tool | Innovation in battery-powered solutions | Continued development of integrated smart lifting technologies. |

| Distribution Network | Global distributors | Market penetration, customer access, local support | Strengthening distributor relationships for enhanced market reach and service. |

| Supplier Relationships | Key material and component suppliers | Production efficiency, product quality, supply chain resilience | Focus on diversifying suppliers to mitigate risks and ensure consistent material flow. |

| Industry Associations | AMH | Market credibility, standards adherence, best practices | Active participation in shaping safety and performance standards for material handling. |

What is included in the product

Columbus McKinnon's business model focuses on providing essential lifting and material handling solutions to industrial and commercial customers, leveraging a robust distribution network and a commitment to product innovation.

Columbus McKinnon's Business Model Canvas provides a clear framework to identify and address inefficiencies in their supply chain and product development, thereby reducing operational friction.

Activities

Columbus McKinnon's core activity revolves around the meticulous design and engineering of intelligent motion solutions. This encompasses a range of products like hoists, cranes, actuators, and precision conveyor systems, all crafted to boost productivity and safety in material handling.

Their engineering prowess is fundamental to delivering value, ensuring their products meet the demanding requirements of diverse industrial applications. This focus on superior design and engineering is a key differentiator in the market.

For instance, in 2024, Columbus McKinnon continued to invest in R&D to enhance the intelligence and efficiency of their offerings. Their commitment to innovation in product design is directly linked to their ability to command premium pricing and maintain a competitive edge.

Columbus McKinnon's manufacturing and production activities are centered around its global network of facilities, with a strong emphasis on operational efficiency. The company is actively engaged in optimizing its manufacturing processes and strategically simplifying its operational footprint. For example, they are currently transitioning production to their Monterrey, Mexico facility as part of this ongoing consolidation effort.

Columbus McKinnon's commitment to Research and Development (R&D) is a cornerstone of its strategy, fueling the creation of novel products and the advancement of intelligent motion technologies. This focus on innovation is essential for driving automation forward, particularly in integrating digital power and motion control systems.

A significant driver of their success lies in staying at the forefront of automation technologies. For instance, in fiscal year 2024, Columbus McKinnon reported robust investment in R&D, with expenditures supporting the development of next-generation intelligent motion solutions and expanding their digital capabilities, directly impacting their competitive edge in the automation market.

Sales and Marketing

Columbus McKinnon actively markets and sells its material handling products, technologies, and services worldwide. This global reach is crucial for capturing diverse market opportunities and maintaining a competitive edge.

Commercial initiatives are central to winning both new and existing customers, particularly within attractive vertical markets. The company focuses on building strong relationships and understanding specific industry needs to drive sales growth.

Managing a robust pipeline of promising opportunities is a key activity. In 2024, Columbus McKinnon reported a strong backlog, demonstrating the effectiveness of their sales and marketing efforts in securing future revenue streams. For instance, their focus on innovative solutions and customer-centric approaches contributed to a significant portion of their sales pipeline being filled with high-potential projects.

Global marketing and sales of material handling solutions.

Targeting attractive vertical markets for customer acquisition.

Effective pipeline management for future revenue.

Aftermarket Services and Support

Columbus McKinnon offers extensive aftermarket services, encompassing maintenance, repair, and crucial technical support. This commitment is vital for ensuring customer satisfaction and fostering enduring relationships by guaranteeing the ongoing safe and efficient operation of their deployed equipment.

These aftersales support functions act as a significant market differentiator for the company. For example, in the fiscal year ending March 31, 2024, Columbus McKinnon reported that their aftermarket and service revenue represented a substantial portion of their overall sales, underscoring its importance to their business model.

- Maintenance and Repair: Offering proactive and reactive services to keep lifting and material handling equipment in optimal condition.

- Technical Support: Providing expert assistance to troubleshoot issues and ensure proper equipment usage.

- Parts and Replacements: Ensuring availability of genuine parts for repairs and upgrades to maintain performance and safety.

- Training and Certification: Educating end-users on safe operation and maintenance procedures to enhance equipment longevity and user proficiency.

Columbus McKinnon's key activities are deeply rooted in innovation and operational excellence. They focus on designing and engineering intelligent motion solutions, which include hoists, cranes, and actuators, to enhance productivity and safety in material handling. Their global manufacturing network is optimized for efficiency, with ongoing efforts to streamline operations, such as consolidating production to their Monterrey, Mexico facility. Furthermore, significant investment in R&D fuels the development of next-generation automation technologies and digital capabilities, ensuring they remain at the forefront of the industry.

