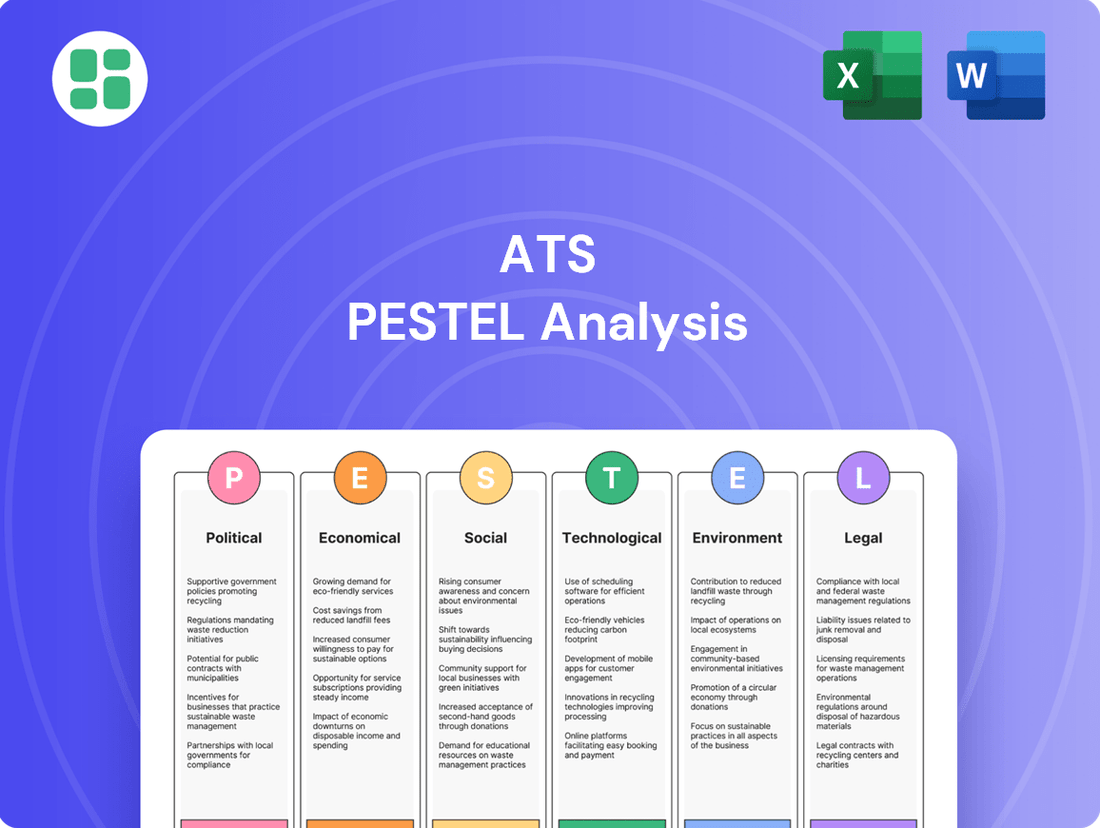

ATS PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

ATS Bundle

Navigate the complex external forces shaping ATS with our comprehensive PESTLE analysis. Understand the political, economic, social, technological, legal, and environmental factors that could impact your strategy. Unlock actionable insights to anticipate challenges and seize opportunities by downloading the full report today.

Political factors

Government policies, including tax incentives, subsidies, and grants for advanced manufacturing and automation adoption, significantly influence the demand for ATS's solutions. For instance, the United States' CHIPS and Science Act of 2022 aims to boost domestic semiconductor manufacturing through substantial financial incentives, potentially driving demand for automation solutions in that sector.

Nations aiming to boost industrial competitiveness or reshore production often provide financial encouragement for automation investments. Germany's Industry 4.0 initiative, supported by government funding, encourages the digital transformation of manufacturing, creating a favorable market environment for automation providers.

These policies can create a favorable market environment for companies like ATS, driving client capital expenditure. In 2024, many governments are expected to continue or expand programs supporting advanced manufacturing, with projections indicating significant growth in government R&D spending for industrial automation technologies.

Changes in global trade agreements and the imposition of tariffs directly influence ATS's supply chain costs for essential components. For instance, the ongoing recalibration of trade relationships, particularly between major economic blocs, can introduce new duties or alter existing preferential access, impacting the landed cost of goods. This, in turn, affects the overall competitiveness of ATS's automation systems in diverse international markets, as demonstrated by the potential for tariffs to increase the price of imported machinery for end-users.

Trade tensions and the emergence of new trade pacts can significantly shift the economic calculus for clients considering automation investments. Regions experiencing protectionist policies might see a decrease in foreign direct investment in advanced manufacturing, influencing where ATS's clients prioritize the deployment of new automation solutions. For example, a shift towards regionalized supply chains, a trend observed throughout 2024 and projected into 2025, could lead clients to favor automation suppliers with a stronger local presence or those less exposed to international trade disputes.

Navigating these intricate international trade dynamics is crucial for ATS to optimize its global operations and refine its pricing strategies. The ability to adapt to evolving trade landscapes, such as understanding the implications of agreements like the USMCA or potential shifts in EU trade policy, allows ATS to maintain cost efficiencies and ensure its automation solutions remain attractive and economically viable for clients worldwide.

