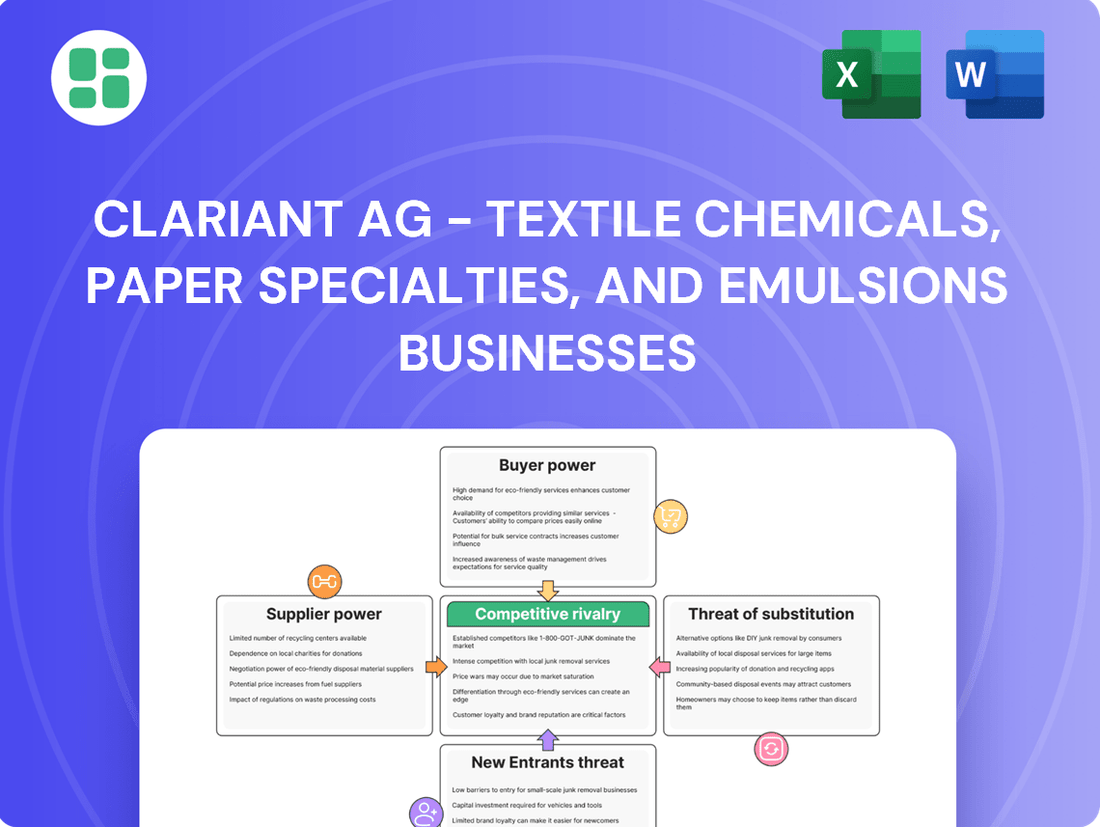

Clariant AG - Textile Chemicals, Paper Specialties, and Emulsions Businesses Porter's Five Forces Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Clariant AG - Textile Chemicals, Paper Specialties, and Emulsions Businesses Bundle

Clariant AG's Textile Chemicals, Paper Specialties, and Emulsions businesses face a complex competitive landscape shaped by moderate buyer power and significant supplier influence due to specialized raw materials. The threat of new entrants is somewhat mitigated by capital requirements and established brand loyalty, but substitute products pose a growing challenge.

The complete report reveals the real forces shaping Clariant AG - Textile Chemicals, Paper Specialties, and Emulsions Businesses’s industry—from supplier influence to threat of new entrants. Gain actionable insights to drive smarter decision-making.

Suppliers Bargaining Power

Raw material volatility, particularly for petrochemicals and base chemicals, significantly impacts suppliers' bargaining power. For Clariant's former textile chemicals, paper specialties, and emulsions divisions, these price swings directly influenced production costs and profit margins, as seen in the fluctuating commodity markets throughout 2024.