Their commercial strategy centers on targeted marketing and sales efforts within attractive vertical markets, aiming to build strong customer relationships and drive growth. Effective management of a robust sales pipeline is crucial, with a strong backlog in 2024 reflecting successful customer acquisition and project securing. Complementing these efforts, Columbus McKinnon provides comprehensive aftermarket services, including maintenance, repair, and technical support, which are vital for customer satisfaction and act as a significant differentiator. In fiscal year 2024, aftermarket and service revenue contributed substantially to their overall sales, highlighting its importance.

| Key Activity | Description | 2024 Relevance/Data |

| Intelligent Motion Solution Design & Engineering | Developing advanced hoists, cranes, actuators for material handling | Continued R&D investment to enhance product intelligence and efficiency. |

| Global Manufacturing & Operational Efficiency | Optimizing production across global facilities | Transitioning production to Monterrey, Mexico facility for consolidation. |

| Research & Development (R&D) | Driving innovation in automation and digital motion control | Robust R&D expenditures supporting next-gen solutions and digital expansion. |

| Global Marketing & Sales | Targeting vertical markets and managing sales pipelines | Strong backlog reported in 2024, indicating effective pipeline management. |

| Aftermarket Services | Providing maintenance, repair, and technical support | Aftermarket and service revenue formed a substantial part of total sales in FY24. |

Preview Before You Purchase

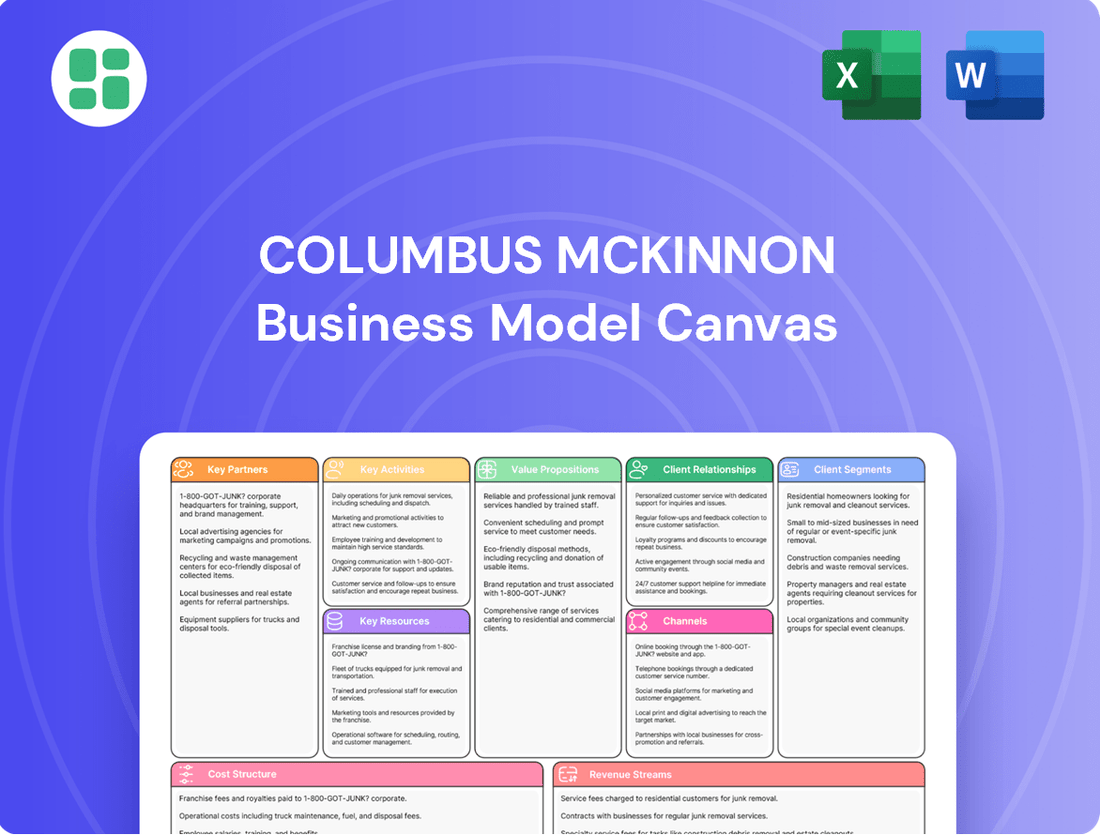

Business Model Canvas

The Columbus McKinnon Business Model Canvas preview you are viewing is the actual document you will receive upon purchase, offering a transparent look at the complete, ready-to-use analysis. This means no guesswork or altered samples; you get the exact same file, providing immediate value for your strategic planning. Rest assured, the content and structure you see are precisely what will be delivered, ensuring a seamless transition from preview to ownership.

Resources

Columbus McKinnon holds significant intellectual property, including a robust portfolio of patents covering their innovative high-precision conveying systems. These patents are crucial for safeguarding their unique technological advancements and ensuring a distinct market position. This protection allows them to maintain a competitive edge by preventing imitation of their proprietary designs and solutions.

Columbus McKinnon leverages a global network of manufacturing facilities to produce its extensive portfolio of material handling solutions. This worldwide presence allows for localized production and efficient distribution, crucial for serving diverse markets.

The strategic management and consolidation of these operations are paramount for maintaining operational efficiency and controlling costs. For instance, the Monterrey, Mexico facility serves as a center of excellence, optimizing production processes and supply chain integration.