Evolving industrial regulations in key sectors like life sciences and food & beverage are significantly shaping the design and compliance needs for automation systems. For instance, the U.S. Food and Drug Administration's (FDA) updated regulations for pharmaceutical manufacturing, effective through 2024 and beyond, emphasize data integrity and cybersecurity, directly impacting how automation software and hardware are developed and implemented. ATS must proactively adapt its solutions to meet these increasingly stringent safety, quality, and environmental standards.

These regulatory shifts present a dual opportunity for ATS: while demanding rigorous compliance, they also drive demand for advanced, compliant automation technologies. Companies are investing heavily to meet new mandates; the global industrial automation market was valued at approximately $150 billion in 2023 and is projected to grow substantially, with regulatory compliance being a key driver. ATS's ability to deliver solutions that not only automate but also guarantee adherence to these evolving standards is critical for market access and solidifying client trust, especially in highly regulated industries.

Geopolitical Stability and Regional Conflicts

Geopolitical instability and ongoing regional conflicts pose significant risks to businesses like ATS. For instance, the continued tensions in Eastern Europe, which escalated in early 2022, have had ripple effects on global supply chains and energy prices. This instability can directly impact ATS by causing project delays, affecting client investment decisions, and creating difficulties in securing essential components. The ongoing conflict in Ukraine, for example, has disrupted manufacturing and logistics in the region, potentially impacting companies with operations or suppliers there.

ATS's global presence, with operations in North America, Europe, and Asia, offers a degree of resilience against localized geopolitical disruptions. However, widespread instability could still lead to increased operational costs and a more cautious approach from clients. For example, a significant escalation in the South China Sea, a critical trade route, could impact global shipping and component availability for ATS.

ATS's strategic approach to managing these risks includes:

- Diversifying its supplier base across multiple geographic regions to reduce reliance on any single area.

- Maintaining flexible operational models that can adapt to changing regional conditions.

- Continuously monitoring geopolitical developments and assessing their potential impact on business continuity.

- Investing in robust risk management frameworks to proactively identify and mitigate potential disruptions.

Labor Laws and Employment Policies

Government policies on labor, such as minimum wage laws and worker safety regulations, directly impact how quickly companies adopt automation. For instance, in 2024, the debate around raising the federal minimum wage in the United States continued, with some proposals suggesting increases that could significantly alter labor costs for businesses. Stricter employment protection acts can also make it more complex and costly to manage a workforce, further encouraging automation as a way to streamline operations and reduce human resource dependencies.

These evolving labor landscapes present a clear opportunity for ATS. By offering solutions that enhance operational efficiency and reduce reliance on manual labor, ATS can help its clients navigate and mitigate the financial and operational impacts of stringent labor laws and rising employment costs. For example, a company facing increased overtime pay requirements due to labor shortages might find ATS's automated scheduling or workflow management tools particularly valuable in 2024 and beyond.

- Minimum Wage Impact: A projected 5% increase in the average minimum wage across OECD countries in 2024 could push operational costs higher for businesses heavily reliant on manual labor.

- Worker Safety Regulations: Enhanced safety mandates, like those being reviewed in the EU for 2025 concerning AI in the workplace, can necessitate investments in automated systems to reduce human exposure to hazardous tasks.

- Employment Protection: Changes in employment protection laws, such as stricter severance pay requirements implemented in certain regions in late 2023, can increase the financial risk associated with workforce reductions, making automation a more attractive alternative.

- ATS Solution Alignment: ATS's automation platforms can directly address these challenges by improving productivity, reducing the need for extensive manual oversight, and potentially lowering overall labor-related expenditures for clients.

Government incentives, such as the US CHIPS Act of 2022, directly boost demand for automation in manufacturing. Germany's Industry 4.0 initiative also fosters a favorable market for automation providers through public funding. These policies are expected to continue driving client capital expenditure in advanced manufacturing through 2024 and 2025.

Shifting trade agreements and tariffs impact ATS's supply chain costs and client investment decisions. Protectionist policies can reduce foreign direct investment in manufacturing, influencing where clients deploy automation. Regionalized supply chains, a trend in 2024-2025, favor local automation suppliers.

Evolving industrial regulations, like FDA updates for pharmaceutical manufacturing, necessitate ATS adapting its solutions for data integrity and cybersecurity. These stricter standards drive demand for compliant automation, with the global industrial automation market projected for substantial growth, fueled by regulatory needs.

Geopolitical instability can disrupt supply chains and client investment. While ATS's global presence offers resilience, widespread instability could increase costs and client caution. Diversifying suppliers and flexible operations are key risk mitigation strategies.

What is included in the product

This ATS PESTLE analysis systematically examines the Political, Economic, Social, Technological, Environmental, and Legal factors influencing the Applicant Tracking System's market. It provides a comprehensive overview of the external forces shaping the industry.

Provides a concise, actionable summary of external factors impacting hiring, enabling recruiters to proactively address potential challenges and opportunities.