Supplier concentration significantly amplifies their bargaining power. If Clariant's former textile chemicals, paper specialties, and emulsions businesses relied on a small number of providers for essential raw materials like specialized dyes or high-performance polymers, those suppliers could dictate terms. For instance, in 2024, the global specialty chemicals market saw continued consolidation, with key players in pigment production reporting strong pricing power due to limited alternatives for certain advanced formulations.

Clariant faces significant bargaining power from its suppliers in the textile chemicals, paper specialties, and emulsions businesses due to high switching costs. These costs can include the necessity to re-qualify new raw materials, reconfigure intricate production processes, and renegotiate complex supply contracts. For instance, in the specialty chemicals sector, a change in supplier typically necessitates extensive testing and rigorous approval procedures to guarantee consistent product performance and quality, making it both expensive and time-consuming for Clariant to make a switch.

These substantial switching barriers effectively tie Clariant to its existing suppliers, even in scenarios where suppliers might attempt to increase prices. The investment in time, resources, and potential disruption to operations makes it challenging for Clariant to explore alternative sourcing options, thereby enhancing the suppliers' leverage in negotiations. This dependency underscores the importance of strong supplier relationships and careful contract management for Clariant's operational stability and cost control.

Forward Integration Threat

The threat of forward integration by suppliers significantly amplifies their bargaining power within Clariant's textile chemicals, paper specialties, and emulsions segments. If suppliers possess the means and motivation to enter these markets directly, Clariant would face increased pressure to offer competitive pricing and superior service to deter them from becoming direct rivals. This scenario could also lead to restricted access to essential raw materials or intermediates for Clariant's operations.

Consider the implications for Clariant's Emulsions business. Many key raw materials for emulsion production, such as monomers and surfactants, are supplied by large chemical conglomerates. For instance, companies like BASF or Dow Chemical, major players in the petrochemical industry, have the scale and technical expertise to potentially integrate forward into producing specialized emulsion polymers themselves. In 2024, the global emulsion polymers market was valued at approximately $35 billion, indicating a substantial market for potential entrants.

- Supplier Capability: Suppliers often possess deep technical knowledge of their own products, which are often key intermediates for Clariant's finished goods.

- Market Attractiveness: The established demand and profitability within Clariant's target segments can incentivize suppliers to explore forward integration.

- Competitive Landscape: If Clariant's competitors are already facing or have successfully managed supplier forward integration, it highlights the viability of this threat.

- Impact on Clariant: Forward integration by suppliers could lead to increased input costs, reduced product differentiation, and a potential loss of market share for Clariant.

Uniqueness of Inputs

Suppliers offering highly specialized or patented chemicals, particularly those crucial for performance enhancement or eco-friendly product lines, wield significant bargaining power. Clariant's past reliance on such unique inputs for its Textile Chemicals, Paper Specialties, and Emulsions businesses meant these suppliers had considerable leverage.

The growing market demand for sustainable and bio-based chemical inputs is a key factor here. For instance, by 2024, the global bio-based chemicals market was projected to reach over $200 billion, a figure that underscores the increasing importance and potential power of suppliers in this niche.

- Suppliers of patented or highly differentiated chemical ingredients gain leverage.

- Clariant's innovation in textile, paper, and emulsion sectors historically depended on access to these unique inputs.

- The increasing demand for sustainable and bio-based chemicals empowers suppliers in these specialized areas.

Clariant's former textile chemicals, paper specialties, and emulsions businesses faced substantial supplier bargaining power, driven by factors like raw material price volatility and supplier concentration. The high switching costs associated with re-qualifying materials and reconfiguring production processes further solidified this power, making it difficult for Clariant to change suppliers even when prices rose. This dynamic was particularly evident in 2024, with the specialty chemicals market experiencing consolidation, giving key pigment producers increased pricing leverage.

The threat of forward integration by suppliers, such as large chemical conglomerates like BASF or Dow Chemical, presented a significant challenge. These companies, with their scale and technical expertise, could potentially enter Clariant's markets directly, leading to increased input costs and reduced product differentiation for Clariant. The global emulsion polymers market, valued at approximately $35 billion in 2024, highlights the attractiveness of these segments for potential new entrants.