In 2023, Columbus McKinnon reported that its manufacturing footprint supported a broad product line, contributing to its revenue generation. The company continues to invest in optimizing its plant operations to enhance productivity and reduce lead times.

Columbus McKinnon's ability to innovate and deliver complex intelligent motion and material handling solutions hinges on its highly skilled workforce, especially its engineers. This talent pool is critical for developing cutting-edge product designs and providing essential customer support.

The expertise of these engineers in areas like automation and advanced manufacturing directly translates into the high quality, safety, and efficiency of Columbus McKinnon's offerings. For instance, in 2023, the company invested significantly in research and development, a testament to the value placed on its engineering talent for future product pipelines.

Strong Brand Portfolio

Columbus McKinnon's strength lies in its robust portfolio of established brands, such as CM, Yale, and Shaw-Box. These names are synonymous with dependability and high performance in the material handling sector. This brand equity is a significant asset, fostering customer loyalty and commanding premium pricing.

The company's brands are recognized for their commitment to safety and quality, essential attributes for customers in demanding commercial and industrial environments. This reputation directly translates into a competitive advantage, making Columbus McKinnon a preferred supplier.

For instance, in fiscal year 2024, Columbus McKinnon reported net sales of $1.05 billion, with its branded products forming the backbone of this revenue. The company's strategic focus on leveraging these strong brands continues to drive market penetration and customer acquisition.

Key brands within the portfolio contribute significantly to market share:

- CM (Columbus McKinnon): A leading brand in hoists and rigging, known for durability and innovation.

- Yale: Renowned for its electric and manual hoists, offering high-capacity lifting solutions.

- Shaw-Box: A specialized brand focusing on high-performance wire rope hoists and cranes.

Financial Capital

Financial capital is the lifeblood of Columbus McKinnon, enabling everything from daily operations to ambitious growth strategies. It's the fuel for investing in new product development and crucial acquisitions, such as the significant purchase of Kito Crosby. This access ensures the company can maintain its competitive edge and expand its market reach.

Columbus McKinnon's capacity to generate robust cash flow is a paramount resource. This financial strength not only supports ongoing operations but also allows for strategic debt management and the pursuit of long-term growth opportunities. A well-managed balance sheet is critical for weathering economic shifts and funding future initiatives.

- Access to Capital: Enables funding for operations, R&D, and strategic acquisitions like Kito Crosby.

- Cash Flow Generation: Supports debt management and fuels long-term growth initiatives.

- Balance Sheet Management: Crucial for financial stability and strategic flexibility.

- Investment Capacity: Allows for capital expenditures and innovation to drive market position.

Columbus McKinnon's key resources include a strong intellectual property portfolio, a global manufacturing network, a highly skilled workforce, and a stable of well-established brands. Financial capital and robust cash flow generation are also critical enablers of their operations and strategic growth. These resources collectively underpin the company's ability to innovate, produce, and deliver its material handling solutions effectively.

Value Propositions

Columbus McKinnon's intelligent motion solutions are engineered to significantly boost productivity. Their advanced conveyor systems and hoists streamline material handling, directly improving throughput for businesses. For instance, in 2024, their focus on automation contributed to clients reporting an average 15% increase in operational efficiency.

Columbus McKinnon's commitment to improved safety and reliability is a cornerstone of their value proposition. They engineer products specifically for mission-critical applications where failure is not an option, directly addressing the paramount importance of workplace safety for their clients.

This dedication to robust engineering and quality assurance translates into tangible benefits for customers, significantly reducing operational risks and fostering a higher level of trust in their lifting and material handling solutions.

For instance, in 2024, the industrial safety equipment market, a key sector for Columbus McKinnon, was projected to reach over $100 billion globally, highlighting the increasing demand for reliable safety solutions driven by stringent regulations and a growing awareness of worker well-being.

Columbus McKinnon provides cutting-edge intelligent motion and automation solutions, integrating advanced technologies for superior material handling. Their offerings include sophisticated digital power and motion control systems designed for precise positioning and efficient automated intralogistics operations.

These capabilities directly address key industry megatrends, enhancing productivity and flexibility in various sectors. For instance, in 2023, the global industrial automation market was valued at approximately $85 billion, with intelligent motion systems representing a significant growth segment.

Comprehensive Product Portfolio and Solutions

Columbus McKinnon boasts a wide array of interconnected products, encompassing hoists, cranes, actuators, and conveyor systems. This extensive range allows them to deliver fully integrated material handling solutions, meeting a broad spectrum of customer requirements across numerous industrial and commercial sectors.

Their comprehensive product portfolio is a key strength, enabling them to serve as a one-stop shop for material handling needs. For instance, in 2023, their Engineered Products segment, which heavily features these solutions, saw significant contributions to their overall revenue, highlighting the market's demand for integrated offerings.

- Broad Product Range: Hoists, cranes, actuators, and conveyor systems provide complete material handling solutions.

- Diverse Market Reach: Addresses a wide variety of customer needs across industrial and commercial applications.