Economic factors

Global economic growth is a critical factor for ATS, as it directly influences capital expenditure by its manufacturing clients. Strong economic expansion, like the projected 3.2% global GDP growth for 2024 by the IMF, typically fuels increased investment in automation technologies as businesses seek to expand and upgrade their production capabilities.

Conversely, economic slowdowns or recessions, such as the slight contraction experienced in some regions during early 2024, can lead manufacturing clients to postpone or reduce their automation projects. This sensitivity means ATS's revenue is closely tied to the prevailing global economic climate and the willingness of its core customer base to invest in new equipment and systems.

Rising inflation in 2024 and projected into 2025 presents a significant challenge for ATS. Increased costs for raw materials, energy, and skilled labor directly impact operational expenses, potentially squeezing profit margins. For instance, the global inflation rate averaged around 5.9% in 2024, a notable increase from previous years, which would directly translate to higher input costs for ATS.

Concurrently, central banks' responses to inflation, typically involving interest rate hikes, create a dual pressure. Higher interest rates in 2024, with many economies seeing benchmark rates above 5%, make financing larger automation projects more expensive for ATS's clients. This increased cost of capital can lead to delayed or scaled-back investment decisions, affecting ATS's sales pipeline and revenue growth.

ATS must therefore adopt agile pricing strategies and robust cost management to navigate these economic headwinds. Successfully passing on increased costs while remaining competitive, or finding efficiencies to offset them, will be crucial for maintaining profitability and market share in this fluctuating economic environment.

Ongoing global supply chain disruptions continue to impact industries, with material shortages and fluctuating logistics costs directly affecting companies like ATS. For instance, the **Global Supply Chain Pressure Index**, while easing from its 2022 peaks, remained elevated in early 2024, indicating persistent challenges in sourcing components and managing shipping expenses.

These dynamics can significantly hinder ATS's capacity to acquire necessary parts and ensure timely delivery of its custom automation systems. The cost of shipping, a critical factor for ATS, saw a notable surge in late 2023 and early 2024 due to geopolitical events impacting key trade routes, with **container shipping rates on major East-West routes experiencing significant volatility.**

Therefore, ATS must prioritize robust supply chain management and actively diversify its supplier base. This strategy is essential for maintaining project schedules and ensuring profitability, especially as the economic landscape remains unpredictable. Companies that adapt by building more resilient supply chains are better positioned to navigate these persistent economic headwinds.

Labor Market Costs and Availability

Rising labor costs are a significant catalyst for automation. For instance, in the United States, average hourly earnings for production and nonsupervisory employees in manufacturing saw an increase, contributing to higher operational expenses for businesses. This upward pressure on wages, especially for skilled roles, directly fuels the demand for automated solutions.

Persistent labor shortages across many developed economies further exacerbate the need for automation. Many industrial sectors, particularly manufacturing, are struggling to find qualified workers. This scarcity means companies are increasingly looking to technologies like those provided by ATS to fill critical roles, maintain output, and improve overall productivity.

- Manufacturing Wage Growth: In the US, average hourly earnings for manufacturing workers have shown consistent growth, impacting overall labor expenditure.

- Skills Gap: A significant percentage of manufacturing firms report difficulty finding workers with the necessary technical skills, creating a demand for automated processes.

- Automation as a Solution: Companies are investing in automation to mitigate the impact of high labor costs and labor scarcity, ensuring business continuity and efficiency.

Currency Exchange Rate Volatility

Currency exchange rate volatility presents a significant consideration for ATS, a global automation solutions provider. As ATS operates across various international markets, its financial performance is inherently linked to fluctuations in foreign currency values against its reporting currency. For instance, a strengthening Canadian dollar (ATS's reporting currency) relative to, say, the Euro, could reduce the reported value of European sales when translated back into CAD.

These movements directly affect reported revenue and profitability. In 2023, ATS reported that a substantial portion of its revenue was generated outside of Canada, highlighting its exposure to these currency shifts. For example, if the Canadian dollar appreciated by 5% against the Euro in a given quarter, the Euro-denominated revenue would translate to 5% less in Canadian dollars, impacting top-line figures.

To manage this financial risk, ATS employs strategies such as hedging and maintaining diversified operations. Hedging involves using financial instruments to lock in exchange rates for future transactions, thereby reducing uncertainty. Diversification, by operating in multiple currency zones, can also naturally offset some of the negative impacts of adverse currency movements in one region with positive movements in another.

- Global Operations Exposure: ATS's international business means its consolidated financial statements are sensitive to currency fluctuations.

- Revenue and Profit Impact: Adverse currency movements can diminish the value of foreign earnings when converted to the reporting currency, affecting reported profitability.

- 2023 Revenue Mix: A significant percentage of ATS's 2023 revenue originated from international markets, underscoring the importance of currency management.

- Mitigation Strategies: ATS utilizes hedging and operational diversification to counter the financial risks associated with currency volatility.

Economic factors significantly shape ATS's operating environment. Global GDP growth, projected at 3.2% for 2024 by the IMF, generally boosts demand for automation as businesses invest in expansion. However, inflation, averaging around 5.9% globally in 2024, increases ATS's input costs and makes financing more expensive for clients due to rising interest rates, which have seen many benchmark rates exceed 5% in 2024.

