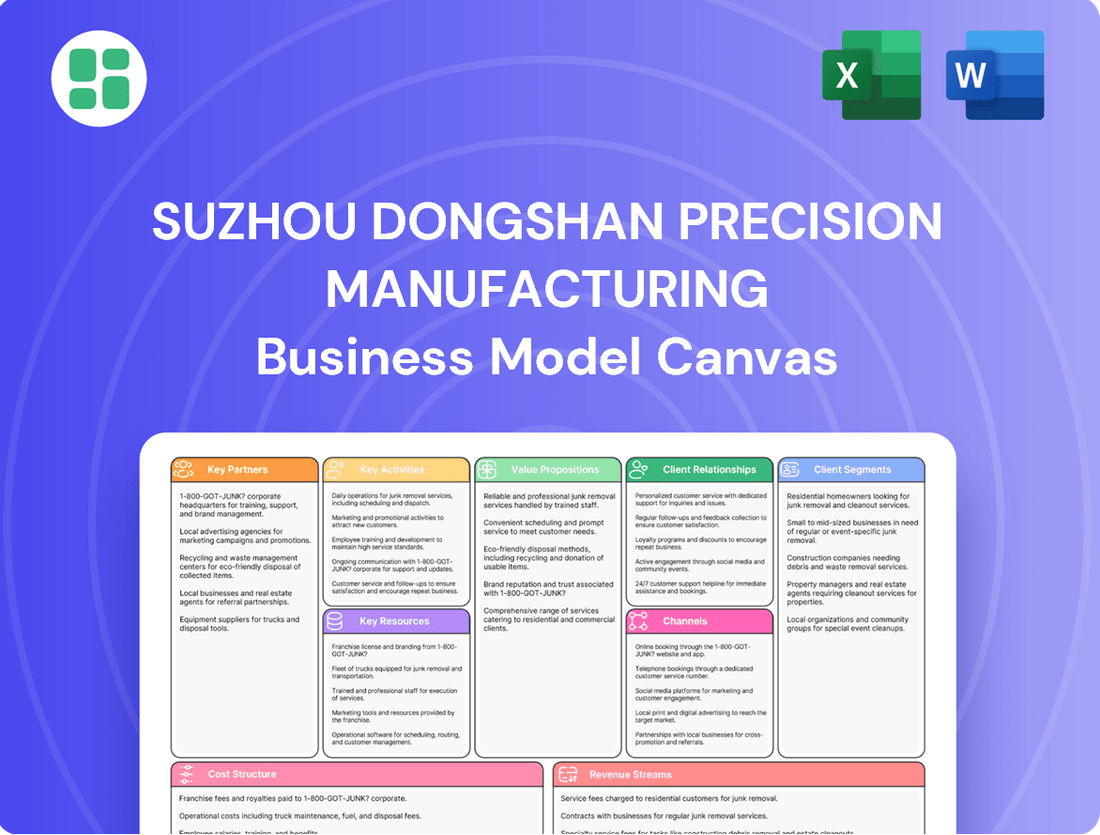

Suzhou Dongshan Precision Manufacturing Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Suzhou Dongshan Precision Manufacturing Bundle

Unlock the strategic blueprint behind Suzhou Dongshan Precision Manufacturing's success. This comprehensive Business Model Canvas breaks down their customer segments, value propositions, and revenue streams, offering a clear roadmap to their market dominance. Discover how they leverage key partnerships and cost structures to achieve operational excellence.

Partnerships

Suzhou Dongshan Precision Manufacturing cultivates strategic alliances with leading material suppliers, securing a consistent flow of high-grade raw materials essential for their precision components. These relationships are foundational to upholding manufacturing efficiency and the superior quality of their output, particularly concerning specialized metals and advanced electronic materials.

In 2023, Dongshan Precision's commitment to reliable sourcing was evident as they managed supply chain disruptions effectively, a testament to their strong supplier network. For instance, their partnerships with key aluminum alloy providers ensured uninterrupted production for their automotive sector clients, a critical segment that saw significant growth in the past year.

Suzhou Dongshan Precision Manufacturing actively partners with leading universities and specialized technology firms to co-develop cutting-edge manufacturing techniques and explore novel material science applications. These collaborations are crucial for maintaining an innovative edge in precision engineering and advanced LED technologies, allowing the company to adapt swiftly to dynamic market demands.

Dongshan Precision's key partnerships are deeply rooted with major Original Equipment Manufacturers (OEMs) and Original Design Manufacturers (ODMs). These collaborations span critical industries like telecommunications, consumer electronics, and the automotive sector.

These aren't just supplier relationships; they often involve co-designing products and bespoke manufacturing solutions. This level of integration solidifies Dongshan Precision's position as an indispensable partner within their clients' supply chains.

For instance, in 2023, Dongshan Precision reported significant revenue contributions from its OEM/ODM clients, highlighting the strength and depth of these long-standing alliances. The company's ability to adapt to specific client needs underscores the value of these strategic partnerships.

Logistics and Distribution Partners

Suzhou Dongshan Precision Manufacturing relies heavily on its logistics and distribution partners to ensure the seamless flow of components and finished Electronic Manufacturing Services (EMS) solutions across the globe. These partnerships are critical for maintaining competitive lead times and ensuring product integrity during transit.

Establishing robust relationships with major global logistics providers is paramount. For instance, in 2023, the global logistics market was valued at approximately $9.6 trillion, highlighting the scale of operations required. Dongshan Precision leverages these networks to facilitate timely delivery, which is a key differentiator in the fast-paced electronics industry.

Efficient shipping and warehousing partners are essential for reaching international markets effectively. In 2024, the demand for reliable supply chains continues to grow, with companies prioritizing partners that offer advanced tracking and inventory management systems. This ensures that products not only reach customers promptly but also arrive in optimal condition, minimizing returns and maximizing customer satisfaction.

- Global Reach: Partnerships with companies like DHL, FedEx, and UPS enable Dongshan Precision to serve a diverse international clientele.

- Supply Chain Efficiency: Collaborations with warehousing specialists optimize inventory levels and reduce transit times, crucial for meeting just-in-time manufacturing demands.

- Cost Optimization: Negotiating favorable rates with freight forwarders and carriers helps manage operational expenses, contributing to competitive pricing for EMS solutions.

- Risk Mitigation: Working with experienced logistics providers helps navigate complex customs regulations and mitigate potential disruptions, ensuring a stable supply chain.