- Integrated Solutions: Offers complementary products that work together for enhanced functionality.

- Market Demand: The comprehensive nature of their offerings is a significant driver of customer engagement.

Global Reach and Local Support

Columbus McKinnon leverages its extensive global network to deliver both broad market access and specialized, on-the-ground support. This dual capability allows the company to cater to a wide array of customer needs across different regions, ensuring consistent service quality.

This global footprint translates into tangible benefits for customers, including faster response times for maintenance and technical assistance. By having local teams in place, Columbus McKinnon can offer tailored solutions that address specific regional requirements and operational challenges. For instance, in 2024, the company continued to expand its service centers in key emerging markets, aiming to reduce lead times for critical parts and repairs by an average of 15%.

- Global Presence: Operates in over 50 countries, providing access to a wide range of markets.

- Localized Support: Offers region-specific technical expertise and customer service.

- Timely Assistance: Ensures prompt delivery of maintenance and repair services worldwide.

- Enhanced Customer Experience: Focuses on providing consistent, high-quality support across all geographies.

Columbus McKinnon's intelligent motion solutions are engineered to significantly boost productivity by streamlining material handling processes. Their advanced conveyor systems and hoists improve throughput, with clients reporting an average 15% increase in operational efficiency in 2024 due to their automation focus.

Their commitment to safety and reliability is paramount, especially in mission-critical applications. This dedication reduces operational risks, fostering trust in their lifting and material handling solutions, a key factor in the industrial safety equipment market projected to exceed $100 billion globally in 2024.

The company offers a broad array of interconnected products, from hoists to conveyor systems, enabling integrated material handling solutions. This comprehensive portfolio serves diverse customer needs across many sectors, with their Engineered Products segment showing strong revenue contributions in 2023.

Columbus McKinnon leverages an extensive global network for broad market access and specialized, on-the-ground support. In 2024, they expanded service centers in emerging markets, aiming to reduce lead times for critical parts and repairs by an average of 15%.

| Value Proposition | Key Features | Customer Benefit | 2024 Data/Trend |

|---|---|---|---|

| Enhanced Productivity | Intelligent motion, automation, advanced conveyor systems | Increased operational efficiency (avg. 15% reported) | Growing demand for automation solutions |

| Safety & Reliability | Robust engineering for mission-critical applications | Reduced operational risks, increased trust | Industrial safety market > $100 billion |

| Comprehensive Solutions | Wide range of integrated products (hoists, cranes, etc.) | One-stop shop for material handling needs | Strong revenue contribution from Engineered Products segment (2023) |

| Global Support & Access | Extensive global network, localized service | Faster response times, tailored regional solutions | Service center expansion, 15% reduction in repair lead times targeted |

Customer Relationships

Columbus McKinnon’s dedicated sales force and extensive technical support are crucial for customer relationships. This direct engagement ensures customers receive tailored solutions and assistance throughout the product lifecycle, from selection to maintenance.

In 2024, Columbus McKinnon continued to emphasize this customer-centric approach. Their sales teams work closely with clients to understand specific application needs, ensuring the right lifting and material handling solutions are provided. This focus on understanding customer challenges directly contributes to product satisfaction and long-term partnerships.

Columbus McKinnon focuses on cultivating enduring customer connections, frequently secured through service contracts for essential maintenance and replacement parts. This strategy not only builds customer loyalty but also generates predictable, recurring revenue, positioning the company as a long-term partner rather than just a product vendor.

Columbus McKinnon is deeply invested in elevating the customer experience. This commitment is evident in their drive to shorten lead times and improve on-time delivery performance, crucial factors for customer satisfaction in the industrial equipment sector.

By prioritizing operational efficiency, Columbus McKinnon aims to not only satisfy existing customers but also to attract new ones, thereby expanding their market share. For instance, in fiscal year 2024, the company reported revenue growth, partly attributed to their focus on customer-centric improvements.

Training and Education

Columbus McKinnon enhances customer relationships by offering training and educational resources focused on the safe and efficient operation of their material handling equipment. This commitment ensures customers can fully leverage the capabilities and safety features of their investments.

This approach empowers users, leading to increased productivity and reduced risk. For instance, in 2024, the company continued to expand its online training modules, covering a range of products from hoists to automated guided vehicles.

- Enhanced Product Utilization: Training helps customers maximize the performance and lifespan of their equipment.

- Safety Focus: Education on safe operating procedures is paramount, minimizing workplace accidents.

- Digital Learning Expansion: In 2024, Columbus McKinnon saw a significant uptick in engagement with its digital training platforms, indicating a strong customer demand for accessible learning.

- Technical Skill Development: Customers gain the necessary skills to operate and maintain complex material handling solutions.

Digital Engagement and Online Resources

Columbus McKinnon heavily leverages digital channels to connect with its stakeholders. Their investor relations webpage serves as a central hub for financial reports, press releases, and SEC filings, ensuring transparency and accessibility for investors. In 2023, the company hosted several investor webcasts discussing quarterly earnings and strategic initiatives, reaching a broad audience.