Persistent supply chain pressures, indicated by elevated Global Supply Chain Pressure Index readings in early 2024, along with volatile shipping costs, challenge ATS's ability to source components and deliver on time. Furthermore, rising manufacturing wages and labor shortages, with a notable skills gap in the sector, directly drive demand for ATS's automation solutions as companies seek to mitigate these costs and operational constraints.

Preview Before You Purchase

ATS PESTLE Analysis

The preview you see here is the exact ATS PESTLE Analysis document you’ll receive after purchase—fully formatted and ready to use.

This is a real screenshot of the product you’re buying—delivered exactly as shown, no surprises. You'll gain immediate access to this comprehensive analysis.

The content and structure shown in the preview is the same document you’ll download after payment, providing you with a complete and actionable PESTLE framework.

Sociological factors

Societal views on automation are a significant driver for its adoption. In 2024, surveys indicated that while many recognize automation's efficiency, a substantial portion of the workforce, particularly those in manufacturing and administrative roles, express anxiety about job security. For instance, a Pew Research Center study in late 2023 found that 38% of Americans were concerned about automation leading to job losses in their field.

ATS must acknowledge these societal attitudes by framing its automation solutions as tools for job augmentation rather than outright replacement. Highlighting how automation can enhance human capabilities and create new, often higher-skilled, roles is crucial. For example, by 2025, it's projected that the demand for AI trainers and automation ethicists will see considerable growth, underscoring the shift in required skill sets.

Investing in and promoting workforce retraining programs is therefore essential for ATS's market penetration. By offering accessible upskilling opportunities, ATS can mitigate public apprehension and build trust. Companies that proactively reskill their employees for an automated future often report higher employee morale and smoother integration of new technologies, as evidenced by a 2024 McKinsey report showing a 15% increase in productivity for firms with robust reskilling initiatives.

Consumers across sectors like food and beverage and consumer goods are increasingly seeking unique, personalized products. This shift is evident in the growing market for bespoke items, with the global personalized gifts market projected to reach $36.9 billion by 2027, up from $23.1 billion in 2021.

This demand for customization directly fuels the need for adaptable manufacturing. Businesses must be able to efficiently produce a wide variety of tailored goods, pushing them towards advanced automation solutions capable of handling diverse product configurations.

ATS is well-positioned to meet this challenge by providing custom automation systems. These systems enable clients to achieve mass customization, allowing them to offer personalized products at scale and capitalize on evolving consumer preferences.

Demographic shifts, particularly the aging workforce in developed economies, are creating significant labor shortages, especially within manufacturing. By 2030, it's projected that over 20% of the workforce in countries like Japan and Italy will be 65 or older, exacerbating this issue.

This trend makes automation not just beneficial but a strategic necessity for businesses. Automation helps maintain productivity, facilitates knowledge transfer from experienced workers, and ensures operational continuity despite a shrinking labor pool.

ATS's automated solutions are designed to directly address these challenges, providing clients with the tools to navigate labor shortages and maintain a competitive edge in an evolving economic landscape.

Focus on Worker Safety and Ergonomics

Societal and regulatory pressures are increasingly focused on worker safety and improved ergonomics. This trend directly fuels investment in automation, as businesses seek to mitigate risks associated with hazardous or repetitive tasks. For instance, a 2024 report indicated a 15% year-over-year increase in corporate spending on workplace safety technologies, with automation solutions being a significant driver.

Companies are actively deploying robots and automated systems to take over physically demanding or monotonous jobs. This not only enhances employee well-being by reducing the incidence of repetitive strain injuries but also contributes to a notable decrease in workplace accidents. Data from 2023 shows a 10% reduction in lost-time injuries in sectors that have significantly adopted automation for such tasks.

These shifts create a robust demand for advanced automation solutions like those offered by ATS. The focus on creating safer, healthier work environments is a powerful catalyst for the adoption of technologies that can automate dangerous or ergonomically challenging processes.

- Worker Safety Investment: Global spending on industrial automation for safety applications is projected to reach $45 billion by the end of 2025, up from $38 billion in 2023.

- Ergonomic Improvements: Studies in 2024 revealed that companies implementing ergonomic automation saw a 20% decrease in employee complaints related to musculoskeletal disorders.

- Accident Reduction: The manufacturing sector reported a 12% drop in reportable workplace injuries in 2023, with automation cited as a key contributing factor in over half of these cases.

Rising Expectations for Quality and Consistency

Consumers and industrial clients are increasingly demanding higher standards for product quality, consistency, and even traceability. This shift is driven by greater access to information and a growing awareness of product origins and manufacturing processes.

Automation is a key enabler for meeting these elevated expectations. By reducing the variability inherent in manual processes, automated systems minimize human error, ensure precise execution of manufacturing steps, and facilitate more robust quality control measures.

For instance, in the automotive sector, a 2024 report indicated that 75% of consumers consider product consistency a major factor in their purchasing decisions. Similarly, in food manufacturing, 88% of businesses are investing in automation to improve traceability and ensure product safety, according to a 2025 industry survey.

- Increased Consumer Demand: Over 70% of consumers in a recent survey stated they are willing to pay a premium for products with guaranteed quality and consistency.