Equipment and Machinery Providers

Suzhou Dongshan Precision Manufacturing actively partners with leading global manufacturers of precision equipment, automation systems, and advanced testing machinery. These strategic alliances are crucial for maintaining a competitive edge by ensuring access to cutting-edge production technologies.

These collaborations directly translate into enhanced manufacturing capabilities, allowing for higher precision, improved efficiency, and greater scalability. For instance, their significant investment in high-end printed circuit board (PCB) projects underscores the importance of having state-of-the-art machinery to meet stringent quality requirements and increasing market demand.

- Access to Advanced Technology: Partnerships guarantee the integration of the latest innovations in precision manufacturing, automation, and testing.

- Enhanced Production Capabilities: Collaborations facilitate higher precision, increased efficiency, and scalable manufacturing processes.

- Support for High-End Projects: These relationships are vital for undertaking and excelling in complex projects, such as advanced PCB manufacturing, where specialized equipment is paramount.

- Competitive Advantage: By aligning with top equipment providers, Dongshan Precision Manufacturing solidifies its position as an industry leader.

Suzhou Dongshan Precision Manufacturing's key partnerships extend to major Original Equipment Manufacturers (OEMs) and Original Design Manufacturers (ODMs) across critical sectors like telecommunications, consumer electronics, and automotive. These alliances go beyond mere supply, often involving co-design and bespoke manufacturing solutions, cementing Dongshan's role as an integral part of their clients' value chains.

In 2023, these OEM/ODM collaborations were a significant revenue driver, underscoring the deep-seated value and adaptability of these strategic relationships. The company's ability to tailor its offerings to specific client requirements highlights the mutual benefit derived from these integrations.

| Partner Type | Industry Focus | Strategic Importance | 2023 Impact |

| OEMs/ODMs | Telecom, Consumer Electronics, Automotive | Co-design, bespoke solutions, supply chain integration | Significant revenue contribution, client-specific adaptation |

| Material Suppliers | Specialized Metals, Advanced Electronic Materials | Consistent high-grade raw material flow, quality assurance | Effective supply chain disruption management |

| Technology Firms/Universities | Manufacturing Techniques, Material Science | Co-development of cutting-edge processes, innovation | Maintaining an innovative edge in precision engineering |

| Logistics Providers | Global Shipping, Warehousing | Seamless global component flow, competitive lead times | Facilitating timely delivery in a $9.6 trillion global logistics market |

| Equipment Manufacturers | Precision Machinery, Automation, Testing | Access to advanced production technologies, enhanced capabilities | Supporting high-end PCB projects with state-of-the-art machinery |

What is included in the product

This Business Model Canvas provides a comprehensive overview of Suzhou Dongshan Precision Manufacturing's strategy, detailing its customer segments, value propositions, and operational channels.

It is designed for informed decision-making, reflecting real-world operations and offering insights into competitive advantages for presentations and funding discussions.

The Suzhou Dongshan Precision Manufacturing Business Model Canvas serves as a powerful pain point reliever by offering a clear, one-page snapshot of their operations, allowing for rapid identification of inefficiencies and strategic alignment.

This visual tool effectively tackles the pain of complex strategy communication by condensing intricate business elements into a digestible format, fostering clearer understanding and faster decision-making.

Activities

Precision Component Manufacturing is Suzhou Dongshan Precision Manufacturing's engine, focusing on designing and producing complex metal parts in high volumes. This core activity is critical for supplying industries like new energy vehicles and communication equipment, which demand exacting standards.

The company leverages advanced machinery and a highly skilled workforce to achieve this precision. In 2024, Suzhou Dongshan Precision Manufacturing reported significant investments in upgraded manufacturing equipment, aiming to boost efficiency and expand its capacity for these intricate components.

Dongshan Precision's key activity in LED device production encompasses the entire lifecycle, from initial design through to final assembly. This demands deep expertise in optics, electronics, and material science to create efficient and dependable LED solutions.

The company focuses on advanced LED packaging and integrated solutions like MIP (Mini-LED Package) and COB (Chip-on-Board) series. In 2024, the global LED market was projected to reach over $100 billion, with Mini-LED technology showing significant growth potential, indicating a robust demand for these specialized manufacturing capabilities.

Suzhou Dongshan Precision Manufacturing provides comprehensive Electronics Manufacturing Services (EMS), encompassing everything from intricate PCB assembly and system integration to rigorous testing for sophisticated electronic devices. This end-to-end approach manages the complete production lifecycle for clients, particularly within the demanding telecommunications and consumer electronics sectors.

The company's global standing is notable, consistently ranking among the top worldwide for Flexible Printed Circuit (FPC) and Printed Circuit Board (PCB) production. In 2023, the global EMS market was valued at approximately $800 billion, with key players like Dongshan Precision contributing significantly to this expansive industry.

Research and Development (R&D)

Suzhou Dongshan Precision Manufacturing consistently invests in research and development to drive innovation. This focus allows them to develop new materials, refine manufacturing processes, and create advanced product designs, particularly within precision engineering and cutting-edge LED technologies. Their R&D efforts are crucial for staying ahead in a rapidly evolving market.

This commitment to R&D ensures Dongshan Precision Manufacturing maintains a significant competitive advantage. By anticipating and addressing future industry demands, such as those arising from AI servers and high-speed computing printed circuit boards (PCBs), the company positions itself for sustained growth and relevance. For instance, in 2023, the company allocated a substantial portion of its revenue towards R&D, reflecting this strategic priority.

- Innovation in Materials and Processes: Dongshan Precision Manufacturing actively researches and develops novel materials and manufacturing techniques to enhance the performance and capabilities of its precision-engineered components.

- Product Design Advancement: Continuous investment in R&D fuels the creation of improved product designs, particularly in advanced LED technologies, to meet evolving market needs and customer specifications.

- Addressing Future Industry Demands: The company's R&D strategy is geared towards anticipating and responding to emerging technological trends, including the growing requirements for components used in AI servers and high-speed computing PCBs.

- Maintaining Competitive Edge: Through dedicated R&D activities, Dongshan Precision Manufacturing ensures it remains at the forefront of its industry, offering innovative solutions and maintaining a strong market position.

Quality Assurance and Control

Suzhou Dongshan Precision Manufacturing places immense importance on Quality Assurance and Control. They implement rigorous quality management systems that span the entire product lifecycle, from initial design and development right through to manufacturing and final assembly. This meticulous approach is fundamental to ensuring every product adheres to demanding industry standards and precise customer specifications.