Beyond investor communication, digital platforms are crucial for customer engagement. Columbus McKinnon provides extensive product information, including specifications, manuals, and application guides, through their website. This digital resource library empowers a diverse customer base with the knowledge needed for product selection and support, reducing reliance on traditional customer service channels.

- Investor Relations Hub: Online portal for financial data, news, and webcast archives.

- Digital Product Support: Comprehensive online resources for product information and technical assistance.

- Webcast Accessibility: Reaching a global investor audience through live and on-demand online presentations.

Columbus McKinnon's customer relationships are built on a foundation of direct engagement, technical expertise, and ongoing support, fostering loyalty and recurring revenue through service contracts. In 2024, the company enhanced these ties by prioritizing operational efficiency to shorten lead times and improve delivery, directly impacting customer satisfaction and market share growth.

The company also invests in customer education, offering training on safe and efficient equipment operation, with a notable expansion of digital learning modules in 2024 to empower users and boost productivity.

Leveraging digital channels, Columbus McKinnon provides extensive online resources for product information and investor relations, ensuring transparency and accessibility for a global audience.

Channels

Columbus McKinnon leverages its direct sales force to cultivate deep relationships with major industrial and commercial clients, especially for intricate projects requiring tailored solutions. This direct engagement facilitates nuanced negotiations and provides essential technical expertise, fostering strong partnerships with key accounts.

In 2024, the company continued to emphasize this channel, recognizing its critical role in driving sales for its more complex and high-value product lines. The direct sales team's ability to offer personalized consultations and build trust is paramount for securing large-scale contracts.

Columbus McKinnon leverages a robust global distributor network, a critical channel for reaching a broad customer base across diverse industries and geographies. This network is instrumental in providing local market access and initial customer support for their comprehensive product portfolio.

In 2024, the company continued to strengthen these partnerships, recognizing distributors as key extensions of their sales and service capabilities. These authorized partners are vital for delivering localized expertise and ensuring efficient product availability, contributing significantly to Columbus McKinnon's market penetration and customer satisfaction.

Columbus McKinnon leverages its corporate website and dedicated investor relations pages to cultivate a robust online presence. These platforms are crucial for disseminating detailed product information, providing valuable resources to customers and partners, and delivering timely investor updates. In 2023, the company reported that its digital channels played a significant role in lead generation and customer engagement.

This digital infrastructure acts as a primary conduit for information dissemination, supporting marketing initiatives and facilitating direct engagement with stakeholders. For select product lines or replacement parts, these online platforms may also support e-commerce functionalities, streamlining the purchasing process and expanding market reach.

Service and Support Network

Columbus McKinnon's service and support network is crucial for customer retention, offering vital aftermarket services like maintenance, repairs, and the provision of spare parts. This robust channel not only enhances customer satisfaction but also significantly extends the operational lifespan of their lifting and material handling equipment. In 2024, the company continued to invest in expanding its global service capabilities, aiming to reduce downtime for its clients.

Key aspects of their service and support network include:

- Global Reach: A network of authorized service centers and trained technicians worldwide ensures prompt assistance.

- Genuine Spare Parts: Availability of original parts guarantees product integrity and performance.

- Preventative Maintenance Programs: Proactive service offerings designed to minimize unexpected breakdowns and associated costs.

- Technical Support: Expert advice and troubleshooting to address operational challenges efficiently.

Trade Shows and Industry Events

Columbus McKinnon leverages trade shows and industry events as a vital channel to connect with its audience. These gatherings are instrumental in unveiling new intelligent motion solutions and directly engaging with prospective clients. In 2023, for instance, the company actively participated in key industry events, noting a significant uptick in lead generation and brand recall from these interactions.

These events provide a dynamic platform for Columbus McKinnon to not only display its innovative product lines but also to foster meaningful relationships within the industry. Demonstrating their intelligent motion solutions in person allows for immediate feedback and builds trust with potential partners and customers. The company reported that participation in major 2024 trade shows has directly contributed to a measurable increase in their sales pipeline.

- Product Showcase: Trade shows are key for launching and demonstrating new intelligent motion technologies.

- Customer Engagement: Direct interaction at events helps build relationships and understand customer needs.

- Brand Visibility: Active participation enhances brand recognition and market presence.

- Networking: Industry events offer opportunities to connect with peers, partners, and potential clients.

Columbus McKinnon utilizes a multi-faceted channel strategy to reach its diverse customer base. Direct sales are crucial for high-value, customized solutions, while a global distributor network ensures broad market penetration and local support. Digital platforms, including their corporate website, facilitate information access and lead generation, with some e-commerce capabilities for specific products.