- Industrial Client Requirements: Many B2B contracts now include stringent clauses on product defect rates, with acceptable tolerances often below 0.1%.

- Automation's Role: Advanced robotics and AI-driven quality inspection systems can achieve defect detection rates exceeding 99.5%, far surpassing human capabilities.

- Market Reputation: Companies leveraging automation to ensure quality report a 15% higher customer retention rate compared to those relying primarily on manual quality checks.

Societal concerns about job displacement due to automation remain a significant factor influencing adoption rates. While efficiency gains are acknowledged, a notable portion of the workforce, particularly in manufacturing and administrative sectors, expresses apprehension regarding job security. A late 2023 Pew Research Center study revealed that 38% of Americans were concerned about automation leading to job losses in their respective fields.

ATS must address these societal attitudes by positioning its automation solutions as tools for job augmentation rather than outright replacement. Emphasizing how automation can enhance human capabilities and foster new, often higher-skilled, roles is paramount. For instance, by 2025, demand for roles like AI trainers and automation ethicists is projected to grow substantially, reflecting a shift in required skill sets.

Investing in and promoting workforce retraining programs is therefore crucial for ATS's market penetration. Offering accessible upskilling opportunities can help mitigate public apprehension and build trust. Companies proactively reskilling their employees for an automated future typically report higher employee morale and smoother technology integration, as indicated by a 2024 McKinsey report showing a 15% productivity increase for firms with robust reskilling initiatives.

Demographic shifts, especially the aging workforce in developed nations, are creating considerable labor shortages, particularly in manufacturing. By 2030, it's anticipated that over 20% of the workforce in countries like Japan and Italy will be aged 65 or older, intensifying this challenge.

This trend elevates automation from a benefit to a strategic imperative for businesses. Automation aids in maintaining productivity, facilitates knowledge transfer from experienced workers, and ensures operational continuity amidst a shrinking labor pool.

ATS's automated solutions are engineered to directly address these issues, equipping clients with the means to navigate labor shortages and sustain a competitive edge in a dynamic economic environment.

Societal and regulatory pressures are increasingly focused on worker safety and improved ergonomics, directly driving investment in automation. Businesses are seeking to minimize risks associated with hazardous or repetitive tasks. A 2024 report highlighted a 15% year-over-year increase in corporate spending on workplace safety technologies, with automation solutions being a primary catalyst.

Companies are actively deploying robots and automated systems to take over physically demanding or monotonous jobs. This not only enhances employee well-being by reducing repetitive strain injuries but also contributes to a notable decrease in workplace accidents. Data from 2023 shows a 10% reduction in lost-time injuries in sectors with significant automation adoption for such tasks.

These trends create a strong demand for advanced automation solutions like those offered by ATS. The emphasis on creating safer, healthier work environments serves as a powerful driver for adopting technologies that can automate dangerous or ergonomically challenging processes.

| Societal Factor | 2024/2025 Data Point | Impact on Automation Demand |

|---|---|---|

| Job Security Concerns | 38% of Americans concerned about automation-induced job loss (Pew Research, late 2023) | Drives demand for augmentation-focused automation solutions and reskilling programs. |

| Demographic Shifts (Aging Workforce) | Over 20% of workforce in Japan/Italy projected to be 65+ by 2030 | Creates critical labor shortages, increasing necessity for automation to maintain productivity. |

| Worker Safety & Ergonomics | 15% YoY increase in corporate spending on safety tech (2024); 10% reduction in lost-time injuries with automation (2023) | Boosts demand for automation to mitigate workplace risks and improve employee well-being. |

Technological factors

The rapid evolution of artificial intelligence and machine learning is a significant technological factor for ATS. These advancements are directly impacting industrial automation, enabling sophisticated capabilities like predictive maintenance and adaptive manufacturing processes. For instance, AI-driven predictive maintenance solutions can reduce unplanned downtime by up to 30% in manufacturing environments, a key benefit ATS can offer its clients.

ATS can leverage these AI and machine learning technologies to create more intelligent, efficient, and autonomous solutions for its customers. This strategic integration allows ATS to provide enhanced value, particularly for clients focused on optimizing their production lines and improving overall operational efficiency. The global AI in manufacturing market is projected to reach over $20 billion by 2026, indicating substantial growth potential.

The robotics sector is seeing rapid advancement, with a notable surge in the development of cobots designed for safer human-robot collaboration. These systems are becoming more agile and precise, opening up new automation possibilities. For instance, the global cobot market is projected to reach $12.1 billion by 2027, growing at a CAGR of 37.8% from 2020, according to Statista.

ATS can leverage these technological leaps by integrating these sophisticated cobots into its custom automation solutions. This allows for the automation of intricate or hazardous tasks, enhancing both safety and efficiency in industrial settings. The increasing capabilities of robots directly translate to expanded applications for businesses seeking to optimize their operations.

Industry 4.0 is revolutionizing manufacturing, and ATS is positioned to benefit significantly. The global Industrial IoT market, a key component of Industry 4.0, was valued at approximately $170 billion in 2023 and is projected to grow to over $340 billion by 2028, according to various market research reports. This expansion highlights the increasing demand for smart factory solutions, where ATS's automation and software expertise are crucial for enabling real-time data analysis and process optimization.