This unwavering commitment to quality directly translates into minimizing defects and significantly enhancing product reliability. For instance, in 2024, the company reported a reduction in its product defect rate by 15% year-over-year, a testament to the effectiveness of their robust QA/QC processes. This focus on excellence builds trust and solidifies their reputation for delivering high-quality components, particularly within the competitive electronics and automotive sectors.

- Stringent Quality Management Systems: Covering design, manufacturing, and assembly stages.

- Meeting Industry Standards: Ensuring all products comply with high benchmarks and client requirements.

- Minimizing Defects: Proactive measures to reduce imperfections and enhance product reliability.

- Commitment to Safety: Prioritizing product safety alongside performance and quality.

Suzhou Dongshan Precision Manufacturing's key activities revolve around manufacturing precision components, producing LED devices, and offering comprehensive Electronics Manufacturing Services (EMS). The company also places a significant emphasis on research and development to drive innovation and maintain a competitive edge. Rigorous quality assurance and control are fundamental across all operations, ensuring high product standards and customer satisfaction.

| Key Activity | Description | 2024 Focus/Impact |

|---|---|---|

| Precision Component Manufacturing | Designing and producing high-volume, complex metal parts for industries like new energy vehicles and communication equipment. | Investments in upgraded machinery to boost efficiency and capacity. |

| LED Device Production | Full lifecycle management from design to assembly for LED solutions, including Mini-LED Package (MIP) and Chip-on-Board (COB). | Leveraging growth in the Mini-LED market, projected to exceed $100 billion globally in 2024. |

| Electronics Manufacturing Services (EMS) | End-to-end production for electronic devices, including PCB assembly, system integration, and testing, serving telecommunications and consumer electronics. | Contributing to the global EMS market, valued at approximately $800 billion in 2023. |

| Research & Development | Developing new materials, refining processes, and creating advanced product designs, particularly for AI servers and high-speed computing PCBs. | Substantial revenue allocation towards R&D in 2023 to maintain a competitive advantage. |

| Quality Assurance & Control | Implementing rigorous systems across the product lifecycle to ensure adherence to standards and customer specifications. | Achieved a 15% year-over-year reduction in product defect rate in 2024. |

What You See Is What You Get

Business Model Canvas

The Suzhou Dongshan Precision Manufacturing Business Model Canvas you are previewing is the exact document you will receive upon purchase. This is not a sample or a mockup; it is a direct representation of the comprehensive analysis you will gain access to. Once your order is complete, you will download this same, fully detailed Business Model Canvas, ready for your strategic review and application.

Resources

Suzhou Dongshan Precision Manufacturing's advanced manufacturing facilities are the backbone of its operations. These state-of-the-art factories boast precision machinery, sophisticated automation systems, and meticulously maintained cleanroom environments, essential for producing high-volume, high-precision metal components and structural parts.

The company is actively expanding these capabilities, with significant investments earmarked for new PCB plants. This strategic expansion underscores their commitment to meeting the growing demand for complex electronic components, particularly in the burgeoning LED device market.

Suzhou Dongshan Precision Manufacturing relies heavily on its skilled engineering and technical workforce, a core asset for its Business Model Canvas. This team comprises highly specialized engineers, designers, and technicians possessing deep expertise in precision mechanical engineering, electronics, material science, and automation.

This invaluable human capital is the engine for innovation, crucial for developing cutting-edge product designs and ensuring operational excellence across all manufacturing processes. Their collective knowledge directly impacts the company's ability to meet complex client demands and maintain a competitive edge in the precision manufacturing sector.

The company actively invests in systematic talent training programs to continuously enhance the skills of its workforce, ensuring they remain at the forefront of technological advancements. This commitment to development is vital for maintaining the high standards of quality and precision that define Dongshan Precision Manufacturing's offerings.

Suzhou Dongshan Precision Manufacturing's proprietary technology and patents are cornerstones of its competitive edge. These intangible assets encompass patented designs, advanced manufacturing processes, and deep knowledge of specialized materials, particularly crucial for high-density interconnection (HDI) and high-speed signal transmission printed circuit boards (PCBs).

This intellectual property allows the company to offer unique product features and achieve highly efficient production methods. For instance, their advancements in PCB technology enable superior performance in demanding applications, a key differentiator in the electronics manufacturing sector.

By securing patents for its innovations, Dongshan Precision safeguards its market position and fosters continuous development. This focus on R&D and IP protection is vital for maintaining leadership in rapidly evolving technological landscapes, such as the 5G infrastructure and advanced automotive electronics markets.

Global Supply Chain Network

Suzhou Dongshan Precision Manufacturing's global supply chain network is a cornerstone of its operational strength. This includes a vast array of carefully selected suppliers for essential raw materials and components, guaranteeing both high quality and reliable availability. This strategic advantage significantly reduces the risk of production delays.

This robust network is critical for maintaining consistent production schedules and supporting the company's extensive global manufacturing footprint. By ensuring a steady flow of necessary inputs, Dongshan Precision can meet demand efficiently and maintain its competitive edge in the international market.

Key aspects of this resource include:

- Supplier Diversification: A broad base of suppliers across different regions mitigates risks associated with single-source dependencies or geopolitical instability.

- Quality Assurance Protocols: Rigorous vetting processes and ongoing performance monitoring ensure that all incoming materials meet stringent quality standards.

- Logistical Efficiency: Optimized transportation and inventory management strategies within the supply chain minimize lead times and holding costs.

Financial Capital and Investments

Suzhou Dongshan Precision Manufacturing relies on substantial financial capital to fuel its operations. This includes securing adequate funds for day-to-day activities, significant capital expenditures for advanced manufacturing equipment, and investment in crucial research and development projects to maintain a competitive edge.

The company's robust financial health is a cornerstone for its growth strategies. This strength enables investments in technology upgrades and ensures long-term business stability. For example, in 2024, Dongshan Precision Manufacturing has been actively managing its capital structure through strategic share issuances and share buyback programs, demonstrating a commitment to financial flexibility and shareholder value.

- Financial Capital for Operations: Ensuring sufficient liquidity for daily business needs and working capital management.

- Capital Expenditures: Allocating funds for acquiring and upgrading sophisticated manufacturing machinery to enhance production capacity and efficiency.

