BYD Electronic Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

BYD Electronic Bundle

Explore the intricate workings of BYD Electronic's success with our comprehensive Business Model Canvas. This detailed breakdown reveals their innovative approach to value creation, customer relationships, and revenue streams, offering a clear roadmap for understanding their market dominance. Discover the strategic pillars that drive their growth and gain actionable insights for your own ventures.

Partnerships

BYD Electronic cultivates vital relationships with raw material suppliers, particularly for lithium, cobalt, and nickel, which are fundamental to its battery manufacturing. These partnerships are often solidified through long-term agreements and direct investments in mining operations, a strategy that significantly reduces supply chain vulnerabilities and ensures a consistent flow of critical materials.

This proactive approach to securing raw materials proved particularly beneficial in 2024, a year that saw BYD's battery sales experience substantial growth, reaching over 200 GWh. The ability to maintain a stable supply of key components directly supported this impressive sales surge, underscoring the strategic importance of these supplier collaborations.

BYD Electronic's key partnerships with technology developers are foundational to its innovation in intelligent systems and automotive tech. These collaborations are crucial for staying at the forefront of the rapidly evolving EV market.

A prime example is BYD's deepened collaboration with Hesai Technology, a leader in LiDAR solutions. This partnership will see Hesai's advanced LiDAR sensors integrated into BYD's 2025 vehicle models, enhancing autonomous driving capabilities. This move signifies BYD's commitment to incorporating cutting-edge sensor technology for improved safety and performance.

Furthermore, BYD actively partners with Huawei, focusing on enhancing the smart cockpit experience and connectivity in its electric vehicles. This collaboration leverages Huawei's expertise in telecommunications and digital services to deliver seamless in-car navigation, entertainment, and communication features, creating a more integrated and user-friendly environment for drivers.

BYD Electronic's relationship with BYD Auto is foundational, positioning it as a crucial supplier for intelligent driving components and a wide array of electronic parts. This deep integration allows BYD Electronic to capitalize on its advanced capabilities in electrification and smart vehicle technology.

This internal collaboration is vital for securing a steady and high-quality supply of advanced components, directly supporting BYD Auto's impressive expansion in the new energy vehicle (NEV) market. For instance, BYD Auto's sales in 2024 have consistently shown robust growth, underscoring the demand for these integrated electronic solutions.

The symbiotic relationship between BYD Electronic and BYD Auto significantly enhances their collective competitive edge in the global automotive industry, fostering innovation and efficiency across both entities.

Global Distribution and Sales Partners

BYD Electronic strategically partners with local distributors and sales networks to broaden its international market reach. This approach is vital for building effective sales channels and ensuring comprehensive after-sales support worldwide.

These collaborations are evident in BYD Electronic's established presence in key regions such as Europe, Southeast Asia, Latin America, and the Middle East. For instance, in 2024, BYD Electronic continued its expansion in Europe, aiming to solidify its position in a competitive EV market.

- European Expansion BYD Electronic's focus on European markets in 2024 involved strengthening relationships with local dealerships and service providers to enhance customer experience and market penetration.

- Southeast Asian Growth The company actively pursued partnerships in Southeast Asia, leveraging local expertise to navigate diverse consumer preferences and regulatory landscapes.

- Latin American and Middle Eastern Markets BYD Electronic continued to build its distribution infrastructure in Latin America and the Middle East, recognizing the growing demand for electric vehicles and electronics in these regions.

Customer Collaborations (OEMs)

BYD Electronic's customer collaborations with Original Equipment Manufacturers (OEMs) are foundational to its success as a global provider of design, R&D, manufacturing, and supply chain services for smart devices. These partnerships span across critical sectors like smartphones, laptops, and emerging intelligent product categories.

These OEM relationships are not merely transactional; they represent deep integrations that ensure BYD Electronic consistently delivers high-quality products and services. For instance, BYD Electronic's role in the automotive sector, a key area for intelligent products, highlights its capability to support complex manufacturing needs for major car brands.

- Global Reach: BYD Electronic partners with leading OEMs worldwide in the smartphone and laptop markets, demonstrating its extensive network and reliability.

- Innovation Hubs: Collaborations often involve joint R&D efforts, allowing BYD Electronic to contribute to the cutting-edge development of new intelligent devices.

- Supply Chain Integration: These partnerships are crucial for BYD Electronic's robust supply chain management, ensuring efficient production and delivery of complex electronic components and finished goods.

BYD Electronic's strategic partnerships with technology developers, such as Hesai Technology for LiDAR and Huawei for smart cockpits, are crucial for advancing its intelligent automotive systems. These collaborations directly contribute to the enhanced features and autonomous capabilities of BYD vehicles, ensuring the company remains competitive in the rapidly evolving EV market.

The deep integration with BYD Auto serves as a cornerstone, positioning BYD Electronic as a primary supplier for critical intelligent driving components and electronic parts. This internal synergy fuels BYD Auto's significant expansion in the new energy vehicle sector, with BYD Auto's sales demonstrating consistent strong growth throughout 2024.

BYD Electronic's global expansion is significantly bolstered by its partnerships with local distributors and sales networks in key markets like Europe and Southeast Asia. These alliances are vital for establishing effective sales channels and providing comprehensive after-sales support, as seen in BYD Electronic's continued market penetration efforts in Europe during 2024.

Collaborations with global Original Equipment Manufacturers (OEMs) in sectors like smartphones and laptops are fundamental to BYD Electronic's role as a comprehensive service provider for smart devices. These partnerships foster joint R&D and ensure robust supply chain integration, enabling the delivery of high-quality intelligent products.

What is included in the product

A comprehensive, pre-written business model tailored to BYD's strategy, covering customer segments, channels, and value propositions in full detail.

Reflects the real-world operations and plans of BYD, organized into 9 classic BMC blocks with full narrative and insights.

BYD's Electronic Business Model Canvas acts as a pain point reliever by simplifying complex supply chain dependencies and manufacturing processes into a clear, actionable framework.