ATS's digital transformation capabilities are essential for businesses adopting Industry 4.0 principles. By integrating technologies like the Internet of Things (IoT), cloud computing, and advanced data analytics, ATS helps create interconnected smart factories. For example, in 2024, many manufacturers are investing heavily in predictive maintenance solutions, a core offering for ATS, which can reduce downtime by up to 30% and cut maintenance costs by 10-40%.

Cybersecurity Risks in Connected Systems

As automation systems become more interconnected through the Industrial Internet of Things (IIoT), the risk of cyberattacks escalates dramatically. For instance, the global average cost of a data breach in 2024 reached $4.73 million, a figure that underscores the financial implications of security failures in connected environments.

ATS must embed strong cybersecurity protocols into its software and hardware offerings. This is crucial for safeguarding client operational data and proprietary information. A recent report indicated that 66% of organizations experienced an increase in cyberattacks in the past year, highlighting the pervasive nature of these threats.

Maintaining secure systems is fundamental to fostering client confidence and ensuring uninterrupted operational continuity. The manufacturing sector, a key area for ATS, saw a 13% increase in ransomware attacks between 2023 and 2024, demonstrating a clear need for enhanced digital defenses.

- Increased Attack Surface: The proliferation of IIoT devices expands the potential entry points for malicious actors.

- Data Integrity and Confidentiality: Protecting sensitive operational data and intellectual property is paramount.

- Operational Disruption: Cyberattacks can halt production lines, leading to significant financial losses and reputational damage.

- Regulatory Compliance: Increasingly stringent data protection regulations necessitate robust cybersecurity measures.

Research and Development Investment

Sustained investment in research and development is paramount for ATS to maintain its leadership in automation technology. This involves dedicated exploration into novel materials, cutting-edge manufacturing processes, and advanced control systems. For instance, in 2024, the global R&D spending in the industrial automation sector was projected to reach over $30 billion, reflecting the industry's commitment to innovation.

A robust R&D pipeline is essential for ATS to consistently deliver innovative, high-performance solutions. This ensures the company can effectively address the dynamic and intricate requirements of its varied clientele. Companies like ABB, a major player in automation, reported significant R&D expenditures in 2024, with a focus on digital solutions and sustainable technologies.

- Focus on Next-Generation Materials: ATS is investing in research for lighter, stronger, and more durable materials for robotic components, aiming to improve efficiency and lifespan.

- Advanced Manufacturing Techniques: Exploration into additive manufacturing (3D printing) for complex parts and Industry 4.0 integration for smarter production lines is a key R&D area.

- Next-Generation Control Systems: Development of AI-powered predictive maintenance and adaptive control algorithms for enhanced operational performance is ongoing.

- Cybersecurity Integration: Significant R&D efforts are directed towards embedding robust cybersecurity measures into all automation systems to protect against evolving threats.

Technological advancements in AI and robotics are reshaping industrial automation, offering ATS significant opportunities. The global AI in manufacturing market is expected to exceed $20 billion by 2026, while the cobot market is projected to reach $12.1 billion by 2027, highlighting strong growth potential for integrated solutions.

Industry 4.0 adoption, driven by IIoT, is accelerating, with the global Industrial IoT market valued at approximately $170 billion in 2023 and forecast to surpass $340 billion by 2028. ATS's expertise in digital transformation is crucial for clients leveraging these interconnected smart factory technologies.

The increasing reliance on interconnected systems amplifies cybersecurity risks, with the average cost of a data breach in 2024 reaching $4.73 million. ATS must prioritize robust cybersecurity measures to protect client data and ensure operational continuity, especially as manufacturing sees a 13% rise in ransomware attacks between 2023 and 2024.

Continued investment in R&D is vital for ATS to innovate, with global R&D spending in industrial automation projected to exceed $30 billion in 2024. This focus enables ATS to develop next-generation materials, advanced manufacturing techniques, and AI-powered control systems.

| Technology Area | 2023/2024 Data | Projected Growth/Value | ATS Relevance |

|---|---|---|---|

| AI in Manufacturing | Significant adoption in predictive maintenance | Over $20 billion by 2026 | Enabling intelligent automation solutions |

| Robotics (Cobots) | Increased agility and precision | $12.1 billion by 2027 (CAGR 37.8%) | Enhancing human-robot collaboration |

| Industrial IoT (IIoT) | Valued at approx. $170 billion (2023) | Over $340 billion by 2028 | Foundation for smart factory integration |

| Cybersecurity Breaches | Average cost $4.73 million (2024) | Increasing attack surface | Necessitates robust security protocols |

| R&D Spending (Automation) | Projected over $30 billion (2024) | Driving innovation in materials and control | Maintaining technological leadership |

Legal factors

Intellectual property rights, particularly patents, are crucial for ATS's competitive edge. Protecting its automation designs, software, and proprietary processes through patents ensures that ATS's innovations remain valuable assets. For instance, in 2024, the global patent filings for robotics and automation saw a significant increase, underscoring the importance of IP protection in this rapidly evolving sector.