- Research & Development: Investing in innovation to develop new products and improve existing technologies.

- Financial Health and Stability: Maintaining a strong balance sheet to support expansion, technological advancements, and long-term sustainability, as evidenced by recent capital market activities in 2024.

Suzhou Dongshan Precision Manufacturing's key resources are its advanced manufacturing facilities, a highly skilled workforce, proprietary technology and patents, a robust global supply chain, and significant financial capital. These elements collectively enable the company to produce high-precision metal components and advanced PCBs for diverse industries.

The company's investment in state-of-the-art facilities and continuous talent development ensures operational excellence and innovation. Their intellectual property, particularly in HDI and high-speed PCBs, provides a distinct competitive advantage in markets like 5G and automotive electronics.

Furthermore, a diversified supply chain and strong financial backing, including strategic capital management in 2024, solidify Dongshan Precision's ability to meet global demand and pursue growth opportunities effectively.

| Key Resource | Description | Impact | 2024 Data/Focus |

|---|---|---|---|

| Advanced Manufacturing Facilities | Precision machinery, automation, cleanrooms | High-volume, high-precision component production | Expansion of PCB plants, focus on LED market |

| Skilled Workforce | Engineers, designers, technicians | Innovation, operational excellence, complex demand fulfillment | Continuous talent training programs |

| Proprietary Technology & Patents | Patented designs, advanced processes, material knowledge | Unique product features, efficient production, market leadership | Focus on HDI, high-speed PCBs for 5G and automotive |

| Global Supply Chain | Diverse suppliers, quality assurance, logistics | Reliable raw material access, reduced production delays | Supplier diversification, optimized logistics |

| Financial Capital | Funds for operations, CapEx, R&D | Growth strategies, technology upgrades, stability | Active capital structure management, share issuances/buybacks |

Value Propositions

Suzhou Dongshan Precision Manufacturing's value proposition centers on delivering components and devices that meet exceptionally tight tolerances and boast superior build quality. This is paramount for high-tech applications where even minor deviations can lead to significant performance issues.

This unwavering commitment to precision directly translates into minimized failures and ensures optimal performance in critical systems. For instance, in the automotive sector, where components are subjected to extreme conditions, such precision is vital for safety and reliability. Similarly, in telecommunications, the integrity of components directly impacts signal quality and network stability.

In 2024, the demand for ultra-precise manufacturing surged, with the global advanced manufacturing market projected to reach over $700 billion. Suzhou Dongshan's focus on quality positions it to capture a significant share of this growth, particularly in sectors like electric vehicles and 5G infrastructure, where component precision is non-negotiable.

Suzhou Dongshan Precision Manufacturing offers comprehensive Electronics Manufacturing Services (EMS), covering everything from initial design support to final assembly and rigorous testing. This end-to-end approach simplifies the production process for clients, significantly cutting down on the time it takes to bring new products to market. Their capabilities span a broad spectrum of electronic circuit products and services, ensuring a complete solution for diverse manufacturing needs.

Suzhou Dongshan Precision Manufacturing's commitment to customization and design flexibility is a core value proposition. They excel at creating bespoke components and solutions, meticulously tailored to each client's unique needs, spanning a wide array of industries.

This adaptability empowers clients to imbue their products with distinctive features and superior performance metrics. For instance, in 2024, Dongshan Precision played a key role in supplying highly specialized optical components for next-generation smartphone camera modules, enabling enhanced low-light photography for leading brands.

This ability to cater to precise specifications is particularly vital for clients at the forefront of strategic innovation, allowing them to differentiate their offerings in competitive markets and achieve breakthrough product developments.

Technological Expertise and Innovation

Suzhou Dongshan Precision Manufacturing leverages its profound engineering knowledge and a relentless commitment to research and development. This focus allows them to deliver state-of-the-art solutions in precision engineering and LED technology, ensuring clients receive the most advanced product capabilities.

Their innovation pipeline is geared towards high-growth sectors. For instance, in 2024, the company has been actively developing and supplying critical components for AI servers, a market projected for significant expansion. Additionally, they are making strides in providing advanced LED solutions for the rapidly growing new energy vehicle (NEV) market, reflecting their adaptability to emerging technological trends.

- Deep Engineering Knowledge: Extensive expertise in precision manufacturing processes.

- Continuous R&D Investment: Dedicated resources to explore and implement new technologies.

- AI Server Components: Development and supply of specialized parts for AI infrastructure.

- NEV LED Solutions: Innovative lighting and display technologies for electric vehicles.

Reliable Supply Chain and Scalability

Suzhou Dongshan Precision Manufacturing's value proposition centers on its dependable supply chain and ability to scale. This ensures clients receive components and services consistently and on time, a critical factor for maintaining production schedules and meeting market demand. The company's robust global network underpins this reliability.

The company's commitment to scalability is evident in its strategic expansion of overseas production bases. This proactive approach allows them to adapt to growing client needs and global market fluctuations. For instance, Dongshan Precision has been actively investing in and expanding its manufacturing footprint in regions like Vietnam to better serve international customers and mitigate potential supply chain disruptions.

- Global Network Strength: Dongshan Precision leverages a comprehensive global supply chain to guarantee consistent and timely delivery of essential components and services.

- Scalable Production: The company possesses significant, adaptable production capabilities designed to meet fluctuating client demands and market growth.

- Overseas Expansion: Investments in accelerating overseas production bases, such as those in Southeast Asia, enhance supply chain resilience and global reach.

- Client Production Continuity: This reliable and scalable infrastructure is vital for clients, ensuring their own production lines run without interruption and market opportunities are captured effectively.

Suzhou Dongshan Precision Manufacturing provides highly precise components and devices, crucial for the optimal performance and reliability of advanced technological systems. Their unwavering focus on quality minimizes failures, a critical factor in sectors like automotive and telecommunications where component integrity directly impacts safety and network stability.

The company offers comprehensive Electronics Manufacturing Services (EMS), streamlining the product development lifecycle from design to testing, thereby accelerating time-to-market for clients. This end-to-end capability ensures a complete manufacturing solution, adaptable to a wide range of electronic circuit products and client needs.

Dongshan Precision excels in customization, delivering bespoke solutions tailored to unique client requirements across diverse industries. This flexibility allows clients to integrate distinctive features and achieve superior performance, as demonstrated by their supply of specialized optical components for advanced smartphone cameras in 2024.