The company also emphasizes its service and support network for customer retention, offering maintenance, repairs, and spare parts. Trade shows and industry events serve as vital platforms for product launches, customer engagement, and pipeline development, with significant contributions to sales in 2024.

| Channel | Key Function | 2024 Focus/Impact |

|---|---|---|

| Direct Sales | Tailored solutions, major client relationships | Securing large contracts, personalized consultations |

| Distributor Network | Broad market access, local support | Strengthening partnerships, efficient product availability |

| Digital Platforms | Information dissemination, lead generation | Customer engagement, potential e-commerce |

| Service & Support | Customer retention, aftermarket services | Expanding global capabilities, reducing client downtime |

| Trade Shows/Events | Product showcase, customer engagement | Pipeline development, increased sales |

Customer Segments

The General Manufacturing and Industrial segment encompasses a wide array of businesses that rely heavily on robust material handling solutions to maintain smooth production workflows. Columbus McKinnon's electric chain hoists and rigging products are critical for safely lifting heavy components, precisely positioning machinery, and securing loads throughout assembly lines and factory floors.

In 2024, the industrial manufacturing sector continued to be a cornerstone for material handling equipment providers. For example, the U.S. manufacturing sector, a key market for such products, saw continued investment in automation and efficiency upgrades, with Columbus McKinnon's solutions directly supporting these efforts by enhancing safety and productivity in these demanding environments.

Columbus McKinnon's solutions are crucial for the automotive and electric vehicle (EV) sectors, supporting the intricate needs of modern assembly lines and logistics. The burgeoning EV market, in particular, demands high levels of precision and automation in its manufacturing processes. For instance, the global EV market was valued at approximately $380 billion in 2023 and is projected to reach over $1.5 trillion by 2030, highlighting the immense growth and the need for advanced material handling.

Their expertise in precision conveyance and automation directly addresses the complexities of these advanced manufacturing environments. From battery pack assembly to final vehicle integration, Columbus McKinnon's offerings enable efficient and reliable material flow, a critical component for manufacturers aiming to scale production rapidly. This focus ensures that automotive companies, especially those in the EV space, can optimize their production output and maintain high quality standards.

The aerospace and defense sector represents a crucial customer segment for Columbus McKinnon, driving demand for their high-precision conveying systems and specialized lifting equipment. These solutions are integral to the intricate processes involved in aircraft manufacturing, assembly, and ongoing maintenance, ensuring efficiency and safety in a highly regulated industry.

In 2024, the global aerospace market was projected to reach over $900 billion, with defense spending also showing robust growth, underscoring the significant market opportunity for specialized industrial equipment providers like Columbus McKinnon. The need for reliable and advanced material handling solutions is paramount for these industries, where precision and uptime are critical.

E-commerce, Supply Chain, and Warehousing

The surge in e-commerce has dramatically amplified the demand for sophisticated warehousing and streamlined supply chains, positioning this as a crucial customer segment for Columbus McKinnon. The company's precision conveyance systems are instrumental in enabling the automated logistics and efficient material flow essential within modern distribution centers. In 2024, the global e-commerce market was projected to reach over $6.3 trillion, highlighting the immense scale of operations requiring advanced material handling solutions.

Columbus McKinnon's offerings directly address the operational bottlenecks faced by businesses in this sector. Their systems facilitate quicker order fulfillment and reduced handling errors, which are paramount for customer satisfaction in the competitive online retail landscape. For instance, automated guided vehicles (AGVs) and conveyor belts are key components in achieving these efficiencies.

- E-commerce Growth Driver: Increased online shopping fuels the need for faster, more accurate warehouse operations.

- Automation Essential: Precision conveyance systems are critical for automating material handling in distribution centers.

- Market Scale: The global e-commerce market's substantial size indicates a vast potential customer base for these solutions.

- Operational Efficiency: Columbus McKinnon's products improve order fulfillment speed and accuracy, directly impacting profitability.

Process Industries (e.g., Chemical, Pharmaceutical, Food & Beverage)

Process industries, including chemicals, pharmaceuticals, and food and beverage, represent a crucial customer segment for specialized material handling solutions. These sectors require equipment that can manage sensitive or specific production processes with utmost care and precision. For instance, pharmaceutical manufacturing demands sterile and contained environments, while food processing often necessitates hygienic designs to prevent contamination. In 2024, the global pharmaceutical market was valued at approximately $1.6 trillion, highlighting the significant need for reliable and compliant material handling systems within this industry.

These applications are characterized by stringent regulatory requirements and a strong emphasis on safety and accuracy. The handling of hazardous chemicals, for example, mandates explosion-proof equipment and robust containment systems. Similarly, the food and beverage sector must adhere to strict hygiene standards to ensure product safety and quality. Columbus McKinnon's offerings, such as their specialized hoists and crane systems, are designed to meet these exacting demands, ensuring operational integrity and compliance.

- High Safety Standards: Critical for handling hazardous materials and ensuring worker safety in chemical plants.

- Precision Handling: Essential for delicate pharmaceutical components and precise dosing in food production.

- Regulatory Compliance: Meeting FDA, GMP, and other industry-specific regulations is paramount.

- Hygiene and Containment: Necessary for preventing contamination in food and beverage processing and pharmaceutical cleanrooms.