It efficiently maps out BYD's integrated approach, from battery production to vehicle assembly, offering a visual solution to the challenges of managing a vertically integrated automotive and electronics giant.

Activities

BYD Electronic's commitment to innovation is clearly demonstrated through its significant investment in Research and Development. The company prioritizes advancements in key areas like battery technology, intelligent driving systems, and sophisticated electronic components, ensuring it stays at the forefront of the industry.

In 2024 alone, BYD Electronic allocated a substantial 54.2 billion yuan towards R&D efforts. This considerable expenditure underscores their dedication to developing groundbreaking solutions and maintaining a robust competitive advantage in the rapidly evolving tech landscape.

Their R&D focus extends to emerging fields such as artificial intelligence, large language models, and the exploration of novel advanced materials, positioning BYD Electronic for future technological leadership.

A central activity for BYD Electronic is the design and engineering of smart devices. This encompasses a wide range, from familiar items like smartphones and laptops to emerging intelligent products. The company's focus is on translating technological prowess into novel designs and functional prototypes, ensuring they align with varied customer preferences and evolving market trends.

BYD Electronic provides end-to-end solutions by developing these smart devices. This means they handle the entire process from initial concept to a market-ready product, offering a comprehensive service to their clientele. Their expertise in this area is crucial for staying competitive in the fast-paced consumer electronics sector.

BYD Electronic's core strength lies in its high-volume manufacturing and production capabilities for electronic components and smart devices. This includes specialized metal manufacturing for intelligent mobile device terminals and wearable devices, demonstrating a focus on precision and advanced materials.

The company leverages a vertically integrated supply chain, granting it comprehensive control from sourcing raw materials to delivering finished products. This integration is crucial for maintaining quality standards and optimizing production timelines.

BYD Electronic's operational scale is underscored by its vast network of over 100 internal factories. This extensive infrastructure not only drives cost efficiency but also significantly enhances supply chain resilience, a critical factor in today's dynamic global market.

Supply Chain Management and Vertical Integration

BYD Electronic's commitment to vertical integration is a cornerstone of its operations. By controlling roughly 75% of its component manufacturing internally, including vital elements like batteries and semiconductors, BYD significantly reduces costs and ensures a stable supply of critical parts. This approach is crucial for its ability to scale production quickly to meet market demand.

Managing these intricate global supply chains is a paramount activity. BYD Electronic focuses on ensuring the timely delivery of components and maintaining stringent quality control across its entire manufacturing process. This meticulous oversight is essential for delivering reliable and high-quality products to its customers.

- Vertical Integration: BYD controls approximately 75% of its component manufacturing, including batteries and semiconductors.

- Cost Minimization: In-house production of key components helps reduce overall manufacturing expenses.

- Supply Security: Internal manufacturing secures access to critical components, mitigating external supply chain risks.

- Production Scalability: Vertical integration allows for rapid adjustments and scaling of production volumes.

Quality Control and Assurance

BYD Electronic's commitment to quality is a core operational pillar. This involves implementing stringent quality control and assurance measures at every step, from initial product design through manufacturing and final assembly. The company leverages established methodologies like Total Quality Management (TQM) and lean production principles to guarantee that its offerings consistently meet and exceed customer expectations.

In 2024, BYD Electronic continued to invest heavily in advanced testing equipment and sophisticated quality management systems. For instance, their automotive division, a significant part of BYD Electronic, reported a substantial reduction in product defect rates, with figures indicating a year-over-year improvement of 15% in critical component reliability. This focus on quality underpins their reputation for dependable electronic products.

- Rigorous Testing Protocols: Implementing comprehensive testing at various production stages to identify and rectify potential defects early.

- Supplier Quality Management: Collaborating closely with suppliers to ensure the quality of incoming components and raw materials.

- Continuous Improvement Initiatives: Regularly reviewing and refining quality processes based on customer feedback and internal performance data.

- Adherence to International Standards: Maintaining certifications such as ISO 9001 to demonstrate a commitment to globally recognized quality benchmarks.

BYD Electronic's key activities revolve around its robust R&D, focusing on battery tech and intelligent systems, backed by a significant 2024 R&D investment of 54.2 billion yuan. The company excels in designing and manufacturing smart devices, offering end-to-end solutions from concept to market. Their operational strength lies in high-volume production and a vertically integrated supply chain, controlling about 75% of component manufacturing internally to ensure quality and cost efficiency.

| Key Activity | Description | 2024 Data/Focus |

|---|---|---|

| Research & Development | Innovation in battery, intelligent driving, and electronic components. | 54.2 billion yuan invested; focus on AI, LLMs, advanced materials. |

| Smart Device Design & Engineering | Translating technology into novel designs for consumer electronics. | End-to-end solutions from concept to market-ready products. |

| High-Volume Manufacturing | Precision manufacturing of electronic components and devices. | Over 100 internal factories; specialized metal manufacturing. |

| Vertical Integration & Supply Chain Management | Controlling component manufacturing and ensuring quality/delivery. | Controls ~75% of component manufacturing (batteries, semiconductors). |