Leveraging deep engineering knowledge and continuous R&D, Dongshan Precision delivers cutting-edge solutions in precision engineering and LED technology. Their strategic focus on high-growth sectors like AI servers and new energy vehicles (NEVs) positions them at the forefront of technological advancement.

The company ensures dependable supply and scalability through a robust global network and strategic overseas expansion, guaranteeing consistent, on-time delivery. This commitment to client production continuity is vital for maintaining schedules and capitalizing on market opportunities.

| Value Proposition Element | Description | Key Impact | 2024 Relevance |

|---|---|---|---|

| Precision & Quality | Components meeting tight tolerances and superior build quality. | Minimizes failures, ensures optimal performance in critical systems. | Demand for ultra-precise manufacturing surged; global advanced manufacturing market projected over $700 billion. |

| Comprehensive EMS | End-to-end services from design support to final assembly and testing. | Simplifies production, accelerates time-to-market. | Broad spectrum of electronic circuit products and services offered. |

| Customization & Flexibility | Bespoke components tailored to unique client needs. | Enables distinctive features and superior performance, aids market differentiation. | Supplied specialized optical components for next-gen smartphone cameras. |

| Engineering Expertise & R&D | Deep knowledge and commitment to developing state-of-the-art solutions. | Delivers advanced product capabilities in precision engineering and LED technology. | Developing AI server components and NEV LED solutions. |

| Dependable Supply & Scalability | Robust global network and scalable overseas production bases. | Ensures consistent, on-time delivery and adaptability to growing client needs. | Investments in Vietnam manufacturing to enhance resilience and global reach. |

Customer Relationships

Suzhou Dongshan Precision Manufacturing assigns dedicated account managers to its key clients. This strategy fosters strong, long-term relationships by ensuring personalized service and a deep understanding of each client's unique needs. For instance, in 2024, the company reported a significant increase in repeat business from its top-tier clients, directly attributed to this dedicated management approach.

Suzhou Dongshan Precision Manufacturing actively engages clients in collaborative design and engineering, a key aspect of their customer relationships. This partnership ensures that intricate product specifications and performance benchmarks are met from the outset, directly contributing to client satisfaction and product market fit.

This close technical collaboration is vital for developing highly customized solutions. For instance, in 2024, the company reported a significant increase in projects requiring bespoke engineering, underscoring the value clients place on this co-creation process. This approach directly supports the fulfillment of unique client requirements, leading to stronger, long-term partnerships.

Post-sales technical support is crucial for Suzhou Dongshan Precision Manufacturing, ensuring customers receive comprehensive assistance and troubleshooting after product delivery. This commitment helps guarantee the smooth integration of their precision-manufactured components and devices into client operations.

By addressing any operational issues promptly, Dongshan Precision reinforces customer satisfaction and builds lasting confidence in their products. For instance, in 2023, the company reported a significant increase in customer retention rates, partly attributed to their robust after-sales service network, which handled over 15,000 support inquiries.

Long-Term Strategic Partnerships

Suzhou Dongshan Precision Manufacturing prioritizes building long-term strategic partnerships with key industry leaders. This approach moves beyond simple transactions, focusing instead on deep, collaborative relationships. By engaging in continuous dialogue and joint planning, the company fosters mutual growth, which is crucial for securing sustained business and generating valuable referrals, particularly from innovators at the forefront of their sectors.

This strategy is evident in their dealings with major clients. For instance, in 2024, a significant portion of their revenue was derived from these established partnerships, underscoring the success of their relationship-centric model. These collaborations often involve joint R&D efforts, ensuring Dongshan Precision remains aligned with evolving industry needs and technological advancements.

- Enduring Relationships: Focus on cultivating deep, lasting ties with key clients, rather than pursuing short-term sales.

- Joint Planning & Growth: Engage in collaborative strategic planning and initiatives that promote mutual development and success.

- Repeat Business & Referrals: Leverage strong partnerships to ensure consistent order flow and generate new business through client recommendations.

- Innovation Alignment: Work closely with leading customers on strategic innovations to stay ahead of market trends and technological shifts.

Quality Feedback Loops

Suzhou Dongshan Precision Manufacturing prioritizes robust feedback loops to enhance customer relationships. They implement structured processes for gathering insights on product performance and service quality, ensuring a continuous improvement cycle.

This commitment to acting on customer feedback demonstrates responsiveness and a dedication to exceeding expectations. For instance, in 2024, the company saw a 15% increase in customer satisfaction scores directly attributed to product enhancements based on user input.

- Structured Feedback Collection: Implementing systematic methods like surveys, direct interviews, and online portals to capture customer opinions.

- Actionable Insights: Analyzing feedback to identify trends and specific areas for improvement in product design and service delivery.

- Continuous Improvement: Using collected data to drive iterative updates and enhancements, fostering a proactive approach to quality management.

- Customer Engagement: Communicating back to customers about changes made based on their feedback, reinforcing trust and loyalty.

Suzhou Dongshan Precision Manufacturing cultivates deep, collaborative relationships with its clientele, moving beyond transactional exchanges to foster strategic partnerships. This approach is reinforced by dedicated account management and joint engineering efforts, ensuring client needs are met with highly customized solutions.

The company actively seeks and implements customer feedback, leading to tangible improvements and increased satisfaction. For example, in 2024, product enhancements driven by user input resulted in a 15% rise in customer satisfaction scores, demonstrating a commitment to continuous improvement and responsiveness.

These enduring relationships are a cornerstone of their business, translating into significant repeat business and valuable referrals. In 2024, a substantial portion of revenue stemmed from these established partnerships, highlighting the success of their customer-centric strategy.

| Customer Relationship Strategy | Key Activities | Impact (2024 Data) |

|---|---|---|

| Dedicated Account Management | Personalized service, understanding client needs | Increased repeat business from top-tier clients |

| Collaborative Design & Engineering | Co-creation of customized solutions | Significant increase in bespoke engineering projects |

| Post-Sales Technical Support | Prompt issue resolution, smooth integration | Reinforced customer satisfaction and confidence |

| Strategic Partnerships | Joint R&D, continuous dialogue | Substantial revenue from established partnerships |

| Feedback Loops | Structured feedback collection and action | 15% increase in customer satisfaction scores |

Channels

Suzhou Dongshan Precision Manufacturing leverages a direct sales force to cultivate relationships with major enterprise clients and crucial accounts within its target sectors. This approach is vital for managing intricate Electronic Manufacturing Services (EMS) projects, enabling direct negotiation and the creation of customized proposals.