Suppliers of specialized or patented chemicals, especially those crucial for sustainable and bio-based product lines, also wielded considerable influence. The growing demand for these inputs, with the bio-based chemicals market projected to exceed $200 billion by 2024, empowered suppliers in these niche areas. This dependence on unique inputs for innovation meant Clariant often had to accept supplier-dictated terms.

| Factor | Impact on Clariant (Textile, Paper, Emulsions) | 2024 Market Context |

|---|---|---|

| Raw Material Volatility | Increased production costs and squeezed profit margins. | Fluctuating commodity markets for petrochemicals and base chemicals. |

| Supplier Concentration | Limited alternatives, leading to dictated terms and pricing. | Consolidation in specialty chemicals, strengthening key players' pricing power. |

| High Switching Costs | Tied Clariant to existing suppliers, hindering cost negotiation. | Extensive testing and approval needed for new raw materials in specialty chemicals. |

| Forward Integration Threat | Risk of increased input costs and loss of market share. | Large chemical conglomerates possess capability to enter markets like emulsion polymers (valued at ~$35 billion in 2024). |

| Specialized/Patented Inputs | Leverage for suppliers of unique, performance-enhancing, or sustainable chemicals. | Growing demand for bio-based chemicals (projected >$200 billion by 2024) empowers niche suppliers. |

What is included in the product

This analysis examines the competitive intensity, buyer and supplier power, threat of new entrants, and availability of substitutes impacting Clariant AG's Textile Chemicals, Paper Specialties, and Emulsions businesses.

Navigate the complex competitive landscape of Clariant's Textile Chemicals, Paper Specialties, and Emulsions with a concise Porter's Five Forces analysis, offering a clear, one-sheet summary for rapid strategic insights.

Gain immediate clarity on competitive pressures and identify key threats and opportunities across these diverse business units, enabling more informed and agile decision-making.

Customers Bargaining Power

Customers in Clariant's former textile, paper, and emulsions sectors, especially major industrial buyers, often exhibit significant price sensitivity. This is driven by their own intense competition and often tight profit margins, making them highly attuned to chemical input costs.

This customer price sensitivity directly pressures Clariant's historical businesses, forcing them to maintain competitive pricing. Consequently, their capacity to absorb or pass on rising raw material or operational expenses becomes limited, impacting profitability.

The market for many chemical products within these segments is characterized by a degree of commoditization. This further amplifies the price pressure, as buyers can more readily switch suppliers based on minor price differences, reducing Clariant's pricing power.

Customer concentration, particularly within Clariant's Textile Chemicals and Paper Specialties segments, can significantly amplify buyer bargaining power. The presence of a few major clients, such as large textile manufacturers or global paper conglomerates, means these entities can leverage their substantial order volumes to negotiate more favorable pricing and terms. For instance, if a handful of textile mills account for a quarter of Clariant's textile chemical sales, they gain considerable leverage to demand price reductions or preferential service, directly impacting Clariant's profit margins in these divisions.

The availability of substitutes significantly amplifies customer bargaining power. If clients can readily switch to alternative chemical suppliers or adopt different chemical types and processes, they gain leverage. For example, in the paper chemicals market, numerous competing solutions exist, forcing Clariant's former divisions to consistently innovate and provide superior value to maintain customer loyalty.

Backward Integration Threat

The bargaining power of customers is a key factor for Clariant's Textile Chemicals, Paper Specialties, and Emulsions Businesses. A significant aspect of this power is the potential for backward integration, where customers might decide to produce their own chemicals if it proves more economical or strategically beneficial. This threat compels Clariant to maintain competitive pricing and offer unique, high-value solutions that are challenging for clients to replicate in-house.

Large industrial customers, in particular, often possess the financial resources and technical capabilities to explore in-house chemical production. For instance, major textile manufacturers or paper mills could invest in the necessary infrastructure and expertise. This capability directly influences their negotiation leverage with suppliers like Clariant.

- Customer Threat of Backward Integration: Customers may produce chemicals internally if cost-effective or strategically beneficial, pressuring Clariant on pricing and specialization.

- Customer Capabilities: Large industrial customers often have the capital and technical expertise to pursue backward integration.