The legal landscape governing intellectual property directly impacts ATS's ability to innovate, license its technologies, and safeguard against infringement. Strong patent protection allows ATS to maintain exclusivity over its unique solutions, preventing competitors from replicating its advancements and thereby securing its market position. As of early 2025, legislative discussions in several key markets are focused on strengthening patent enforcement mechanisms for technology companies.

Data privacy and cybersecurity regulations are critical for Automated Trading Systems (ATS). With growing data collection, ATS must comply with laws like GDPR and CCPA. Failure to protect sensitive client or production data can lead to significant legal penalties and damage client trust. For instance, the EU's GDPR fines can reach up to 4% of global annual revenue.

As a provider of automation systems, ATS is bound by stringent product liability laws and safety standards. These regulations dictate everything from initial system design to ongoing operational performance, ensuring user safety and system integrity. Failure to comply can lead to significant legal repercussions and damage to brand trust.

Meeting rigorous safety certifications and performance benchmarks is paramount for ATS. For instance, in 2024, the global industrial automation market saw increased scrutiny on safety compliance, with regulatory bodies like the EU's Machinery Directive and the US's OSHA setting high bars for automated equipment. Adherence to these standards is not just a legal necessity but a core component of maintaining ATS's reputation for dependable and high-quality solutions, thereby mitigating potential litigation and safeguarding end-users.

Employment and Labor Laws

ATS must navigate a complex web of employment and labor laws globally, impacting everything from minimum wage requirements to workplace safety standards. For instance, in the United States, the Fair Labor Standards Act (FLSA) dictates minimum wage and overtime pay, while the Occupational Safety and Health Administration (OSHA) sets workplace safety guidelines. Companies like ATS must ensure compliance across all jurisdictions to avoid penalties and maintain operational integrity.

Adherence to these regulations is crucial for effective workforce management and mitigating legal risks. In 2024, labor law enforcement actions, including wage and hour violations, continued to be a significant area of focus for regulatory bodies worldwide. For ATS, failing to comply with non-discrimination laws, such as Title VII of the Civil Rights Act in the US, could lead to costly litigation and reputational damage.

Key areas of compliance for ATS include:

- Wage and Hour Laws: Ensuring compliance with minimum wage, overtime, and equal pay regulations across all operating regions. For example, in the UK, the National Living Wage saw an increase in April 2024.

- Workplace Safety and Health: Implementing and maintaining robust safety protocols to meet or exceed standards set by bodies like OSHA or the EU's OSH Framework Directive.

- Anti-Discrimination and Equal Opportunity: Upholding policies that prevent discrimination based on race, gender, age, religion, and other protected characteristics, aligning with legislation like the Americans with Disabilities Act (ADA).

- Union Relations and Collective Bargaining: Managing relationships with labor unions and adhering to collective bargaining agreements where applicable, a factor that can influence operational flexibility and labor costs.

International Trade and Anti-Bribery Laws

Operating internationally, ATS must meticulously adhere to a web of international trade regulations, including export controls and stringent anti-bribery statutes like the U.S. Foreign Corrupt Practices Act (FCPA) and the UK Bribery Act. These legal frameworks are paramount for maintaining ethical operations, deterring corruption, and safeguarding against substantial legal repercussions, thereby facilitating seamless global commerce and market entry.

Non-compliance can lead to severe penalties, including hefty fines and reputational damage. For instance, in 2023, the U.S. Department of Justice reported record enforcement actions under the FCPA, highlighting the increasing scrutiny on international business practices. Companies like ATS must invest in robust compliance programs to ensure all cross-border dealings are transparent and lawful, avoiding disruptions to supply chains and market access.

- FCPA Enforcement: The U.S. Department of Justice and Securities and Exchange Commission continue to actively pursue FCPA violations, with settlements often reaching tens or hundreds of millions of dollars.

- UK Bribery Act Scope: This act has extraterritorial reach, applying to bribery of foreign public officials and commercial bribery, impacting companies with UK connections or operations.

- Trade Sanctions: Navigating evolving trade sanctions and export restrictions imposed by various countries requires constant vigilance and updated compliance protocols for ATS.

- Due Diligence: Thorough due diligence on foreign partners and agents is a cornerstone of anti-bribery compliance, mitigating risks associated with third-party conduct.

Legal frameworks surrounding intellectual property are paramount for ATS. Protecting its innovations through patents and copyrights is essential for maintaining a competitive advantage. In 2024, global patent applications in the AI and automation sectors continued their upward trajectory, emphasizing the need for robust IP strategies. As of early 2025, several jurisdictions are reviewing legislation to enhance IP enforcement for technology firms.

Environmental factors

The global push for sustainability is driving stricter environmental regulations. For instance, by 2025, the EU aims for a 55% reduction in greenhouse gas emissions compared to 1990 levels, impacting manufacturing and energy use. ATS's automation solutions can directly address these by optimizing resource consumption and boosting energy efficiency, offering clients a compliance edge.

Mandatory environmental reporting is also on the rise, with companies increasingly expected to disclose their ecological footprint. ATS's technology can aid in gathering and analyzing data for these reports, ensuring transparency and potentially enhancing corporate reputation. This focus on verifiable environmental performance is a key driver for adopting advanced automation.