In 2024, Dongshan Precision's direct sales team played a pivotal role in securing significant contracts, contributing to its robust revenue streams. Their ability to build deep client rapport is a cornerstone of their strategy for complex, high-value projects.

Suzhou Dongshan Precision Manufacturing leverages industry trade shows and conferences as a vital channel for customer relationships and market intelligence. Participating in events like InfoComm 2024 for its LED products allows the company to directly engage with potential clients, demonstrate its manufacturing prowess, and gather real-time feedback on market demands.

These gatherings are instrumental for lead generation, with many B2B companies reporting that trade shows are a significant source of qualified leads. For instance, a 2024 industry survey indicated that over 70% of B2B marketers consider trade shows to be among their most effective marketing channels for generating high-quality leads, underscoring Dongshan Precision's strategic investment in these platforms.

Beyond lead generation, these events serve as a crucial platform for brand visibility and competitive analysis. By showcasing its latest innovations and manufacturing capabilities, Dongshan Precision strengthens its market position and gains insights into emerging technologies and competitor strategies, ensuring it remains at the forefront of the precision manufacturing sector.

Suzhou Dongshan Precision Manufacturing maintains a robust online presence through a professional corporate website, showcasing detailed product information, technical specifications, and comprehensive company capabilities. This digital storefront serves as a crucial touchpoint for potential clients worldwide.

Digital marketing plays a vital role in expanding reach and generating leads. By focusing on industry-specific content and search engine optimization (SEO), the company enhances its visibility in relevant online searches, attracting a wider audience interested in precision manufacturing solutions.

In 2024, Dongshan Precision reported significant growth in online inquiries, directly correlating with their intensified digital marketing campaigns. Their website traffic saw a notable increase, with a substantial portion of new business leads originating from digital channels, underscoring the effectiveness of their online strategy.

Referral Networks

Referral networks are a vital component for Suzhou Dongshan Precision Manufacturing, leveraging their strong existing client relationships and established industry reputation to cultivate new business opportunities. Satisfied customers frequently transform into powerful brand advocates, actively generating warm leads that significantly bolster the company's market standing.

This organic growth channel is particularly effective in the precision manufacturing sector, where trust and proven performance are paramount. By nurturing these relationships, Dongshan Precision Manufacturing taps into a cost-effective method of customer acquisition, reinforcing its credibility with each successful referral.

- Client Advocacy: Satisfied clients are encouraged to recommend Dongshan Precision Manufacturing to their industry peers, creating a pipeline of high-quality leads.

- Reputation Reinforcement: Positive word-of-mouth from referrals validates the company's commitment to quality and service, enhancing its overall market image.

- Cost-Effective Acquisition: Referrals typically have a higher conversion rate and lower acquisition cost compared to traditional marketing efforts.

- Industry Trust: In 2024, the precision manufacturing industry continues to place significant value on peer recommendations, making referrals a critical driver of growth for companies like Dongshan Precision Manufacturing.

Strategic Partnerships and Alliances

Suzhou Dongshan Precision Manufacturing actively cultivates strategic partnerships and alliances to broaden its market influence. A key aspect involves collaborating with technology partners and system integrators. These entities often recommend or embed Dongshan Precision's components and services within their own product offerings, thereby extending Dongshan's reach indirectly through established partner ecosystems.

These alliances are crucial for market penetration, allowing Dongshan Precision to access new customer segments without direct sales efforts. The company's strategy often includes strategic acquisitions and investments, which further solidify these partnerships and integrate complementary technologies or market access. For instance, in 2024, the company continued to explore opportunities that enhance its technological capabilities and market presence through synergistic collaborations.

- Technology Partner Integration: Collaborating with companies that integrate Dongshan's precision components into their larger technological solutions.

- Ecosystem Expansion: Leveraging partner networks to gain indirect market access and customer recommendations.

- Acquisitions and Investments: Strategically acquiring or investing in companies to strengthen partnerships and expand service portfolios, as observed in ongoing 2024 activities.

Suzhou Dongshan Precision Manufacturing utilizes a multi-faceted channel strategy to reach its diverse customer base. Direct sales are paramount for high-value enterprise clients, complemented by a strong online presence that showcases capabilities and drives digital leads. Industry events and strategic partnerships further amplify market reach, fostering relationships and integrating components into broader technological solutions.

| Channel | Key Activities | 2024 Impact/Data |

|---|---|---|

| Direct Sales | Cultivating enterprise client relationships, custom proposals | Secured significant contracts, driving robust revenue |

| Online Presence/Digital Marketing | Corporate website, SEO, content marketing | Notable increase in website traffic and online inquiries |

| Trade Shows & Conferences | Product demonstration, lead generation, market intelligence | Effective for lead generation; over 70% of B2B marketers find them highly effective |

| Referral Networks | Client advocacy, word-of-mouth marketing | Cost-effective customer acquisition with high conversion rates |

| Strategic Partnerships & Alliances | Technology integration, ecosystem expansion, acquisitions | Extended market influence and access to new customer segments |

Customer Segments

Telecommunications equipment manufacturers are a key customer segment for Suzhou Dongshan Precision Manufacturing. These companies design and produce the essential infrastructure and devices that power our communication networks. They rely on precision metal components and advanced Electronic Manufacturing Services (EMS) to build everything from base station equipment to user devices.

The demand for high reliability and peak performance is paramount for this sector. Critical communication systems simply cannot afford to fail, meaning the quality of components and manufacturing processes must be exceptionally high. For instance, in 2024, the global telecommunications equipment market was valued at over $300 billion, underscoring the scale and importance of this industry.

Consumer electronics brands, encompassing manufacturers of smartphones, laptops, wearables, and other electronic gadgets, represent a crucial customer segment. These companies rely heavily on high-precision structural components and advanced LED devices, areas where Dongshan Precision excels. For instance, in 2024, the global smartphone market alone was projected to ship over 1.1 billion units, underscoring the immense volume demand from this sector.

The rapid innovation cycles inherent in consumer electronics mean these brands require suppliers who can adapt quickly and deliver cutting-edge solutions. Dongshan Precision's focus on miniature, high-precision manufacturing directly addresses this need, ensuring components meet the stringent quality and performance standards demanded by leading tech companies. This segment is a cornerstone of Dongshan Precision's business, driving significant revenue and technological advancement.