- Clariant's Response: Clariant must offer competitive pricing and specialized solutions to deter customers from in-house production.

Product Differentiation and Switching Costs for Customers

Clariant’s historical focus on specialty chemicals, particularly in textile, paper, and emulsion segments, aimed to create value through differentiation. If these products were viewed as interchangeable commodities, customers would face minimal switching costs, thereby amplifying their bargaining power.

However, by offering highly differentiated products with distinct performance advantages or bundled service packages, Clariant could significantly increase customer switching costs. This strategy directly diminishes the bargaining power of customers, as the effort and potential disruption involved in changing suppliers become more substantial.

The increasing market demand for sustainable and high-performance solutions plays a crucial role in shaping customer purchasing decisions. Customers are more inclined to switch to suppliers offering eco-friendly alternatives or superior performance, which can influence their perception of switching costs and supplier loyalty.

- Product Differentiation: Clariant's success in creating unique value propositions for its textile, paper, and emulsion chemicals directly impacts customer switching costs.

- Switching Costs: High switching costs, stemming from product integration, specialized knowledge, or contractual obligations, reduce customer bargaining power.

- Market Trends: The growing emphasis on sustainability and performance in these sectors provides customers with more options, potentially increasing their leverage if Clariant's offerings are not sufficiently differentiated.

- Customer Perception: If customers perceive Clariant's products as commodities rather than high-value specialties, their bargaining power increases due to the ease of finding alternative suppliers.

Customers in Clariant's former textile, paper, and emulsions businesses wield significant bargaining power, primarily due to their price sensitivity and the availability of substitutes. Large industrial buyers, in particular, can leverage their substantial order volumes to negotiate better terms, as seen in the textile sector where major manufacturers often dictate pricing. For instance, if a few key paper mills represent a substantial portion of sales, their ability to demand price concessions directly impacts profitability.

The threat of backward integration by customers further amplifies their power. Major players in the paper and textile industries possess the financial and technical capacity to produce chemicals in-house, compelling Clariant to offer competitive pricing and specialized solutions. This capability is a direct driver of their negotiation leverage, as demonstrated by the potential for large textile mills to explore internal chemical production if it becomes more economical.

Clariant's strategy to counter this power relied heavily on product differentiation and increasing customer switching costs. By offering unique performance advantages and bundled services, the company aimed to make it more difficult and costly for customers to switch to competitors. However, market trends favoring sustainability and high performance mean customers are more open to alternatives, potentially increasing their leverage if Clariant's offerings are not sufficiently distinct.

| Factor | Impact on Clariant's Bargaining Power | Example/Data Point |

|---|---|---|

| Price Sensitivity | High | Customers in textile and paper industries often operate on thin margins, making them highly sensitive to chemical input costs. |

| Availability of Substitutes | High | Numerous alternative chemical solutions exist in the paper chemicals market, allowing customers to switch suppliers easily. |

| Customer Concentration | Moderate to High | A few large textile manufacturers can account for a significant percentage of sales, granting them considerable negotiation leverage. |

| Backward Integration Threat | Moderate | Large industrial customers have the financial and technical capability to consider in-house chemical production. |

| Switching Costs | Varies (aimed to be high) | Clariant sought to increase switching costs through product differentiation and specialized services. |

Preview Before You Purchase

Clariant AG - Textile Chemicals, Paper Specialties, and Emulsions Businesses Porter's Five Forces Analysis

This preview shows the exact document you'll receive immediately after purchase—no surprises, no placeholders. The comprehensive Porter's Five Forces analysis for Clariant AG's Textile Chemicals, Paper Specialties, and Emulsions Businesses details the competitive landscape, including the threat of new entrants and the bargaining power of buyers and suppliers. It thoroughly examines the intensity of rivalry among existing competitors and the threat of substitute products or services within these key sectors.

Rivalry Among Competitors

The specialty chemicals market, encompassing textile chemicals, paper specialties, and emulsions, is a crowded space with many global and regional competitors. This sheer number and variety of players naturally fuels intense rivalry.

Clariant's former textile chemicals, paper specialties, and emulsions businesses contended with both massive, diversified chemical giants and smaller, highly focused niche companies. Each type of competitor aims to capture market share through different strategies, intensifying the competitive landscape.