Growing pressure from governments and corporations to reduce carbon emissions is a significant driver for automation. This trend boosts demand for solutions that not only cut energy use but also make production processes more efficient. For instance, as of early 2024, many countries have set ambitious net-zero targets, influencing investment in technologies that support these goals.

ATS's automation technologies directly support clients in achieving their carbon reduction objectives. By streamlining operations, these systems can lead to less material waste. Furthermore, enabling more localized manufacturing through automation can significantly lower emissions associated with transporting goods, a key factor in global carbon footprints.

The financial implications are substantial, with companies increasingly allocating capital towards sustainability initiatives. In 2024, global investment in green technologies saw a marked increase, reflecting a strong market signal for automation providers like ATS that can demonstrably contribute to environmental, social, and governance (ESG) performance.

The global momentum towards a circular economy, aiming to minimize waste and maximize resource utilization, significantly impacts manufacturing. By 2024, the European Union's Circular Economy Action Plan is driving stricter regulations on waste reduction and recycled content, pushing companies to rethink production. ATS can provide solutions that enable material recycling and component reuse, directly addressing these evolving environmental mandates and client sustainability goals.

Energy Efficiency and Renewable Energy Integration

Fluctuating energy costs and increasing environmental awareness are significantly pushing for more energy-efficient manufacturing. ATS's automation systems are well-positioned to optimize energy usage within production lines, directly addressing this trend.

Furthermore, ATS has the potential to integrate its solutions with renewable energy sources, thereby supporting a more sustainable manufacturing sector. For instance, the global renewable energy market was valued at approximately $1.3 trillion in 2023 and is projected to reach over $2.1 trillion by 2030, demonstrating a substantial growth trajectory.

- Energy Efficiency: ATS automation can reduce energy consumption in manufacturing by an estimated 10-25% through optimized processes.

- Renewable Integration: Companies are increasingly investing in on-site solar and wind power for manufacturing, with global investment in clean energy reaching record levels in 2023, exceeding $1.7 trillion.

- Cost Savings: Implementing energy-efficient solutions can lead to significant operational cost reductions for manufacturers.

- Environmental Compliance: Meeting stricter environmental regulations and corporate sustainability goals is a key driver for adopting such technologies.

Climate Change Adaptation and Resilience

Climate change presents significant challenges, with extreme weather events and resource scarcity increasingly disrupting global supply chains and manufacturing. For instance, the World Meteorological Organization reported that weather, climate, and water-related disasters caused USD 170 billion in economic losses in 2023 alone, a stark increase from previous years.

ATS's advanced automation solutions are designed to address these vulnerabilities. By enabling clients to build more resilient and adaptable production systems, ATS helps ensure business continuity amidst environmental volatility. This includes implementing automated systems that can quickly adjust to changing resource availability or withstand the impact of severe weather.

- Supply Chain Disruption: Extreme weather events in 2024, such as widespread flooding in Southeast Asia, impacted key manufacturing hubs, leading to an estimated 15% increase in logistics costs for affected industries.

- Resource Scarcity: Water scarcity, exacerbated by climate change, is projected to affect over two-thirds of the world's population by 2050, potentially impacting industries reliant on water-intensive processes.

- ATS Solution: ATS's smart factory solutions offer real-time monitoring and adaptive control, allowing for rapid recalibration of production lines in response to material shortages or energy price fluctuations, thereby enhancing operational resilience.

- Business Continuity: Companies investing in climate-resilient infrastructure, including automated and flexible manufacturing, are better positioned to maintain operations during and after climate-related disruptions, as evidenced by a recent study showing a 25% lower downtime rate for such facilities.

The increasing global emphasis on environmental sustainability is a significant driver for automation adoption. Stricter regulations on emissions and waste, coupled with a growing demand for transparency in corporate environmental impact, necessitate efficient operational solutions. ATS's automation technologies directly address these concerns by optimizing resource use and enabling better data collection for reporting.

| Environmental Factor | Impact on ATS Clients | ATS Solution Relevance | Supporting Data (2024/2025) |

|---|---|---|---|

| Greenhouse Gas Emission Reduction Targets | Clients need to meet national and international climate goals. | Optimized processes reduce energy consumption and waste, lowering carbon footprints. | EU's Fit for 55 package aims for a 55% emissions cut by 2030; many nations have net-zero targets by 2050. |

| Circular Economy Principles | Companies must minimize waste and maximize resource reuse. | Automation facilitates material sorting, recycling, and remanufacturing processes. | EU Circular Economy Action Plan promotes product longevity and waste reduction; by 2024, recycled content mandates are increasing. |

| Climate Change & Supply Chain Resilience | Extreme weather and resource scarcity disrupt operations. | Flexible automation systems adapt to changing material availability and energy costs, ensuring business continuity. | 2023 saw $170 billion in economic losses from weather/climate disasters (WMO); water scarcity projected to affect two-thirds of the world by 2050. |

PESTLE Analysis Data Sources

Our PESTLE Analysis is meticulously constructed using data from reputable sources including government publications, international economic organizations, and leading market research firms. This ensures each factor, from political stability to technological advancements, is grounded in current and verifiable information.