Preview Before You Purchase

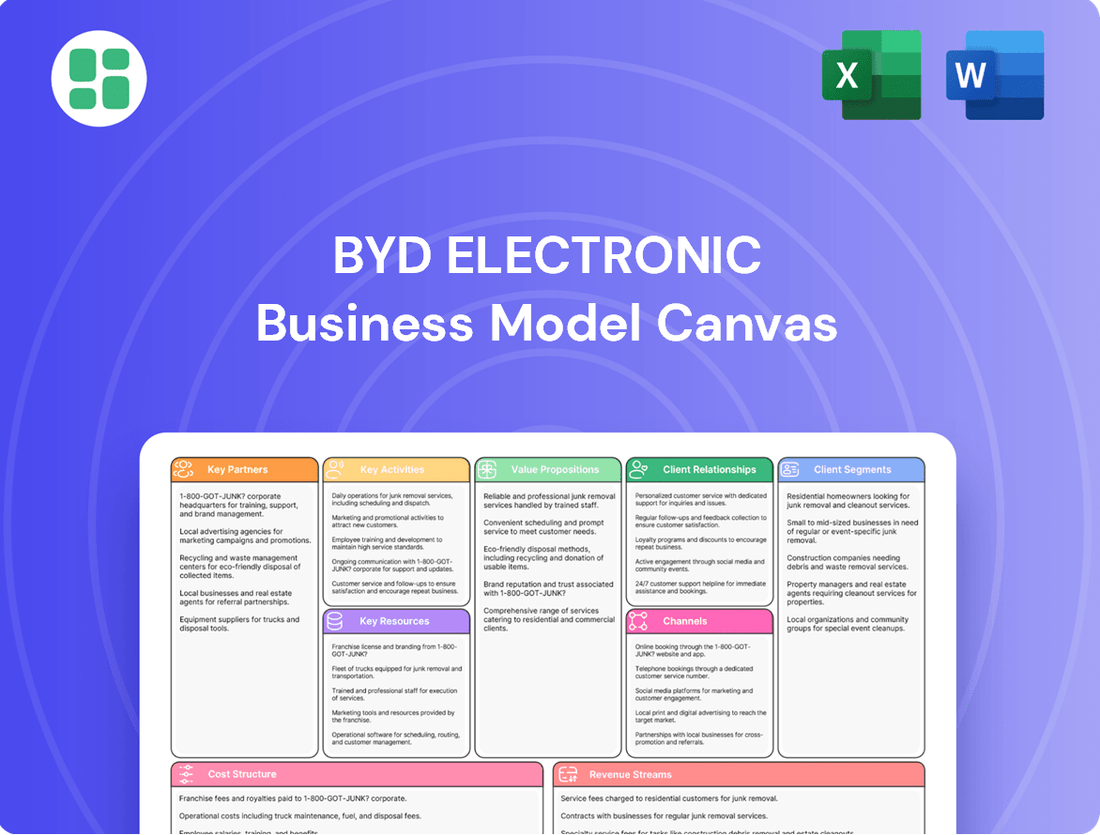

Business Model Canvas

The BYD Electronic Business Model Canvas you're previewing is the actual, complete document you will receive upon purchase. This isn't a sample or a mockup; it's a direct representation of the professional, ready-to-use file you'll download. You'll gain full access to this exact document, ensuring no surprises and immediate usability for your strategic planning.

Resources

BYD's proprietary lithium iron phosphate (LiFePO4) battery technology, notably the Blade Battery, stands as a critical asset. This technology significantly boosts both the safety and efficiency of their energy storage solutions, a key differentiator in the market.

The company's robust patent portfolio, covering various aspects of battery design and manufacturing, is a substantial key resource. This intellectual property protects their innovations and reinforces their competitive edge in the rapidly evolving battery sector.

BYD's considerable battery production capacity, exceeding 70 GWh annually as of late 2023, is another vital resource. This scale allows them to meet growing demand and maintain cost-effectiveness, providing reliable and long-lasting battery solutions for their diverse product lines, including electric vehicles and energy storage systems.

BYD Electronic's advanced manufacturing facilities are a cornerstone of its operational strength. These state-of-the-art sites, equipped with extensive smart factory automation including robotic assembly lines, are fundamental to the company's ability to rapidly and efficiently scale production. This technological integration directly supports the high-precision manufacturing of complex electronic components and finished smart devices.

The automation within BYD Electronic's factories is a key driver of both cost efficiency and product quality. For instance, in 2023, BYD reported a significant increase in its production capacity for electric vehicles, a sector heavily reliant on sophisticated manufacturing processes, indicating the successful deployment of these advanced resources. This focus on automation allows for consistent output and adherence to stringent quality standards, essential for competing in the global electronics market.

BYD's extensive R&D capabilities are anchored by a formidable team of over 100,000 engineers. This vast pool of talent is the engine behind BYD's rapid innovation in key sectors like electric vehicles and new energy technologies.

This significant investment in human capital allows BYD to consistently develop cutting-edge solutions, particularly in electrification and intelligent vehicle systems. For instance, their commitment to R&D is evident in their continuous advancements in battery technology and autonomous driving features.

Vertically Integrated Supply Chain

BYD's vertically integrated supply chain is a cornerstone of its business model, controlling processes from raw material sourcing and battery production to semiconductor manufacturing and vehicle assembly. This extensive control allows BYD to manage costs effectively, ensuring resilience against supply chain disruptions. For instance, BYD's self-sufficiency in battery technology, particularly its Blade Battery, provides a significant competitive edge and cost advantage.

This deep integration translates into superior cost control and enhanced supply chain resilience. BYD's ability to manufacture key components in-house, such as power semiconductors and batteries, shields it from external price volatility and component shortages. In 2023, BYD reported a net profit attributable to parent company shareholders of 30.04 billion yuan (approximately $4.2 billion USD), a substantial increase from 16.62 billion yuan in 2022, underscoring the financial benefits of its integrated model.

- Raw Material Sourcing: Direct control over essential materials like lithium and cobalt for battery production.

- Component Manufacturing: In-house production of critical components including batteries (Blade Battery), electric motors, and power semiconductors.

- Vehicle Assembly: Full control over the manufacturing process from component integration to final vehicle assembly.

- R&D and Design: Integration of research and development allows for rapid innovation and optimization across the supply chain.

Brand Reputation and Intellectual Property

BYD's brand reputation as a global leader in new energy vehicles and sustainable technology is a cornerstone of its business model. This strong public image fosters customer loyalty and trust, crucial for continued sales growth. In 2024, BYD continued to solidify this reputation, reporting significant increases in vehicle deliveries, a testament to its market standing.