In the paper chemicals sector, major players like BASF, Solenis, and Kemira are significant forces, known for their broad product portfolios and extensive reach. Meanwhile, the textile chemicals arena sees companies such as Archroma as key competitors, demonstrating the specialized nature of competition within segments.

In mature segments of the textile, paper, and emulsions chemical sectors, competitive rivalry is often heightened. This intensity stems from companies vying for a limited customer base, leading to more aggressive pricing and marketing tactics.

While the broader specialty chemicals market shows robust growth, certain niches within textile, paper, and emulsion chemicals may experience slower expansion. For instance, the global paper chemicals market is expected to see only modest growth in the coming years, intensifying competition among existing players.

Clariant's strategy heavily relies on product differentiation, particularly in its textile, paper, and emulsions segments. This approach aims to lessen direct competition by offering unique performance, enhanced sustainability, or specialized applications. For instance, their focus on eco-friendly textile auxiliaries caters to a growing market demand for sustainable fashion, a key differentiator.

Maintaining this differentiation demands continuous innovation. Competitors are also investing in similar sustainable and bio-based alternatives, intensifying the need for Clariant to stay ahead. The company's commitment to R&D is crucial, as evidenced by its ongoing development of new formulations and processes to meet evolving industry standards and customer expectations.

In 2023, Clariant reported increased sales in its Care Chemicals segment, which includes many of its specialty applications, signaling the market's positive reception to its differentiated offerings. This segment's performance underscores the importance of innovation in a competitive landscape where technological advancements and sustainability are paramount.

Exit Barriers

Clariant AG's divestment of its Textile Chemicals, Paper Specialties, and Emulsions businesses highlights significant exit barriers within the chemical industry. These barriers, often rooted in specialized assets and substantial capital investments, can trap companies in segments even when profitability wanes.

The chemical sector's capital-intensive nature means that exiting a business line involves considerable sunk costs. For instance, specialized production facilities and R&D investments represent significant financial commitments that are difficult to recoup. This can lead to companies remaining in competitive markets, contributing to sustained rivalry and potential overcapacity as firms are reluctant to abandon their investments.

- High Capital Intensity: The chemical industry often requires substantial upfront investment in plant and equipment, making it costly to exit specific business segments.

- Specialized Assets: Production lines and technologies are frequently tailored to particular chemical processes, limiting their resale value or applicability in other industries.

- Long-Term Contracts: Existing supply agreements and customer commitments can create obligations that extend beyond a company's desire to exit a market.

- Employee and Social Costs: Laying off a specialized workforce or closing facilities can incur significant severance packages and community impact costs, acting as a deterrent to exit.

Capacity Utilization and Overcapacity

Periods of overcapacity in the textile, paper, or emulsions chemical markets significantly intensify rivalry. Companies tend to lower prices to keep their production lines running, directly impacting profitability. This pressure necessitates efficient operations and careful strategic capacity management for companies like Clariant.

The broader chemical industry has indeed grappled with challenges stemming from weak demand and global overcapacities. For instance, in 2023, many chemical producers reported lower capacity utilization rates due to economic slowdowns and shifts in consumer spending, leading to increased price competition across various segments, including those relevant to Clariant's former businesses.

- Intensified Price Wars: Overcapacity forces companies to cut prices to maintain sales volume, eroding profit margins.

- Pressure on Efficiency: Companies must operate at peak efficiency to remain competitive during periods of oversupply.

- Strategic Capacity Management: Clariant, like its peers, needs to actively manage its production capacity to avoid being caught in oversupply situations.

- Impact on Profitability: Historically strong profitability can be significantly challenged when market supply outstrips demand.

The competitive rivalry within Clariant's former textile chemicals, paper specialties, and emulsions businesses was significant, driven by a mix of large, diversified players and specialized niche firms. This intense competition was further amplified by mature market segments where companies fought for a limited customer base, often resorting to aggressive pricing and marketing strategies.

Companies like BASF, Solenis, and Kemira actively competed in the paper chemicals sector, while Archroma was a notable rival in textile chemicals. Clariant's strategy of product differentiation, particularly through eco-friendly innovations in textile auxiliaries, aimed to mitigate this rivalry. However, competitors were also investing in similar sustainable alternatives, necessitating continuous R&D investment from Clariant to maintain its edge.