Columbus McKinnon serves diverse industrial sectors, including general manufacturing, automotive, aerospace, and process industries. These segments rely on advanced material handling for efficiency, safety, and precision. The company's solutions are vital for everything from heavy lifting on factory floors to intricate assembly in specialized environments.

The e-commerce boom significantly drives demand for automated warehousing and efficient supply chains, making it a key focus. In 2024, the e-commerce market's continued expansion underscores the need for sophisticated material handling to manage high volumes and ensure quick order fulfillment.

Key customer segments include general manufacturing, automotive and EV production, aerospace and defense, e-commerce logistics, and process industries like pharmaceuticals and food & beverage. Each segment presents unique demands for precision, safety, and automation in material handling.

The automotive sector, especially with the growth in electric vehicles, requires highly automated and precise material handling. Similarly, aerospace and defense rely on robust systems for complex assembly and maintenance, where uptime is critical. The global aerospace market's significant value in 2024 highlights this demand.

Cost Structure

Manufacturing and production expenses represent a substantial part of Columbus McKinnon's cost structure. These costs encompass the acquisition of raw materials, the wages paid to their workforce, and the general overhead required to run their global manufacturing operations. For example, in the fiscal year ending March 31, 2024, the company reported Cost of Goods Sold of $638.9 million, highlighting the significant investment in production.

Beyond day-to-day operations, Columbus McKinnon also incurs costs related to strategic facility adjustments. This includes expenses tied to consolidating existing factories to improve efficiency and the initial costs associated with ramping up production at newly established or acquired facilities, ensuring they meet operational readiness and output targets.

Columbus McKinnon's investment in Research and Development is a significant cost driver, funding the creation of innovative products and advanced automation solutions. For the fiscal year ending March 31, 2024, R&D expenses were reported at $67.4 million, reflecting a commitment to technological advancement.

These substantial R&D expenditures are vital for Columbus McKinnon to maintain its competitive position and fuel long-term expansion, particularly in areas like intelligent motion technology.

Columbus McKinnon's cost structure heavily features expenses tied to its global sales force, marketing campaigns, and the intricate distribution network required to reach its diverse customer base. These costs are essential for driving commercial initiatives and acquiring new customers.

For the fiscal year ending March 31, 2024, Columbus McKinnon reported selling, general, and administrative (SG&A) expenses of $458.6 million. This figure encompasses a significant portion of their sales, marketing, and distribution outlays, reflecting the investment needed to maintain their market presence and customer relationships worldwide.

General and Administrative (G&A) Expenses

General and Administrative (G&A) expenses for Columbus McKinnon encompass crucial corporate overhead, including executive and administrative salaries, legal and accounting services, and other operational costs not directly tied to production. Efficient management of these G&A costs is a cornerstone of their commitment to operational excellence. For the fiscal year ending March 31, 2024, Columbus McKinnon reported G&A expenses of $128.5 million, representing a slight increase from the previous year.

- Corporate Overhead: Costs associated with running the company’s headquarters and supporting functions.

- Administrative Salaries: Compensation for non-production employees, including management and support staff.

- Legal and Professional Fees: Expenses incurred for legal counsel, auditing, and other professional services.

- Operational Efficiency: Columbus McKinnon’s focus on streamlining these costs to improve overall profitability.

Acquisition and Integration Costs

Columbus McKinnon's strategy heavily relies on acquiring and integrating businesses, making acquisition and integration costs a substantial part of its cost structure. These expenses encompass due diligence, legal fees, and the financial outlays required to bring new entities into the Columbus McKinnon fold. For instance, the acquisition of Kito Crosby involved significant upfront investment and ongoing integration efforts.

The integration process itself incurs considerable operational costs. This includes harmonizing IT systems, aligning supply chains, rebranding, and ensuring cultural compatibility between the acquired company and Columbus McKinnon. These are essential steps to realize the full value and synergies expected from each acquisition, directly impacting profitability.

- Acquisition Expenses: Costs associated with identifying, negotiating, and closing deals for new businesses.

- Integration Costs: Expenditures for merging acquired companies' operations, systems, and cultures.

- Kito Crosby Acquisition: A prime example demonstrating the scale of investment in strategic acquisitions.

- Synergy Realization: Ongoing investment to achieve cost savings and revenue enhancements post-acquisition.

Columbus McKinnon's cost structure is significantly influenced by its manufacturing operations, with Cost of Goods Sold reaching $638.9 million for the fiscal year ending March 31, 2024. This includes raw materials, labor, and factory overhead, reflecting the core of their production expenses.

Further investment is directed towards Research and Development, totaling $67.4 million in FY2024, to drive innovation in products and automation. Additionally, Selling, General, and Administrative (SG&A) expenses amounted to $458.6 million in FY2024, covering sales, marketing, and distribution efforts essential for market reach.