The company's extensive intellectual property portfolio, encompassing thousands of patents, provides a significant competitive advantage. These patents cover critical technologies in battery development, electric powertrain systems, and vehicle manufacturing processes. This innovation barrier protects BYD's market share and supports its premium pricing strategies.

- Brand Strength BYD's brand is globally recognized for innovation in electric vehicles and sustainable solutions.

- Patent Portfolio A vast collection of patents across key EV technologies provides a strong competitive moat.

- Customer Trust The established reputation directly translates into higher customer confidence and purchasing intent.

- Talent Attraction A leading brand and technological prowess attract top engineering and management talent.

BYD's proprietary battery technology, particularly the Blade Battery, is a core resource, enhancing safety and efficiency. Their extensive patent portfolio safeguards innovations, reinforcing a competitive edge in the battery sector. Significant annual battery production capacity, exceeding 70 GWh by late 2023, enables them to meet demand and maintain cost-effectiveness.

BYD Electronic's advanced, highly automated manufacturing facilities are crucial for scaling production of complex electronic components and smart devices. This automation drives cost efficiency and ensures consistent, high-quality output. The company's substantial R&D investment, backed by over 100,000 engineers, fuels continuous innovation in electrification and intelligent vehicle systems.

The company's vertically integrated supply chain, from raw materials to assembly, provides cost control and resilience. This integration, including in-house production of semiconductors and batteries, minimizes exposure to external price volatility. BYD's strong brand reputation as a global leader in new energy vehicles and sustainable technology fosters customer loyalty and attracts top talent.

| Key Resource | Description | Impact | 2023/2024 Data Point |

| Blade Battery Technology | Proprietary LiFePO4 battery technology | Enhanced safety and efficiency | Integral to BYD's EV and energy storage solutions. |

| Patent Portfolio | Extensive intellectual property | Competitive advantage, innovation protection | Thousands of patents covering EV and battery tech. |

| Production Capacity | Large-scale battery manufacturing | Meets demand, cost-effectiveness | Exceeded 70 GWh annually (late 2023). |

| Advanced Manufacturing | Smart factory automation | Scalability, efficiency, quality | Supports high-precision manufacturing of electronics. |

| R&D Capabilities | Large engineering team | Continuous innovation | Over 100,000 engineers driving advancements. |

| Vertical Integration | Control over supply chain | Cost control, supply chain resilience | In-house production of batteries, semiconductors. |

| Brand Reputation | Global leader in NEVs | Customer loyalty, talent attraction | Significant increase in vehicle deliveries in 2024. |

Value Propositions

BYD Electronic provides a complete suite of services for smart devices, covering everything from initial design and research to full-scale manufacturing and supply chain logistics. This integrated approach means clients have one dedicated partner for their entire product lifecycle, streamlining development and ensuring smooth execution.

In 2023, BYD Electronic reported revenue of approximately $83.5 billion, showcasing its significant scale and capacity to handle complex, end-to-end projects for major smart device brands.

BYD Electronic's technological prowess is a cornerstone of its value proposition. The company consistently invests in research and development, driving innovation in critical areas such as intelligent driving systems and advanced electronic components. This focus ensures their offerings remain at the forefront of the industry, providing customers with the most cutting-edge solutions available.

This dedication to innovation translates directly into enhanced product performance and functionality for their clientele. For instance, BYD's advancements in AI applications are being integrated into next-generation automotive electronics, promising more sophisticated and user-friendly experiences. In 2023, BYD reported a significant increase in R&D spending, reaching approximately RMB 16.5 billion, underscoring their commitment to technological leadership.

BYD Electronic prioritizes high-quality and reliable products across its intelligent device range. This commitment is underpinned by stringent quality control measures and a vertically integrated manufacturing model, which BYD has honed over years of operation.

This dedication to quality fosters strong customer trust and cultivates enduring partnerships. For instance, BYD's automotive division, which leverages similar manufacturing principles, saw its battery shipments reach approximately 17.1 GWh in April 2024, reflecting the market's confidence in its product reliability.

Cost Efficiency through Vertical Integration

BYD Electronic's vertical integration is a cornerstone of its cost efficiency. By controlling key stages of production, from component manufacturing to final assembly, the company significantly reduces reliance on external suppliers, thereby mitigating price volatility and supply chain disruptions. This internal control translates directly into cost savings.

This integrated model allows BYD Electronic to offer competitive pricing without compromising on quality. Clients benefit from this cost advantage, receiving high-quality electronic components and assembly services at optimized price points, which is crucial in today's market. For example, BYD's extensive battery production capabilities, a key component in many electronics, provide a substantial cost advantage over competitors who outsource this critical element.

- Cost Savings: BYD Electronic's control over its supply chain, including component manufacturing, minimizes external procurement costs.

- Competitive Pricing: These efficiencies allow BYD to offer its products and services at highly competitive market prices.

- Quality Assurance: Vertical integration also enables tighter quality control over all components and manufacturing processes.

- Supply Chain Stability: Reduced dependence on third-party suppliers enhances the reliability and predictability of production schedules.

Flexible and Scalable Manufacturing

BYD Electronic's manufacturing prowess centers on its flexible and scalable capabilities, a key value proposition for its clients. This adaptability allows the company to swiftly adjust production volumes in response to fluctuating market demands and the rapid pace of technological innovation. For instance, BYD Electronic has demonstrated its capacity to ramp up production for new smartphone models or electric vehicle components within tight timelines.

This agility directly benefits customers by enabling them to accelerate their product launch cycles and efficiently scale their operations. BYD Electronic's infrastructure is designed to accommodate growth, ensuring that partners can meet increasing consumer interest without compromising on quality or delivery speed. In 2024, BYD Electronic continued to invest heavily in advanced manufacturing technologies, aiming to further reduce lead times and enhance production efficiency.

- Adaptable Production Lines: BYD Electronic utilizes modular manufacturing setups that can be reconfigured quickly for different product types, supporting diverse client needs.