The chemical industry's high capital intensity and the presence of specialized assets created substantial exit barriers, compelling companies to remain in competitive markets even when profitability declined. This contributed to sustained rivalry and potential overcapacity. For instance, in 2023, many chemical producers experienced lower capacity utilization rates due to economic slowdowns, leading to increased price competition across various segments, including those relevant to Clariant's former businesses.

The divestment of these businesses by Clariant AG underscores the challenges of exiting such capital-intensive and specialized markets. The need to recoup significant sunk costs in plant, equipment, and R&D often keeps companies engaged in competitive battles, impacting overall profitability and market dynamics.

SSubstitutes Threaten

The threat of substitutes for Clariant's textile, paper, and emulsions businesses is significant, stemming from alternative chemical formulations and entirely new technologies that can deliver comparable end-user outcomes. For example, advancements in textile finishing might reduce reliance on specific Clariant dyes or auxiliaries, while paper manufacturers could adopt bio-based coatings that negate the need for traditional chemical additives.

Emerging innovations in sustainable chemistry are particularly potent substitutes, offering environmentally friendly alternatives that could displace established chemical solutions. The increasing demand for eco-conscious products across industries means that Clariant must continually innovate to remain competitive against these evolving substitute threats.

Process innovations are a significant threat to Clariant's textile, paper, and emulsions businesses. For instance, advancements in mechanical pulping techniques for paper production can drastically cut down the need for chemical bleaching agents. This shift directly impacts demand for Clariant's paper specialty chemicals, potentially eroding market share.

Similarly, the textile industry is seeing a rise in water-free dyeing technologies. These innovations reduce the reliance on traditional chemical dyes and auxiliaries. In 2024, the global textile chemicals market is projected to reach over $20 billion, but such disruptive technologies could reshape this landscape, posing a direct threat to Clariant's established revenue streams in textile chemicals.

Growing environmental awareness and stricter regulations are fueling a move towards bio-based or natural alternatives, which can replace synthetic chemicals. This trend is particularly noticeable in the paper and textile chemical sectors, where eco-friendly options are increasingly sought after, potentially sidelining conventional chemical products. For instance, Clariant has been actively transitioning its product lines to be PFAS-free, reflecting this market shift.

Customer DIY or In-House Production

Customers might opt for in-house production of certain basic chemical compounds if the necessary technology becomes readily available and economically viable. This move would allow them to exert more control over their supply chain, potentially impacting Clariant's market share for more standardized offerings.

While complex specialty chemicals are less susceptible, the DIY or in-house production trend poses a substitution threat, particularly for less differentiated products within Clariant's Textile Chemicals and Paper Specialties segments. This could lead to a reduction in the overall market size for external suppliers.

For example, in 2024, the global chemical industry saw increased investment in process intensification and modular manufacturing, making smaller-scale, in-house production more feasible for some downstream users. This trend is particularly relevant for commodity chemicals where margins are tighter and direct cost control is paramount.

- DIY Production Viability: Technology advancements in areas like microreactors and additive manufacturing are lowering the barrier to entry for in-house chemical production.

- Cost-Effectiveness Driver: Customers may pursue in-house production to bypass supplier markups and gain direct control over input costs, especially for high-volume, lower-margin products.

- Supply Chain Control: A desire for greater supply chain resilience and predictability can motivate customers to bring certain chemical processes in-house, reducing reliance on external suppliers.

- Market Size Impact: A significant shift towards in-house production for basic formulations could shrink the addressable market for specialty chemical providers like Clariant, forcing a strategic focus on higher-value, more complex solutions.

Changes in End-Product Design or Material Science

Innovations in end-product design or material science can significantly impact Clariant's textile and paper chemical businesses. For example, the development of inherently stain-resistant fabrics could reduce the demand for specialized textile finishing chemicals. Similarly, advancements in paper production, such as new pulping techniques or fiber treatments, might lessen the need for certain paper specialty chemicals used for enhancing properties like strength or water resistance.