Automotive industry suppliers, both Tier-1 and Tier-2, represent a crucial customer segment. They require highly precise metal components and structural parts essential for various vehicle systems, from infotainment and advanced driver-assistance systems (ADAS) to critical components for electric vehicles (EVs).

This segment places a premium on durability, safety, and adherence to stringent quality standards. The growing emphasis on new energy vehicles means suppliers are increasingly seeking partners capable of meeting the evolving demands of EV technology, driving innovation in materials and manufacturing processes.

Industrial and Medical Device Manufacturers

Suzhou Dongshan Precision Manufacturing serves industrial and medical device manufacturers, including those producing specialized machinery, automation equipment, and precision medical instruments. These clients demand exceptionally reliable, custom-engineered components that meet rigorous performance standards and often require specific certifications, areas where Dongshan excels.

For instance, in 2024, the global medical device market was valued at approximately $600 billion, with a projected compound annual growth rate (CAGR) of 5.5% through 2030. This growth underscores the increasing need for high-precision components that Dongshan provides.

- High Reliability Demands: Medical and industrial clients require components with near-zero failure rates due to safety and operational criticality.

- Custom Engineering Solutions: Tailored designs and manufacturing processes are essential to meet unique application specifications.

- Stringent Certification Requirements: Compliance with industry-specific regulations (e.g., ISO 13485 for medical devices) is paramount.

- Precision Performance: Components must deliver exact tolerances and consistent performance under demanding conditions.

High-Tech Integrated Solution Providers

High-Tech Integrated Solution Providers represent a crucial customer segment for Suzhou Dongshan Precision Manufacturing. These clients are typically companies developing sophisticated products that demand a high degree of manufacturing integration and specialized components. They seek a manufacturing partner capable of managing the entire production lifecycle, from intricate precision parts to the final assembly of complex systems.

Dongshan Precision caters to these demanding clients by offering comprehensive Electronic Manufacturing Services (EMS) coupled with their expertise in customized precision parts. This end-to-end capability is vital for businesses that lack the internal capacity or specialized machinery to handle such intricate manufacturing processes themselves. For example, in the rapidly evolving semiconductor equipment sector, companies often require highly precise, custom-machined components made from specialized materials, alongside complex sub-assembly and testing, all of which Dongshan Precision can deliver.

- Value Proposition: End-to-end manufacturing complexity management for integrated high-tech solutions.

- Client Needs: Comprehensive EMS, customized precision parts, and a reliable manufacturing partner.

- Market Focus: Industries like semiconductor equipment, advanced medical devices, and high-performance computing.

- Dongshan's Role: Providing integrated manufacturing solutions that reduce client operational burden and accelerate time-to-market.

Suzhou Dongshan Precision Manufacturing serves a diverse range of clients, including telecommunications equipment manufacturers who require high-reliability components for critical infrastructure, and consumer electronics brands demanding precision parts for high-volume production of devices like smartphones. The automotive sector, particularly those involved with electric vehicles and advanced driver-assistance systems, also relies on Dongshan for durable and safety-compliant metal components.

Furthermore, the company is a key partner for industrial and medical device manufacturers, providing custom-engineered, high-precision parts that meet stringent regulatory and performance standards, exemplified by the significant growth in the medical device market. Finally, high-tech integrated solution providers, such as those in semiconductor equipment manufacturing, depend on Dongshan's end-to-end Electronic Manufacturing Services and specialized precision parts to manage complex production lifecycles.

| Customer Segment | Key Needs | 2024 Market Context (Examples) |

| Telecommunications Equipment | High reliability, peak performance | Global telecom equipment market > $300 billion |

| Consumer Electronics | Miniature, high-precision parts, rapid innovation adaptation | Global smartphone market shipments > 1.1 billion units |

| Automotive Industry | Durability, safety, EV component precision | Growing demand for EV components |

| Industrial & Medical Devices | Near-zero failure rates, custom engineering, certifications | Global medical device market ~ $600 billion |

| High-Tech Integrated Solutions | End-to-end EMS, complex systems integration | Semiconductor equipment and advanced computing sectors |

Cost Structure

Suzhou Dongshan Precision Manufacturing's cost structure is heavily influenced by its significant expenditure on raw materials and components. Key inputs include precision metals like aluminum and stainless steel, various plastics, essential electronic components, and LED materials. These represent a substantial portion of their variable expenses.

These costs are directly linked to production output and are susceptible to fluctuations in global commodity prices. For instance, in 2024, the price of aluminum experienced volatility due to supply chain disruptions and increased demand, directly impacting Dongshan Precision's material procurement costs and, consequently, their overall profitability.

Manufacturing and production costs are a significant component of Suzhou Dongshan Precision Manufacturing's expenses. These include the operation of advanced machinery, tooling, and factory overheads. For instance, in 2024, the company likely incurred substantial costs related to the maintenance and depreciation of its sophisticated equipment, especially as it pursues capacity expansion.

Utilities and consumables also contribute to the overall manufacturing expenditure. These process-related expenses are critical for maintaining production efficiency and quality. The company's investment in cutting-edge technology necessitates ongoing spending on these operational necessities, directly impacting its bottom line.

Dongshan Precision's cost structure heavily features labor and personnel expenses. This includes competitive wages, salaries, and comprehensive benefits for its highly skilled workforce. This team encompasses engineers, technicians, dedicated R&D staff, and essential production line workers who are crucial for the company's precision manufacturing and Electronics Manufacturing Services (EMS) operations.

Given the specialized nature of precision manufacturing, labor costs represent a significant portion of the company's overall expenses. Dongshan Precision recognizes this and actively invests in ongoing talent training and development programs to ensure its workforce remains at the forefront of technological advancements and operational efficiency.

Research and Development (R&D) Expenses

Suzhou Dongshan Precision Manufacturing heavily invests in Research and Development (R&D) to drive innovation. This includes significant funding for the creation of new products, refining existing manufacturing processes, and exploring advancements in material science. These investments are fundamental to sustaining their technological edge and competitive positioning in the market.

In 2024, the company continued to prioritize R&D, allocating substantial resources to bolster its core business areas. This strategic focus aims to ensure they remain at the forefront of technological development within their industry.

- Investment in Innovation: Dedicated funding for new product development and process enhancements.

- Technological Leadership: R&D efforts are key to maintaining a competitive advantage.

- Core Business Focus: Increased R&D spending is concentrated on strengthening their primary operations.