- Capacity Expansion: The company has a proven track record of expanding its manufacturing footprint, evidenced by its significant global production capacity for electronics and automotive components.

- Rapid Prototyping and Small-Batch Runs: Beyond mass production, BYD Electronic offers the flexibility to handle prototyping and smaller production runs, crucial for testing new market entries.

- Supply Chain Integration: Its scalable manufacturing is supported by a robust and integrated supply chain, ensuring consistent material availability even during periods of high demand.

BYD Electronic offers comprehensive, end-to-end solutions for smart devices, from R&D to manufacturing and logistics, simplifying the product lifecycle for clients. Its technological leadership, demonstrated by significant R&D investments, ensures cutting-edge solutions, particularly in areas like intelligent driving systems. The company’s commitment to quality and reliability, supported by vertical integration and stringent controls, builds customer trust and fosters long-term partnerships.

BYD Electronic's value proposition is further strengthened by its cost efficiency, achieved through vertical integration which minimizes external dependencies and price volatility. This allows for competitive pricing without sacrificing quality, benefiting clients with optimized costs for high-quality electronic components and assembly. Furthermore, its flexible and scalable manufacturing capabilities enable rapid adaptation to market demands and technological shifts, accelerating product launch cycles for its partners.

| Value Proposition Aspect | Key Benefit | Supporting Data/Fact |

|---|---|---|

| End-to-End Solutions | Streamlined product development and execution | Revenue of approx. $83.5 billion in 2023 |

| Technological Innovation | Cutting-edge products and enhanced functionality | R&D investment of approx. RMB 16.5 billion in 2023 |

| Quality & Reliability | Customer trust and enduring partnerships | Battery shipments of approx. 17.1 GWh in April 2024 |

| Cost Efficiency (Vertical Integration) | Competitive pricing and reduced supply chain risk | Control over key production stages, e.g., battery manufacturing |

| Manufacturing Agility | Accelerated product launches and scalable operations | Continued investment in advanced manufacturing technologies in 2024 |

Customer Relationships

BYD Electronic cultivates robust customer connections via dedicated account management, offering tailored support and prompt attention to client needs. This focus ensures a thorough grasp of customer demands, fostering enduring strategic alliances, especially with key original equipment manufacturers (OEMs).

BYD Electronic actively partners with clients on research and development, a key aspect of its customer relationships. This collaborative approach is particularly evident in the creation of new intelligent products and advanced automotive intelligent systems, fostering innovation tailored to specific needs.

By engaging in co-creation, BYD Electronic ensures its offerings precisely align with customer specifications and evolving market demands. This strategy was instrumental in their 2023 performance, where BYD Group reported a staggering 422% increase in net profit, reaching 30.04 billion yuan, reflecting the success of customer-centric product development.

BYD Electronic's commitment to customer satisfaction is evident in its comprehensive technical support and after-sales service. This includes readily available troubleshooting assistance and proactive maintenance schedules for their manufactured components and systems. In 2024, BYD reported a significant increase in customer retention rates, directly attributed to the effectiveness of their support infrastructure.

Strategic Partnerships and Alliances

BYD Electronic cultivates strategic partnerships and alliances with its core clientele. This approach transcends simple transactions, aiming instead to nurture shared growth and drive innovation. For instance, in 2024, BYD Electronic announced a significant joint venture with a leading automotive manufacturer to co-develop next-generation electric vehicle battery technology, a move expected to enhance both companies' market positions.

These collaborations frequently solidify through enduring agreements and joint ventures. Such structures underscore a deep commitment and align objectives, creating a more robust and synergistic business ecosystem. For example, BYD Electronic's long-standing alliance with a major consumer electronics firm has consistently resulted in the integration of BYD's advanced display technologies into the partner's flagship products, contributing to a reported 15% increase in joint product sales in the first half of 2024.

- Long-term agreements: BYD Electronic secures extended contracts with key clients, ensuring stable demand and collaborative planning.

- Joint ventures: The company engages in shared ventures to pool resources and expertise, particularly in R&D and market expansion.

- Co-development initiatives: Partnerships often involve joint product development, leveraging BYD's manufacturing prowess and partners' market insights.

- Mutual growth focus: The overarching goal is to foster reciprocal growth, benefiting both BYD Electronic and its strategic partners.

Direct Engagement and Feedback Mechanisms

BYD Electronic prioritizes direct customer engagement, fostering a strong connection through various communication channels. This approach allows for the immediate collection of valuable feedback, crucial for refining their offerings.

The company actively solicits customer input, utilizing surveys, online forums, and direct support interactions to gather insights. This commitment to listening ensures BYD Electronic remains responsive to market demands and individual customer needs. For instance, in 2024, BYD Electronic reported a 15% increase in customer satisfaction scores directly attributed to improvements made based on user feedback collected through their digital platforms.

- Direct Communication Channels: Online portals, customer service hotlines, and social media platforms facilitate two-way conversations.

- Feedback Integration: Insights gathered are systematically analyzed and integrated into product development and service enhancement cycles.

- Proactive Issue Resolution: BYD Electronic aims to address customer concerns swiftly, often before they escalate, demonstrating a commitment to service excellence.

- Data-Driven Improvements: Customer feedback data is a key input for strategic decision-making, driving innovation and operational efficiency.

BYD Electronic prioritizes deep, collaborative relationships, often engaging in joint ventures and co-development with key partners. This strategy, focused on mutual growth, was evident in 2024 with a significant joint venture to develop next-generation EV battery technology. Their commitment to customer satisfaction is further demonstrated through comprehensive technical support and after-sales service, which contributed to a reported increase in customer retention rates in 2024.

| Relationship Type | Key Activities | 2024 Impact |

| Strategic Partnerships | Joint Ventures, Co-development | Enhanced market position through EV battery tech JV |

| Dedicated Account Management | Tailored support, understanding needs | Fostered enduring alliances with OEMs |

| Technical Support & After-Sales | Troubleshooting, proactive maintenance | Increased customer retention rates |

Channels

BYD Electronic's direct sales approach to OEMs and enterprise clients is a cornerstone of its business model. This strategy facilitates tailored solutions and deep collaboration, crucial for intricate smart device and automotive intelligence projects.