The emergence of smart textiles, incorporating conductive threads or embedded sensors, also presents a dynamic shift. This trend could create new opportunities for chemical treatments that enable these functionalities, but it also poses a threat if these smart materials bypass traditional chemical finishing processes altogether. Clariant’s 2024 focus on sustainable solutions and advanced materials will be crucial in navigating these evolving product designs.

- Material Innovation: New materials with inherent properties (e.g., self-cleaning, water-repellent) can directly substitute chemical treatments.

- Smart Textiles: The integration of electronics and sensors in fabrics may alter or eliminate the need for certain chemical finishes.

- Paper Product Evolution: Advances in paper manufacturing could reduce reliance on specialty chemicals for specific performance enhancements.

- R&D Investment: Clariant's continued investment in research and development is vital to adapt to these design and material science changes, as seen in their 2024 strategic priorities.

The threat of substitutes for Clariant's textile, paper, and emulsions businesses is substantial, driven by both alternative chemical formulations and entirely new technologies that achieve similar end results. For instance, innovations in textile finishing could reduce the need for specific Clariant dyes or auxiliaries, while paper manufacturers might adopt bio-based coatings that eliminate the requirement for traditional chemical additives. The global textile chemicals market, projected to exceed $20 billion in 2024, faces disruption from water-free dyeing technologies, directly impacting Clariant's established revenue streams.

Increasing environmental awareness and stricter regulations are accelerating the adoption of bio-based or natural alternatives, particularly in the paper and textile chemical sectors. These eco-friendly options can displace conventional chemical products, as exemplified by Clariant's strategic move towards PFAS-free product lines in response to market shifts. Furthermore, advancements in process intensification and modular manufacturing in 2024 are making smaller-scale, in-house chemical production more feasible for some downstream users, especially for commodity chemicals where direct cost control is paramount.

Innovations in end-product design and material science also pose a significant threat. The development of inherently stain-resistant fabrics could decrease demand for specialized textile finishing chemicals, while new pulping techniques in paper production might lessen the need for certain paper specialty chemicals. The rise of smart textiles, incorporating electronics and sensors, could bypass traditional chemical finishing processes altogether, necessitating Clariant's continued investment in R&D, a key focus in their 2024 strategic priorities.

| Threat Category | Examples | Impact on Clariant | 2024 Relevance |

|---|---|---|---|

| Alternative Chemical Formulations | Bio-based coatings, natural dyes | Reduced demand for synthetic chemicals | Growing preference for sustainable inputs |

| New Technologies | Water-free dyeing, advanced pulping | Disruption of established chemical processes | Reshaping market dynamics in textiles and paper |

| Material Science Innovations | Inherently stain-resistant fabrics, smart textiles | Substitution of chemical treatments | Shifting product design and functionality needs |

| DIY/In-house Production | Modular manufacturing, microreactors | Shrinking addressable market for basic chemicals | Increased feasibility for downstream users |

Entrants Threaten

The specialty chemicals sector, encompassing Clariant's former textile, paper, and emulsion businesses, demands massive upfront investment. This includes substantial outlays for research and development, state-of-the-art manufacturing plants, and highly specialized machinery.

These considerable capital requirements create a formidable barrier for any newcomers. For instance, building a new specialty chemical plant can easily run into hundreds of millions of dollars, a sum that deters many potential entrants.

This high barrier to entry means that established players, like Clariant historically, benefit from a more protected market. New companies would need significant financial backing and a long-term vision to even consider entering this capital-intensive arena.

The chemical industry, including segments like textile chemicals, paper specialties, and emulsions, faces substantial regulatory hurdles. Stringent environmental protection laws, rigorous safety standards, and complex product registration processes act as significant deterrents for new companies looking to enter these markets. For instance, REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe requires extensive data submission and can involve substantial costs, potentially running into hundreds of thousands of euros per substance, making market entry a costly endeavor.

Existing players in the textile chemicals, paper specialties, and emulsions markets, such as Clariant, have cultivated deep brand loyalty and robust customer relationships over many years. These established connections mean new entrants must overcome significant hurdles to win over clients who value proven reliability and consistent quality for essential chemical components.