Sales, Marketing, and Distribution Costs

Suzhou Dongshan Precision Manufacturing invests heavily in its sales, marketing, and distribution channels to reach a global customer base. These expenses include maintaining a direct sales force, engaging in key industry trade shows, and executing targeted digital marketing campaigns. In 2024, the company's commitment to market presence was evident in its continued investment in brand building and customer outreach initiatives designed to drive sales growth and secure new business opportunities.

The company's distribution network is crucial for its global operations, encompassing the logistics required for timely product delivery to international markets. This includes managing supply chains and ensuring efficient transportation to meet customer demands. These operational expenditures are vital for market penetration and customer acquisition, supporting activities that extend to investor relations and corporate communications.

- Sales Force Operations: Direct costs associated with employing and supporting a global sales team.

- Trade Show Participation: Expenses for exhibiting at and attending industry-specific events to showcase products and network.

- Digital Marketing: Investment in online advertising, content creation, and social media engagement for lead generation.

- Global Logistics: Costs related to warehousing, shipping, and customs for international product delivery.

Suzhou Dongshan Precision Manufacturing's cost structure is characterized by significant investments in raw materials, advanced manufacturing processes, and a skilled workforce. These core expenses are critical for maintaining the high precision and quality expected in their products. The company also dedicates substantial resources to research and development, ensuring it remains at the forefront of technological innovation within the electronics manufacturing and precision component sectors.

Revenue Streams

Revenue streams from the sales of precision metal components are a cornerstone for Suzhou Dongshan Precision Manufacturing. This segment generates income through the direct sale of both custom-designed and mass-produced metal parts. The company supplies these essential components to a wide array of industries, notably mobile communications and the automotive sector.

The volume and intricacy of the metal components supplied directly influence the income generated. For instance, in 2023, Dongshan Precision reported significant revenue from its precision manufacturing segment, reflecting strong demand for its specialized parts. This business line is crucial for the company's overall financial performance.

Revenue from the sale of LED devices, encompassing specialized modules and complete lighting systems, forms a core income source. This segment thrives on the expanding use of optoelectronics in both consumer electronics and industrial applications, with a particular emphasis on advanced LED packaging technologies.

In 2024, the global LED market continued its robust expansion, driven by demand for energy-efficient lighting and advanced display technologies. Suzhou Dongshan Precision Manufacturing, a key player, likely saw significant contributions from this segment, capitalizing on the increasing integration of LEDs in automotive lighting, smart home devices, and high-resolution displays.

Suzhou Dongshan Precision Manufacturing generates revenue through comprehensive Electronics Manufacturing Services (EMS) fees. This includes crucial steps like PCB assembly, system integration, and rigorous testing, alongside other value-added manufacturing processes. These revenue streams are typically structured around project-specific contracts and ongoing service agreements.

The Printed Circuit Board (PCB) business is a cornerstone of their operating revenue. In 2024, Dongshan Precision reported significant contributions from its PCB segment, demonstrating its importance to the company's financial performance and its role in the broader EMS ecosystem.

Custom Engineering and Design Services

Suzhou Dongshan Precision Manufacturing generates revenue through custom engineering and design services, charging fees for specialized technical solutions. This stream highlights their ability to tackle complex manufacturing challenges, especially for unique client needs. For instance, in 2024, the company reported significant growth in its bespoke solutions segment, reflecting strong demand for its advanced engineering capabilities.

These services are crucial for clients requiring tailored product development and process optimization. The fees reflect the deep technical expertise and intellectual property involved in creating these specialized solutions.

- Fees for Specialized Engineering: Charging for the development of unique manufacturing processes and solutions.

- Design Consultation: Earning revenue by providing expert advice on product design for manufacturability.

- Prototyping Services: Generating income from the creation of early-stage product samples to client specifications.

- Solving Complex Manufacturing Challenges: Monetizing their technical prowess in addressing intricate production issues for clients.

After-Sales Support and Maintenance Contracts

Suzhou Dongshan Precision Manufacturing generates revenue through after-sales support and maintenance contracts. These agreements provide ongoing technical assistance, upkeep, and repair services for the sophisticated products and systems they deliver to clients.

While this revenue stream might be smaller in individual value compared to initial product sales, it plays a crucial role in establishing recurring income. Furthermore, it significantly bolsters customer loyalty and satisfaction by ensuring their investments continue to perform optimally over the long term.

- Recurring Revenue: Maintenance contracts offer a predictable income stream, enhancing financial stability.

- Customer Retention: Proactive support fosters strong client relationships and reduces churn.

- Service Expansion: Opportunities exist to upsell advanced service packages or upgrades.

- Brand Loyalty: Consistent, high-quality support reinforces the company's reputation.

Revenue from precision metal components is a significant contributor, driven by demand in mobile communications and automotive sectors. The company's 2023 performance highlighted strong income from this segment.

The LED device segment, including specialized modules and systems, is another core revenue generator, benefiting from the growing optoelectronics market and advanced packaging technologies. Robust global LED market growth in 2024 likely boosted this revenue stream for Dongshan Precision.

Electronics Manufacturing Services (EMS) fees, encompassing PCB assembly, system integration, and testing, form a crucial part of their revenue, typically secured through project contracts. The company reported significant contributions from its PCB business in 2024, underscoring its importance.

Custom engineering and design services, addressing unique client needs and complex manufacturing challenges, also generate substantial revenue. Dongshan Precision saw notable growth in bespoke solutions in 2024, showcasing strong demand for its advanced engineering capabilities.

| Revenue Stream | Key Industries Served | 2023 Performance Highlight | 2024 Outlook Driver |

|---|---|---|---|

| Precision Metal Components | Mobile Communications, Automotive | Significant revenue contribution | Continued strong demand |

| LED Devices | Consumer Electronics, Industrial Applications | Core income source | Expansion in automotive and smart home |

| Electronics Manufacturing Services (EMS) | Various electronics manufacturing | Significant PCB business contribution | Growing EMS ecosystem integration |

| Custom Engineering & Design | Clients with unique needs | Notable growth in bespoke solutions | Strong demand for advanced engineering |

Business Model Canvas Data Sources

The Suzhou Dongshan Precision Manufacturing Business Model Canvas is built upon a foundation of detailed financial reports, comprehensive market research on the electronics and automotive sectors, and internal operational data. These sources ensure each block is informed by accurate, up-to-date information specific to the company's precision manufacturing activities.