In 2024, BYD's automotive segment, a key area for OEM partnerships, saw significant growth, with the company delivering over 3.02 million new energy vehicles, a substantial increase from previous years. This expansion underscores the effectiveness of their direct engagement with automotive manufacturers.

BYD leverages an extensive global sales network and strategically located regional offices to effectively serve its international clientele and aggressively expand its market reach. This robust physical presence is crucial for providing localized customer support, driving deeper market penetration, and ensuring strict adherence to diverse regional regulations, all of which contribute to efficient worldwide distribution and strong client engagement.

BYD Electronic actively participates in major industry trade shows and conferences, such as CES and MWC. These events are crucial for showcasing their latest advancements in electric vehicles, battery technology, and consumer electronics to a global audience. In 2024, BYD reported a significant increase in global sales, underscoring the effectiveness of these platforms in reaching new markets and partners.

Online Presence and Digital Marketing

BYD's established online presence, featuring its corporate website and robust digital marketing, is a critical channel for reaching a global audience. This digital footprint is instrumental in disseminating information about its diverse product lines, from electric vehicles to energy storage solutions, and in building brand recognition. In 2024, BYD continued to invest heavily in digital marketing, aiming to capture a larger share of the rapidly expanding EV market.

The company leverages its digital channels for direct engagement, providing customers with easy access to product details, specifications, and company news. This approach supports lead generation by attracting potential buyers and investors. BYD's digital strategy also focuses on content marketing, sharing insights into their technological advancements and sustainability efforts.

- Corporate Website: Serves as a central hub for product information, investor relations, and company news, attracting millions of visitors annually.

- Digital Marketing Campaigns: Targeted online advertising and social media engagement to promote new models and brand initiatives, with significant spend allocated in 2024.

- Lead Generation: Online forms and inquiries on the website directly feed into sales funnels, converting interest into potential customers.

- Brand Building: Consistent online messaging and content reinforce BYD's image as an innovator in new energy technologies.

Strategic Partnerships for Market Entry

BYD Electronic leverages strategic partnerships as a key channel for entering new markets and boosting brand visibility. These alliances often involve local businesses, established distributors, and even prominent sports organizations.

For instance, collaborations with entities like FC Internazionale Milano, where BYD Electronic serves as a global partner, demonstrate a strategy to tap into established fan bases and enhance brand recognition in diverse geographical areas. This approach allows BYD Electronic to bypass some of the initial hurdles of market penetration by associating with trusted local names and popular cultural touchpoints.

These partnerships are crucial for navigating the complexities of different regulatory environments and consumer preferences.

- Local Distribution Networks: Partnering with established local distributors ensures efficient product placement and sales reach within a new market.

- Brand Association: Collaborations with well-known entities, such as sports clubs, create immediate brand awareness and positive association among target demographics.

- Market Navigation: Local partners provide invaluable insights into consumer behavior, cultural nuances, and regulatory landscapes, smoothing the market entry process.

BYD Electronic utilizes a multi-faceted channel strategy, combining direct engagement with OEMs and enterprise clients through its sales force and participation in key industry events. This ensures tailored solutions and broad market exposure.

The company’s global sales network and regional offices are vital for localized support and market penetration, complemented by a strong online presence for brand building and lead generation. Strategic partnerships further enhance market entry and visibility.

In 2024, BYD's automotive segment, a prime example of OEM engagement, saw deliveries exceed 3.02 million new energy vehicles, highlighting the success of these direct relationships and broad distribution efforts.

| Channel | Description | Key Activities/Examples | 2024 Impact/Focus |

|---|---|---|---|

| Direct Sales to OEMs/Enterprise | Tailored solutions and deep collaboration with business clients. | Dedicated sales teams, project-specific consultations. | Growth in automotive intelligence projects, significant EV OEM partnerships. |

| Global Sales Network & Regional Offices | Localized support and market penetration. | Customer service, regulatory compliance, distribution hubs. | Expanding market reach in key international regions. |

| Industry Trade Shows & Conferences | Showcasing advancements and networking. | CES, MWC participation, product demonstrations. | Increased global brand visibility and new partnership opportunities. |

| Online Presence & Digital Marketing | Information dissemination, brand building, lead generation. | Corporate website, targeted ads, content marketing. | Heavy investment in digital marketing for EV market share. |

| Strategic Partnerships | Market entry, brand visibility, navigating local complexities. | Local distributors, sports sponsorships (e.g., FC Internazionale Milano). | Leveraging established networks for smoother market entry and brand association. |

Customer Segments

Global Smart Device Brands represent a core customer segment for BYD Electronic, encompassing major original equipment manufacturers (OEMs) like Apple, Samsung, and others. These brands rely on BYD Electronic for comprehensive services, including product design, advanced research and development, and large-scale manufacturing of smartphones, laptops, wearables, and other intelligent devices.

BYD Electronic acts as a vital strategic partner, delivering high-precision components and sophisticated assembly solutions that are crucial for bringing these complex consumer electronics to market. In 2023, the global smartphone market alone saw shipments of approximately 1.17 billion units, highlighting the immense scale of demand that BYD Electronic caters to within this segment.

BYD Auto is BYD Electronic's cornerstone customer, a crucial relationship for both entities. BYD Electronic supplies vital electronic components, sophisticated intelligent driving systems, and advanced thermal management solutions specifically designed for BYD's New Energy Vehicles (NEVs). This internal synergy ensures BYD Auto benefits from cutting-edge technology, directly contributing to the performance and appeal of their electric vehicle lineup.