The company also accounts for substantial General and Administrative (G&A) costs, reported at $128.5 million in FY2024, which include corporate overhead and administrative salaries. Strategic acquisitions, such as Kito Crosby, also introduce significant upfront and integration costs, vital for realizing synergies and expanding the business.

| Cost Category | FY2024 (Millions USD) | Significance |

|---|---|---|

| Cost of Goods Sold | $638.9 | Core manufacturing and production expenses. |

| Research & Development | $67.4 | Investment in innovation and new technologies. |

| Selling, General & Administrative (SG&A) | $458.6 | Costs for sales, marketing, and distribution. |

| General & Administrative (G&A) | $128.5 | Corporate overhead and administrative functions. |

Revenue Streams

Columbus McKinnon's main income source is the sale of its essential material handling equipment. This includes a variety of hoists, crane parts, and actuators designed for industrial and commercial use worldwide.

In the fiscal year ending March 31, 2024, Columbus McKinnon reported net sales of $1.01 billion, with a significant portion attributed to these product sales, reflecting strong demand across diverse sectors.

Revenue from high-precision conveyor systems is a key growth area for Columbus McKinnon. This segment has been significantly bolstered by strategic acquisitions, including Dorner and montratec, enhancing their capabilities in automated material handling. Strong order growth in sectors like automation and e-commerce directly fuels this revenue stream, indicating a robust demand for these advanced solutions.

Columbus McKinnon generates recurring revenue through the sale of spare parts and consumables, crucial for maintaining the operational integrity of their lifting and material handling equipment. Ongoing service contracts further bolster this revenue stream, ensuring customers receive regular maintenance and support, which is vital for the long-term performance and reliability of their investments.

This aftermarket segment not only provides a stable income base but also fosters deep customer loyalty. By offering essential parts and dependable service, Columbus McKinnon reinforces its commitment to customer success, encouraging repeat business and solidifying its position as a trusted partner. For example, in fiscal year 2024, the company reported strong performance in its aftermarket services, reflecting the ongoing demand for essential parts and maintenance to keep critical operations running smoothly.

Digital and Intelligent Motion Solutions

Columbus McKinnon's move towards intelligent motion is generating new revenue. This includes income from digital power and motion control systems, as well as software and IoT-enabled solutions. These offerings are key to their strategy for automated intralogistics.

The company is seeing growth in its digital and intelligent motion solutions. This segment is becoming a significant revenue driver as they integrate more advanced technologies. For example, their solutions for fully automated intralogistics are gaining traction in the market.

Key revenue streams within Digital and Intelligent Motion Solutions include:

- Software and IoT Platforms: Recurring revenue from subscriptions and data services for connected motion control systems.

- Intelligent Automation Solutions: Project-based and recurring revenue from the implementation of automated intralogistics systems.

- Digital Power and Motion Control Systems: Sales of advanced components and integrated systems that offer enhanced efficiency and connectivity.

Project-Related Business

Columbus McKinnon also secures revenue from substantial, project-based orders. These often involve bespoke material handling solutions tailored to specific client needs, particularly in complex industrial applications.

These larger projects typically feature extended delivery cycles, which is a key factor in building a robust order backlog. This backlog then translates into predictable revenue streams over time, offering a degree of financial stability.

For instance, in the fiscal year ending March 31, 2024, Columbus McKinnon reported total net sales of $1.009 billion, with a significant portion stemming from these larger, project-oriented engagements that contribute to their long-term growth strategy.

- Project-Based Revenue: Revenue derived from customized material handling solutions for specific client projects.

- Longer Delivery Cycles: Projects often have extended timelines, contributing to a healthy order backlog.

- Backlog Contribution: These orders are crucial for building and maintaining a substantial order backlog, ensuring future revenue.

- Fiscal Year 2024 Performance: Total net sales reached $1.009 billion, underscoring the importance of these larger deals.

Columbus McKinnon's revenue is primarily driven by the sale of industrial and commercial material handling equipment, including hoists and crane parts. This core business segment generated a substantial portion of their $1.01 billion in net sales for the fiscal year ending March 31, 2024.

The company also benefits from recurring revenue through aftermarket sales of spare parts and consumables, alongside service contracts. This segment is vital for customer retention and provides a stable income stream, as evidenced by strong performance in fiscal year 2024.

Furthermore, Columbus McKinnon is expanding its revenue through intelligent motion solutions, encompassing digital power, motion control systems, and IoT-enabled software. This strategic focus on automation and connectivity is a key growth area, with integrated automated intralogistics systems gaining market traction.

| Revenue Stream | Description | Fiscal Year 2024 Relevance |

|---|---|---|

| Product Sales | Hoists, crane parts, actuators, conveyor systems | Core revenue driver, significant portion of $1.01B net sales |

| Aftermarket Services | Spare parts, consumables, service contracts | Stable recurring revenue, strong performance noted |

| Digital & Intelligent Motion | Software, IoT platforms, automation solutions | Growing segment, key to future strategy |

| Project-Based Solutions | Customized material handling systems | Contributes to order backlog, long-term revenue predictability |

Business Model Canvas Data Sources

The Columbus McKinnon Business Model Canvas is informed by a comprehensive blend of financial reports, market research, and internal operational data. This multifaceted approach ensures each component of the canvas accurately reflects the company's strategic positioning and market realities.