Access to Distribution Channels and Raw Materials

New companies entering the textile chemicals, paper specialties, and emulsions markets face significant hurdles in establishing robust distribution channels. Clariant, for instance, has cultivated long-standing relationships with manufacturers globally, ensuring its products reach diverse end-users efficiently. This established network is a formidable barrier for newcomers who must invest heavily to replicate such reach.

Securing reliable and cost-effective access to raw materials presents another substantial challenge. The chemical industry relies on a complex web of suppliers, and established players like Clariant often benefit from bulk purchasing power and long-term contracts. In 2023, global chemical feedstock prices saw volatility, making it harder for new entrants without established supplier relationships to secure competitive pricing, potentially impacting their cost structure significantly.

- Distribution Network Barriers: New entrants often lack the established logistics and customer relationships that incumbents like Clariant possess, making market penetration difficult.

- Raw Material Sourcing: Securing consistent, quality raw materials at competitive prices is challenging due to established supplier agreements and potential supply chain disruptions.

- Economies of Scale: Larger, established companies benefit from economies of scale in both production and procurement, giving them a cost advantage over smaller, newer firms.

- Capital Investment: Building out the necessary infrastructure for distribution and securing raw material supply requires substantial upfront capital, a significant deterrent for potential new entrants.

Technological Expertise and R&D Investment

The specialty chemicals sector, including areas like textile chemicals, paper specialties, and emulsions, demands substantial technological proficiency and ongoing investment in research and development. New companies entering this market must commit significant capital to develop unique formulations and manufacturing processes. For instance, Clariant, a key player, has consistently invested in R&D to maintain its competitive edge, with its 2023 R&D expenses totaling CHF 223 million, underscoring the high barrier to entry.

Established players like Clariant benefit from robust intellectual property portfolios, including extensive patents and accumulated know-how, which are critical for protecting proprietary innovations. New entrants face the challenge of replicating or circumventing this existing intellectual property, often requiring substantial upfront investment in their own R&D to achieve parity. This focus on innovation is particularly crucial in the current market, where sustainable solutions are increasingly sought after, necessitating further R&D expenditure.

- High R&D Investment: New entrants must commit significant capital to R&D to develop proprietary formulations and processes.

- Intellectual Property: Established firms possess extensive patents and know-how, creating a barrier for newcomers.

- Technological Expertise: Deep technological understanding is essential for producing specialty chemicals effectively.

- Sustainable Innovation: The growing demand for eco-friendly products requires continuous R&D investment, further increasing entry barriers.

The threat of new entrants into Clariant's former textile chemicals, paper specialties, and emulsions businesses is significantly mitigated by several factors. High capital requirements for R&D, manufacturing, and regulatory compliance, estimated in the hundreds of millions for new plants, present a substantial financial barrier. Established brands, deep customer loyalty, and extensive distribution networks, cultivated over years by incumbents like Clariant, are difficult and costly for newcomers to replicate.

Furthermore, securing reliable raw material supply chains and navigating complex intellectual property landscapes pose additional challenges. The need for specialized technological expertise and continuous investment in sustainable innovation further elevates the entry barriers, making it a high-risk proposition for potential new competitors. For example, Clariant's 2023 R&D expenditure of CHF 223 million highlights the ongoing investment required to remain competitive.

| Barrier Type | Description | Example Impact |

|---|---|---|

| Capital Requirements | Significant investment needed for R&D, plants, and machinery. | Building a new specialty chemical plant can cost hundreds of millions. |

| Brand Loyalty & Distribution | Established customer relationships and logistics networks. | New entrants struggle to gain market share against trusted suppliers. |

| Raw Material Access | Securing consistent, cost-effective supply. | 2023 saw feedstock price volatility, impacting new entrants without long-term contracts. |

| Intellectual Property | Patents and proprietary know-how protect innovations. | New companies must invest heavily in R&D to match existing technological capabilities. |

Porter's Five Forces Analysis Data Sources

Our Porter's Five Forces analysis for Clariant AG's Textile Chemicals, Paper Specialties, and Emulsions Businesses is built upon comprehensive data from Clariant's annual reports and investor presentations, alongside industry-specific market research from firms like IHS Markit and Mordor Intelligence.