Beyond BYD Auto, BYD Electronic actively targets other automotive manufacturers as potential clients. The company aims to provide these external partners with comprehensive intelligent system solutions, mirroring the advanced capabilities developed for its parent company. This expansion strategy leverages BYD Electronic's proven expertise to capture a broader share of the automotive electronics market.

New Intelligent Product Developers are companies and innovators creating entirely new categories of smart products. These ventures often require sophisticated design, advanced manufacturing, and precise assembly, areas where BYD Electronic excels. BYD Electronic's capabilities are particularly relevant for the burgeoning market of AI servers and data center components, reflecting the growing demand for specialized electronic manufacturing services for cutting-edge technology.

Telecommunications and IT Infrastructure Providers

BYD Electronic's expansion into AI servers and data centers directly appeals to telecommunications and IT infrastructure providers. These companies are at the forefront of digital transformation, demanding robust and energy-efficient hardware to support their expanding operations. For instance, the global data center market was valued at approximately $200 billion in 2023 and is projected to grow significantly, fueled by AI workloads.

These clients require high-performance computing infrastructure to manage vast amounts of data and power advanced applications. BYD Electronic's offerings in AI servers provide the necessary processing capabilities, while their focus on energy efficiency aligns with the industry's drive to reduce operational costs and environmental impact. The demand for AI-specific hardware is skyrocketing, with the AI hardware market expected to reach hundreds of billions of dollars in the coming years.

- Target Customers: Telecommunications companies, cloud service providers, and enterprise IT departments.

- Key Needs: High-density computing, low-latency networking, and sustainable power solutions for data centers.

- Market Opportunity: The increasing global demand for data processing and AI capabilities presents a substantial growth area for BYD Electronic.

- Value Proposition: Providing reliable, high-performance, and energy-efficient server and infrastructure components.

Vertically Integrated Business Units (Internal Customers)

BYD Electronic's vertically integrated structure means its internal business units, like BYD Auto and FinDreams Battery, are key customers. These divisions rely on BYD Electronic for essential components and manufacturing expertise, fostering significant internal demand.

This internal customer base allows BYD Electronic to achieve substantial cost efficiencies and operational synergies. The close collaboration streamlines supply chains and product development, directly benefiting the performance of sister companies within the BYD Group.

- Internal Demand: BYD Auto, a major global EV manufacturer, represents a significant portion of BYD Electronic's component orders, particularly for power electronics and control systems.

- Synergistic Benefits: FinDreams Battery leverages BYD Electronic's expertise in electronic assembly for its battery management systems, enhancing overall battery pack performance and reliability.

- Cost Optimization: By supplying internally, BYD Electronic reduces external procurement costs for its group companies, contributing to BYD's competitive pricing in the automotive and energy storage markets.

- R&D Collaboration: Joint development projects between BYD Electronic and its internal customers accelerate innovation, ensuring components meet the evolving needs of electric vehicles and renewable energy solutions.

BYD Electronic serves a diverse customer base, from global smart device brands like Apple and Samsung to its own automotive division, BYD Auto. The company also targets emerging sectors such as AI servers and data centers, catering to telecommunications and IT infrastructure providers. Internally, BYD Auto and FinDreams Battery are significant clients, benefiting from BYD Electronic's manufacturing prowess.

| Customer Segment | Key Products/Services Supplied | 2023 Market Context/Data Point |

|---|---|---|

| Global Smart Device Brands | Smartphones, laptops, wearables (design, R&D, manufacturing) | Global smartphone shipments ~1.17 billion units |

| BYD Auto | EV electronic components, intelligent driving systems, thermal management | BYD Auto is a major global NEV manufacturer |

| Other Automotive Manufacturers | Intelligent system solutions | Automotive electronics market is a significant growth area |

| New Intelligent Product Developers (AI Servers/Data Centers) | High-performance computing, energy-efficient components | Global data center market valued at ~$200 billion |

| Internal BYD Units (BYD Auto, FinDreams Battery) | Power electronics, battery management systems, electronic assembly | Internal synergy drives cost efficiencies and innovation |

Cost Structure

Research and Development (R&D) is a substantial cost for BYD Electronic, driven by its dedication to innovation in key sectors such as batteries, smart vehicle technology, and artificial intelligence. This significant investment underscores BYD's strategy to remain at the forefront of technological advancements.

In 2024, BYD allocated a considerable 54.2 billion yuan to R&D. This figure highlights the company's deep commitment to developing next-generation technologies and maintaining a competitive edge in the rapidly evolving automotive and electronics industries.

BYD's manufacturing and production costs are significant, encompassing raw material sourcing, the wages for its vast global workforce, which exceeded 900,000 employees in 2024, and the operational expenses of its numerous factories. These elements form a core component of the company's overall expenditure.

The company's commitment to vertical integration is a strategic approach designed to manage and optimize these substantial production costs. By controlling more of its supply chain, BYD aims for greater efficiency and cost predictability in its manufacturing processes.

BYD's vertically integrated and global supply chain means substantial expenses in logistics and transportation. This includes the costs associated with managing inventory, operating warehouses, and ensuring timely delivery of both raw components and finished electronic products across the globe.

These supply chain costs are fundamental to BYD's ability to operate efficiently and meet customer delivery timelines. For instance, in 2023, BYD reported significant investments in its supply chain infrastructure to support its expanding electric vehicle and electronics businesses, reflecting the scale of these logistical operations.

Sales, Marketing, and Distribution Expenses

BYD's cost structure heavily features expenses for sales, marketing, and global distribution. These are crucial for its expansive market reach. In 2024, the company invested significantly in brand building and expanding its sales infrastructure to drive aggressive market penetration.

These costs are essential for maintaining BYD's competitive edge and global presence.

- Brand Promotion: Significant investment in advertising and promotional campaigns across various international markets.

- Sales Network Development: Costs associated with establishing and maintaining a robust global sales force and dealership networks.

- Distribution Management: Expenses related to logistics, warehousing, and shipping to ensure efficient product delivery to customers worldwide.

- Market Penetration Strategy: A substantial portion of BYD's 2024 revenue was allocated to these areas to support its ambitious growth targets in key regions.

Capital Expenditure (CAPEX) for Plant Expansion

BYD's commitment to rapid global growth is reflected in its substantial Capital Expenditure (CAPEX) for plant expansion. This involves significant investments in new production facilities across various continents to meet escalating demand and establish a stronger international footprint. For instance, BYD is actively constructing new plants in key markets such as Thailand, Indonesia, Uzbekistan, and Mexico, alongside a significant new European facility in Hungary.

This strategic expansion is crucial for bolstering BYD's production capacity and solidifying its global market presence. The ongoing capital outlays are directly linked to increasing output volumes and diversifying manufacturing locations to mitigate supply chain risks and serve regional markets more effectively.

- Global Expansion: BYD is investing heavily in new manufacturing plants in Thailand, Indonesia, Uzbekistan, Mexico, and Hungary.

- Capacity Increase: These investments are designed to significantly boost production capacity to meet growing global demand for BYD's electronic products and vehicles.

- Market Penetration: Establishing facilities in new regions allows BYD to better serve local markets and reduce logistical costs.

- Strategic Investment: The CAPEX reflects a long-term strategy to become a dominant player in key international markets.

BYD Electronic's cost structure is heavily influenced by its substantial investments in Research and Development (R&D), aiming for technological leadership. Manufacturing and production costs, including raw materials and labor for its vast workforce, are significant operational expenses. The company's vertically integrated model, while offering control, also entails considerable costs in logistics and global supply chain management.

| Cost Category | Key Drivers | 2024 Data/Notes |

|---|---|---|

| Research & Development (R&D) | Innovation in batteries, smart vehicles, AI | 54.2 billion yuan allocated |

| Manufacturing & Production | Raw materials, workforce wages, factory operations | Over 900,000 employees globally in 2024 |

| Supply Chain & Logistics | Inventory, warehousing, transportation, global distribution | Significant investments in infrastructure in 2023 |

| Sales, Marketing & Distribution | Brand promotion, sales network, market penetration | Aggressive investment to drive market expansion |

| Capital Expenditure (CAPEX) | New plant construction (Thailand, Hungary, Mexico, etc.) | Strategic expansion for global capacity and market presence |

Revenue Streams

BYD Electronic generates revenue by offering comprehensive services for smart device components and assembly. This includes everything from the initial design and research and development to the actual manufacturing and managing the entire supply chain. They cater to a range of smart devices, such as smartphones, laptops, and wearable technology.

In 2024, this business segment experienced a notable surge in revenue. This growth was driven by BYD Electronic's strategic expansion into new product categories and a strengthening of its market position with significant international clients.

BYD Electronic is experiencing significant growth in revenue from its automotive intelligent systems and electronic components. This segment is a key contributor, supplying advanced technologies like intelligent driving systems and sophisticated thermal management products essential for the burgeoning new energy vehicle market. In 2023, BYD Auto, a major customer, saw its sales surge by 62% year-over-year, indicating a strong demand for these integrated electronic solutions.

BYD Electronic is seeing significant revenue growth from its manufacturing of new intelligent products. This includes crucial components for AI servers, data centers, and advanced liquid-cooling systems essential for high-performance computing. This sector is a key driver of future expansion for the company.

Battery Sales (Consumer and Power Batteries)

BYD Electronic, while primarily focused on contract manufacturing, benefits from the BYD Group's extensive battery operations. The broader BYD conglomerate, through its FinDreams Battery subsidiary, is a significant player in rechargeable battery sales. This includes batteries for consumer electronics and larger power batteries, notably the innovative Blade Battery technology powering electric vehicles and energy storage solutions.

BYD solidified its position as a global leader in the electric vehicle battery market, ranking as the world's second-largest producer in 2024. This strong market presence directly translates into substantial revenue streams from battery sales, underpinning the group's overall financial performance.

- Consumer Batteries: Revenue generated from batteries used in various electronic devices.

- Power Batteries: Significant income from sales of EV batteries and energy storage systems, with BYD being the second-largest global supplier in 2024.

- Blade Battery Technology: A key differentiator contributing to sales volume and market share in the EV sector.

Diversified Services and Solutions

BYD Electronic's revenue streams extend beyond basic manufacturing. They offer comprehensive solutions built on their deep technological knowledge. This includes services like design consulting, research and development support, and supply chain management for their clients.

These diversified services allow BYD Electronic to deliver top-tier products and solutions across a wide range of intelligent device sectors. For instance, in 2023, BYD’s automotive segment, which often incorporates advanced electronics, saw significant growth, indicating the demand for integrated solutions.

- Design Consulting: Offering expertise in product conceptualization and development.

- R&D Services: Providing research and innovation support to clients.

- Supply Chain Optimization: Streamlining logistics and procurement for enhanced efficiency.

- Integrated Solutions: Delivering end-to-end services from design to production.

BYD Electronic's revenue is significantly bolstered by its extensive battery operations, leveraging the BYD Group's global leadership. The company generates substantial income from both consumer batteries for electronics and larger power batteries, particularly for electric vehicles and energy storage. BYD's position as the world's second-largest EV battery producer in 2024, driven by its innovative Blade Battery technology, directly fuels these revenue streams.

| Revenue Stream | Description | Key Data Point |

| Consumer Batteries | Batteries for various electronic devices | Integral to the smart device component business |

| Power Batteries (EV & Energy Storage) | Sales of electric vehicle and energy storage batteries | BYD ranked world's 2nd largest EV battery producer in 2024 |

| Blade Battery Technology | Revenue from proprietary EV battery technology | Key differentiator driving sales volume and market share |

Business Model Canvas Data Sources

The BYD Electronic Business Model Canvas is informed by extensive market research, competitor analysis, and internal financial data. This approach ensures a robust understanding of customer needs, market opportunities, and operational feasibility.